ESP NISSAN NAVARA 2005 Repair Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1590 of 3171

FL-6

FUEL FILTER

lIf air cannot be bled easily (pumping of priming pump does not become heavy), disconnect feed-side of

hose between fuel filter and electronically controlled fuel pump. After that, operate priming pump and con-

firm that fuel comes out.

CAUTION:

Prepare a tray to collect fuel. Prevent fuel from adhering to rubber parts, especially the engine

mounting insulator.

Draining Water from Fuel FilterEBS01E75

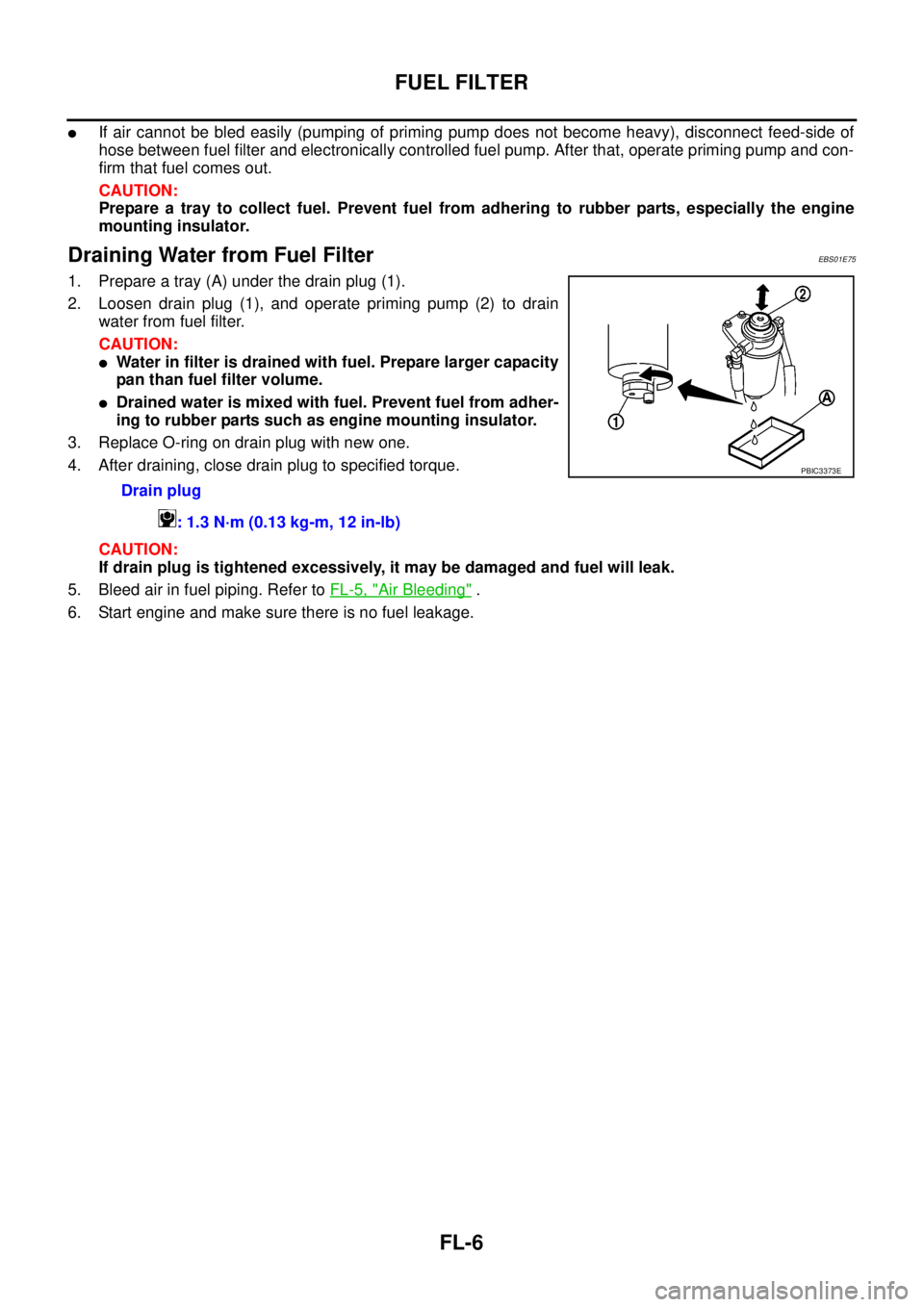

1. Prepare a tray (A) under the drain plug (1).

2. Loosen drain plug (1), and operate priming pump (2) to drain

water from fuel filter.

CAUTION:

lWater in filter is drained with fuel. Prepare larger capacity

pan than fuel filter volume.

lDrained water is mixed with fuel. Prevent fuel from adher-

ing to rubber parts such as engine mounting insulator.

3. Replace O-ring on drain plug with new one.

4. After draining, close drain plug to specified torque.

CAUTION:

If drain plug is tightened excessively, it may be damaged and fuel will leak.

5. Bleed air in fuel piping. Refer toFL-5, "

Air Bleeding".

6. Start engine and make sure there is no fuel leakage.Drain plug

: 1.3 N·m (0.13 kg-m, 12 in-lb)

PBIC3373E

Page 1595 of 3171

FUEL TANK

FL-11

C

D

E

F

G

H

I

J

K

L

MA

FL

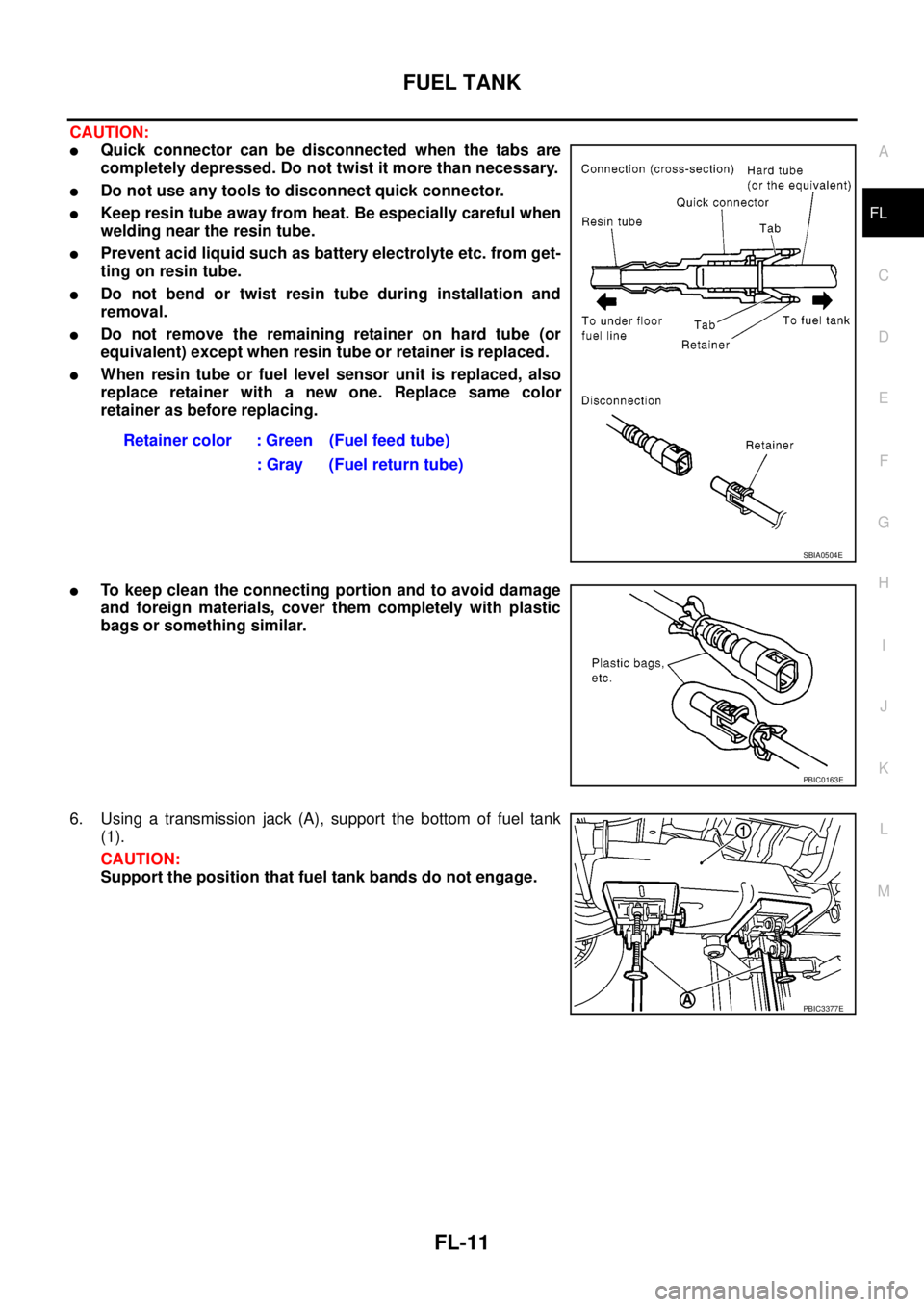

CAUTION:

lQuick connector can be disconnected when the tabs are

completely depressed. Do not twist it more than necessary.

lDo not use any tools to disconnect quick connector.

lKeep resin tube away from heat. Be especially careful when

welding near the resin tube.

lPrevent acid liquid such as battery electrolyte etc. from get-

ting on resin tube.

lDo not bend or twist resin tube during installation and

removal.

lDo not remove the remaining retainer on hard tube (or

equivalent) except when resin tube or retainer is replaced.

lWhen resin tube or fuel level sensor unit is replaced, also

replace retainer with a new one. Replace same color

retainer as before replacing.

lTo keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something similar.

6. Using a transmission jack (A), support the bottom of fuel tank

(1).

CAUTION:

Support the position that fuel tank bands do not engage.Retainer color : Green (Fuel feed tube)

: Gray (Fuel return tube)

SBIA0504E

PBIC0163E

PBIC3377E

Page 1626 of 3171

GI-4

PRECAUTIONS

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the²ACC²position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the²LOCK²position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

General PrecautionsEAS001GJ

lDo not operate the engine for an extended period of time without

proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refriger-

ant gas, etc. When working in a pit or other enclosed area, be

sure to properly ventilate the area before working with hazard-

ous materials.

Do not smoke while working on the vehicle.

lBefore jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before working

on the vehicle.

These operations should be done on a level surface.

lWhen removing a heavy component such as the engine or

transaxle/transmission, be careful not to lose your balance and

drop them. Also, do not allow them to strike adjacent parts,

especially the brake tubes and master cylinder.

lBefore starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

lIf the battery terminals are disconnected, recorded memory of

radio and each control unit is erased.

SGI285

SGI231

SEF289H

Page 1637 of 3171

HOW TO USE THIS MANUAL

GI-15

C

D

E

F

G

H

I

J

K

L

MB

GI

How to Read Wiring DiagramsEAS001GY

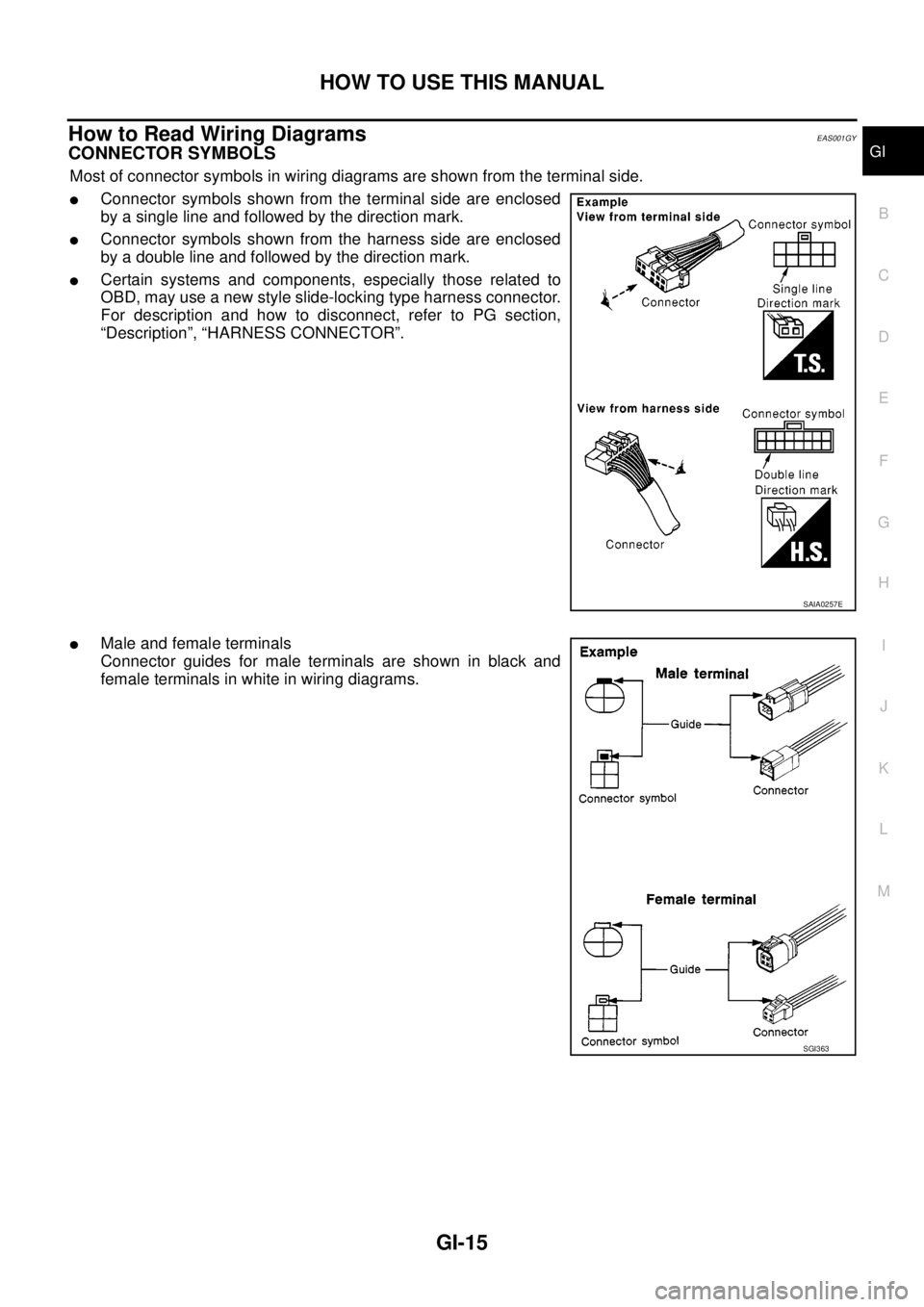

CONNECTOR SYMBOLS

Most of connector symbols in wiring diagrams are shown from the terminal side.

lConnector symbols shown from the terminal side are enclosed

by a single line and followed by the direction mark.

lConnector symbols shown from the harness side are enclosed

by a double line and followed by the direction mark.

lCertain systems and components, especially those related to

OBD, may use a new style slide-locking type harness connector.

For description and how to disconnect, refer to PG section,

“Description”, “HARNESS CONNECTOR”.

lMale and female terminals

Connector guides for male terminals are shown in black and

female terminals in white in wiring diagrams.

SAIA0257E

SGI363

Page 1640 of 3171

GI-18

HOW TO USE THIS MANUAL

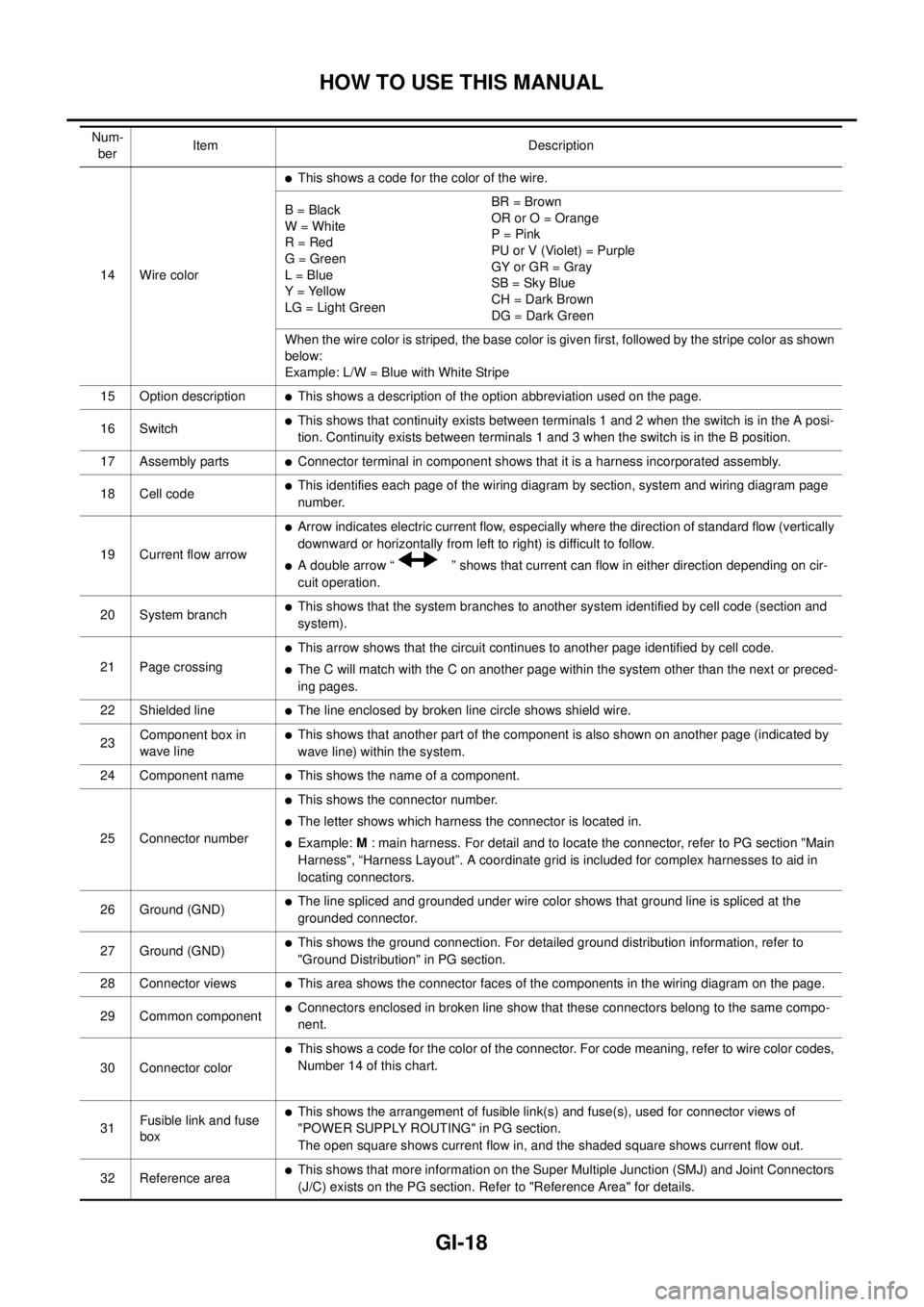

14 Wire color

lThis shows a code for the color of the wire.

B=Black

W=White

R=Red

G = Green

L=Blue

Y = Yellow

LG = Light GreenBR = Brown

OR or O = Orange

P=Pink

PU or V (Violet) = Purple

GY or GR = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe color as shown

below:

Example: L/W = Blue with White Stripe

15 Option description

lThis shows a description of the option abbreviation used on the page.

16 Switch

lThis shows that continuity exists between terminals 1 and 2 when the switch is in the A posi-

tion. Continuity exists between terminals 1 and 3 when the switch is in the B position.

17 Assembly parts

lConnector terminal in component shows that it is a harness incorporated assembly.

18 Cell code

lThis identifies each page of the wiring diagram by section, system and wiring diagram page

number.

19 Current flow arrow

lArrow indicates electric current flow, especially where the direction of standard flow (vertically

downward or horizontally from left to right) is difficult to follow.

lA double arrow “ ” shows that current can flow in either direction depending on cir-

cuit operation.

20 System branch

lThis shows that the system branches to another system identified by cell code (section and

system).

21 Page crossing

lThis arrow shows that the circuit continues to another page identified by cell code.

lThe C will match with the C on another page within the system other than the next or preced-

ing pages.

22 Shielded line

lThe line enclosed by broken line circle shows shield wire.

23Component box in

wave line

lThis shows that another part of the component is also shown on another page (indicated by

wave line) within the system.

24 Component name

lThis shows the name of a component.

25 Connector number

lThis shows the connector number.

lThe letter shows which harness the connector is located in.

lExample:M: main harness. For detail and to locate the connector, refer to PG section "Main

Harness", “Harness Layout”. A coordinate grid is included for complex harnesses to aid in

locating connectors.

26 Ground (GND)

lThe line spliced and grounded under wire color shows that ground line is spliced at the

grounded connector.

27 Ground (GND)

lThis shows the ground connection. For detailed ground distribution information, refer to

"Ground Distribution" in PG section.

28 Connector views

lThis area shows the connector faces of the components in the wiring diagram on the page.

29 Common component

lConnectors enclosed in broken line show that these connectors belong to the same compo-

nent.

30 Connector color

lThis shows a code for the color of the connector. For code meaning, refer to wire color codes,

Number 14 of this chart.

31Fusible link and fuse

box

lThis shows the arrangement of fusible link(s) and fuse(s), used for connector views of

"POWER SUPPLY ROUTING" in PG section.

The open square shows current flow in, and the shaded square shows current flow out.

32 Reference area

lThis shows that more information on the Super Multiple Junction (SMJ) and Joint Connectors

(J/C) exists on the PG section. Refer to "Reference Area" for details. Num-

berItem Description

Page 1691 of 3171

SQUEAK AND RATTLE TROUBLE DIAGNOSES

GW-5

C

D

E

F

G

H

J

K

L

MA

B

GW

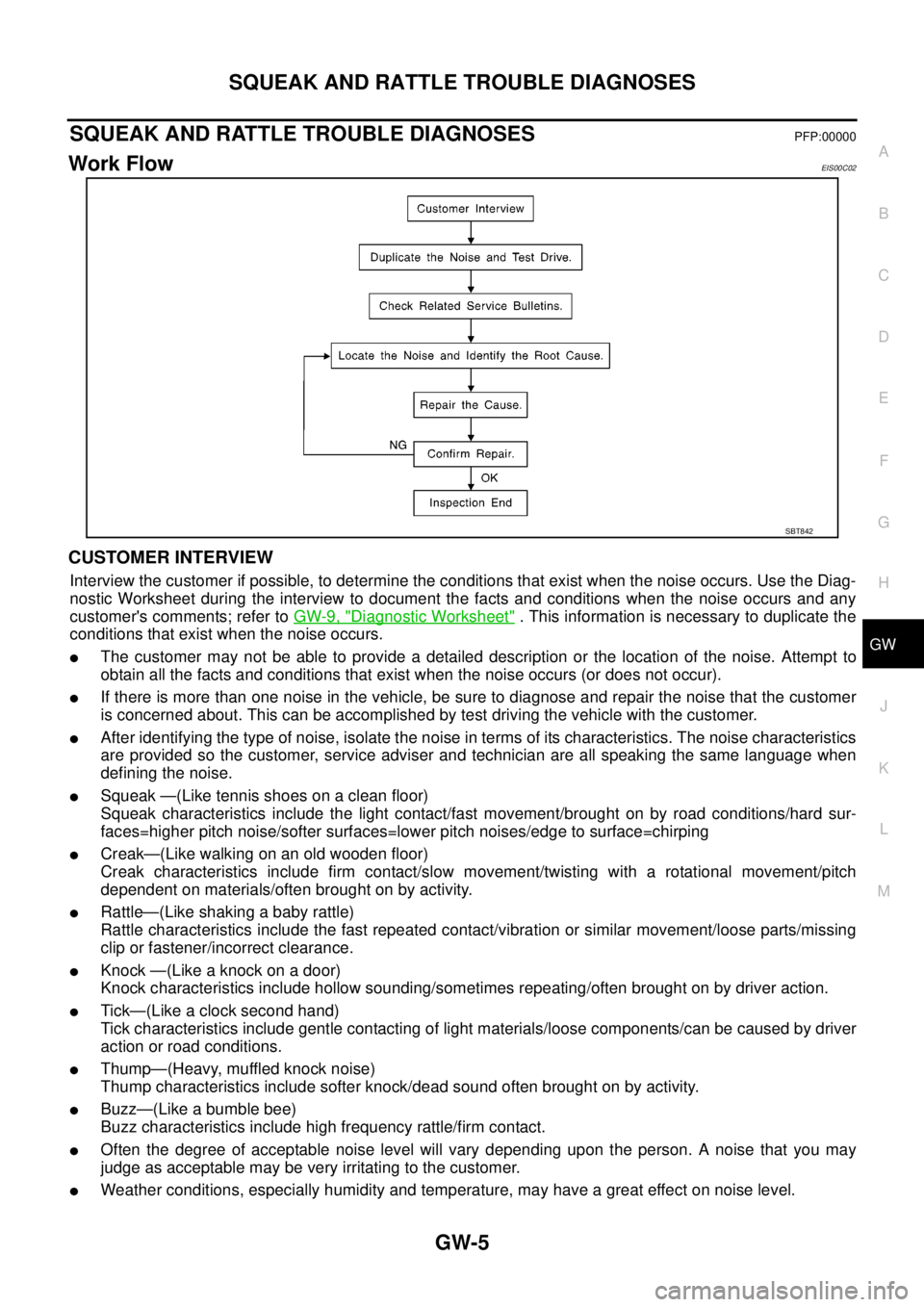

SQUEAK AND RATTLE TROUBLE DIAGNOSESPFP:00000

Work FlowEIS00C02

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer toGW-9, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

lThe customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

lIf there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

lAfter identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

lSqueak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces=higher pitch noise/softer surfaces=lower pitch noises/edge to surface=chirping

lCreak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

lRattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

lKnock—(Likeaknockonadoor)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

lTick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

lThump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

lBuzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

lOften the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

lWeather conditions, especially humidity and temperature, may have a great effect on noise level.

SBT842

Page 1692 of 3171

GW-6

SQUEAK AND RATTLE TROUBLE DIAGNOSES

DUPLICATE THE NOISE AND TEST DRIVE

If possible, drive the vehicle with the customer until the noise is duplicated. Note any additional information on

the Diagnostic Worksheet regarding the conditions or location of the noise. This information can be used to

duplicate the same conditions when you confirm the repair.

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

lDrive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

lIf it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area. To help pinpoint the source of the noise, use a listening tool

(Engine Ear or mechanics stethoscope).

2. Narrowdownthenoisetoamorespecificareaandidentifythecauseofthenoiseby:

lremoving the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fastener can be broken

or lost during the repair, resulting in the creation of new noise.

ltapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only

temporarily.

lfeeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

lplacing a piece of paper between components that you suspect are causing the noise.

llooking for loose components and contact marks.

Refer toGW-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

lIf the cause is a loose component, tighten the component securely.

lIf the cause is insufficient clearance between components:

–separate components by repositioning or loosening and retightening the component, if possible.

–insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or ure-

thane tape are available through your authorized Nissan Parts Department.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

NOTE:

Always check with the Parts Department for the latest parts information.

Each item can be ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100´135 mm (3.94´5.31 in)/76884-71L01: 60´85 mm (2.36´3.35 in)/76884-71L02: 15´

25 mm (0.59´0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50´50 mm (1.97´1.97 in)/73982-50Y00: 10 mm (0.39 in) think, 50

´50 mm (1.97´1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30´50 mm (1.18´1.97 in)

Page 1763 of 3171

IP-4

SQUEAK AND RATTLE TROUBLE DIAGNOSES

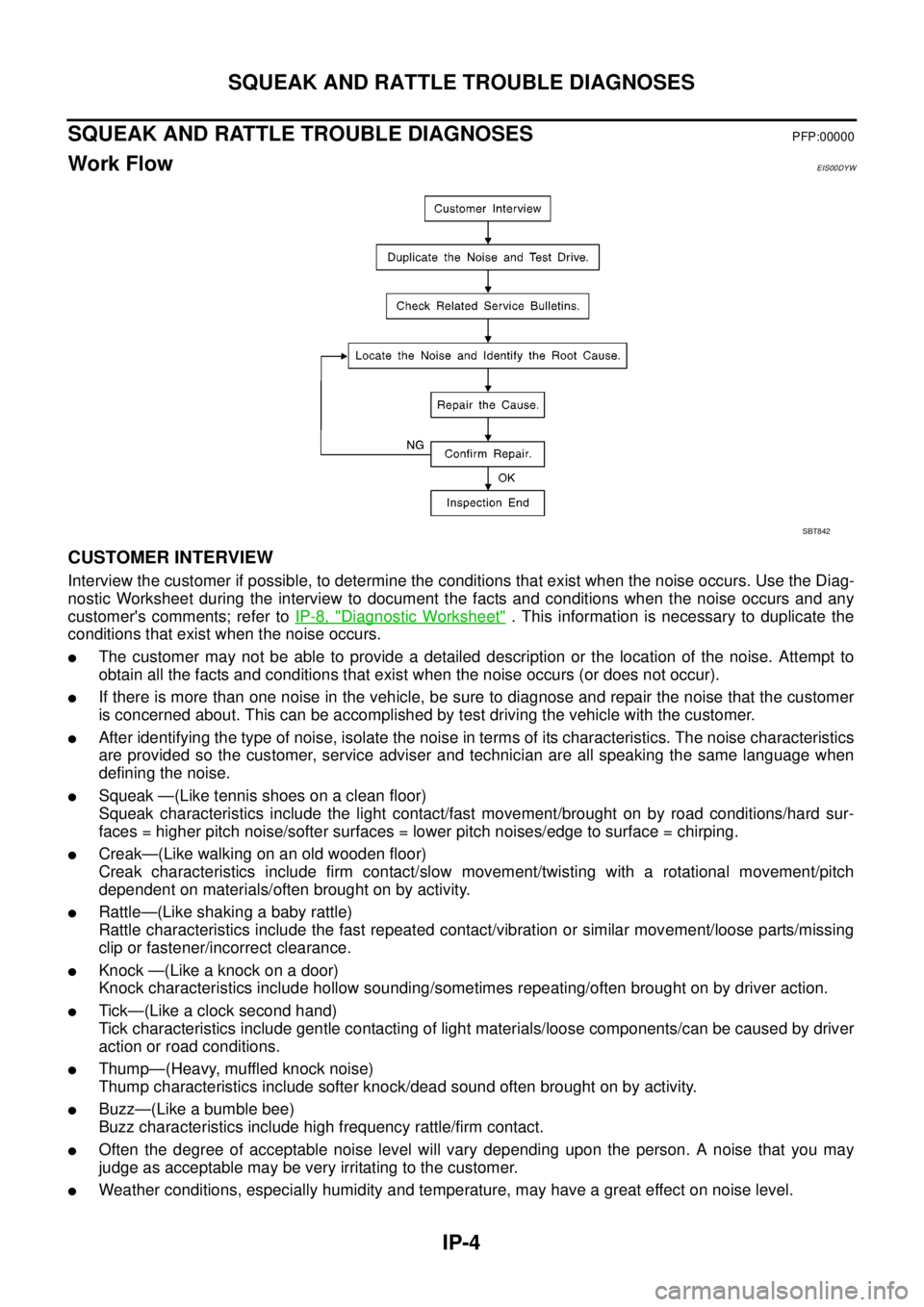

SQUEAK AND RATTLE TROUBLE DIAGNOSES

PFP:00000

Work FlowEIS00DYW

CUSTOMER INTERVIEW

Interview the customer if possible, to determine the conditions that exist when the noise occurs. Use the Diag-

nostic Worksheet during the interview to document the facts and conditions when the noise occurs and any

customer's comments; refer toIP-8, "

Diagnostic Worksheet". This information is necessary to duplicate the

conditions that exist when the noise occurs.

lThe customer may not be able to provide a detailed description or the location of the noise. Attempt to

obtain all the facts and conditions that exist when the noise occurs (or does not occur).

lIf there is more than one noise in the vehicle, be sure to diagnose and repair the noise that the customer

is concerned about. This can be accomplished by test driving the vehicle with the customer.

lAfter identifying the type of noise, isolate the noise in terms of its characteristics. The noise characteristics

are provided so the customer, service adviser and technician are all speaking the same language when

defining the noise.

lSqueak —(Like tennis shoes on a clean floor)

Squeak characteristics include the light contact/fast movement/brought on by road conditions/hard sur-

faces = higher pitch noise/softer surfaces = lower pitch noises/edge to surface = chirping.

lCreak—(Like walking on an old wooden floor)

Creak characteristics include firm contact/slow movement/twisting with a rotational movement/pitch

dependent on materials/often brought on by activity.

lRattle—(Like shaking a baby rattle)

Rattle characteristics include the fast repeated contact/vibration or similar movement/loose parts/missing

clip or fastener/incorrect clearance.

lKnock —(Like a knock on a door)

Knock characteristics include hollow sounding/sometimes repeating/often brought on by driver action.

lTick—(Like a clock second hand)

Tick characteristics include gentle contacting of light materials/loose components/can be caused by driver

action or road conditions.

lThump—(Heavy, muffled knock noise)

Thump characteristics include softer knock/dead sound often brought on by activity.

lBuzz—(Like a bumble bee)

Buzz characteristics include high frequency rattle/firm contact.

lOften the degree of acceptable noise level will vary depending upon the person. A noise that you may

judge as acceptable may be very irritating to the customer.

lWeather conditions, especially humidity and temperature, may have a great effect on noise level.

SBT842

Page 2088 of 3171

HEADLAMP -CONVENTIONAL TYPE-

LT-5

C

D

E

F

G

H

I

J

L

MA

B

LT

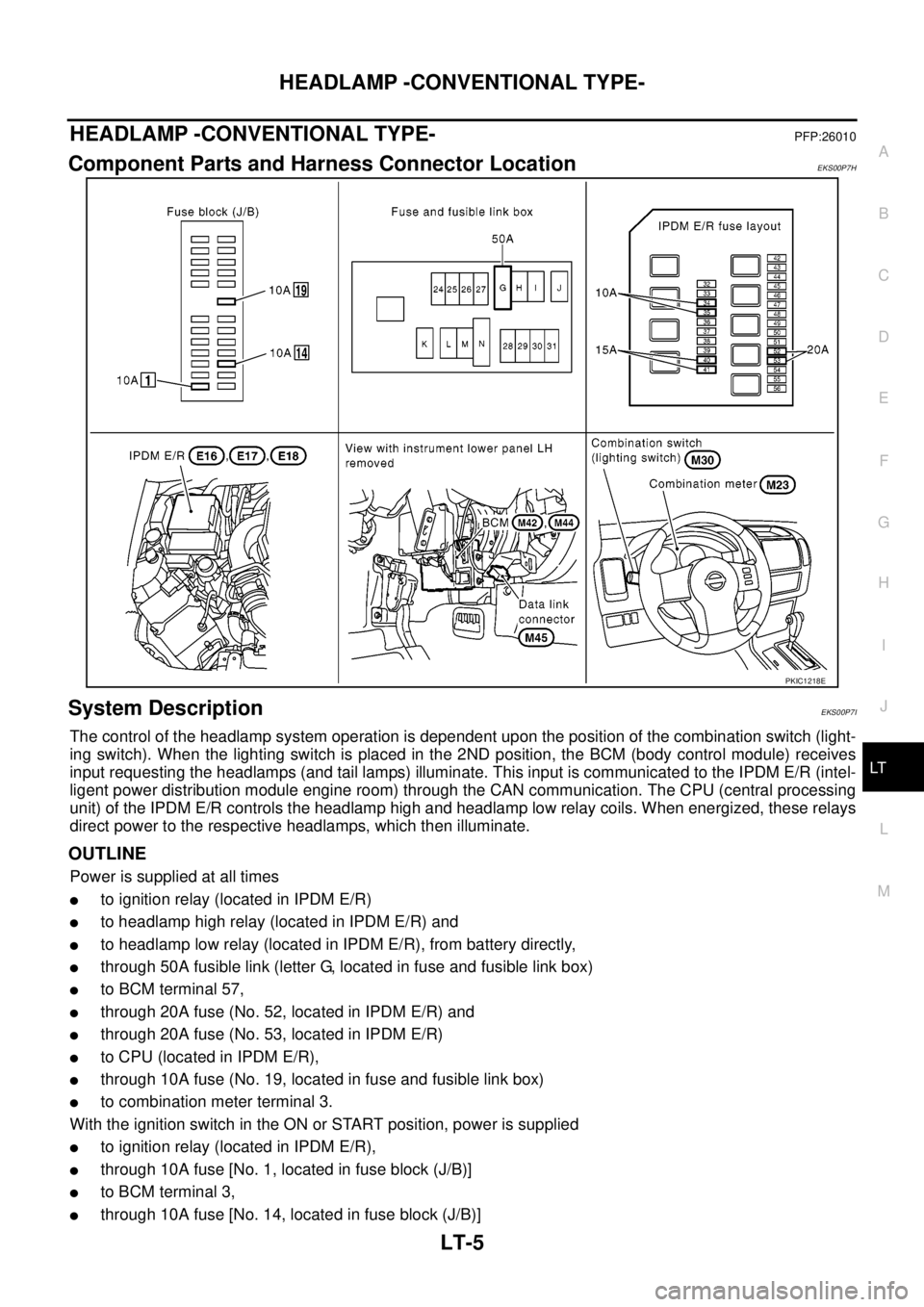

HEADLAMP -CONVENTIONAL TYPE-PFP:26010

Component Parts and Harness Connector LocationEKS00P7H

System DescriptionEKS00P7I

The control of the headlamp system operation is dependent upon the position of the combination switch (light-

ing switch). When the lighting switch is placed in the 2ND position, the BCM (body control module) receives

input requesting the headlamps (and tail lamps) illuminate. This input is communicated to the IPDM E/R (intel-

ligent power distribution module engine room) through the CAN communication. The CPU (central processing

unit) of the IPDM E/R controls the headlamp high and headlamp low relay coils. When energized, these relays

direct power to the respective headlamps, which then illuminate.

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R)

lto headlamp high relay (located in IPDM E/R) and

lto headlamp low relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse (No. 19, located in fuse and fusible link box)

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

PKIC1218E

Page 2202 of 3171

COMBINATION SWITCH

LT-119

C

D

E

F

G

H

I

J

L

MA

B

LT

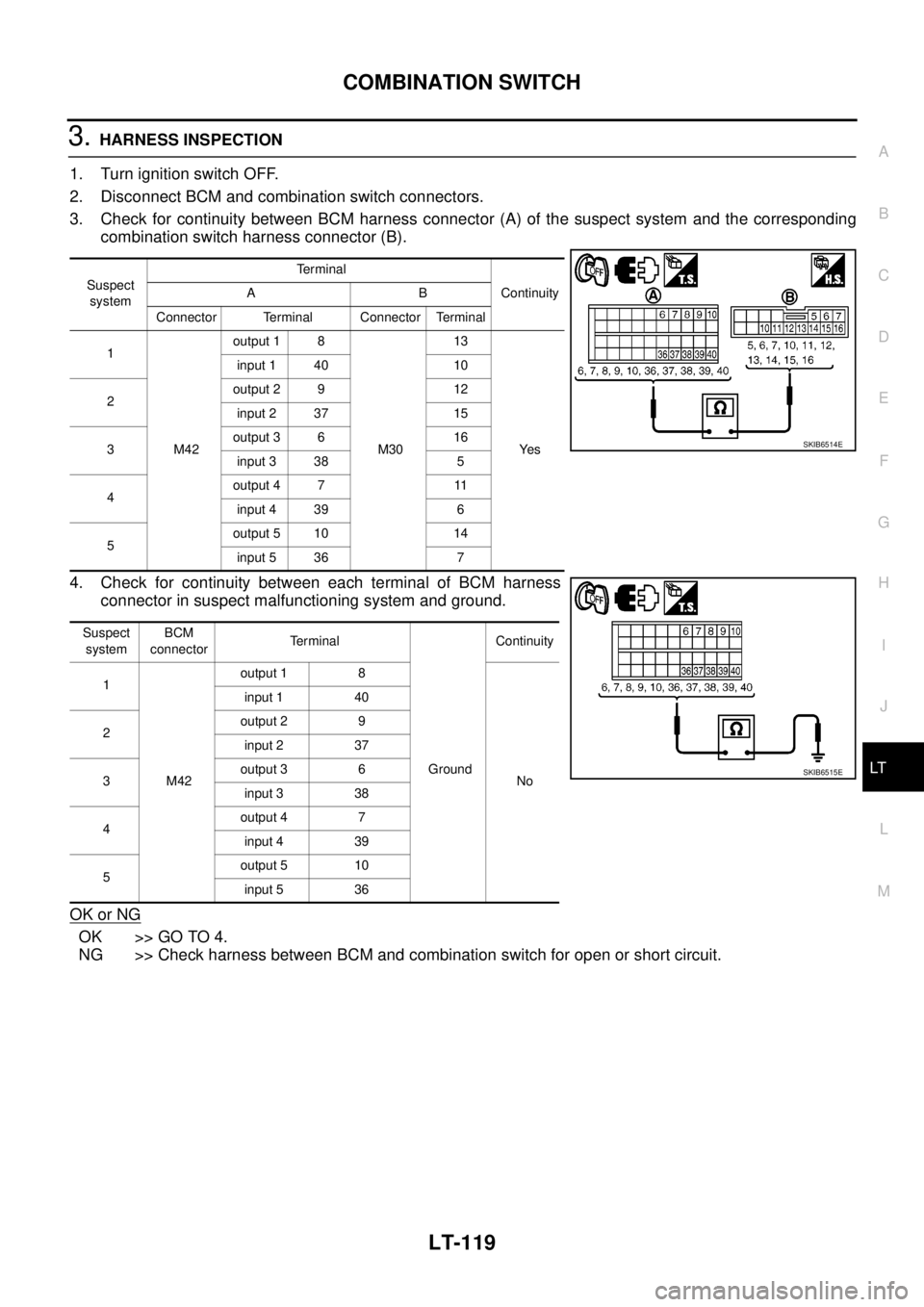

3.HARNESS INSPECTION

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check for continuity between BCM harness connector (A) of the suspect system and the corresponding

combination switch harness connector (B).

4. Check for continuity between each terminal of BCM harness

connector in suspect malfunctioning system and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness between BCM and combination switch for open or short circuit.

Suspect

systemTerminal

Continuity AB

Connector Terminal Connector Terminal

1

M42output 1 8

M3013

Ye s input 1 40 10

2output 2 9 12

input 2 37 15

3output 3 6 16

input 3 38 5

4output 4 7 11

input 4 39 6

5output 5 10 14

input 5 36 7

Suspect

systemBCM

connectorTerminal

GroundContinuity

1

M42output 1 8

No input 1 40

2output 2 9

input 2 37

3output 3 6

input 3 38

4output 4 7

input 4 39

5output 5 10

input 5 36

SKIB6514E

SKIB6515E