tow NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 712 of 3171

BL-128

FRONT DOOR LOCK

12. Remove the front gasket and rear gasket.

13. Remove the TORX bolts (T30), remove the door lock assembly.

14. While pulling outside handle bracket, slide toward rear of vehicle

to remove the outside handle bracket and door lock assembly.

15. Disconnect the door lock actuator connector.

16. Reach in to separate the key cylinder rod and outside handle

cable connection.

MIIB0559E

: 5.8 N·m (0.60 kg-m, 51.4 in-lb)

MIIB0633E

MIIB0634E

PIIB2878J

Page 717 of 3171

REAR DOOR LOCK

BL-133

C

D

E

F

G

H

J

K

L

MA

B

BL

7. Remove the door side grommet, and remove the outside handle

bracket bolt from grommet hole.

CAUTION:

Do not forcibly remove the TORX bolt.

8. While pulling the outside handle, remove outside handle

escutcheon in order of (1) and (2).

9. While pulling outside handle, slide toward rear of vehicle to

remove the outside handle in order of (1) and (2).

10. Remove the front gasket and rear gasket.

11. Remove the TORX bolts (T30), remove the door lock assembly.: 6.1 N·m (0.63 kg-m, 54.0 in-lb)

MIIB0630E

LIIA1971E

MIIB0632E

MIIB0559E

: 5.8 N·m (0.60 kg-m, 51.4 in-lb)

MIIB0633E

Page 718 of 3171

BL-134

REAR DOOR LOCK

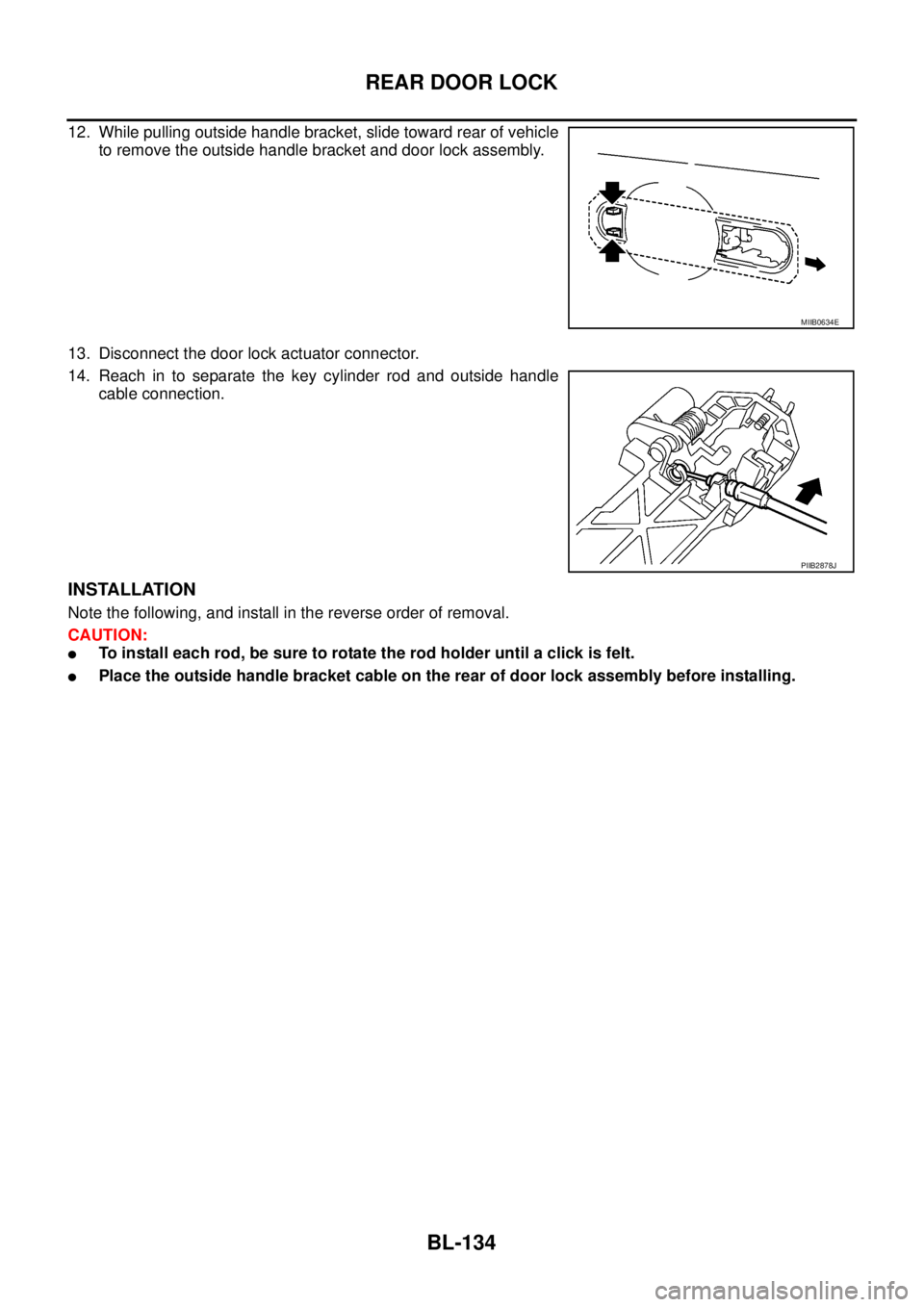

12. While pulling outside handle bracket, slide toward rear of vehicle

to remove the outside handle bracket and door lock assembly.

13. Disconnect the door lock actuator connector.

14. Reach in to separate the key cylinder rod and outside handle

cable connection.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

lTo install each rod, be sure to rotate the rod holder until a click is felt.

lPlace the outside handle bracket cable on the rear of door lock assembly before installing.

MIIB0634E

PIIB2878J

Page 753 of 3171

THEFT WARNING SYSTEM

BL-169

C

D

E

F

G

H

J

K

L

MA

B

BL

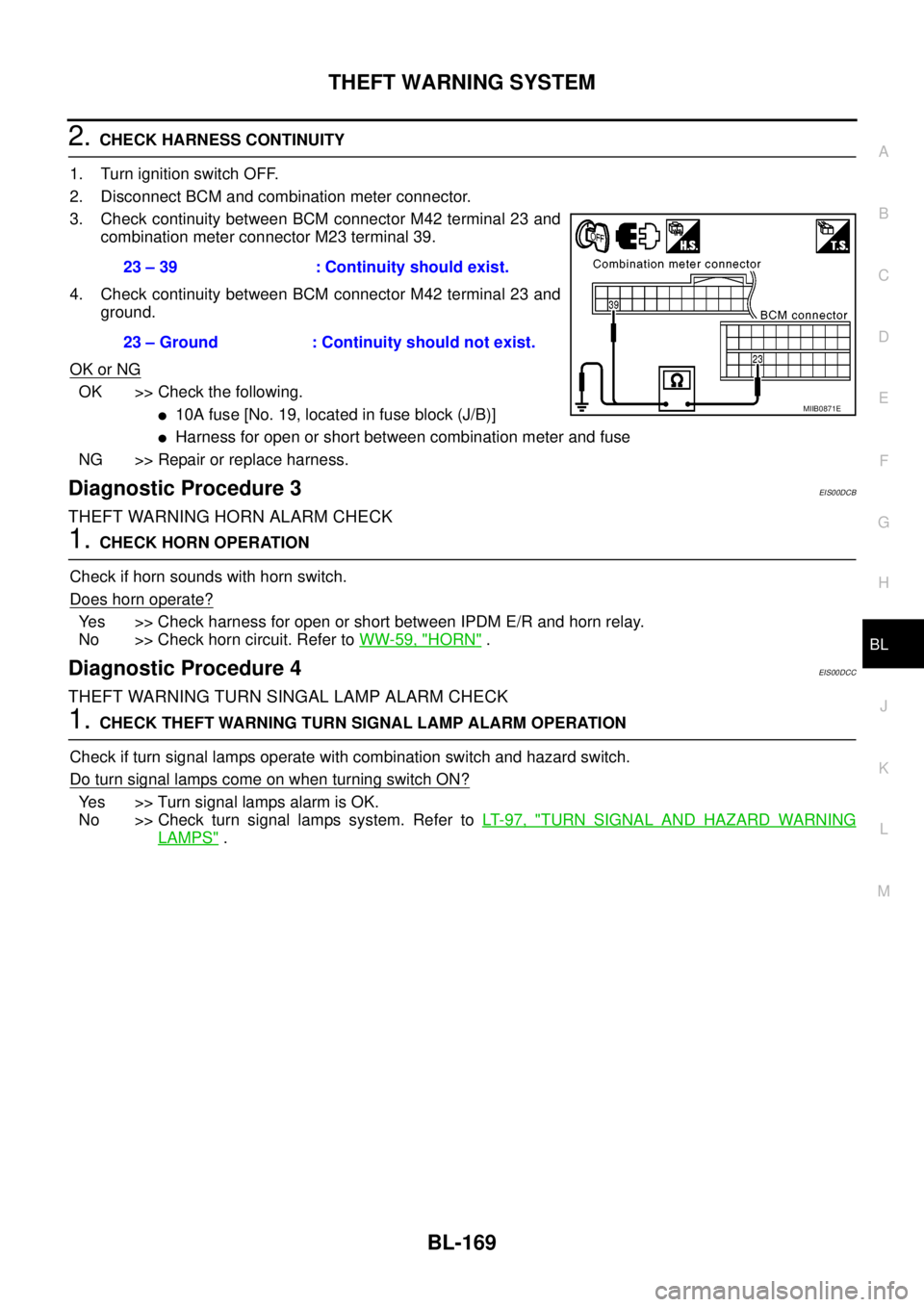

2.CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect BCM and combination meter connector.

3. Check continuity between BCM connector M42 terminal 23 and

combination meter connector M23 terminal 39.

4. Check continuity between BCM connector M42 terminal 23 and

ground.

OK or NG

OK >> Check the following.

l10Afuse[No.19,locatedinfuseblock(J/B)]

lHarness for open or short between combination meter and fuse

NG >> Repair or replace harness.

Diagnostic Procedure 3EIS00DCB

THEFT WARNING HORN ALARM CHECK

1.CHECK HORN OPERATION

Check if horn sounds with horn switch.

Does horn operate?

Yes >> Check harness for open or short between IPDM E/R and horn relay.

No >> Check horn circuit. Refer toWW-59, "

HORN".

Diagnostic Procedure 4EIS00DCC

THEFT WARNING TURN SINGAL LAMP ALARM CHECK

1.CHECK THEFT WARNING TURN SIGNAL LAMP ALARM OPERATION

Check if turn signal lamps operate with combination switch and hazard switch.

DoturnsignallampscomeonwhenturningswitchON?

Yes >> Turn signal lamps alarm is OK.

No >> Check turn signal lamps system. Refer toLT- 9 7 , "

TURN SIGNAL AND HAZARD WARNING

LAMPS". 23 – 39 : Continuity should exist.

23 – Ground : Continuity should not exist.

MIIB0871E

Page 903 of 3171

COOLING FAN

CO-19

C

D

E

F

G

H

I

J

K

L

MA

CO

COOLING FANPFP:21140

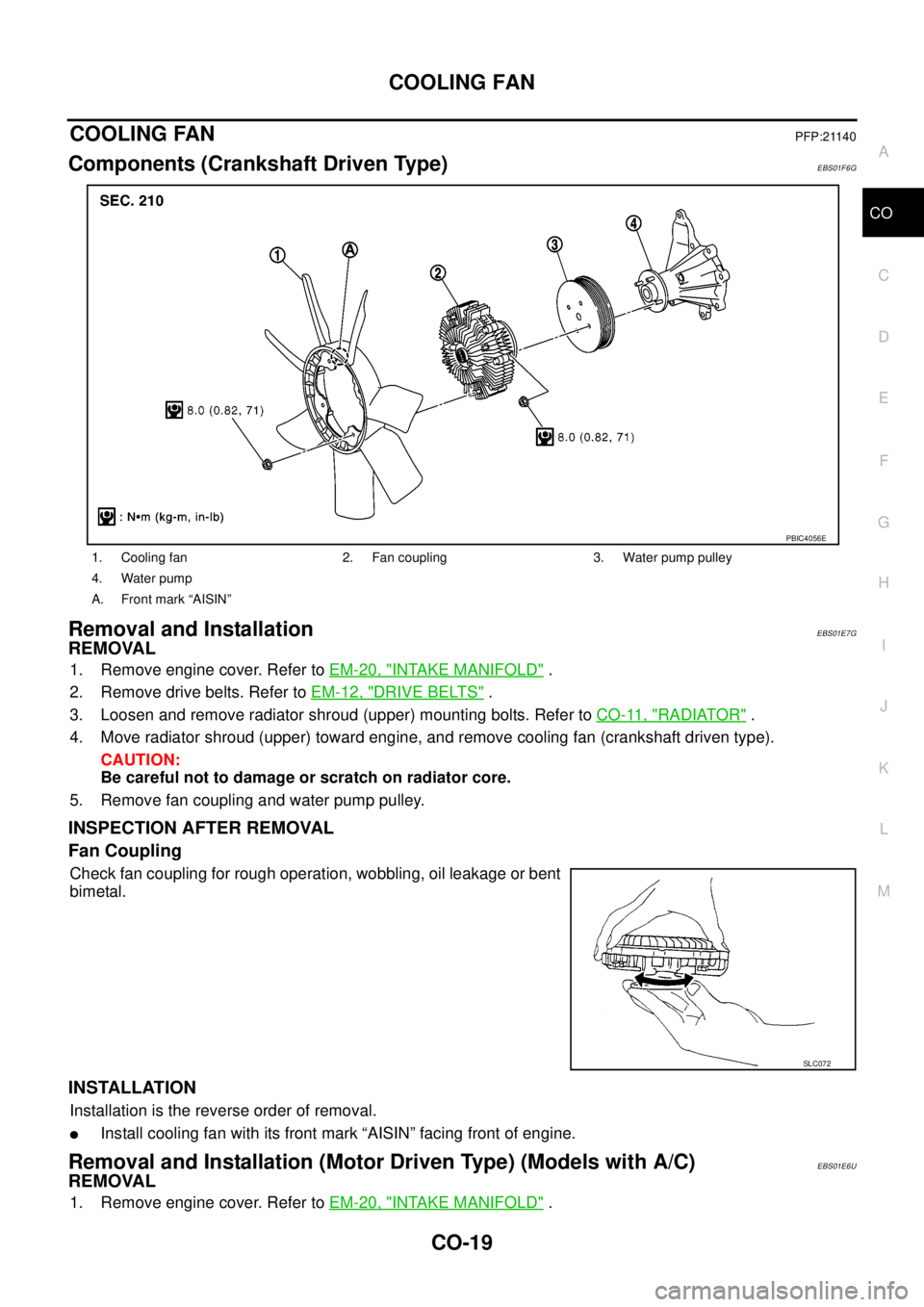

Components (Crankshaft Driven Type)EBS01F6G

Removal and InstallationEBS01E7G

REMOVAL

1. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

2. Remove drive belts. Refer toEM-12, "

DRIVE BELTS".

3. Loosen and remove radiator shroud (upper) mounting bolts. Refer toCO-11, "

RADIATOR".

4. Move radiator shroud (upper) toward engine, and remove cooling fan (crankshaft driven type).

CAUTION:

Be careful not to damage or scratch on radiator core.

5. Remove fan coupling and water pump pulley.

INSPECTION AFTER REMOVAL

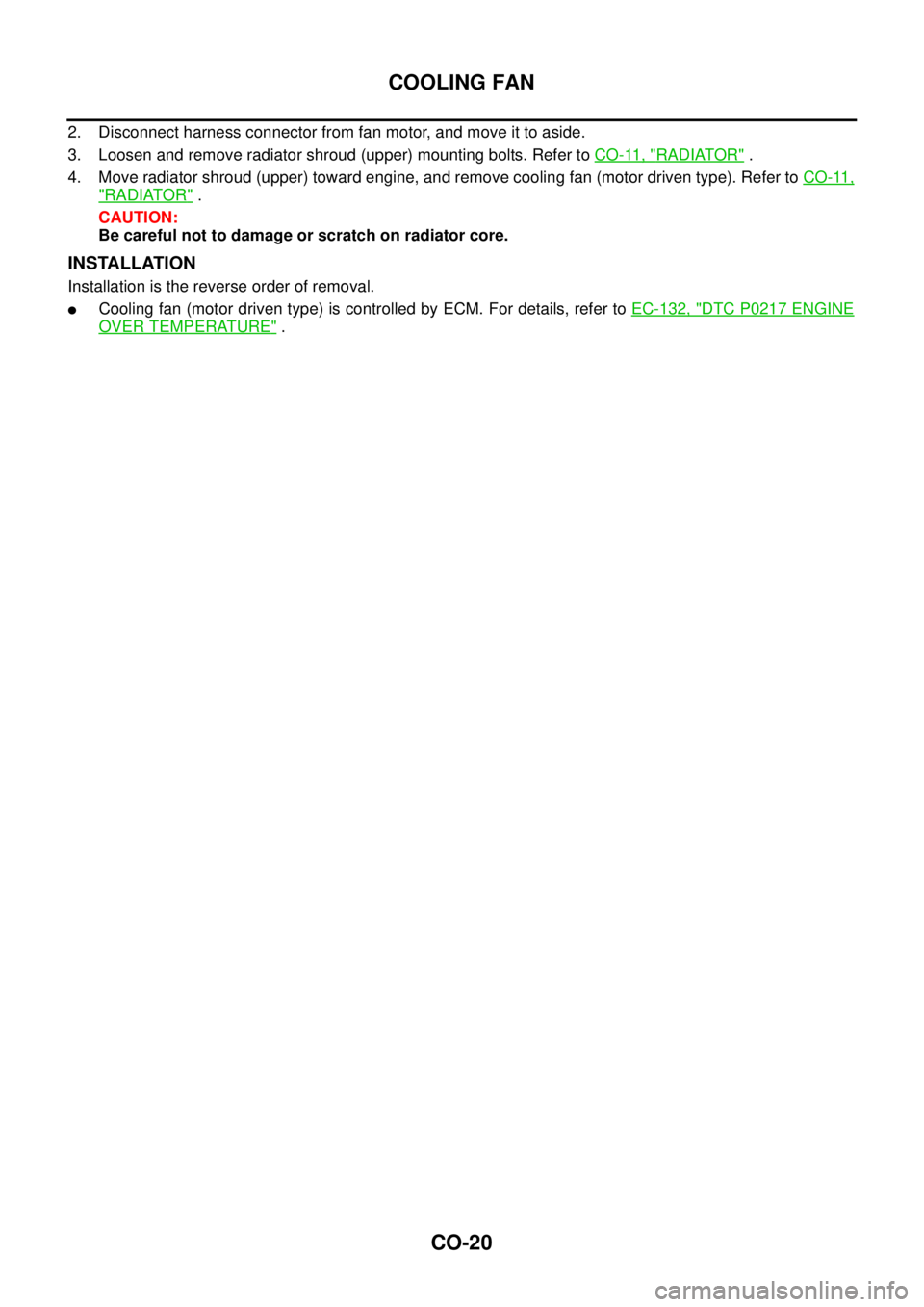

Fan Coupling

Check fan coupling for rough operation, wobbling, oil leakage or bent

bimetal.

INSTALLATION

Installation is the reverse order of removal.

lInstall cooling fan with its front mark “AISIN” facing front of engine.

Removal and Installation (Motor Driven Type) (Models with A/C)EBS01E6U

REMOVAL

1. Remove engine cover. Refer toEM-20, "INTAKE MANIFOLD".

1. Cooling fan 2. Fan coupling 3. Water pump pulley

4. Water pump

A. Front mark “AISIN”

PBIC4056E

SLC072

Page 904 of 3171

CO-20

COOLING FAN

2. Disconnect harness connector from fan motor, and move it to aside.

3. Loosen and remove radiator shroud (upper) mounting bolts. Refer toCO-11, "

RADIATOR".

4. Move radiator shroud (upper) toward engine, and remove cooling fan (motor driven type). Refer toCO-11,

"RADIATOR".

CAUTION:

Be careful not to damage or scratch on radiator core.

INSTALLATION

Installation is the reverse order of removal.

lCooling fan (motor driven type) is controlled by ECM. For details, refer toEC-132, "DTC P0217 ENGINE

OVER TEMPERATURE".

Page 936 of 3171

DI-26

COMBINATION METERS

4.QUESTION 4

During driving, does the fuel gauge pointer move gradually toward EMPTY position?

YES >> Check the fuel level sensor unit. Refer toDI-27, "FUEL LEVEL SENSOR UNIT CHECK".

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

DTC [U1000] CAN Communication CircuitEKS00L8X

Symptom: Displays “CAN COMM CIRC [U1000]” at the self-diagnosis result for combination meter.

1.CHECK CAN COMMUNICATION

1. Select “SELF-DIAG RESULTS” mode for “METER” with CONSULT-II.

2. Print out CONSULT-II screen.

>> Go to “LAN SYSTEM”. Refer toLAN-3, "

Precautions When Using CONSULT-II".

DTC [B2205] Vehicle Speed CircuitEKS00L8Y

Symptom: Displays “VEHICLE SPEED CIRC [B2205]” at the self-diagnosis result for combination meter.

Perform the ABS actuator and electric unit (control unit) self-diagnosis, and repair or replace malfunctioning

parts. Refer toBRC-17, "

CONSULT- II Functions".

Page 976 of 3171

DI-66

COMPASS

COMPASS

PFP:24835

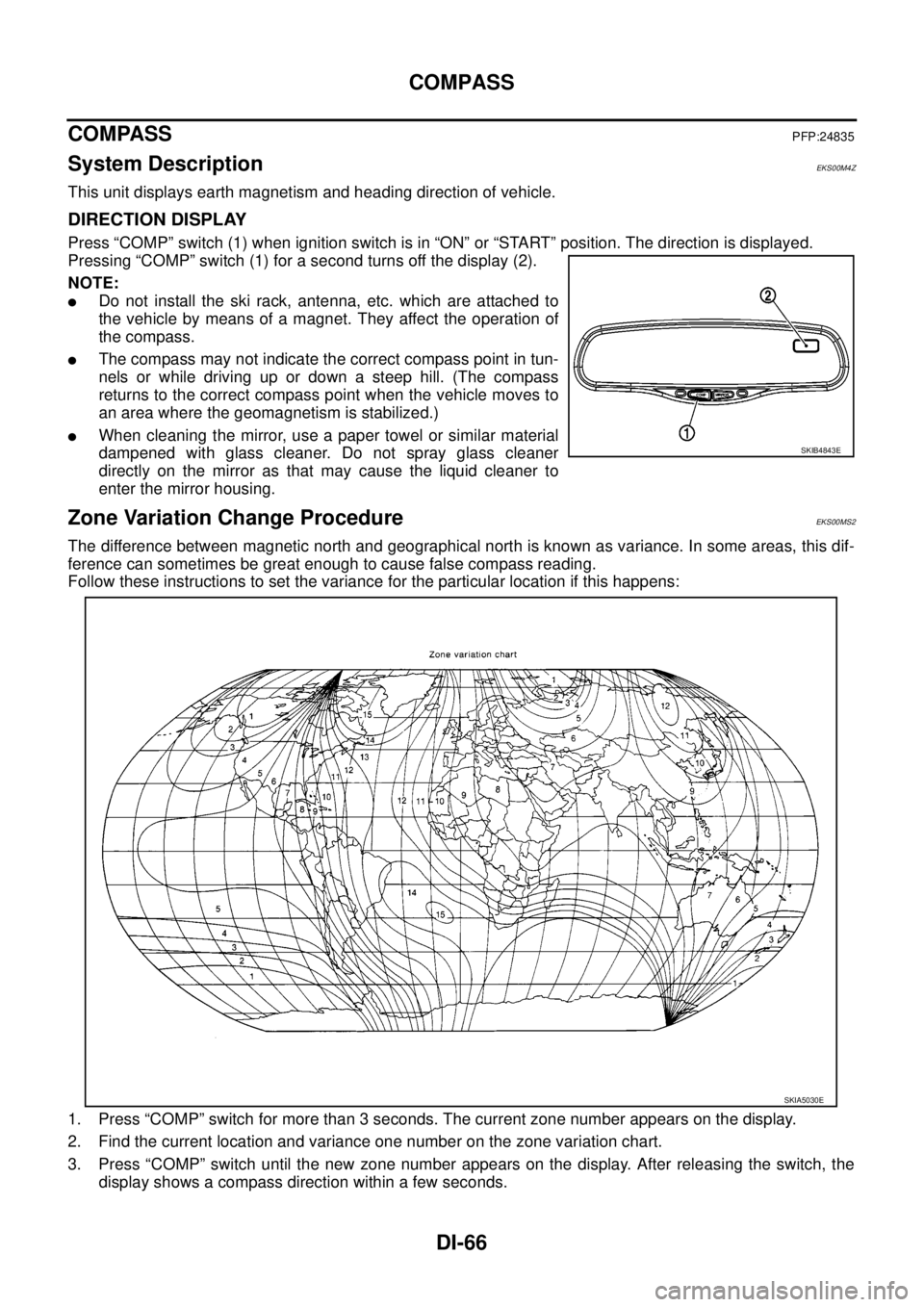

System DescriptionEKS00M4Z

This unit displays earth magnetism and heading direction of vehicle.

DIRECTION DISPLAY

Press “COMP” switch (1) when ignition switch is in “ON” or “START” position. The direction is displayed.

Pressing “COMP” switch (1) for a second turns off the display (2).

NOTE:

lDo not install the ski rack, antenna, etc. which are attached to

the vehicle by means of a magnet. They affect the operation of

the compass.

lThe compass may not indicate the correct compass point in tun-

nels or while driving up or down a steep hill. (The compass

returns to the correct compass point when the vehicle moves to

an area where the geomagnetism is stabilized.)

lWhen cleaning the mirror, use a paper towel or similar material

dampened with glass cleaner. Do not spray glass cleaner

directly on the mirror as that may cause the liquid cleaner to

enter the mirror housing.

Zone Variation Change ProcedureEKS00MS2

The difference between magnetic north and geographical north is known as variance. In some areas, this dif-

ference can sometimes be great enough to cause false compass reading.

Follow these instructions to set the variance for the particular location if this happens:

1. Press “COMP” switch for more than 3 seconds. The current zone number appears on the display.

2. Find the current location and variance one number on the zone variation chart.

3. Press “COMP” switch until the new zone number appears on the display. After releasing the switch, the

display shows a compass direction within a few seconds.

SKIB4843E

SKIA5030E

Page 1341 of 3171

PRECAUTIONS

EI-3

C

D

E

F

G

H

J

K

L

MA

B

EI

PRECAUTIONSPFP:00001

Service NoticeEIS00DY1

lWhen removing or installing various parts, place a cloth or padding on the vehicle body to prevent

scratches.

lHandle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

lApply sealing compound where necessary when installing parts.

lWhen applying sealing compound, be careful that the sealing compound does not protrude from parts.

lWhen replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00DZ5

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEIS00DZ2

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lThe air bag diagnosis sensor unit must always be installed with the arrow marks “Ü” pointing toward the

front of the vehicle for proper operation. Also check the air bag diagnosis sensor unit for cracks, deformi-

ties or rust before installation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and seat mounted front side air bag module standing with the stud bolt side facing

down.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

Page 1358 of 3171

EI-20

COWL TOP

COWL TOP

PFP:66100

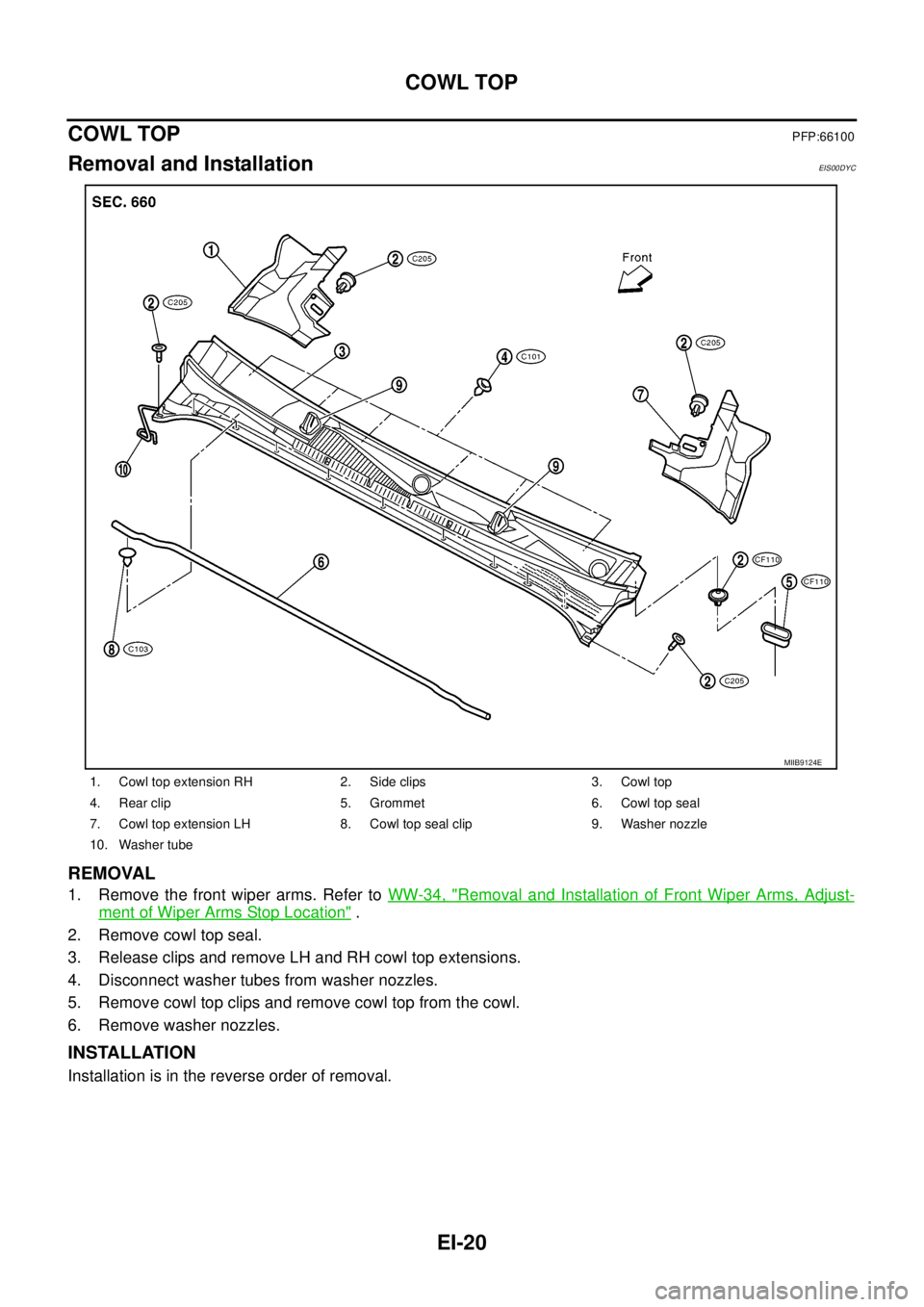

Removal and InstallationEIS00DYC

REMOVAL

1. Remove the front wiper arms. Refer toWW-34, "Removal and Installation of Front Wiper Arms, Adjust-

ment of Wiper Arms Stop Location".

2. Remove cowl top seal.

3. Release clips and remove LH and RH cowl top extensions.

4. Disconnect washer tubes from washer nozzles.

5. Remove cowl top clips and remove cowl top from the cowl.

6. Remove washer nozzles.

INSTALLATION

Installation is in the reverse order of removal.

1. Cowl top extension RH 2. Side clips 3. Cowl top

4. Rear clip 5. Grommet 6. Cowl top seal

7. Cowl top extension LH 8. Cowl top seal clip 9. Washer nozzle

10. Washer tube

MIIB9124E