wheel NISSAN NAVARA 2005 Repair Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1538 of 3171

FAX-6

WHEEL HUB

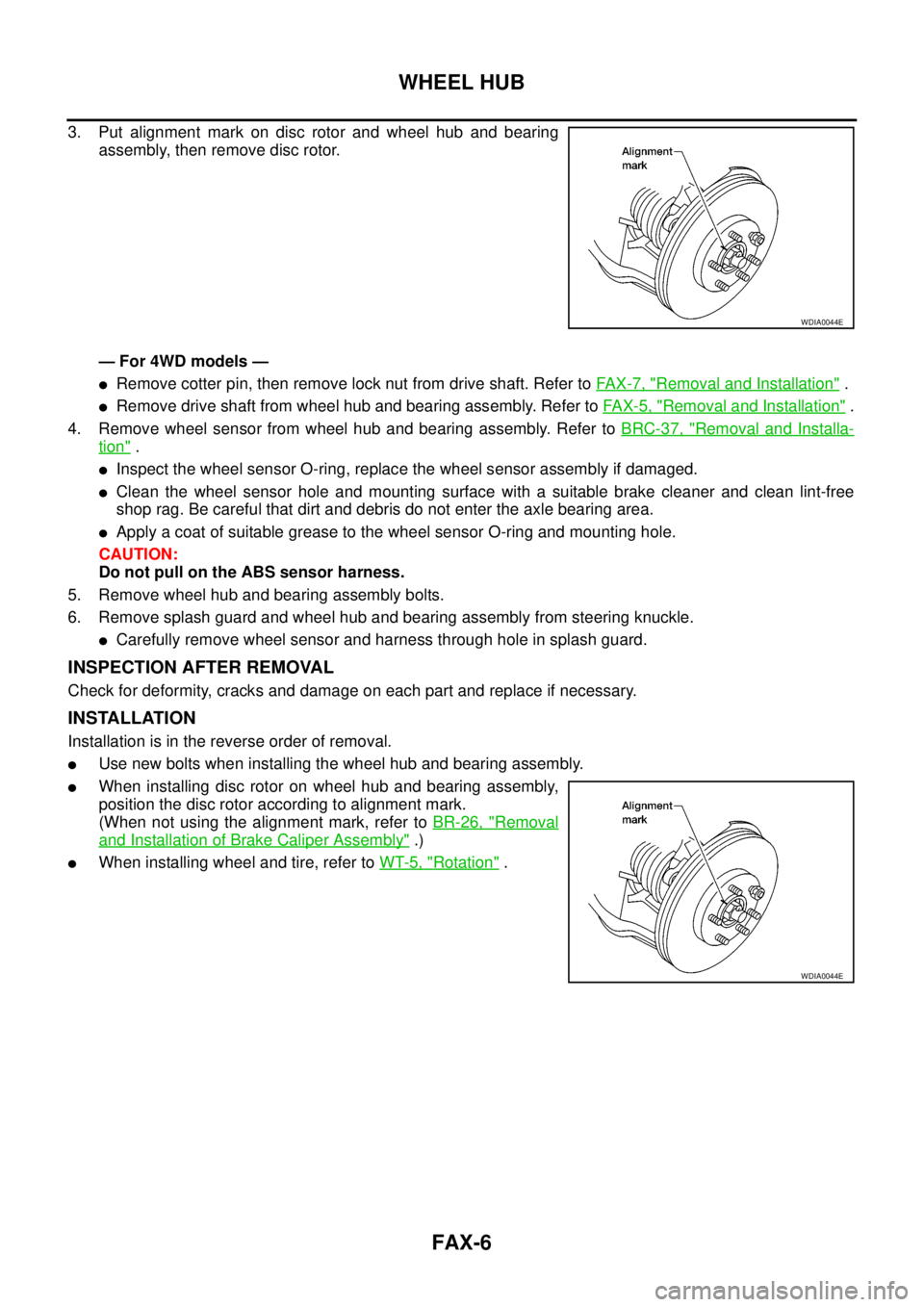

3. Put alignment mark on disc rotor and wheel hub and bearing

assembly, then remove disc rotor.

— For 4WD models —

lRemove cotter pin, then remove lock nut from drive shaft. Refer toFA X - 7 , "Removal and Installation".

lRemove drive shaft from wheel hub and bearing assembly. Refer toFAX-5, "Removal and Installation".

4. Remove wheel sensor from wheel hub and bearing assembly. Refer toBRC-37, "

Removal and Installa-

tion".

lInspect the wheel sensor O-ring, replace the wheel sensor assembly if damaged.

lClean the wheel sensor hole and mounting surface with a suitable brake cleaner and clean lint-free

shop rag. Be careful that dirt and debris do not enter the axle bearing area.

lApply a coat of suitable grease to the wheel sensor O-ring and mounting hole.

CAUTION:

Do not pull on the ABS sensor harness.

5. Remove wheel hub and bearing assembly bolts.

6. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

lCarefully remove wheel sensor and harness through hole in splash guard.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lUse new bolts when installing the wheel hub and bearing assembly.

lWhen installing disc rotor on wheel hub and bearing assembly,

position the disc rotor according to alignment mark.

(When not using the alignment mark, refer toBR-26, "

Removal

and Installation of Brake Caliper Assembly".)

lWhen installing wheel and tire, refer toWT-5, "Rotation".

WDIA0044E

WDIA0044E

Page 1539 of 3171

DRIVE SHAFT

FAX-7

C

E

F

G

H

I

J

K

L

MA

B

FA X

DRIVE SHAFTPFP:39100

Removal and InstallationEDS003I9

REMOVAL

1. Remove wheel.

2. Remove ABS sensor harness from mount on knuckle, then disconnect ABS sensor harness connector.

CAUTION:

Do not pull on ABS sensor harness.

3. Remove steering knuckle. Refer toFSU-16, "

Removal and Installation".

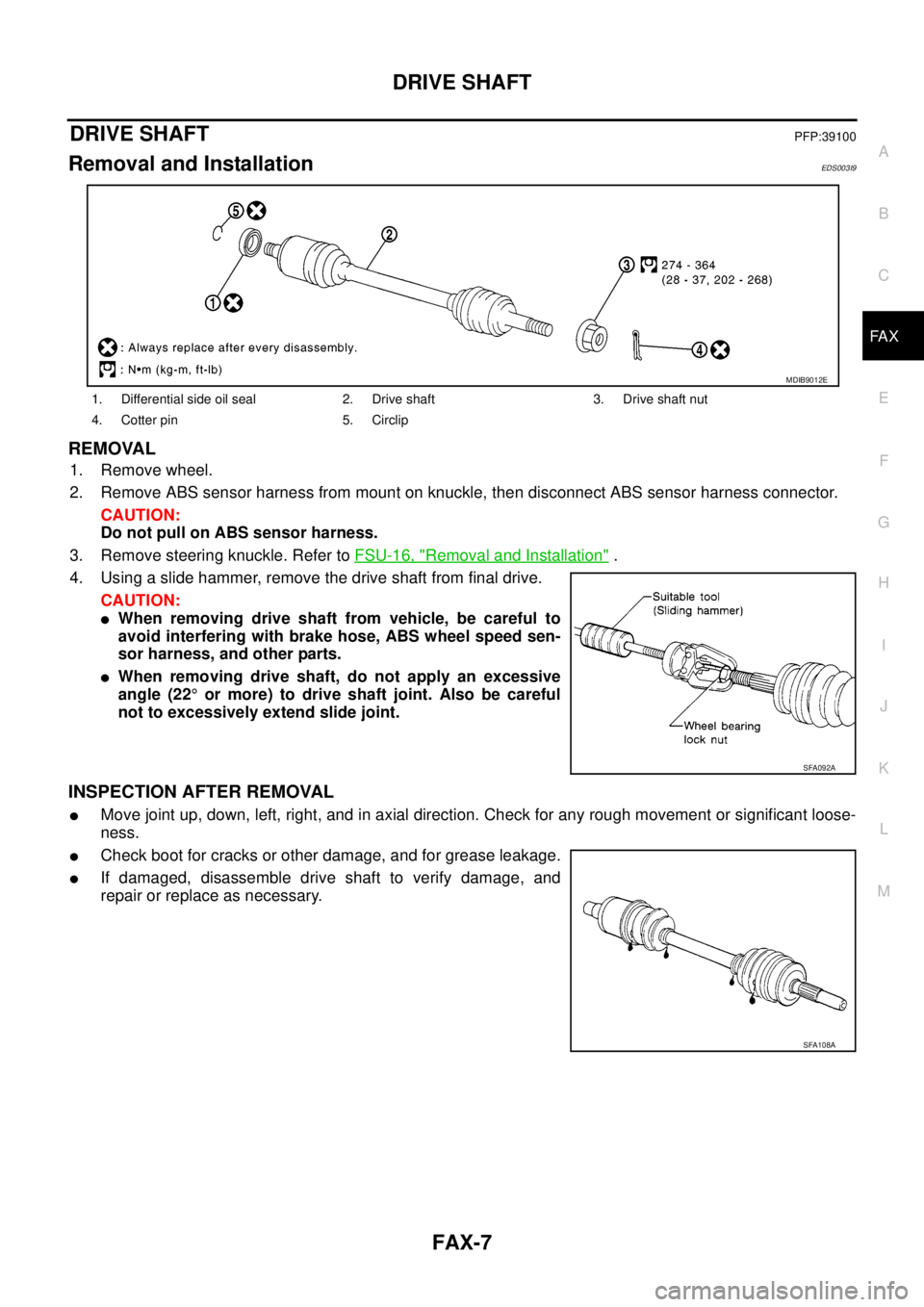

4. Using a slide hammer, remove the drive shaft from final drive.

CAUTION:

lWhen removing drive shaft from vehicle, be careful to

avoid interfering with brake hose, ABS wheel speed sen-

sor harness, and other parts.

lWhen removing drive shaft, do not apply an excessive

angle (22°or more) to drive shaft joint. Also be careful

not to excessively extend slide joint.

INSPECTION AFTER REMOVAL

lMove joint up, down, left, right, and in axial direction. Check for any rough movement or significant loose-

ness.

lCheck boot for cracks or other damage, and for grease leakage.

lIf damaged, disassemble drive shaft to verify damage, and

repair or replace as necessary.

1. Differential side oil seal 2. Drive shaft 3. Drive shaft nut

4. Cotter pin 5. Circlip

MDIB9012E

SFA092A

SFA108A

Page 1541 of 3171

DRIVE SHAFT

FAX-9

C

E

F

G

H

I

J

K

L

MA

B

FA X

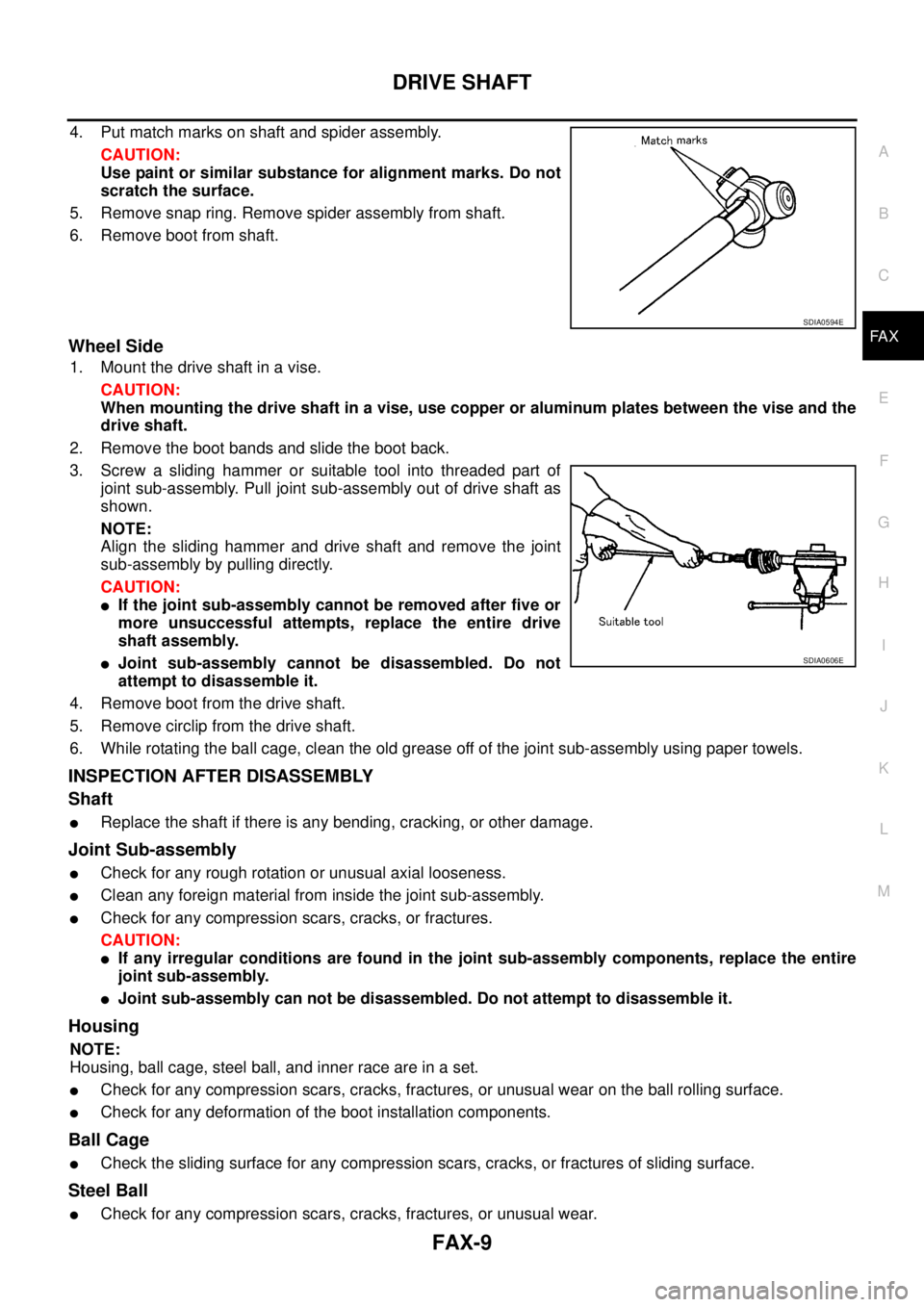

4. Put match marks on shaft and spider assembly.

CAUTION:

Use paint or similar substance for alignment marks. Do not

scratch the surface.

5. Remove snap ring. Remove spider assembly from shaft.

6. Remove boot from shaft.

Wheel Side

1. Mount the drive shaft in a vise.

CAUTION:

When mounting the drive shaft in a vise, use copper or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands and slide the boot back.

3. Screw a sliding hammer or suitable tool into threaded part of

joint sub-assembly. Pull joint sub-assembly out of drive shaft as

shown.

NOTE:

Align the sliding hammer and drive shaft and remove the joint

sub-assembly by pulling directly.

CAUTION:

lIf the joint sub-assembly cannot be removed after five or

more unsuccessful attempts, replace the entire drive

shaft assembly.

lJoint sub-assembly cannot be disassembled. Do not

attempt to disassemble it.

4. Remove boot from the drive shaft.

5. Remove circlip from the drive shaft.

6. While rotating the ball cage, clean the old grease off of the joint sub-assembly using paper towels.

INSPECTION AFTER DISASSEMBLY

Shaft

lReplace the shaft if there is any bending, cracking, or other damage.

Joint Sub-assembly

lCheck for any rough rotation or unusual axial looseness.

lClean any foreign material from inside the joint sub-assembly.

lCheck for any compression scars, cracks, or fractures.

CAUTION:

lIf any irregular conditions are found in the joint sub-assembly components, replace the entire

joint sub-assembly.

lJoint sub-assembly can not be disassembled. Do not attempt to disassemble it.

Housing

NOTE:

Housing, ball cage, steel ball, and inner race are in a set.

lCheck for any compression scars, cracks, fractures, or unusual wear on the ball rolling surface.

lCheck for any deformation of the boot installation components.

Ball Cage

lCheck the sliding surface for any compression scars, cracks, or fractures of sliding surface.

Steel Ball

lCheck for any compression scars, cracks, fractures, or unusual wear.

SDIA0594E

SDIA0606E

Page 1544 of 3171

FAX-12

DRIVE SHAFT

13. Install circlip and dust cover to housing.

NOTE:

Do not reuse circlip and dust cover.

Wheel Side

1. Insert the Genuine NISSAN Grease or equivalent, into the joint

sub-assembly serration hole until the grease begins to ooze

from the ball groove and serration hole. Refer toMA-14, "

REC-

OMMENDED FLUIDS AND LUBRICANTS". After inserting the

grease, use a shop cloth to wipe off the grease that has oozed

out.

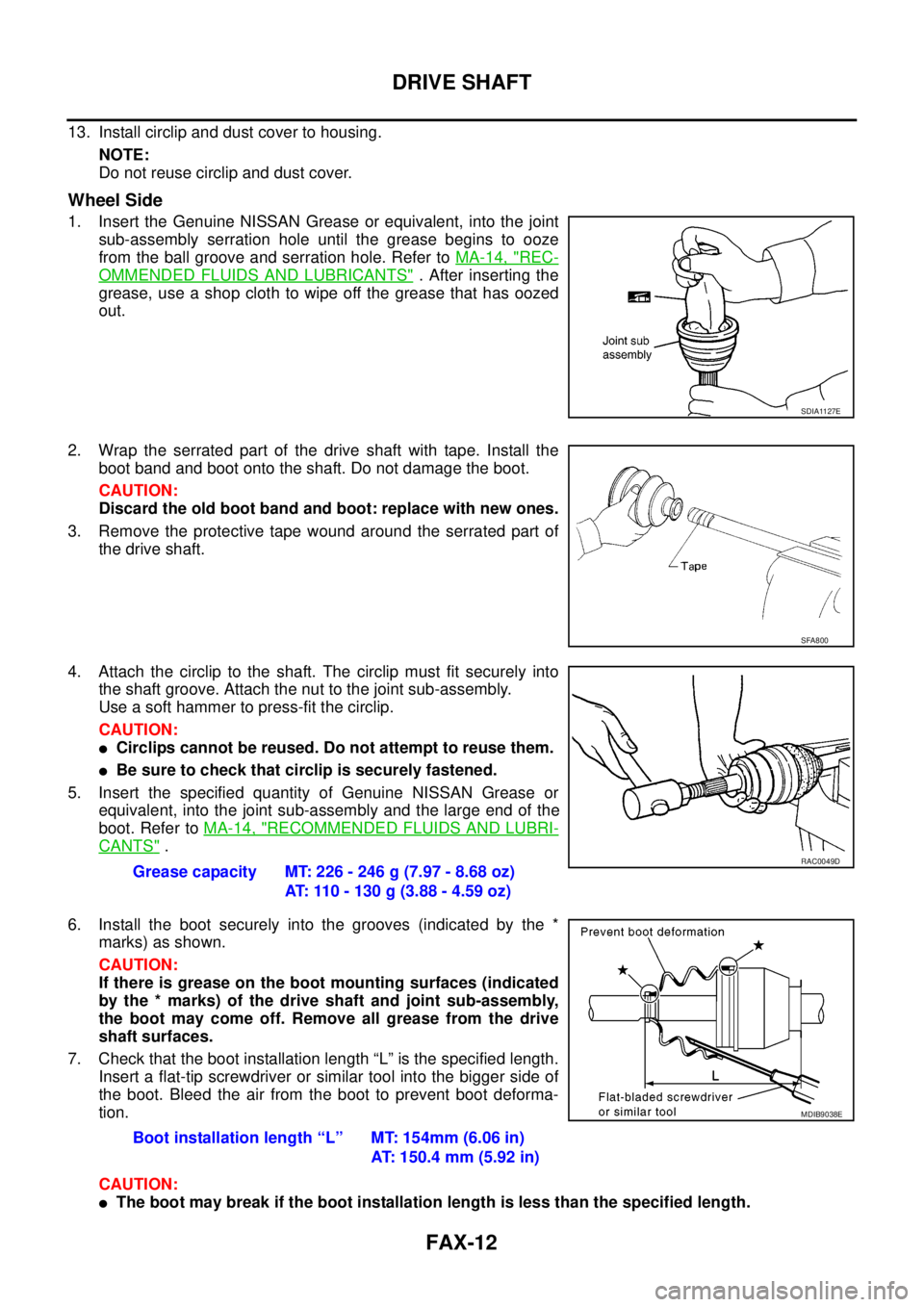

2. Wrap the serrated part of the drive shaft with tape. Install the

boot band and boot onto the shaft. Do not damage the boot.

CAUTION:

Discard the old boot band and boot: replace with new ones.

3. Remove the protective tape wound around the serrated part of

the drive shaft.

4. Attach the circlip to the shaft. The circlip must fit securely into

the shaft groove. Attach the nut to the joint sub-assembly.

Useasofthammertopress-fitthecirclip.

CAUTION:

lCirclips cannot be reused. Do not attempt to reuse them.

lBe sure to check that circlip is securely fastened.

5. Insert the specified quantity of Genuine NISSAN Grease or

equivalent, into the joint sub-assembly and the large end of the

boot. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRI-

CANTS".

6. Install the boot securely into the grooves (indicated by the *

marks) as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by the * marks) of the drive shaft and joint sub-assembly,

the boot may come off. Remove all grease from the drive

shaft surfaces.

7. Check that the boot installation length “L” is the specified length.

Insert a flat-tip screwdriver or similar tool into the bigger side of

the boot. Bleed the air from the boot to prevent boot deforma-

tion.

CAUTION:

lThe boot may break if the boot installation length is less than the specified length.

SDIA1127E

SFA800

Grease capacity MT: 226 - 246 g (7.97 - 8.68 oz)

AT: 110 - 130 g (3.88 - 4.59 oz)RAC0049D

Boot installation length “L” MT: 154mm (6.06 in)

AT: 150.4 mm (5.92 in)

MDIB9038E

Page 1546 of 3171

FAX-14

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

PFP:00030

Wheel BearingEDS003IB

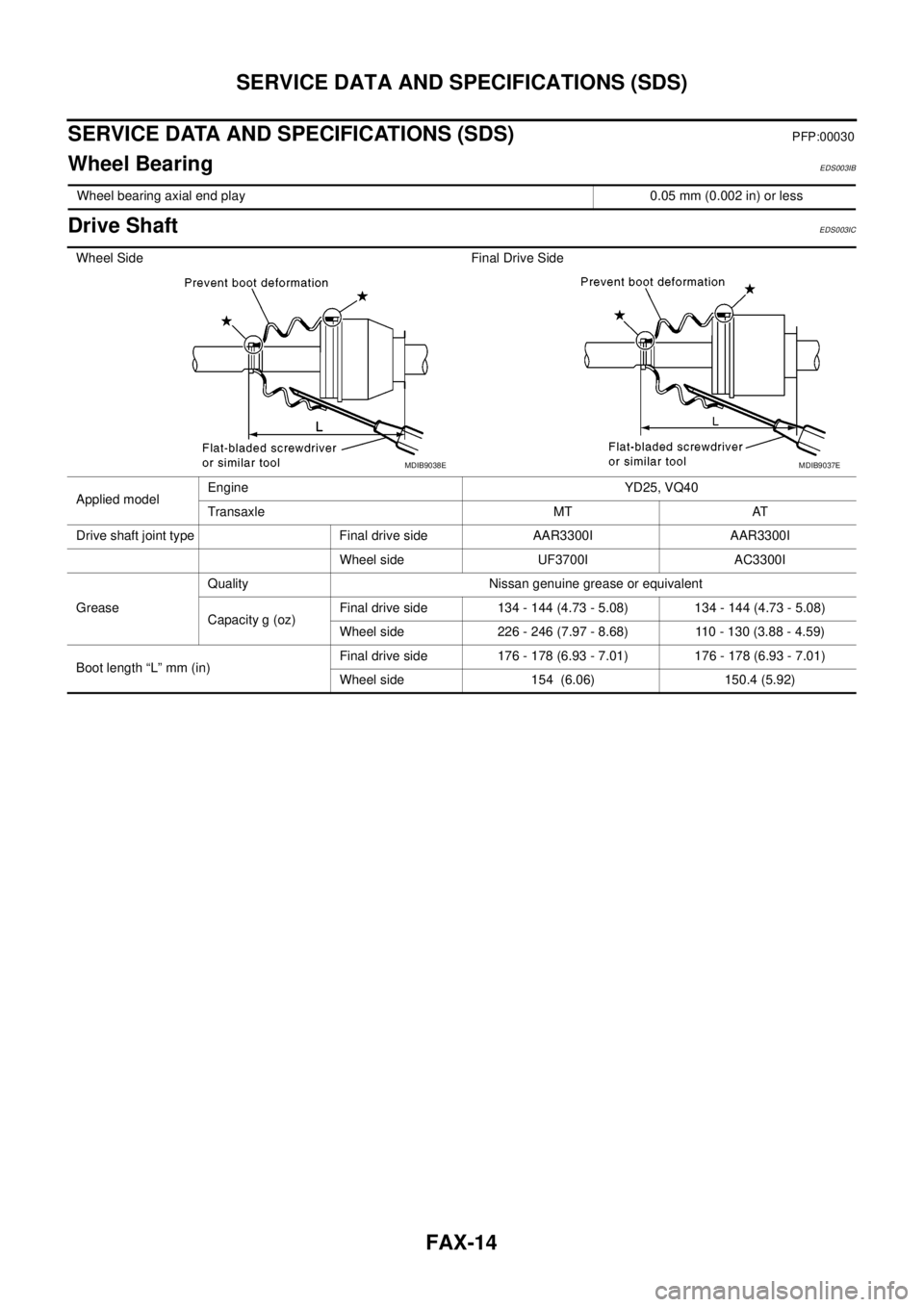

Drive ShaftEDS003IC

Wheel bearing axial end play 0.05 mm (0.002 in) or less

Wheel Side Final Drive Side

Applied modelEngine YD25, VQ40

Transaxle MT AT

Drive shaft joint type Final drive side AAR3300I AAR3300I

Wheel side UF3700I AC3300I

GreaseQuality Nissan genuine grease or equivalent

Capacity g (oz)Final drive side 134 - 144 (4.73 - 5.08) 134 - 144 (4.73 - 5.08)

Wheel side 226 - 246 (7.97 - 8.68) 110 - 130 (3.88 - 4.59)

Boot length “L” mm (in)Final drive side 176 - 178 (6.93 - 7.01) 176 - 178 (6.93 - 7.01)

Wheel side 154 (6.06) 150.4 (5.92)

MDIB9038EMDIB9037E

Page 1552 of 3171

FFD-6

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

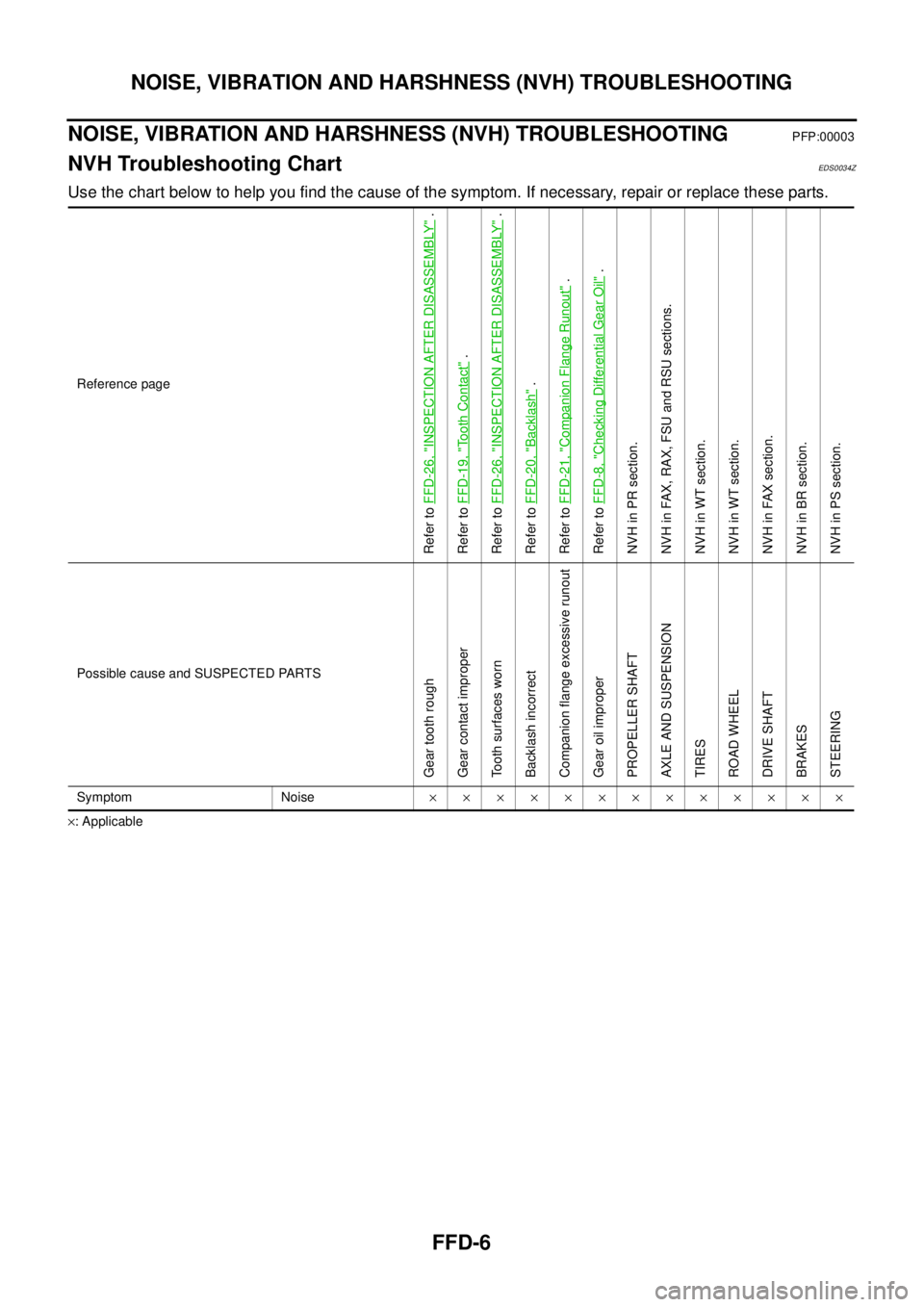

NVH Troubleshooting ChartEDS0034Z

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

Refer toFFD-26, "

INSPECTION AFTER DISASSEMBLY

".

Refer toFFD-19, "

To o t h C o n t a c t

".

Refer toFFD-26, "

INSPECTION AFTER DISASSEMBLY

".

Refer toFFD-20, "

Backlash

".

Refer toFFD-21, "

Companion Flange Runout

".

Refer toFFD-8, "

Checking Differential Gear Oil

".

NVH in PR section.

NVH in FAX, RAX, FSU and RSU sections.

NVH in WT section.

NVH in WT section.

NVH in FAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom Noise´´´´´´´´´´´´´

Page 1555 of 3171

FRONT OIL SEAL

FFD-9

C

E

F

G

H

I

J

K

L

MA

B

FFD

FRONT OIL SEALPFP:38189

Removal and InstallationEDS00353

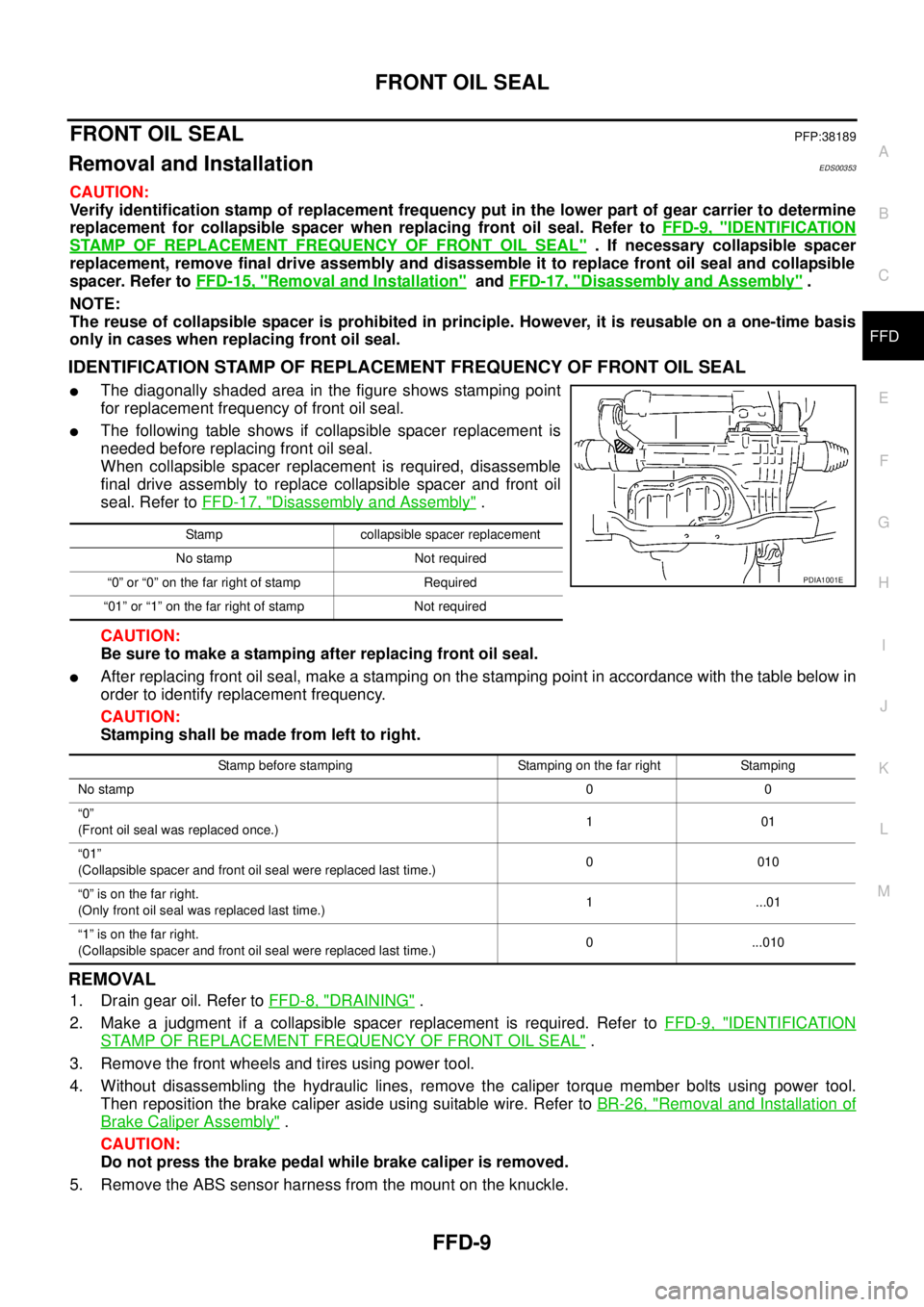

CAUTION:

Verify identification stamp of replacement frequency put in the lower part of gear carrier to determine

replacement for collapsible spacer when replacing front oil seal. Refer toFFD-9, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL". If necessary collapsible spacer

replacement, remove final drive assembly and disassemble it to replace front oil seal and collapsible

spacer. Refer toFFD-15, "

Removal and Installation"andFFD-17, "Disassembly and Assembly".

NOTE:

The reuse of collapsible spacer is prohibited in principle. However, it is reusable on a one-time basis

only in cases when replacing front oil seal.

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL

lThe diagonally shaded area in the figure shows stamping point

for replacement frequency of front oil seal.

lThe following table shows if collapsible spacer replacement is

needed before replacing front oil seal.

When collapsible spacer replacement is required, disassemble

final drive assembly to replace collapsible spacer and front oil

seal. Refer toFFD-17, "

Disassembly and Assembly".

CAUTION:

Be sure to make a stamping after replacing front oil seal.

lAfter replacing front oil seal, make a stamping on the stamping point in accordance with the table below in

order to identify replacement frequency.

CAUTION:

Stamping shall be made from left to right.

REMOVAL

1. Drain gear oil. Refer toFFD-8, "DRAINING".

2. Make a judgment if a collapsible spacer replacement is required. Refer toFFD-9, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL".

3. Remove the front wheels and tires using power tool.

4. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

5. Remove the ABS sensor harness from the mount on the knuckle.

Stamp collapsible spacer replacement

No stamp Not required

“0” or “0” on the far right of stamp Required

“01” or “1” on the far right of stamp Not required

PDIA1001E

Stamp before stamping Stamping on the far right Stamping

No stamp00

“0”

(Front oil seal was replaced once.)101

“01”

(Collapsible spacer and front oil seal were replaced last time.)0010

“0”isonthefarright.

(Only front oil seal was replaced last time.)1 ...01

“1”isonthefarright.

(Collapsible spacer and front oil seal were replaced last time.)0 ...010

Page 1558 of 3171

FFD-12

FRONT OIL SEAL

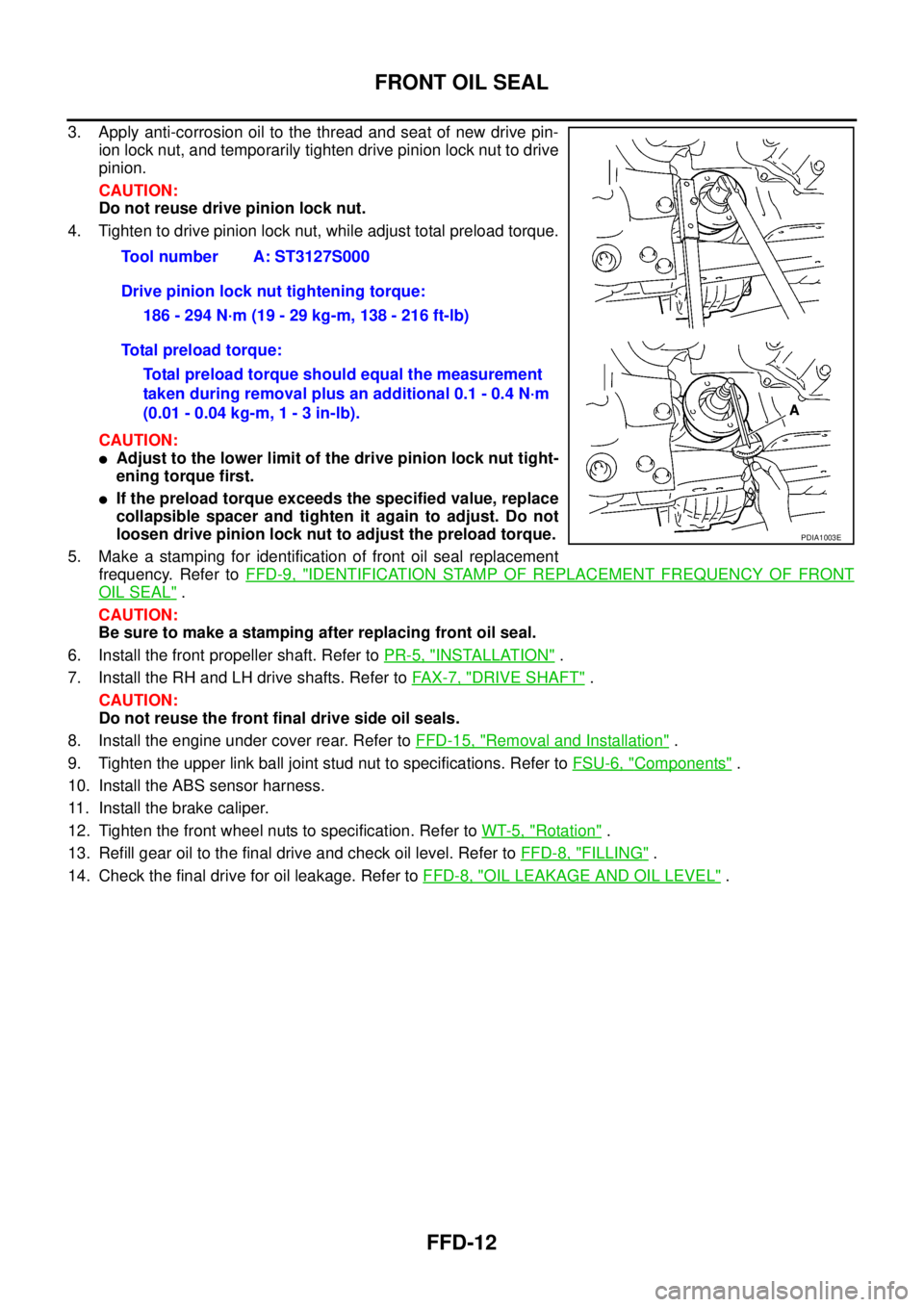

3. Apply anti-corrosion oil to the thread and seat of new drive pin-

ion lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Do not reuse drive pinion lock nut.

4. Tighten to drive pinion lock nut, while adjust total preload torque.

CAUTION:

lAdjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

lIf the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Do not

loosen drive pinion lock nut to adjust the preload torque.

5. Make a stamping for identification of front oil seal replacement

frequency. Refer toFFD-9, "

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT

OIL SEAL".

CAUTION:

Be sure to make a stamping after replacing front oil seal.

6. Install the front propeller shaft. Refer toPR-5, "

INSTALLATION".

7. Install the RH and LH drive shafts. Refer toFA X - 7 , "

DRIVE SHAFT".

CAUTION:

Do not reuse the front final drive side oil seals.

8. Install the engine under cover rear. Refer toFFD-15, "

Removal and Installation".

9. Tighten the upper link ball joint stud nut to specifications. Refer toFSU-6, "

Components".

10. Install the ABS sensor harness.

11. Install the brake caliper.

12. Tighten the front wheel nuts to specification. Refer toWT-5, "

Rotation".

13. Refill gear oil to the final drive and check oil level. Refer toFFD-8, "

FILLING".

14. Check the final drive for oil leakage. Refer toFFD-8, "

OIL LEAKAGE AND OIL LEVEL". Tool number A: ST3127S000

Drive pinion lock nut tightening torque:

186 - 294 N·m (19 - 29 kg-m, 138 - 216 ft-lb)

Total preload torque:

Total preload torque should equal the measurement

taken during removal plus an additional 0.1 - 0.4 N·m

(0.01 - 0.04 kg-m, 1 - 3 in-lb).

PDIA1003E

Page 1559 of 3171

SIDE OIL SEAL

FFD-13

C

E

F

G

H

I

J

K

L

MA

B

FFD

SIDE OIL SEALPFP:33142

Removal and InstallationEDS00354

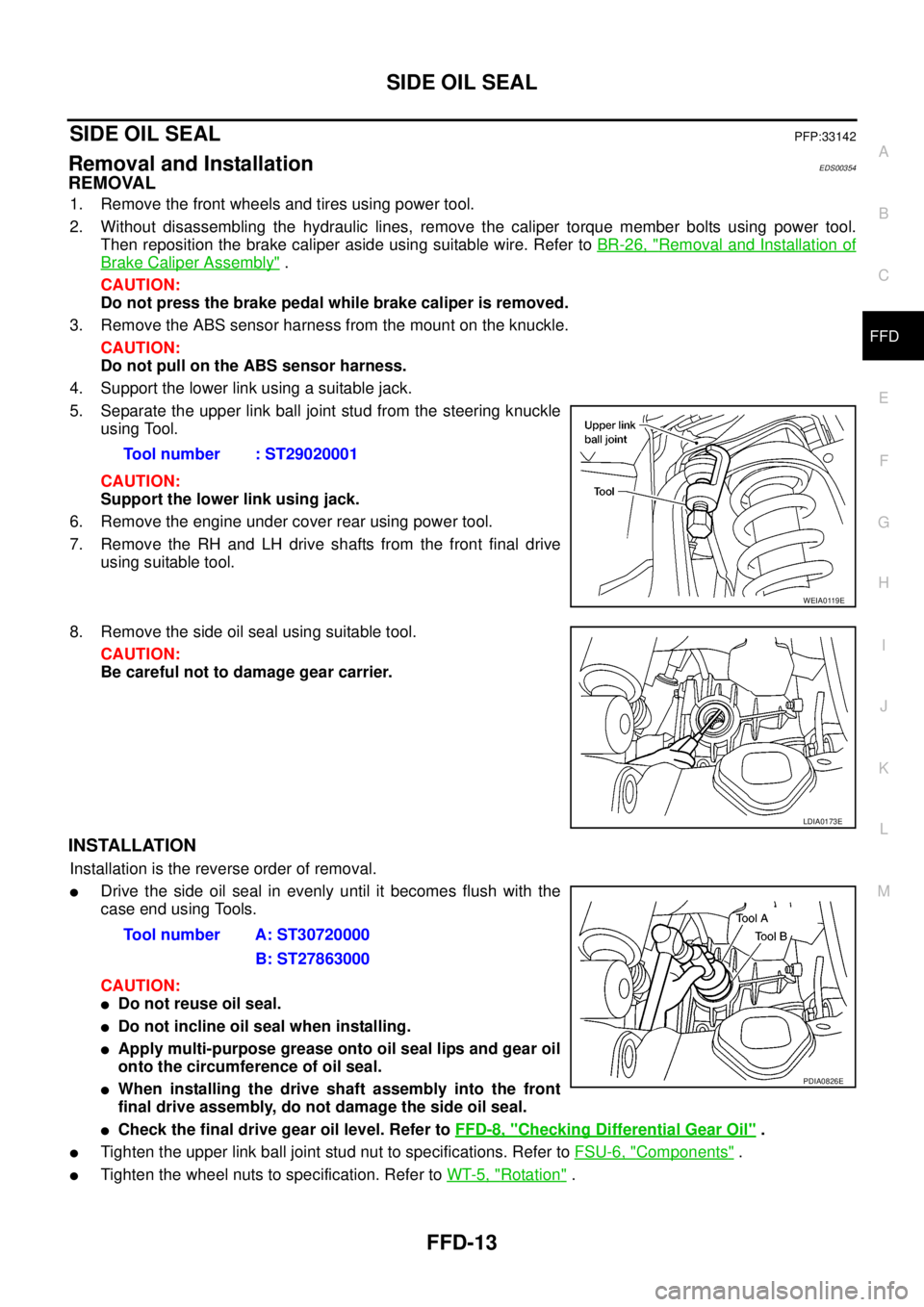

REMOVAL

1. Remove the front wheels and tires using power tool.

2. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

3. Remove the ABS sensor harness from the mount on the knuckle.

CAUTION:

Do not pull on the ABS sensor harness.

4. Support the lower link using a suitable jack.

5. Separate the upper link ball joint stud from the steering knuckle

using Tool.

CAUTION:

Support the lower link using jack.

6. Remove the engine under cover rear using power tool.

7. Remove the RH and LH drive shafts from the front final drive

using suitable tool.

8. Remove the side oil seal using suitable tool.

CAUTION:

Be careful not to damage gear carrier.

INSTALLATION

Installation is the reverse order of removal.

lDrive the side oil seal in evenly until it becomes flush with the

case end using Tools.

CAUTION:

lDo not reuse oil seal.

lDo not incline oil seal when installing.

lApply multi-purpose grease onto oil seal lips and gear oil

onto the circumference of oil seal.

lWhen installing the drive shaft assembly into the front

final drive assembly, do not damage the side oil seal.

lCheck the final drive gear oil level. Refer toFFD-8, "Checking Differential Gear Oil".

lTighten the upper link ball joint stud nut to specifications. Refer toFSU-6, "Components".

lTighten the wheel nuts to specification. Refer toWT-5, "Rotation". Tool number : ST29020001

WEIA0119E

LDIA0173E

Tool number A: ST30720000

B: ST27863000

PDIA0826E

Page 1561 of 3171

FRONT FINAL DRIVE ASSEMBLY

FFD-15

C

E

F

G

H

I

J

K

L

MA

B

FFD

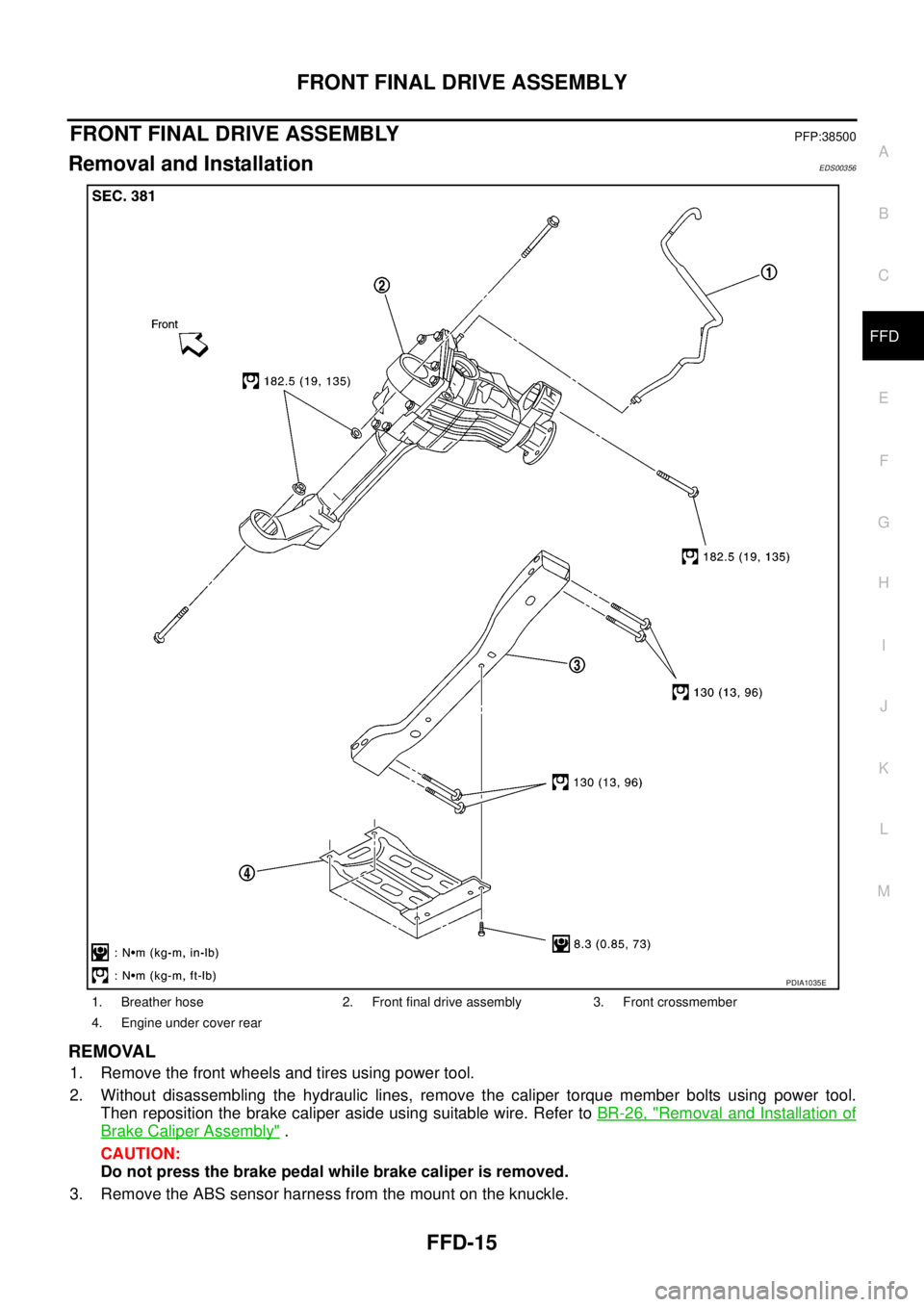

FRONT FINAL DRIVE ASSEMBLYPFP:38500

Removal and InstallationEDS00356

REMOVAL

1. Remove the front wheels and tires using power tool.

2. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

3. Remove the ABS sensor harness from the mount on the knuckle.

1. Breather hose 2. Front final drive assembly 3. Front crossmember

4. Engine under cover rear

PDIA1035E