ABS NISSAN NAVARA 2005 Repair Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1189 of 3171

DTC P0580, P0581 ASCD STEERING SWITCH

EC-209

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KIA

1.CHECK GROUND CONNECTIONS

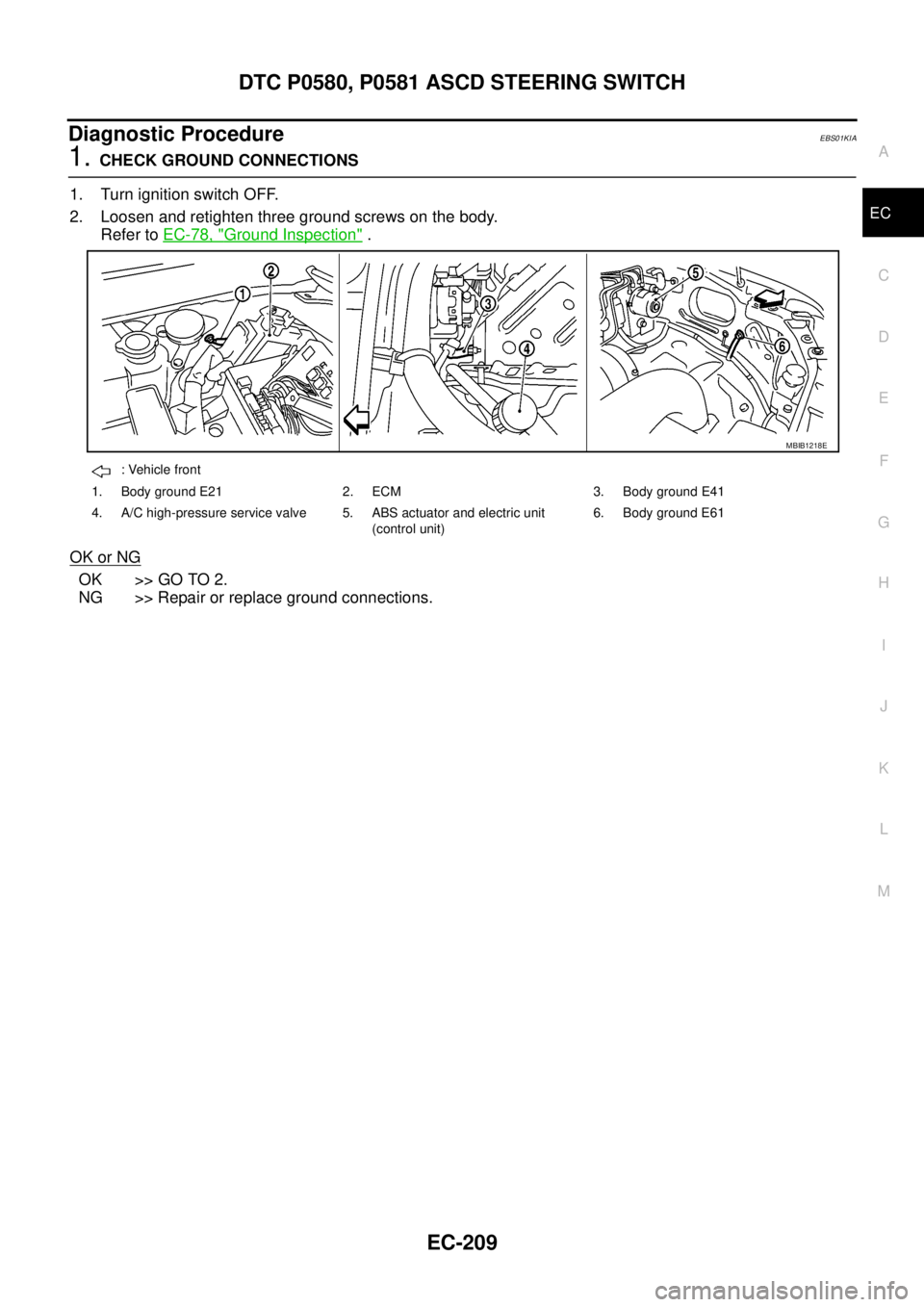

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

Page 1205 of 3171

DTC P0642, P0643 SENSOR POWER SUPPLY

EC-225

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KIX

1.CHECK GROUND CONNECTIONS

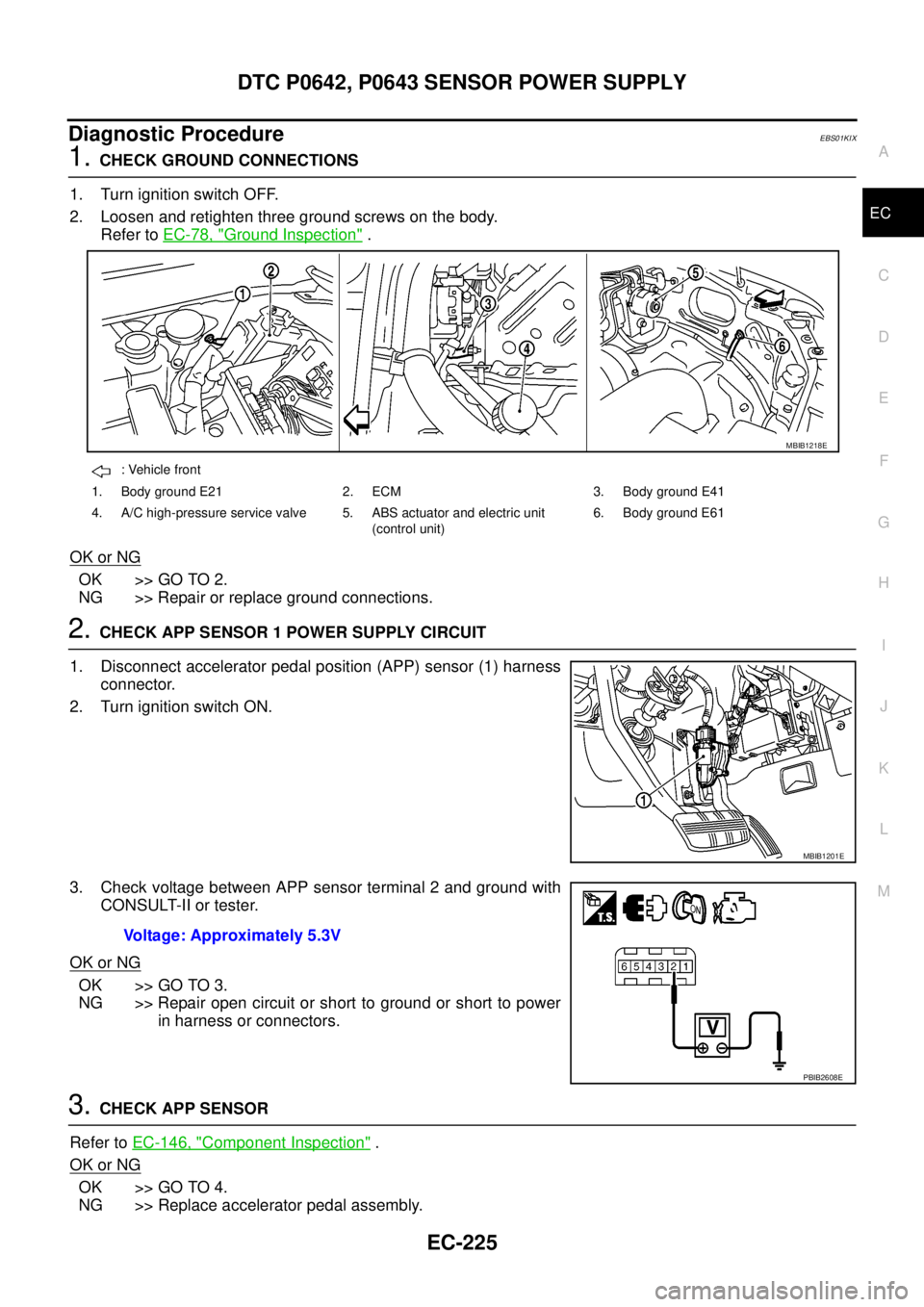

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK APP SENSOR 1 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor (1) harness

connector.

2. Turn ignition switch ON.

3. Check voltage between APP sensor terminal 2 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

3.CHECK APP SENSOR

Refer toEC-146, "

Component Inspection".

OK or NG

OK >> GO TO 4.

NG >> Replace accelerator pedal assembly.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1201E

Voltage: Approximately 5.3V

PBIB2608E

Page 1210 of 3171

EC-230

DTC P0652, P0653 SENSOR POWER SUPPLY

Diagnostic Procedure

EBS01KJ2

1.CHECK GROUND CONNECTIONS

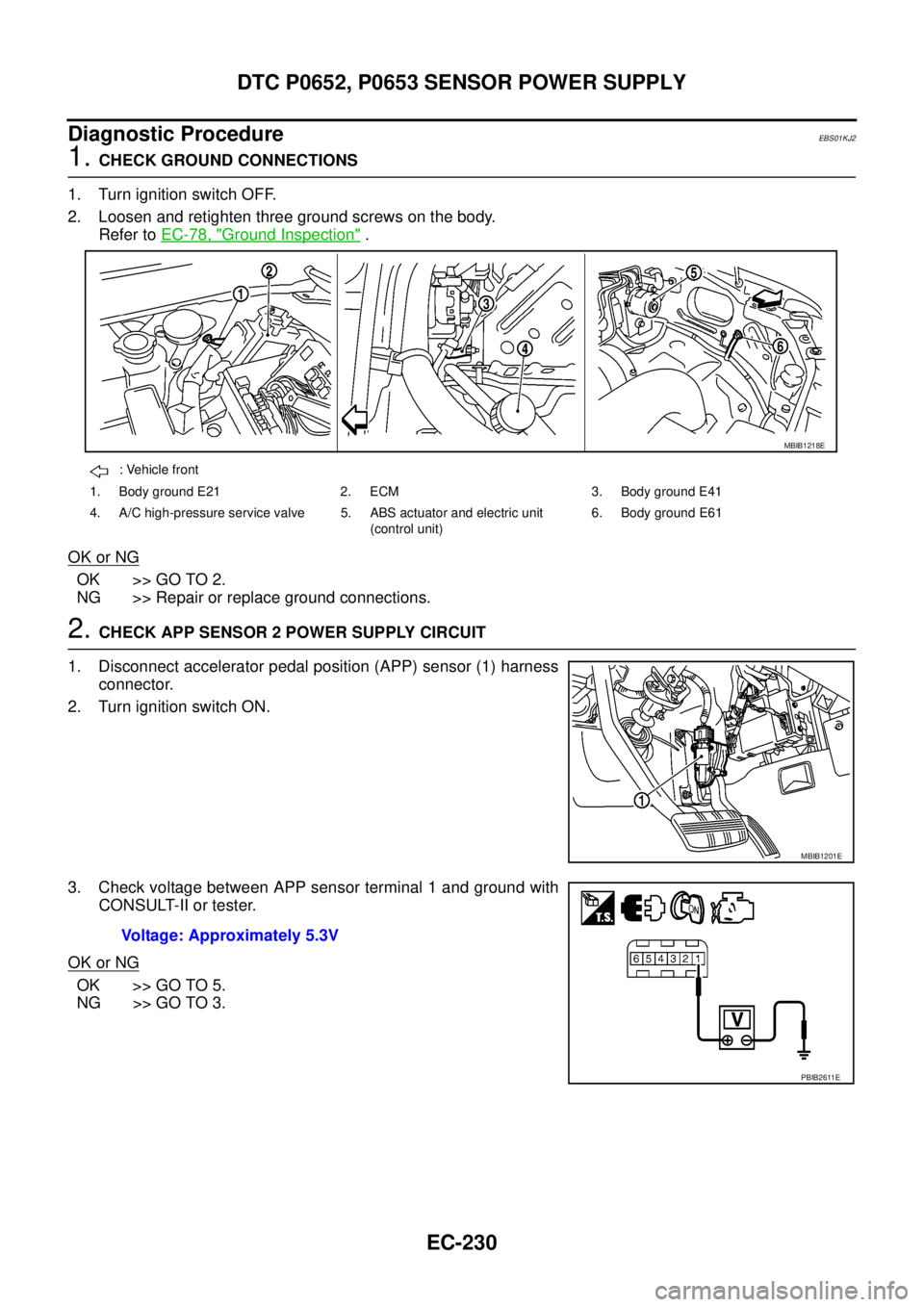

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK APP SENSOR 2 POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor (1) harness

connector.

2. Turn ignition switch ON.

3. Check voltage between APP sensor terminal 1 and ground with

CONSULT-II or tester.

OK or NG

OK >> GO TO 5.

NG >> GO TO 3.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1201E

Voltage: Approximately 5.3V

PBIB2611E

Page 1258 of 3171

EC-278

DTC P2135 APP SENSOR

Diagnostic Procedure

EBS01KKZ

1.CHECK GROUND CONNECTIONS

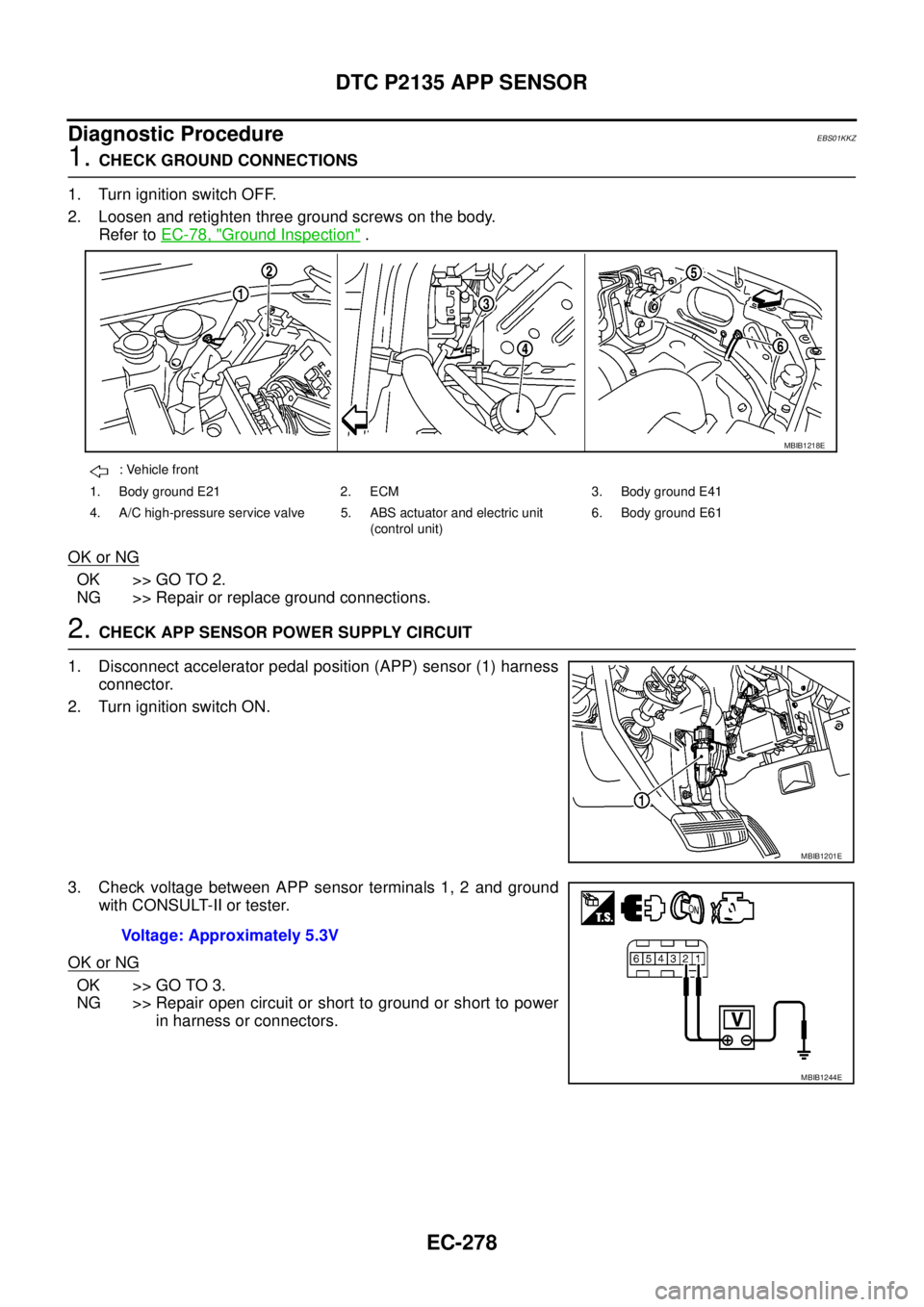

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

2.CHECK APP SENSOR POWER SUPPLY CIRCUIT

1. Disconnect accelerator pedal position (APP) sensor (1) harness

connector.

2. Turn ignition switch ON.

3. Check voltage between APP sensor terminals 1, 2 and ground

with CONSULT-II or tester.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power

in harness or connectors.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

MBIB1201E

Voltage: Approximately 5.3V

MBIB1244E

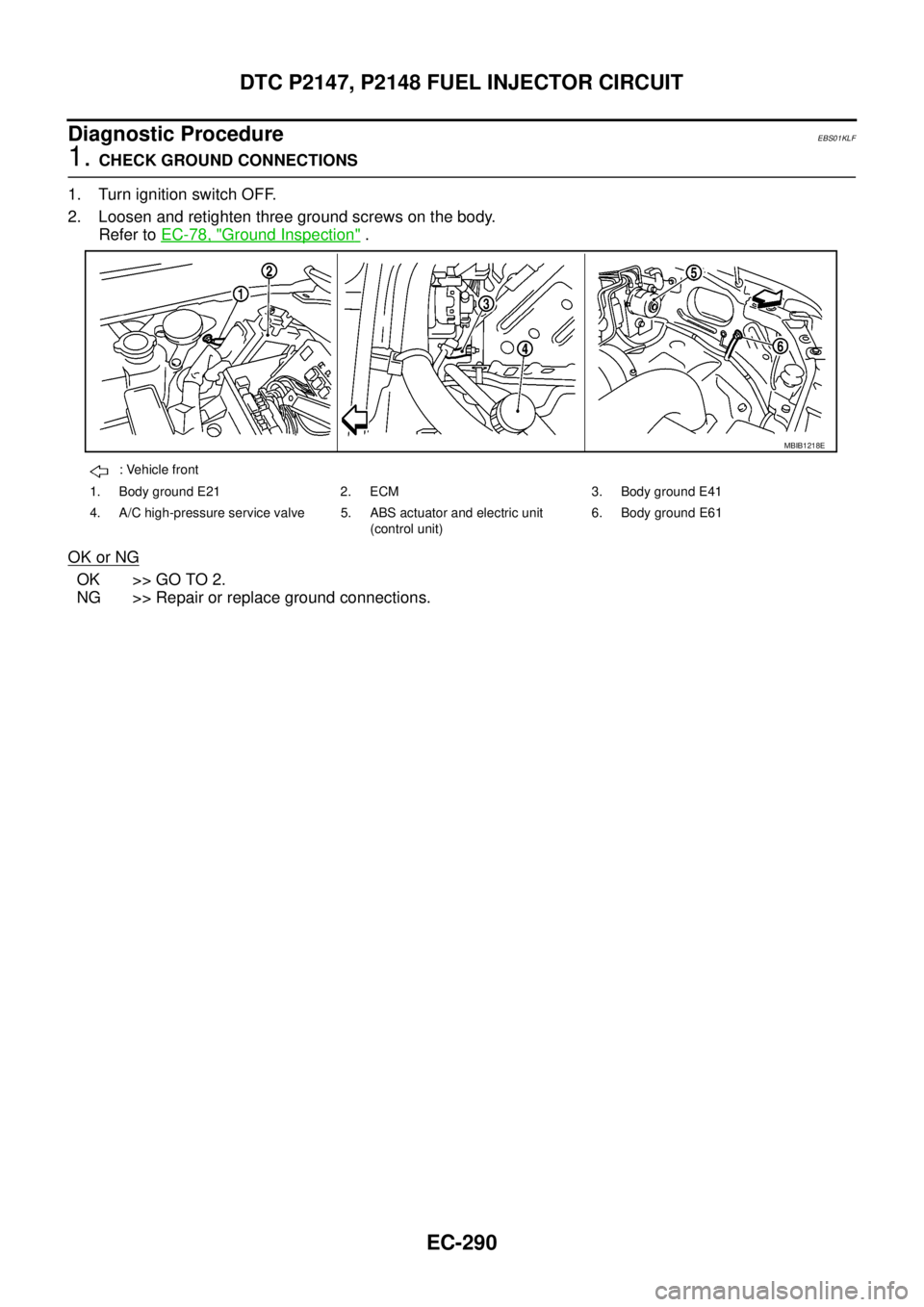

Page 1270 of 3171

EC-290

DTC P2147, P2148 FUEL INJECTOR CIRCUIT

Diagnostic Procedure

EBS01KLF

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 2.

NG >> Repair or replace ground connections.

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

Page 1307 of 3171

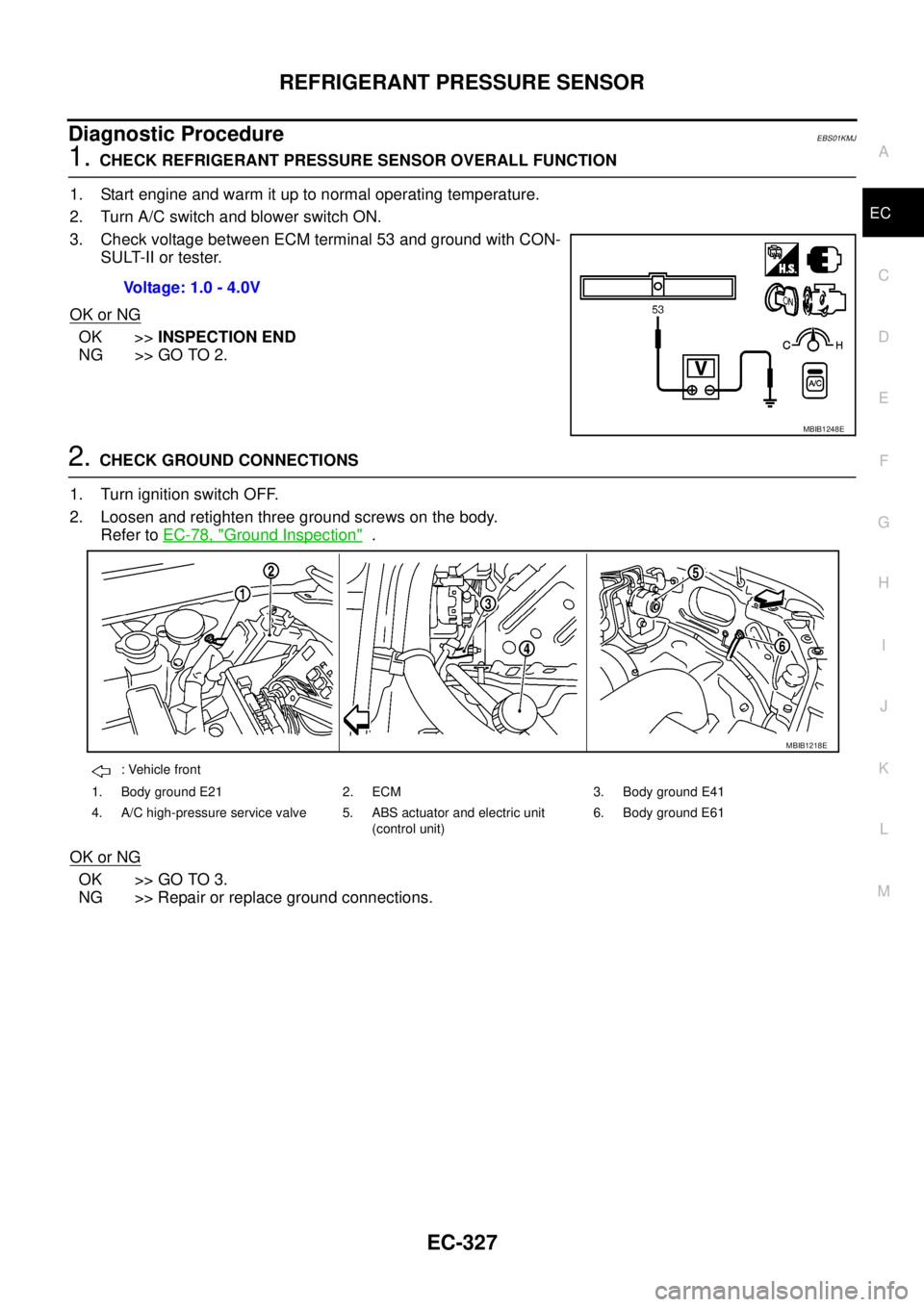

REFRIGERANT PRESSURE SENSOR

EC-327

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KMJ

1.CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ON.

3. Check voltage between ECM terminal 53 and ground with CON-

SULT-II or tester.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

Refer toEC-78, "

Ground Inspection".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace ground connections.Voltage: 1.0 - 4.0V

MBIB1248E

: Vehicle front

1. Body ground E21 2. ECM 3. Body ground E41

4. A/C high-pressure service valve 5. ABS actuator and electric unit

(control unit)6. Body ground E61

MBIB1218E

Page 1353 of 3171

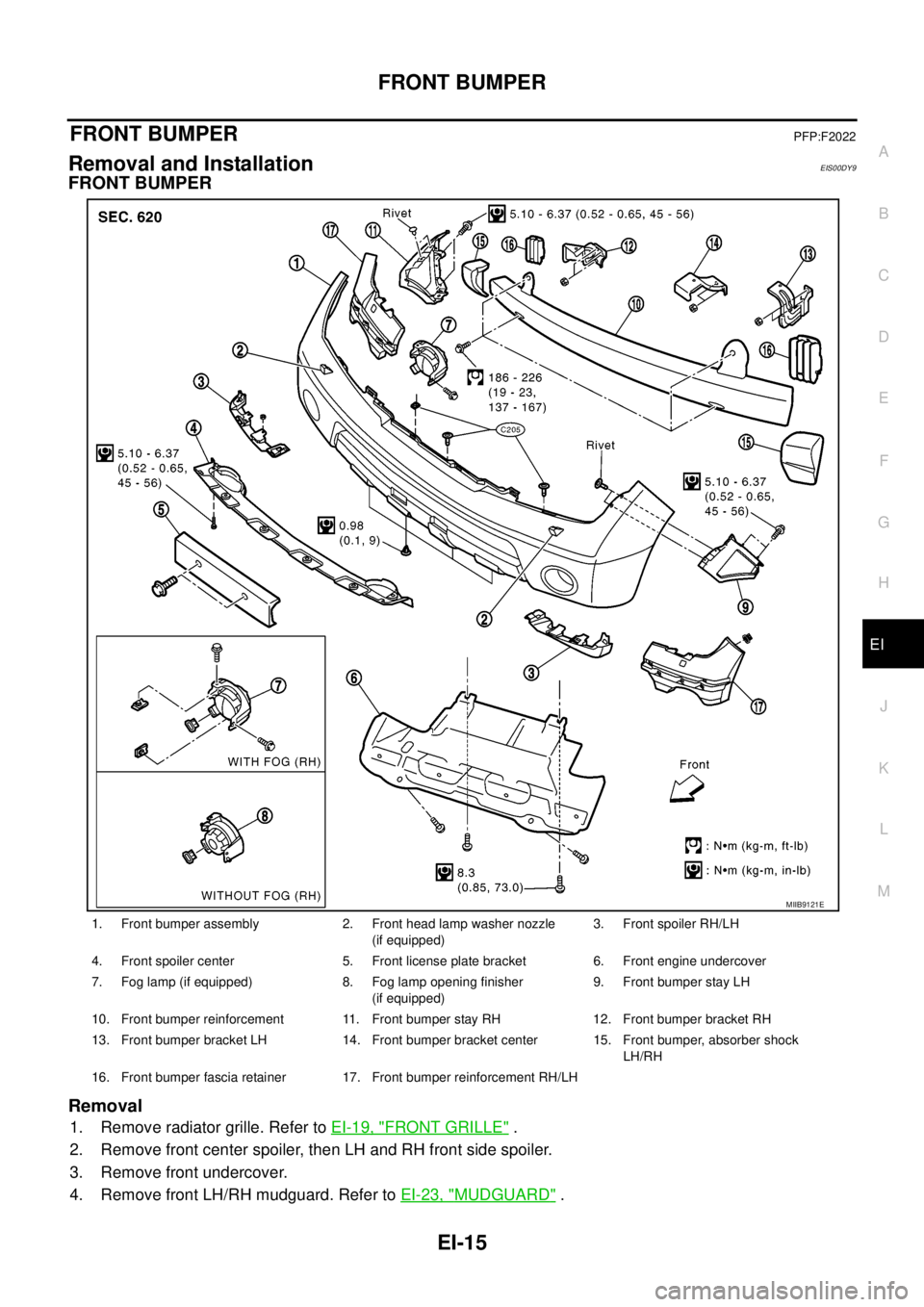

FRONT BUMPER

EI-15

C

D

E

F

G

H

J

K

L

MA

B

EI

FRONT BUMPERPFP:F2022

Removal and InstallationEIS00DY9

FRONT BUMPER

Removal

1. Remove radiator grille. Refer toEI-19, "FRONT GRILLE".

2. Remove front center spoiler, then LH and RH front side spoiler.

3. Remove front undercover.

4. Remove front LH/RH mudguard. Refer toEI-23, "

MUDGUARD".

1. Front bumper assembly 2. Front head lamp washer nozzle

(if equipped)3. Front spoiler RH/LH

4. Front spoiler center 5. Front license plate bracket 6. Front engine undercover

7. Fog lamp (if equipped) 8. Fog lamp opening finisher

(if equipped)9. Front bumper stay LH

10. Front bumper reinforcement 11. Front bumper stay RH 12. Front bumper bracket RH

13. Front bumper bracket LH 14. Front bumper bracket center 15. Front bumper, absorber shock

LH/RH

16. Front bumper fascia retainer 17. Front bumper reinforcement RH/LH

MIIB9121E

Page 1538 of 3171

FAX-6

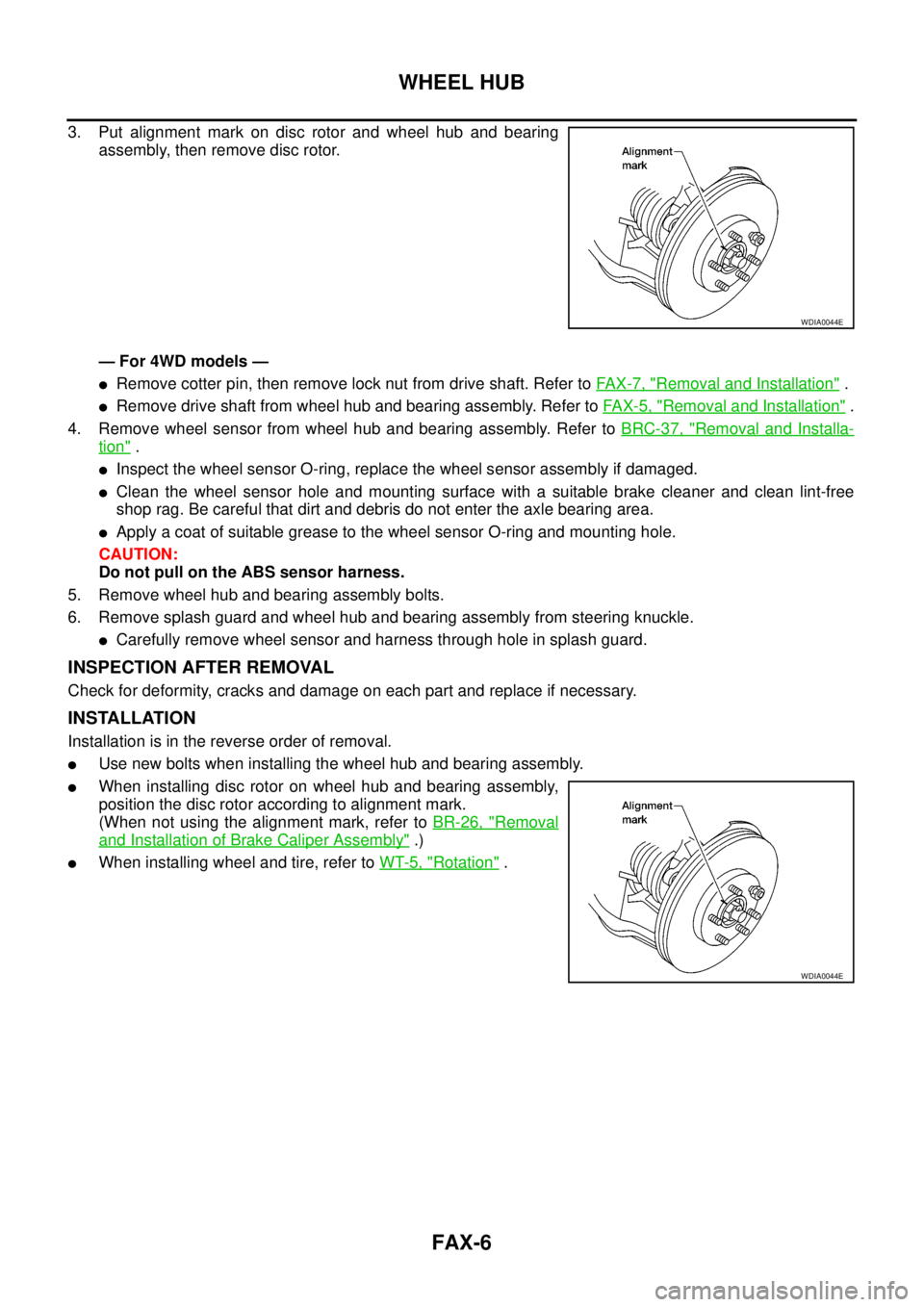

WHEEL HUB

3. Put alignment mark on disc rotor and wheel hub and bearing

assembly, then remove disc rotor.

— For 4WD models —

lRemove cotter pin, then remove lock nut from drive shaft. Refer toFA X - 7 , "Removal and Installation".

lRemove drive shaft from wheel hub and bearing assembly. Refer toFAX-5, "Removal and Installation".

4. Remove wheel sensor from wheel hub and bearing assembly. Refer toBRC-37, "

Removal and Installa-

tion".

lInspect the wheel sensor O-ring, replace the wheel sensor assembly if damaged.

lClean the wheel sensor hole and mounting surface with a suitable brake cleaner and clean lint-free

shop rag. Be careful that dirt and debris do not enter the axle bearing area.

lApply a coat of suitable grease to the wheel sensor O-ring and mounting hole.

CAUTION:

Do not pull on the ABS sensor harness.

5. Remove wheel hub and bearing assembly bolts.

6. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

lCarefully remove wheel sensor and harness through hole in splash guard.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

lUse new bolts when installing the wheel hub and bearing assembly.

lWhen installing disc rotor on wheel hub and bearing assembly,

position the disc rotor according to alignment mark.

(When not using the alignment mark, refer toBR-26, "

Removal

and Installation of Brake Caliper Assembly".)

lWhen installing wheel and tire, refer toWT-5, "Rotation".

WDIA0044E

WDIA0044E

Page 1539 of 3171

DRIVE SHAFT

FAX-7

C

E

F

G

H

I

J

K

L

MA

B

FA X

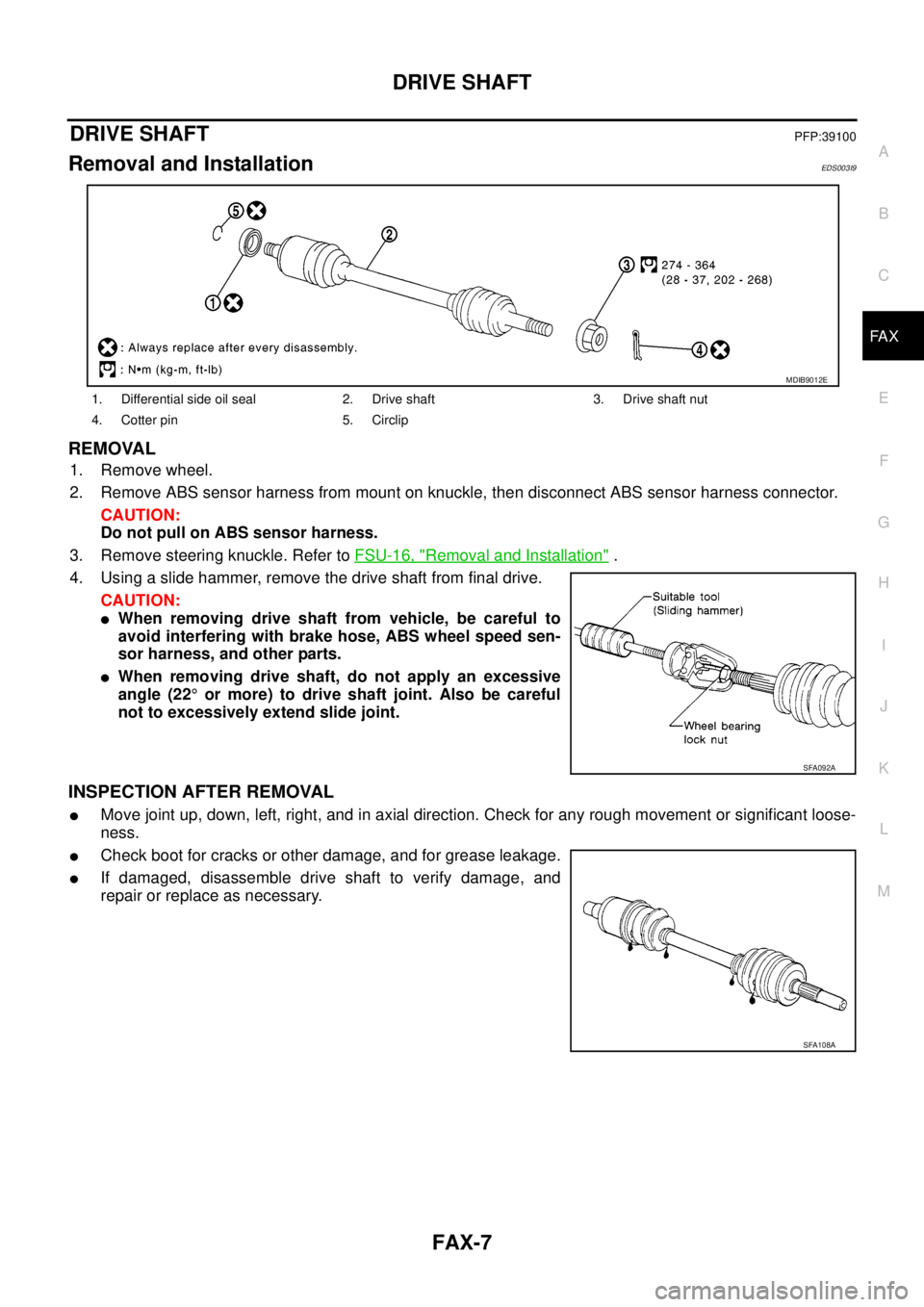

DRIVE SHAFTPFP:39100

Removal and InstallationEDS003I9

REMOVAL

1. Remove wheel.

2. Remove ABS sensor harness from mount on knuckle, then disconnect ABS sensor harness connector.

CAUTION:

Do not pull on ABS sensor harness.

3. Remove steering knuckle. Refer toFSU-16, "

Removal and Installation".

4. Using a slide hammer, remove the drive shaft from final drive.

CAUTION:

lWhen removing drive shaft from vehicle, be careful to

avoid interfering with brake hose, ABS wheel speed sen-

sor harness, and other parts.

lWhen removing drive shaft, do not apply an excessive

angle (22°or more) to drive shaft joint. Also be careful

not to excessively extend slide joint.

INSPECTION AFTER REMOVAL

lMove joint up, down, left, right, and in axial direction. Check for any rough movement or significant loose-

ness.

lCheck boot for cracks or other damage, and for grease leakage.

lIf damaged, disassemble drive shaft to verify damage, and

repair or replace as necessary.

1. Differential side oil seal 2. Drive shaft 3. Drive shaft nut

4. Cotter pin 5. Circlip

MDIB9012E

SFA092A

SFA108A

Page 1555 of 3171

FRONT OIL SEAL

FFD-9

C

E

F

G

H

I

J

K

L

MA

B

FFD

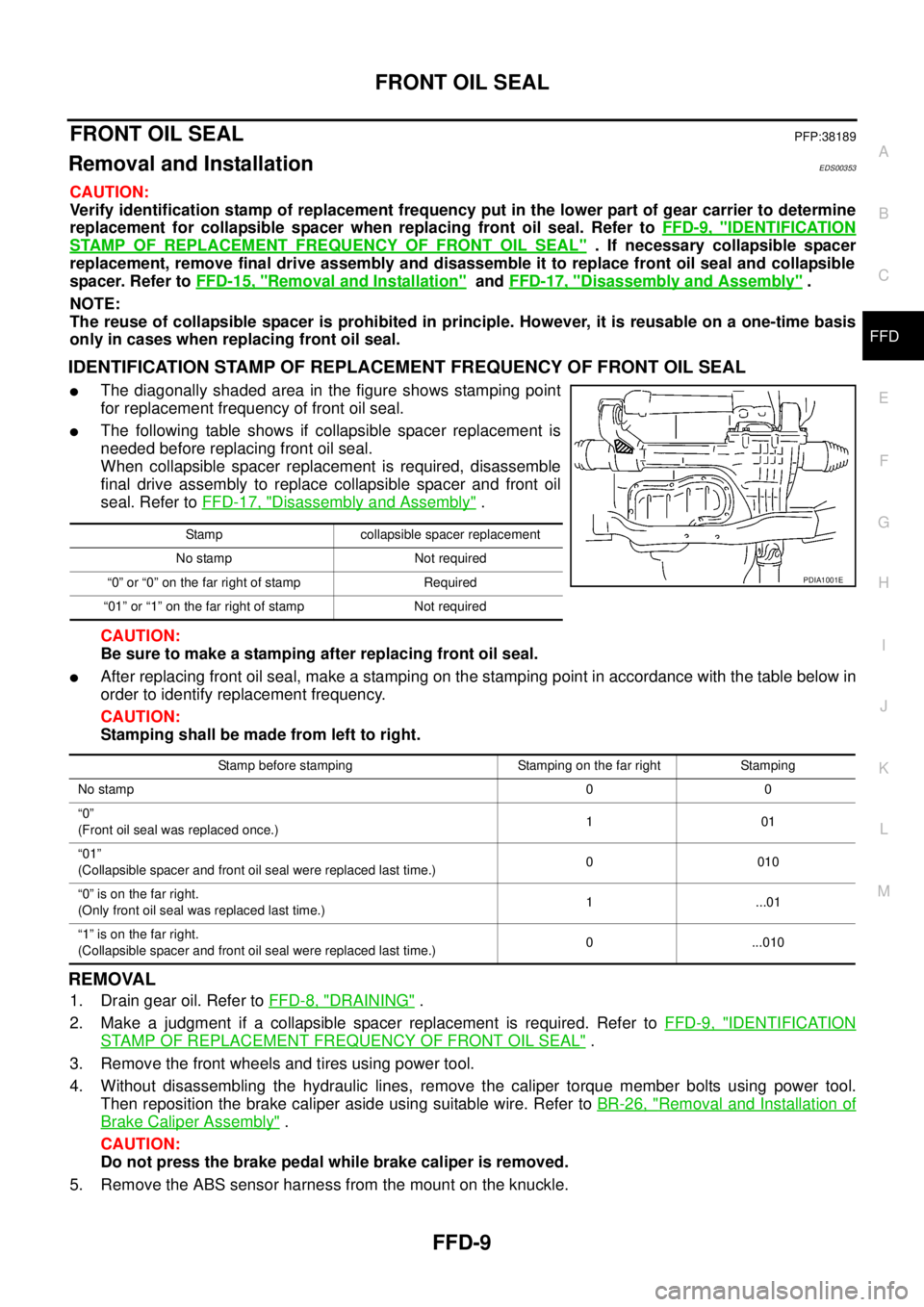

FRONT OIL SEALPFP:38189

Removal and InstallationEDS00353

CAUTION:

Verify identification stamp of replacement frequency put in the lower part of gear carrier to determine

replacement for collapsible spacer when replacing front oil seal. Refer toFFD-9, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL". If necessary collapsible spacer

replacement, remove final drive assembly and disassemble it to replace front oil seal and collapsible

spacer. Refer toFFD-15, "

Removal and Installation"andFFD-17, "Disassembly and Assembly".

NOTE:

The reuse of collapsible spacer is prohibited in principle. However, it is reusable on a one-time basis

only in cases when replacing front oil seal.

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL

lThe diagonally shaded area in the figure shows stamping point

for replacement frequency of front oil seal.

lThe following table shows if collapsible spacer replacement is

needed before replacing front oil seal.

When collapsible spacer replacement is required, disassemble

final drive assembly to replace collapsible spacer and front oil

seal. Refer toFFD-17, "

Disassembly and Assembly".

CAUTION:

Be sure to make a stamping after replacing front oil seal.

lAfter replacing front oil seal, make a stamping on the stamping point in accordance with the table below in

order to identify replacement frequency.

CAUTION:

Stamping shall be made from left to right.

REMOVAL

1. Drain gear oil. Refer toFFD-8, "DRAINING".

2. Make a judgment if a collapsible spacer replacement is required. Refer toFFD-9, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL".

3. Remove the front wheels and tires using power tool.

4. Without disassembling the hydraulic lines, remove the caliper torque member bolts using power tool.

Then reposition the brake caliper aside using suitable wire. Refer toBR-26, "

Removal and Installation of

Brake Caliper Assembly".

CAUTION:

Do not press the brake pedal while brake caliper is removed.

5. Remove the ABS sensor harness from the mount on the knuckle.

Stamp collapsible spacer replacement

No stamp Not required

“0” or “0” on the far right of stamp Required

“01” or “1” on the far right of stamp Not required

PDIA1001E

Stamp before stamping Stamping on the far right Stamping

No stamp00

“0”

(Front oil seal was replaced once.)101

“01”

(Collapsible spacer and front oil seal were replaced last time.)0010

“0”isonthefarright.

(Only front oil seal was replaced last time.)1 ...01

“1”isonthefarright.

(Collapsible spacer and front oil seal were replaced last time.)0 ...010