display NISSAN NAVARA 2005 Repair Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 177 of 3171

BRAKE SIGNAL CIRCUIT

AT-169

D

E

F

G

H

I

J

K

L

MA

B

AT

BRAKE SIGNAL CIRCUITPFP:25320

CONSULT-II Reference ValueECS00G26

Diagnostic ProcedureECS00G27

1.CHECK CAN COMMUNICATION LINE

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is a malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK STOP LAMP SWITCH CIRCUIT

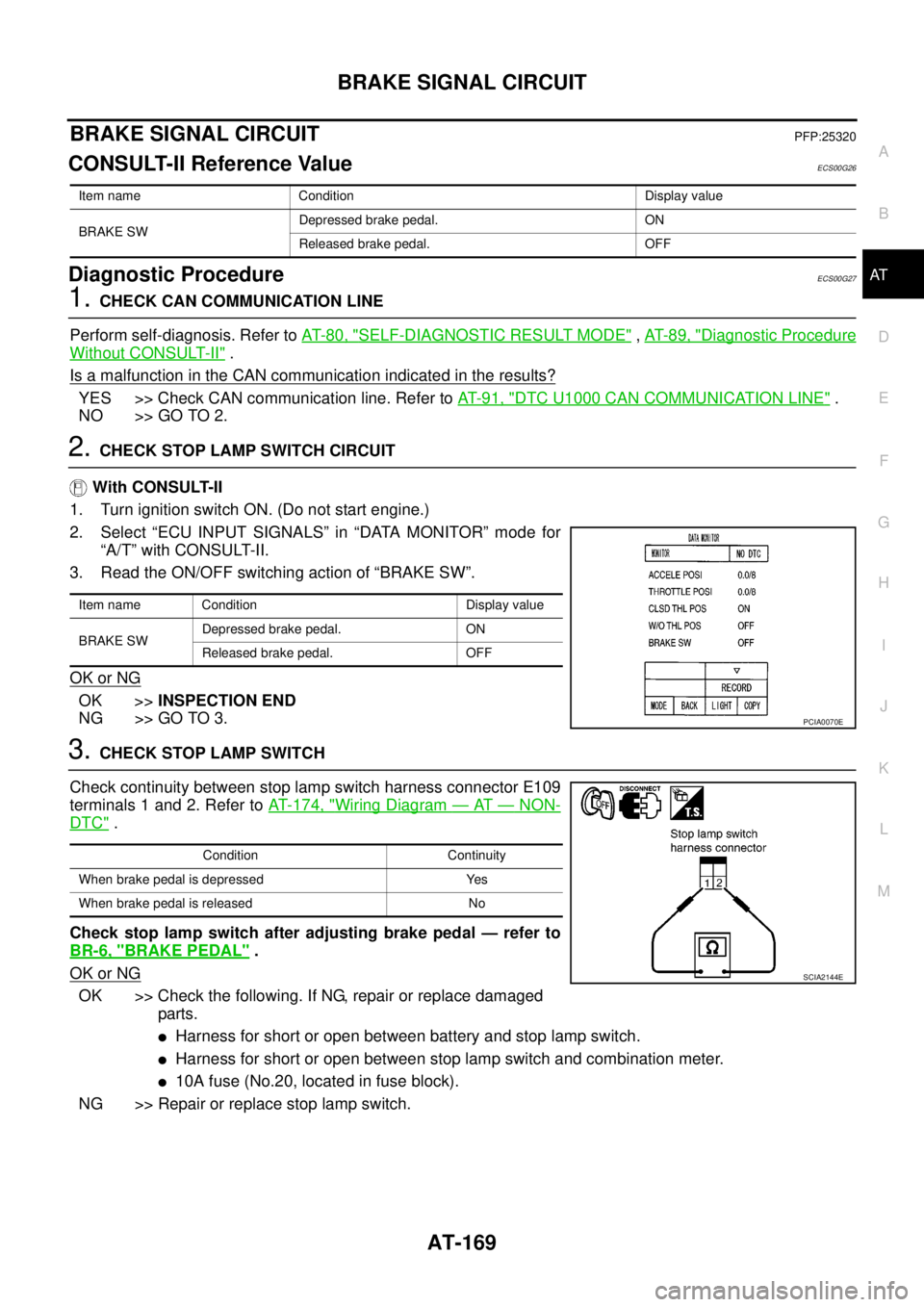

With CONSULT-II

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read the ON/OFF switching action of “BRAKE SW”.

OK or NG

OK >>INSPECTION END

NG >> GO TO 3.

3.CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch harness connector E109

terminals 1 and 2. Refer toAT- 1 7 4 , "

Wiring Diagram—AT—NON-

DTC".

Check stop lamp switch after adjusting brake pedal — refer to

BR-6, "

BRAKE PEDAL".

OK or NG

OK >> Check the following. If NG, repair or replace damaged

parts.

lHarness for short or open between battery and stop lamp switch.

lHarness for short or open between stop lamp switch and combination meter.

l10A fuse (No.20, located in fuse block).

NG >> Repair or replace stop lamp switch.

Item name Condition Display value

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

Item name Condition Display value

BRAKE SWDepressed brake pedal. ON

Released brake pedal. OFF

PCIA0070E

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SCIA2144E

Page 178 of 3171

AT-170

1ST POSITION SWITCH

1ST POSITION SWITCH

PFP:31918

CONSULT-II Reference ValueECS00I5W

Diagnostic ProcedureECS00I5X

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK 1ST POSITION SWITCH CIRCUIT

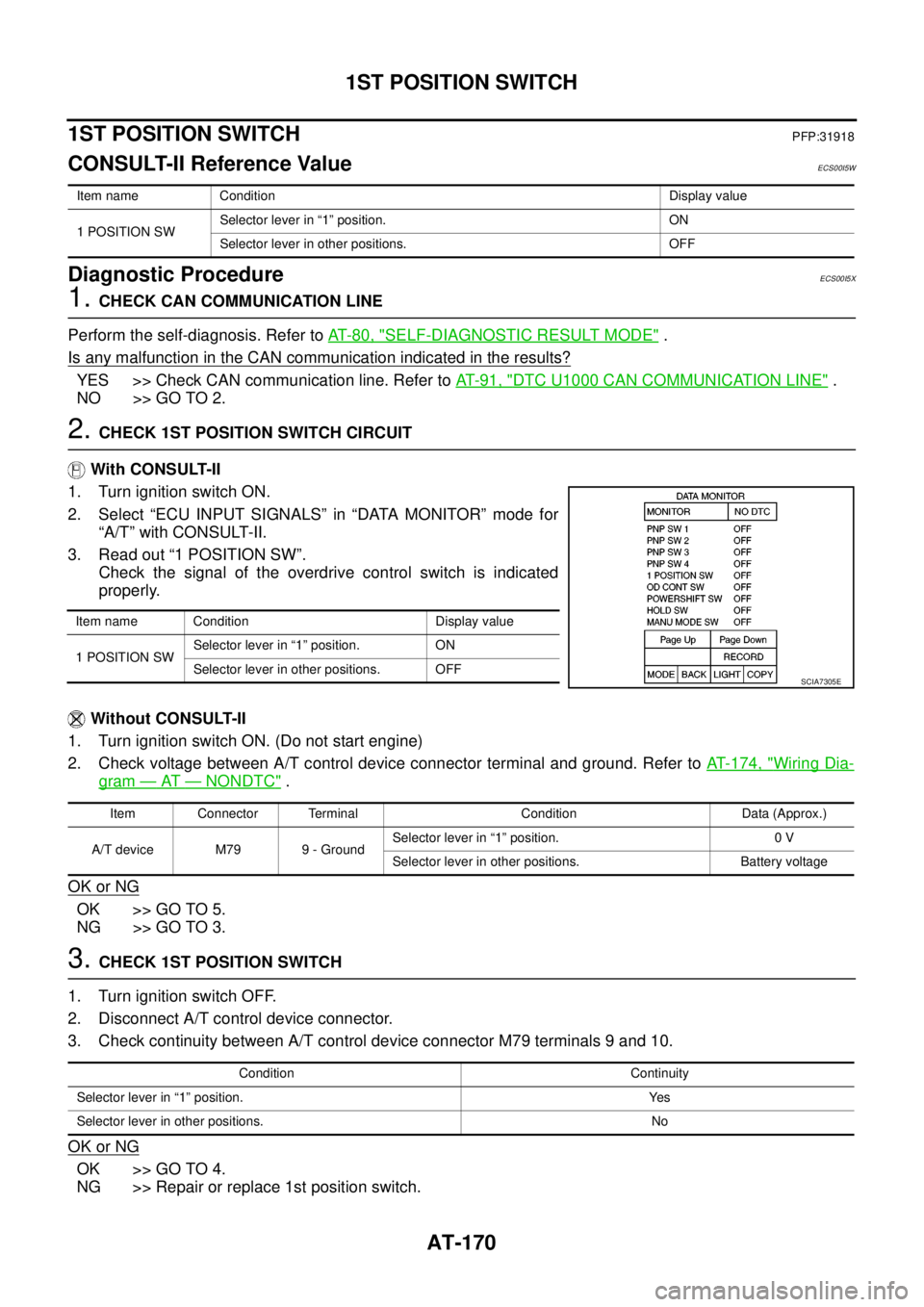

With CONSULT-II

1. Turn ignition switch ON.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “1 POSITION SW”.

Check the signal of the overdrive control switch is indicated

properly.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T control device connector terminal and ground. Refer toAT- 1 7 4 , "

Wiring Dia-

gram—AT—NONDTC".

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK 1ST POSITION SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T control device connector.

3. Check continuity between A/T control device connector M79 terminals 9 and 10.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace 1st position switch.

Item name Condition Display value

1 POSITION SWSelector lever in “1” position. ON

Selector lever in other positions. OFF

Item name Condition Display value

1 POSITION SWSelector lever in “1” position. ON

Selector lever in other positions. OFF

SCIA7305E

Item Connector Terminal Condition Data (Approx.)

A/T device M79 9 - GroundSelector lever in “1” position. 0 V

Selector lever in other positions. Battery voltage

Condition Continuity

Selector lever in “1” position. Yes

Selector lever in other positions. No

Page 180 of 3171

AT-172

OVERDRIVE CONTROL SWITCH

OVERDRIVE CONTROL SWITCH

PFP:25130

CONSULT-II Reference ValueECS00HQY

Diagnostic ProcedureECS00HQZ

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE".

Is any malfunction in the CAN communication indicated in the results?

YES >> Check CAN communication line. Refer toAT-91, "DTC U1000 CAN COMMUNICATION LINE".

NO >> GO TO 2.

2.CHECK OVERDRIVE CONTOROL SWITCH CIRCUIT

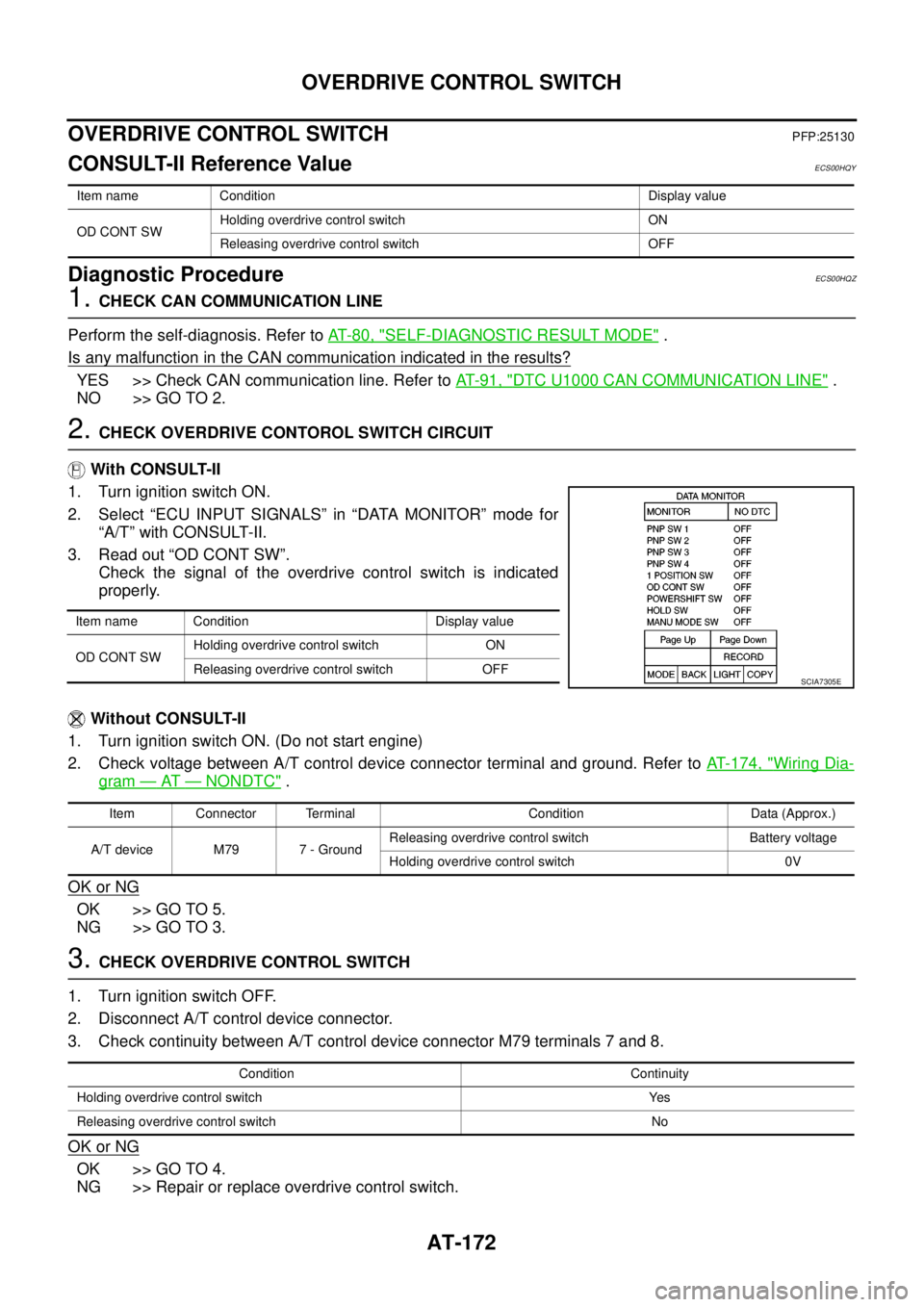

With CONSULT-II

1. Turn ignition switch ON.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Read out “OD CONT SW”.

Check the signal of the overdrive control switch is indicated

properly.

Without CONSULT-II

1. Turn ignition switch ON. (Do not start engine)

2. Check voltage between A/T control device connector terminal and ground. Refer toAT- 1 7 4 , "

Wiring Dia-

gram—AT—NONDTC".

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

3.CHECK OVERDRIVE CONTROL SWITCH

1. Turn ignition switch OFF.

2. Disconnect A/T control device connector.

3. Check continuity between A/T control device connector M79 terminals 7 and 8.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace overdrive control switch.

Item name Condition Display value

OD CONT SWHolding overdrive control switch ON

Releasing overdrive control switch OFF

Item name Condition Display value

OD CONT SWHolding overdrive control switch ON

Releasing overdrive control switch OFF

SCIA7305E

Item Connector Terminal Condition Data (Approx.)

A/T device M79 7 - GroundReleasing overdrive control switch Battery voltage

Holding overdrive control switch 0V

Condition Continuity

Holding overdrive control switch Yes

Releasing overdrive control switch No

Page 335 of 3171

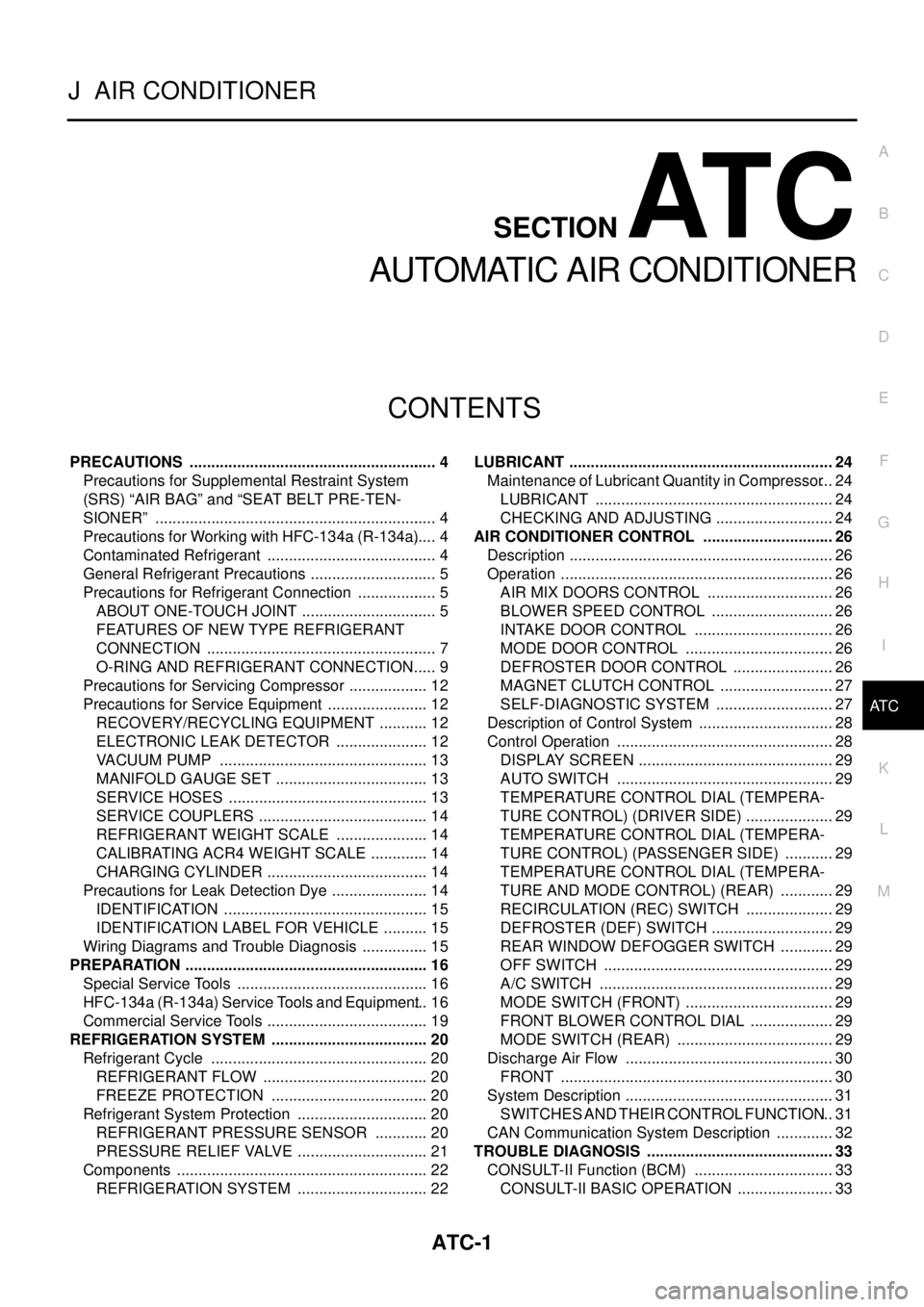

ATC-1

AUTOMATIC AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTIONAT C

A

B

AT C

AUTOMATIC AIR CONDITIONER

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for Working with HFC-134a (R-134a)..... 4

Contaminated Refrigerant ........................................ 4

General Refrigerant Precautions .............................. 5

Precautions for Refrigerant Connection ................... 5

ABOUT ONE-TOUCH JOINT ................................ 5

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION ...................................................... 7

O-RING AND REFRIGERANT CONNECTION..... 9

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 12

RECOVERY/RECYCLING EQUIPMENT ............ 12

ELECTRONIC LEAK DETECTOR ...................... 12

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 13

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CALIBRATING ACR4 WEIGHT SCALE .............. 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 14

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

Wiring Diagrams and Trouble Diagnosis ................ 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment... 16

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 21

Components ........................................................... 22

REFRIGERATION SYSTEM ............................... 22LUBRICANT .............................................................. 24

Maintenance of Lubricant Quantity in Compressor... 24

LUBRICANT ........................................................ 24

CHECKING AND ADJUSTING ............................ 24

AIR CONDITIONER CONTROL ............................... 26

Description .............................................................. 26

Operation ................................................................ 26

AIR MIX DOORS CONTROL .............................. 26

BLOWER SPEED CONTROL ............................. 26

INTAKE DOOR CONTROL ................................. 26

MODE DOOR CONTROL ................................... 26

DEFROSTER DOOR CONTROL ........................ 26

MAGNET CLUTCH CONTROL ........................... 27

SELF-DIAGNOSTIC SYSTEM ............................ 27

Description of Control System ................................ 28

Control Operation ................................................... 28

DISPLAY SCREEN .............................................. 29

AUTO SWITCH ................................................... 29

TEMPERATURE CONTROL DIAL (TEMPERA-

TURE CONTROL) (DRIVER SIDE) ..................... 29

TEMPERATURE CONTROL DIAL (TEMPERA-

TURE CONTROL) (PASSENGER SIDE) ............ 29

TEMPERATURE CONTROL DIAL (TEMPERA-

TURE AND MODE CONTROL) (REAR) ............. 29

RECIRCULATION (REC) SWITCH ..................... 29

DEFROSTER (DEF) SWITCH ............................. 29

REAR WINDOW DEFOGGER SWITCH ............. 29

OFF SWITCH ...................................................... 29

A/C SWITCH ....................................................... 29

MODE SWITCH (FRONT) ................................... 29

FRONT BLOWER CONTROL DIAL .................... 29

MODE SWITCH (REAR) ..................................... 29

Discharge Air Flow ................................................. 30

FRONT ................................................................ 30

System Description ................................................. 31

SWITCHES AND THEIR CONTROL FUNCTION... 31

CAN Communication System Description .............. 32

TROUBLE DIAGNOSIS ............................................ 33

CONSULT-II Function (BCM) ................................. 33

CONSULT-II BASIC OPERATION ....................... 33

Page 347 of 3171

PRECAUTIONS

ATC-13

C

D

E

F

G

H

I

K

L

MA

B

AT C

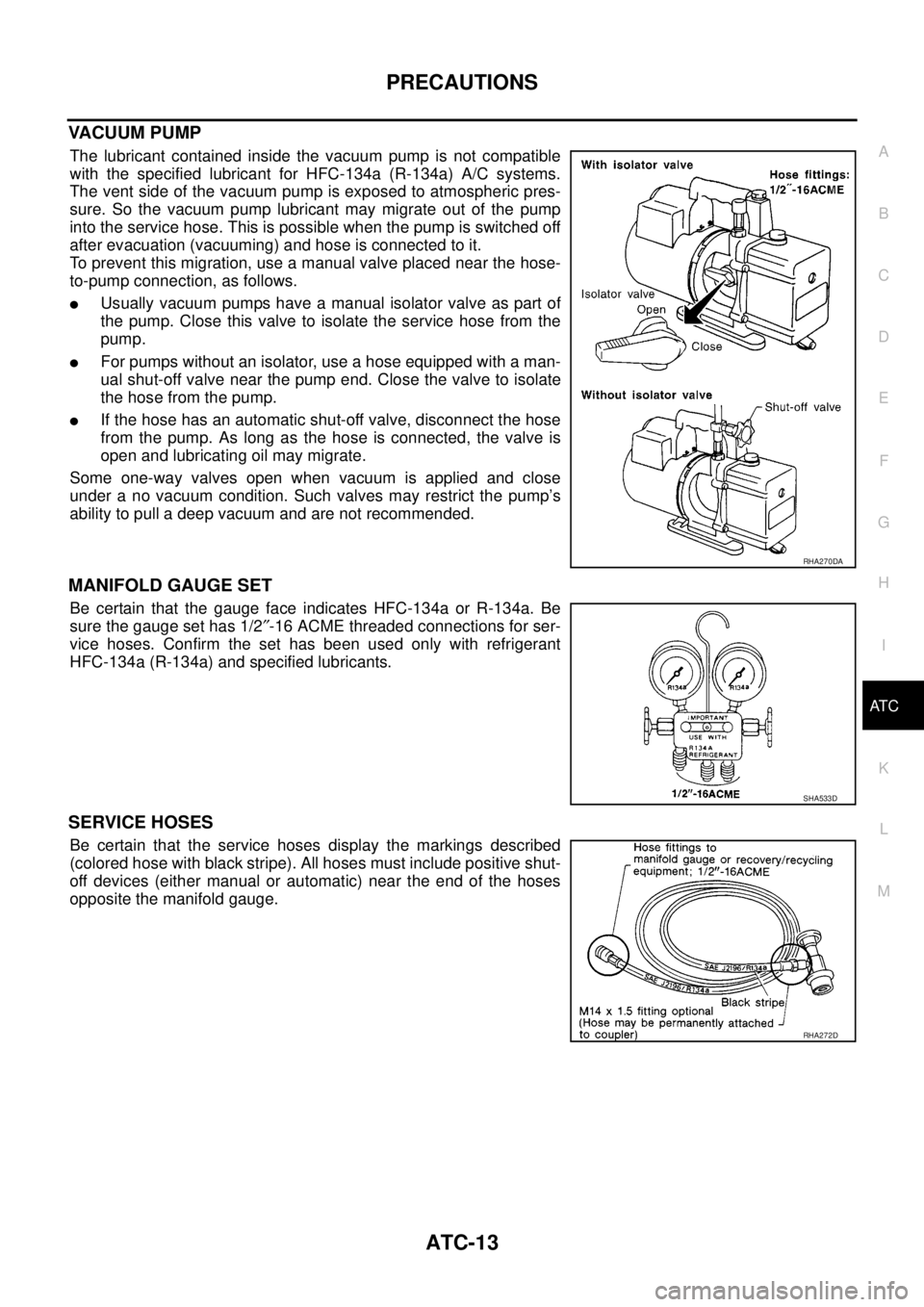

VACUUM PUMP

The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

The vent side of the vacuum pump is exposed to atmospheric pres-

sure. So the vacuum pump lubricant may migrate out of the pump

into the service hose. This is possible when the pump is switched off

after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve placed near the hose-

to-pump connection, as follows.

lUsually vacuum pumps have a manual isolator valve as part of

the pump. Close this valve to isolate the service hose from the

pump.

lFor pumps without an isolator, use a hose equipped with a man-

ual shut-off valve near the pump end. Close the valve to isolate

the hose from the pump.

lIf the hose has an automatic shut-off valve, disconnect the hose

from the pump. As long as the hose is connected, the valve is

open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump’s

ability to pull a deep vacuum and are not recommended.

MANIFOLD GAUGE SET

Be certain that the gauge face indicates HFC-134a or R-134a. Be

sure the gauge set has 1/2²-16 ACME threaded connections for ser-

vice hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) and specified lubricants.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

RHA270DA

SHA533D

RHA272D

Page 348 of 3171

ATC-14

PRECAUTIONS

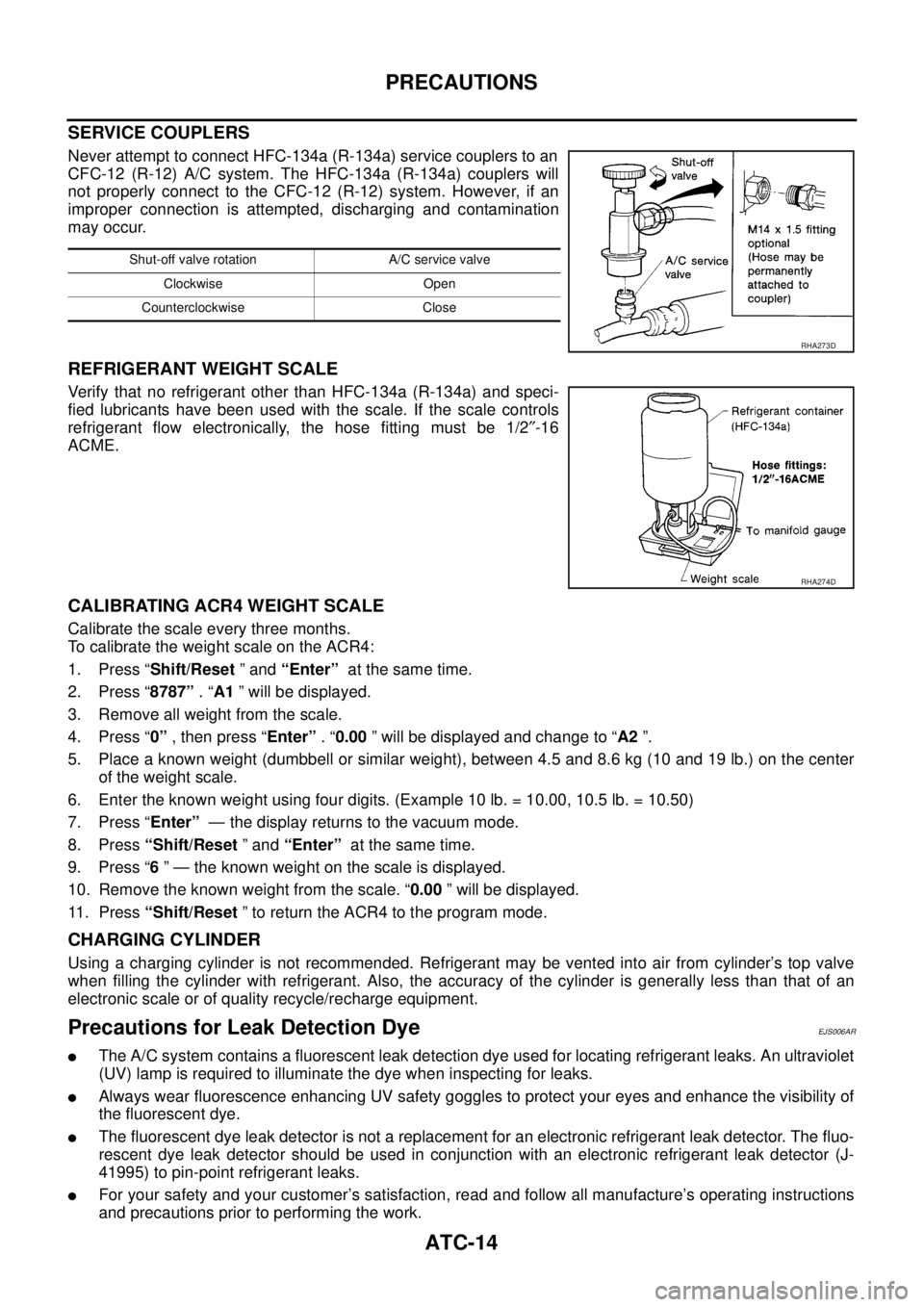

SERVICE COUPLERS

Never attempt to connect HFC-134a (R-134a) service couplers to an

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

REFRIGERANT WEIGHT SCALE

Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. If the scale controls

refrigerant flow electronically, the hose fitting must be 1/2²-16

ACME.

CALIBRATING ACR4 WEIGHT SCALE

Calibrate the scale every three months.

To calibrate the weight scale on the ACR4:

1. Press “Shift/Reset”and“Enter”at the same time.

2. Press “8787”.“A1” will be displayed.

3. Remove all weight from the scale.

4. Press “0”, then press “Enter”.“0.00” will be displayed and change to “A2”.

5. Place a known weight (dumbbell or similar weight), between 4.5 and 8.6 kg (10 and 19 lb.) on the center

of the weight scale.

6. Enter the known weight using four digits. (Example 10 lb. = 10.00, 10.5 lb. = 10.50)

7. Press “Enter”— the display returns to the vacuum mode.

8. Press“Shift/Reset”and“Enter”at the same time.

9. Press “6” — the known weight on the scale is displayed.

10. Remove the known weight from the scale. “0.00” will be displayed.

11. Press“Shift/Reset” to return the ACR4 to the program mode.

CHARGING CYLINDER

Using a charging cylinder is not recommended. Refrigerant may be vented into air from cylinder’s top valve

when filling the cylinder with refrigerant. Also, the accuracy of the cylinder is generally less than that of an

electronic scale or of quality recycle/recharge equipment.

Precautions for Leak Detection DyeEJS006AR

lThe A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

lAlways wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

lThe fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjunction with an electronic refrigerant leak detector (J-

41995) to pin-point refrigerant leaks.

lFor your safety and your customer’s satisfaction, read and follow all manufacture’s operating instructions

and precautions prior to performing the work.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

RHA274D

Page 358 of 3171

ATC-24

LUBRICANT

LUBRICANT

PFP:KLG00

Maintenance of Lubricant Quantity in CompressorEJS006AZ

The lubricant in the compressor circulates through the system with the refrigerant. Add lubricant to compres-

sor when replacing any component or after a large refrigerant leakage has occurred. It is important to maintain

the specified amount.

If lubricant quantity is not maintained properly, the following malfunctions may result:

lLack of lubricant: May lead to a seized compressor

lExcessive lubricant: Inadequate cooling (thermal exchange interference)

LUBRICANT

Name: NISSAN A/C System Lubricant Type S (DH-PS) or equivalent

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

Start the engine and set the following conditions:

Test Condition

lEngine speed: Idling to 1,200 rpm

lA/C switch: On

lBlower speed: Max. position

lTemp. control: Optional [Set so that intake air temperature is 25°to 30°C(77°to 86°F)]

lIntake position: Recirculation ( )

lPerform lubricant return operation for about ten minutes

Adjust the lubricant quantity according to the following table.

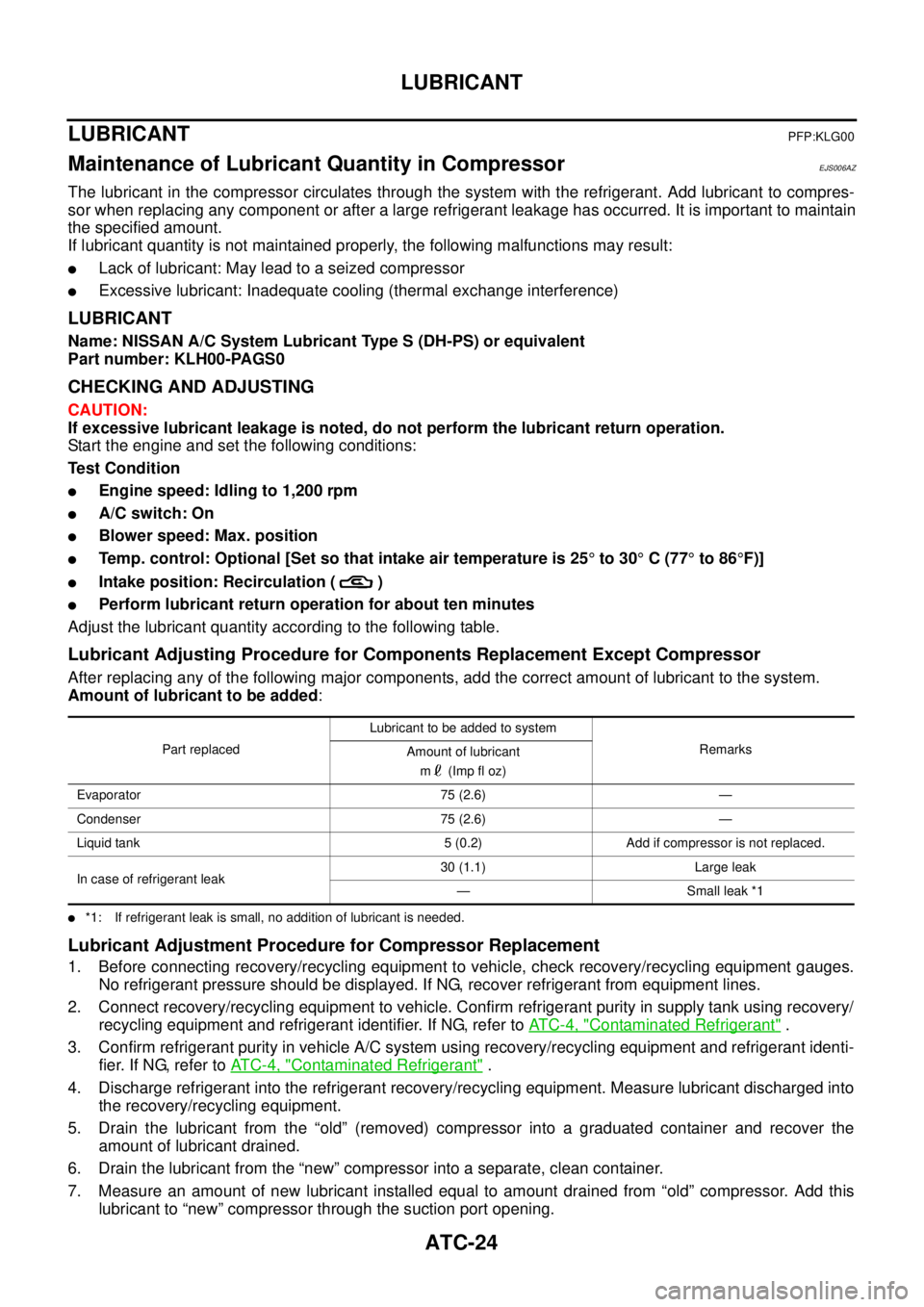

Lubricant Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of lubricant to the system.

Amount of lubricant to be added:

l*1: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjustment Procedure for Compressor Replacement

1. Before connecting recovery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycling equipment to vehicle. Confirm refrigerant purity in supply tank using recovery/

recycling equipment and refrigerant identifier. If NG, refer toAT C - 4 , "

Contaminated Refrigerant".

3. Confirm refrigerant purity in vehicle A/C system using recovery/recycling equipment and refrigerant identi-

fier. If NG, refer toAT C - 4 , "

Contaminated Refrigerant".

4. Discharge refrigerant into the refrigerant recovery/recycling equipment. Measure lubricant discharged into

the recovery/recycling equipment.

5. Drain the lubricant from the “old” (removed) compressor into a graduated container and recover the

amount of lubricant drained.

6. Drain the lubricant from the “new” compressor into a separate, clean container.

7. Measure an amount of new lubricant installed equal to amount drained from “old” compressor. Add this

lubricant to “new” compressor through the suction port opening.

Part replacedLubricant to be added to system

Remarks

Amount of lubricant

m(Impfloz)

Evaporator 75 (2.6) —

Condenser 75 (2.6) —

Liquid tank 5 (0.2) Add if compressor is not replaced.

In case of refrigerant leak30 (1.1) Large leak

— Small leak *1

Page 363 of 3171

AIR CONDITIONER CONTROL

ATC-29

C

D

E

F

G

H

I

K

L

MA

B

AT C

DISPLAY SCREEN

Displays the operational status of the system.

AUTO SWITCH

lThe compressor, intake door, air mix doors, outlet doors and blower speed are automatically controlled so

that the in-vehicle temperature will reach, and be maintained at the set temperature selected by the oper-

ator.

lWhen pressing AUTO switch, air inlet, air outlet, blower speed, and discharge air temperature are auto-

matically controlled.

TEMPERATURE CONTROL DIAL (TEMPERATURE CONTROL) (DRIVER SIDE)

Increases or decreases the set temperature.

TEMPERATURE CONTROL DIAL (TEMPERATURE CONTROL) (PASSENGER SIDE)

Increases or decreases the set temperature.

TEMPERATURE CONTROL DIAL (TEMPERATURE AND MODE CONTROL) (REAR)

Increases or decreases the set temperature. The mode also changes from foot at full hot setting, to foot/vent

mid-range (warm) setting, and then to vent on full cold setting.

RECIRCULATION (REC) SWITCH

lWhen REC switch is ON, REC switch indicator turns ON, and air inlet is set to REC.

lWhen REC switch is turned OFF, or when compressor is turned from ON to OFF, REC switch is automati-

cally turned OFF. REC mode can be re-entered by pressing REC switch again.

lREC switch is not operated when DEF switch is turned ON, or at the D/F position.

DEFROSTER (DEF) SWITCH

Positions the air outlet doors to the defrost position. Also positions the intake doors to the outside air position.

REAR WINDOW DEFOGGER SWITCH

When switch is ON, rear window is defogged.

OFF SWITCH

The compressor and blower are OFF, the intake doors are set to the outside air position, and the air outlet

doors are set to the foot (75% foot and 25% defrost) position.

A/C SWITCH

The compressor is ON or OFF.

(Pressing the A/C switch when the AUTO switch is ON will turn off the A/C switch and compressor.)

MODE SWITCH (FRONT)

Controls the air discharge outlets.

FRONT BLOWER CONTROL DIAL

Manually control the blower speed. Seven speeds are available for manual control (as shown on the display

screen).

MODE SWITCH (REAR)

Controls the air/temperature at discharge outlets.

Page 367 of 3171

TROUBLE DIAGNOSIS

ATC-33

C

D

E

F

G

H

I

K

L

MA

B

AT C

TROUBLE DIAGNOSISPFP:00004

CONSULT-II Function (BCM)EJS006B8

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

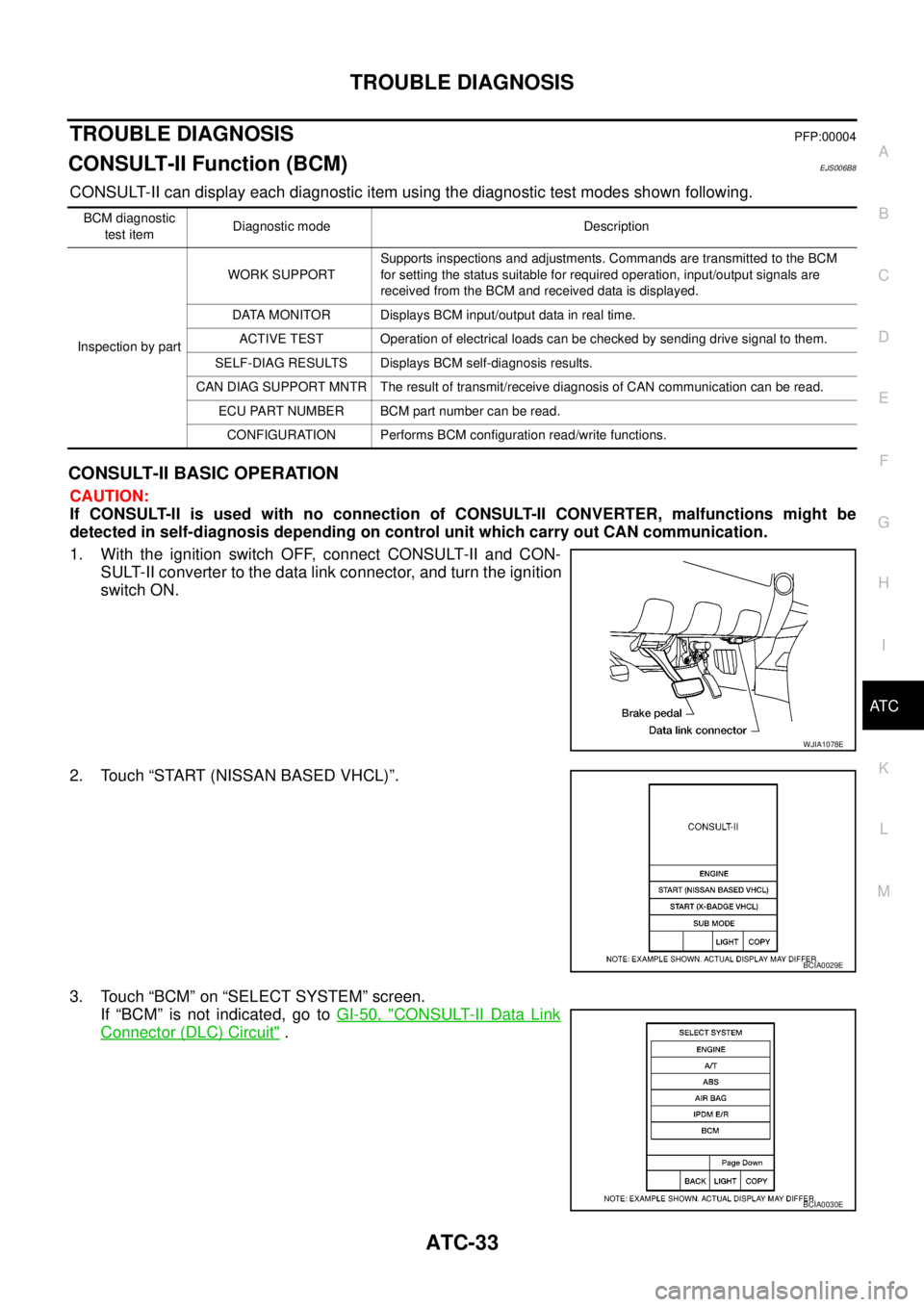

CONSULT-II BASIC OPERATION

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. With the ignition switch OFF, connect CONSULT-II and CON-

SULT-II converter to the data link connector, and turn the ignition

switch ON.

2. Touch “START (NISSAN BASED VHCL)”.

3. Touch “BCM” on “SELECT SYSTEM” screen.

If “BCM” is not indicated, go toGI-50, "

CONSULT-II Data Link

Connector (DLC) Circuit".

BCM diagnostic

test itemDiagnostic mode Description

Inspection by partWORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM

for setting the status suitable for required operation, input/output signals are

received from the BCM and received data is displayed.

DATA MONITOR Displays BCM input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

SELF-DIAG RESULTS Displays BCM self-diagnosis results.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ECU PART NUMBER BCM part number can be read.

CONFIGURATION Performs BCM configuration read/write functions.

WJIA1078E

BCIA0029E

BCIA0030E

Page 368 of 3171

ATC-34

TROUBLE DIAGNOSIS

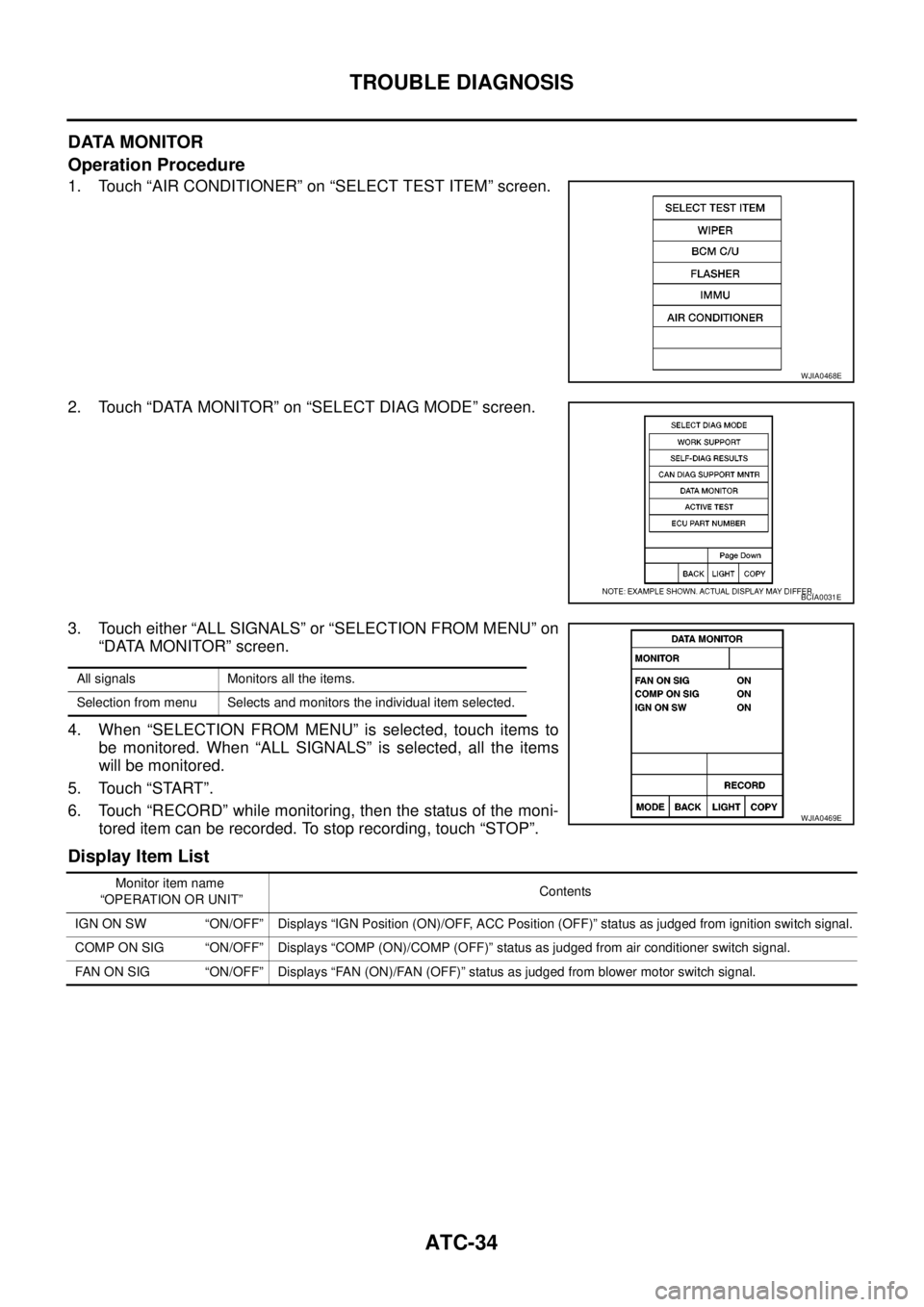

DATA MONITOR

Operation Procedure

1. Touch “AIR CONDITIONER” on “SELECT TEST ITEM” screen.

2. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

3. Touch either “ALL SIGNALS” or “SELECTION FROM MENU” on

“DATA MONITOR” screen.

4. When “SELECTION FROM MENU” is selected, touch items to

be monitored. When “ALL SIGNALS” is selected, all the items

will be monitored.

5. Touch “START”.

6. Touch “RECORD” while monitoring, then the status of the moni-

tored item can be recorded. To stop recording, touch “STOP”.

Display Item List

WJIA0468E

BCIA0031E

All signals Monitors all the items.

Selection from menu Selects and monitors the individual item selected.

WJIA0469E

Monitor item name

“OPERATION OR UNIT”Contents

IGN ON SW “ON/OFF” Displays “IGN Position (ON)/OFF, ACC Position (OFF)” status as judged from ignition switch signal.

COMP ON SIG “ON/OFF” Displays “COMP (ON)/COMP (OFF)” status as judged from air conditioner switch signal.

FAN ON SIG “ON/OFF” Displays “FAN (ON)/FAN (OFF)” status as judged from blower motor switch signal.