tow NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2359 of 3171

MT-42

TRANSMISSION ASSEMBLY

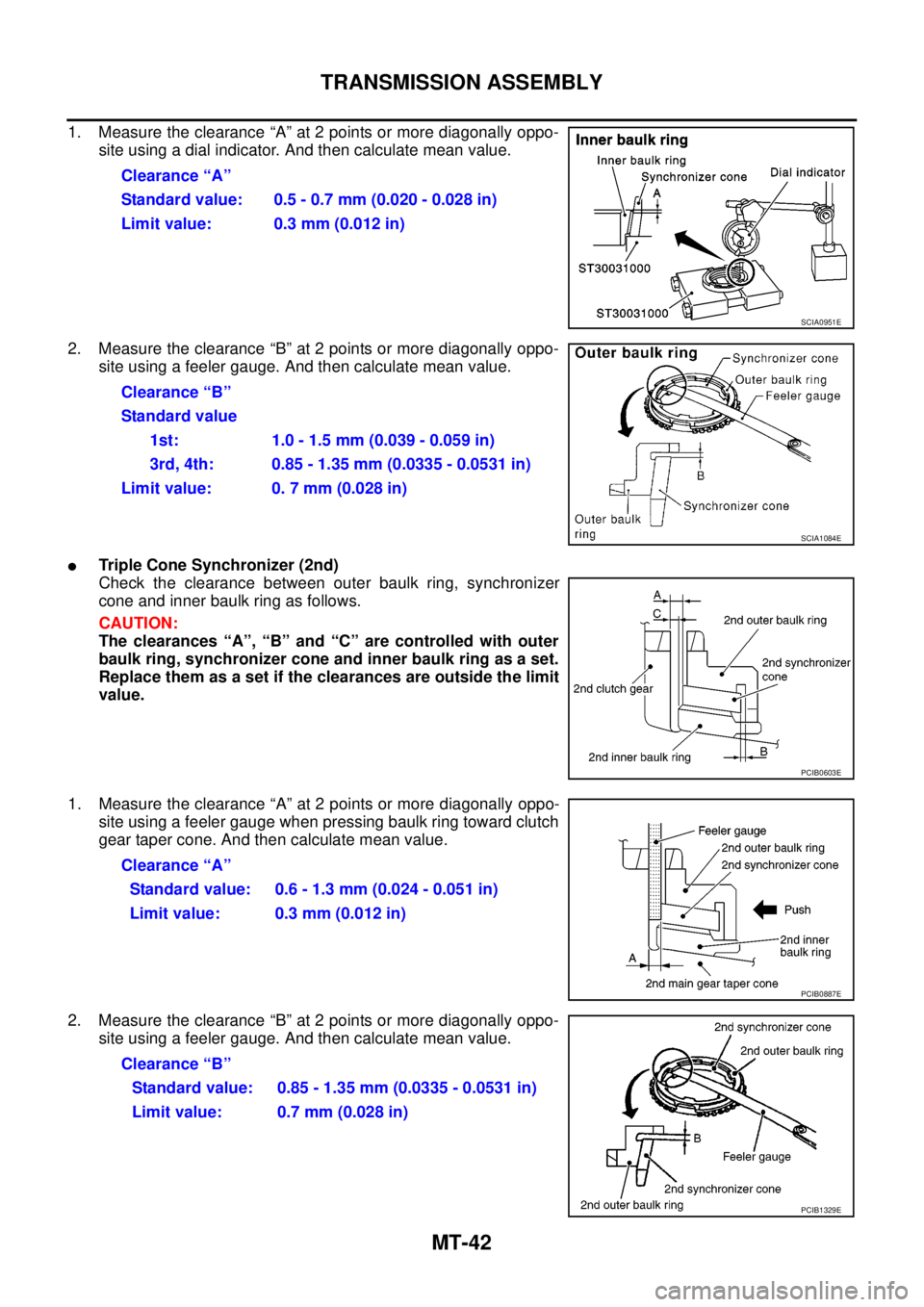

1. Measure the clearance “A” at 2 points or more diagonally oppo-

site using a dial indicator. And then calculate mean value.

2. Measure the clearance “B” at 2 points or more diagonally oppo-

site using a feeler gauge. And then calculate mean value.

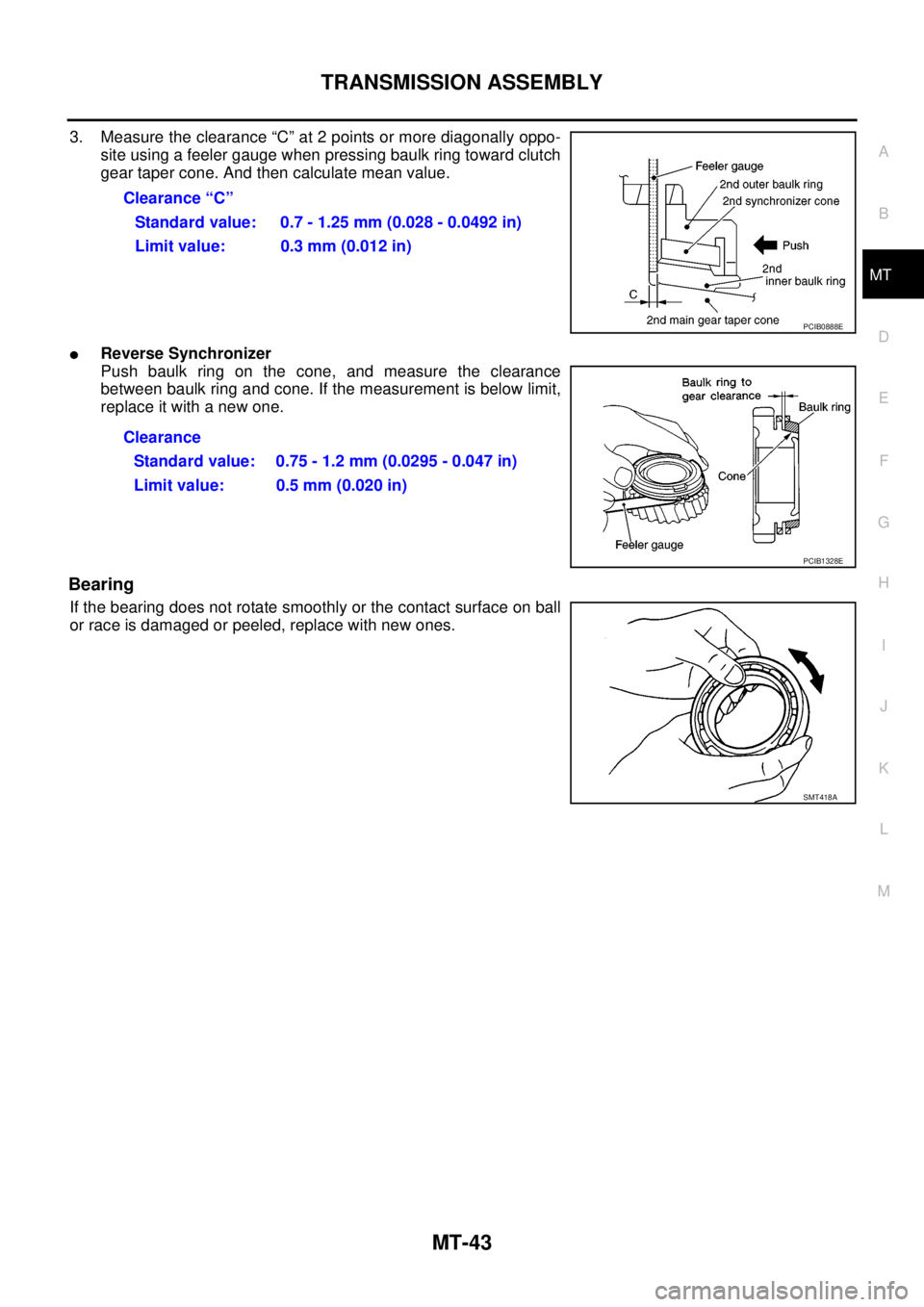

lTriple Cone Synchronizer (2nd)

Check the clearance between outer baulk ring, synchronizer

cone and inner baulk ring as follows.

CAUTION:

The clearances “A”, “B” and “C” are controlled with outer

baulk ring, synchronizer cone and inner baulk ring as a set.

Replace them as a set if the clearances are outside the limit

value.

1. Measure the clearance “A” at 2 points or more diagonally oppo-

site using a feeler gauge when pressing baulk ring toward clutch

gear taper cone. And then calculate mean value.

2. Measure the clearance “B” at 2 points or more diagonally oppo-

site using a feeler gauge. And then calculate mean value.Clearance “A”

Standard value: 0.5 - 0.7 mm (0.020 - 0.028 in)

Limit value: 0.3 mm (0.012 in)

SCIA0951E

Clearance “B”

Standard value

1st: 1.0-1.5mm(0.039-0.059in)

3rd, 4th: 0.85 - 1.35 mm (0.0335 - 0.0531 in)

Limit value: 0. 7 mm (0.028 in)

SCIA1084E

PCIB0603E

Clearance “A”

Standard value: 0.6 - 1.3 mm (0.024 - 0.051 in)

Limit value: 0.3 mm (0.012 in)

PCIB0887E

Clearance “B”

Standard value: 0.85 - 1.35 mm (0.0335 - 0.0531 in)

Limit value: 0.7 mm (0.028 in)

PCIB1329E

Page 2360 of 3171

TRANSMISSION ASSEMBLY

MT-43

D

E

F

G

H

I

J

K

L

MA

B

MT

3. Measure the clearance “C” at 2 points or more diagonally oppo-

site using a feeler gauge when pressing baulk ring toward clutch

gear taper cone. And then calculate mean value.

lReverse Synchronizer

Push baulk ring on the cone, and measure the clearance

between baulk ring and cone. If the measurement is below limit,

replace it with a new one.

Bearing

If the bearing does not rotate smoothly or the contact surface on ball

or race is damaged or peeled, replace with new ones.Clearance “C”

Standard value: 0.7 - 1.25 mm (0.028 - 0.0492 in)

Limit value: 0.3 mm (0.012 in)

PCIB0888E

Clearance

Standard value: 0.75 - 1.2 mm (0.0295 - 0.047 in)

Limit value: 0.5 mm (0.020 in)

PCIB1328E

SMT418A

Page 2509 of 3171

MTC-122

REFRIGERANT LINES

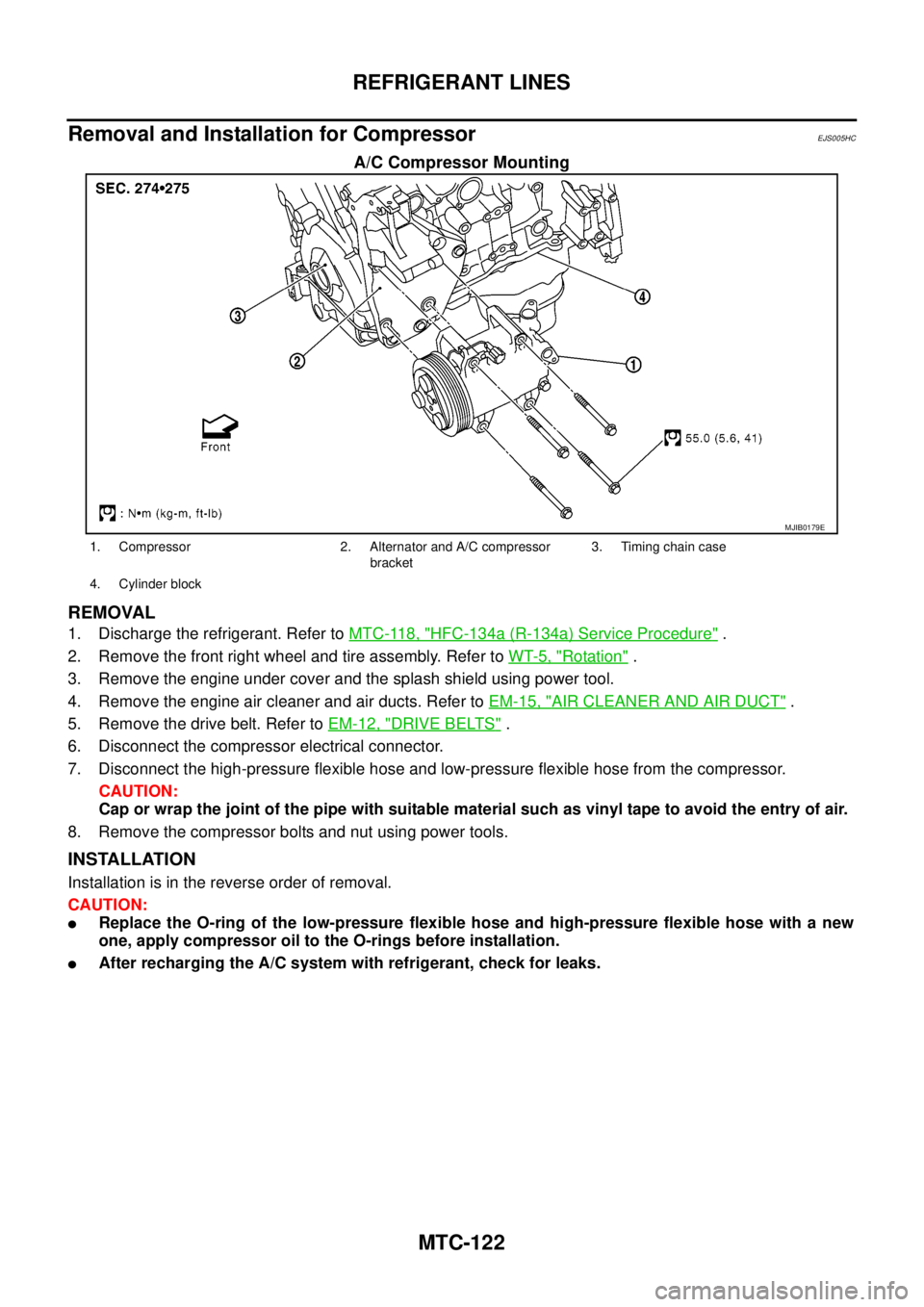

Removal and Installation for Compressor

EJS005HC

A/C Compressor Mounting

REMOVAL

1. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

2. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

3. Remove the engine under cover and the splash shield using power tool.

4. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

5. Remove the drive belt. Refer toEM-12, "

DRIVE BELTS".

6. Disconnect the compressor electrical connector.

7. Disconnect the high-pressure flexible hose and low-pressure flexible hose from the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

8. Remove the compressor bolts and nut using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

lReplace the O-ring of the low-pressure flexible hose and high-pressure flexible hose with a new

one, apply compressor oil to the O-rings before installation.

lAfter recharging the A/C system with refrigerant, check for leaks.

MJIB0179E

1. Compressor 2. Alternator and A/C compressor

bracket3. Timing chain case

4. Cylinder block

Page 2513 of 3171

MTC-126

REFRIGERANT LINES

BREAK-IN OPERATION

When replacing compressor clutch assembly, always conduct the break-in operation. This is done by engag-

ing and disengaging the clutch about 30 times. Break-in operation raises the level of transmitted torque.

Removal and Installation for Low-pressure Flexible HoseEJS005HE

REMOVAL

1. Remove the engine room cover using power tools.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

3. Remove the cowl top extension. Refer toEI-20, "

COWL TOP".

4. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

5. Remove the low-pressure flexible hose. Refer toMTC-120, "

Components".

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the low-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure Flexible HoseEJS005HF

REMOVAL

1. Remove the engine under cover.

2. Remove the engine air cleaner and air ducts. Refer toEM-15, "

AIR CLEANER AND AIR DUCT"

3. Discharge the refrigerant. Refer toMTC-118, "HFC-134a (R-134a) Service Procedure".

4. Remove the high-pressure flexible hose. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

CAUTION:

lReplace the O-ring of the high-pressure flexible hose with a new one, then apply compressor oil to

it when installing it.

lAfter charging refrigerant, check for leaks.

Removal and Installation for High-pressure PipeEJS005HG

REMOVAL

1. Remove the cowl top extension. Refer toEI-20, "COWL TOP".

2. Disconnect the battery negative cable.

3. Reposition the IPDM E/R aside.

4. Remove the front right wheel and tire assembly. Refer toWT-5, "

Rotation".

5. Position aside the front floor insulator.

6. Discharge the refrigerant. Refer toMTC-118, "

HFC-134a (R-134a) Service Procedure".

7. Remove the low pressure pipe. Refer toMTC-127, "

Removal and Installation for Low-pressure Pipe".

8. Remove the high-pressure pipe. Refer toMTC-120, "

Components".

CAUTION:

Cap or wrap the joint of the pipe with suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

Refer toMTC-120, "

Components".

Page 2629 of 3171

PS-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EGS001M0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Steering SystemEGS001L9

lIn case of removing steering gear assembly, make the final tightening with grounded and unloaded vehi-

cle condition, and then check wheel alignment.

lObserve the following precautions when disassembling.

–Before disassembly, thoroughly clean the outside of the unit.

–Disassembly should be done in a clean work area. It is important to prevent the internal parts from becom-

ing contaminated by dirt or other foreign matter.

–For easier and proper assembly, place disassembled parts in order on a parts rack.

–Use nylon cloth or paper towels to clean the parts; common shop rags can leave lint that might interfere

with their operation.

–Do not reuse non-reusable parts.

–Before assembling, apply the specified grease to the directed parts.

Page 2655 of 3171

PS-28

POWER STEERING OIL PUMP

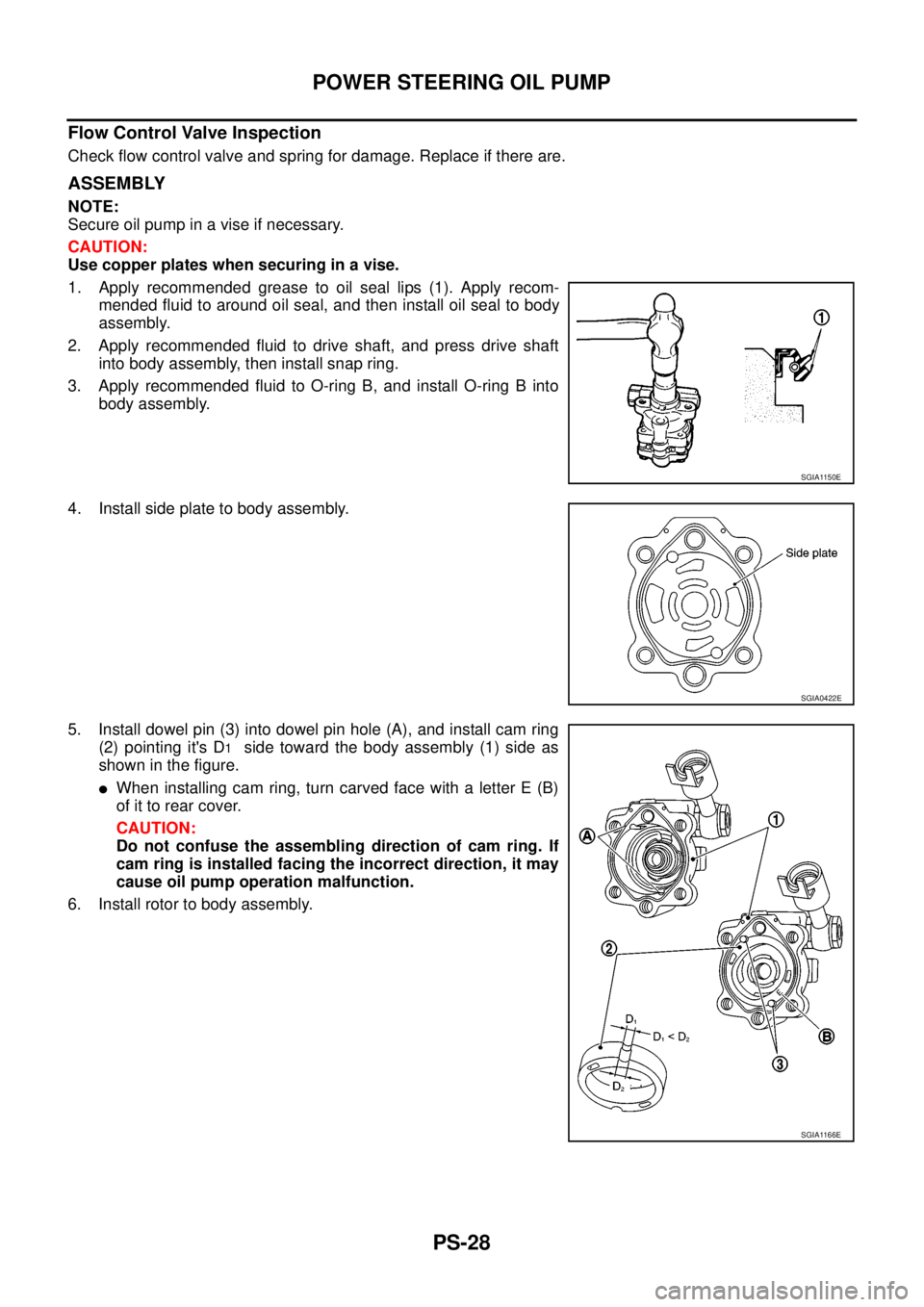

Flow Control Valve Inspection

Check flow control valve and spring for damage. Replace if there are.

ASSEMBLY

NOTE:

Secureoilpumpinaviseifnecessary.

CAUTION:

Use copper plates when securing in a vise.

1. Apply recommended grease to oil seal lips (1). Apply recom-

mended fluid to around oil seal, and then install oil seal to body

assembly.

2. Apply recommended fluid to drive shaft, and press drive shaft

into body assembly, then install snap ring.

3. Apply recommended fluid to O-ring B, and install O-ring B into

body assembly.

4. Install side plate to body assembly.

5. Install dowel pin (3) into dowel pin hole (A), and install cam ring

(2) pointing it's D

1side toward the body assembly (1) side as

showninthefigure.

lWhen installing cam ring, turn carved face with a letter E (B)

of it to rear cover.

CAUTION:

Do not confuse the assembling direction of cam ring. If

cam ring is installed facing the incorrect direction, it may

cause oil pump operation malfunction.

6. Install rotor to body assembly.

SGIA1150E

SGIA0422E

SGIA1166E

Page 2672 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a NISSAN NAVARA 2005 Repair Repair Manual AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting a](/img/5/57362/w960_57362-2671.png)

AXLE SHAFT

RAX-9

[M226]

C

E

F

G

H

I

J

K

L

MA

B

RAX

INSPECTION AFTER REMOVAL

Axle Shaft Bearing and Cup

lCheck that the axle shaft bearing and cup roll freely and are free from noise, cracks, pitting and wear.

Replace if necessary.

Axle Shaft Retainer

lCheck for deformation and cracks. Replace if necessary.

Rear Axle Case

lCheck the exterior and inner machined surfaces for deformation and cracks. Replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

When installing pay attention to following points:

lInstall a new shaft guide and a new oil seal into the rear axle case.

CAUTION:

lDo not reuse the axle oil seal. The axle oil seal must be replaced every time the axle shaft assem-

bly is removed from the axle shaft housing.

lWhen installing oil seals, apply multi-purpsose grease to oil seal lips.

lInstall four new lock nuts to secure the axle shaft assembly to the rear axle case, and tighten lock nuts to

the specified torque. Refer toRAX-7, "

Removal and Installation".

lReinstall the rear brake drum. Refer toBR-31, "Removal and Installation of Drum Brake Assembly".

lAdjust the differential gear oil level.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 without LD.

Refer toRFD-9, "

DIFFERENTIAL GEAR OIL", for M226 with LD.

lReinstall the wheel. Refer toWT-5, "Rotation".

DISASSEMBLY

1. Remove the ABS sensor rotor. Refer toBRC-39, "SENSOR ROTOR".

2. Remove the snap ring from the axle shaft using a suitable snap ring pliers.

3. Secure the axle shaft in a suitable vise as shown, and use a

brass hammer to remove studs (4) from the axle shaft retainer.

CAUTION:

lMount the axle shaft using a soft jaw vise to avoid dam-

aging the axle shaft retainer.

MDIB9051E

Page 2912 of 3171

PRECAUTIONS

SRS-3

C

D

E

F

G

I

J

K

L

MA

B

SRS

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EHS001Y8

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for SRS “AIR BAG” and “SEAT BELT PRE-TENSIONER” ServiceEHS001Y9

lDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least 3 min-

utes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

lDiagnosis sensor unit must always be installed with their arrow marks “Ü” pointing towards the front of the

vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before instal-

lation and replace as required.

lThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

lHandle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module standing with stud bolt side setting bottom.

lConduct self-diagnosis to check entire SRS for proper function after replacing any components.

lAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

lAlways replace instrument panel pad following front passenger air bag deployment.

Precautions for Trouble DiagnosisEHS001YA

When you read wiring diagrams, refer to the following:

lGI-15, "How to Read Wiring Diagrams"in GI section

lPG-4, "POWER SUPPLY ROUTING CIRCUIT"in PG section

When you perform trouble diagnosis, refer to the following:

lGI-11, "How to Follow Trouble Diagnoses"in GI section

lGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"in GI section

Check for any service bulletins before servicing the vehicle.

Page 2945 of 3171

SRS-36

DRIVER AIR BAG MODULE

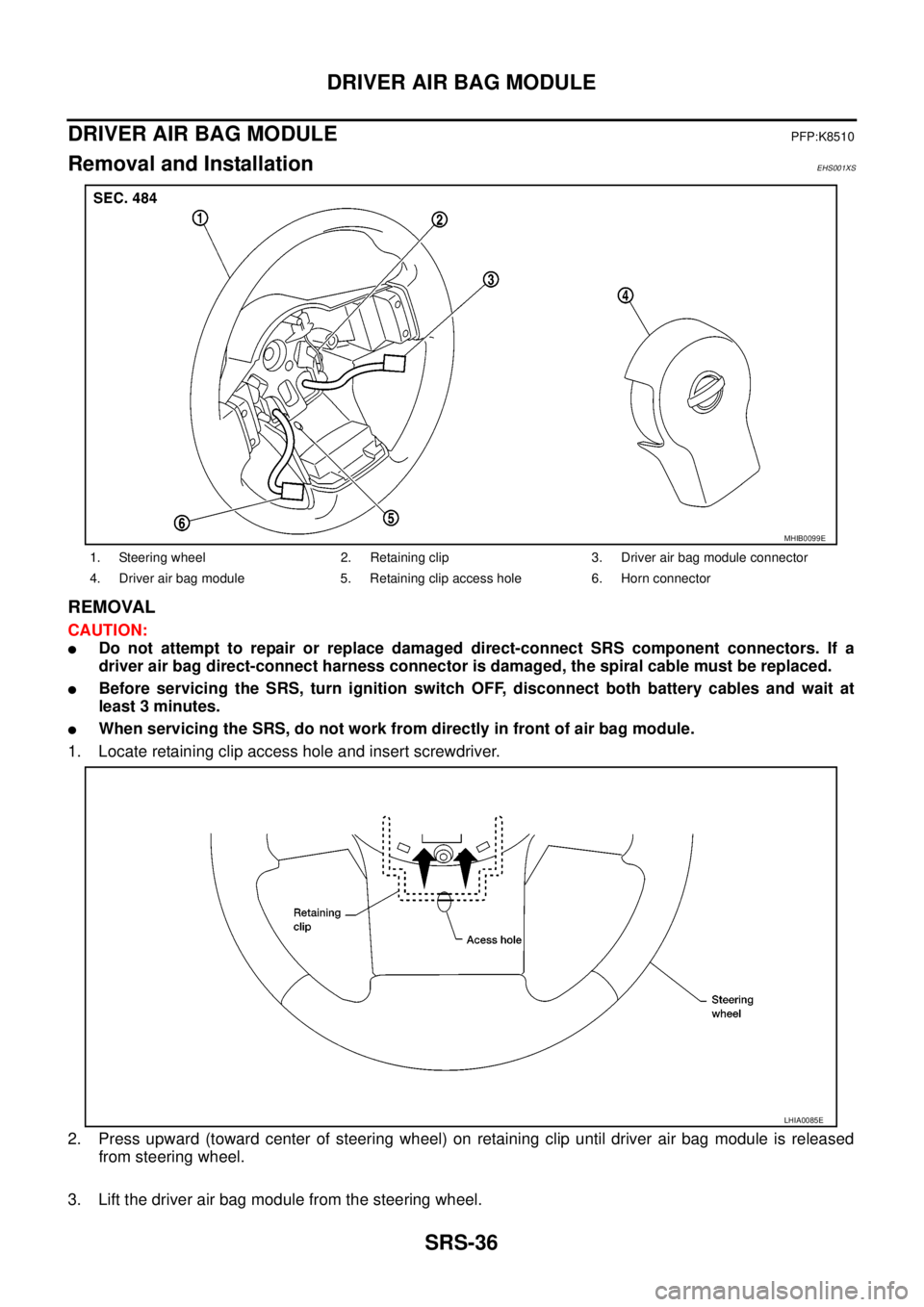

DRIVER AIR BAG MODULE

PFP:K8510

Removal and InstallationEHS001XS

REMOVAL

CAUTION:

lDo not attempt to repair or replace damaged direct-connect SRS component connectors. If a

driver air bag direct-connect harness connector is damaged, the spiral cable must be replaced.

lBefore servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at

least 3 minutes.

lWhen servicing the SRS, do not work from directly in front of air bag module.

1. Locate retaining clip access hole and insert screwdriver.

2. Press upward (toward center of steering wheel) on retaining clip until driver air bag module is released

from steering wheel.

3. Lift the driver air bag module from the steering wheel.

1. Steering wheel 2. Retaining clip 3. Driver air bag module connector

4. Driver air bag module 5. Retaining clip access hole 6. Horn connector

MHIB0099E

LHIA0085E

Page 2948 of 3171

SPIRAL CABLE

SRS-39

C

D

E

F

G

I

J

K

L

MA

B

SRS

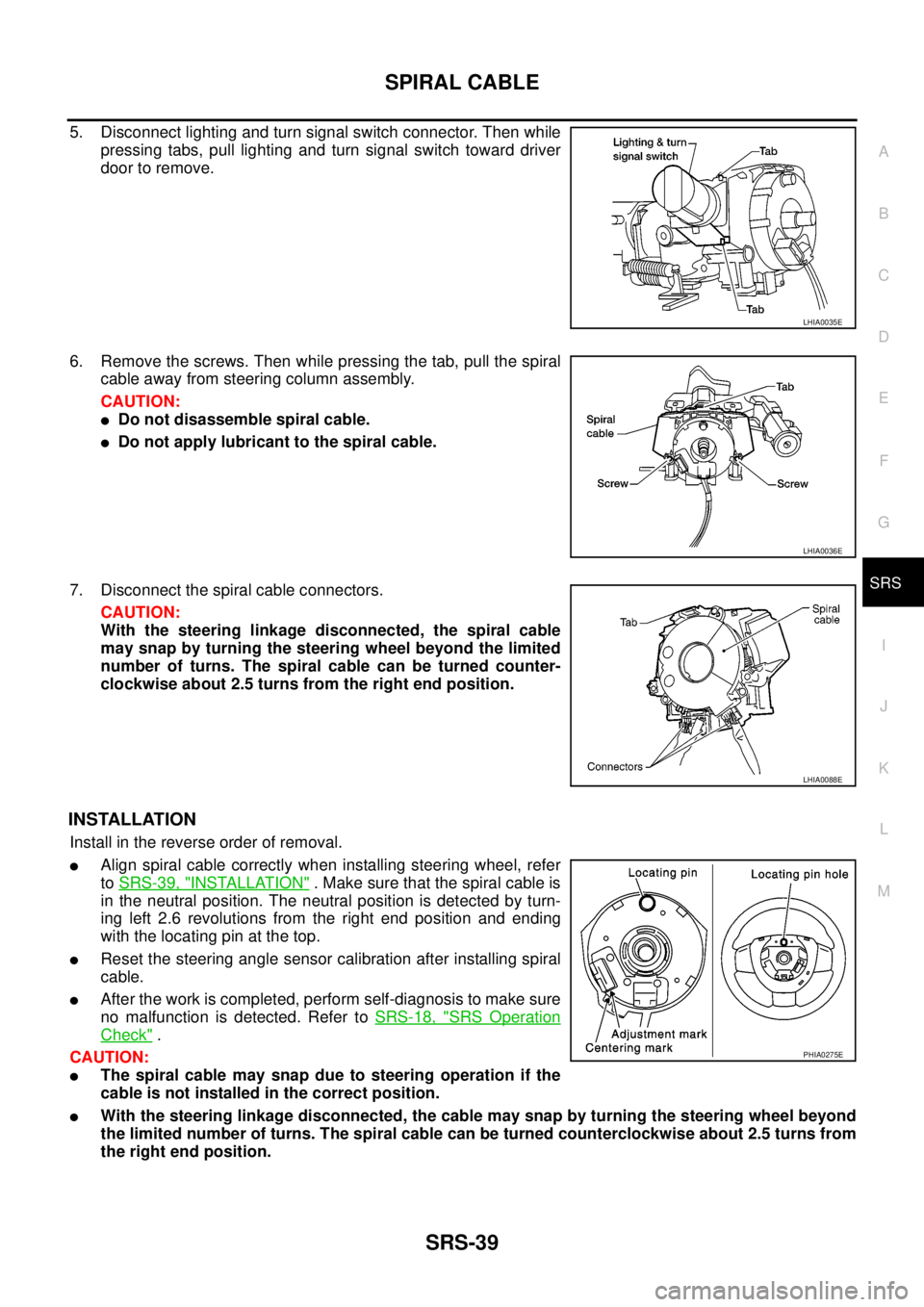

5. Disconnect lighting and turn signal switch connector. Then while

pressing tabs, pull lighting and turn signal switch toward driver

door to remove.

6. Remove the screws. Then while pressing the tab, pull the spiral

cable away from steering column assembly.

CAUTION:

lDo not disassemble spiral cable.

lDo not apply lubricant to the spiral cable.

7. Disconnect the spiral cable connectors.

CAUTION:

With the steering linkage disconnected, the spiral cable

may snap by turning the steering wheel beyond the limited

number of turns. The spiral cable can be turned counter-

clockwise about 2.5 turns from the right end position.

INSTALLATION

Install in the reverse order of removal.

lAlign spiral cable correctly when installing steering wheel, refer

toSRS-39, "

INSTALLATION". Make sure that the spiral cable is

in the neutral position. The neutral position is detected by turn-

ing left 2.6 revolutions from the right end position and ending

with the locating pin at the top.

lReset the steering angle sensor calibration after installing spiral

cable.

lAfter the work is completed, perform self-diagnosis to make sure

no malfunction is detected. Refer toSRS-18, "

SRS Operation

Check".

CAUTION:

lThe spiral cable may snap due to steering operation if the

cable is not installed in the correct position.

lWith the steering linkage disconnected, the cable may snap by turning the steering wheel beyond

the limited number of turns. The spiral cable can be turned counterclockwise about 2.5 turns from

the right end position.

LHIA0035E

LHIA0036E

LHIA0088E

PHIA0275E