belt NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2606 of 3171

HARNESS CONNECTOR

PG-77

C

D

E

F

G

H

I

J

L

MA

B

PG

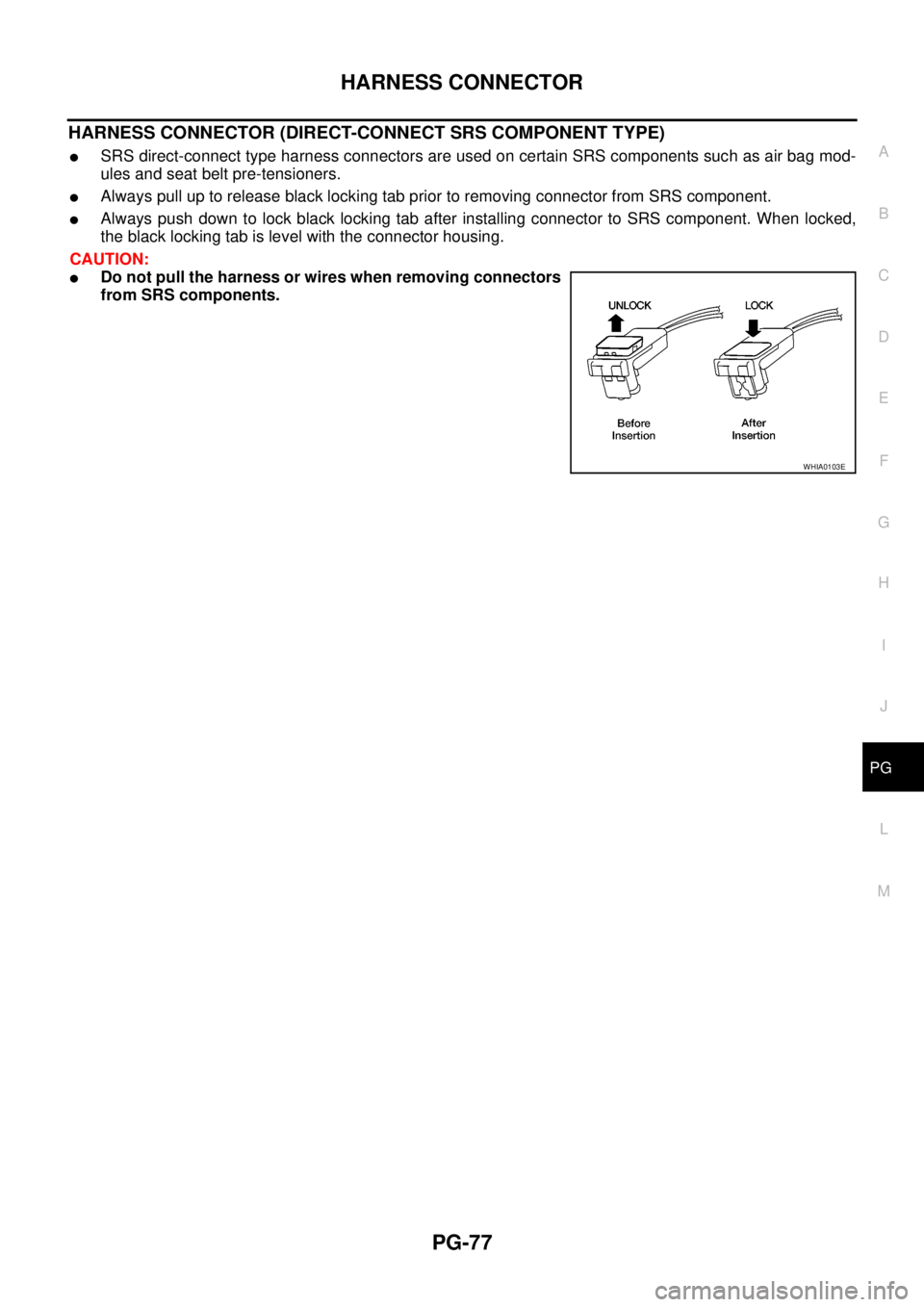

HARNESS CONNECTOR (DIRECT-CONNECT SRS COMPONENT TYPE)

lSRS direct-connect type harness connectors are used on certain SRS components such as air bag mod-

ules and seat belt pre-tensioners.

lAlways pull up to release black locking tab prior to removing connector from SRS component.

lAlways push down to lock black locking tab after installing connector to SRS component. When locked,

the black locking tab is level with the connector housing.

CAUTION:

lDo not pull the harness or wires when removing connectors

from SRS components.

WHIA0103E

Page 2628 of 3171

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTIONPS

A

B

PS

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions for Steering System .............................. 2

PREPARATION ........................................................... 3

Special Service Tools [SST] ..................................... 3

Commercial Service Tools ........................................ 4

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

POWER STEERING FLUID ........................................ 6

Checking Fluid Level ................................................ 6

Checking Fluid Leakage ........................................... 6

Air Bleeding Hydraulic System ................................. 6

STEERING WHEEL .................................................... 8

On-Vehicle Inspection and Service .......................... 8

CHECKING CONDITION OF INSTALLATION ...... 8

CHECKING STEERING WHEEL PLAY ................ 8

CHECKING NEUTRAL POSITION STEERING

WHEEL ................................................................. 8

CHECKING STEERING WHEEL TURNING

FORCE .................................................................. 8

CHECKING FRONT WHEEL TURNING ANGLE..... 9

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION ................................................... 10

STEERING COLUMN ................................................11

Removal and Installation ......................................... 11

COMPONENT ...................................................... 11

REMOVAL ............................................................ 11

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 12

INSPECTION AFTER INSTALLATION ............... 13

POWER STEERING GEAR AND LINKAGE ............ 14Removal and Installation ........................................ 14

COMPONENT ..................................................... 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 15

INSPECTION AFTER INSTALLATION ................ 15

Disassembly and Assembly .................................... 16

COMPONENT ..................................................... 16

DISASSEMBLY ................................................... 17

INSPECTION AFTER DISASSEMBLY ................ 18

ASSEMBLY ......................................................... 20

POWER STEERING OIL PUMP ............................... 25

On-Vehicle Inspection and Service ......................... 25

CHECKING RELIEF OIL PRESSURE ................ 25

Removal and Installation ........................................ 25

REMOVAL ........................................................... 25

INSTALLATION ................................................... 26

Disassembly and Assembly .................................... 26

COMPONENT ..................................................... 26

INSPECTION BEFORE DISASSEMBLY ............. 26

DISASSEMBLY ................................................... 27

INSPECTION AFTER DISASSEMBLY ................ 27

ASSEMBLY ......................................................... 28

HYDRAULIC LINE .................................................... 30

Component (RHD Models) ..................................... 30

Component (LHD Models) ...................................... 32

Removal and Installation ........................................ 33

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 34

Steering Wheel ....................................................... 34

Steering Angle ........................................................ 34

Steering Column ..................................................... 34

Steering Outer Socket and Inner Socket ................ 34

Steering Gear ......................................................... 35

Oil Pump ................................................................. 35

Steering Fluid .......................................................... 35

Page 2629 of 3171

PS-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EGS001M0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Steering SystemEGS001L9

lIn case of removing steering gear assembly, make the final tightening with grounded and unloaded vehi-

cle condition, and then check wheel alignment.

lObserve the following precautions when disassembling.

–Before disassembly, thoroughly clean the outside of the unit.

–Disassembly should be done in a clean work area. It is important to prevent the internal parts from becom-

ing contaminated by dirt or other foreign matter.

–For easier and proper assembly, place disassembled parts in order on a parts rack.

–Use nylon cloth or paper towels to clean the parts; common shop rags can leave lint that might interfere

with their operation.

–Do not reuse non-reusable parts.

–Before assembling, apply the specified grease to the directed parts.

Page 2632 of 3171

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

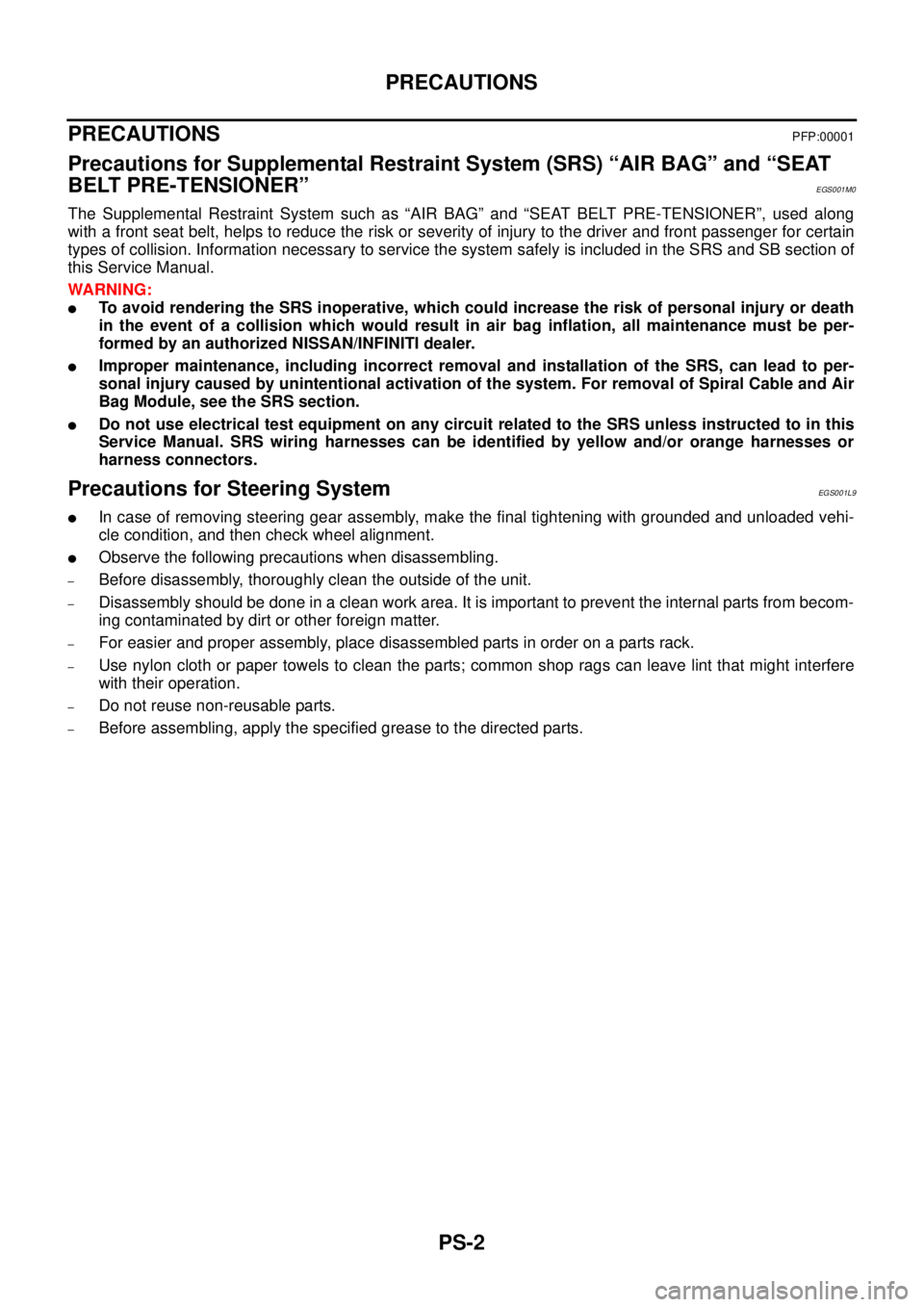

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartEGS001LC

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

PS-6PS-6PS-18PS-18PS-18PS-6PS-8PS-8EM-12PS-8—

PS-18PS-12PS-11PS-16

NVHinPRsection

NVH in RFD section

NVH in FAX, RAX, FSU, RSU section

NVH in WT section

NVH in WT section

NVHinBRsection

NVHinBRsection

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TYRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom SteeringNoise´ ´ ´´´´´ ´ ´ ´´´´´´ ´

Shake´´´ ´ ´´´´ ´

Vibration´´´´´ ´ ´´ ´

Shimmy´´´ ´ ´´´ ´

Shudder´ ´ ´´´ ´

Page 2652 of 3171

POWER STEERING OIL PUMP

PS-25

C

D

E

F

H

I

J

K

L

MA

B

PS

POWER STEERING OIL PUMPPFP:49110

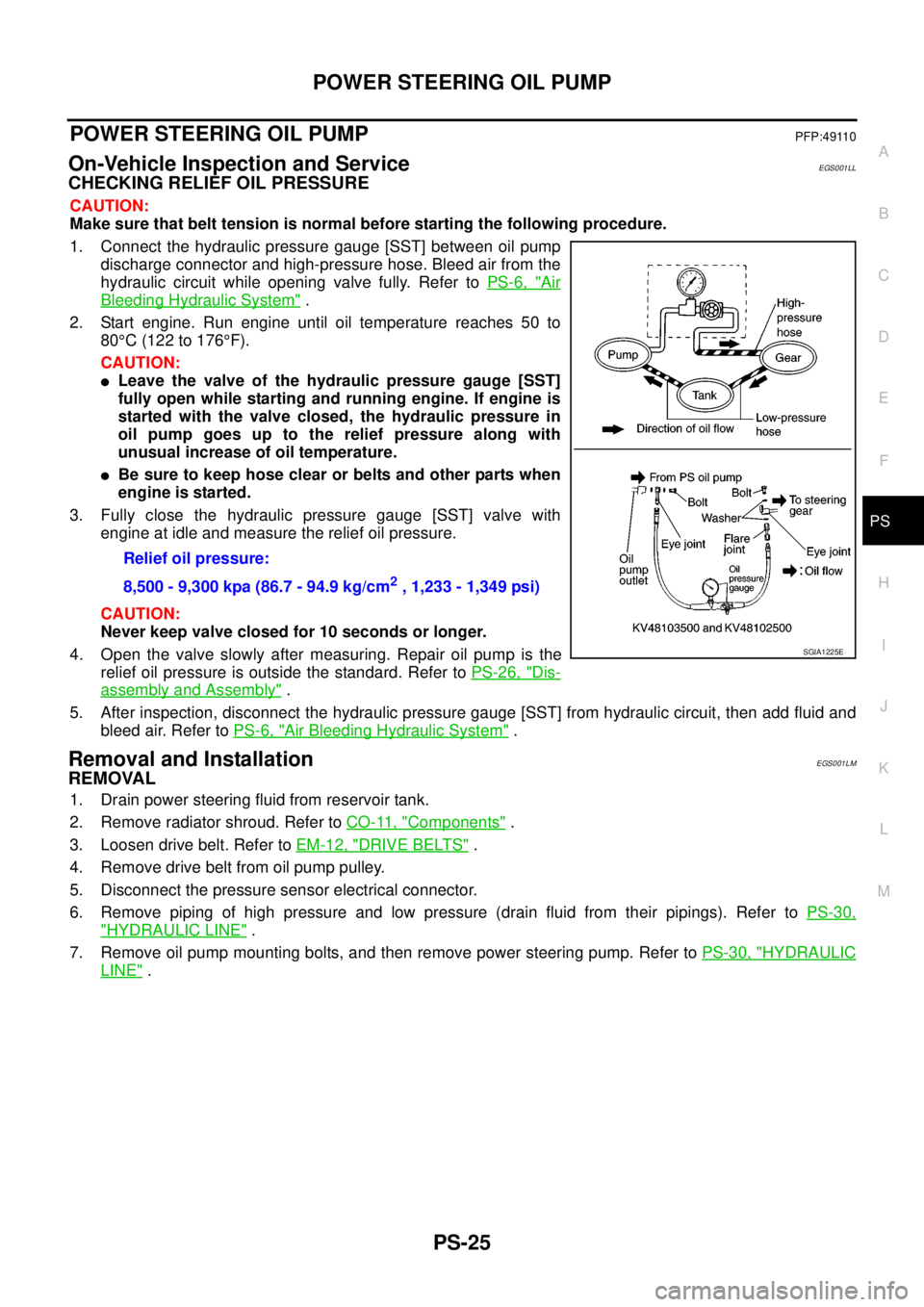

On-Vehicle Inspection and ServiceEGS001LL

CHECKING RELIEF OIL PRESSURE

CAUTION:

Make sure that belt tension is normal before starting the following procedure.

1. Connect the hydraulic pressure gauge [SST] between oil pump

discharge connector and high-pressure hose. Bleed air from the

hydraulic circuit while opening valve fully. Refer toPS-6, "

Air

Bleeding Hydraulic System".

2. Start engine. Run engine until oil temperature reaches 50 to

80°C(122to176°F).

CAUTION:

lLeave the valve of the hydraulic pressure gauge [SST]

fully open while starting and running engine. If engine is

started with the valve closed, the hydraulic pressure in

oil pump goes up to the relief pressure along with

unusual increase of oil temperature.

lBe sure to keep hose clear or belts and other parts when

engineisstarted.

3. Fully close the hydraulic pressure gauge [SST] valve with

engine at idle and measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump is the

relief oil pressure is outside the standard. Refer toPS-26, "

Dis-

assembly and Assembly".

5. After inspection, disconnect the hydraulic pressure gauge [SST] from hydraulic circuit, then add fluid and

bleed air. Refer toPS-6, "

Air Bleeding Hydraulic System".

Removal and InstallationEGS001LM

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove radiator shroud. Refer toCO-11, "

Components".

3. Loosen drive belt. Refer toEM-12, "

DRIVE BELTS".

4. Remove drive belt from oil pump pulley.

5. Disconnect the pressure sensor electrical connector.

6. Remove piping of high pressure and low pressure (drain fluid from their pipings). Refer toPS-30,

"HYDRAULIC LINE".

7. Remove oil pump mounting bolts, and then remove power steering pump. Refer toPS-30, "

HYDRAULIC

LINE". Relief oil pressure:

8,500 - 9,300 kpa (86.7 - 94.9 kg/cm

2, 1,233 - 1,349 psi)

SGIA1225E

Page 2653 of 3171

PS-26

POWER STEERING OIL PUMP

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer toPS-30, "HYDRAULIC LINE".

lPerform the following procedure after installing.

–Adjust belt tension. Refer toEM-12, "DRIVE BELTS".

–Bleed air. Refer toPS-6, "Air Bleeding Hydraulic System".

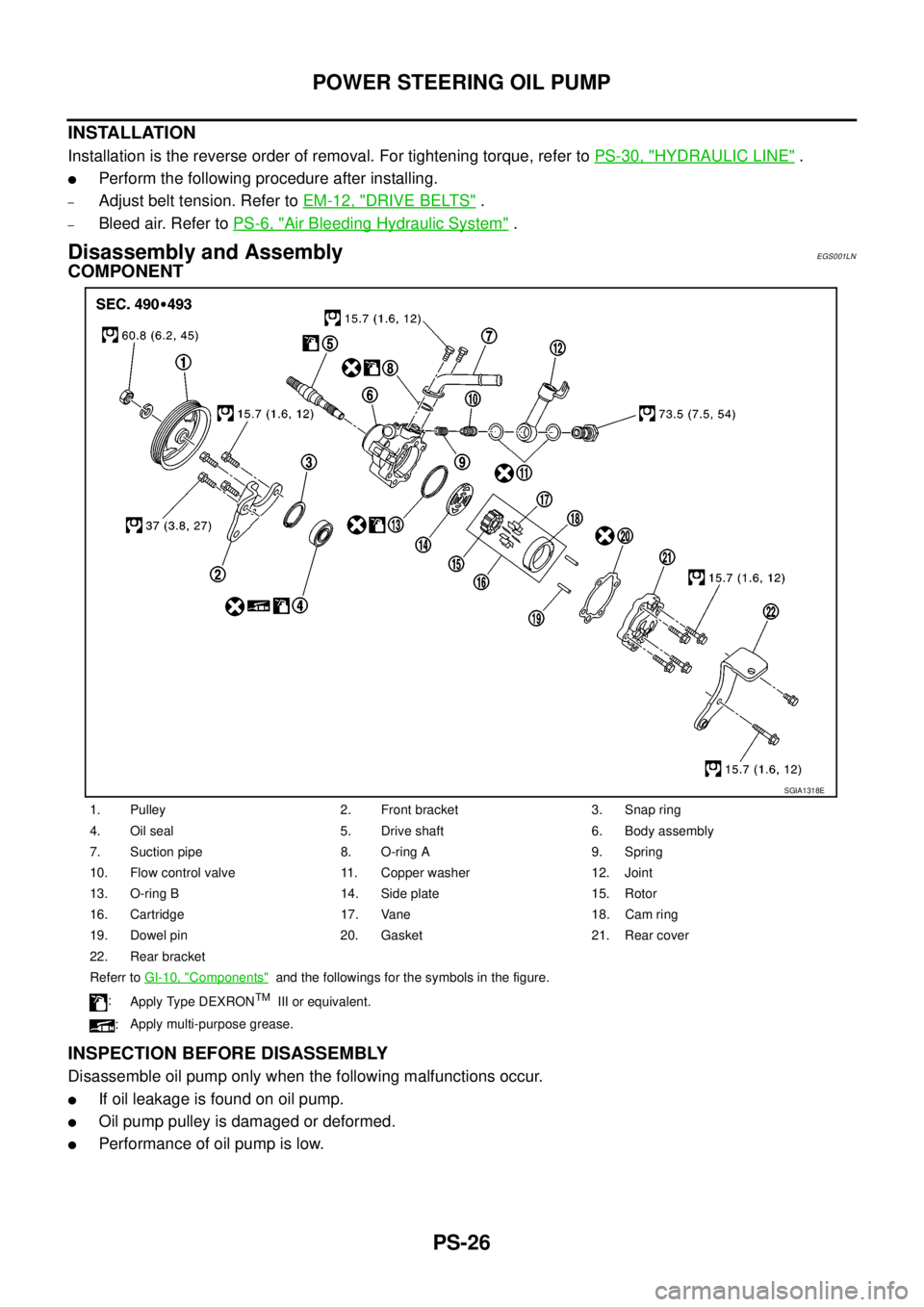

Disassembly and AssemblyEGS001LN

COMPONENT

INSPECTION BEFORE DISASSEMBLY

Disassemble oil pump only when the following malfunctions occur.

lIf oil leakage is found on oil pump.

lOil pump pulley is damaged or deformed.

lPerformance of oil pump is low.

1. Pulley 2. Front bracket 3. Snap ring

4. Oil seal 5. Drive shaft 6. Body assembly

7. Suction pipe 8. O-ring A 9. Spring

10. Flow control valve 11. Copper washer 12. Joint

13. O-ring B 14. Side plate 15. Rotor

16. Cartridge 17. Vane 18. Cam ring

19. Dowel pin 20. Gasket 21. Rear cover

22. Rear bracket

Referr toGI-10, "

Components"and the followings for the symbols in the figure.

:

Apply Type DEXRON

TMIII or equivalent.

:Apply multi-purpose grease.

SGIA1318E

Page 2678 of 3171

RF-1

ROOF

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONRF

A

B

RF

ROOF

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Commercial Service Tool ......................................... 3

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 4

Work Flow ................................................................ 4

CUSTOMER INTERVIEW ..................................... 4

DUPLICATE THE NOISE AND TEST DRIVE ....... 5

CHECK RELATED SERVICE BULLETINS ........... 5

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 5

REPAIR THE CAUSE ........................................... 5

CONFIRM THE REPAIR ....................................... 6

Generic Squeak and Rattle Troubleshooting ........... 6

INSTRUMENT PANEL .......................................... 6

CENTER CONSOLE ............................................. 6

DOORS ................................................................. 6

TRUNK .................................................................. 7

SUNROOF/HEADLINING ..................................... 7

SEATS ................................................................... 7

UNDERHOOD ....................................................... 7

Diagnostic Worksheet .............................................. 8

SUNROOF ................................................................ 10

Component Parts and Harness Connector Location... 10

System Description ................................................. 11

TILT UP / SLIDE CLOSE OPERATION ................ 11

TILT DOWN / SLIDE OPEN OPERATION ........... 11AUTO OPERATION ............................................. 11

ANTI-PINCH FUNCTION .................................... 11

MEMORY RESET PROCEDURE ....................... 12

INITIALIZATION PROCEDURE .......................... 12

CAN Communication System Description .............. 13

CAN Communication Unit ....................................... 13

Wiring Diagram — SROOF — ................................ 14

Terminals and Reference Value for BCM ............... 15

Terminals and Reference Value for Sunroof Motor

Assembly ................................................................ 15

Work Flow ............................................................... 16

Trouble Diagnosis Symptom Chart ......................... 16

BCM Power Supply and Ground Circuit Check ...... 16

Sunroof Motor Assembly Power Supply and Ground

Circuit Check .......................................................... 17

Sunroof Switch System Check ............................... 18

Fitting Adjustment ................................................... 20

GAP ADJUSTMENT ............................................ 20

HEIGHT DIFFERENCE ADJUSTMENT .............. 20

Removal and Installation ........................................ 21

SUNROOF UNIT ................................................. 22

GLASS LID .......................................................... 22

WIND DEFLECTOR ............................................ 23

SUNSHADE ........................................................ 23

SUNROOF MOTOR ............................................ 23

DRAIN HOSES .................................................... 25

WEATHERSTRIP ................................................ 25

REAR DRAIN ASSEMBLY .................................. 25

LINK AND WIRE ASSEMBLY ............................. 26

Page 2679 of 3171

RF-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EIS00CE9

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

PrecautionsEIS00B92

lDisconnect both battery cables in advance.

lNever tamper with or force air bag lid open, as this may adversely affect air bag performance.

lBe careful not to scratch pad and other parts.

lWhen removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

lWhen removing parts with a screwdriver or other tool, protect parts by wrapping them with vinyl or tape.

lKeep removed parts protected with cloth.

lIf a clip is deformed or damaged, replace it.

lIf an unreusable part is removed, replace it with a new one.

lTighten bolts and nuts firmly to the specified torque.

lAfter re-assembly has been completed, make sure each part functions correctly.

lRemove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Thenwipetheareawithasoftdrycloth.

lDo not use any organic solvent, such as thinner or benzine.

Page 2704 of 3171

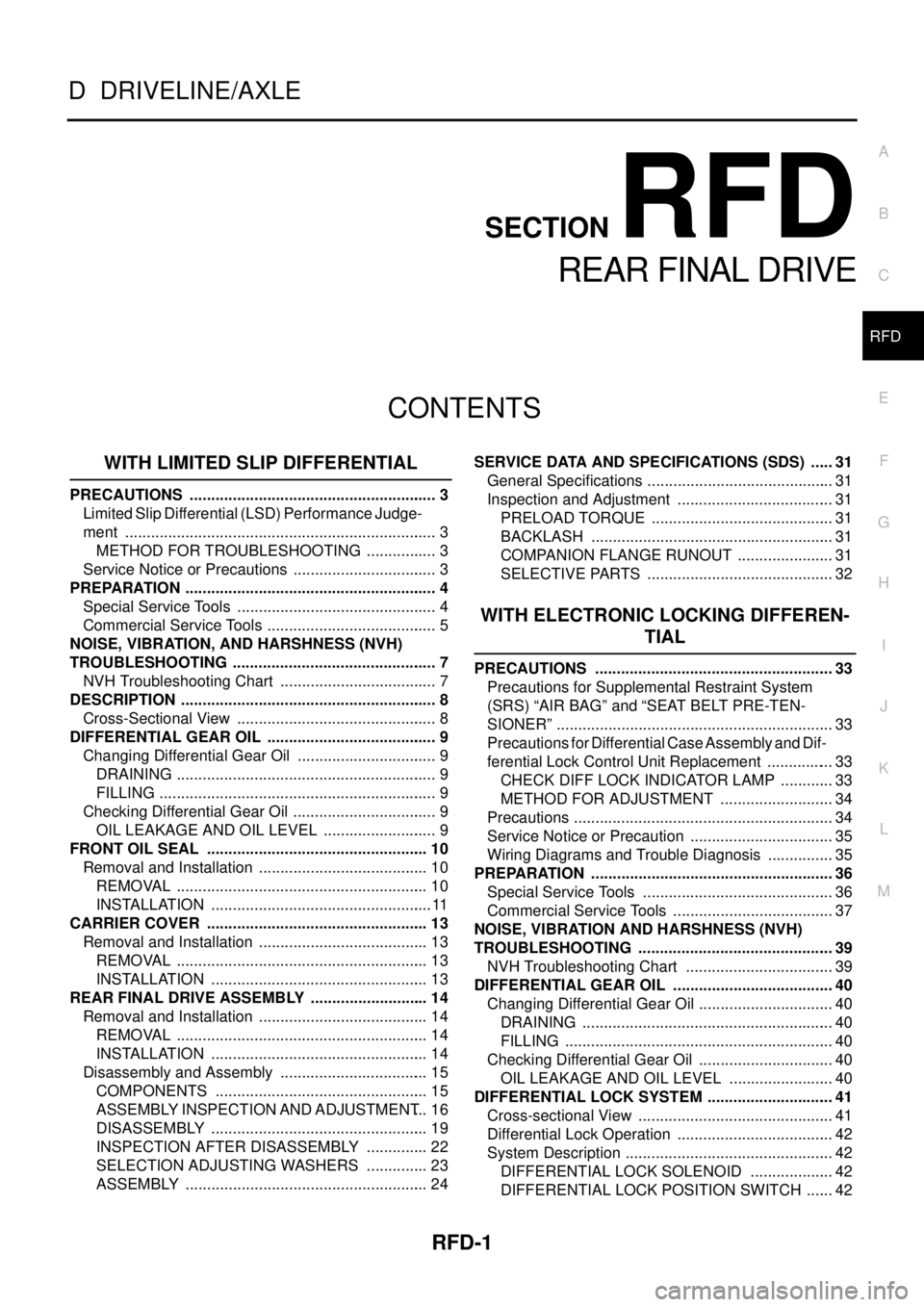

RFD-1

REAR FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTIONRFD

A

B

RFD

REAR FINAL DRIVE

WITH LIMITED SLIP DIFFERENTIAL

PRECAUTIONS .......................................................... 3

Limited Slip Differential (LSD) Performance Judge-

ment ......................................................................... 3

METHOD FOR TROUBLESHOOTING ................. 3

Service Notice or Precautions .................................. 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 5

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

DESCRIPTION ............................................................ 8

Cross-Sectional View ............................................... 8

DIFFERENTIAL GEAR OIL ........................................ 9

Changing Differential Gear Oil ................................. 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking Differential Gear Oil .................................. 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

FRONT OIL SEAL .................................................... 10

Removal and Installation ........................................ 10

REMOVAL ........................................................... 10

INSTALLATION .................................................... 11

CARRIER COVER .................................................... 13

Removal and Installation ........................................ 13

REMOVAL ........................................................... 13

INSTALLATION ................................................... 13

REAR FINAL DRIVE ASSEMBLY ............................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Disassembly and Assembly ................................... 15

COMPONENTS .................................................. 15

ASSEMBLY INSPECTION AND ADJUSTMENT... 16

DISASSEMBLY ................................................... 19

INSPECTION AFTER DISASSEMBLY ............... 22

SELECTION ADJUSTING WASHERS ............... 23

ASSEMBLY ......................................................... 24SERVICE DATA AND SPECIFICATIONS (SDS) ...... 31

General Specifications ............................................ 31

Inspection and Adjustment ..................................... 31

PRELOAD TORQUE ........................................... 31

BACKLASH ......................................................... 31

COMPANION FLANGE RUNOUT ....................... 31

SELECTIVE PARTS ............................................ 32

WITH ELECTRONIC LOCKING DIFFEREN-

TIAL

PRECAUTIONS ........................................................ 33

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” ................................................................. 33

Precautions for Differential Case Assembly and Dif-

ferential Lock Control Unit Replacement ................ 33

CHECK DIFF LOCK INDICATOR LAMP ............. 33

METHOD FOR ADJUSTMENT ........................... 34

Precautions ............................................................. 34

Service Notice or Precaution .................................. 35

Wiring Diagrams and Trouble Diagnosis ................ 35

PREPARATION ......................................................... 36

Special Service Tools ............................................. 36

Commercial Service Tools ...................................... 37

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 39

NVH Troubleshooting Chart ................................... 39

DIFFERENTIAL GEAR OIL ...................................... 40

Changing Differential Gear Oil ................................ 40

DRAINING ........................................................... 40

FILLING ............................................................... 40

Checking Differential Gear Oil ................................ 40

OIL LEAKAGE AND OIL LEVEL ......................... 40

DIFFERENTIAL LOCK SYSTEM .............................. 41

Cross-sectional View .............................................. 41

Differential Lock Operation ..................................... 42

System Description ................................................. 42

DIFFERENTIAL LOCK SOLENOID .................... 42

DIFFERENTIAL LOCK POSITION SWITCH ....... 42

Page 2736 of 3171

![NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A NISSAN NAVARA 2005 Repair Workshop Manual PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “A](/img/5/57362/w960_57362-2735.png)

PRECAUTIONS

RFD-33

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

[WITH ELECTRONIC LOCKING DIFFERENTIAL]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EDS003IE

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Differential Case Assembly and Differential Lock Control Unit

Replacement

EDS003AG

lWhen replacing differential case assembly or differential lock control unit, check the DIFF LOCK indicator

pattern and adjustment of the position between differential case assembly and differential lock control unit

if necessary.

CHECK DIFF LOCK INDICATOR LAMP

1. Start engine. Run engine for at least 10 seconds.

2. Turn 4WD shift switch to “4LO” and confirm 4LO indicator lamp is turned on. Refer toTF-16, "

4WD SHIFT

SWITCH AND INDICATOR LAMP".

3. Stop vehicle and turn differential lock mode switch to “ON”.

4. Drive vehicle at 7 km/h (4 MPH) or less.

NOTE:

Differential case assembly must be given a rotation from rear left wheel and rear right wheel.

5. Check if DIFF LOCK indicator lamp flashes to turn on.

6. Check if DIFF LOCK indicator lamp and 4LO indicator lamp are changed properly as follows.

lIf each indication and state is OK, rear final drive assembly and differential lock control unit is working cor-

rectly.

lIf each indication and state is NG, rear final drive assembly and differential lock control unit is not working

correctly. Refer toRFD-34, "

METHOD FOR ADJUSTMENT".

Differential lock mode

switch4LO indicator lamp Vehicle speed (VSS)Differential case assem-

bly stateDIFF LOCK indicator

lamp

ONOFF7 km/h (4 MPH) < VSS

Disengage Flash VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7 km/h (4 MPH) Disengage®Engage Flash®ON

OFFOFF7 km/h (4 MPH) < VSS

Disengage OFF VSS£7km/h(4MPH)

ON7 km/h (4 MPH) < VSS

VSS£7km/h(4MPH)