ESP NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1044 of 3171

![NISSAN NAVARA 2005 Repair Repair Manual EC-64

TROUBLE DIAGNOSIS

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

INT/M PRES SE [kPa]

lTurbocharger boost (de NISSAN NAVARA 2005 Repair Repair Manual EC-64

TROUBLE DIAGNOSIS

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

INT/M PRES SE [kPa]

lTurbocharger boost (de](/img/5/57362/w960_57362-1043.png)

EC-64

TROUBLE DIAGNOSIS

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ACTIVE TEST MODE

INT/M PRES SE [kPa]

lTurbocharger boost (determined by

the signal voltage from the turbo-

charger boost sensor) is displayed.

CYL COUNT [1/2/3/4]

lThe cylinder being injected is dis-

played.

1 ... Cylinder No.1 is injected.

2 ... Cylinder No.2 is injected.

3 ... Cylinder No.3 is injected.

4 ... Cylinder No.4 is injected.

SET SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

SET/COAST switch signal.

RESUME/ACC SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

RESUME/ACCEL switch signal.

CANCEL SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

CANCEL switch signal.

MAIN SW

[ON/OFF]´

lIndicates [ON/OFF] condition from

MAIN switch signal.

ASCD APPLY [YES/NO]

lDisplaying ASCD application status

stored in ECM.

VDC APPLY [YES/NO]

lDisplaying ESP application status

stored in ECM.

AC PRESS SEN [V]

lThe signal voltage from the refrigerant

pressure sensor is displayed.

Voltage [V]

Voltage, frequency, duty cycle or pulse

width measured by the probe.Only “#” is displayed if item is unable to

be measured.

Figures with “#”s are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured. [Hz] or [%] Frequency

[msec],[Hz]or[%]

DUTY-HI

DUTY-LOW

PLS WIDTH-HI

PLS WIDTH-LOWMONITOR ITEMECM

INPUT

SIG-

NALMAIN

SIG-

NALSCONDITION SPECIFICATION

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

POWER BAL-

ANCE

lEngine: After warming up, idle the

engine.

lA/C switch: OFF

lShift lever: P or N (A/T), Neutral

(M/T)

lCut off each injector signal one at

a time using CONSULT-IIEngine runs rough or dies.

lHarness and connectors

lCompression

lFuel injector

COOLING FAN *

lIgnition switch: ON

lOperate the cooling fan at LOW,

HI speed and turn OFF using

CONSULT-II.Cooling fan moves at LOW, HI

speed and stops.lHarness and connector

lCooling fan motor

lCooling fan relay

ENG COOLANT

TEMP

lEngine: Return to the original

trouble condition

lChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.

lHarness and connectors

lEngine coolant temperature sen-

sor

lFuel injector

Page 1045 of 3171

TROUBLE DIAGNOSIS

EC-65

C

D

E

F

G

H

I

J

K

L

MA

EC

*: Leaving cooling fan OFF with CONSULT-II while engine is running may cause the engine to overheat.

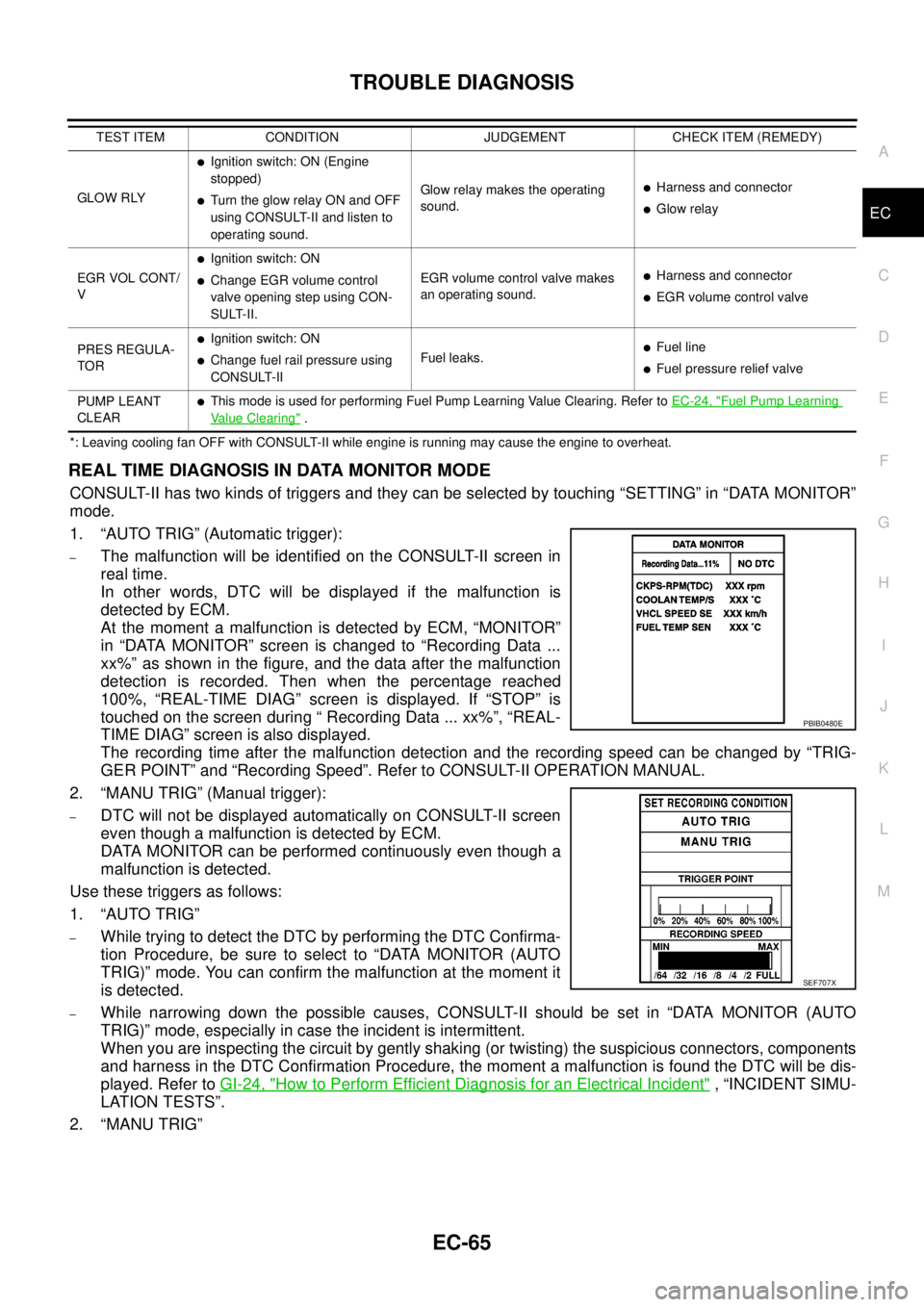

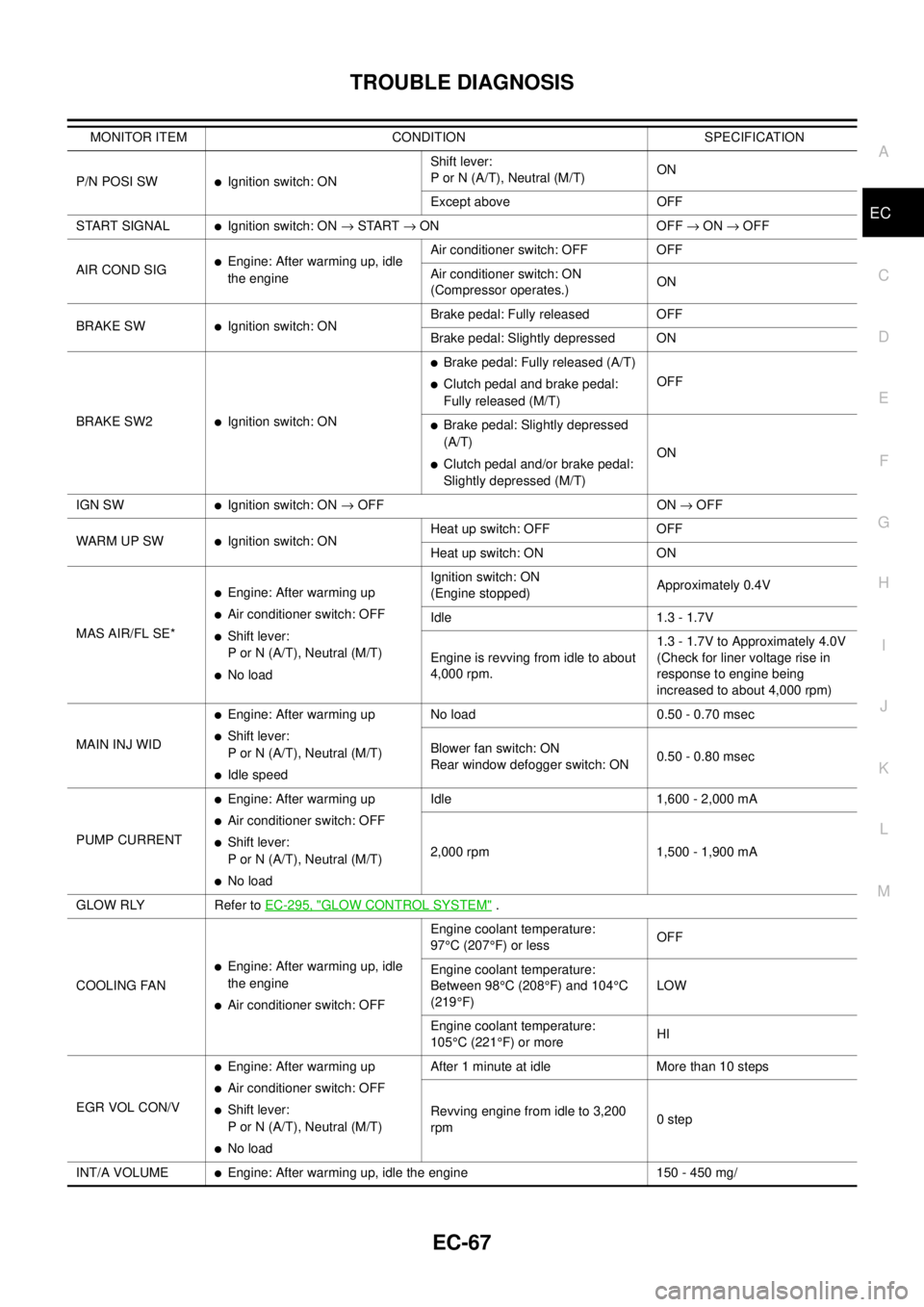

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

CONSULT-II has two kinds of triggers and they can be selected by touching “SETTING” in “DATA MONITOR”

mode.

1. “AUTO TRIG” (Automatic trigger):

–The malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC will be displayed if the malfunction is

detected by ECM.

At the moment a malfunction is detected by ECM, “MONITOR”

in “DATA MONITOR” screen is changed to “Recording Data ...

xx%” as shown in the figure, and the data after the malfunction

detection is recorded. Then when the percentage reached

100%, “REAL-TIME DIAG” screen is displayed. If “STOP” is

touched on the screen during “ Recording Data ... xx%”, “REAL-

TIME DIAG” screen is also displayed.

The recording time after the malfunction detection and the recording speed can be changed by “TRIG-

GER POINT” and “Recording Speed”. Refer to CONSULT-II OPERATION MANUAL.

2. “MANU TRIG” (Manual trigger):

–DTC will not be displayed automatically on CONSULT-II screen

even though a malfunction is detected by ECM.

DATA MONITOR can be performed continuously even though a

malfunction is detected.

Use these triggers as follows:

1. “AUTO TRIG”

–While trying to detect the DTC by performing the DTC Confirma-

tion Procedure, be sure to select to “DATA MONITOR (AUTO

TRIG)” mode. You can confirm the malfunction at the moment it

is detected.

–While narrowing down the possible causes, CONSULT-II should be set in “DATA MONITOR (AUTO

TRIG)” mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, components

and harness in the DTC Confirmation Procedure, the moment a malfunction is found the DTC will be dis-

played. Refer toGI-24, "

How to Perform Efficient Diagnosis for an Electrical Incident", “INCIDENT SIMU-

LATION TESTS”.

2. “MANU TRIG”

GLOW RLY

lIgnition switch: ON (Engine

stopped)

lTurn the glow relay ON and OFF

using CONSULT-II and listen to

operating sound.Glow relay makes the operating

sound.lHarness and connector

lGlow relay

EGR VOL CONT/

V

lIgnition switch: ON

lChange EGR volume control

valve opening step using CON-

SULT-II.EGR volume control valve makes

an operating sound.lHarness and connector

lEGR volume control valve

PRES REGULA-

TOR

lIgnition switch: ON

lChange fuel rail pressure using

CONSULT-IIFuel leaks.lFuel line

lFuel pressure relief valve

PUMP LEANT

CLEAR

lThis mode is used for performing Fuel Pump Learning Value Clearing. Refer toEC-24, "Fuel Pump Learning

Value Clearing". TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

PBIB0480E

SEF707X

Page 1047 of 3171

TROUBLE DIAGNOSIS

EC-67

C

D

E

F

G

H

I

J

K

L

MA

EC

P/N POSI SWlIgnition switch: ONShift lever:

P or N (A/T), Neutral (M/T)ON

Except above OFF

START SIGNAL

lIgnition switch: ON®START®ON OFF®ON®OFF

AIRCONDSIG

lEngine: After warming up, idle

the engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW

lIgnition switch: ONBrake pedal: Fully released OFF

Brake pedal: Slightly depressed ON

BRAKE SW2

lIgnition switch: ON

lBrake pedal: Fully released (A/T)

lClutch pedal and brake pedal:

Fully released (M/T)OFF

lBrake pedal: Slightly depressed

(A/T)

lClutch pedal and/or brake pedal:

Slightly depressed (M/T)ON

IGN SW

lIgnition switch: ON®OFF ON®OFF

WARM UP SW

lIgnition switch: ONHeat up switch: OFF OFF

Heat up switch: ON ON

MAS AIR/FL SE*

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIgnition switch: ON

(Engine stopped)Approximately 0.4V

Idle 1.3 - 1.7V

Engine is revving from idle to about

4,000 rpm.1.3 - 1.7V to Approximately 4.0V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

MAIN INJ WID

lEngine: After warming up

lShift lever:

P or N (A/T), Neutral (M/T)

lIdle speedNo load 0.50 - 0.70 msec

Blower fan switch: ON

Rear window defogger switch: ON0.50 - 0.80 msec

PUMP CURRENT

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadIdle 1,600 - 2,000 mA

2,000 rpm 1,500 - 1,900 mA

GLOW RLY Refer toEC-295, "

GLOW CONTROL SYSTEM".

COOLING FAN

lEngine: After warming up, idle

the engine

lAir conditioner switch: OFFEngine coolant temperature:

97°C (207°F) or lessOFF

Engine coolant temperature:

Between 98°C(208°F) and 104°C

(219°F)LOW

Engine coolant temperature:

105°C(221°F) or moreHI

EGR VOL CON/V

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever:

P or N (A/T), Neutral (M/T)

lNo loadAfter 1 minute at idle More than 10 steps

Revving engine from idle to 3,200

rpm0step

INT/A VOLUME

lEngine: After warming up, idle the engine 150 - 450 mg/ MONITOR ITEM CONDITION SPECIFICATION

Page 1070 of 3171

EC-90

DTC P0093 FUEL SYSTEM

5.REPLACE FUEL PUMP

1. Replace fuel pump.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

Component InspectionEBS01KDT

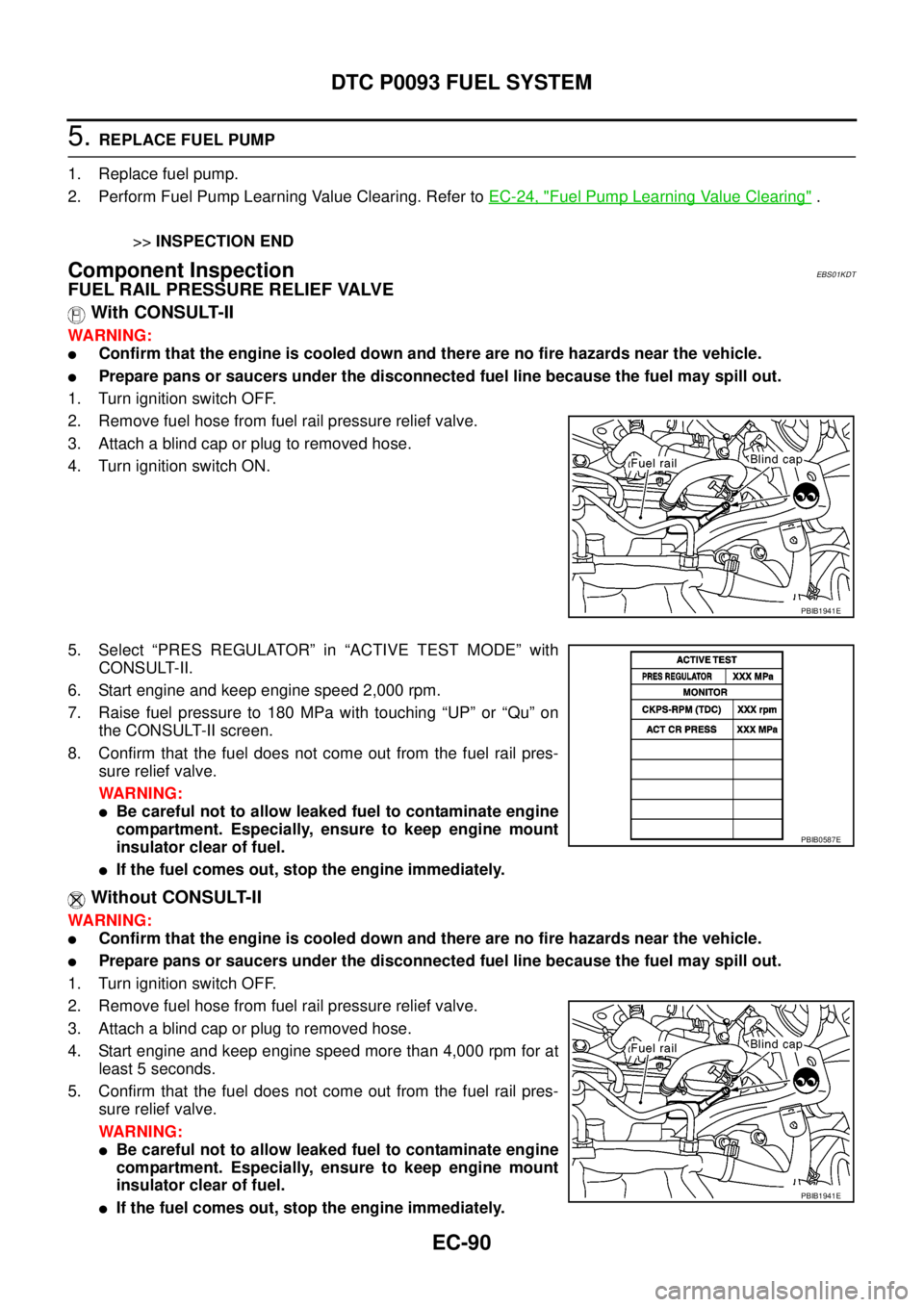

FUEL RAIL PRESSURE RELIEF VALVE

With CONSULT-II

WARNING:

lConfirm that the engine is cooled down and there are no fire hazards near the vehicle.

lPrepare pans or saucers under the disconnected fuel line because the fuel may spill out.

1. Turn ignition switch OFF.

2. Remove fuel hose from fuel rail pressure relief valve.

3. Attach a blind cap or plug to removed hose.

4. Turn ignition switch ON.

5. Select “PRES REGULATOR” in “ACTIVE TEST MODE” with

CONSULT-II.

6. Start engine and keep engine speed 2,000 rpm.

7. Raisefuelpressureto180MPawithtouching“UP”or“Qu”on

the CONSULT-II screen.

8. Confirm that the fuel does not come out from the fuel rail pres-

sure relief valve.

WARNING:

lBe careful not to allow leaked fuel to contaminate engine

compartment. Especially, ensure to keep engine mount

insulator clear of fuel.

lIf the fuel comes out, stop the engine immediately.

Without CONSULT-II

WARNING:

lConfirm that the engine is cooled down and there are no fire hazards near the vehicle.

lPrepare pans or saucers under the disconnected fuel line because the fuel may spill out.

1. Turn ignition switch OFF.

2. Remove fuel hose from fuel rail pressure relief valve.

3. Attach a blind cap or plug to removed hose.

4. Start engine and keep engine speed more than 4,000 rpm for at

least 5 seconds.

5. Confirm that the fuel does not come out from the fuel rail pres-

sure relief valve.

WARNING:

lBe careful not to allow leaked fuel to contaminate engine

compartment. Especially, ensure to keep engine mount

insulator clear of fuel.

lIf the fuel comes out, stop the engine immediately.

PBIB1941E

PBIB0587E

PBIB1941E

Page 1072 of 3171

EC-92

DTC P0102, P0103 MAF SENSOR

DTC P0102, P0103 MAF SENSOR

PFP:22680

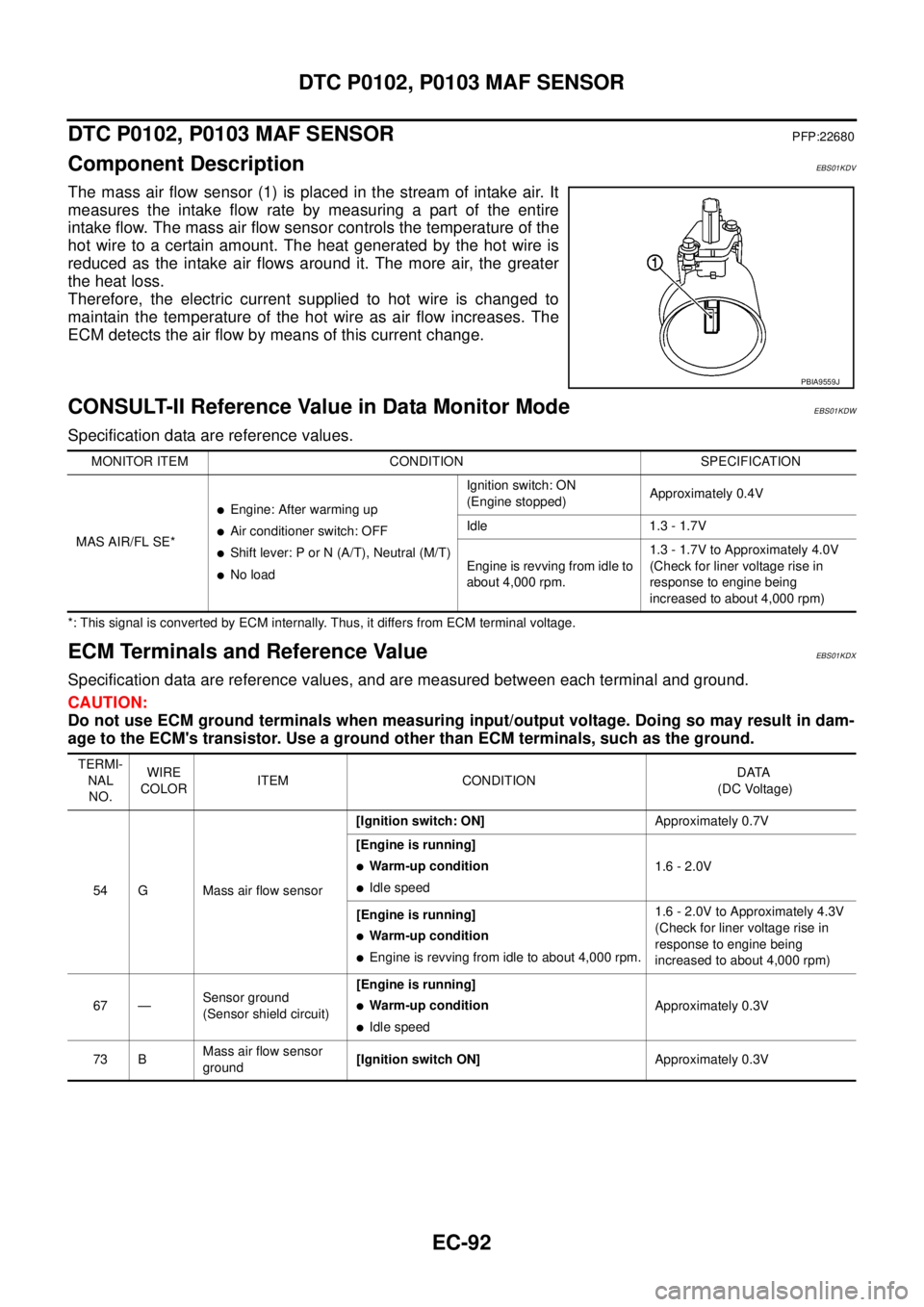

Component DescriptionEBS01KDV

The mass air flow sensor (1) is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sensor controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

CONSULT-II Reference Value in Data Monitor ModeEBS01KDW

Specification data are reference values.

*: This signal is converted by ECM internally. Thus, it differs from ECM terminal voltage.

ECM Terminals and Reference ValueEBS01KDX

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

PBIA9559J

MONITOR ITEM CONDITION SPECIFICATION

MAS AIR/FL SE*

lEngine: After warming up

lAir conditioner switch: OFF

lShift lever: P or N (A/T), Neutral (M/T)

lNo loadIgnition switch: ON

(Engine stopped)Approximately 0.4V

Idle 1.3 - 1.7V

Engine is revving from idle to

about 4,000 rpm.1.3 - 1.7V to Approximately 4.0V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage)

54 G Mass air flow sensor[Ignition switch: ON]Approximately 0.7V

[Engine is running]

lWarm-up condition

lIdle speed1.6 - 2.0V

[Engine is running]

lWarm-up condition

lEngine is revving from idle to about 4,000 rpm.1.6 - 2.0V to Approximately 4.3V

(Check for liner voltage rise in

response to engine being

increased to about 4,000 rpm)

67 —Sensor ground

(Sensor shield circuit)[Engine is running]

lWarm-up condition

lIdle speedApproximately 0.3V

73 BMass air flow sensor

ground[Ignition switch ON]Approximately 0.3V

Page 1077 of 3171

DTC P0102, P0103 MAF SENSOR

EC-97

C

D

E

F

G

H

I

J

K

L

MA

EC

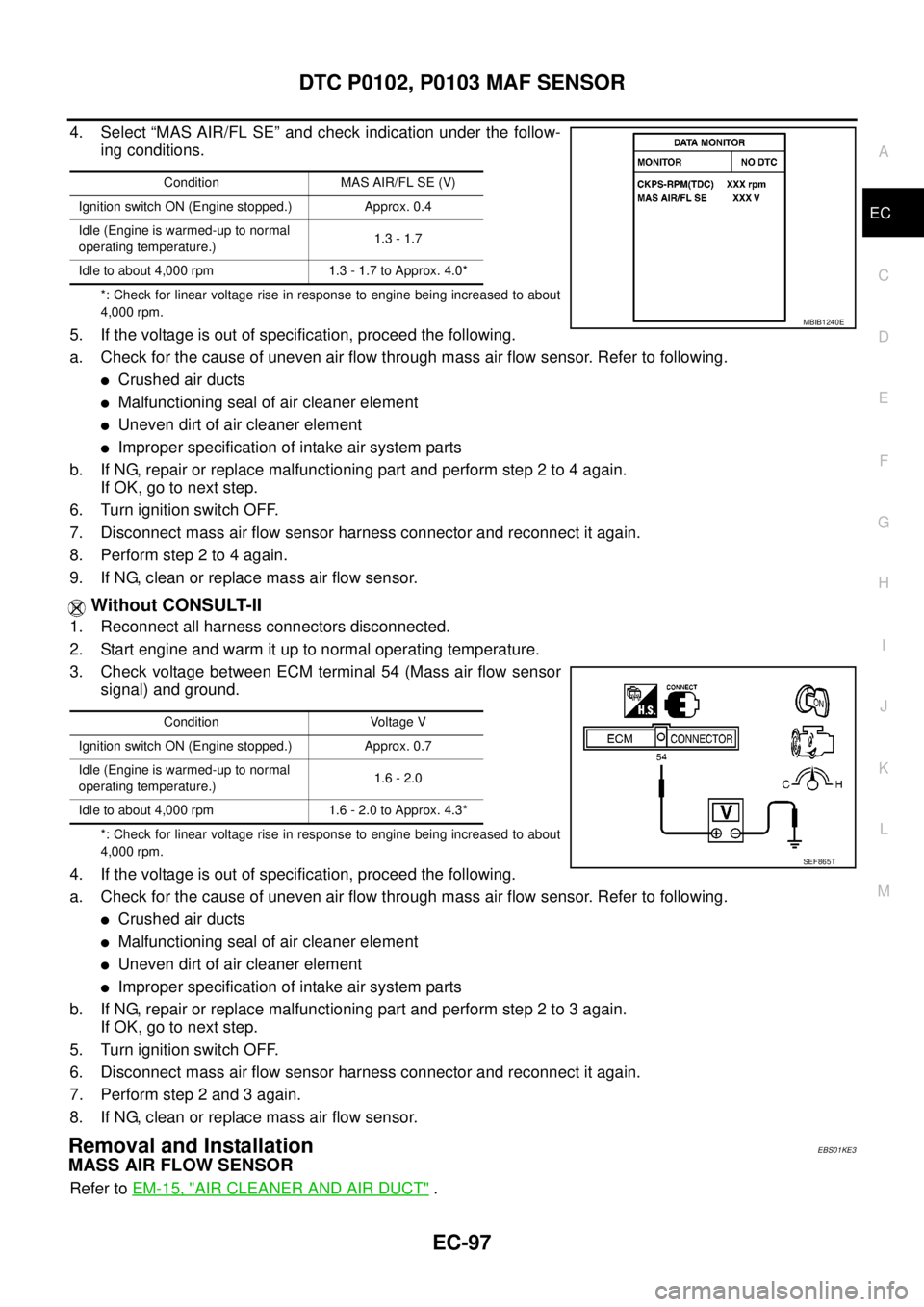

4. Select “MAS AIR/FL SE” and check indication under the follow-

ing conditions.

*: Check for linear voltage rise in response to engine being increased to about

4,000 rpm.

5. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

lCrushed air ducts

lMalfunctioning seal of air cleaner element

lUneven dirt of air cleaner element

lImproper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 4 again.

IfOK,gotonextstep.

6. Turn ignition switch OFF.

7. Disconnect mass air flow sensor harness connector and reconnect it again.

8. Performstep2to4again.

9. If NG, clean or replace mass air flow sensor.

Without CONSULT-II

1. Reconnect all harness connectors disconnected.

2. Start engine and warm it up to normal operating temperature.

3. Check voltage between ECM terminal 54 (Mass air flow sensor

signal) and ground.

*: Check for linear voltage rise in response to engine being increased to about

4,000 rpm.

4. If the voltage is out of specification, proceed the following.

a. Check for the cause of uneven air flow through mass air flow sensor. Refer to following.

lCrushed air ducts

lMalfunctioning seal of air cleaner element

lUneven dirt of air cleaner element

lImproper specification of intake air system parts

b. If NG, repair or replace malfunctioning part and perform step 2 to 3 again.

IfOK,gotonextstep.

5. Turn ignition switch OFF.

6. Disconnect mass air flow sensor harness connector and reconnect it again.

7. Perform step 2 and 3 again.

8. If NG, clean or replace mass air flow sensor.

Removal and InstallationEBS01KE3

MASS AIR FLOW SENSOR

Refer toEM-15, "AIR CLEANER AND AIR DUCT".

Condition MAS AIR/FL SE (V)

Ignition switch ON (Engine stopped.) Approx. 0.4

Idle (Engine is warmed-up to normal

operating temperature.)1.3 - 1.7

Idle to about 4,000 rpm 1.3 - 1.7 to Approx. 4.0*

MBIB1240E

Condition Voltage V

Ignition switch ON (Engine stopped.) Approx. 0.7

Idle (Engine is warmed-up to normal

operating temperature.)1.6 - 2.0

Idle to about 4,000 rpm 1.6 - 2.0 to Approx. 4.3*

SEF865T

Page 1078 of 3171

EC-98

DTC P0112, P0113 IAT SENSOR

DTC P0112, P0113 IAT SENSOR

PFP:22630

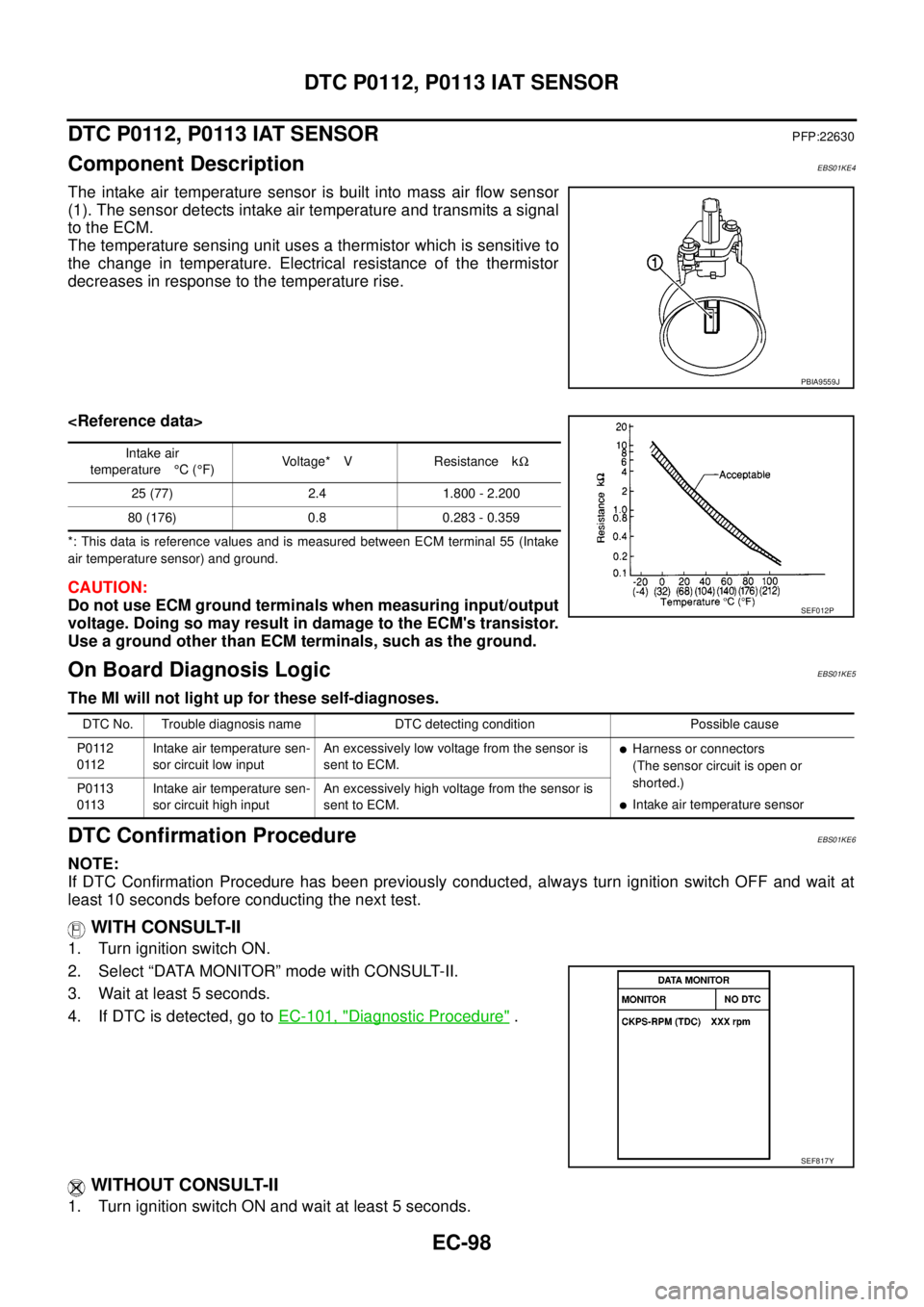

Component DescriptionEBS01KE4

The intake air temperature sensor is built into mass air flow sensor

(1). The sensor detects intake air temperature and transmits a signal

to the ECM.

The temperature sensing unit uses a thermistor which is sensitive to

the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

*: This data is reference values and is measured between ECM terminal 55 (Intake

air temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output

voltage. Doing so may result in damage to the ECM's transistor.

Use a ground other than ECM terminals, such as the ground.

On Board Diagnosis LogicEBS01KE5

The MI will not light up for these self-diagnoses.

DTC Confirmation ProcedureEBS01KE6

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Wait at least 5 seconds.

4. If DTC is detected, go toEC-101, "

Diagnostic Procedure".

WITHOUT CONSULT-II

1. Turn ignition switch ON and wait at least 5 seconds.

PBIA9559J

Intake air

temperature°C(°F)Voltage* V Resistance kW

25 (77) 2.4 1.800 - 2.200

80 (176) 0.8 0.283 - 0.359

SEF012P

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0112

0112Intake air temperature sen-

sor circuit low inputAn excessively low voltage from the sensor is

sent to ECM.

lHarness or connectors

(The sensor circuit is open or

shorted.)

lIntake air temperature sensor P0113

0113Intake air temperature sen-

sor circuit high inputAn excessively high voltage from the sensor is

sent to ECM.

SEF817Y

Page 1109 of 3171

DTC P0201 - P0204 FUEL INJECTOR

EC-129

C

D

E

F

G

H

I

J

K

L

MA

EC

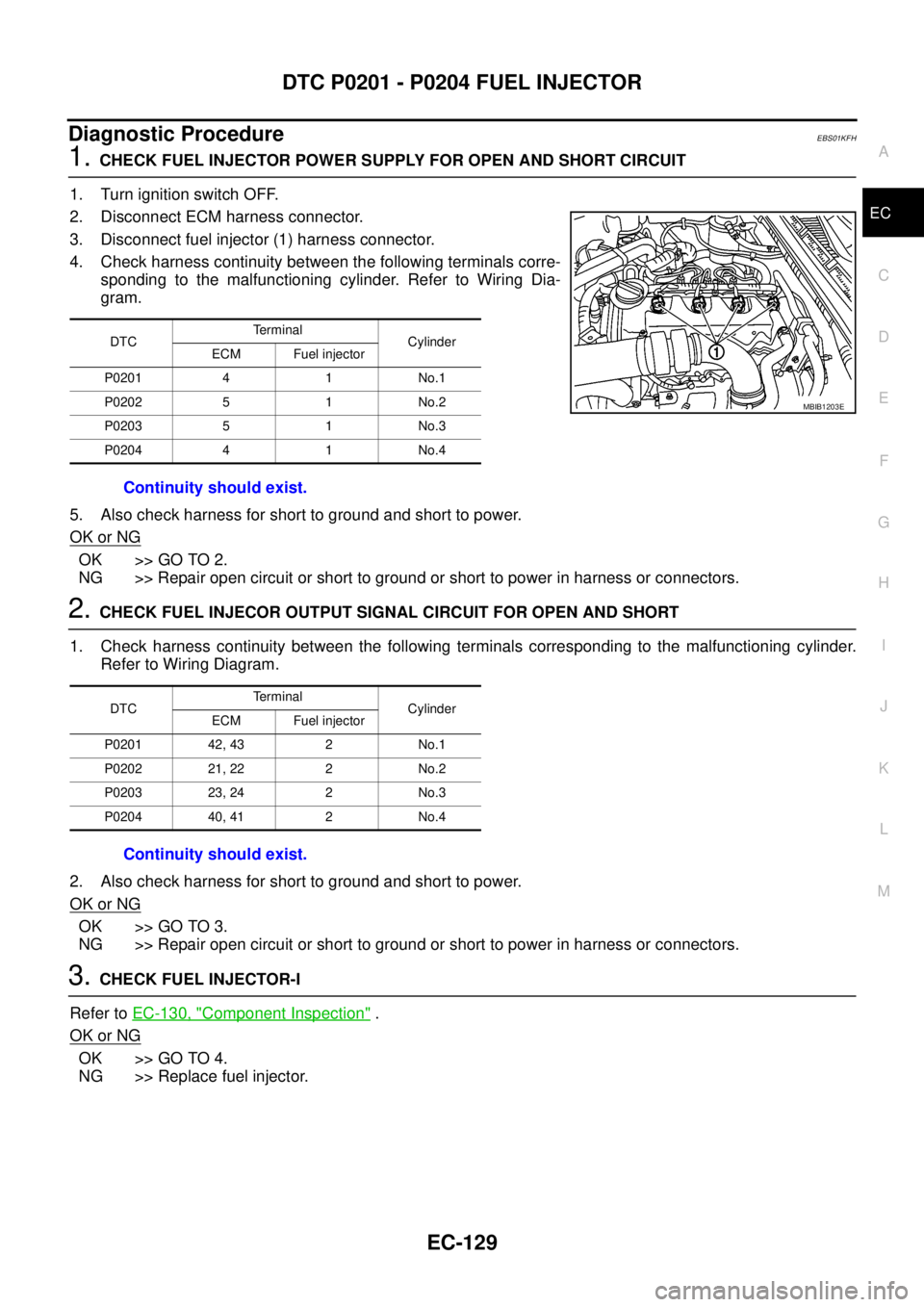

Diagnostic ProcedureEBS01KFH

1.CHECK FUEL INJECTOR POWER SUPPLY FOR OPEN AND SHORT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Disconnect fuel injector (1) harness connector.

4. Check harness continuity between the following terminals corre-

sponding to the malfunctioning cylinder. Refer to Wiring Dia-

gram.

5. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 2.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

2.CHECK FUEL INJECOR OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between the following terminals corresponding to the malfunctioning cylinder.

Refer to Wiring Diagram.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK FUEL INJECTOR-I

Refer toEC-130, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Replace fuel injector.

DTCTe r m i n a l

Cylinder

ECM Fuel injector

P0201 4 1 No.1

P0202 5 1 No.2

P0203 5 1 No.3

P0204 4 1 No.4

Continuity should exist.

MBIB1203E

DTCTe r m i n a l

Cylinder

ECM Fuel injector

P0201 42, 43 2 No.1

P0202 21, 22 2 No.2

P0203 23, 24 2 No.3

P0204 40, 41 2 No.4

Continuity should exist.

Page 1112 of 3171

EC-132

DTC P0217 ENGINE OVER TEMPERATURE

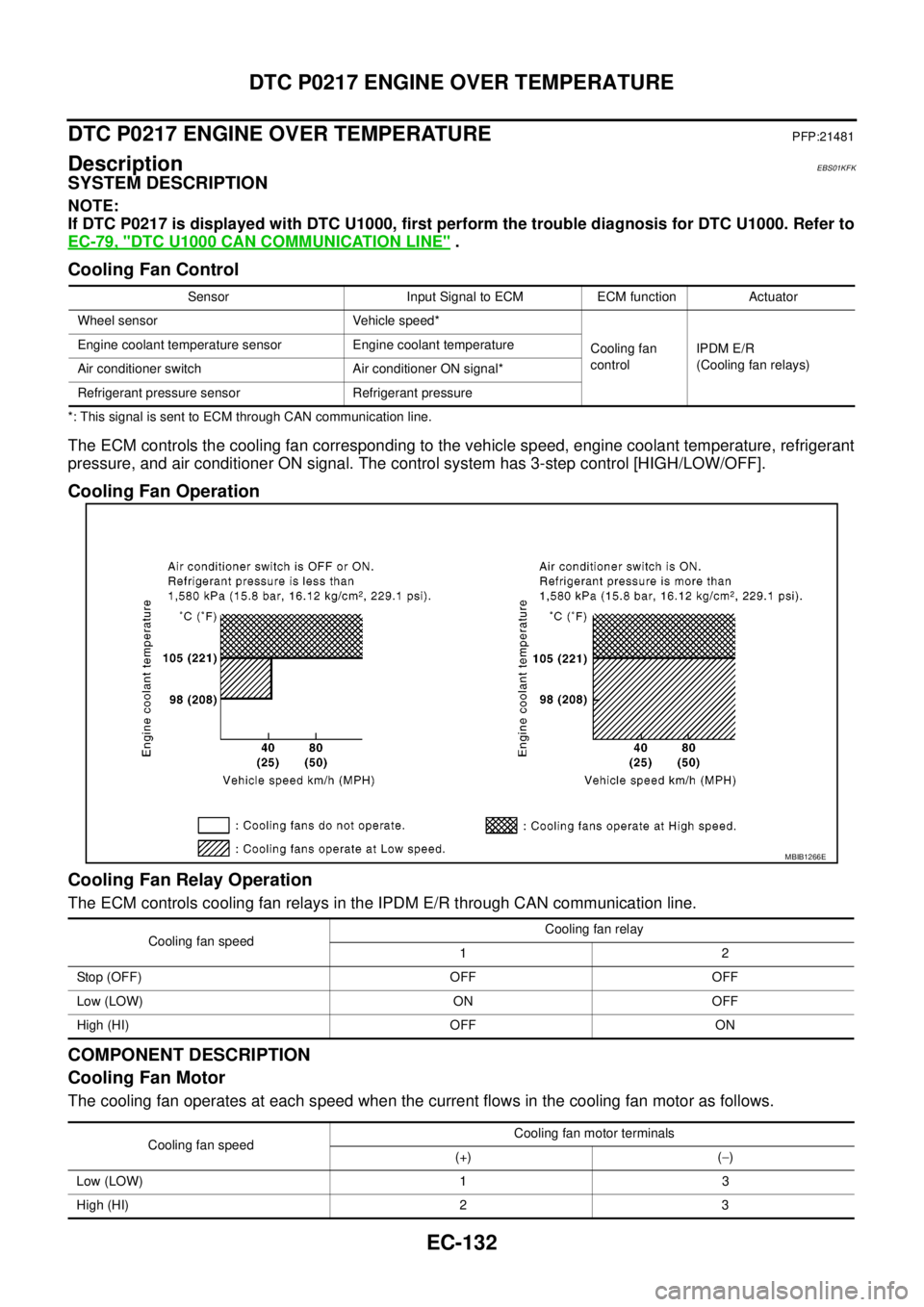

DTC P0217 ENGINE OVER TEMPERATURE

PFP:21481

DescriptionEBS01KFK

SYSTEM DESCRIPTION

NOTE:

If DTC P0217 is displayed with DTC U1000, first perform the trouble diagnosis for DTC U1000. Refer to

EC-79, "

DTC U1000 CAN COMMUNICATION LINE".

Cooling Fan Control

*: This signal is sent to ECM through CAN communication line.

The ECM controls the cooling fan corresponding to the vehicle speed, engine coolant temperature, refrigerant

pressure, and air conditioner ON signal. The control system has 3-step control [HIGH/LOW/OFF].

Cooling Fan Operation

Cooling Fan Relay Operation

The ECM controls cooling fan relays in the IPDM E/R through CAN communication line.

COMPONENT DESCRIPTION

Cooling Fan Motor

The cooling fan operates at each speed when the current flows in the cooling fan motor as follows.

Sensor Input Signal to ECM ECM function Actuator

Wheel sensor Vehicle speed*

Cooling fan

controlIPDM E/R

(Cooling fan relays) Engine coolant temperature sensor Engine coolant temperature

Air conditioner switch Air conditioner ON signal*

Refrigerant pressure sensor Refrigerant pressure

MBIB1266E

Cooling fan speedCooling fan relay

12

Stop (OFF) OFF OFF

Low (LOW) ON OFF

High (HI) OFF ON

Cooling fan speedCooling fan motor terminals

(+) (-)

Low (LOW) 1 3

High (HI) 2 3

Page 1171 of 3171

DTC P0504 ASCD BRAKE SWITCH

EC-191

C

D

E

F

G

H

I

J

K

L

MA

EC

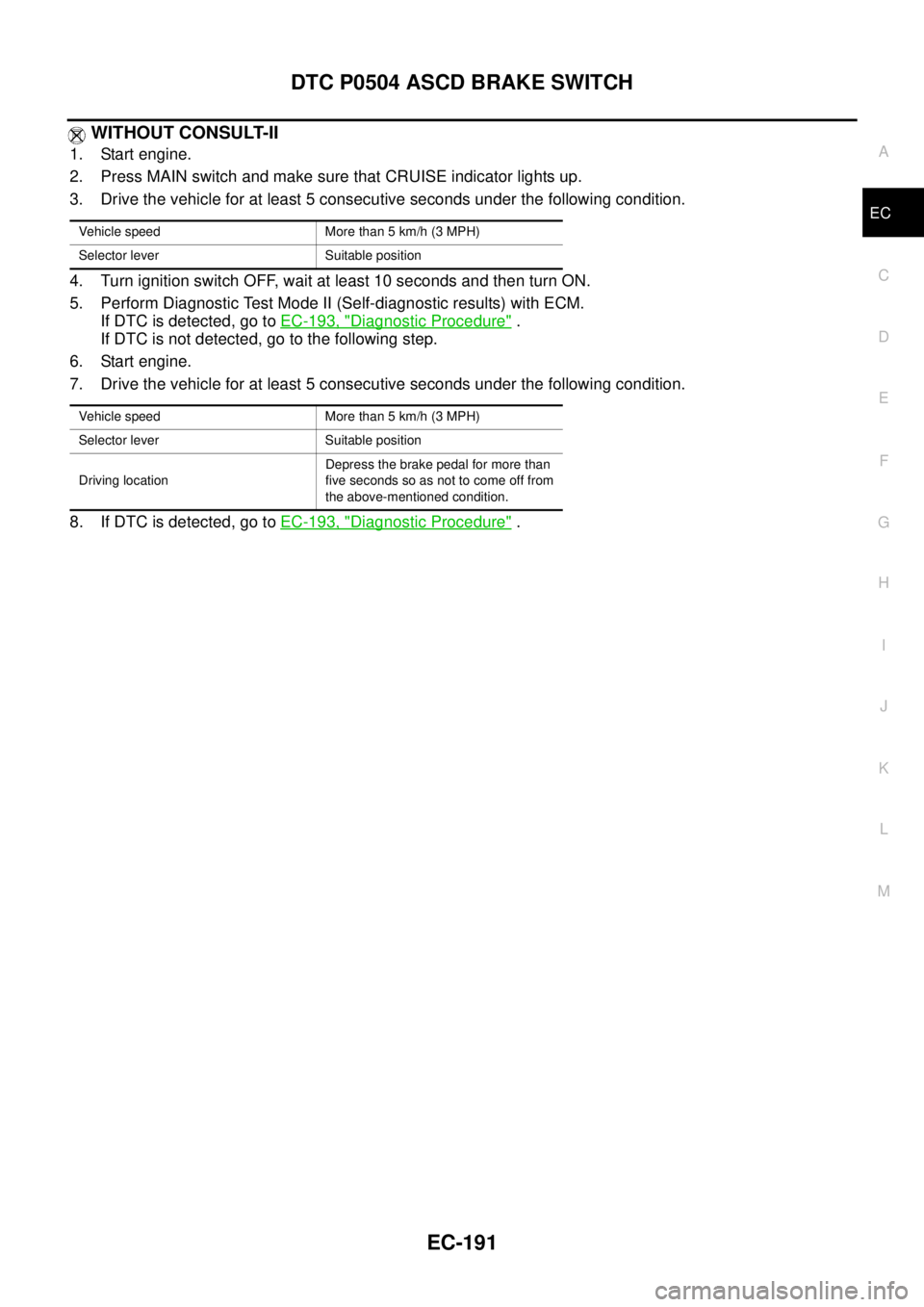

WITHOUT CONSULT-II

1. Start engine.

2. Press MAIN switch and make sure that CRUISE indicator lights up.

3. Drive the vehicle for at least 5 consecutive seconds under the following condition.

4. Turn ignition switch OFF, wait at least 10 seconds and then turn ON.

5. Perform Diagnostic Test Mode II (Self-diagnostic results) with ECM.

If DTC is detected, go toEC-193, "

Diagnostic Procedure".

If DTC is not detected, go to the following step.

6. Start engine.

7. Drive the vehicle for at least 5 consecutive seconds under the following condition.

8. If DTC is detected, go toEC-193, "

Diagnostic Procedure".

Vehiclespeed Morethan5km/h(3MPH)

Selector lever Suitable position

Vehiclespeed Morethan5km/h(3MPH)

Selector lever Suitable position

Driving locationDepress the brake pedal for more than

five seconds so as not to come off from

the above-mentioned condition.