tow NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1607 of 3171

ON-VEHICLE SERVICE

FSU-7

C

D

F

G

H

I

J

K

L

MA

B

FSU

ON-VEHICLE SERVICEPFP:00000

Front Suspension PartsEES002KM

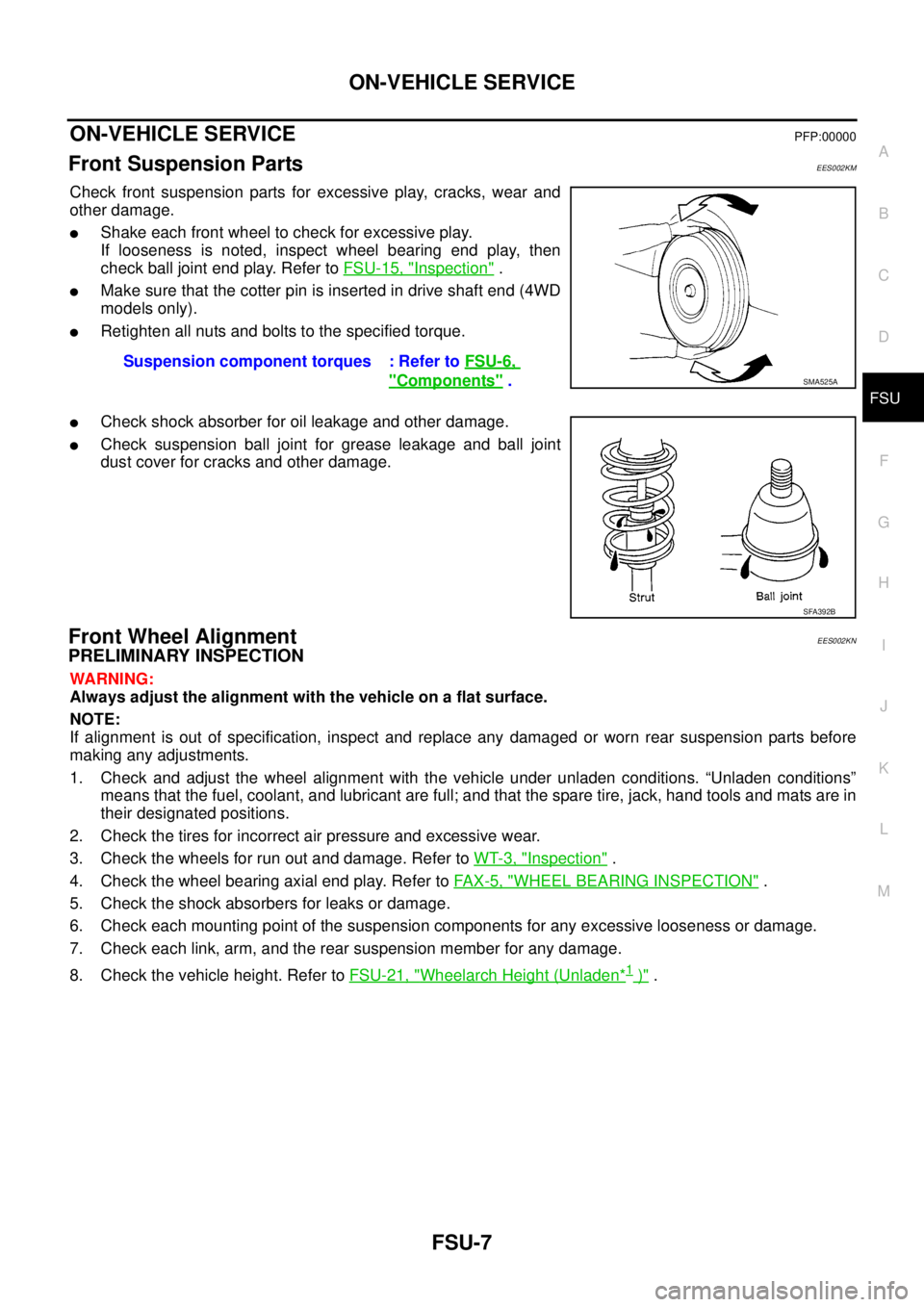

Check front suspension parts for excessive play, cracks, wear and

other damage.

lShake each front wheel to check for excessive play.

If looseness is noted, inspect wheel bearing end play, then

check ball joint end play. Refer toFSU-15, "

Inspection".

lMake sure that the cotter pin is inserted in drive shaft end (4WD

models only).

lRetighten all nuts and bolts to the specified torque.

lCheck shock absorber for oil leakage and other damage.

lCheck suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

Front Wheel AlignmentEES002KN

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer toWT-3, "

Inspection".

4. Check the wheel bearing axial end play. Refer toFA X - 5 , "

WHEEL BEARING INSPECTION".

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer toFSU-21, "

Wheelarch Height (Unladen*1)". Suspension component torques : Refer toFSU-6,

"Components".SMA525A

SFA392B

Page 1610 of 3171

FSU-10

COIL SPRING AND SHOCK ABSORBER

COIL SPRING AND SHOCK ABSORBER

PFP:56210

Removal and InstallationEES002KO

REMOVAL

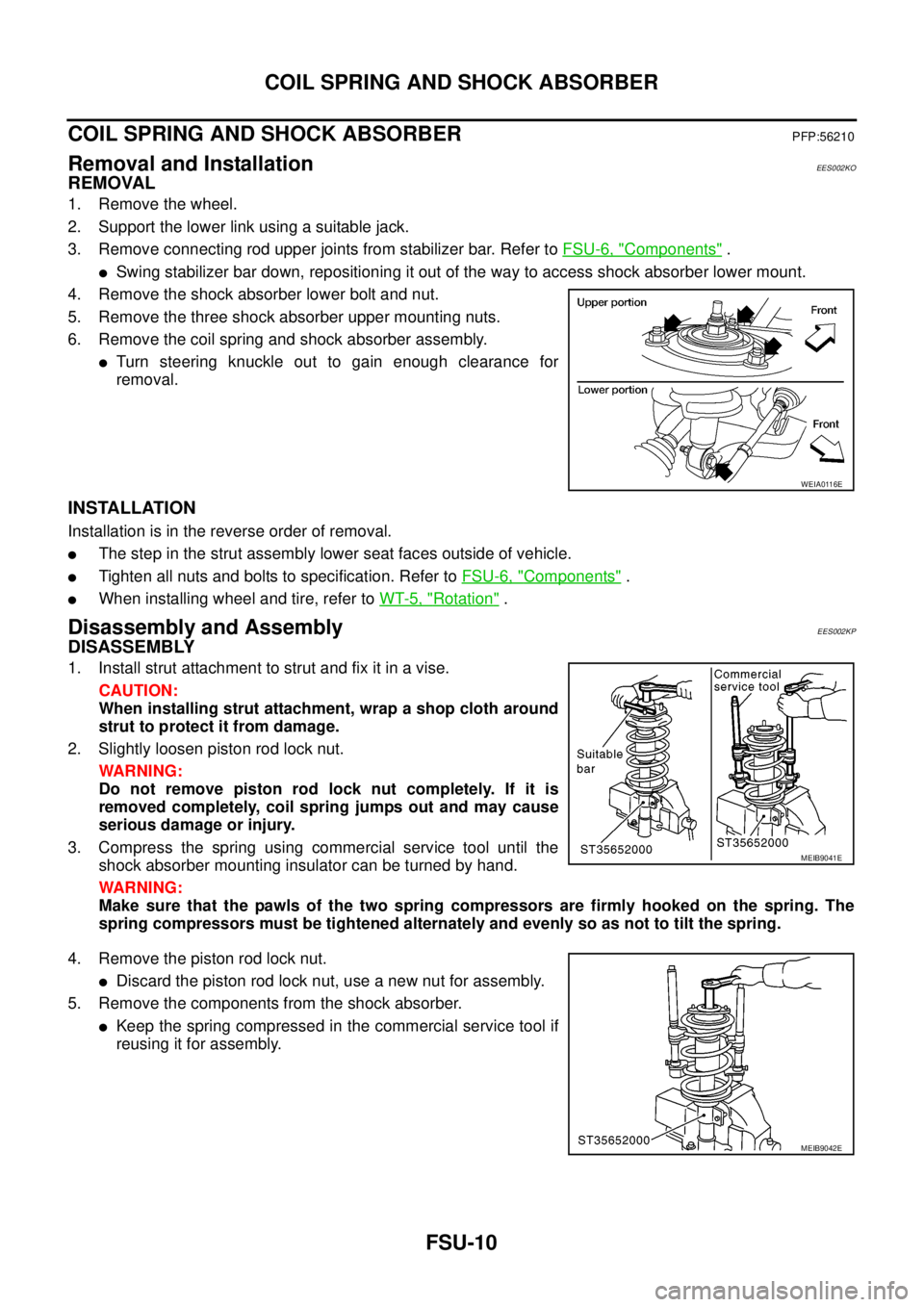

1. Remove the wheel.

2. Support the lower link using a suitable jack.

3. Remove connecting rod upper joints from stabilizer bar. Refer toFSU-6, "

Components".

lSwing stabilizer bar down, repositioning it out of the way to access shock absorber lower mount.

4. Remove the shock absorber lower bolt and nut.

5. Remove the three shock absorber upper mounting nuts.

6. Remove the coil spring and shock absorber assembly.

lTurn steering knuckle out to gain enough clearance for

removal.

INSTALLATION

Installation is in the reverse order of removal.

lThe step in the strut assembly lower seat faces outside of vehicle.

lTighten all nuts and bolts to specification. Refer toFSU-6, "Components".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

Disassembly and AssemblyEES002KP

DISASSEMBLY

1. Install strut attachment to strut and fix it in a vise.

CAUTION:

When installing strut attachment, wrap a shop cloth around

strut to protect it from damage.

2. Slightly loosen piston rod lock nut.

WARNING:

Do not remove piston rod lock nut completely. If it is

removed completely, coil spring jumps out and may cause

serious damage or injury.

3. Compress the spring using commercial service tool until the

shock absorber mounting insulator can be turned by hand.

WARNING:

Make sure that the pawls of the two spring compressors are firmly hooked on the spring. The

spring compressors must be tightened alternately and evenly so as not to tilt the spring.

4. Remove the piston rod lock nut.

lDiscard the piston rod lock nut, use a new nut for assembly.

5. Remove the components from the shock absorber.

lKeep the spring compressed in the commercial service tool if

reusing it for assembly.

WEIA0116E

MEIB9041E

MEIB9042E

Page 1613 of 3171

UPPER LINK

FSU-13

C

D

F

G

H

I

J

K

L

MA

B

FSU

UPPER LINKPFP:54524

Removal and InstallationEES002KR

REMOVAL

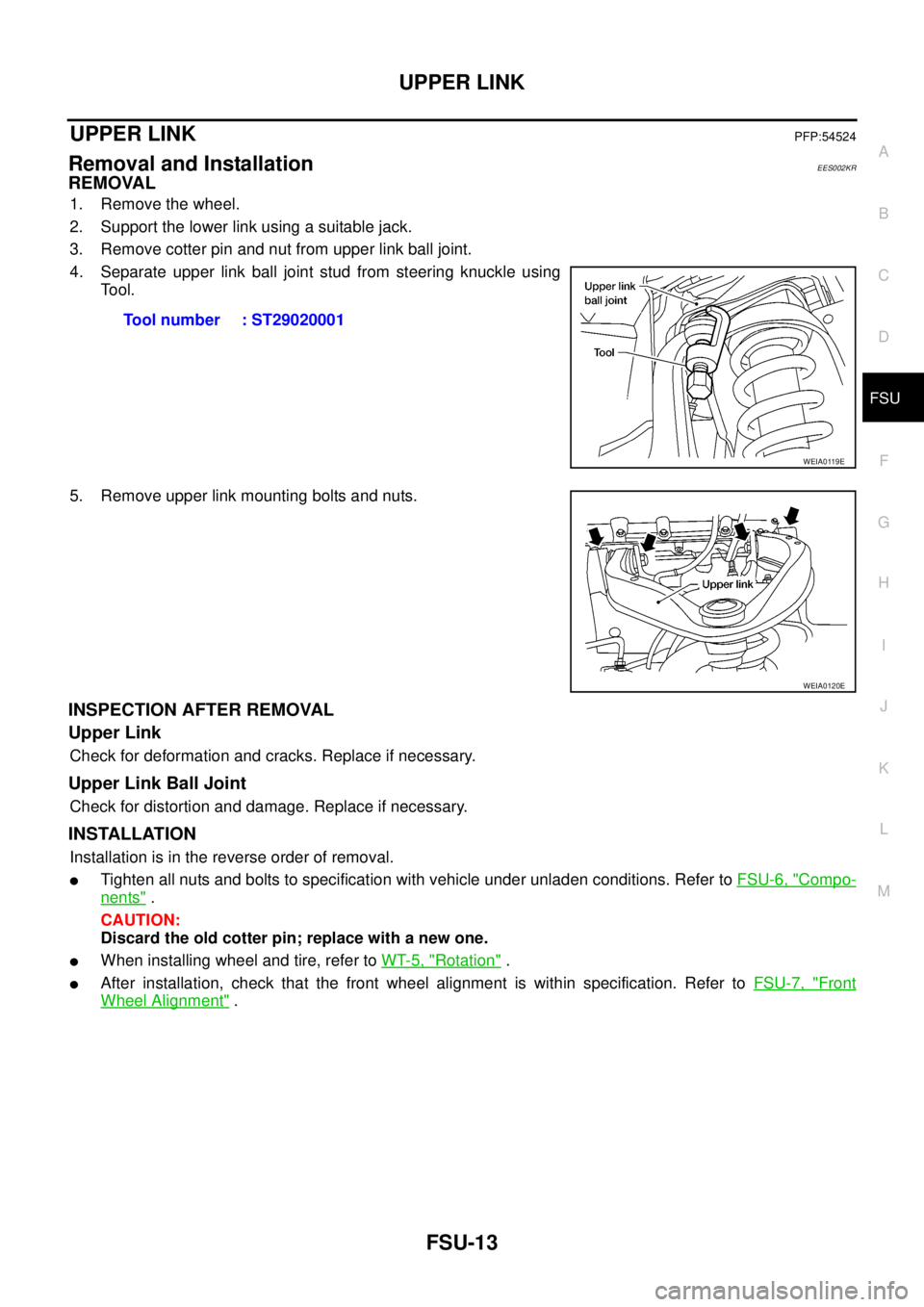

1. Remove the wheel.

2. Support the lower link using a suitable jack.

3. Remove cotter pin and nut from upper link ball joint.

4. Separate upper link ball joint stud from steering knuckle using

Tool.

5. Remove upper link mounting bolts and nuts.

INSPECTION AFTER REMOVAL

Upper Link

Check for deformation and cracks. Replace if necessary.

Upper Link Ball Joint

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lTighten all nuts and bolts to specification with vehicle under unladen conditions. Refer toFSU-6, "Compo-

nents".

CAUTION:

Discard the old cotter pin; replace with a new one.

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lAfter installation, check that the front wheel alignment is within specification. Refer toFSU-7, "Front

Wheel Alignment". Tool number : ST29020001

WEIA0119E

WEIA0120E

Page 1614 of 3171

FSU-14

LOWER LINK

LOWER LINK

PFP:55020

Removal and InstallationEES002KS

REMOVAL

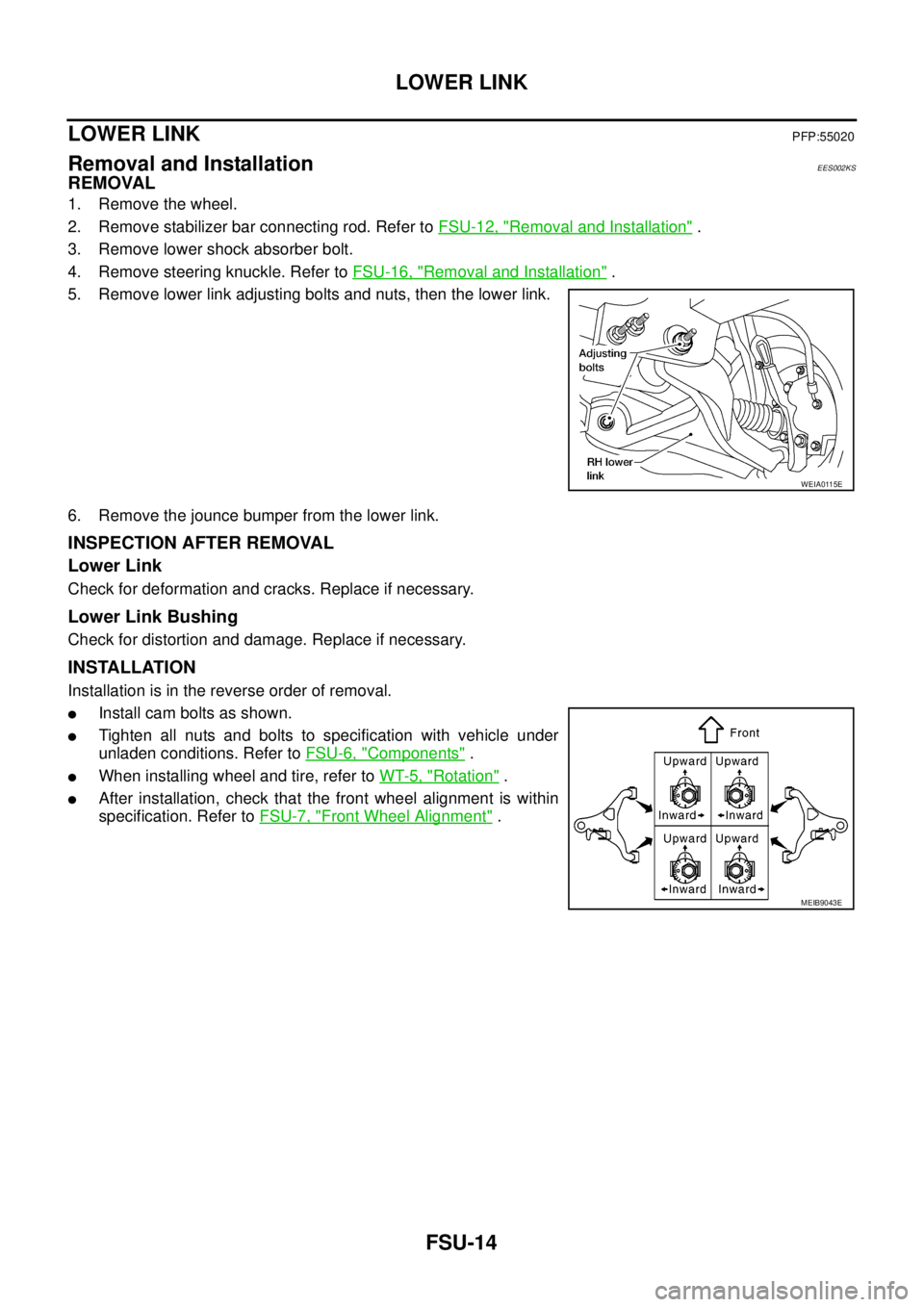

1. Remove the wheel.

2. Remove stabilizer bar connecting rod. Refer toFSU-12, "

Removal and Installation".

3. Remove lower shock absorber bolt.

4. Remove steering knuckle. Refer toFSU-16, "

Removal and Installation".

5. Remove lower link adjusting bolts and nuts, then the lower link.

6. Remove the jounce bumper from the lower link.

INSPECTION AFTER REMOVAL

Lower Link

Check for deformation and cracks. Replace if necessary.

Lower Link Bushing

Check for distortion and damage. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lInstall cam bolts as shown.

lTighten all nuts and bolts to specification with vehicle under

unladen conditions. Refer toFSU-6, "

Components".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lAfter installation, check that the front wheel alignment is within

specification. Refer toFSU-7, "

Front Wheel Alignment".

WEIA0115E

MEIB9043E

Page 1618 of 3171

FSU-18

KNUCKLE

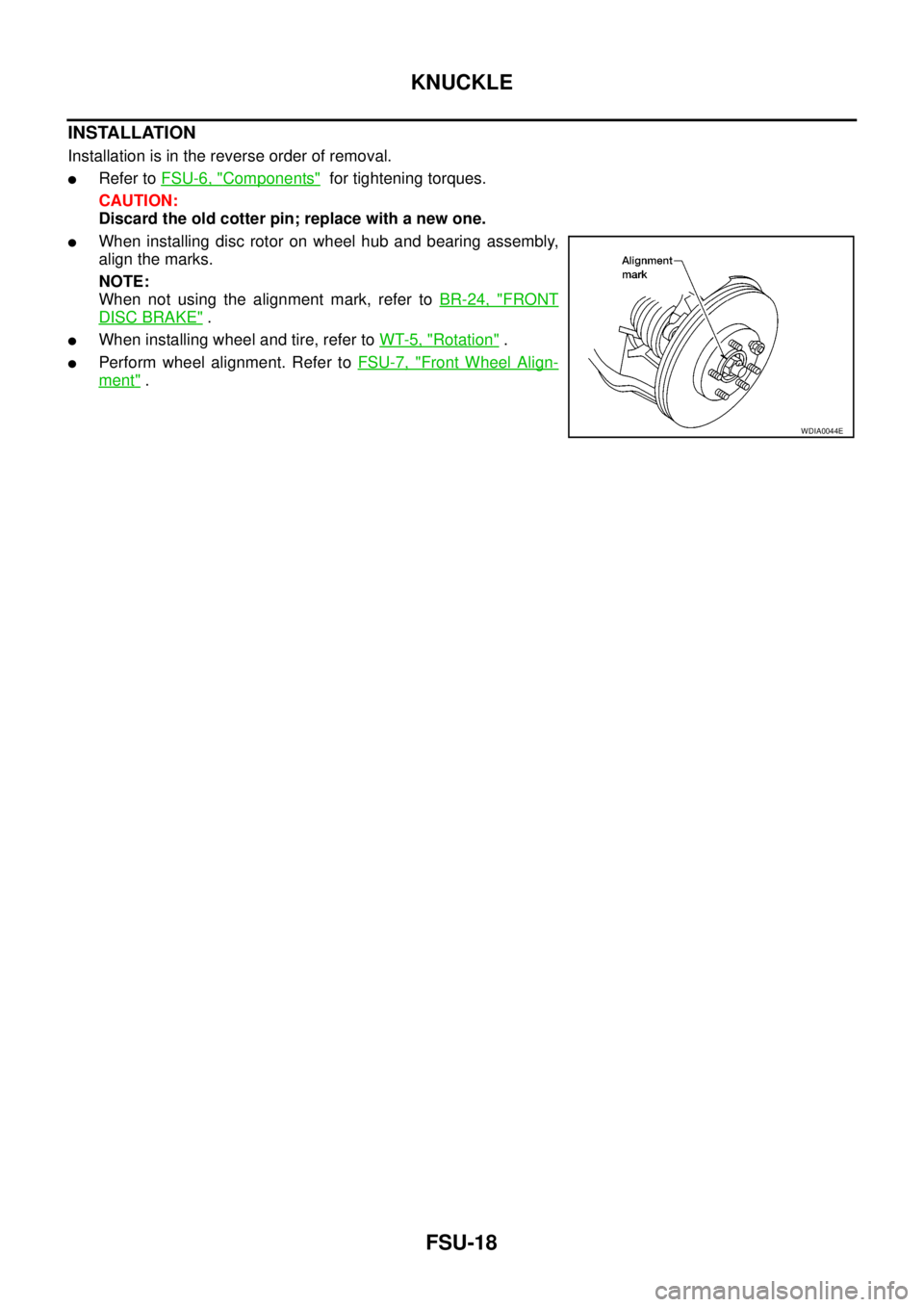

INSTALLATION

Installation is in the reverse order of removal.

lRefer toFSU-6, "Components"for tightening torques.

CAUTION:

Discard the old cotter pin; replace with a new one.

lWhen installing disc rotor on wheel hub and bearing assembly,

align the marks.

NOTE:

When not using the alignment mark, refer toBR-24, "

FRONT

DISC BRAKE".

lWhen installing wheel and tire, refer toWT-5, "Rotation".

lPerform wheel alignment. Refer toFSU-7, "Front Wheel Align-

ment".

WDIA0044E

Page 1623 of 3171

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTIONGI

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions for NATS (NISSAN ANTI-THEFT SYS-

TEM) ........................................................................ 3

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 3

OPERATION PROCEDURE ................................. 4

General Precautions ................................................ 4

Precautions for Three Way Catalyst ......................... 5

Precautions for Fuel ................................................. 5

GASOLINE ENGINE ............................................. 5

DIESEL ENGINE ................................................... 6

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 6

Precautions for Turbocharger (If Equipped) ............. 6

Precautions for Hoses .............................................. 6

HOSE REMOVAL AND INSTALLATION ............... 6

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 7

HEALTH PROTECTION PRECAUTIONS ............. 7

ENVIRONMENTAL PROTECTION PRECAU-

TIONS ................................................................... 8

Precautions for Air Conditioning ............................... 8

HOW TO USE THIS MANUAL ................................... 9

Description ............................................................... 9

Terms ....................................................................... 9

Units ......................................................................... 9

Contents ................................................................... 9

Components ........................................................... 10

SYMBOLS ........................................................... 10

How to Follow Trouble Diagnoses ........................... 11

DESCRIPTION ..................................................... 11

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ................................................ 11

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ....................................... 12

KEY TO SYMBOLS SIGNIFYING MEASURE-MENTS OR PROCEDURES ............................... 13

How to Read Wiring Diagrams ............................... 15

CONNECTOR SYMBOLS ................................... 15

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 16

DESCRIPTION .................................................... 17

Abbreviations .......................................................... 23

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 24

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 24

WORK FLOW ...................................................... 24

INCIDENT SIMULATION TESTS ........................ 24

CIRCUIT INSPECTION ....................................... 27

Control Units and Electrical Parts ........................... 32

PRECAUTIONS .................................................. 32

CONTROL UNIT CONFIGURATION PROCEDURE... 34

Description .............................................................. 34

Part Replacement procedure Reference Table ...... 34

Work Procedure ...................................................... 36

Configuration (BCM) ............................................... 37

DESCRIPTION .................................................... 37

READ CONFIGURATION PROCEDURE ............ 37

WRITE CONFIGURATION PROCEDURE .......... 41

CONSULT-II CHECKING SYSTEM .......................... 47

Description .............................................................. 47

Function and System Application ........................... 47

Nickel Metal Hydride Battery Replacement ............ 48

Checking Equipment .............................................. 49

CONSULT-II Start Procedure .................................. 49

CONSULT-II Data Link Connector (DLC) Circuit .... 50

INSPECTION PROCEDURE .............................. 51

LIFTING POINT ......................................................... 52

Pantograph Jack, Garage Jack and Safety Stand... 52

2-Pole Lift ............................................................... 52

TOW TRUCK TOWING ............................................. 53

Tow Truck Towing ................................................... 53

4X2 MODEL ........................................................ 53

4X4 MODEL ........................................................ 54

TOWING POINT .................................................. 54

Vehicle Recovery (Freeing a Stuck Vehicle) ........... 54

Page 1675 of 3171

TOW TRUCK TOWING

GI-53

C

D

E

F

G

H

I

J

K

L

MB

GI

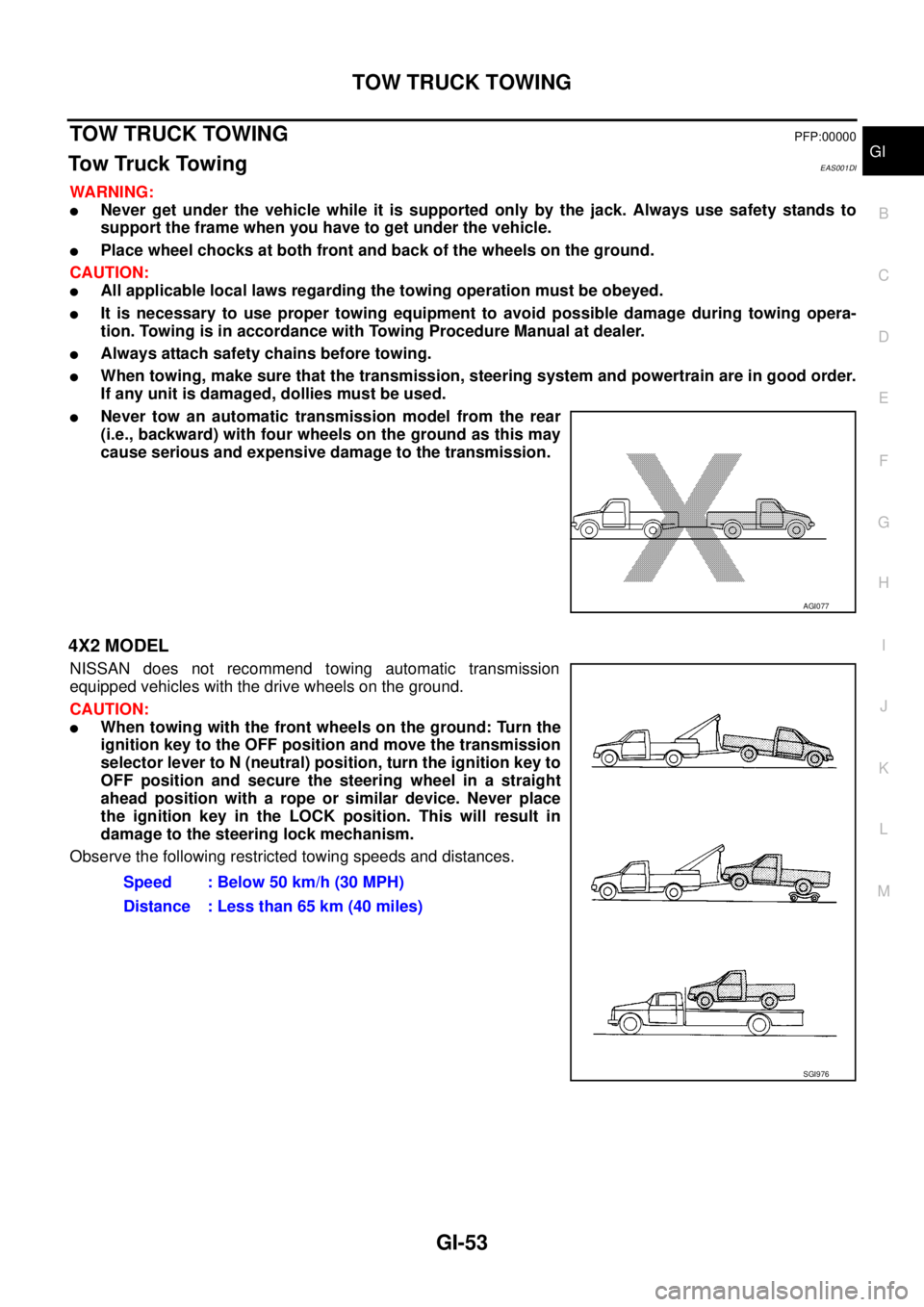

TOW TRUCK TOWINGPFP:00000

To w Tr u c k To w i n gEAS001DI

WARNING:

lNever get under the vehicle while it is supported only by the jack. Always use safety stands to

support the frame when you have to get under the vehicle.

lPlace wheel chocks at both front and back of the wheels on the ground.

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage during towing opera-

tion. Towing is in accordance with Towing Procedure Manual at dealer.

lAlways attach safety chains before towing.

lWhen towing, make sure that the transmission, steering system and powertrain are in good order.

If any unit is damaged, dollies must be used.

lNever tow an automatic transmission model from the rear

(i.e., backward) with four wheels on the ground as this may

cause serious and expensive damage to the transmission.

4X2 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground: Turn the

ignition key to the OFF position and move the transmission

selector lever to N (neutral) position, turn the ignition key to

OFF position and secure the steering wheel in a straight

ahead position with a rope or similar device. Never place

the ignition key in the LOCK position. This will result in

damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

AGI077

Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI976

Page 1676 of 3171

GI-54

TOW TRUCK TOWING

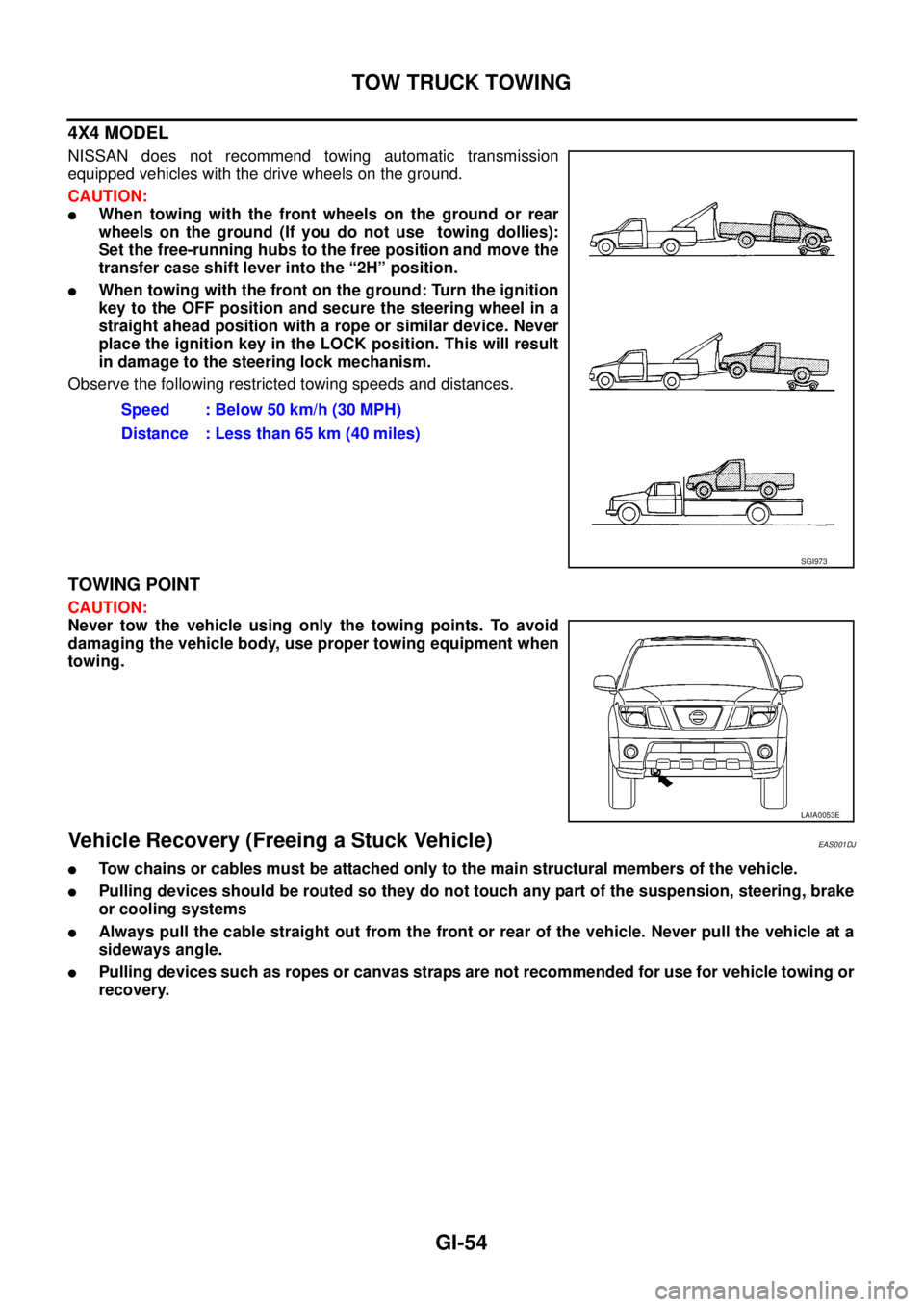

4X4 MODEL

NISSAN does not recommend towing automatic transmission

equipped vehicles with the drive wheels on the ground.

CAUTION:

lWhen towing with the front wheels on the ground or rear

wheels on the ground (If you do not use towing dollies):

Set the free-running hubs to the free position and move the

transfer case shift lever into the “2H” position.

lWhen towing with the front on the ground: Turn the ignition

key to the OFF position and secure the steering wheel in a

straight ahead position with a rope or similar device. Never

place the ignition key in the LOCK position. This will result

in damage to the steering lock mechanism.

Observe the following restricted towing speeds and distances.

TOWING POINT

CAUTION:

Never tow the vehicle using only the towing points. To avoid

damaging the vehicle body, use proper towing equipment when

towing.

Vehicle Recovery (Freeing a Stuck Vehicle)EAS001DJ

lTow chains or cables must be attached only to the main structural members of the vehicle.

lPulling devices should be routed so they do not touch any part of the suspension, steering, brake

or cooling systems

lAlways pull the cable straight out from the front or rear of the vehicle. Never pull the vehicle at a

sideways angle.

lPulling devices such as ropes or canvas straps are not recommended for use for vehicle towing or

recovery.Speed : Below 50 km/h (30 MPH)

Distance : Less than 65 km (40 miles)

SGI973

LAIA0053E

Page 1722 of 3171

GW-36

FRONT DOOR GLASS AND REGULATOR

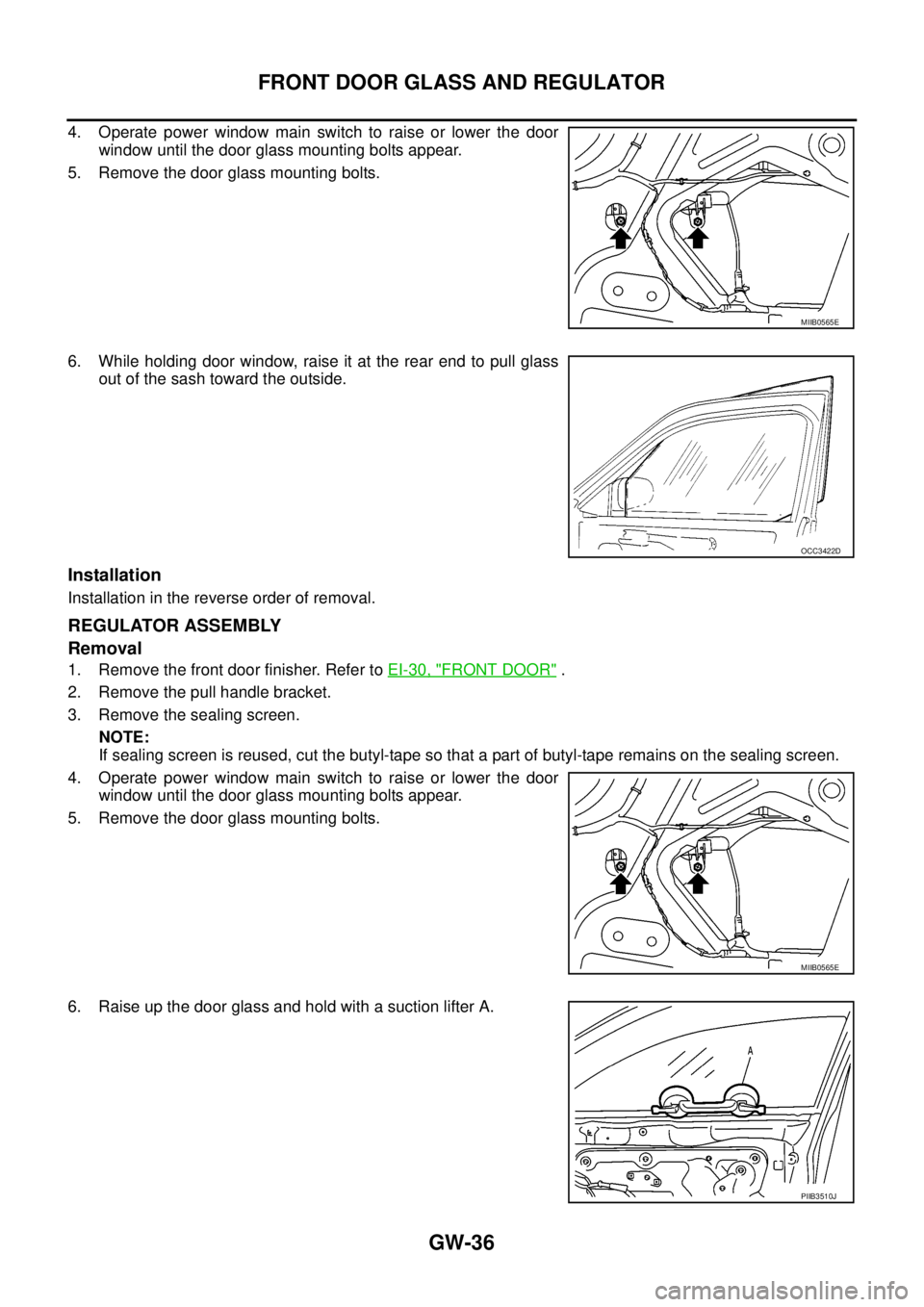

4. Operate power window main switch to raise or lower the door

window until the door glass mounting bolts appear.

5. Remove the door glass mounting bolts.

6. While holding door window, raise it at the rear end to pull glass

out of the sash toward the outside.

Installation

Installation in the reverse order of removal.

REGULATOR ASSEMBLY

Removal

1. Remove the front door finisher. Refer toEI-30, "FRONT DOOR".

2. Remove the pull handle bracket.

3. Remove the sealing screen.

NOTE:

If sealing screen is reused, cut the butyl-tape so that a part of butyl-tape remains on the sealing screen.

4. Operate power window main switch to raise or lower the door

window until the door glass mounting bolts appear.

5. Remove the door glass mounting bolts.

6. RaiseupthedoorglassandholdwithasuctionlifterA.

MIIB0565E

OCC3422D

MIIB0565E

PIIB3510J

Page 1759 of 3171

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

Starter ................................................................SC-27

Starting system ..................................................SC-27

Steering gear, linkage and transfer gear inspection .....

MA-36

,MA-37

Steering linkage .................................................PS-14

Steering wheel and column .................................PS-8

Step lamp .........................................................LT-145

Stop lamp .........................................................LT-121

Stop lamp switch .............................................EC-330

STOP/L - Wiring diagram .................................LT-121

Striking rod (M/T) ...............................................MT-23

Strut (front) ......................................................FSU-10

Sun roof, electric ................................................RF-10

Sunload sensor ..............................................ATC-112

Sunroof ..................................................RF-10,RF-21

Super lock ...........................................................BL-55

Supplemental Restraint System ........................SRS-6

Symbols and abbreviations .....................GI-10,GI-23

Symptom matrix chart ........................................EC-42

Synchronizer (M/T) ............................................MT-21

T

Tachometer ..........................................................DI-4

Tail lamp ...........................................................LT-125

TAIL/L - Wiring diagram ....................................LT-127

TC boost control solnoid valve ........................EC-309

TC boost sensor ..............................................EC-153

TCC/V - Wiring diagram ..................................EC-311

TCM circuit diagram ..........................................AT-42

TCM inspection table .........................................AT-76

Thermostat ........................................................CO-24

Three way catalyst precautions ............................GI-5

Throttle body ......................................................EM-20

Tie-rod ...............................................................PS-14

Timing chain .........................................EM-73,EM-79

Timing gear ........................................................EM-79

Tire rotation .......................................................MA-34

Tire size ..............................................................GI-60

Torque converter installation ...........................AT-250

Torque convertor clutch solenoid valveAT-110,AT-112

Tow truck towing .................................................GI-53

Towing point .......................................................GI-54

Transfer control device .............TF-74,TF-78,TF-105

Transfer control unit inspection table ..................TF-38

Transfer oil replacement ....................................MA-32

Transfer serial number .......................................GI-58

Transmission case (M/T) ...................................MT-19

Transmission serial number ....................GI-58,GI-59

Tread-FR&RR (Dimensions) ..............................GI-60

Trim .....................................................................EI-33

Trouble diagnoses ..............................................GI-11

Turbine revolution sensor ................................AT-123

Turbocharger .....................................................EM-28

Turbocharger charge air cooler .........................EM-18

Turbocharger precautions ....................................GI-6

TURN - Wiring diagram ....................................LT-100

Turn signal lamp .................................................LT-97

Two-pole lift ........................................................GI-52

V

Vacuum hose drawing (Engine control) .............EC-16

Vacuum pump ...................................................EM-42

Valve clearance ................................................EM-66

Valve guide .....................................................EM-101

Valve lifter .........................................................EM-62

Valve seat .......................................................EM-103

Valve spring ....................................................EM-104

Vanity mirror lamp .............................................LT-145

Vehicle identification number ..............................GI-57

Vehicle recovery (freeing a stuck vehicle) ..........GI-54

VEHSEC - Wiring diagram ...............................BL-143

Viscosity number (SAE) ....................................MA-15

W

Wait detection switch ..............................TF-63

,TF-66

WARN - Wiring diagram .....................................DI-30

Warning chime ....................................................DI-51

Warning lamps ....................................................DI-28

Washer, front .....................................................WW-4

Water pump ......................................................CO-21

Water temperature gauge .....................................DI-4

Wheel alignment (front) .....................................FSU-7

Wheel balance ..................................................MA-34

Wheel bearing (front) .........................................FAX-5

Wheel bearing (rear) .........................................RAX-6

Wheel sensors (ABS) .....................................BRC-37

Wheel size ..........................................................GI-60

Wheelbase (Dimensions) ....................................GI-60

Width (Dimensions) ............................................GI-60

WINDOW - Wiring diagram ...............................GW-20

Window, door ......................................GW-35,GW-38

Window, rear .....................................................GW-43

Windshield ........................................................GW-11

WIPER - Wiring diagram ..................................WW-12

Wiper, front ........................................................WW-4

Wiring Diagram (Cell code) list ..........................PG-68

Wiring diagrams ..................................................GI-15