NISSAN NAVARA 2005 Repair Workshop Manual

NAVARA 2005

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57362/w960_57362-0.png

NISSAN NAVARA 2005 Repair Workshop Manual

Trending: water pump, turn signal, steering wheel, coolant temperature, air filter, tow, key

Page 3161 of 3171

WW-50

HEADLAMP WASHER

Headlamp Washer Does Not Operate

EKS00P6G

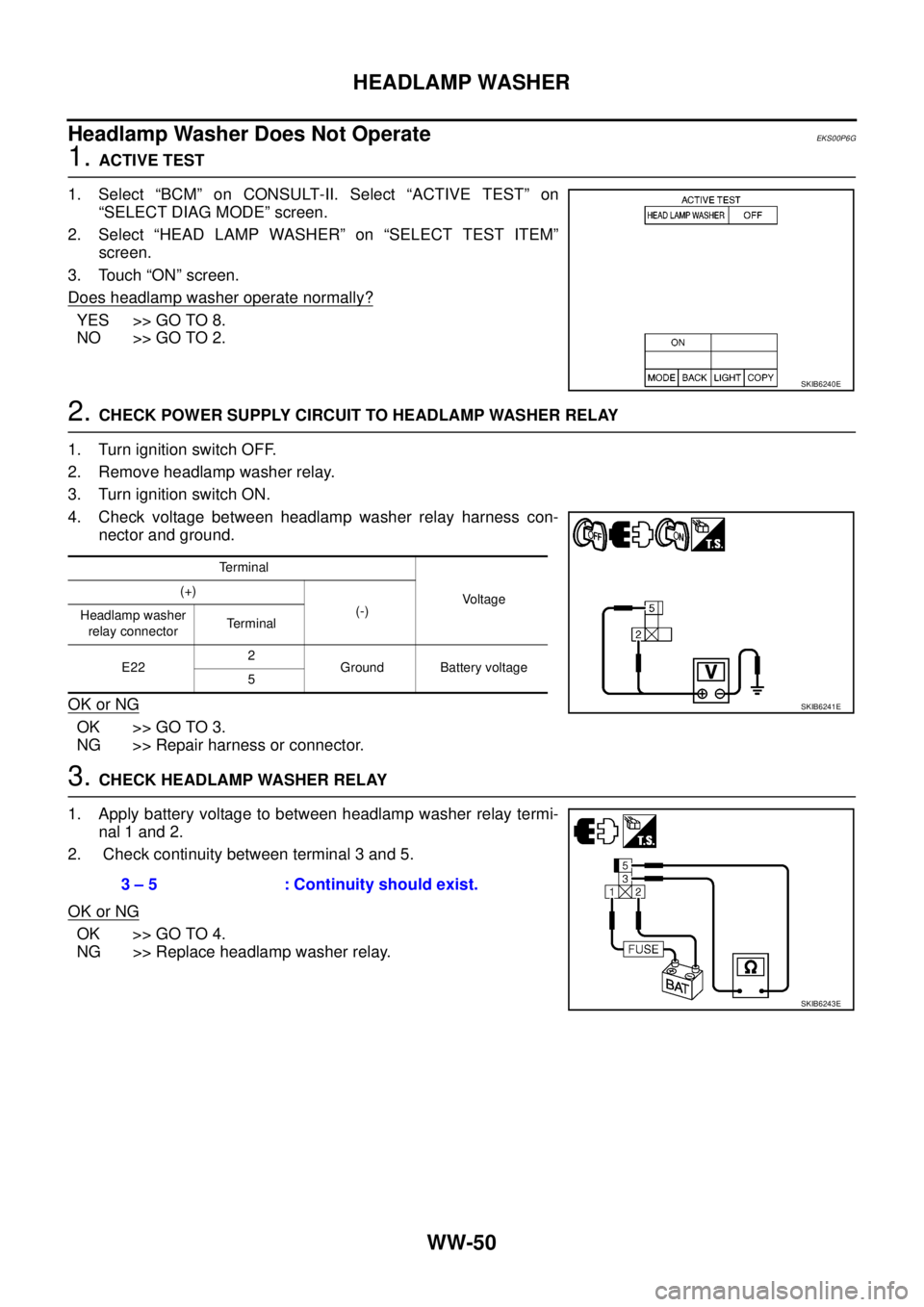

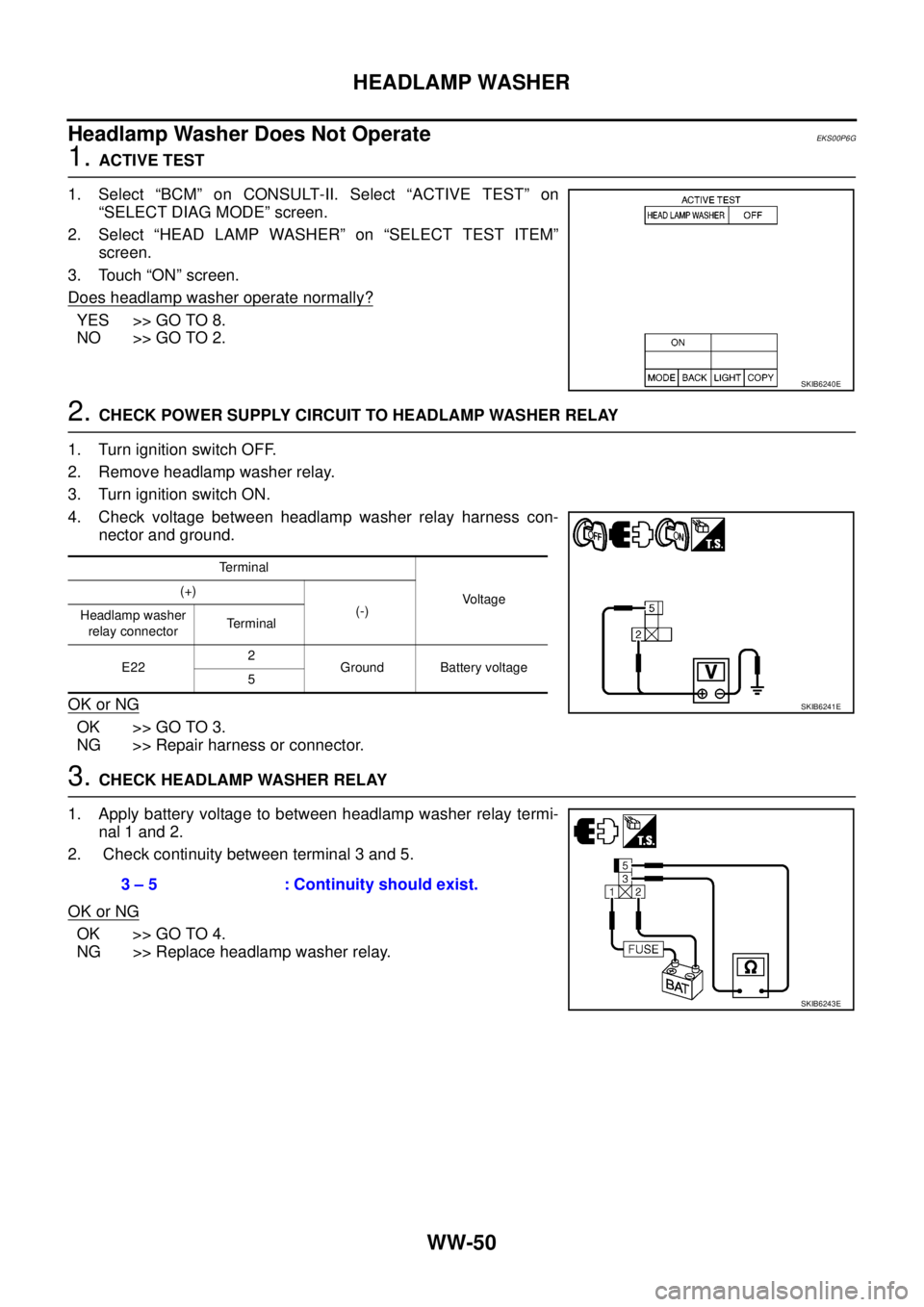

1.ACTIVE TEST

1. Select “BCM” on CONSULT-II. Select “ACTIVE TEST” on

“SELECT DIAG MODE” screen.

2. Select “HEAD LAMP WASHER” on “SELECT TEST ITEM”

screen.

3. Touch “ON” screen.

Does headlamp washer operate normally?

YES >> GO TO 8.

NO >> GO TO 2.

2.CHECK POWER SUPPLY CIRCUIT TO HEADLAMP WASHER RELAY

1. Turn ignition switch OFF.

2. Remove headlamp washer relay.

3. Turn ignition switch ON.

4. Check voltage between headlamp washer relay harness con-

nector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK HEADLAMP WASHER RELAY

1. Apply battery voltage to between headlamp washer relay termi-

nal 1 and 2.

2. Check continuity between terminal 3 and 5.

OK or NG

OK >> GO TO 4.

NG >> Replace headlamp washer relay.

SKIB6240E

Terminal

Voltage (+)

(-)

Headlamp washer

relay connectorTerminal

E222

Ground Battery voltage

5

SKIB6241E

3 – 5 : Continuity should exist.

SKIB6243E

Page 3162 of 3171

HEADLAMP WASHER

WW-51

C

D

E

F

G

H

I

J

L

MA

B

WW

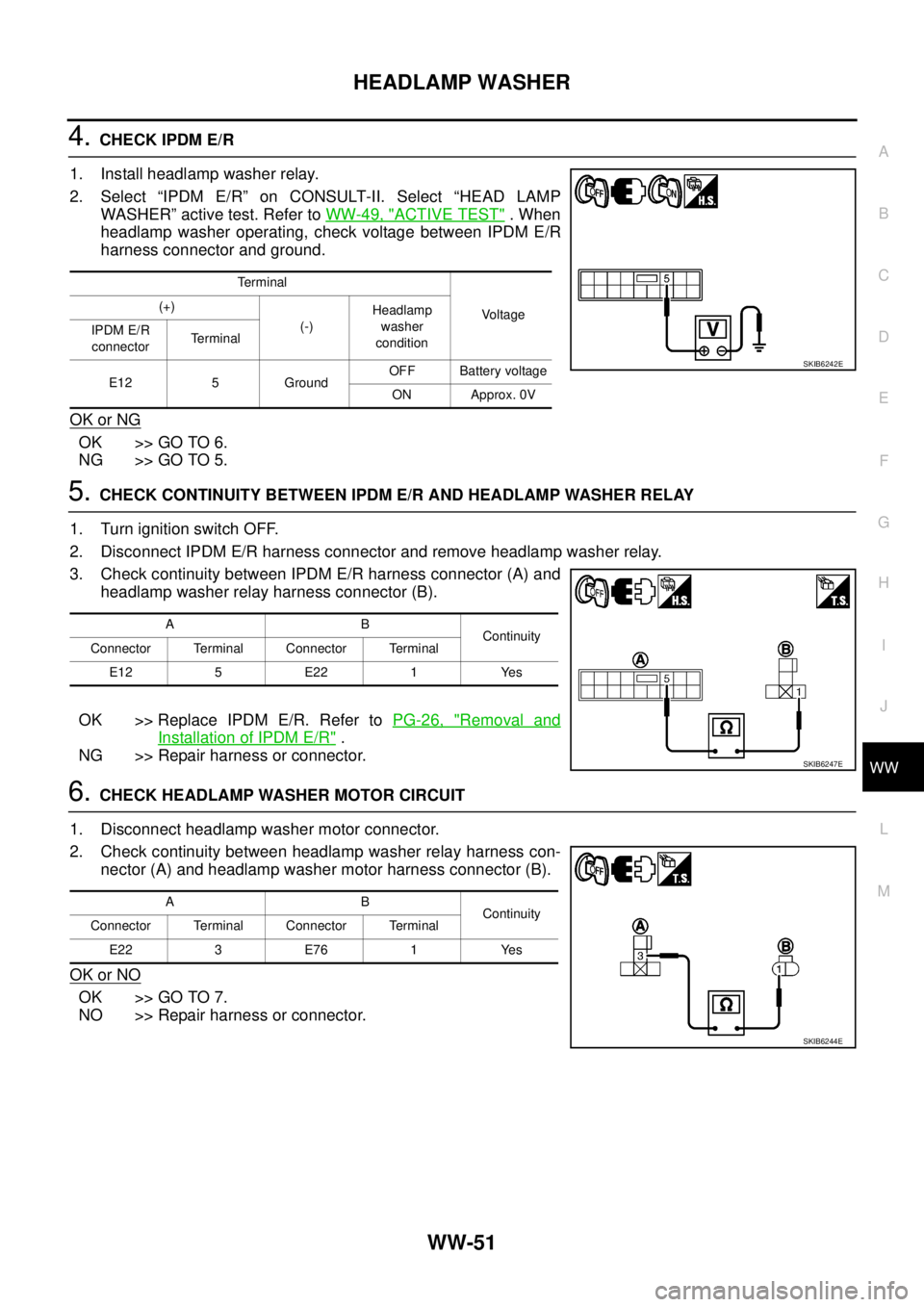

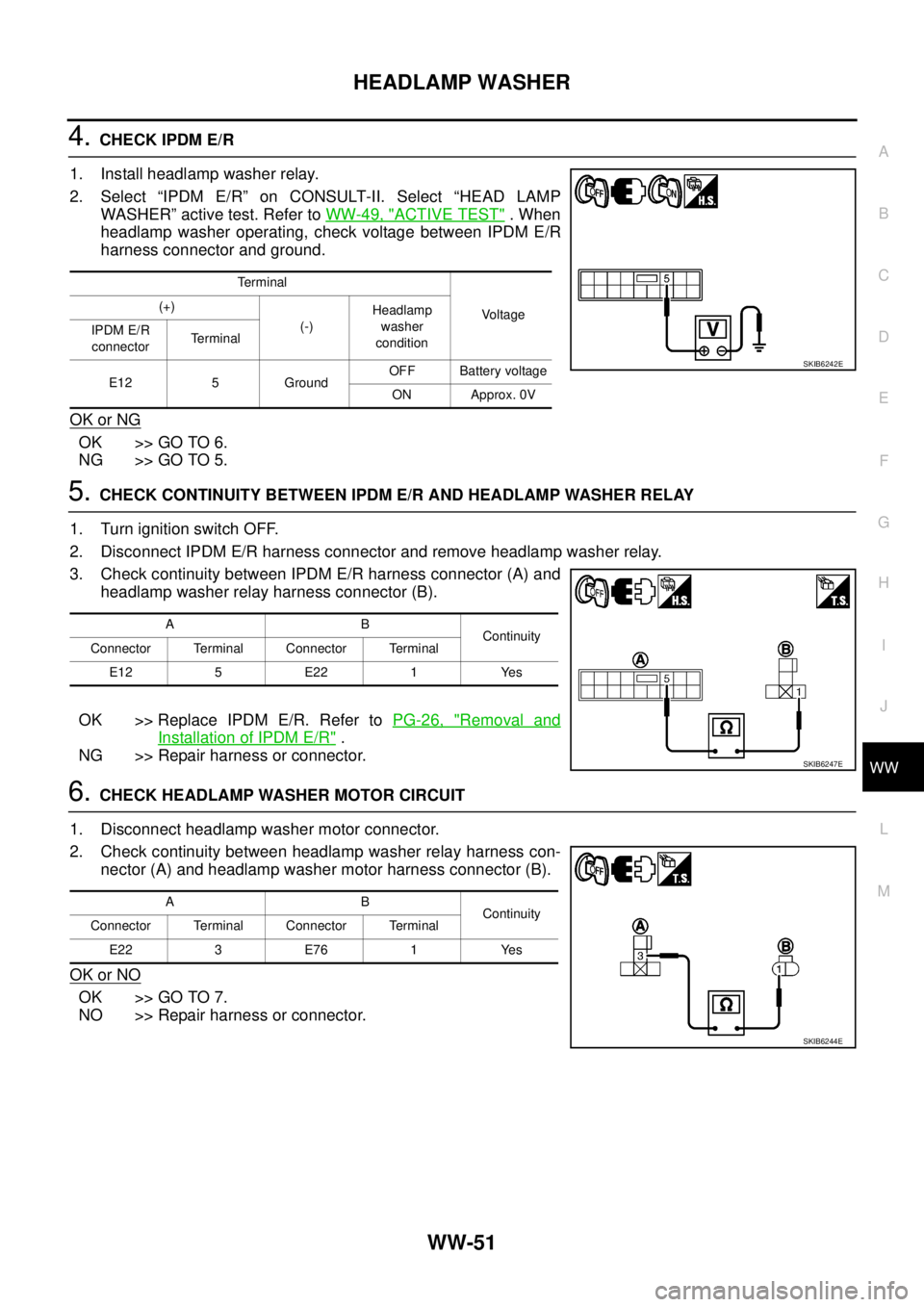

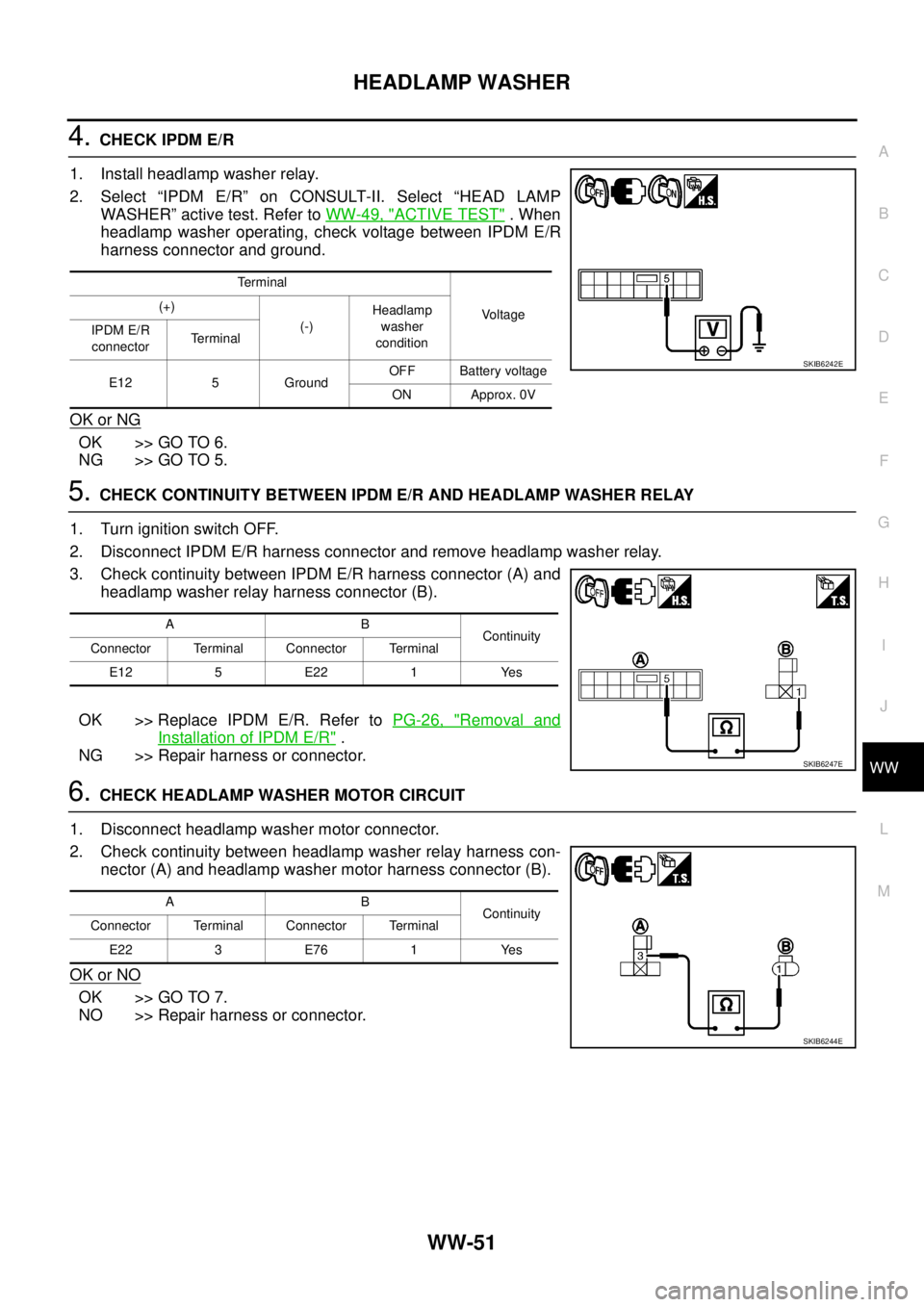

4.CHECK IPDM E/R

1. Install headlamp washer relay.

2. Select “IPDM E/R” on CONSULT-II. Select “HEAD LAMP

WASHER” active test. Refer toWW-49, "

ACTIVE TEST".When

headlamp washer operating, check voltage between IPDM E/R

harness connector and ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.CHECK CONTINUITY BETWEEN IPDM E/R AND HEADLAMP WASHER RELAY

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector and remove headlamp washer relay.

3. Check continuity between IPDM E/R harness connector (A) and

headlamp washer relay harness connector (B).

OK >> Replace IPDM E/R. Refer toPG-26, "

Removal and

Installation of IPDM E/R".

NG >> Repair harness or connector.

6.CHECK HEADLAMP WASHER MOTOR CIRCUIT

1. Disconnect headlamp washer motor connector.

2. Check continuity between headlamp washer relay harness con-

nector (A) and headlamp washer motor harness connector (B).

OK or NO

OK >> GO TO 7.

NO >> Repair harness or connector.

Terminal

Vo l ta g e (+)

(-)Headlamp

washer

condition IPDM E/R

connectorTerminal

E12 5 GroundOFF Battery voltage

ON Approx. 0V

SKIB6242E

AB

Continuity

Connector Terminal Connector Terminal

E12 5 E22 1 Yes

SKIB6247E

AB

Continuity

Connector Terminal Connector Terminal

E22 3 E76 1 Yes

SKIB6244E

Page 3163 of 3171

WW-52

HEADLAMP WASHER

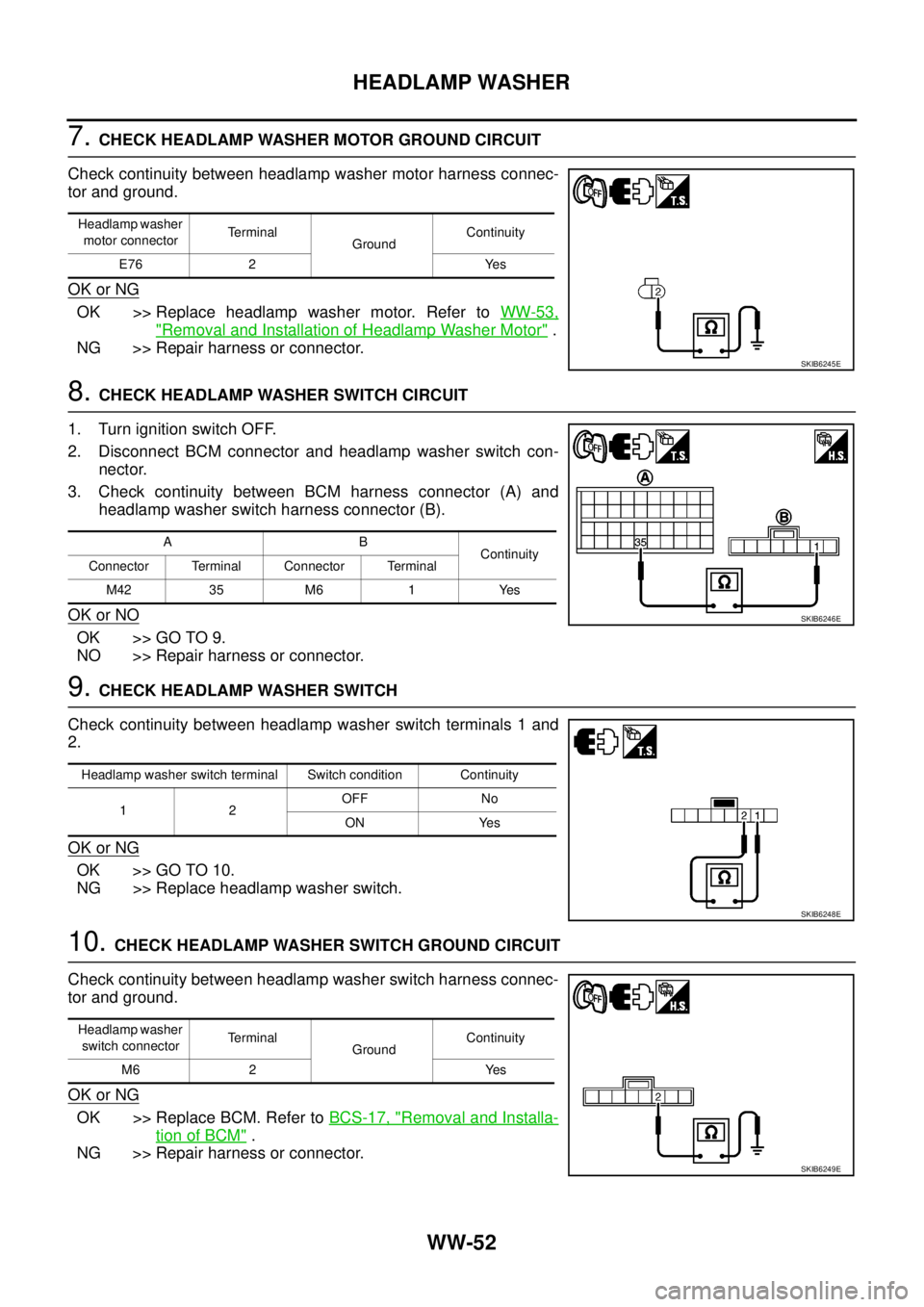

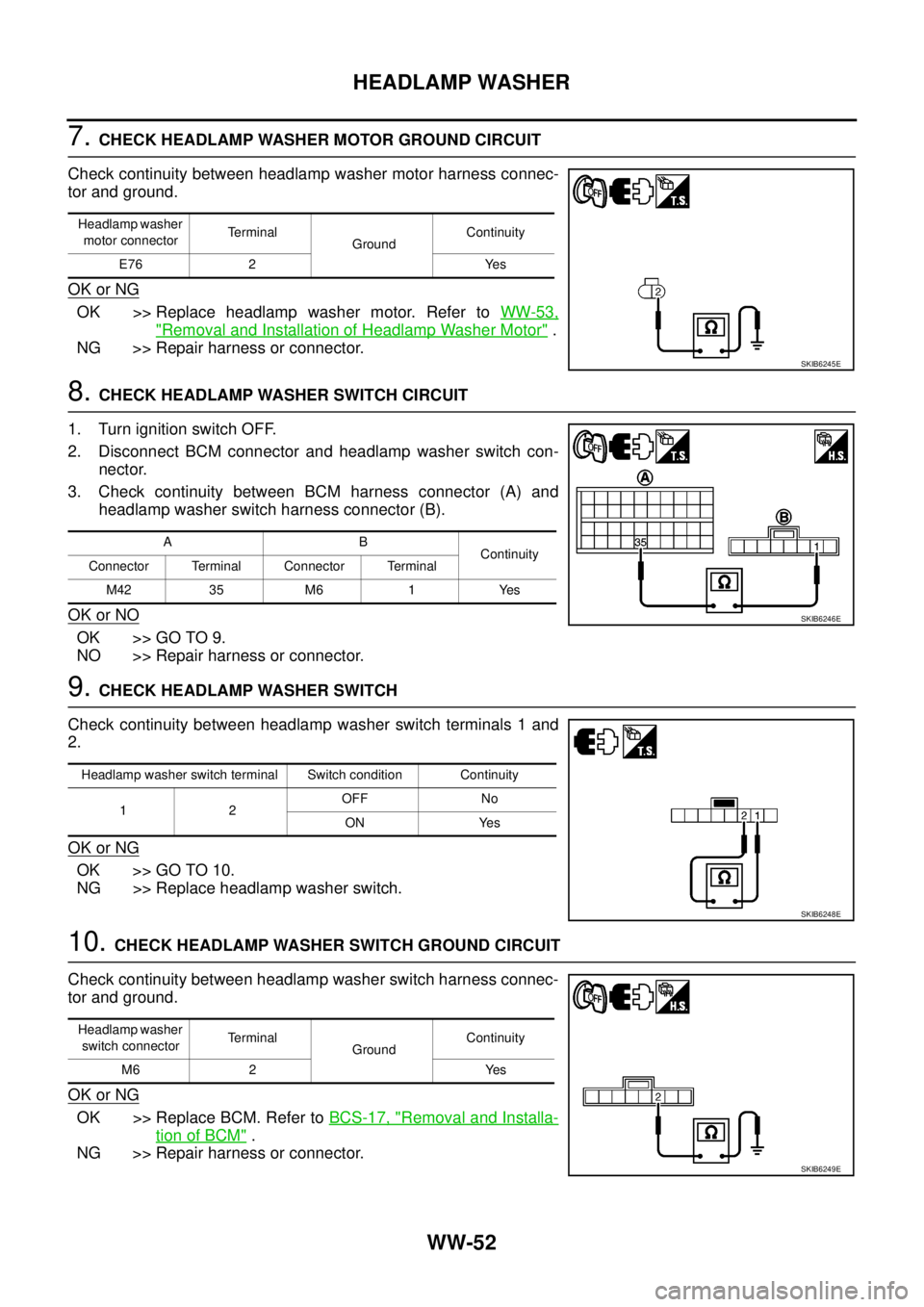

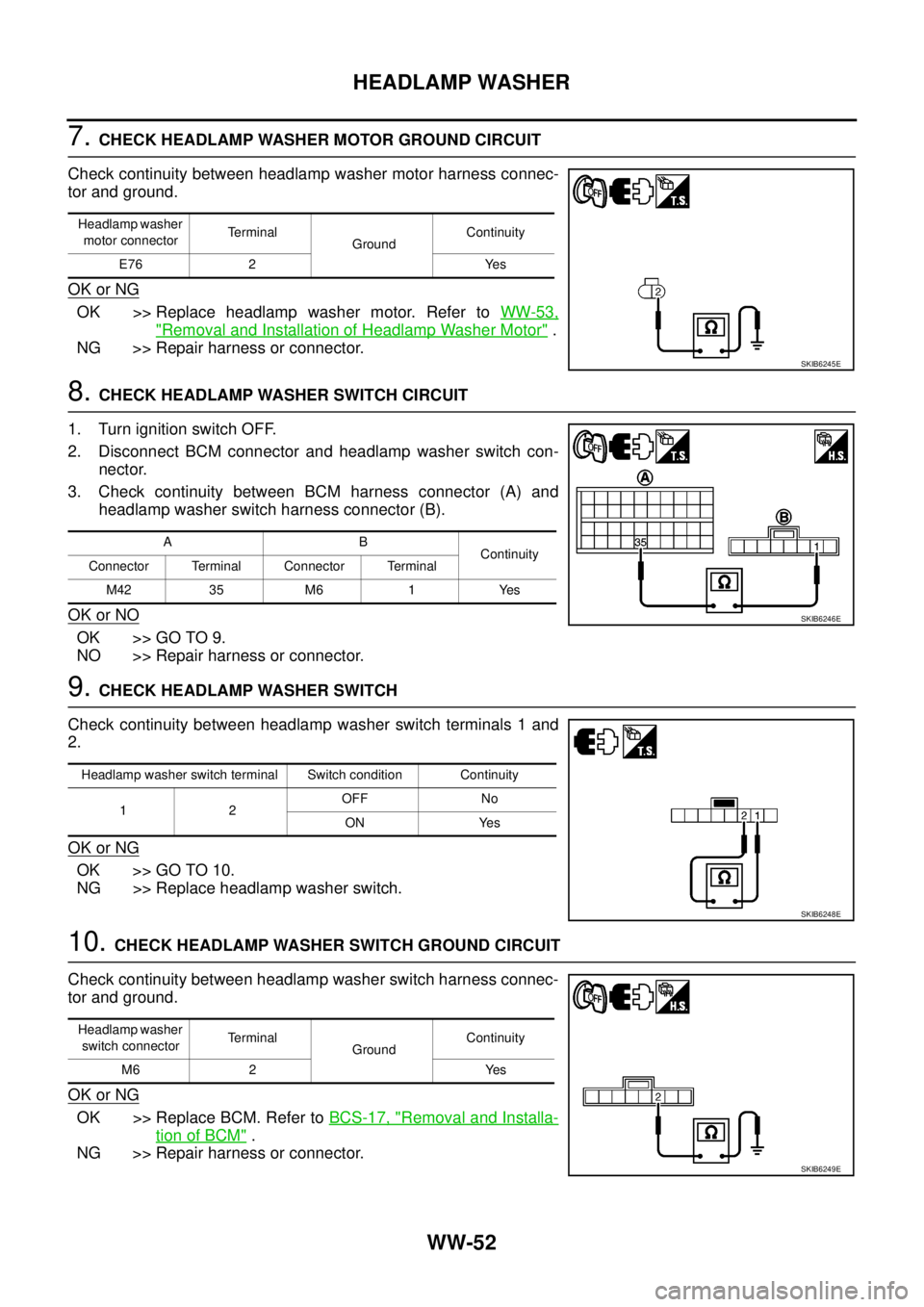

7.CHECK HEADLAMP WASHER MOTOR GROUND CIRCUIT

Check continuity between headlamp washer motor harness connec-

tor and ground.

OK or NG

OK >> Replace headlamp washer motor. Refer toWW-53,

"Removal and Installation of Headlamp Washer Motor".

NG >> Repair harness or connector.

8.CHECK HEADLAMP WASHER SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector and headlamp washer switch con-

nector.

3. Check continuity between BCM harness connector (A) and

headlamp washer switch harness connector (B).

OK or NO

OK >> GO TO 9.

NO >> Repair harness or connector.

9.CHECK HEADLAMP WASHER SWITCH

Check continuity between headlamp washer switch terminals 1 and

2.

OK or NG

OK >> GO TO 10.

NG >> Replace headlamp washer switch.

10.CHECK HEADLAMP WASHER SWITCH GROUND CIRCUIT

Check continuity between headlamp washer switch harness connec-

tor and ground.

OK or NG

OK >> Replace BCM. Refer toBCS-17, "Removal and Installa-

tion of BCM".

NG >> Repair harness or connector.

Headlamp washer

motor connectorTerminal

GroundContinuity

E76 2 Yes

SKIB6245E

AB

Continuity

Connector Terminal Connector Terminal

M42 35 M6 1 Yes

SKIB6246E

Headlamp washer switch terminal Switch condition Continuity

12OFF No

ON Yes

SKIB6248E

Headlamp washer

switch connectorTerminal

GroundContinuity

M6 2 Yes

SKIB6249E

Page 3164 of 3171

HEADLAMP WASHER

WW-53

C

D

E

F

G

H

I

J

L

MA

B

WW

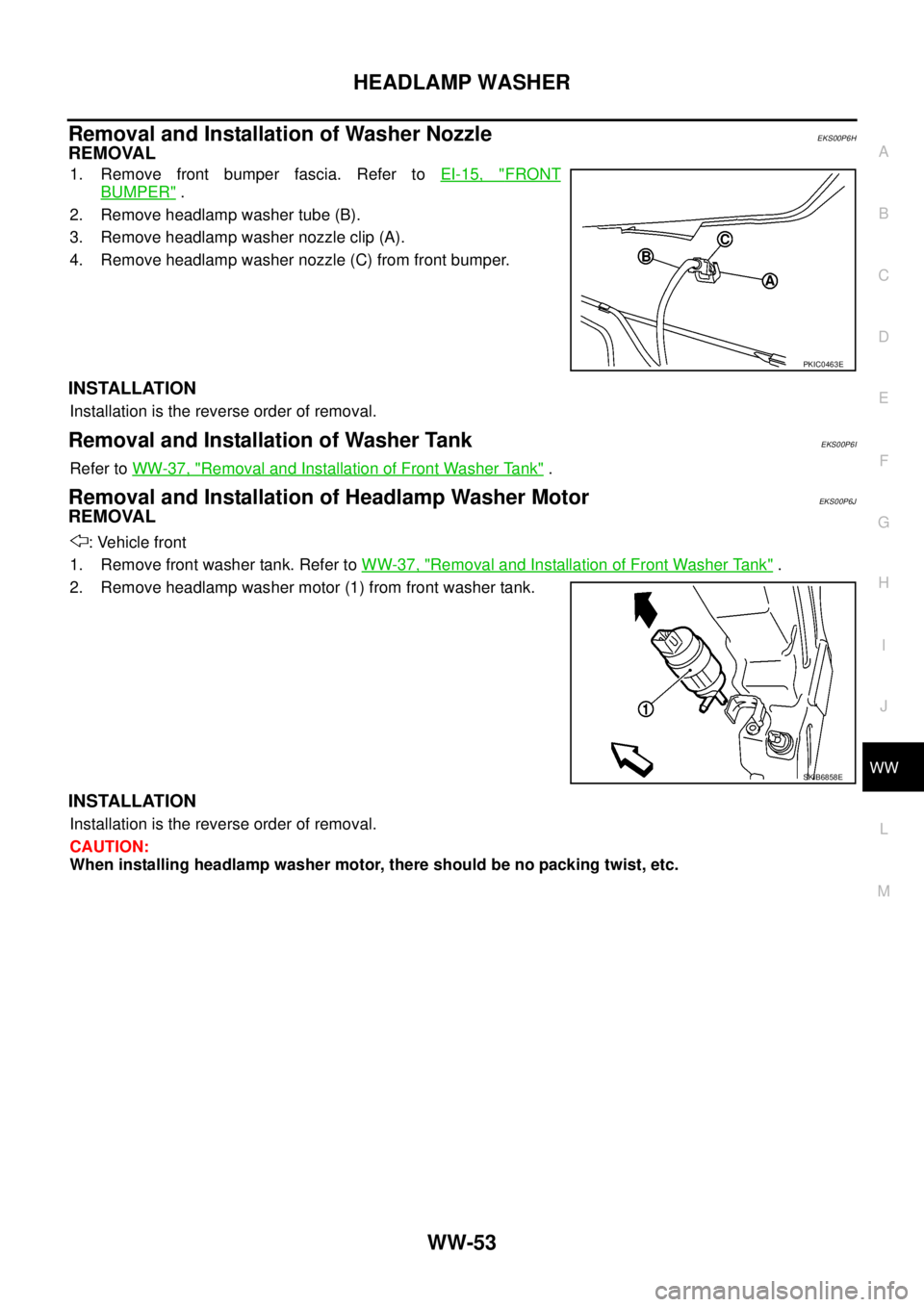

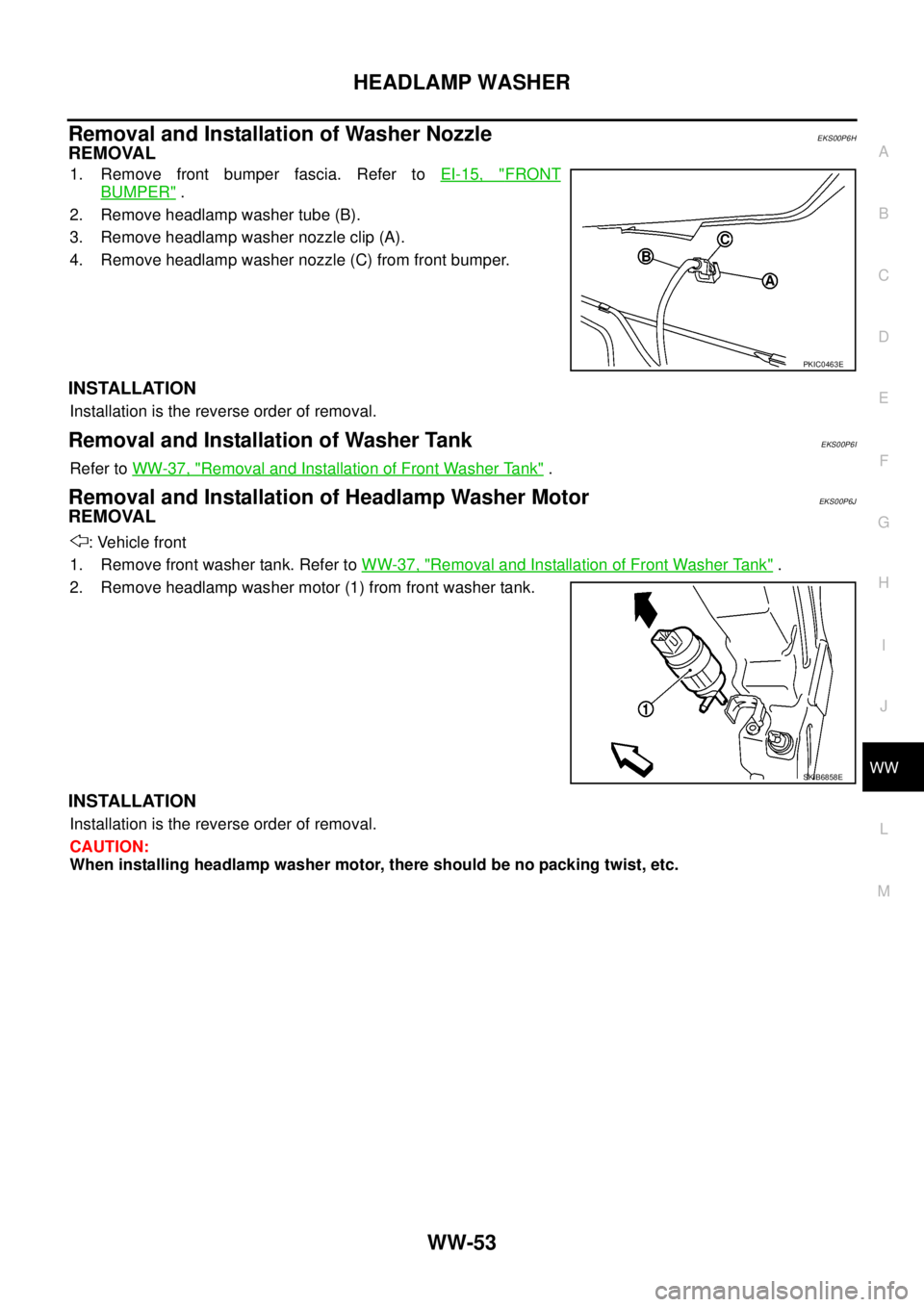

Removal and Installation of Washer NozzleEKS00P6H

REMOVAL

1. Remove front bumper fascia. Refer toEI-15, "FRONT

BUMPER".

2. Remove headlamp washer tube (B).

3. Remove headlamp washer nozzle clip (A).

4. Remove headlamp washer nozzle (C) from front bumper.

INSTALLATION

Installation is the reverse order of removal.

Removal and Installation of Washer TankEKS00P6I

Refer toWW-37, "Removal and Installation of Front Washer Tank".

Removal and Installation of Headlamp Washer MotorEKS00P6J

REMOVAL

: Vehicle front

1. Remove front washer tank. Refer toWW-37, "

Removal and Installation of Front Washer Tank".

2. Remove headlamp washer motor (1) from front washer tank.

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

When installing headlamp washer motor, there should be no packing twist, etc.

PKIC0463E

SKIB6858E

Page 3165 of 3171

WW-54

HEADLAMP WASHER

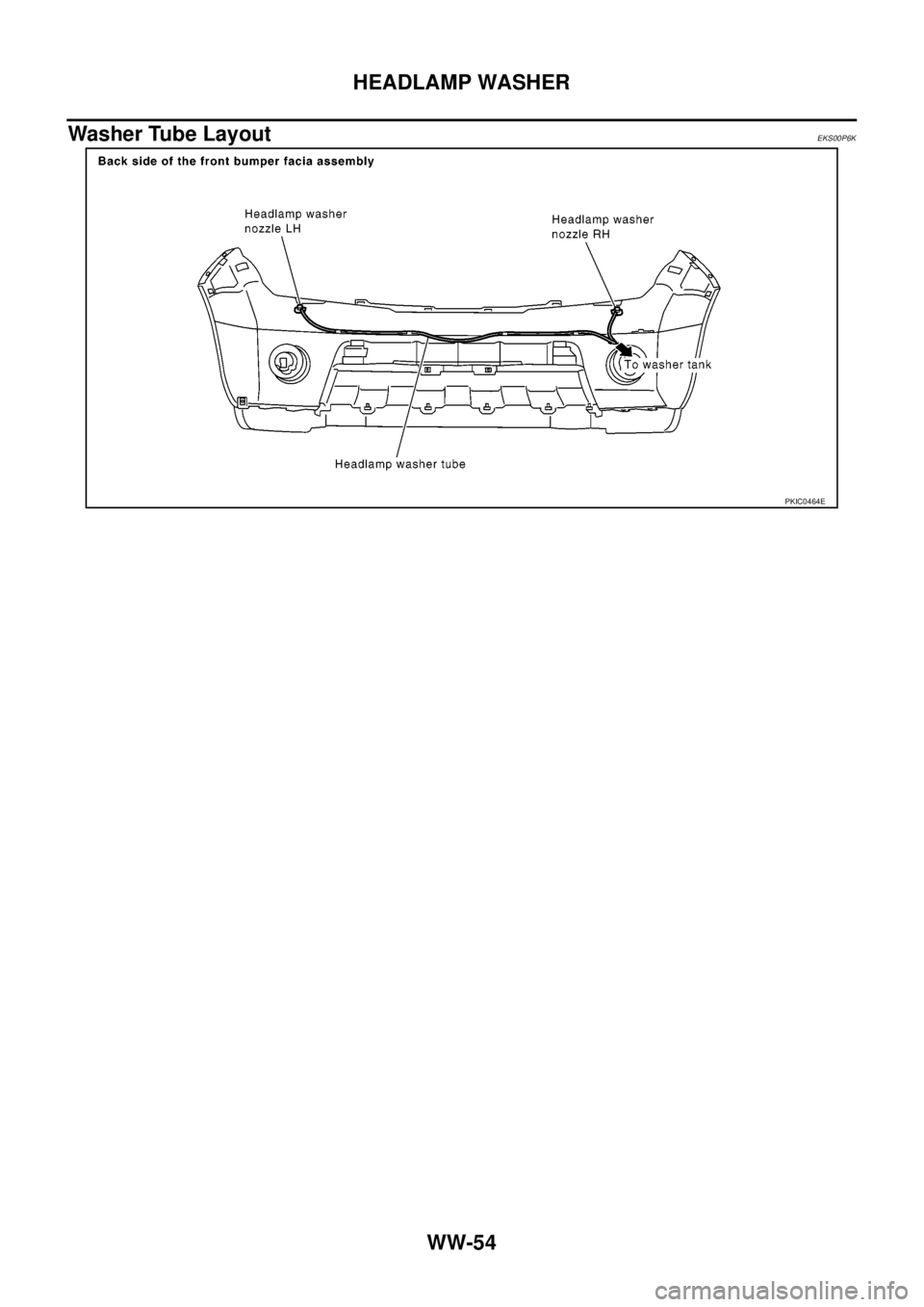

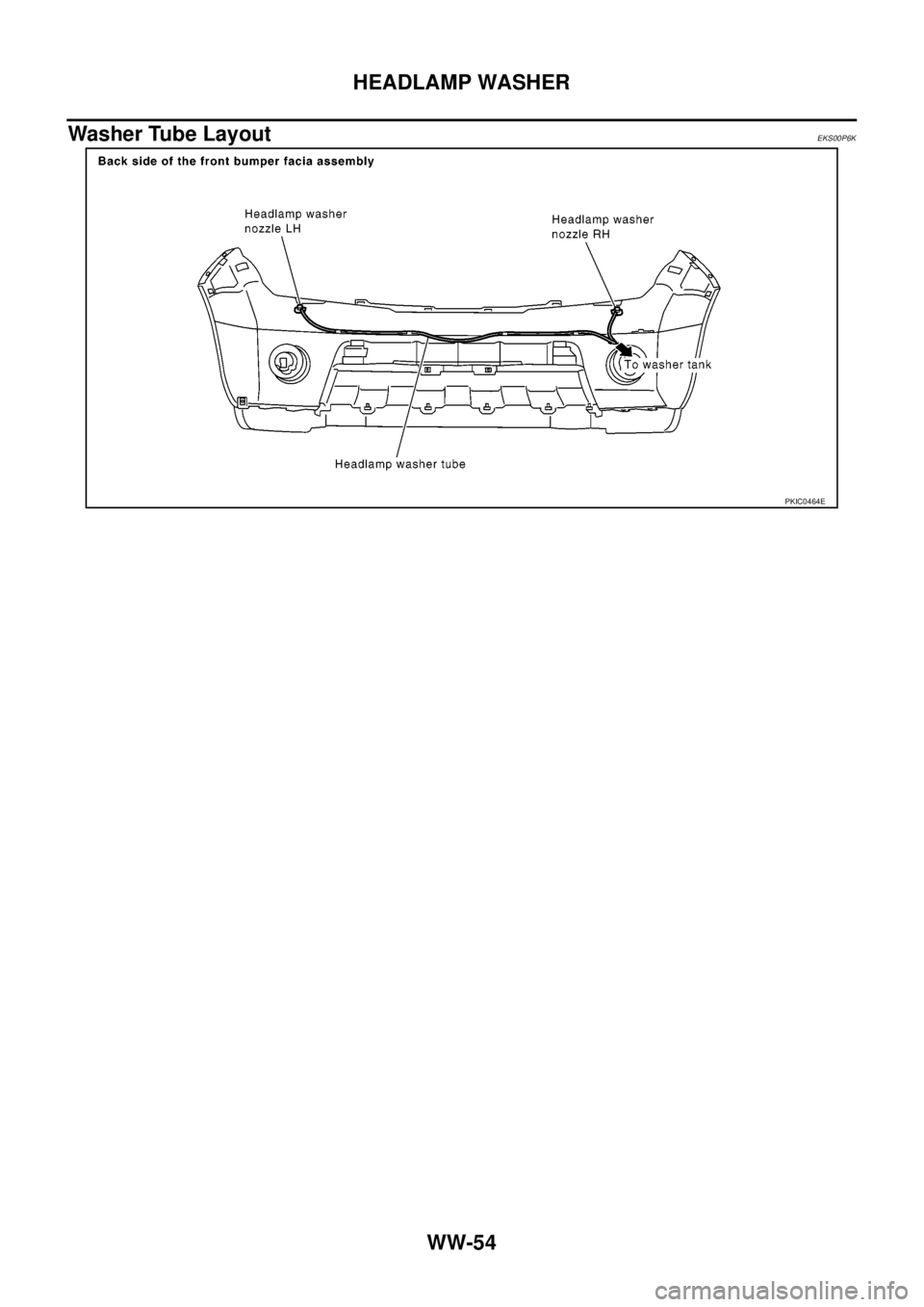

Washer Tube Layout

EKS00P6K

PKIC0464E

Page 3166 of 3171

CIGARETTE LIGHTER

WW-55

C

D

E

F

G

H

I

J

L

MA

B

WW

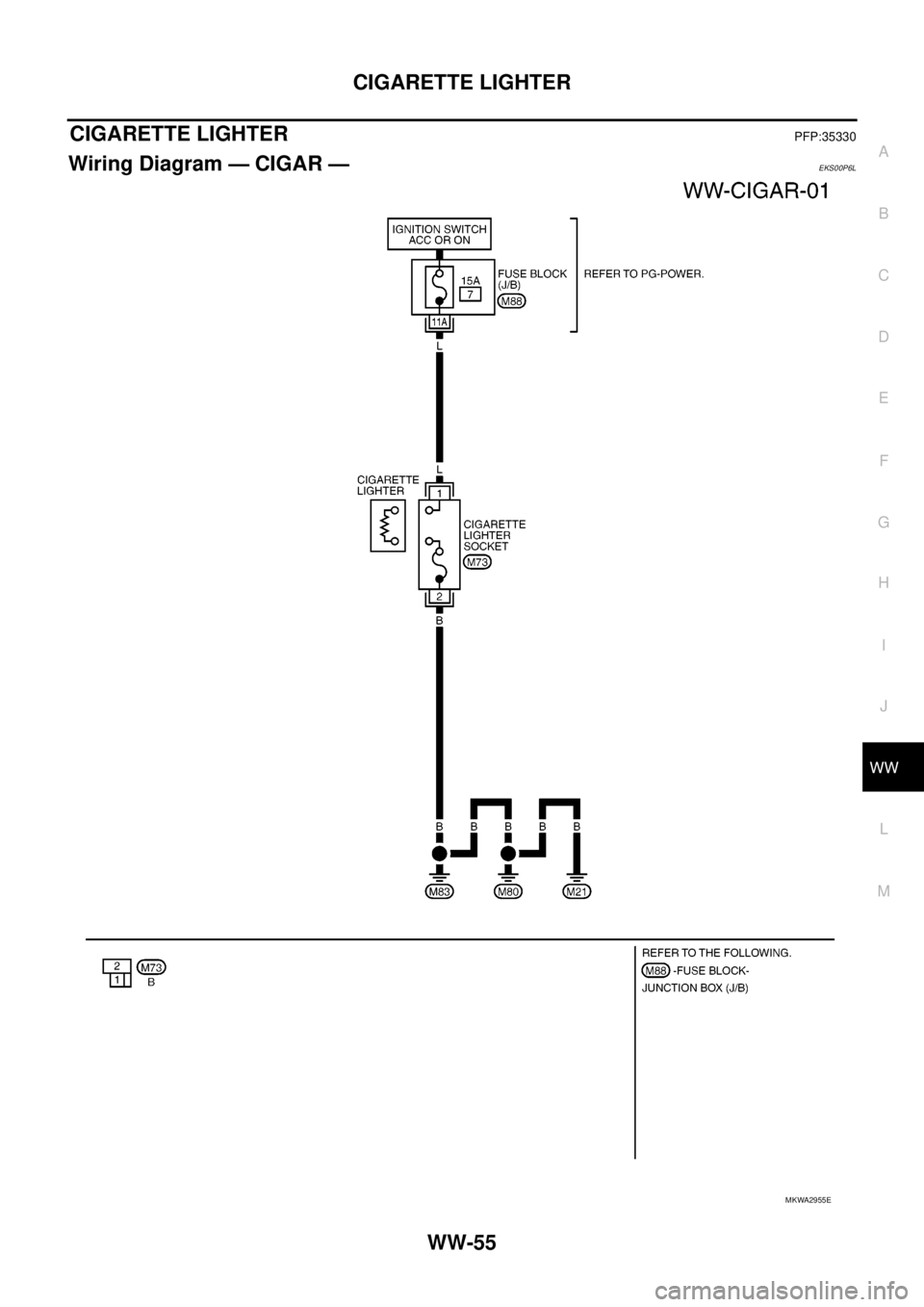

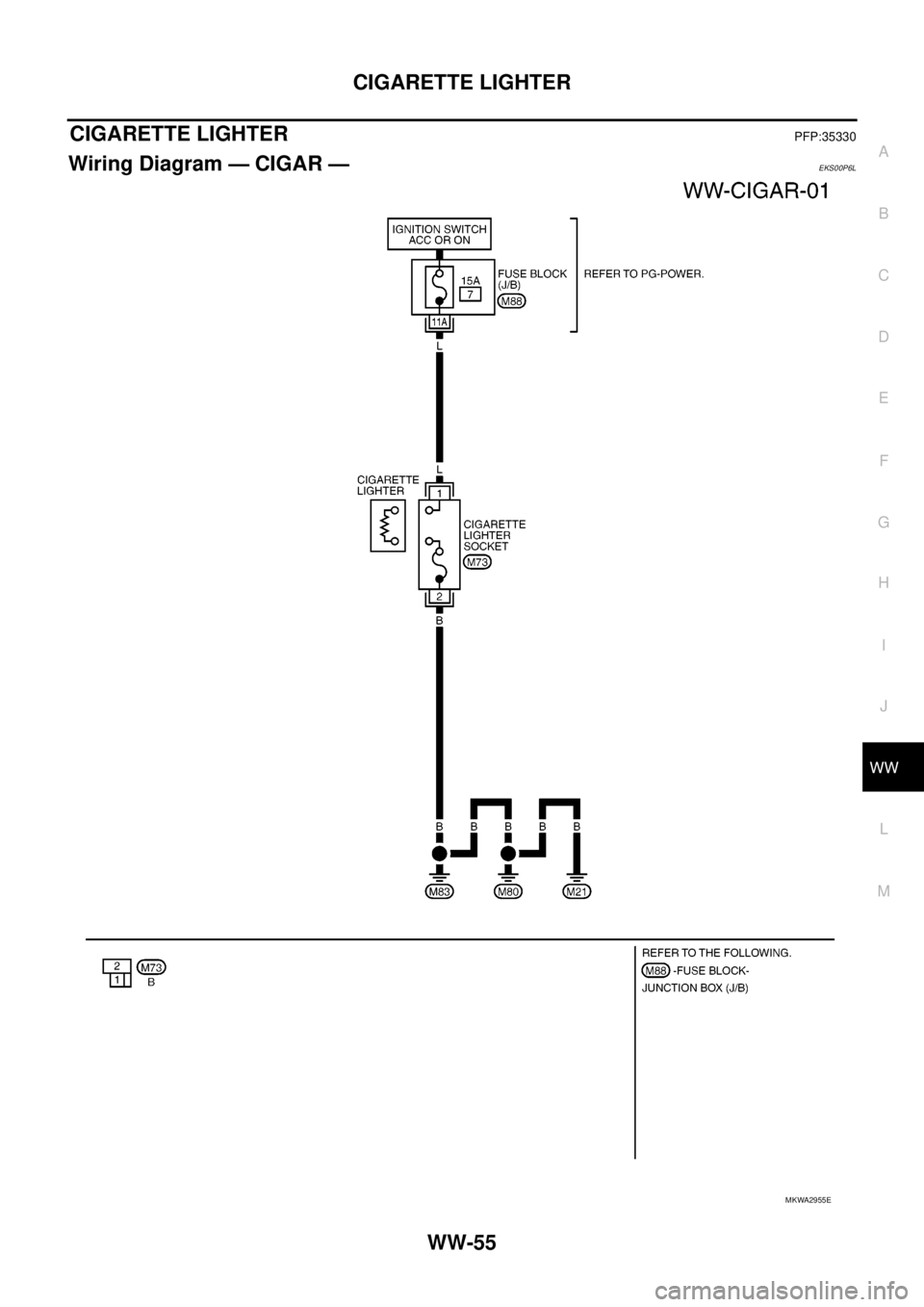

CIGARETTE LIGHTERPFP:35330

Wiring Diagram — CIGAR —EKS00P6L

MKWA2955E

Page 3167 of 3171

WW-56

CIGARETTE LIGHTER

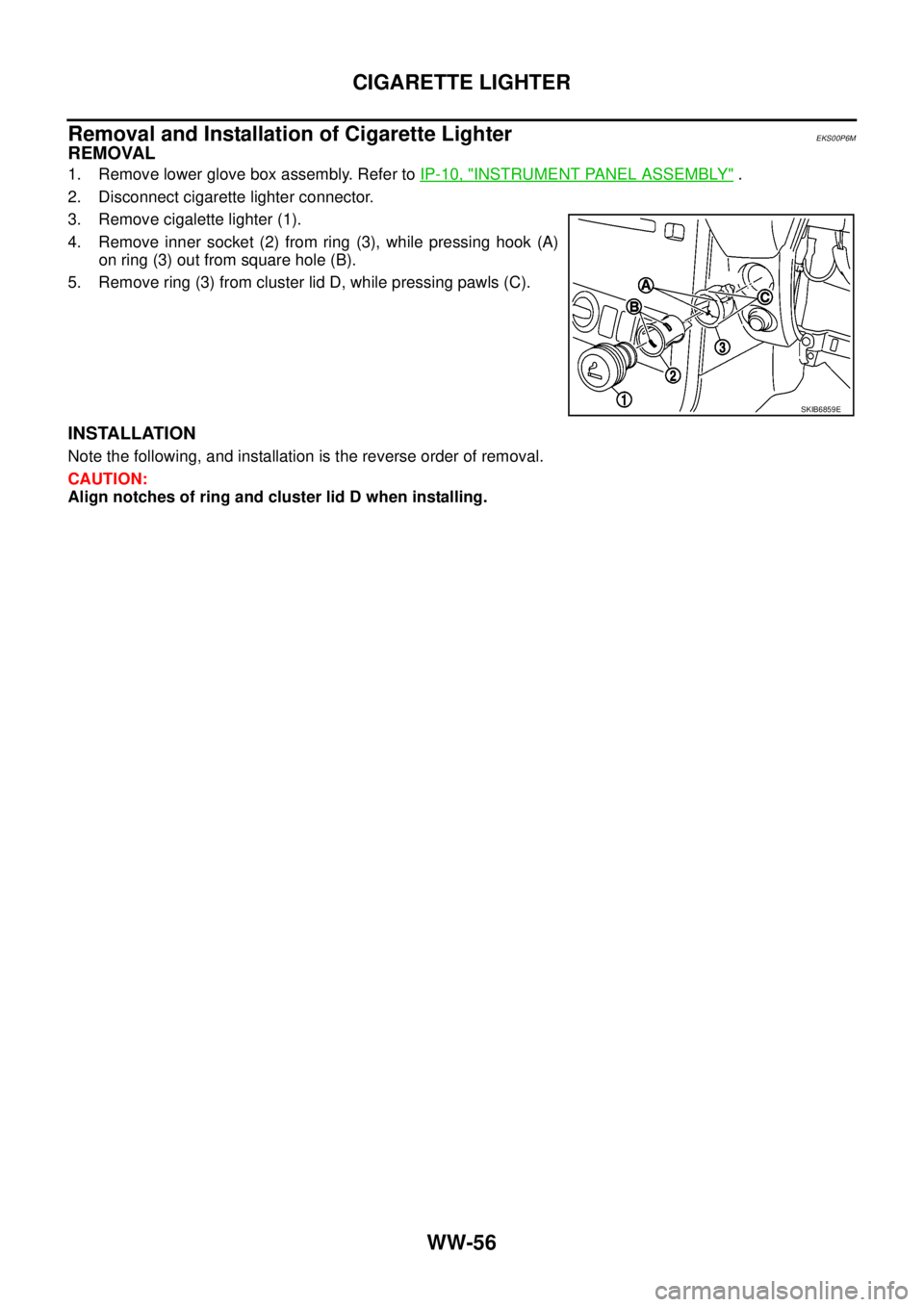

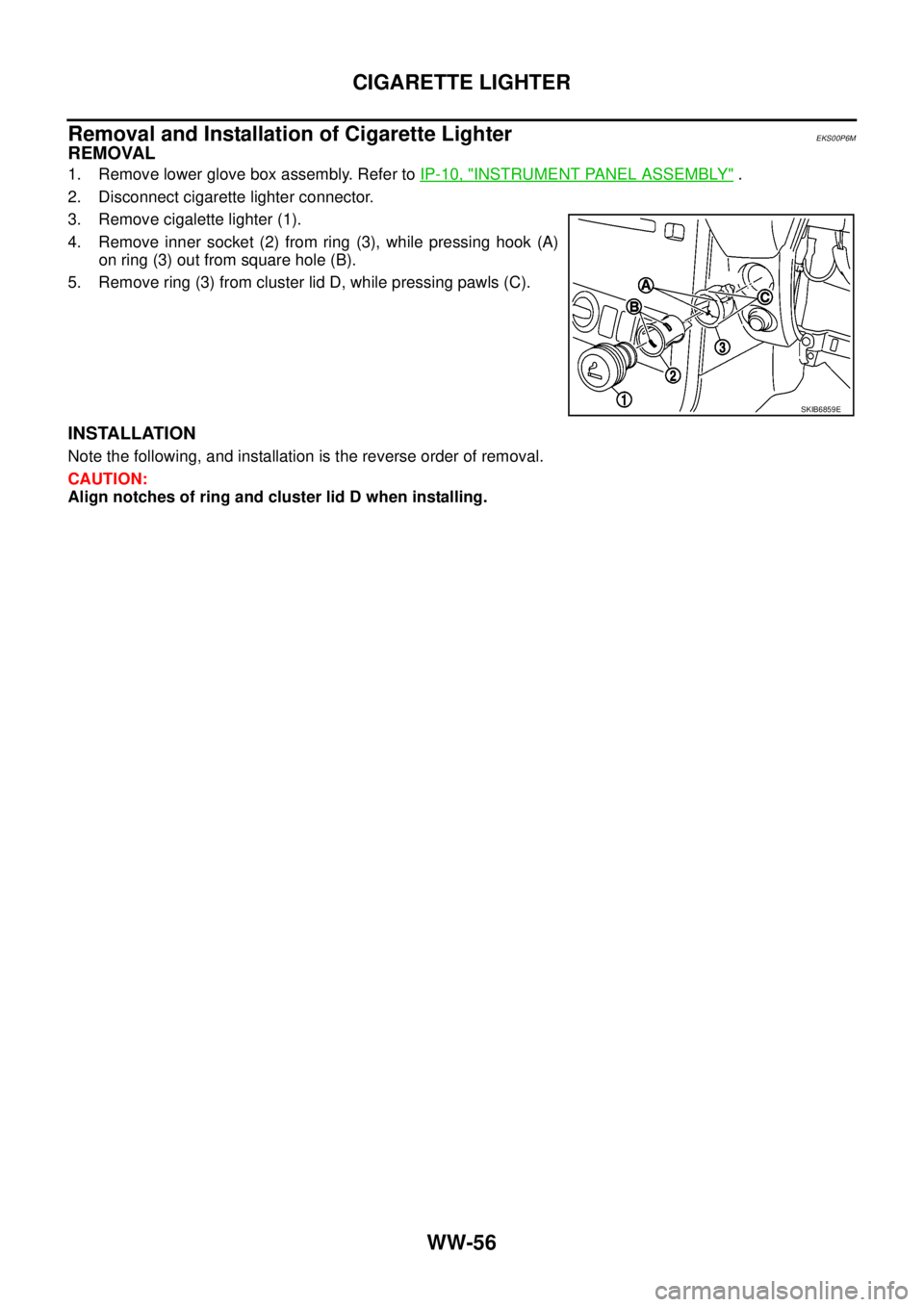

Removal and Installation of Cigarette Lighter

EKS00P6M

REMOVAL

1. Remove lower glove box assembly. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Disconnect cigarette lighter connector.

3. Remove cigalette lighter (1).

4. Remove inner socket (2) from ring (3), while pressing hook (A)

on ring (3) out from square hole (B).

5. Remove ring (3) from cluster lid D, while pressing pawls (C).

INSTALLATION

Note the following, and installation is the reverse order of removal.

CAUTION:

Align notches of ring and cluster lid D when installing.

SKIB6859E

Page 3168 of 3171

POWER SOCKET

WW-57

C

D

E

F

G

H

I

J

L

MA

B

WW

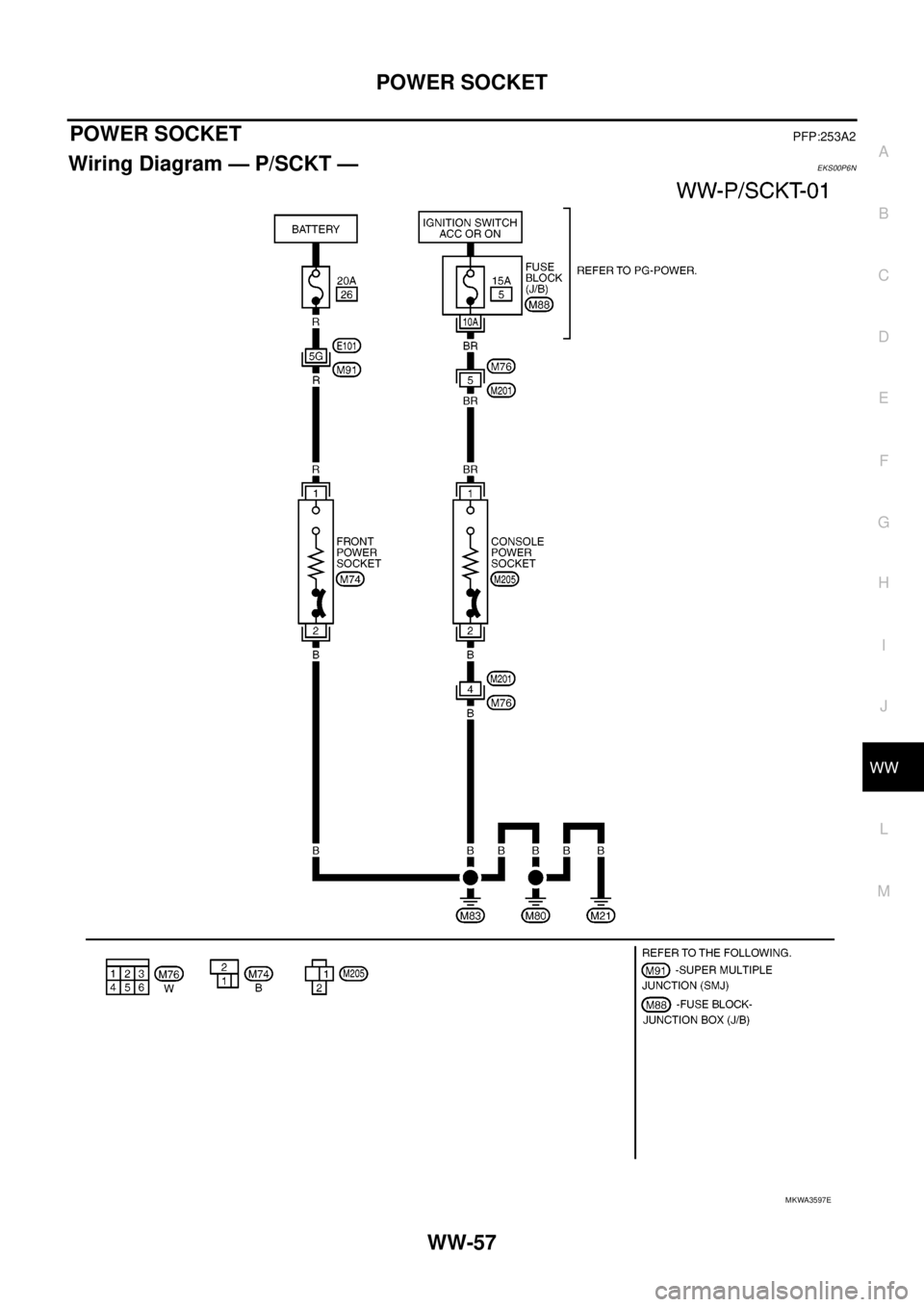

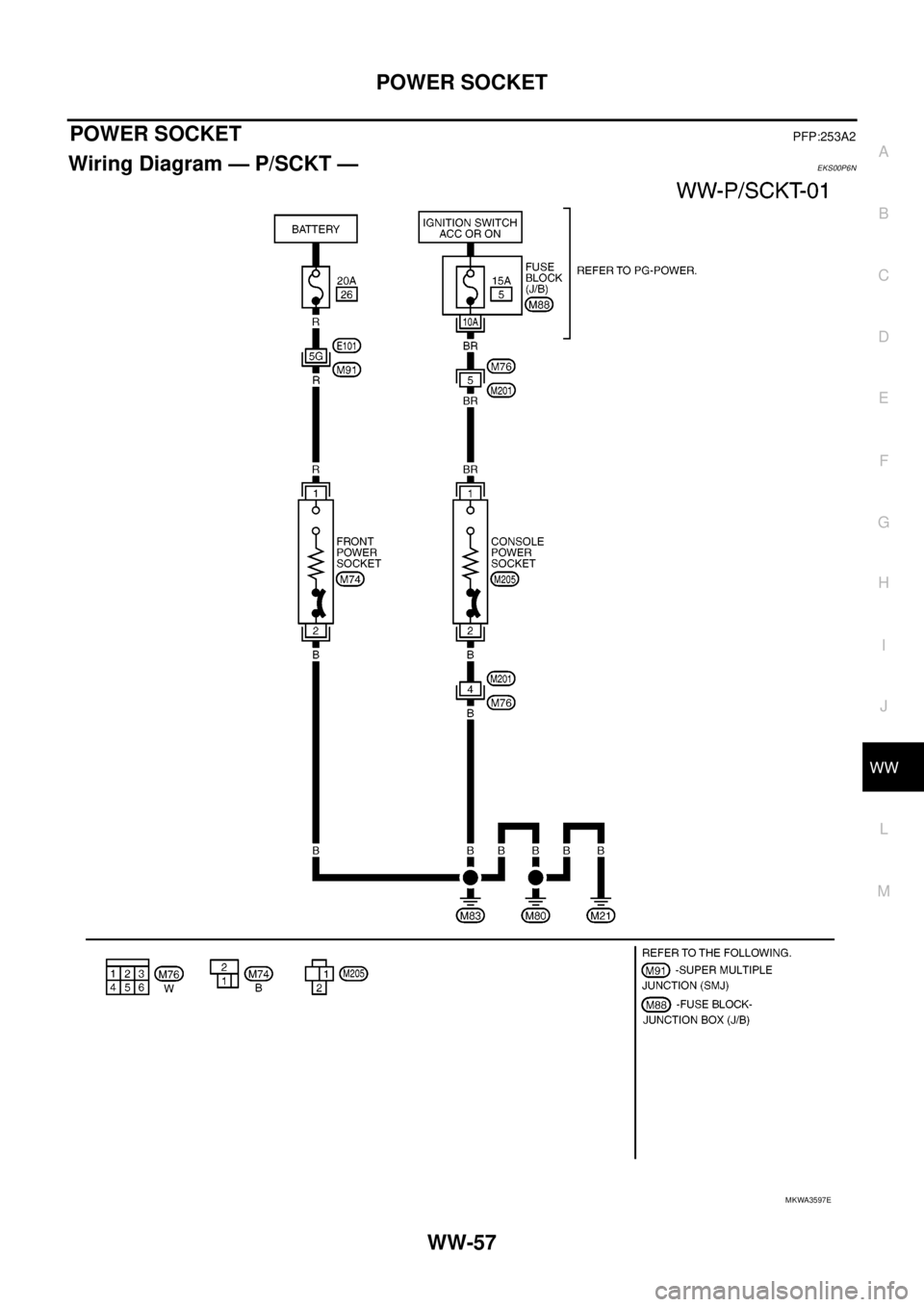

POWER SOCKETPFP:253A2

Wiring Diagram — P/SCKT —EKS00P6N

MKWA3597E

Page 3169 of 3171

WW-58

POWER SOCKET

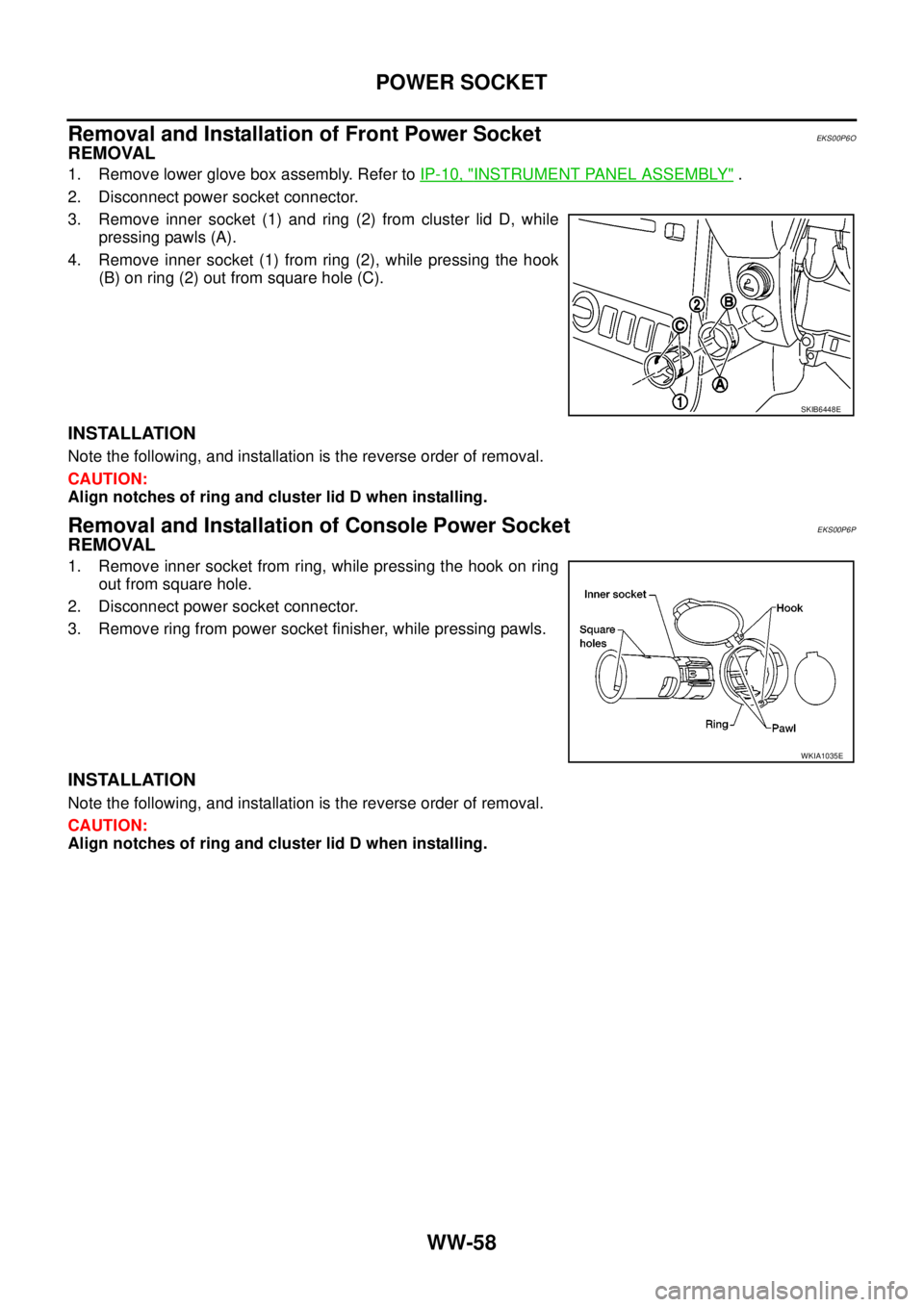

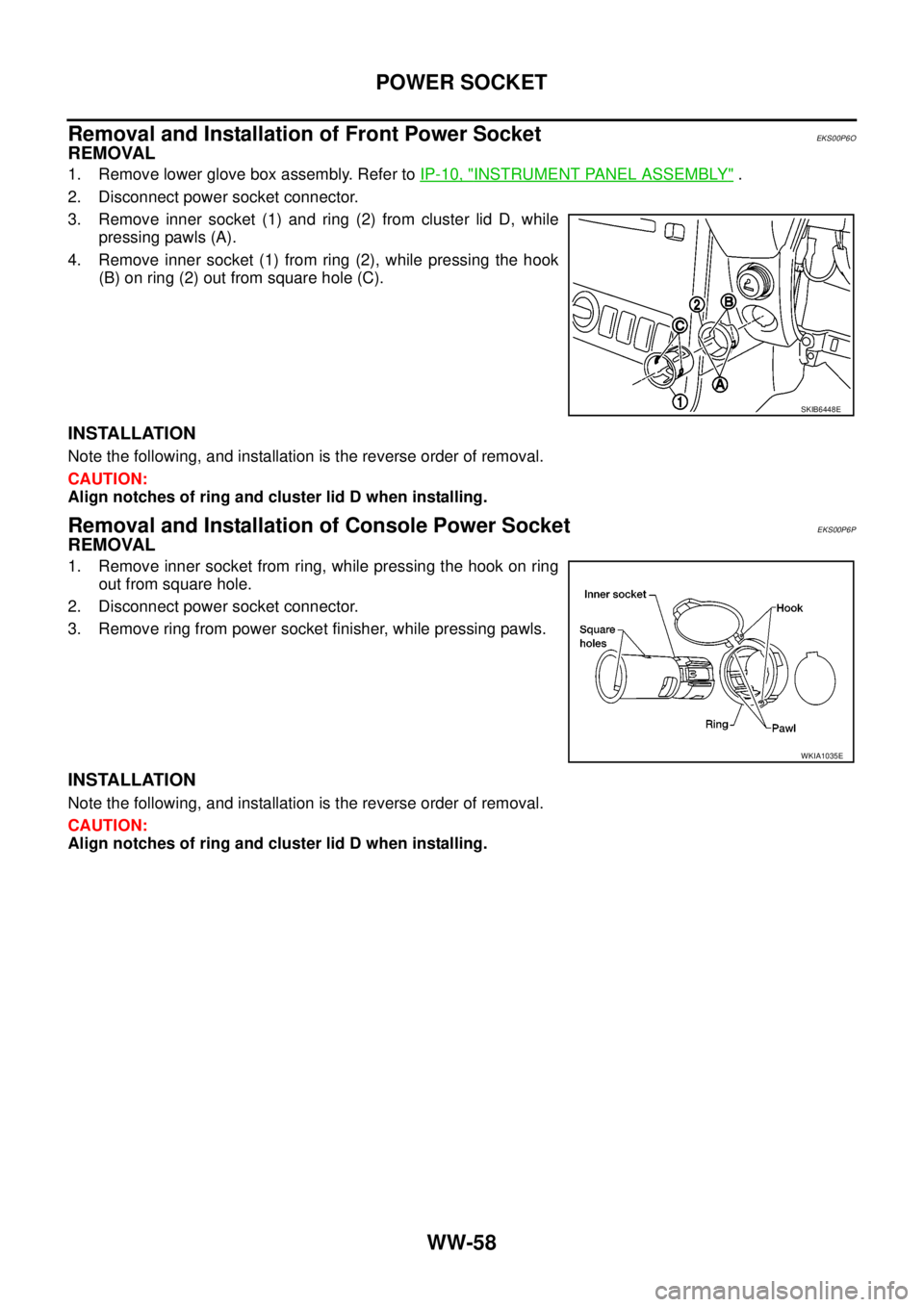

Removal and Installation of Front Power Socket

EKS00P6O

REMOVAL

1. Remove lower glove box assembly. Refer toIP-10, "INSTRUMENT PANEL ASSEMBLY".

2. Disconnect power socket connector.

3. Remove inner socket (1) and ring (2) from cluster lid D, while

pressing pawls (A).

4. Remove inner socket (1) from ring (2), while pressing the hook

(B) on ring (2) out from square hole (C).

INSTALLATION

Note the following, and installation is the reverse order of removal.

CAUTION:

Align notches of ring and cluster lid D when installing.

Removal and Installation of Console Power SocketEKS00P6P

REMOVAL

1. Remove inner socket from ring, while pressing the hook on ring

out from square hole.

2. Disconnect power socket connector.

3. Remove ring from power socket finisher, while pressing pawls.

INSTALLATION

Note the following, and installation is the reverse order of removal.

CAUTION:

Align notches of ring and cluster lid D when installing.

SKIB6448E

WKIA1035E

Page 3170 of 3171

HORN

WW-59

C

D

E

F

G

H

I

J

L

MA

B

WW

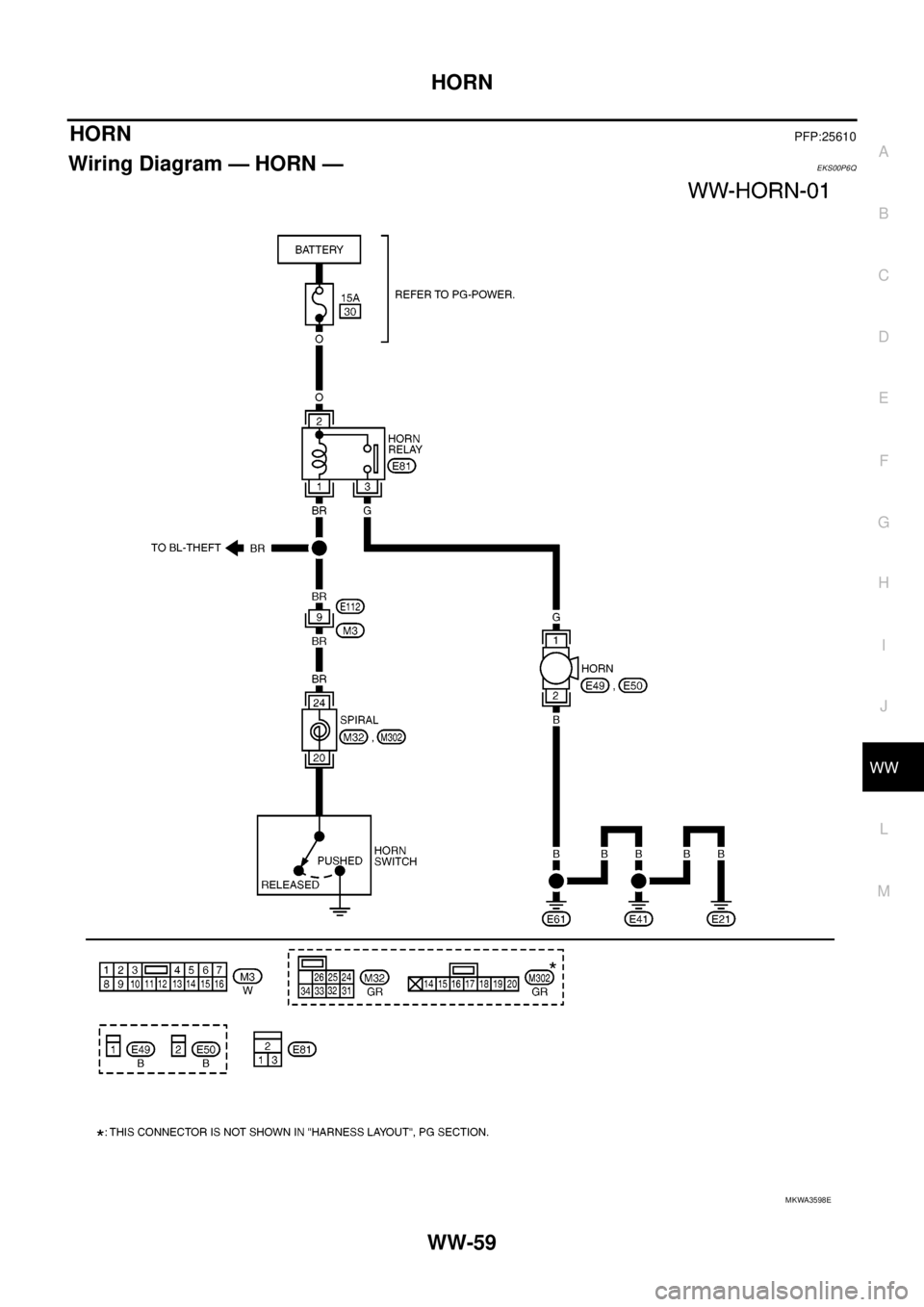

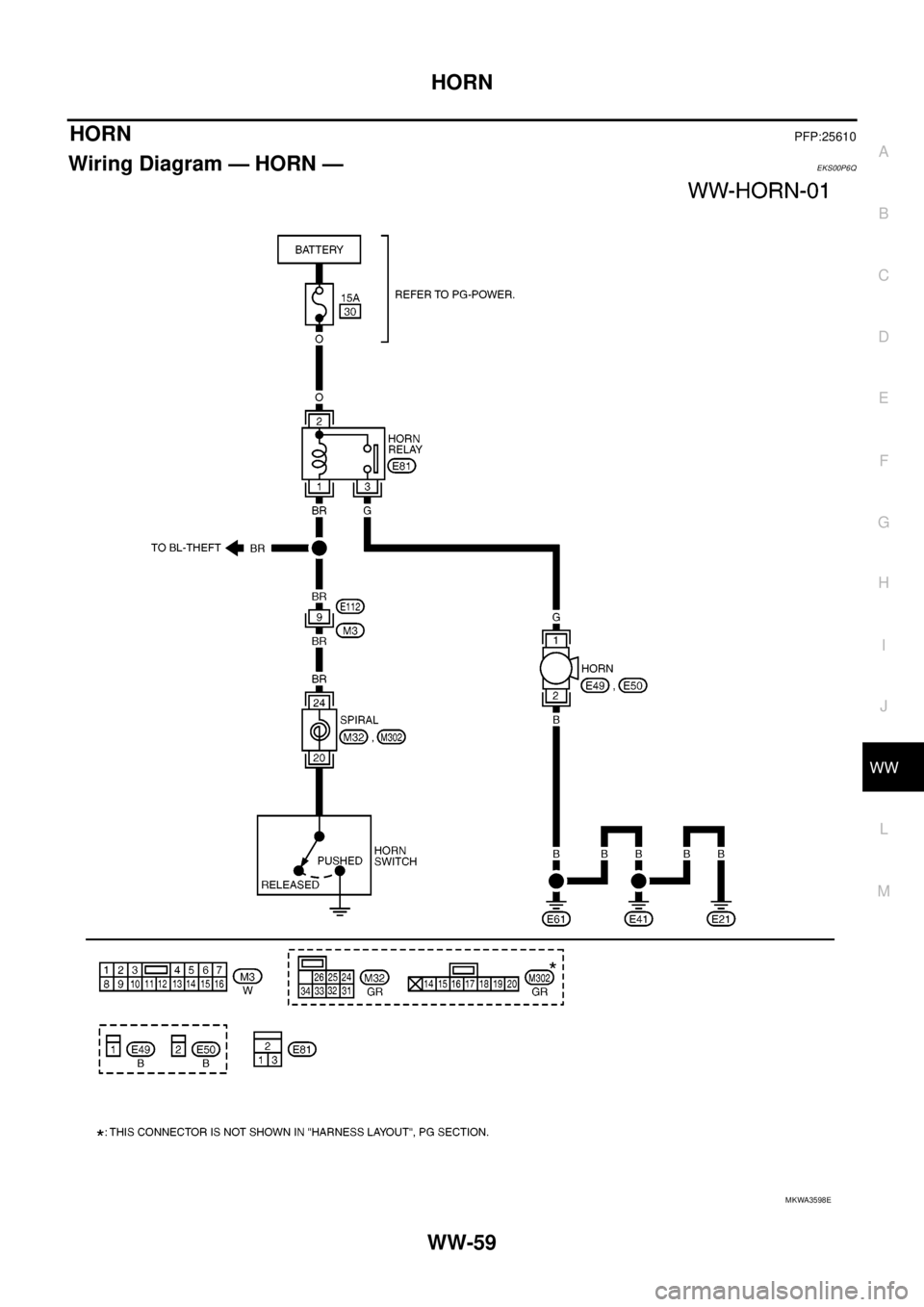

HORNPFP:25610

Wiring Diagram — HORN —EKS00P6Q

MKWA3598E

Trending: instrument panel, trunk release, change time, trip computer, jacking, wheel torque, lug pattern