coolant NISSAN NAVARA 2005 Repair Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1278 of 3171

EC-298

GLOW CONTROL SYSTEM

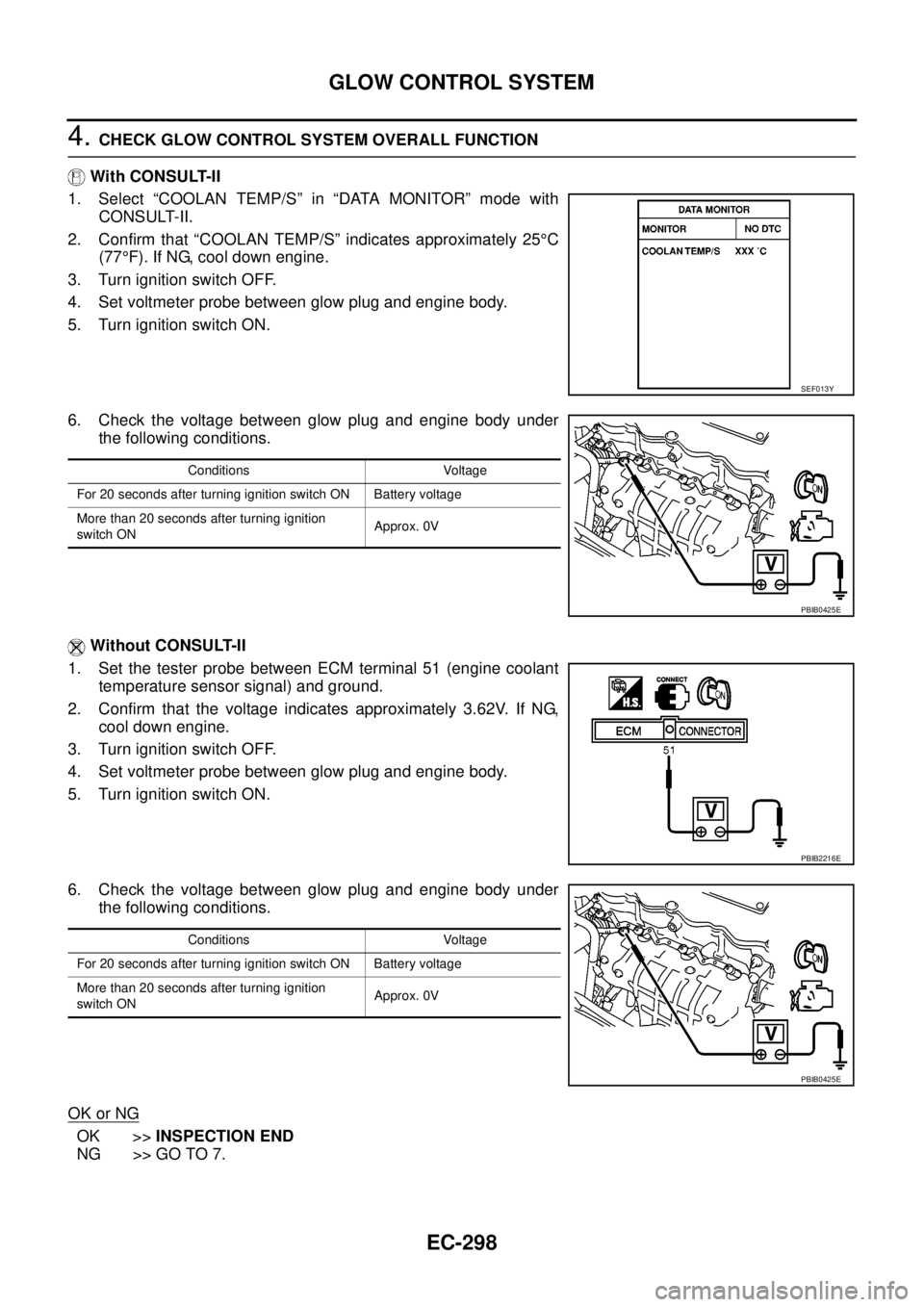

4.CHECK GLOW CONTROL SYSTEM OVERALL FUNCTION

With CONSULT-II

1. Select “COOLAN TEMP/S” in “DATA MONITOR” mode with

CONSULT-II.

2. Confirm that “COOLAN TEMP/S” indicates approximately 25°C

(77°F). If NG, cool down engine.

3. Turn ignition switch OFF.

4. Set voltmeter probe between glow plug and engine body.

5. Turn ignition switch ON.

6. Check the voltage between glow plug and engine body under

the following conditions.

Without CONSULT-II

1. Set the tester probe between ECM terminal 51 (engine coolant

temperature sensor signal) and ground.

2. Confirm that the voltage indicates approximately 3.62V. If NG,

cool down engine.

3. Turn ignition switch OFF.

4. Set voltmeter probe between glow plug and engine body.

5. Turn ignition switch ON.

6. Check the voltage between glow plug and engine body under

the following conditions.

OK or NG

OK >>INSPECTION END

NG >> GO TO 7.

SEF013Y

Conditions Voltage

For 20 seconds after turning ignition switch ON Battery voltage

More than 20 seconds after turning ignition

switch ONApprox. 0V

PBIB0425E

PBIB2216E

Conditions Voltage

For 20 seconds after turning ignition switch ON Battery voltage

More than 20 seconds after turning ignition

switch ONApprox. 0V

PBIB0425E

Page 1282 of 3171

EC-302

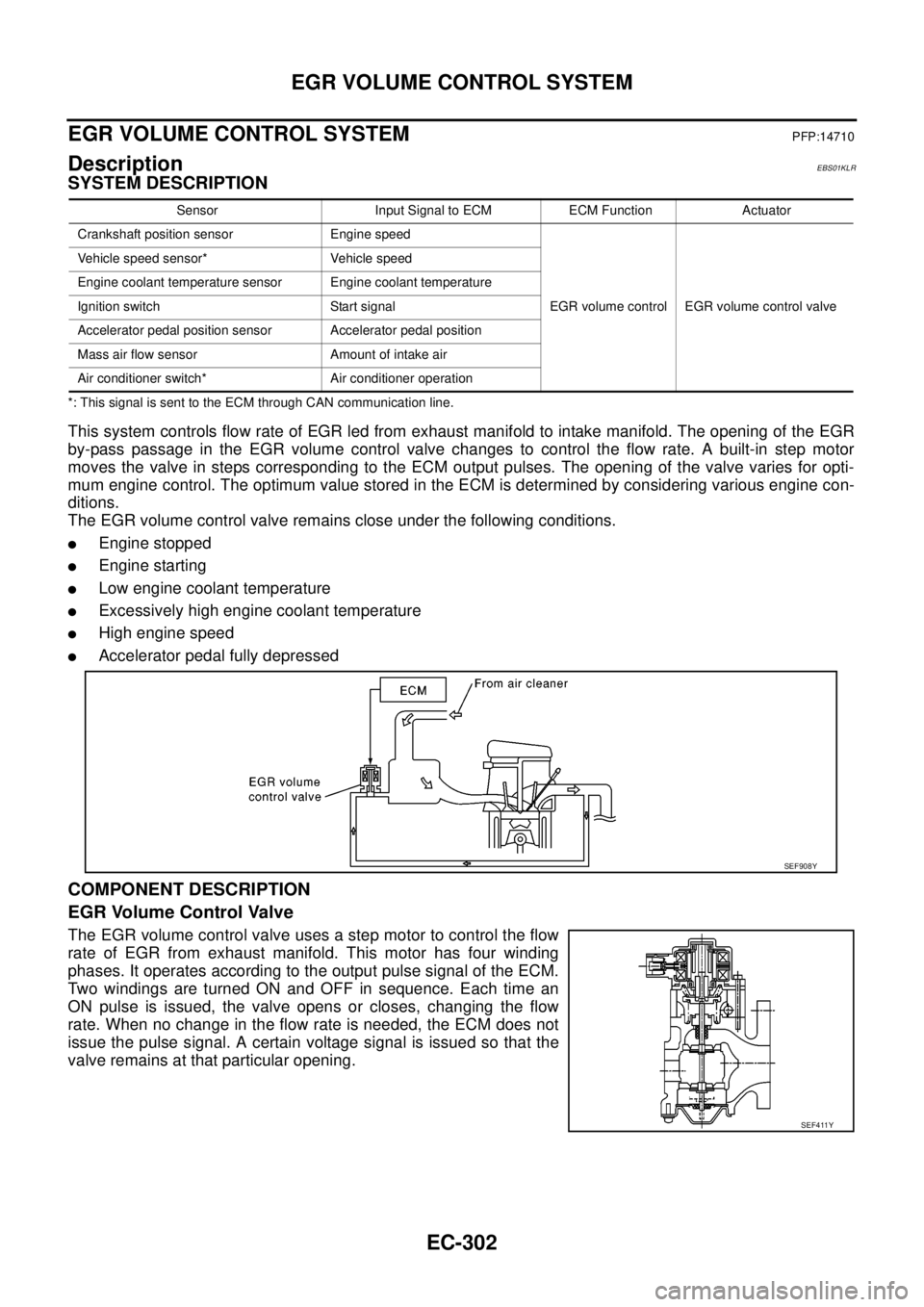

EGR VOLUME CONTROL SYSTEM

EGR VOLUME CONTROL SYSTEM

PFP:14710

DescriptionEBS01KLR

SYSTEM DESCRIPTION

*: This signal is sent to the ECM through CAN communication line.

This system controls flow rate of EGR led from exhaust manifold to intake manifold. The opening of the EGR

by-pass passage in the EGR volume control valve changes to control the flow rate. A built-in step motor

moves the valve in steps corresponding to the ECM output pulses. The opening of the valve varies for opti-

mum engine control. The optimum value stored in the ECM is determined by considering various engine con-

ditions.

The EGR volume control valve remains close under the following conditions.

lEngine stopped

lEngine starting

lLow engine coolant temperature

lExcessively high engine coolant temperature

lHigh engine speed

lAccelerator pedal fully depressed

COMPONENT DESCRIPTION

EGR Volume Control Valve

The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the ECM.

Two windings are turned ON and OFF in sequence. Each time an

ON pulse is issued, the valve opens or closes, changing the flow

rate. When no change in the flow rate is needed, the ECM does not

issue the pulse signal. A certain voltage signal is issued so that the

valve remains at that particular opening.

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor Engine speed

EGR volume control EGR volume control valve Vehicle speed sensor* Vehicle speed

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Accelerator pedal position sensor Accelerator pedal position

Mass air flow sensor Amount of intake air

Air conditioner switch* Air conditioner operation

SEF908Y

SEF411Y

Page 1337 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-357

C

D

E

F

G

H

I

J

K

L

MA

EC

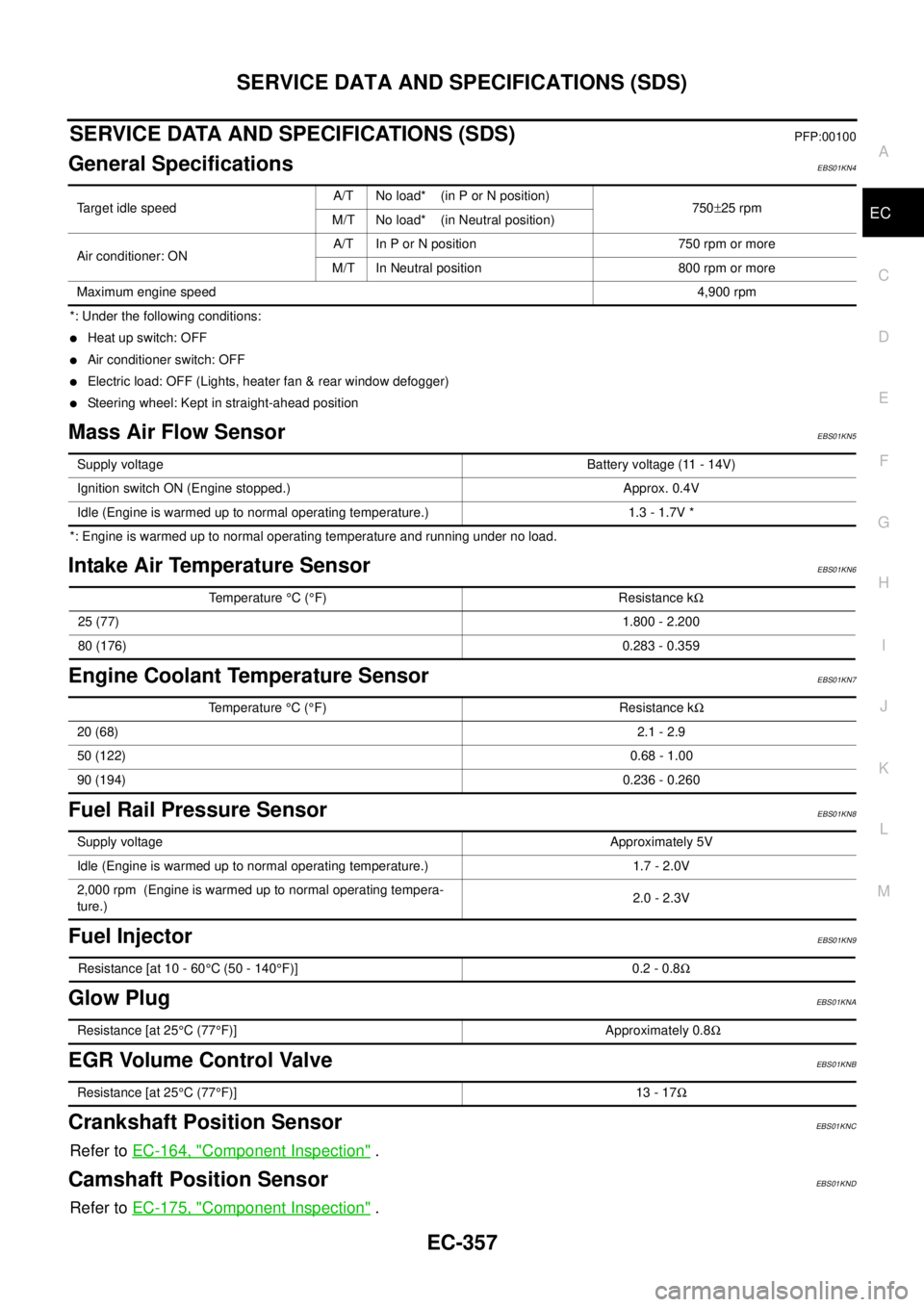

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00100

General SpecificationsEBS01KN4

*: Under the following conditions:

lHeat up switch: OFF

lAir conditioner switch: OFF

lElectric load: OFF (Lights, heater fan & rear window defogger)

lSteering wheel: Kept in straight-ahead position

Mass Air Flow SensorEBS01KN5

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorEBS01KN6

Engine Coolant Temperature SensorEBS01KN7

Fuel Rail Pressure SensorEBS01KN8

Fuel InjectorEBS01KN9

Glow PlugEBS01KNA

EGR Volume Control ValveEBS01KNB

Crankshaft Position SensorEBS01KNC

Refer toEC-164, "Component Inspection".

Camshaft Position SensorEBS01KND

Refer toEC-175, "Component Inspection".

Target idle speedA/T No load* (in P or N position)

750±25 rpm

M/T No load* (in Neutral position)

Air conditioner: ONA/T In P or N position 750 rpm or more

M/T In Neutral position 800 rpm or more

Maximum engine speed4,900 rpm

Supply voltageBattery voltage (11 - 14V)

Ignition switch ON (Engine stopped.) Approx. 0.4V

Idle (Engine is warmed up to normal operating temperature.) 1.3 - 1.7V *

Temperature°C(°F) Resistance kW

25 (77)1.800 - 2.200

80 (176)0.283 - 0.359

Temperature°C(°F) Resistance kW

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Supply voltageApproximately 5V

Idle (Engine is warmed up to normal operating temperature.) 1.7 - 2.0V

2,000 rpm (Engine is warmed up to normal operating tempera-

ture.)2.0 - 2.3V

Resistance [at 10 - 60°C (50 - 140°F)] 0.2 - 0.8W

Resistance [at 25°C(77°F)] Approximately 0.8W

Resistance [at 25°C(77°F)] 13 - 17W

Page 1383 of 3171

EM-1

ENGINE MECHANICAL

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTIONEM

A

EM

ENGINE MECHANICAL

PRECAUTIONS .......................................................... 4

Precautions for Draining Engine Coolant ................. 4

Precautions for Disconnecting Fuel Piping .............. 4

Precautions for Removal and Disassembly ............. 4

Precautions for Inspection, Repair and Replace-

ment ......................................................................... 4

Precautions for Assembly and Installation ............... 4

Parts Requiring Angle Tightening ............................. 4

Precautions For Liquid Gasket ................................. 5

REMOVAL OF LIQUID GASKET .......................... 5

LIQUID GASKET APPLICATION PROCEDURE..... 5

PREPARATION ........................................................... 6

Special Service Tools ............................................... 6

Commercial Service Tools ........................................ 8

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 10

NVH Troubleshooting — Engine Noise .................. 10

Use the Chart Below to Help You Find the Cause

of the Symptom. ...................................................... 11

DRIVE BELTS ........................................................... 12

Checking Drive Belts .............................................. 12

Deflection Adjustment ............................................ 13

POWER STEERING OIL PUMP BELT ............... 13

A/C COMPRESSOR, ALTERNATOR AND

WATER PUMP BELT .......................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

AIR CLEANER AND AIR DUCT ............................... 15

Components ........................................................... 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 16

CHANGING AIR CLEANER FILTER ................... 17

CHARGE AIR COOLER ........................................... 18

Components ........................................................... 18

Removal and Installation ........................................ 18

REMOVAL ........................................................... 18

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19INTAKE MANIFOLD ................................................. 20

Components ........................................................... 20

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL ....................... 22

INSTALLATION ................................................... 22

INSPECTION AFTER INSTALLATION ................ 25

CATALYST ................................................................ 26

Components ........................................................... 26

Removal and Installation ........................................ 26

REMOVAL ........................................................... 26

INSTALLATION ................................................... 27

TURBO CHARGER ................................................... 28

Components ........................................................... 28

Removal and Installation ........................................ 29

REMOVAL ........................................................... 29

INSPECTION AFTER REMOVAL ....................... 30

TROUBLE DIAGNOSIS OF TURBOCHARGER... 32

INSTALLATION ................................................... 33

EXHAUST MANIFOLD ............................................. 34

Components ........................................................... 34

Removal and Installation ........................................ 34

REMOVAL ........................................................... 34

INSPECTION AFTER REMOVAL ....................... 35

INSTALLATION ................................................... 35

INSPECTION AFTER INSTALLATION ................ 35

OIL PAN AND OIL STRAINER ................................. 36

Components ........................................................... 36

Removal and Installation ........................................ 36

REMOVAL ........................................................... 36

INSPECTION AFTER REMOVAL ....................... 38

INSTALLATION ................................................... 38

INSPECTION AFTER INSTALLATION ................ 40

GLOW PLUG ............................................................ 41

Components ........................................................... 41

Removal and Installation ........................................ 41

REMOVAL ........................................................... 41

INSTALLATION ................................................... 41

VACUUM PUMP ........................................................ 42

Page 1386 of 3171

EM-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Draining Engine CoolantEBS01E5H

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel PipingEBS01E5I

lBefore starting work, make sure no fire or spark producing items are in the work area.

lAfter disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyEBS01E5J

lWhen instructed to use SST, use the specified tools. Always be careful to work safely, avoid forceful or

uninstructed operations.

lExercise maximum care to avoid damage to mating or sliding surfaces.

lCover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

lMark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

lWhen loosening nuts and bolts, as a basic rule, start with the one furthest outside, then the one diagonally

opposite, and so on. If the order of loosening is specified, do exactly as specified.

Precautions for Inspection, Repair and ReplacementEBS01E5K

Before repairing or replacing, thoroughly inspect parts. Inspect new replacement parts in the same way, and

replace if necessary.

Precautions for Assembly and InstallationEBS01E5L

lUsetorquewrenchtotightenboltsornutstospecification.

lWhen tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is speci-

fied, do exactly as specified.

lReplace with new liquid gasket, packing, oil seal or O-ring.

lDowel pins are used for several parts alignment. When replacing and reassembling parts with dowel pins,

make sure that dowel pins are installed in the original position.

lThoroughly wash, clean, and air-blow each part. Carefully check engine oil or engine coolant passages for

any restriction and blockage.

lAvoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

lRelease air within route when refilling after draining engine coolant.

lAfter repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust systems for leakage.

Parts Requiring Angle TighteningEBS01E5M

lUse an angle wrench [SST: KV10112100] for the final tightening of the following engine parts:

–Cylinder head bolts

–Main bearing cap bolts

–Connecting rod cap nuts

–Crankshaft pulley bolt (No angle wrench is required as the bolt flange is provided with notches for angle

tightening)

lDo not use a torque value for final tightening.

lThe torque value for these parts are for a preliminary step.

lEnsure thread and seat surfaces are clean and coated with engine oil.

Page 1387 of 3171

PRECAUTIONS

EM-5

C

D

E

F

G

H

I

J

K

L

MA

EM

Precautions For Liquid GasketEBS01E5N

REMOVAL OF LIQUID GASKET

lAfter removing the mounting bolts and nuts, separate the mating

surface using the seal cutter [SST] and remove the old liquid

gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

lTap seal cutter to insert it, and then slide it by tapping on the

side as shown in the figure.

lIn areas where seal cutter [SST] is difficult to use, use plastic

hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason tool such as screwdriver is

used, be careful not to damage the mating surfaces.

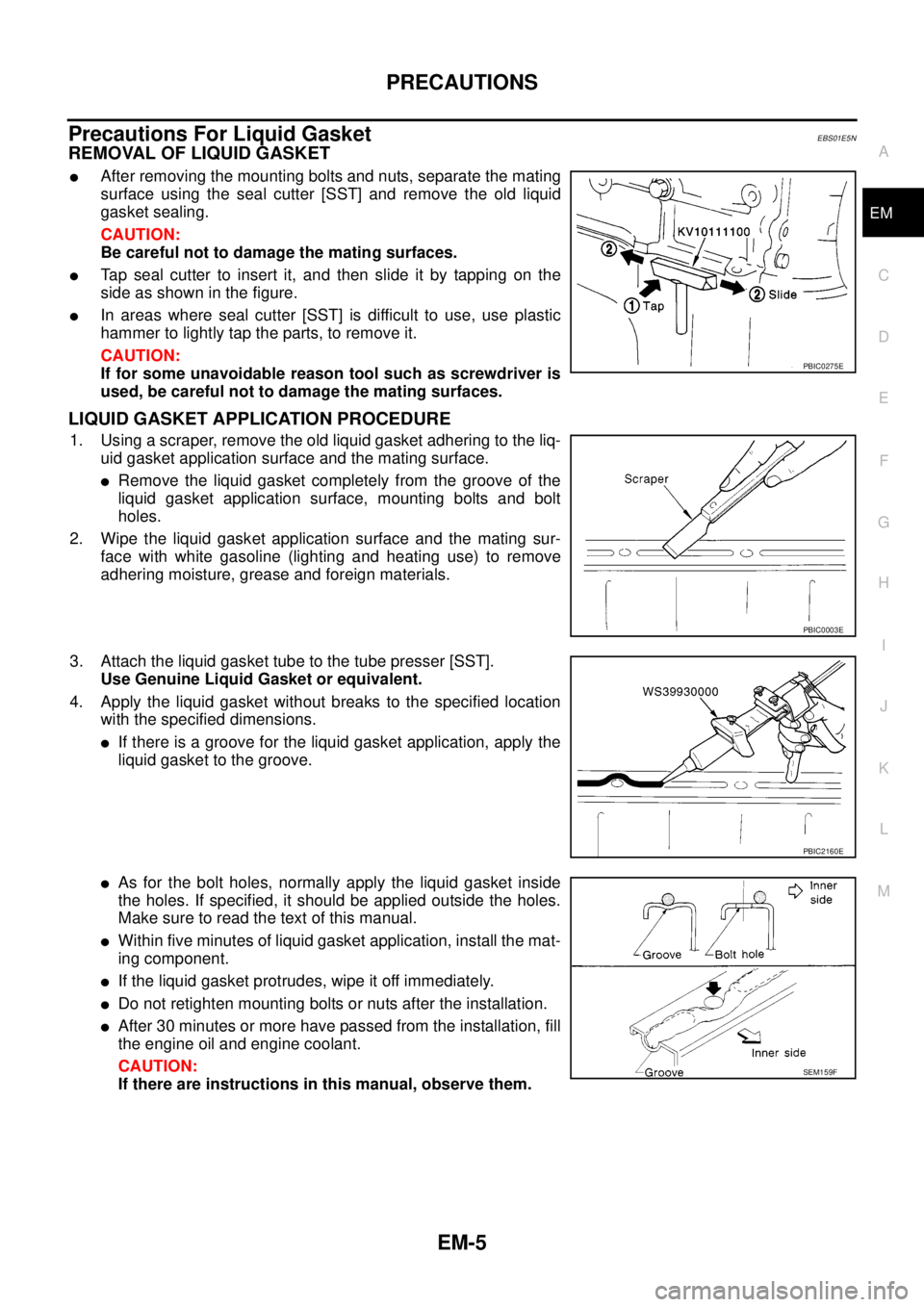

LIQUID GASKET APPLICATION PROCEDURE

1. Using a scraper, remove the old liquid gasket adhering to the liq-

uid gasket application surface and the mating surface.

lRemove the liquid gasket completely from the groove of the

liquid gasket application surface, mounting bolts and bolt

holes.

2. Wipe the liquid gasket application surface and the mating sur-

face with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign materials.

3. Attach the liquid gasket tube to the tube presser [SST].

Use Genuine Liquid Gasket or equivalent.

4. Apply the liquid gasket without breaks to the specified location

with the specified dimensions.

lIf there is a groove for the liquid gasket application, apply the

liquid gasket to the groove.

lAs for the bolt holes, normally apply the liquid gasket inside

the holes. If specified, it should be applied outside the holes.

Make sure to read the text of this manual.

lWithin five minutes of liquid gasket application, install the mat-

ing component.

lIf the liquid gasket protrudes, wipe it off immediately.

lDo not retighten mounting bolts or nuts after the installation.

lAfter 30 minutes or more have passed from the installation, fill

the engine oil and engine coolant.

CAUTION:

If there are instructions in this manual, observe them.

PBIC0275E

PBIC0003E

PBIC2160E

SEM159F

Page 1395 of 3171

DRIVE BELTS

EM-13

C

D

E

F

G

H

I

J

K

L

MA

EM

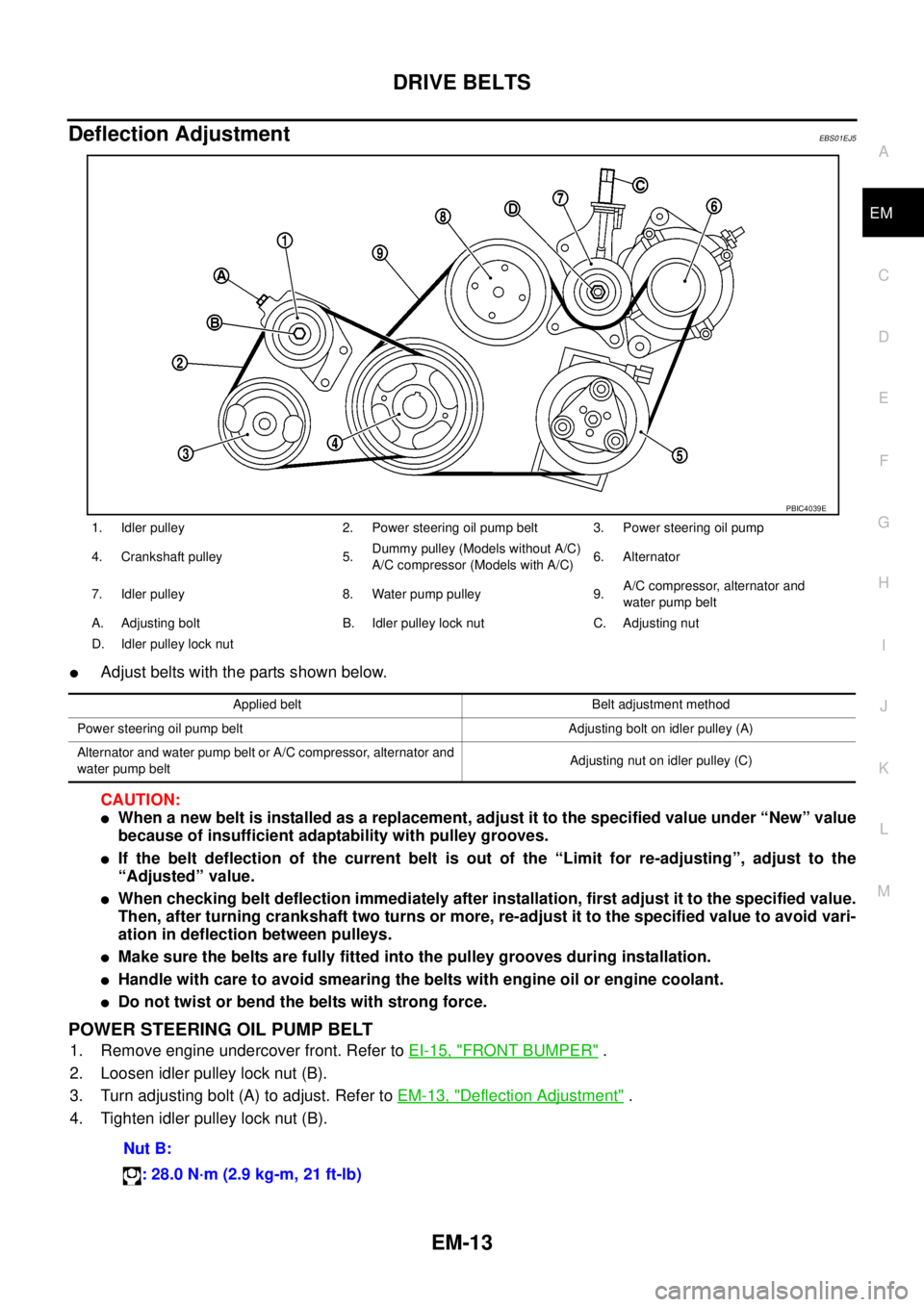

Deflection AdjustmentEBS01EJ5

lAdjust belts with the parts shown below.

CAUTION:

lWhen a new belt is installed as a replacement, adjust it to the specified value under “New” value

because of insufficient adaptability with pulley grooves.

lIf the belt deflection of the current belt is out of the “Limit for re-adjusting”, adjust to the

“Adjusted” value.

lWhen checking belt deflection immediately after installation, first adjust it to the specified value.

Then, after turning crankshaft two turns or more, re-adjust it to the specified value to avoid vari-

ation in deflection between pulleys.

lMake sure the belts are fully fitted into the pulley grooves during installation.

lHandle with care to avoid smearing the belts with engine oil or engine coolant.

lDo not twist or bend the belts with strong force.

POWER STEERING OIL PUMP BELT

1. Remove engine undercover front. Refer toEI-15, "FRONT BUMPER".

2. Loosen idler pulley lock nut (B).

3. Turn adjusting bolt (A) to adjust. Refer toEM-13, "

Deflection Adjustment".

4. Tighten idler pulley lock nut (B).

1. Idler pulley 2. Power steering oil pump belt 3. Power steering oil pump

4. Crankshaft pulley 5.Dummy pulley (Models without A/C)

A/C compressor (Models with A/C)6. Alternator

7. Idler pulley 8. Water pump pulley 9.A/C compressor, alternator and

water pump belt

A. Adjusting bolt B. Idler pulley lock nut C. Adjusting nut

D. Idler pulley lock nut

PBIC4039E

Applied belt Belt adjustment method

Power steering oil pump belt Adjusting bolt on idler pulley (A)

Alternator and water pump belt or A/C compressor, alternator and

water pump beltAdjusting nut on idler pulley (C)

Nut B:

: 28.0 N·m (2.9 kg-m, 21 ft-lb)

Page 1403 of 3171

INTAKE MANIFOLD

EM-21

C

D

E

F

G

H

I

J

K

L

MA

EM

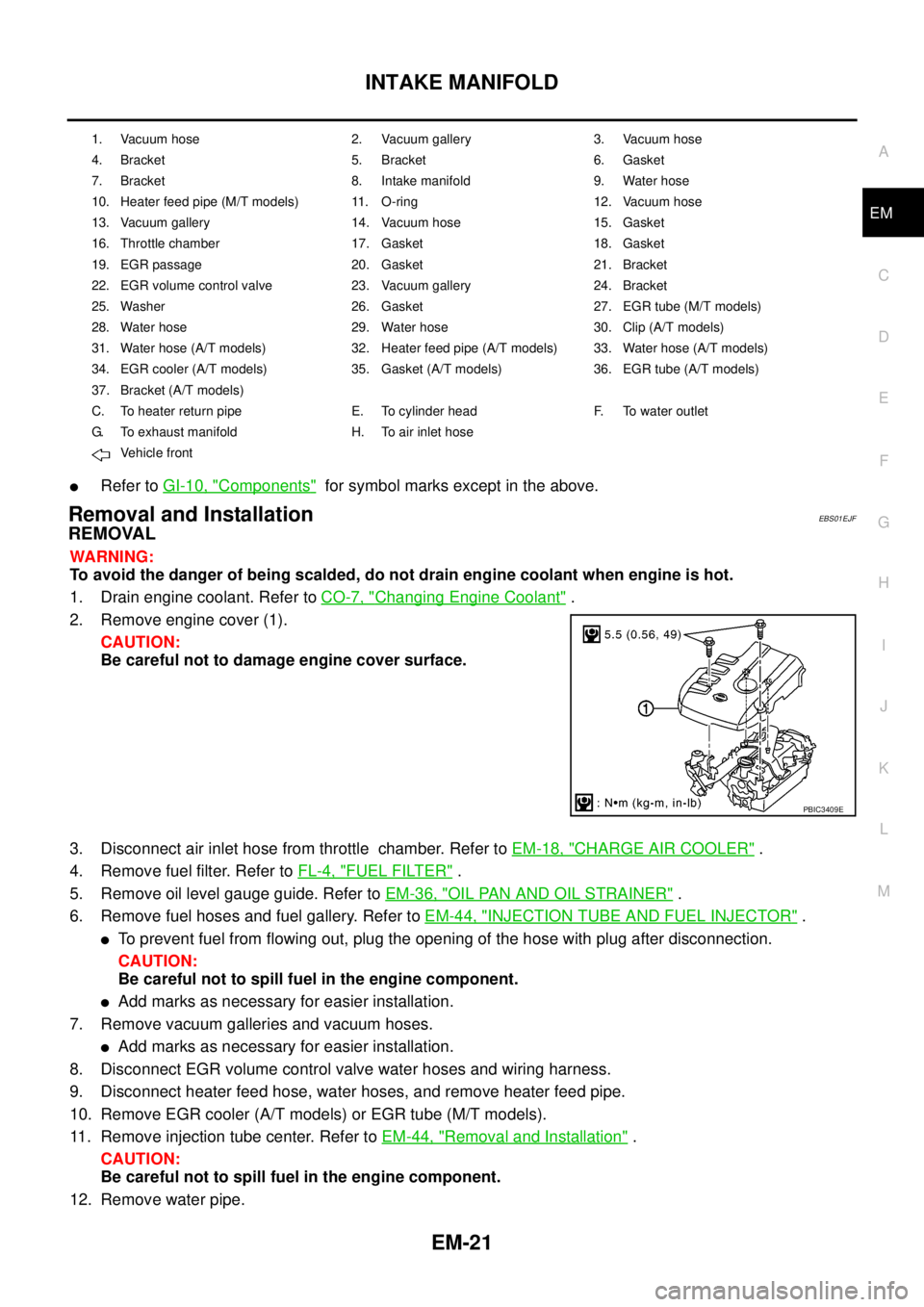

lRefer toGI-10, "Components"for symbol marks except in the above.

Removal and InstallationEBS01EJF

REMOVAL

WARNING:

To avoid the danger of being scalded, do not drain engine coolant when engine is hot.

1. Drain engine coolant. Refer toCO-7, "

Changing Engine Coolant".

2. Remove engine cover (1).

CAUTION:

Be careful not to damage engine cover surface.

3. Disconnect air inlet hose from throttle chamber. Refer toEM-18, "

CHARGE AIR COOLER".

4. Remove fuel filter. Refer toFL-4, "

FUEL FILTER".

5. Remove oil level gauge guide. Refer toEM-36, "

OIL PAN AND OIL STRAINER".

6. Remove fuel hoses and fuel gallery. Refer toEM-44, "

INJECTION TUBE AND FUEL INJECTOR".

lTo prevent fuel from flowing out, plug the opening of the hose with plug after disconnection.

CAUTION:

Be careful not to spill fuel in the engine component.

lAdd marks as necessary for easier installation.

7. Remove vacuum galleries and vacuum hoses.

lAdd marks as necessary for easier installation.

8. Disconnect EGR volume control valve water hoses and wiring harness.

9. Disconnect heater feed hose, water hoses, and remove heater feed pipe.

10. Remove EGR cooler (A/T models) or EGR tube (M/T models).

11. Remove injection tube center. Refer toEM-44, "

Removal and Installation".

CAUTION:

Be careful not to spill fuel in the engine component.

12. Remove water pipe.

1. Vacuum hose 2. Vacuum gallery 3. Vacuum hose

4. Bracket 5. Bracket 6. Gasket

7. Bracket 8. Intake manifold 9. Water hose

10. Heater feed pipe (M/T models) 11. O-ring 12. Vacuum hose

13. Vacuum gallery 14. Vacuum hose 15. Gasket

16. Throttle chamber 17. Gasket 18. Gasket

19. EGR passage 20. Gasket 21. Bracket

22. EGR volume control valve 23. Vacuum gallery 24. Bracket

25. Washer 26. Gasket 27. EGR tube (M/T models)

28. Water hose 29. Water hose 30. Clip (A/T models)

31. Water hose (A/T models) 32. Heater feed pipe (A/T models) 33. Water hose (A/T models)

34. EGR cooler (A/T models) 35. Gasket (A/T models) 36. EGR tube (A/T models)

37. Bracket (A/T models)

C. To heater return pipe E. To cylinder head F. To water outlet

G. To exhaust manifold H. To air inlet hose

Vehicle front

PBIC3409E

Page 1411 of 3171

TURBO CHARGER

EM-29

C

D

E

F

G

H

I

J

K

L

MA

EM

lRefer toGI-10, "Components"for symbol marks in the figure.

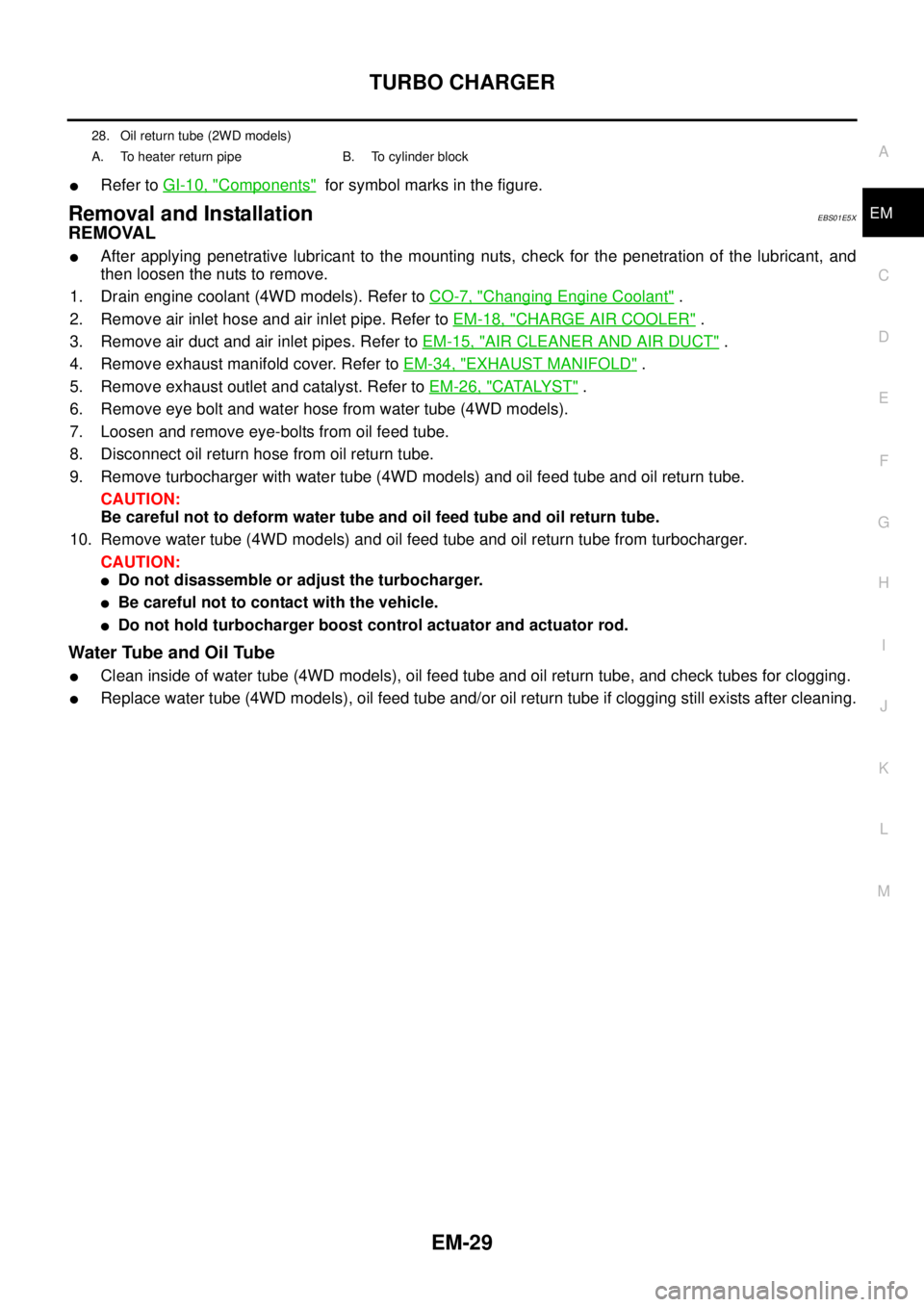

Removal and InstallationEBS01E5X

REMOVAL

lAfter applying penetrative lubricant to the mounting nuts, check for the penetration of the lubricant, and

then loosen the nuts to remove.

1. Drain engine coolant (4WD models). Refer toCO-7, "

Changing Engine Coolant".

2. Remove air inlet hose and air inlet pipe. Refer toEM-18, "

CHARGE AIR COOLER".

3. Remove air duct and air inlet pipes. Refer toEM-15, "

AIR CLEANER AND AIR DUCT".

4. Remove exhaust manifold cover. Refer toEM-34, "

EXHAUST MANIFOLD".

5. Remove exhaust outlet and catalyst. Refer toEM-26, "

CATALYST".

6. Remove eye bolt and water hose from water tube (4WD models).

7. Loosen and remove eye-bolts from oil feed tube.

8. Disconnect oil return hose from oil return tube.

9. Remove turbocharger with water tube (4WD models) and oil feed tube and oil return tube.

CAUTION:

Be careful not to deform water tube and oil feed tube and oil return tube.

10. Remove water tube (4WD models) and oil feed tube and oil return tube from turbocharger.

CAUTION:

lDo not disassemble or adjust the turbocharger.

lBe careful not to contact with the vehicle.

lDo not hold turbocharger boost control actuator and actuator rod.

Water Tube and Oil Tube

lClean inside of water tube (4WD models), oil feed tube and oil return tube, and check tubes for clogging.

lReplace water tube (4WD models), oil feed tube and/or oil return tube if clogging still exists after cleaning.

28. Oil return tube (2WD models)

A. To heater return pipe B. To cylinder block

Page 1412 of 3171

EM-30

TURBO CHARGER

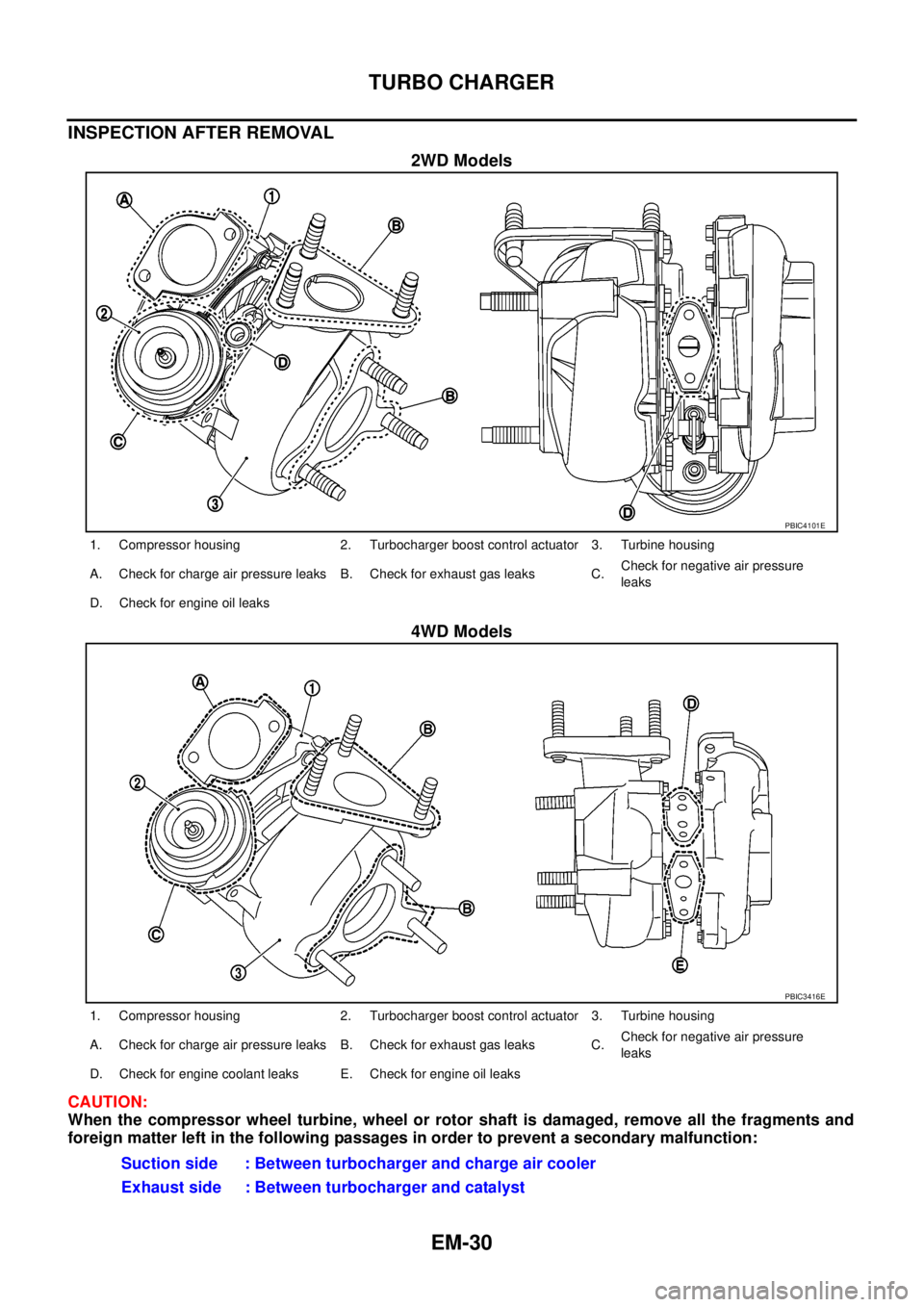

INSPECTION AFTER REMOVAL

2WD Models

4WD Models

CAUTION:

When the compressor wheel turbine, wheel or rotor shaft is damaged, remove all the fragments and

foreign matter left in the following passages in order to prevent a secondary malfunction:

PBIC4101E

1. Compressor housing 2. Turbocharger boost control actuator 3. Turbine housing

A. Check for charge air pressure leaks B. Check for exhaust gas leaks C.Check for negative air pressure

leaks

D. Check for engine oil leaks

PBIC3416E

1. Compressor housing 2. Turbocharger boost control actuator 3. Turbine housing

A. Check for charge air pressure leaks B. Check for exhaust gas leaks C.Check for negative air pressure

leaks

D. Check for engine coolant leaks E. Check for engine oil leaks

Suction side : Between turbocharger and charge air cooler

Exhaust side : Between turbocharger and catalyst