sensor NISSAN NAVARA 2005 Repair Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 91 of 3171

TROUBLE DIAGNOSIS

AT-83

D

E

F

G

H

I

J

K

L

MA

B

AT

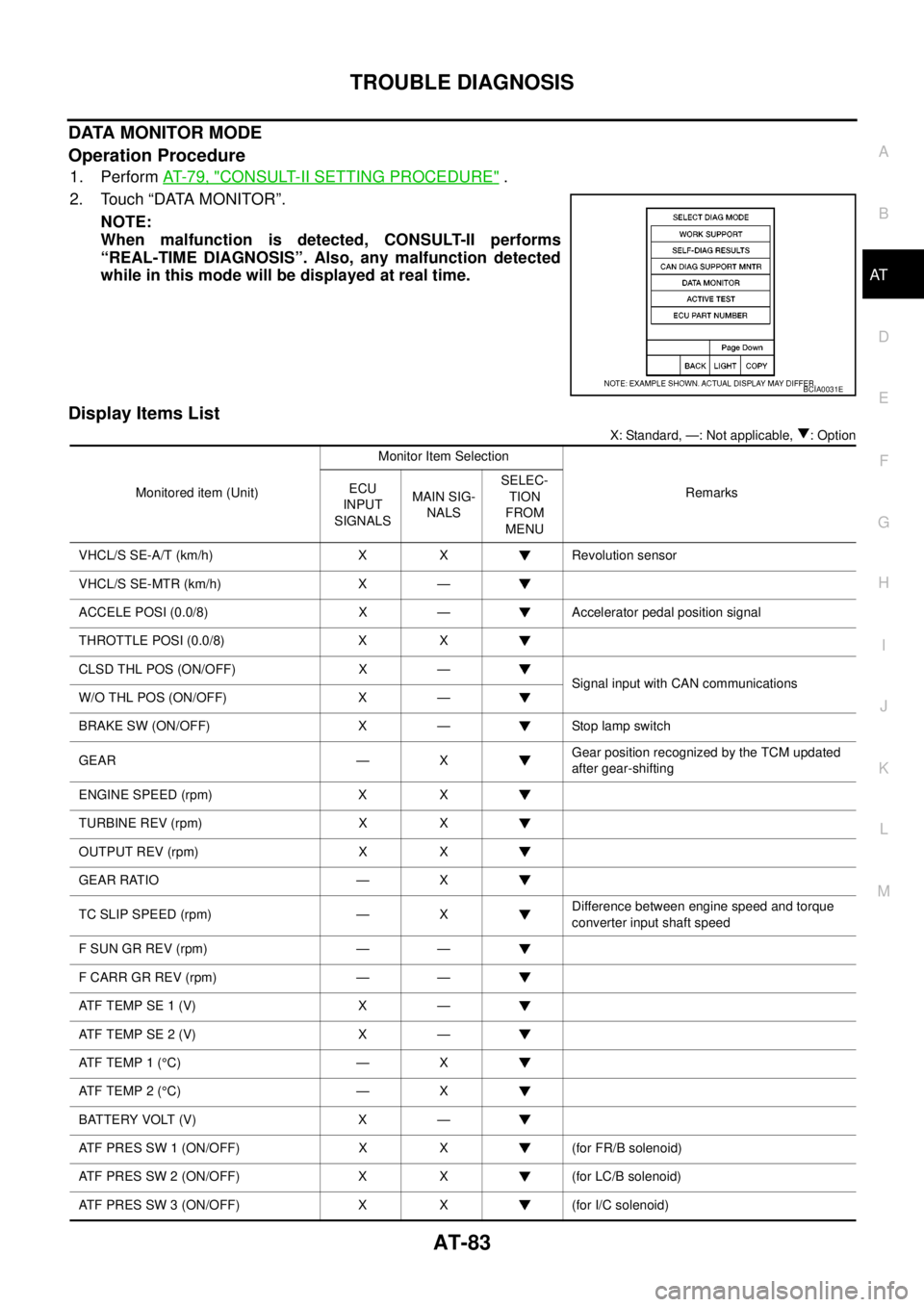

DATA MONITOR MODE

Operation Procedure

1. PerformAT-79, "CONSULT-II SETTING PROCEDURE".

2. Touch “DATA MONITOR”.

NOTE:

When malfunction is detected, CONSULT-II performs

“REAL-TIME DIAGNOSIS”. Also, any malfunction detected

while in this mode will be displayed at real time.

Display Items List

X: Standard, —: Not applicable, : Option

BCIA0031E

Monitored item (Unit)Monitor Item Selection

Remarks ECU

INPUT

SIGNALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

VHCL/S SE-A/T (km/h) X X Revolution sensor

VHCL/S SE-MTR (km/h) X —

ACCELE POSI (0.0/8) X — Accelerator pedal position signal

THROTTLE POSI (0.0/8) X X

CLSD THL POS (ON/OFF) X —

Signal input with CAN communications

W/O THL POS (ON/OFF) X —

BRAKE SW (ON/OFF) X — Stop lamp switch

GEAR — XGear position recognized by the TCM updated

after gear-shifting

ENGINE SPEED (rpm) X X

TURBINE REV (rpm) X X

OUTPUT REV (rpm) X X

GEAR RATIO — X

TC SLIP SPEED (rpm) — XDifference between engine speed and torque

converter input shaft speed

F SUN GR REV (rpm) — —

F CARR GR REV (rpm) — —

ATFTEMPSE1(V) X —

ATFTEMPSE2(V) X —

AT F T E M P 1 (°C) — X

AT F T E M P 2 (°C) — X

BATTERY VOLT (V) X —

ATF PRES SW 1 (ON/OFF) X X (for FR/B solenoid)

ATF PRES SW 2 (ON/OFF) X X (for LC/B solenoid)

ATF PRES SW 3 (ON/OFF) X X (for I/C solenoid)

Page 98 of 3171

AT-90

TROUBLE DIAGNOSIS

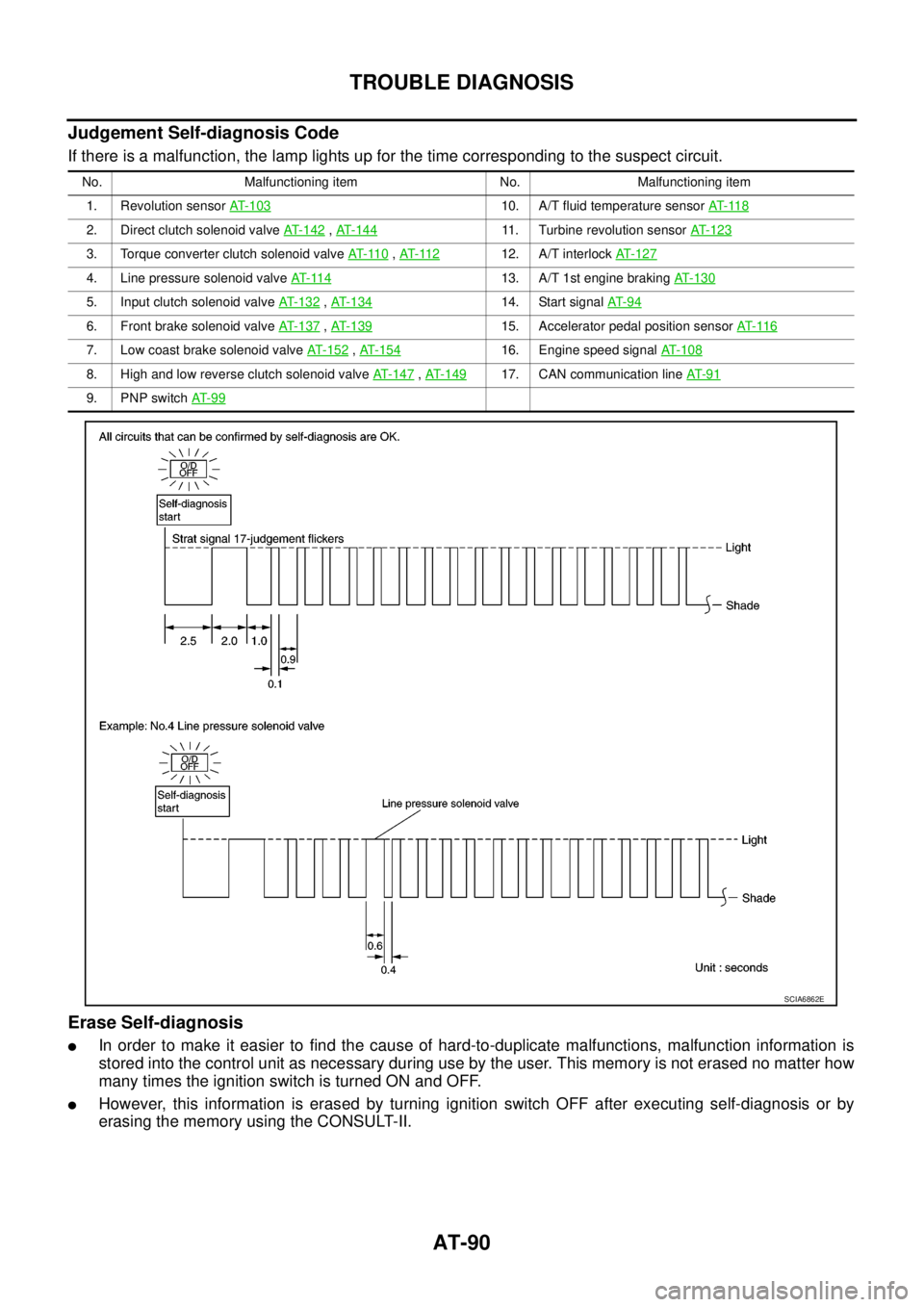

Judgement Self-diagnosis Code

If there is a malfunction, the lamp lights up for the time corresponding to the suspect circuit.

Erase Self-diagnosis

lIn order to make it easier to find the cause of hard-to-duplicate malfunctions, malfunction information is

stored into the control unit as necessary during use by the user. This memory is not erased no matter how

many times the ignition switch is turned ON and OFF.

lHowever, this information is erased by turning ignition switch OFF after executing self-diagnosis or by

erasing the memory using the CONSULT-II.

No. Malfunctioning item No. Malfunctioning item

1. Revolution sensorAT- 1 0 3

10. A/T fluid temperature sensorAT- 11 8

2. Direct clutch solenoid valveAT- 1 4 2,AT-14411. Turbine revolution sensorAT- 1 2 3

3. Torque converter clutch solenoid valveAT- 11 0,AT- 11 212. A/T interlockAT-127

4. Line pressure solenoid valveAT- 11 413. A/T 1st engine brakingAT-130

5. Input clutch solenoid valveAT- 1 3 2,AT- 1 3 414. Start signalAT- 9 4

6. Front brake solenoid valveAT-137,AT- 1 3 915. Accelerator pedal position sensorAT- 11 6

7. Low coast brake solenoid valveAT- 1 5 2,AT- 1 5 416. Engine speed signalAT-108

8. High and low reverse clutch solenoid valveAT-147,AT- 1 4 917. CAN communication lineAT- 9 1

9. PNP switchAT- 9 9

SCIA6862E

Page 105 of 3171

DTC P0615 START SIGNAL CIRCUIT

AT-97

D

E

F

G

H

I

J

K

L

MA

B

AT

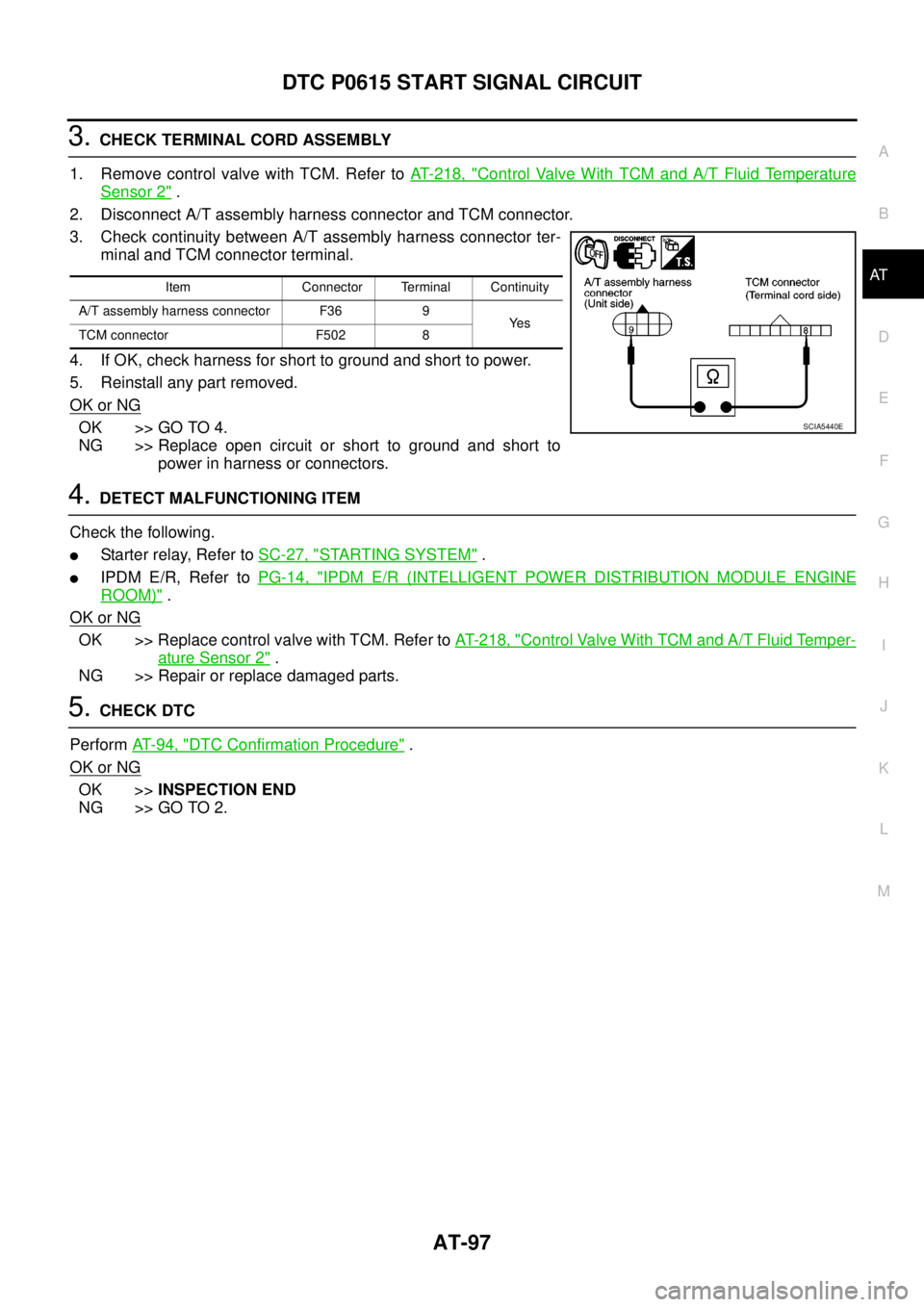

3.CHECK TERMINAL CORD ASSEMBLY

1. Remove control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect A/T assembly harness connector and TCM connector.

3. Check continuity between A/T assembly harness connector ter-

minal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 4.

NG >> Replace open circuit or short to ground and short to

power in harness or connectors.

4.DETECT MALFUNCTIONING ITEM

Check the following.

lStarter relay, Refer toSC-27, "STARTING SYSTEM".

lIPDM E/R, Refer toPG-14, "IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)".

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Repair or replace damaged parts.

5.CHECK DTC

PerformAT-94, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item Connector Terminal Continuity

A/T assembly harness connector F36 9

Ye s

TCM connector F502 8

SCIA5440E

Page 106 of 3171

AT-98

DTC P0700 TCM

DTC P0700 TCM

PFP:31036

DescriptionECS00FXP

TCM consists of a microcomputer and connectors for signal input and output and for power supply. TCM con-

trols A/T.

On Board Diagnosis LogicECS00FXQ

Diagnostic trouble code “P0700 TCM” with CONSULT-II is detected when TCM is malfunctioning.

Possible CauseECS00FXR

TCM

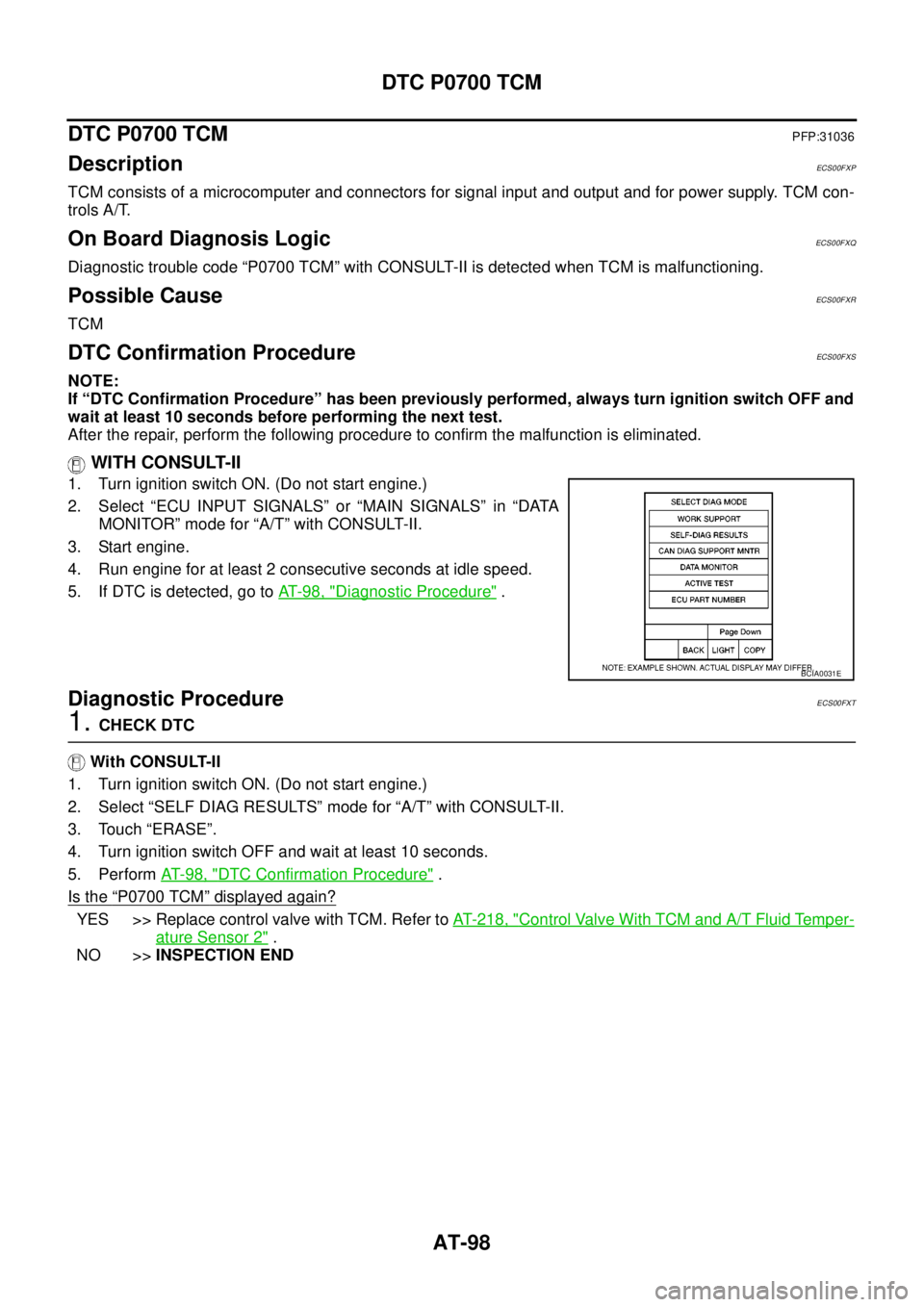

DTC Confirmation ProcedureECS00FXS

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” or “MAIN SIGNALS” in “DATA

MONITOR” mode for “A/T” with CONSULT-II.

3. Start engine.

4. Run engine for at least 2 consecutive seconds at idle speed.

5. If DTC is detected, go toAT-98, "

Diagnostic Procedure".

Diagnostic ProcedureECS00FXT

1.CHECK DTC

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF DIAG RESULTS” mode for “A/T” with CONSULT-II.

3. Touch “ERASE”.

4. Turn ignition switch OFF and wait at least 10 seconds.

5. PerformAT- 9 8 , "

DTC Confirmation Procedure".

Is the

“P0700 TCM”displayed again?

YES >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NO >>INSPECTION END

BCIA0031E

Page 110 of 3171

AT-102

DTC P0705 PARK/NEUTRAL POSITION SWITCH

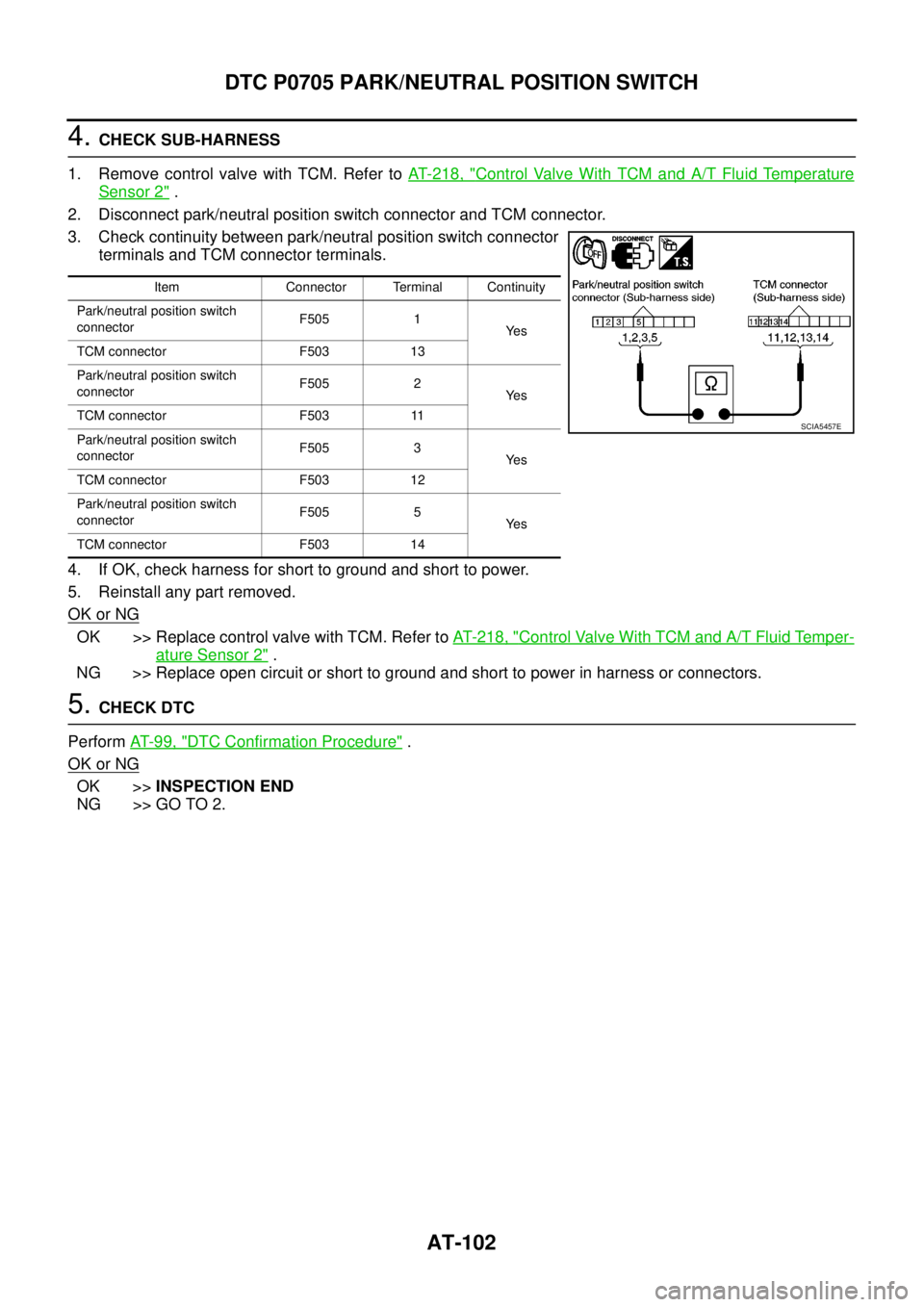

4.CHECK SUB-HARNESS

1. Remove control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect park/neutral position switch connector and TCM connector.

3. Check continuity between park/neutral position switch connector

terminals and TCM connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> Replace control valve with TCM. Refer toAT- 2 1 8 , "Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

5.CHECK DTC

PerformAT-99, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item Connector Terminal Continuity

Park/neutral position switch

connectorF505 1

Ye s

TCM connector F503 13

Park/neutral position switch

connectorF505 2

Ye s

TCM connector F503 11

Park/neutral position switch

connectorF505 3

Ye s

TCM connector F503 12

Park/neutral position switch

connectorF505 5

Ye s

TCM connector F503 14

SCIA5457E

Page 111 of 3171

DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)

AT-103

D

E

F

G

H

I

J

K

L

MA

B

AT

DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)PFP:32702

DescriptionECS00FY1

Revolution sensor detects the revolution of the idler gear parking pawl lock gear and emits a pulse signal. The

pulse signal is sent to TCM which converts it into vehicle speed.

CONSULT-II Reference ValueECS00FY2

On Board Diagnosis LogicECS00FY3

Diagnostic trouble code “P0720 VEH SPD SEN/CIR AT” with CONSULT-II or 1st judgement flicker without

CONSULT-II is detected under the following conditions.

lWhen TCM does not receive the proper voltage signal from the sensor.

lAfter ignition switch is turned ON, irregular signal input from vehicle speed sensor MTR before the vehicle

starts moving.

Possible CauseECS00FY4

lHarness or connectors

(The sensor circuit is open or shorted.)

lRevolution sensor

lVehicle speed sensor MTR

DTC Confirmation ProcedureECS00FY5

CAUTION:

lAlways drive vehicle at a safe speed.

lBe careful not to rev engine into the red zone on the tachometer.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Touch “START”.

4. Start engine.

5. Drive vehicle and check for an increase of “VHCL/S SE-A/T”

value in response to “VHCL/S SE-MTR” value.

If the check result is NG, go toAT- 1 0 6 , "

Diagnostic Procedure".

If the check result is OK, go to following step.

6. Select “DATA MONITOR” mode for “A/T” with CONSULT-II.

7. Drive vehicle and maintain the following conditions for at least 5

consecutive seconds.

VHCL/S SE-A/T: 30 km/h (19 MPH) or more

ACCELE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehicle uphill (increased engine load) will help maintain the driving

conditions required for this test.

If the check result is NG, go toAT- 1 0 6 , "

Diagnostic Procedure".

If the check result is OK, go to following step.

8. Maintain the following conditions for at least 5 consecutive seconds.

ENGINE SPEED: 3,500 rpm or more

ACCELE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Item name Condition Display value

VHCL/S SE-A/T During driving Approximately matches the speedometer reading.

BCIA0031E

Page 112 of 3171

AT-104

DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)

Driving location: Driving the vehicle uphill (increased engine load) will help maintain the driving

conditions required for this test.

If is detected, go toAT- 1 0 6 , "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Start engine.

2. Drive vehicle and maintain the following conditions for at least 5 consecutive seconds.

Vehicle speed: 30 km/h (19 MPH) or more

Accelerator opening: More than 1.0/8

Selector lever position: “D” position

Driving location: Driving the vehicle uphill (increased engine load) will help maintain the driving

conditions required for this test.

3. Perform self-diagnosis. Refer toAT-89, "

Diagnostic Procedure Without CONSULT-II".

4. If DTC is detected, go toAT- 1 0 6 , "

Diagnostic Procedure".

Page 113 of 3171

DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)

AT-105

D

E

F

G

H

I

J

K

L

MA

B

AT

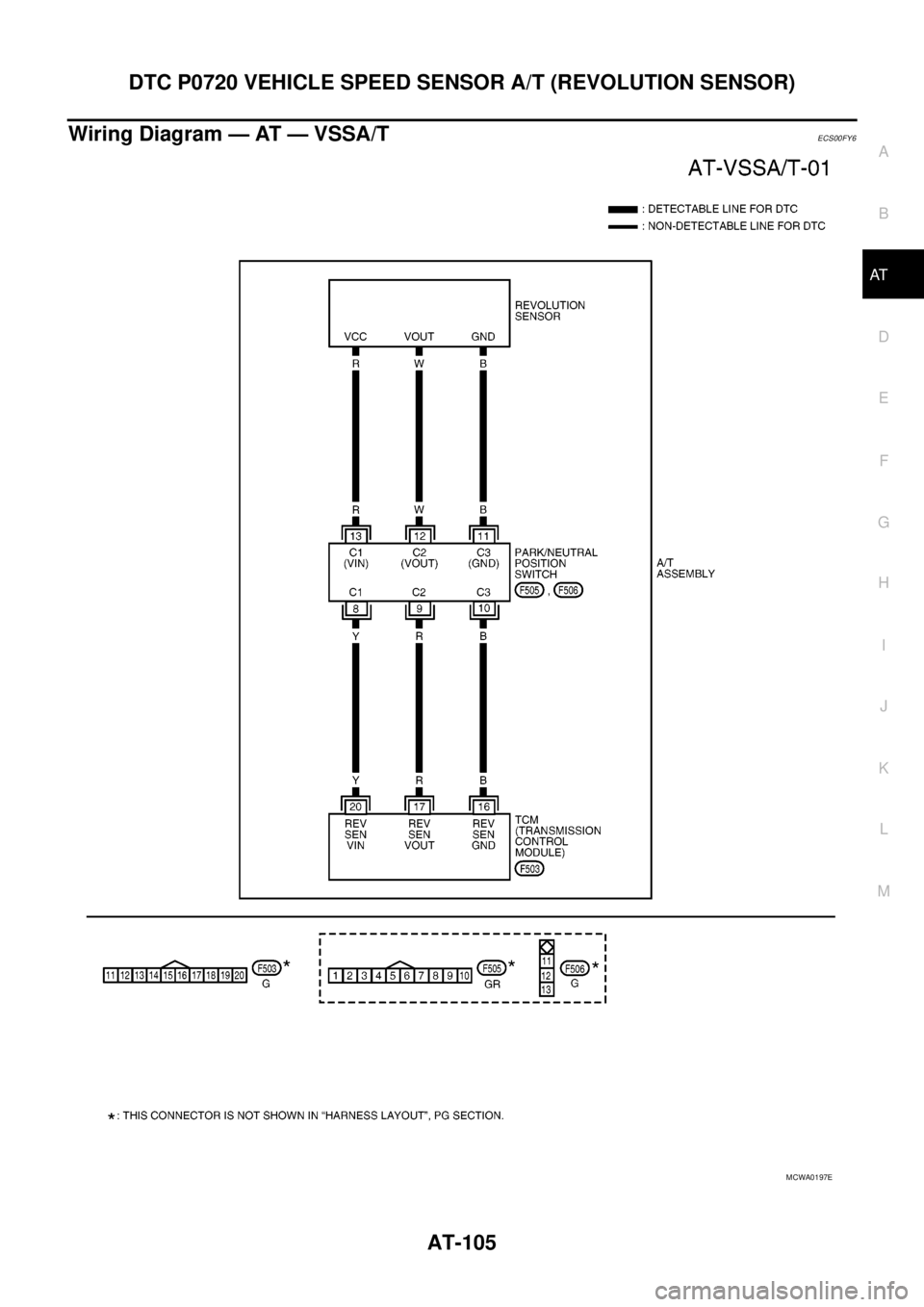

Wiring Diagram — AT — VSSA/TECS00FY6

MCWA0197E

Page 114 of 3171

AT-106

DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)

Diagnostic Procedure

ECS00FY7

1.CHECK INPUT SIGNAL

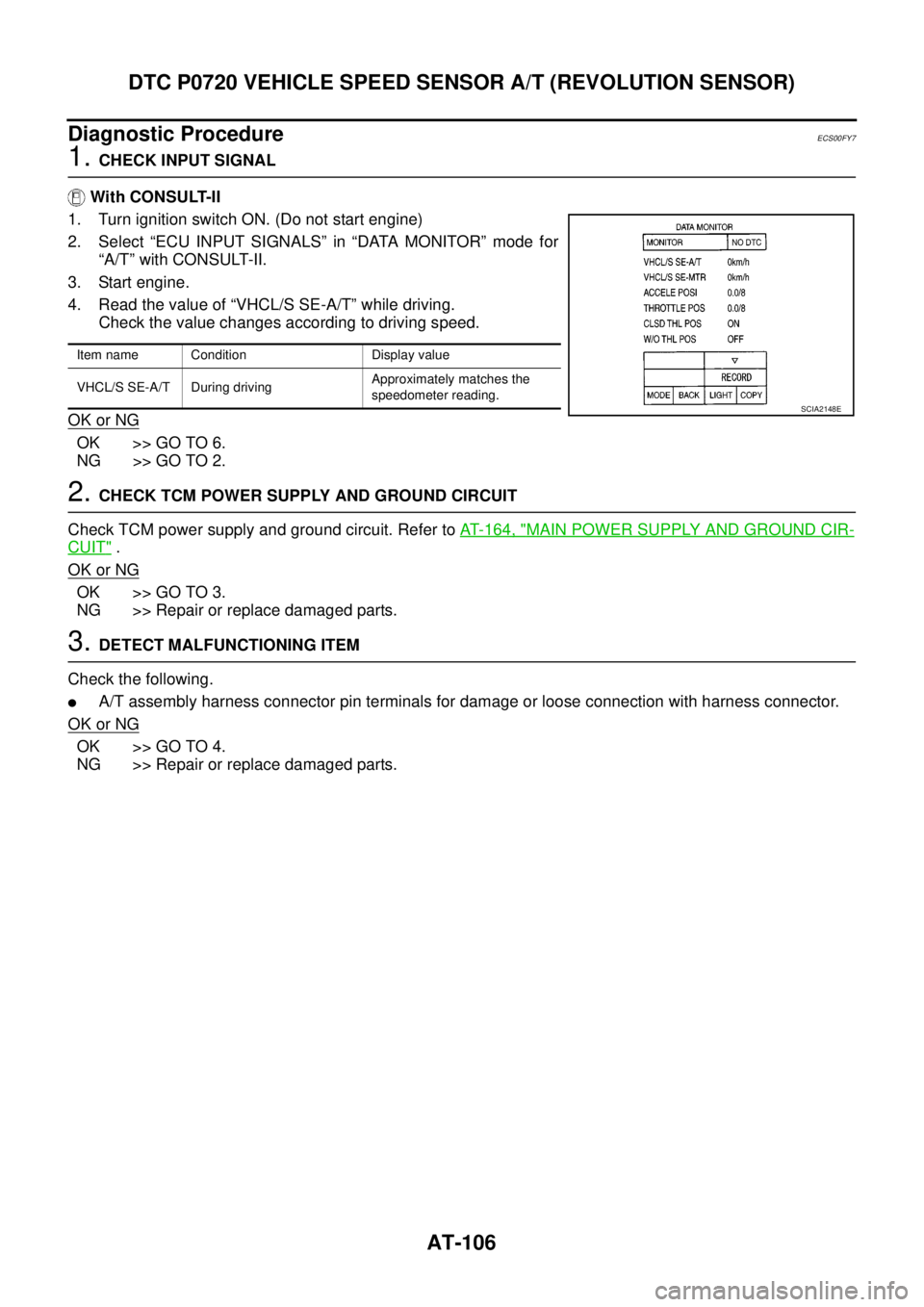

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Start engine.

4. Read the value of “VHCL/S SE-A/T” while driving.

Check the value changes according to driving speed.

OK or NG

OK >> GO TO 6.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer toAT- 1 6 4 , "

MAIN POWER SUPPLY AND GROUND CIR-

CUIT".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following.

lA/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

Item name Condition Display value

VHCL/S SE-A/T During drivingApproximately matches the

speedometer reading.

SCIA2148E

Page 115 of 3171

DTC P0720 VEHICLE SPEED SENSOR A/T (REVOLUTION SENSOR)

AT-107

D

E

F

G

H

I

J

K

L

MA

B

AT

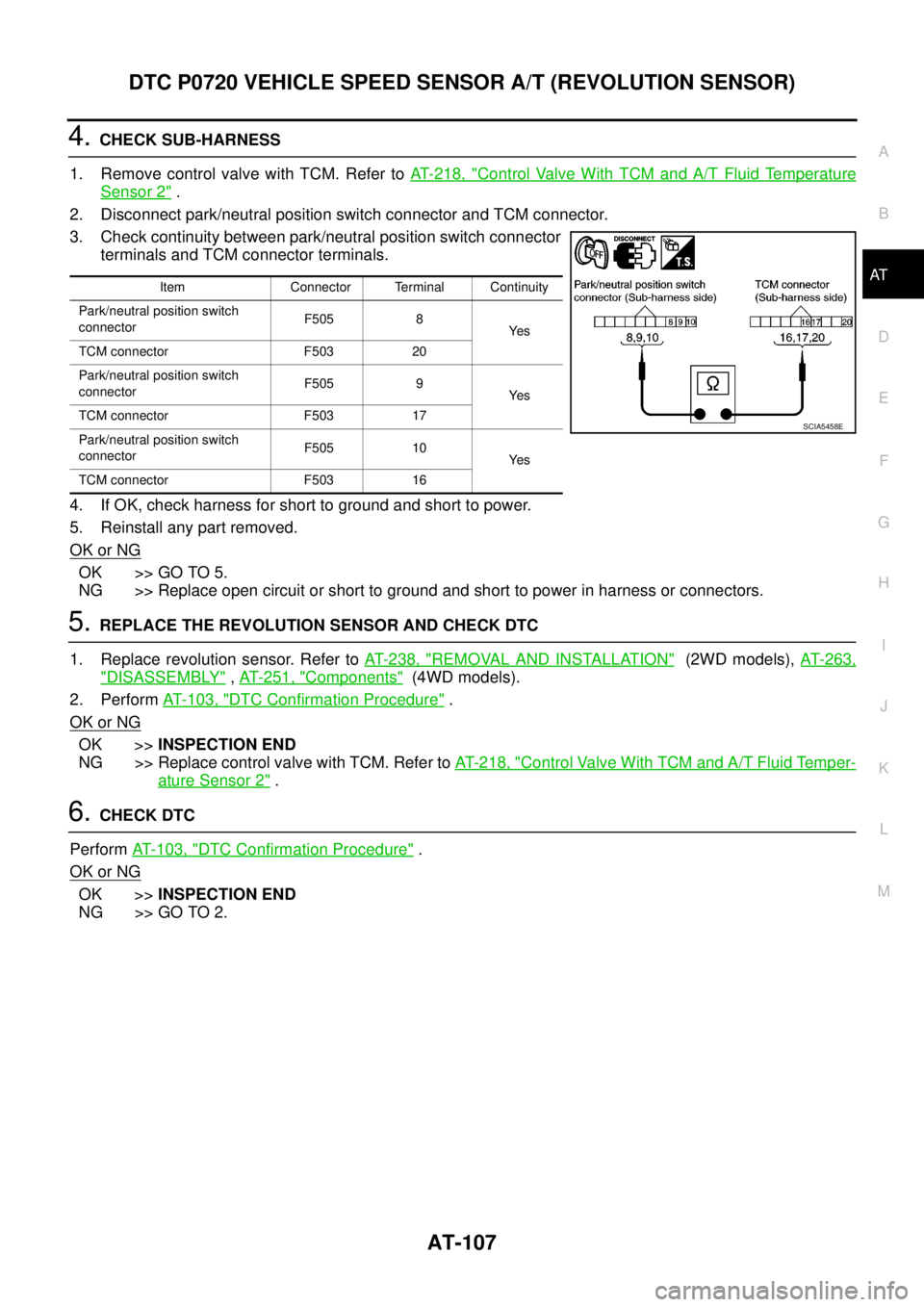

4.CHECK SUB-HARNESS

1. Remove control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect park/neutral position switch connector and TCM connector.

3. Check continuity between park/neutral position switch connector

terminals and TCM connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

5.REPLACE THE REVOLUTION SENSOR AND CHECK DTC

1. Replace revolution sensor. Refer toAT- 2 3 8 , "

REMOVAL AND INSTALLATION"(2WD models),AT- 2 6 3 ,

"DISASSEMBLY",AT- 2 5 1 , "Components"(4WD models).

2. PerformAT- 1 0 3 , "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> Replace control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temper-

ature Sensor 2".

6.CHECK DTC

PerformAT- 1 0 3 , "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item Connector Terminal Continuity

Park/neutral position switch

connectorF505 8

Ye s

TCM connector F503 20

Park/neutral position switch

connectorF505 9

Ye s

TCM connector F503 17

Park/neutral position switch

connectorF505 10

Ye s

TCM connector F503 16

SCIA5458E