audio NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2083 of 3641

INSTRUMENT PANEL ASSEMBLYIP-15

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

Removal and InstallationINFOID:0000000012430778

CAUTION:

• Be careful not to scratch instrument panel pad or other parts.

• Before servicing, turn the ignition switch off, disconnect both battery terminals and wait at least

three minutes.

• Do not tamper with or force air bag lid open, as this may adversely affect air bag performance.

REMOVAL

1. Disconnect the negative and positive battery terminals, then wait at least three minutes. Refer to PG-70,

"Removal and Installation (Battery)".

2. Remove front pillar finishers (LH/RH). Refer to INT-21, "

FRONT PILLAR FINISHER : Removal and Instal-

lation".

3. Remove dash side finishers (LH/RH). Refer to INT-24, "

DASH SIDE FINISHER : Removal and Installa-

tion".

4. Partially remove front body side welts (LH/RH). Refer to INT-21, "

Exploded View".

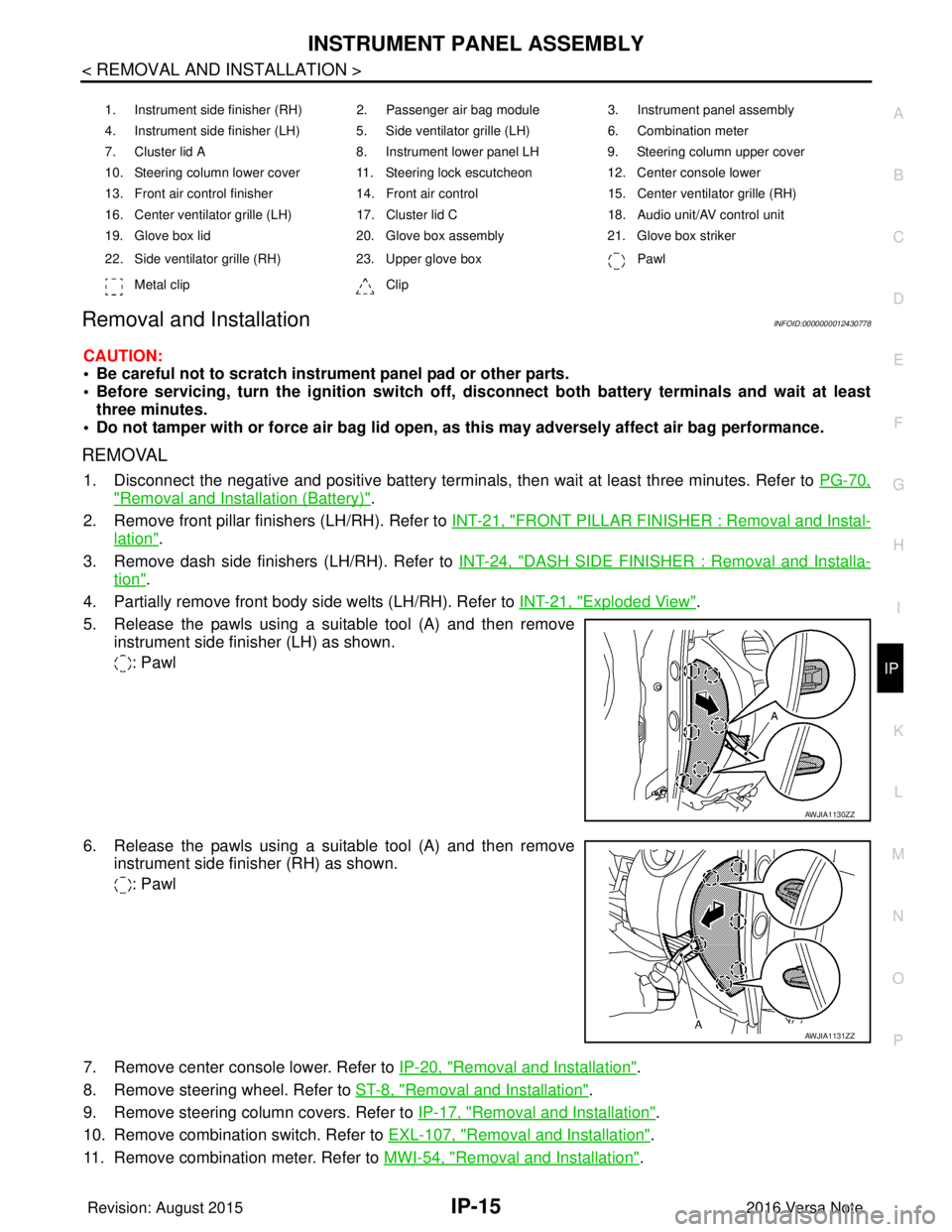

5. Release the pawls using a suitable tool (A) and then remove instrument side finisher (LH) as shown.

: Pawl

6. Release the pawls using a suitable tool (A) and then remove instrument side finisher (RH) as shown.

: Pawl

7. Remove center console lower. Refer to IP-20, "

Removal and Installation".

8. Remove steering wheel. Refer to ST-8, "

Removal and Installation".

9. Remove steering column covers. Refer to IP-17, "

Removal and Installation".

10. Remove combination switch. Refer to EXL-107, "

Removal and Installation".

11. Remove combination meter. Refer to MWI-54, "

Removal and Installation".

1. Instrument side finisher (RH) 2. Passenger air bag module 3. Instrument panel assembly

4. Instrument side finisher (LH) 5. Side ventilator grille (LH) 6. Combination meter

7. Cluster lid A 8. Instrument lower panel LH9. Steering column upper cover

10. Steering column lower cover 11. Steering lock escutcheon 12. Center console lower

13. Front air control finisher 14. Front air control15. Center ventilator grille (RH)

16. Center ventilator grille (LH) 17. Cluster lid C 18. Audio unit/AV control unit

19. Glove box lid 20. Glove box assembly21. Glove box striker

22. Side ventilator grille (RH) 23. Upper glove box Pawl

Metal clip Clip

AWJIA1130ZZ

AWJIA1131ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2084 of 3641

IP-16

< REMOVAL AND INSTALLATION >

INSTRUMENT PANEL ASSEMBLY

12. Remove audio unit. Refer to AV-53, "Removal and Installation" (BASE AUDIO) or AV-113, "Removal and

Installation" (DISPLAY AUDIO).

13. Remove AV control unit (NAVIGATION). Refer to AV-241, "

Removal and Installation".

14. Remove front air control. Refer to HAC-52, "

Removal and Installation".

15. Remove glove box assembly. Refer to IP-25, "

Removal and Installation".

16. Remove front passenger air bag module. Refer to SR-19, "

Removal and Installation".

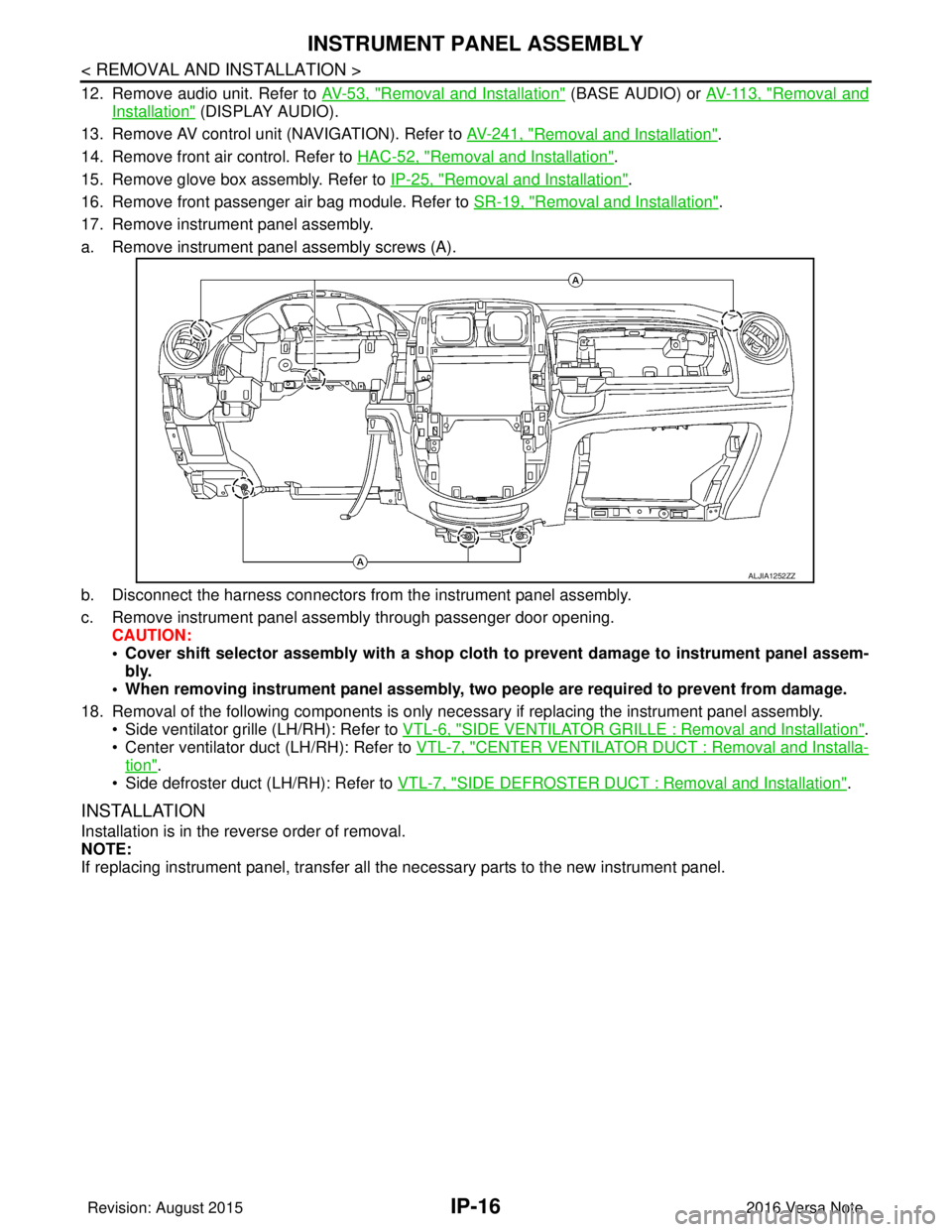

17. Remove instrument panel assembly.

a. Remove instrument panel assembly screws (A).

b. Disconnect the harness connectors from the instrument panel assembly.

c. Remove instrument panel assembly through passenger door opening. CAUTION:

• Cover shift selector assembly with a shop cloth to prevent damage to instrument panel assem-

bly.

• When removing instrument panel assembly, two people are required to prevent from damage.

18. Removal of the following components is only necessary if replacing the instrument panel assembly.

• Side ventilator grille (LH/RH): Refer to VTL-6, "

SIDE VENTILATOR GRILLE : Removal and Installation".

• Center ventilator duct (LH/RH): Refer to VTL-7, "

CENTER VENTILATOR DUCT : Removal and Installa-

tion".

• Side defroster duct (LH/RH): Refer to VTL-7, "

SIDE DEFROSTER DUCT : Removal and Installation".

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

If replacing instrument panel, transfer all the necessary parts to the new instrument panel.

ALJIA1252ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2100 of 3641

INL-6

< SYSTEM DESCRIPTION >

COMPONENT PARTS

5. BCM• Activates the interior room lamp timer depending on the vehicle condition to turn the

interior room lamps ON/OFF.

• Operates the interior room lamp battery saver depending on the vehicle condition to cut the interior room lamp power supply.

• Detects each switch condition by the combination switch reading function.

• Judges the illumination lamp ON/OFF status depending on the vehicle condition.

And then it transmits position light request signal to IPDM E/R and combination

meter (with CAN communication).

Refer to BCS-6, "

BODY CONTROL SYSTEM : Component Part s Location" (with Intel-

ligent Key system) or BCS-77, "

BODY CONTROL SYSTEM : Component Parts Loca-

tion" (without Intelligent Key system) for detailed installation location.

6. Back door switch Refer to DLK-18, "

INTELLIGENT KEY SYSTEM : Ba

ck Door Lock Assembly" (with In-

telligent Key system) or DLK-195, "

REMOTE KEYLESS ENTRY SYSTEM : Back Door

Lock Assembly" (without Intelligent Key system).

7. Push-button ignition switch (if

equipped) Refer to PCS-34, "

POWER DISTRIBUTION SYSTEM : System Description".

8. Combination switch Refer to

BCS-9, "

COMBINATION SWITCH READING SY STEM : System Description"

(with Intelligent Key system) or BCS-79, "

COMBINATION SWITCH READING SYS-

TEM : System Description" (without Intelligent Key system).

9. Combination meter Receives the dimmer signal from BCM. Refer to

MWI-13, "

METER ILLUMINATION

CONTROL : System Description" (type A) or MWI-66, "METER ILLUMINATION CON-

TROL : System Description" (type B).

10. Audio unit (without navigation)

AV control unit (with navigation) Receives the dimmer signal from BCM. Refer to

AV- 8 , "

Audio unit" (base audio), AV-

65, "Audio Unit" (display audio) or AV- 1 3 0 , "AV Control Unit" (navigation).

11. Front door switch LH (RH side similar) Refer to DLK-19, "

INTELLIGENT KEY SYSTEM : Door Switch" (with Intelligent Key

system) or DLK-195, "

REMOTE KEYLESS ENTRY SYSTEM : Door Switch" (without

Intelligent Key system).

12. Rear door switch LH (RH side similar) Refer to DLK-19, "

INTELLIGENT KEY SYSTEM : Door Switch" (with Intelligent Key

system) or DLK-195, "

REMOTE KEYLESS ENTRY SYSTEM : Door Switch" (without

Intelligent Key system).

No.

Part Description

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2162 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-11

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2417 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI

COMPONENT PARTSMWI-59

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432600

The combination meter controls the following items a cco NISSAN NOTE 2016 Service Repair Manual MWI

COMPONENT PARTSMWI-59

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432600

The combination meter controls the following items a cco](/img/5/57363/w960_57363-2416.png)

MWI

COMPONENT PARTSMWI-59

< SYSTEM DESCRIPTION > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

METER SYSTEM : Combination MeterINFOID:0000000012432600

The combination meter controls the following items a ccording to the signals received from each unit via CAN

communication and the signals from switches and sensors:

• Measuring instruments

• Indicator lamps

• Warning lamps

• Meter illumination control

• Information display

ARRANGEMENT OF COMBINATION METER

3. Washer fluid level switch Transmits the washer fluid level switch signal to the combination meter (for Cana-

da).

Refer to

WW-6, "

Component Parts Location" for detailed installation location.

4. Engine oil pressure sensor Transmits the engine oil pressure sensor signal to the ECM.

Refer to

EM-93, "

Exploded View" for detailed installation location.

5. Ambient sensor Transmits the ambient sensor signal to the combination meter.

6. TCM Transmits the shift position signal to the combination meter via CAN communica-

tion (with CVT).

Refer to

TM-61, "

CVT CONTROL SYSTEM : Component Parts Location" for de-

tailed installation location.

7. ECM Transmits the following signals to the combination meter via CAN communication:

• Engine speed signal

• Engine coolant temperature signal

• Fuel consumption monitor signal

• Engine oil pressure sensor signal

Refer to

EC-14, "

ENGINE CONTROL SYSTEM : ComponentPartsLocation" for

detailed installation location.

8. BCM Transmits the following signals to the combination meter via CAN communication:

• Door switch signal

• Buzzer signal

Refer to

BCS-6, "

BODY CONTROL SYSTEM : Component Parts Location" (with

Intelligent Key system) or BCS-77, "

BODY CONTROL SYSTEM : Component

Parts Location" (without Intelligent Key system) for detailed installation location.

9. Steering wheel audio control switches

(meter control switch) Transmits the meter control switch signal to the combination meter.

10. Combination meter Refer to MWI-59, "

METER SYSTEM : Combination Meter".

11 . Fuel level sensor unit and fuel pump (fuel

level sensor) Transmits the fuel level sensor signal to the combination meter.

No.

Component Function

AWNIA3630ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2426 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI-68

< SYSTEM DESCRIPTION >[TYPE B]

OPERATION

OPERATION

Switch Name and FunctionINFOID:0000000012432610

ILLUMINATION CONTROL SWITCH/

TRIP ODOMETER RESET SWITCH

STEERING WHEEL AUDIO CONTROL SWITCH (M NISSAN NOTE 2016 Service Repair Manual MWI-68

< SYSTEM DESCRIPTION >[TYPE B]

OPERATION

OPERATION

Switch Name and FunctionINFOID:0000000012432610

ILLUMINATION CONTROL SWITCH/

TRIP ODOMETER RESET SWITCH

STEERING WHEEL AUDIO CONTROL SWITCH (M](/img/5/57363/w960_57363-2425.png)

MWI-68

< SYSTEM DESCRIPTION >[TYPE B]

OPERATION

OPERATION

Switch Name and FunctionINFOID:0000000012432610

ILLUMINATION CONTROL SWITCH/

TRIP ODOMETER RESET SWITCH

STEERING WHEEL AUDIO CONTROL SWITCH (METER CONTROL SWITCH)

AWNIA3606ZZ

Switch name Operation Description

Illumination control switch (1) Turn An illuminance level of the back light of the combination meter can be adjusted.

Trip odometer reset switch (1) Press • The information display screen can be switched.

• The trip meter can be switched between A and B.

• Trip meter A/B can be reset by pressing and holding the trip reset switch.

• Time can be adjusted.

AWNIA3620GB

Switch name

Operation Description

Steering wheel audio control switch

(meter control switch) (2) Press• Trip computer modes can be selected.

• Trip computer value displayed can be reset by pressing and holding the meter

control switch for 1 second or more.

• All trip computer values displayed can be reset by pressing and holding the

meter control switch for 3 seconds or more.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2461 of 3641

![NISSAN NOTE 2016 Service Repair Manual MWI

STEERING SWITCHMWI-103

< DTC/CIRCUIT DIAGNOSIS > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

STEERING SWITCH

Diagnosis ProcedureINFOID:0000000012432640

Regarding Wiring Diagram information, refer to M NISSAN NOTE 2016 Service Repair Manual MWI

STEERING SWITCHMWI-103

< DTC/CIRCUIT DIAGNOSIS > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

STEERING SWITCH

Diagnosis ProcedureINFOID:0000000012432640

Regarding Wiring Diagram information, refer to M](/img/5/57363/w960_57363-2460.png)

MWI

STEERING SWITCHMWI-103

< DTC/CIRCUIT DIAGNOSIS > [TYPE B]

C

D

E

F

G H

I

J

K L

M B A

O P

STEERING SWITCH

Diagnosis ProcedureINFOID:0000000012432640

Regarding Wiring Diagram information, refer to MWI-79, "Wiring Diagram".

1.CHECK STEERING SWITCH

1. Turn ignition switch OFF.

2. Disconnect combination switch (spiral cable) connector M88.

3. Check for continuity between the termi nals of combination switch connector M88.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Replace steering switches. Refer to AV-58, "

Removal and Installation".

2.CHECK COMBINATION SWITCH (SPIRAL CABLE)

Check continuity between combination swit ch (spiral cable) connectors M88 and M30.

Is the inspection result normal?

YES >> • Display audio system: Refer to AV-104, "Diagnosis Procedure".

• Navigation system: Refer to AV-224, "

Diagnosis Procedure".

NO >> Replace combination switch (spiral cable). Refer to SR-16, "

Removal and Installation".

Combination switch (spiral cable) connector M88

Condition Continuity

Terminal Terminal

16 17When steering switch is pressed.

Yes

Other than above. No

Combination switch (spiral cable)

Continuity

Connector TerminalConnector Terminal

M88 16

M30 32

Ye s

17 33

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2484 of 3641

MIR-10

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2630 of 3641

PG

HARNESSPG-43

< WIRING DIAGRAM >

C

DE

F

G H

I

J

K L

B A

O P

N

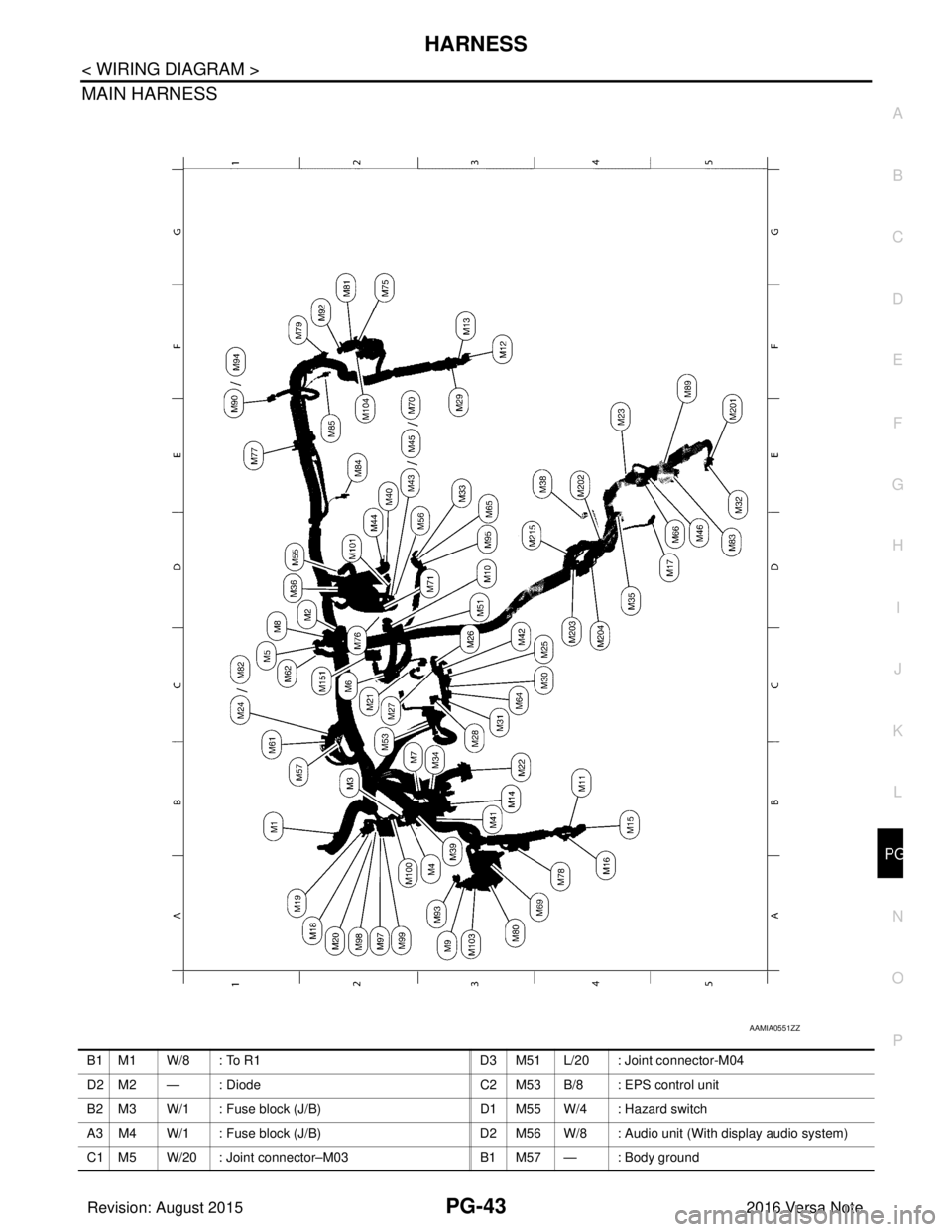

MAIN HARNESS

AAMIA0551ZZ

B1 M1 W/8 : To R1

D3 M51 L/20 : Joint connector-M04

D2 M2 — : Diode C2 M53 B/8 : EPS control unit

B2 M3 W/1 : Fuse block (J/B) D1 M55 W/4 : Hazard switch

A3 M4 W/1 : Fuse block (J/B) D2 M56 W/8 : Audio unit (With display audio system)

C1 M5 W/20 : Joint connector–M03 B1 M57 — : Body ground

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2631 of 3641

PG-44

< WIRING DIAGRAM >

HARNESS

C2 M6 W/4 : Dongle unitB1 M61 — : Body ground

B2 M7 W/16 : Door mirror remote control switch C1 M62 W/2 : Front blower motor

D1 M8 G/20 : Joint connector–M02 C3 M64 W/8 : Steering angle sensor

A3 M9 W/12 : To D1 E3 M65 W/4 : Front air control

D3 M10 L/20 : Joint connector–M01 D5 M66 B/3 : Console power socket

B4 M11 W/2 : To B28 A4 M69 SMJ : To E7

F3 M12 W/16 : To B29 E2 M70 W/20 : AV control unit

F3 M13 W/24 : To B30 D3 M71 W/24 : AV control unit

B3 M14 BR/6 : Rear window defogger relay F2 M75 Y/4 : To D101

B4 M15 W/16 : To B23 D2 M76 GR/5 : AV control unit

A4 M16 W/24 : To B24 E1 M77 Y/4 : Front passenger air bag module

D5 M17 B/1 : Parking brake switch A4 M78 B/2 :To E11

A2 M18 W/40 : BCM (Body contro

l module) (Without

Intelligent Key system) F1 M79 — : Body ground

A1 M19 W/15 : BCM (Body contro

l module) (Without

Intelligent Key system) A 3 M 8 0 Y / 4 : T o D 3

A2 M20 B/15 : BCM (Body contro

l module) (Without

Intelligent Key system) F2 M81 W/12 : To D115

C2 M21 W/4 : NATS antenna amp. C1 M82 W/40 : Combination meter (With type A)

B3 M22 W/16 : Data link connector D5 M83 B/3 : G sensor

E 4 M 2 3 W / 4 : Remote keyless entry receiver (Without

Intelligent Key system) E2 M84 — : Body ground

C1 M24 W/40 : Combination meter (With type B) E2 M85 — : Body ground

C4 M25 W/8 : Push–button ignition swtich F5 M89 L/2 : Inside key antenna (Console)

C3 M26 W/6 : Ignition switch E1 M90 B/4: Remote keyless entry receiver (With

Intelligent Key system without tire pressure

monitoring system)

C2 M27 BR/2 : Key switch F2 M92 W/12 : To D116

C3 M28 W/16 : Combination switch A3 M93 W/24 : To D16

E 3 M 2 9 W / 2 4 : T o B 1 F 1 M 9 4 W / 4: Remote keyless entry receiver (With

Intelligent Key system with tire pressure

monitoring system)

C4 M30 GR/8 : Combination switch (Spiral cable) D3 M95 L/2 : Inside key antenna (Instrument center)

C3 M31 Y/6 : Combination switch (Spiral cable) A2 M97 B/40 : BCM (Body contro

l module) (With

Intelligent Key system)

E5 M32 W/16 : To M201 A2 M98 W/40: BCM (Body contro

l module) (With

Intelligent Key system)

E3 M33 B/15 : Front air control A2 M99 W/15: BCM (Body contro

l module) (With

Intelligent Key system)

B3 M34 GR/6 : VDC off switch A2 M100 B / 1 5: BCM (Body contro

l module) (With

Intelligent Key system)

D4 M35 Y/28 : Air bag diagnosis sensor unit D2 M101 W/16 : Audio unit (With base audio system)

D1 M36 BR/2 : Front passenger air bag off indicator A3 M103 W/12 : Accessory prewire LH

E4 M38 W/8 : CVT shift selector E2 M104 W/12 : Accessory prewire RH

B3 M39 L/4 : Accessory relay–2 C2 M151 BR/4 : Front blower motor resistor

E2 M40 W/32 : Audio unit (With display audio system) Console sub harness

B3 M41 B/5 : Back door lock actuator relay E5 M201 W / 1 6 : T o M 3 2

C3 M42 BR/4 : Thermo control amp. E4 M202 B/3 : Console power socket

E2 M43 W/20 : Audio unit (With base audio system) C4 M203 BR/6 : Heated seat swtich RH

Revision: August 2015 2016 Versa Note

cardiagn.com