belt NISSAN NAVARA 2005 Repair Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1778 of 3171

LAN-1

LAN SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONLAN

A

B

LAN

LAN SYSTEM

CAN

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

Precautions When Using CONSULT-II ..................... 3

CHECK POINTS FOR USING CONSULT-II ......... 3

Precautions For Trouble Diagnosis .......................... 3

CAN SYSTEM ....................................................... 3

Precautions For Harness Repair .............................. 3

CAN SYSTEM ....................................................... 3

TROUBLE DIAGNOSES WORK FLOW .................... 5

When Displaying CAN Communication System

Errors ....................................................................... 5

WHEN A MALFUNCTION IS DETECTED BY

CAN COMMUNICATION SYSTEM ....................... 5

WHEN A MALFUNCTION IS DETECTED

EXCEPT CAN COMMUNICATION SYSTEM ........ 5

TROUBLE DIAGNOSIS FLOW CHART ............... 6

Diagnosis Procedure ................................................ 7

SELECTING CAN SYSTEM TYPE (HOW TO

USE SPECIFICATION TABLE) ............................. 7

ACQUISITION OF DATA BY CONSULT-II ............ 8

HOW TO USE CHECK SHEET TABLE ................ 9

CAN Diagnostic Support Monitor ........................... 15

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ECM ............................... 15

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR TCM ............................... 16

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR NAVI CONTROL UNIT ... 17

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR DIFFERENTIAL LOCK

CONTROL UNIT ................................................. 18

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR FRONT AIR CONTROL... 19

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR BCM ............................... 20

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR TRANSFER CONTROLUNIT .................................................................... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT) ................... 21

DESCRIPTION OF “CAN DIAG SUPPORT

MNTR” SCREEN FOR IPDM E/R ....................... 22

CAN COMMUNICATION ........................................... 23

System Description ................................................. 23

Component Parts and Harness Connector Location... 23

LHD MODELS ..................................................... 23

RHD MODELS .................................................... 24

Schematic ............................................................... 25

Wiring Diagram — CAN — ..................................... 26

CAN Communication Unit ....................................... 30

TYPE 1/ TYPE 2/ TYPE 3 ................................... 32

TYPE 4/ TYPE 5 .................................................. 34

TYPE 6/ TYPE 7/ TYPE 8/ TYPE 9/ TYPE 10/

TYPE 11/ TYPE 16/ TYPE 17 .............................. 36

TYPE 12/ TYPE 13/ TYPE 14/ TYPE 15 ............. 40

CAN SYSTEM (TYPE 1) ........................................... 44

Component Parts and Harness Connector Location... 44

Schematic ............................................................... 44

Wiring Diagram — CAN — ..................................... 44

Check Sheet ........................................................... 45

CHECK SHEET RESULTS (EXAMPLE) ............. 47

CAN SYSTEM (TYPE 2) ........................................... 56

Component Parts and Harness Connector Location... 56

Schematic ............................................................... 56

Wiring Diagram — CAN — ..................................... 56

Check Sheet ........................................................... 57

CHECK SHEET RESULTS (EXAMPLE) ............. 59

CAN SYSTEM (TYPE 3) ........................................... 68

Component Parts and Harness Connector Location... 68

Schematic ............................................................... 68

Wiring Diagram — CAN — ..................................... 68

Check Sheet ........................................................... 69

CHECK SHEET RESULTS (EXAMPLE) ............. 71

CAN SYSTEM (TYPE 4) ........................................... 82

Component Parts and Harness Connector Location... 82

Schematic ............................................................... 82

Page 1780 of 3171

![NISSAN NAVARA 2005 Repair Manual PDF PRECAUTIONS

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00Q9Y

The Supplement NISSAN NAVARA 2005 Repair Manual PDF PRECAUTIONS

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00Q9Y

The Supplement](/img/5/57362/w960_57362-1779.png)

PRECAUTIONS

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00Q9Y

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions When Using CONSULT-IIEKS00LBE

When connecting CONSULT-II to data link connector, connect them through CONSULT-II CONVERTER.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

CHECK POINTS FOR USING CONSULT-II

1. Has CONSULT-II been used without connecting CONSULT-II CONVERTER on this vehicle?

–If YES, GO TO 2.

–If NO, GO TO 5.

2. Is there any indication other than indications relating to CAN communication system in the self-diagnosis

results?

–If YES, GO TO 3.

–If NO, GO TO 4.

3. Based on self-diagnosis results unrelated to CAN communication, carry out the inspection.

4. Malfunctions may be detected in self-diagnosis depending on control units carrying out CAN communica-

tion. Therefore, erase the self-diagnosis results.

5. Diagnose CAN communication system. Refer toLAN-5, "

TROUBLE DIAGNOSES WORK FLOW".

Precautions For Trouble DiagnosisEKS00LBF

CAN SYSTEM

lDo not apply voltage of 7.0 V or higher to the measurement terminals.

lUse the tester with its open terminal voltage being 7.0 V or less.

lBe sure to turn ignition switch off and disconnect negative battery terminal before checking the circuit.

Precautions For Harness RepairEKS00LBG

CAN SYSTEM

lSolder the repaired parts, and wrap with tape. [Frays of twisted

line must be within 110 mm (4.33 in).]

PKIA0306E

Page 2084 of 3171

LT-1

LIGHTING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONLT

A

B

LT

LIGHTING SYSTEM

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

General Precautions for Service Operations ............ 4

Wiring Diagrams and Trouble Diagnosis .................. 4

HEADLAMP -CONVENTIONAL TYPE- ..................... 5

Component Parts and Harness Connector Location..... 5

System Description .................................................. 5

OUTLINE ............................................................... 5

FRIENDLY LIGHTING FUNCTION ....................... 6

CAN Communication System Description ................ 6

Schematic ................................................................ 7

Wiring Diagram - H/LAMP - ...................................... 8

Terminals and Reference Value for BCM ............... 12

Terminals and Reference Values for IPDM E/R ..... 12

How to Proceed With Trouble Diagnosis ................ 13

Preliminary Check .................................................. 13

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 13

CONSULT-II Functions (BCM) ............................... 15

CONSULT-II BASIC OPERATION ....................... 15

WORK SUPPORT ............................................... 16

DATA MONITOR ................................................. 16

ACTIVE TEST ..................................................... 17

CONSULT-II Functions (IPDM E/R) ....................... 18

CONSULT-II BASIC OPERATION ....................... 18

DATA MONITOR ................................................. 19

ACTIVE TEST ..................................................... 19

Headlamp High Beam Does Not Illuminate (Both

Sides) ..................................................................... 20

Headlamp HI Beam Does Not Illuminate (One Side)... 22

High Beam Indicator Lamp Does Not Illuminate .... 23

Headlamp LO Beam Does Not Illuminate (Both

Sides) ..................................................................... 23

Headlamp LO Beam Does Not Illuminate (One Side)

... 25

Headlamps Do Not Turn OFF ................................ 26

Aiming Adjustment ................................................. 28

LOW BEAM AND HIGH BEAM ........................... 28Bulb Replacement .................................................. 29

HEADLAMP HIGH/LOW BEAM .......................... 29

FRONT TURN SIGNAL LAMP ............................ 29

CLEARANCE LAMP ............................................ 29

Removal and Installation ........................................ 30

REMOVAL ........................................................... 30

INSTALLATION ................................................... 30

Disassembly and Assembly .................................... 30

DISASSEMBLY ................................................... 30

HEADLAMP - DAYTIME LIGHT SYSTEM - ............. 31

Component Parts and Harness Connector Location... 31

System Description ................................................. 31

OUTLINE ............................................................. 32

DAYTIME LIGHT OPERATION ........................... 32

COMBINATION SWITCH READING FUNCTION... 33

AUTO LIGHT OPERATION ................................. 33

CAN Communication System Description .............. 33

CAN Communication Unit ....................................... 33

Schematic ............................................................... 34

Wiring Diagram — DTRL — ................................... 35

Terminals and Reference Values for BCM .............. 39

Terminals and Reference Values for IPDM E/R ...... 39

How to Proceed With Trouble Diagnosis ................ 40

Preliminary Check .................................................. 40

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 40

CONSULT-II Functions (BCM) ................................ 42

CONSULT-II BASIC OPERATION ....................... 42

DATA MONITOR ................................................. 43

ACTIVE TEST ..................................................... 44

CONSULT-II Functions (IPDM E/R) ........................ 45

CONSULT-II BASIC OPERATION ....................... 45

DATA MONITOR ................................................. 46

ACTIVE TEST ..................................................... 46

Daytime Light Control Does Not Operate Properly

(Normal Headlamps Operate Properly) .................. 47

Aiming Adjustment .................................................. 48

Bulb Replacement .................................................. 48

Removal and Installation ........................................ 48

Disassembly and Assembly .................................... 48

Page 2087 of 3171

LT-4

PRECAUTIONS

PRECAUTIONS

PFP:00011

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS00N1L

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

General Precautions for Service OperationsEKS00L4H

lNever work with wet hands.

lTurn the lighting switch OFF before disconnecting and connecting the connector.

lWhen checking the headlamp on/off operation, check it on vehicle and with the power connected to the

vehicle-side connector.

lDo not touch the headlamp bulb glass surface with bare hands or allow oil or grease to get on it. Do not

touch the headlamp bulb just after the headlamp is turned off, because it is very hot.

lWhen the bulb has burned out, wrap it in a thick vinyl bag and discard. Do not break the bulb.

lLeaving the bulb removed from the headlamp housing for a long period of time can deteriorate the perfor-

mance of the lens and reflector (dirt, clouding). Always prepare a new bulb and have it on hand when

replacing the bulb.

lDo not use organic solvent (paint thinner or gasoline) to clean lamps and to remove old sealant.

Wiring Diagrams and Trouble DiagnosisEKS00L4I

When you read wiring diagrams, refer to the following:

lRefer toGI-15, "How to Read Wiring Diagrams".

lRefer toPG-4, "POWER SUPPLY ROUTING CIRCUIT".

When you perform trouble diagnosis, refer to the following:

lRefer toGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES".

lRefer toGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident".

Page 2265 of 3171

LU-8

OIL FILTER

OIL FILTER

PFP:15208

Removal and InstallationEBS01E58

REMOVAL

1. Remove engine undercover middle.

2. Place a pan to catch the engine oil under the lower part of drain hose outlet before removing oil filter.

3. Using the oil filter wrench, remove oil filter.

CAUTION:

lBe careful not to get burned when engine and engine oil are hot.

lWhen removing, prepare a shop cloth to absorb any engine oil leakage or spillage.

lDo not allow engine oil to adhere to drive belts.

lCompletely wipe off any engine oil that adhere to engine and vehicle.

lOil filter is provided with a relief valve. Use Genuine Nissan Oil Filter or equivalent.

INSTALLATION

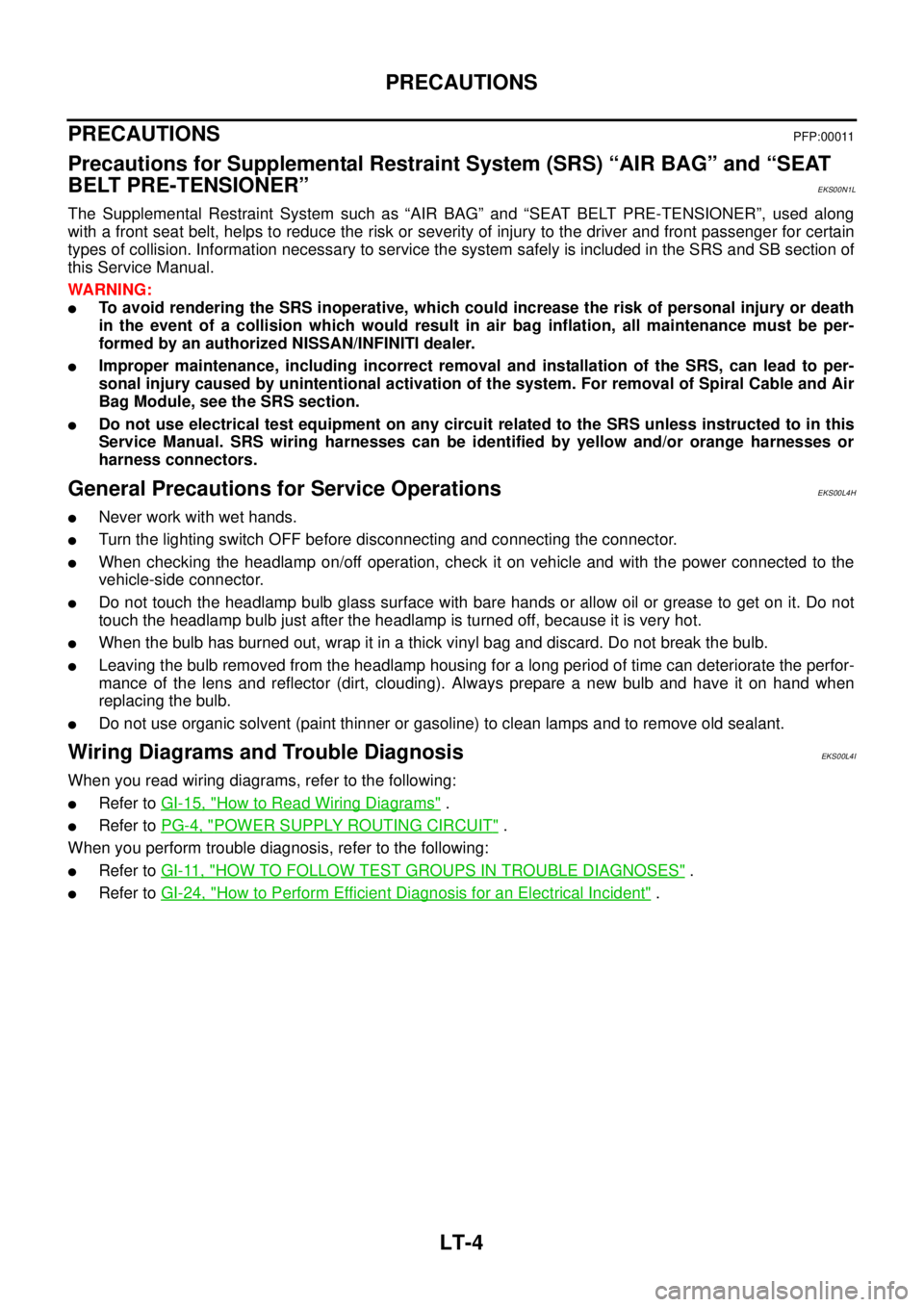

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

Use Genuine Nissan Oil Filter or equivalent.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer toLU-5, "ENGINE OIL".

2. Start engine, and check there is no leakage of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil. Refer toLU-5, "

ENGINE OIL".

SMA010

Oil filter:

: 18 N·m (1.8 Kg-m, 13 ft-lb)

SMA229B

Page 2269 of 3171

LU-12

OIL COOLER

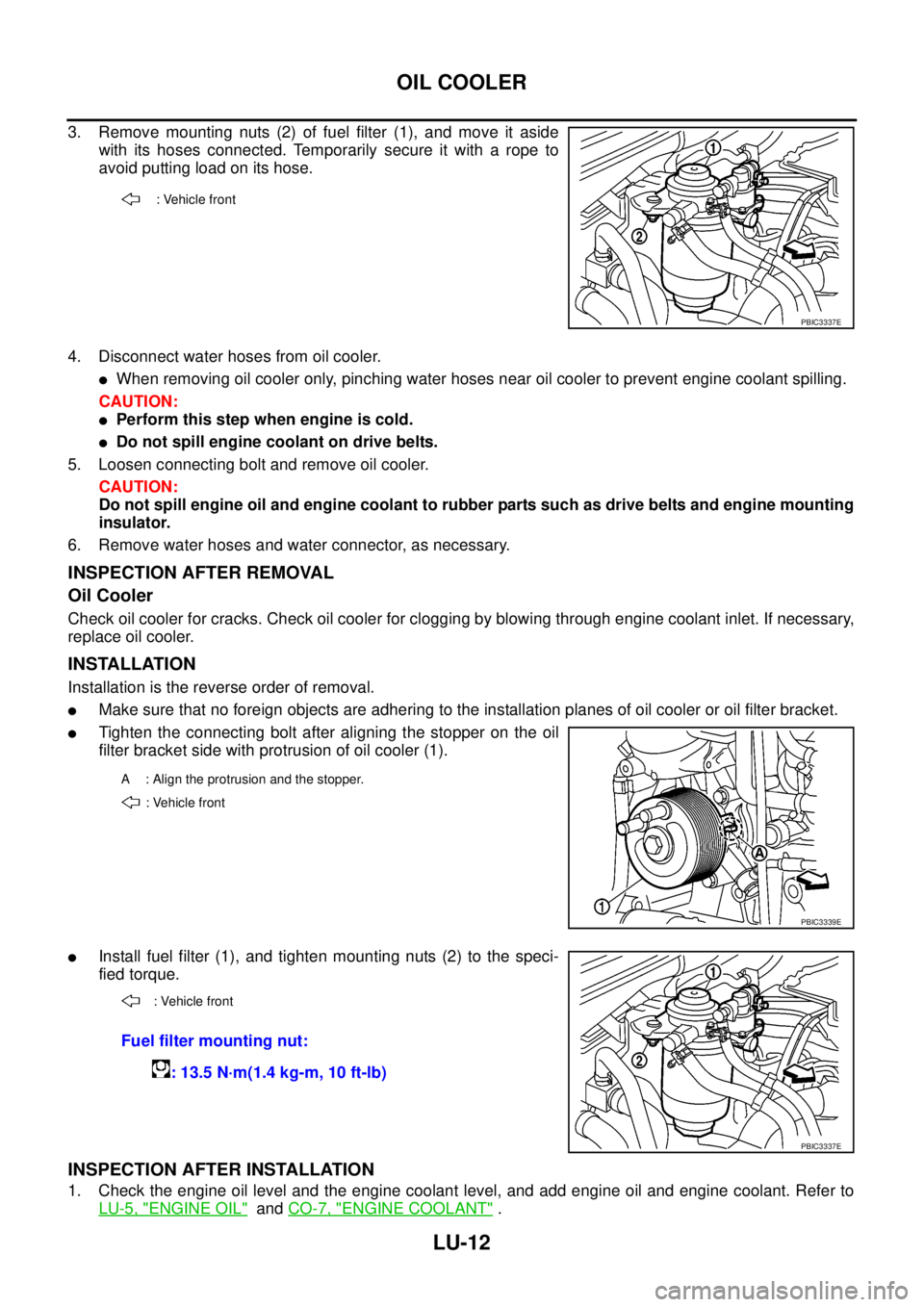

3. Remove mounting nuts (2) of fuel filter (1), and move it aside

with its hoses connected. Temporarily secure it with a rope to

avoid putting load on its hose.

4. Disconnect water hoses from oil cooler.

lWhen removing oil cooler only, pinching water hoses near oil cooler to prevent engine coolant spilling.

CAUTION:

lPerform this step when engine is cold.

lDo not spill engine coolant on drive belts.

5. Loosen connecting bolt and remove oil cooler.

CAUTION:

Do not spill engine oil and engine coolant to rubber parts such as drive belts and engine mounting

insulator.

6. Remove water hoses and water connector, as necessary.

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler.

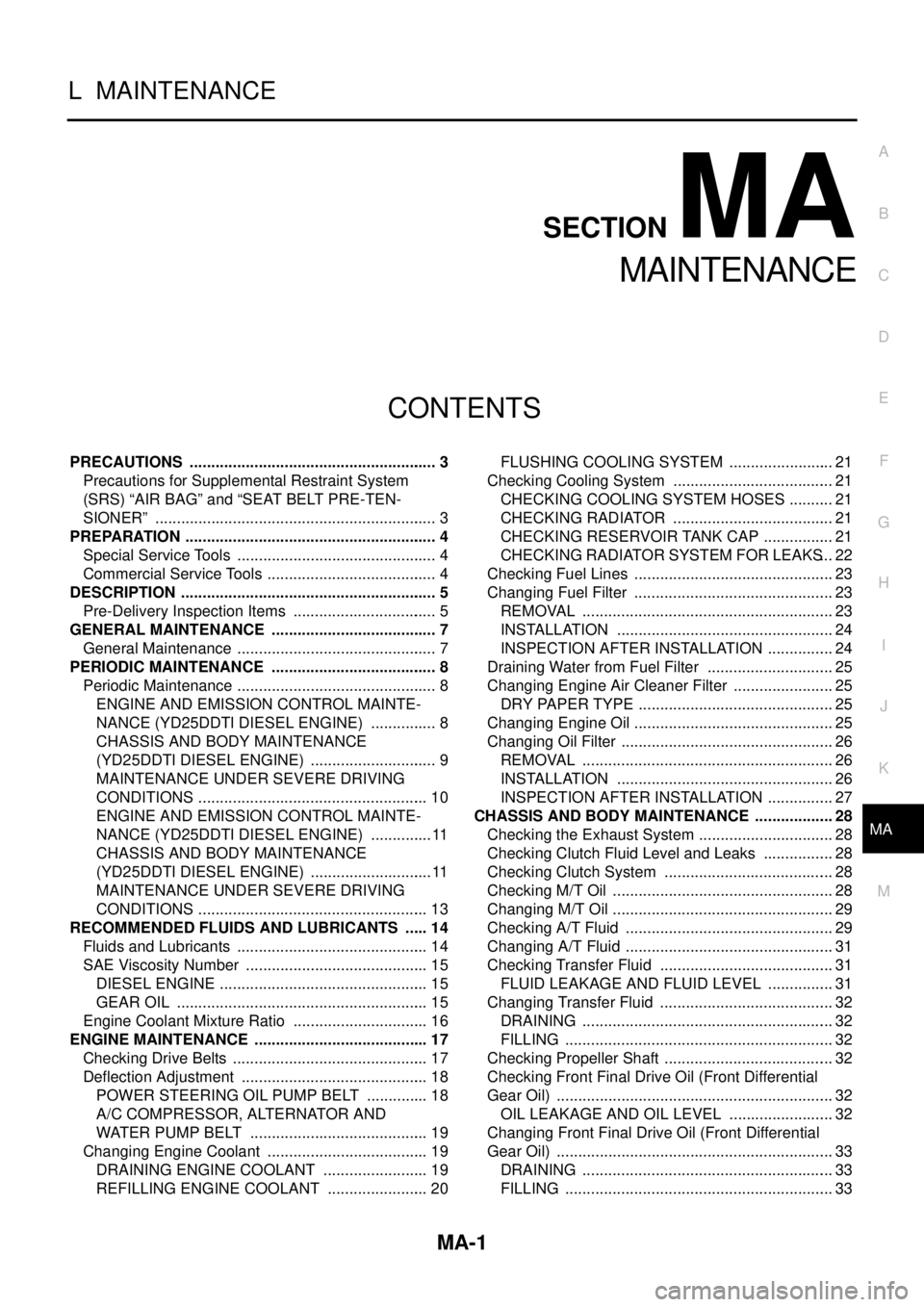

INSTALLATION

Installation is the reverse order of removal.

lMake sure that no foreign objects are adhering to the installation planes of oil cooler or oil filter bracket.

lTighten the connecting bolt after aligning the stopper on the oil

filter bracket side with protrusion of oil cooler (1).

lInstall fuel filter (1), and tighten mounting nuts (2) to the speci-

fied torque.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and the engine coolant level, and add engine oil and engine coolant. Refer to

LU-5, "

ENGINE OIL"andCO-7, "ENGINE COOLANT".

: Vehicle front

PBIC3337E

A : Align the protrusion and the stopper.

: Vehicle front

PBIC3339E

: Vehicle front

Fuel filter mounting nut:

: 13.5 N·m(1.4 kg-m, 10 ft-lb)

PBIC3337E

Page 2276 of 3171

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTIONMA

A

B

MA

MAINTENANCE

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

DESCRIPTION ............................................................ 5

Pre-Delivery Inspection Items .................................. 5

GENERAL MAINTENANCE ....................................... 7

General Maintenance ............................................... 7

PERIODIC MAINTENANCE ....................................... 8

Periodic Maintenance ............................................... 8

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD25DDTI DIESEL ENGINE) ................ 8

CHASSIS AND BODY MAINTENANCE

(YD25DDTI DIESEL ENGINE) .............................. 9

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 10

ENGINE AND EMISSION CONTROL MAINTE-

NANCE (YD25DDTI DIESEL ENGINE) ............... 11

CHASSIS AND BODY MAINTENANCE

(YD25DDTI DIESEL ENGINE) ............................. 11

MAINTENANCE UNDER SEVERE DRIVING

CONDITIONS ...................................................... 13

RECOMMENDED FLUIDS AND LUBRICANTS ...... 14

Fluids and Lubricants ............................................. 14

SAE Viscosity Number ........................................... 15

DIESEL ENGINE ................................................. 15

GEAR OIL ........................................................... 15

Engine Coolant Mixture Ratio ................................ 16

ENGINE MAINTENANCE ......................................... 17

Checking Drive Belts .............................................. 17

Deflection Adjustment ............................................ 18

POWER STEERING OIL PUMP BELT ............... 18

A/C COMPRESSOR, ALTERNATOR AND

WATER PUMP BELT .......................................... 19

Changing Engine Coolant ...................................... 19

DRAINING ENGINE COOLANT ......................... 19

REFILLING ENGINE COOLANT ........................ 20FLUSHING COOLING SYSTEM ......................... 21

Checking Cooling System ...................................... 21

CHECKING COOLING SYSTEM HOSES ........... 21

CHECKING RADIATOR ...................................... 21

CHECKING RESERVOIR TANK CAP ................. 21

CHECKING RADIATOR SYSTEM FOR LEAKS... 22

Checking Fuel Lines ............................................... 23

Changing Fuel Filter ............................................... 23

REMOVAL ........................................................... 23

INSTALLATION ................................................... 24

INSPECTION AFTER INSTALLATION ................ 24

Draining Water from Fuel Filter .............................. 25

Changing Engine Air Cleaner Filter ........................ 25

DRY PAPER TYPE .............................................. 25

Changing Engine Oil ............................................... 25

Changing Oil Filter .................................................. 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 26

INSPECTION AFTER INSTALLATION ................ 27

CHASSIS AND BODY MAINTENANCE ................... 28

Checking the Exhaust System ................................ 28

Checking Clutch Fluid Level and Leaks ................. 28

Checking Clutch System ........................................ 28

Checking M/T Oil .................................................... 28

Changing M/T Oil .................................................... 29

Checking A/T Fluid ................................................. 29

Changing A/T Fluid ................................................. 31

Checking Transfer Fluid ......................................... 31

FLUID LEAKAGE AND FLUID LEVEL ................ 31

Changing Transfer Fluid ......................................... 32

DRAINING ........................................................... 32

FILLING ............................................................... 32

Checking Propeller Shaft ........................................ 32

Checking Front Final Drive Oil (Front Differential

Gear Oil) ................................................................. 32

OIL LEAKAGE AND OIL LEVEL ......................... 32

Changing Front Final Drive Oil (Front Differential

Gear Oil) ................................................................. 33

DRAINING ........................................................... 33

FILLING ............................................................... 33

Page 2277 of 3171

MA-2

Checking Rear Final Drive Oil (Rear Differential

Gear Oil) ................................................................. 33

OIL LEAKAGE AND OIL LEVEL ......................... 33

Changing Rear Final Drive Oil (Rear Differential

Gear Oil) ................................................................. 34

DRAINING ........................................................... 34

FILLING ............................................................... 34

Balancing Wheels ................................................... 34

Tire Rotation ........................................................... 34

Checking Brake Fluid Level and Leaks .................. 35

Checking Brake Lines and Cables ......................... 35

Changing Brake Fluid ............................................. 35

Checking Disc Brake .............................................. 35

ROTOR ................................................................ 35

CALIPER ............................................................. 36

PAD ..................................................................... 36

Checking Drum Brake ............................................ 36

DRUM .................................................................. 36

WHEEL CYLINDER ............................................. 36

LINING ................................................................. 37

Checking Steering Gear and Linkage ..................... 37

STEERING GEAR ............................................... 37

STEERING LINKAGE .......................................... 37

Checking Power Steering Fluid and Lines .............. 37CHECKING FLUID LEVEL .................................. 37

CHECKING LINES ............................................... 37

Checking Axle and Suspension Parts ..................... 38

FRONT AND REAR AXLE AND SUSPENSION

PARTS ................................................................. 38

FRONT DRIVE SHAFT ........................................ 38

Lubricating Locks, Hinges and Hood Latches ......... 39

Checking Seat Belts, Buckles, Retractors, Anchors

and Adjusters .......................................................... 40

Checking Body Corrosion ....................................... 40

HEMMED PANELS .............................................. 40

PANEL JOINT ...................................................... 40

PANEL EDGE ...................................................... 40

PARTS CONTACT ............................................... 40

PROTECTORS .................................................... 40

ANTI-CORROSION MATERIALS ........................ 40

DRAIN HOLES ..................................................... 40

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 41

Standard and Limit .................................................. 41

BELT DEFLECTION ............................................ 41

RESERVOIR TANK ............................................. 41

ENGINE COOLANT CAPACITY (APPROXI-

MATE) .................................................................. 41

ENGINE OIL CAPACITY (APPROXIMATE) ........ 41

Page 2278 of 3171

PRECAUTIONS

MA-3

C

D

E

F

G

H

I

J

K

MA

B

MA

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

ELS001HP

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Page 2280 of 3171

DESCRIPTION

MA-5

C

D

E

F

G

H

I

J

K

MA

B

MA

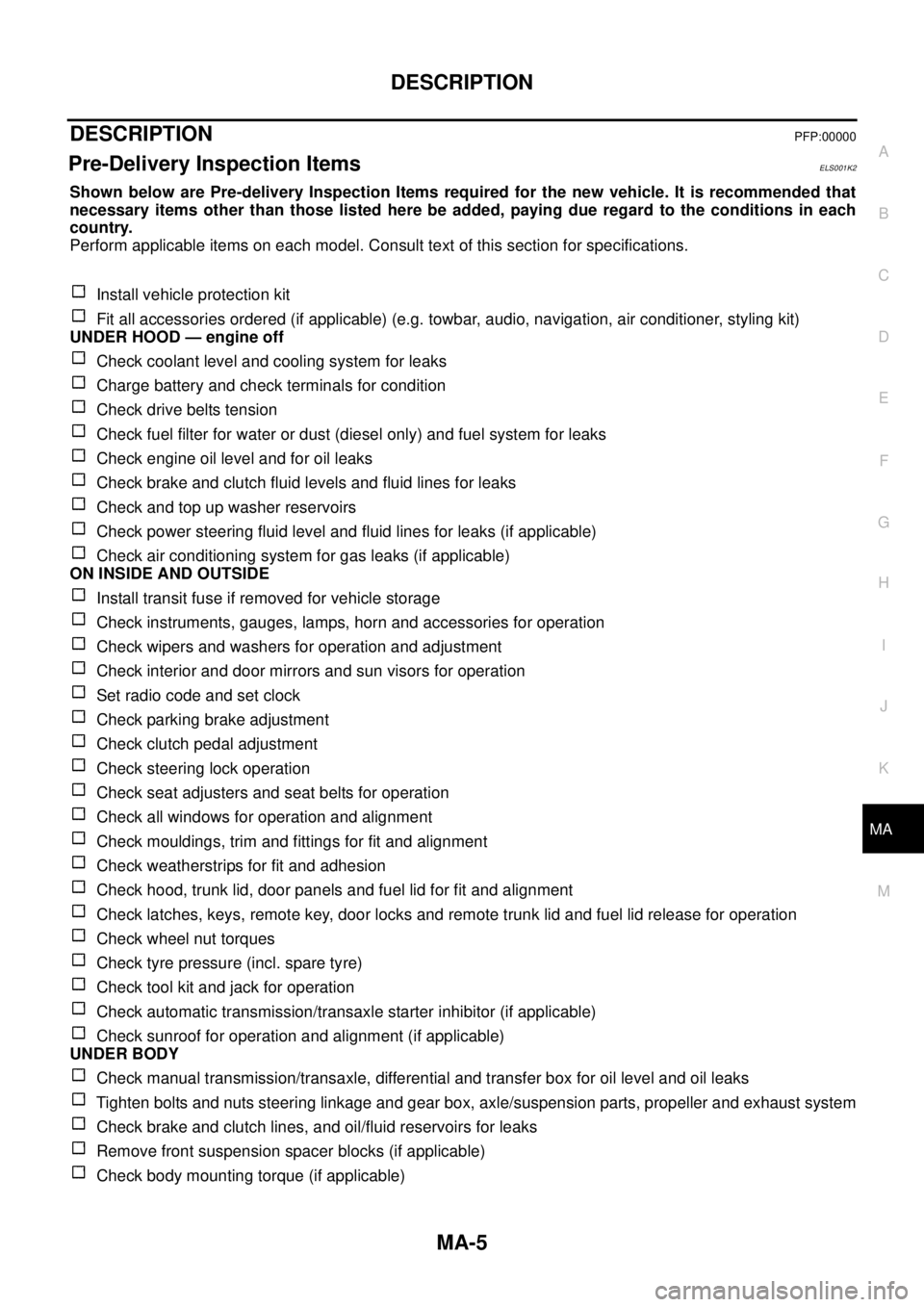

DESCRIPTIONPFP:00000

Pre-Delivery Inspection ItemsELS001K2

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

Install vehicle protection kit

Fit all accessories ordered (if applicable) (e.g. towbar, audio, navigation, air conditioner, styling kit)

UNDER HOOD — engine off

Check coolant level and cooling system for leaks

Charge battery and check terminals for condition

Check drive belts tension

Check fuel filter for water or dust (diesel only) and fuel system for leaks

Check engine oil level and for oil leaks

Check brake and clutch fluid levels and fluid lines for leaks

Check and top up washer reservoirs

Check power steering fluid level and fluid lines for leaks (if applicable)

Check air conditioning system for gas leaks (if applicable)

ON INSIDE AND OUTSIDE

Install transit fuse if removed for vehicle storage

Check instruments, gauges, lamps, horn and accessories for operation

Check wipers and washers for operation and adjustment

Check interior and door mirrors and sun visors for operation

Set radio code and set clock

Check parking brake adjustment

Check clutch pedal adjustment

Check steering lock operation

Check seat adjusters and seat belts for operation

Check all windows for operation and alignment

Check mouldings, trim and fittings for fit and alignment

Check weatherstrips for fit and adhesion

Check hood, trunk lid, door panels and fuel lid for fit and alignment

Check latches, keys, remote key, door locks and remote trunk lid and fuel lid release for operation

Check wheel nut torques

Check tyre pressure (incl. spare tyre)

Check tool kit and jack for operation

Check automatic transmission/transaxle starter inhibitor (if applicable)

Check sunroof for operation and alignment (if applicable)

UNDER BODY

Check manual transmission/transaxle, differential and transfer box for oil level and oil leaks

Tighten bolts and nuts steering linkage and gear box, axle/suspension parts, propeller and exhaust system

Check brake and clutch lines, and oil/fluid reservoirs for leaks

Remove front suspension spacer blocks (if applicable)

Check body mounting torque (if applicable)