wheel NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1855 of 3641

FSU-10

< REMOVAL AND INSTALLATION >

TRANSVERSE LINK

TRANSVERSE LINK

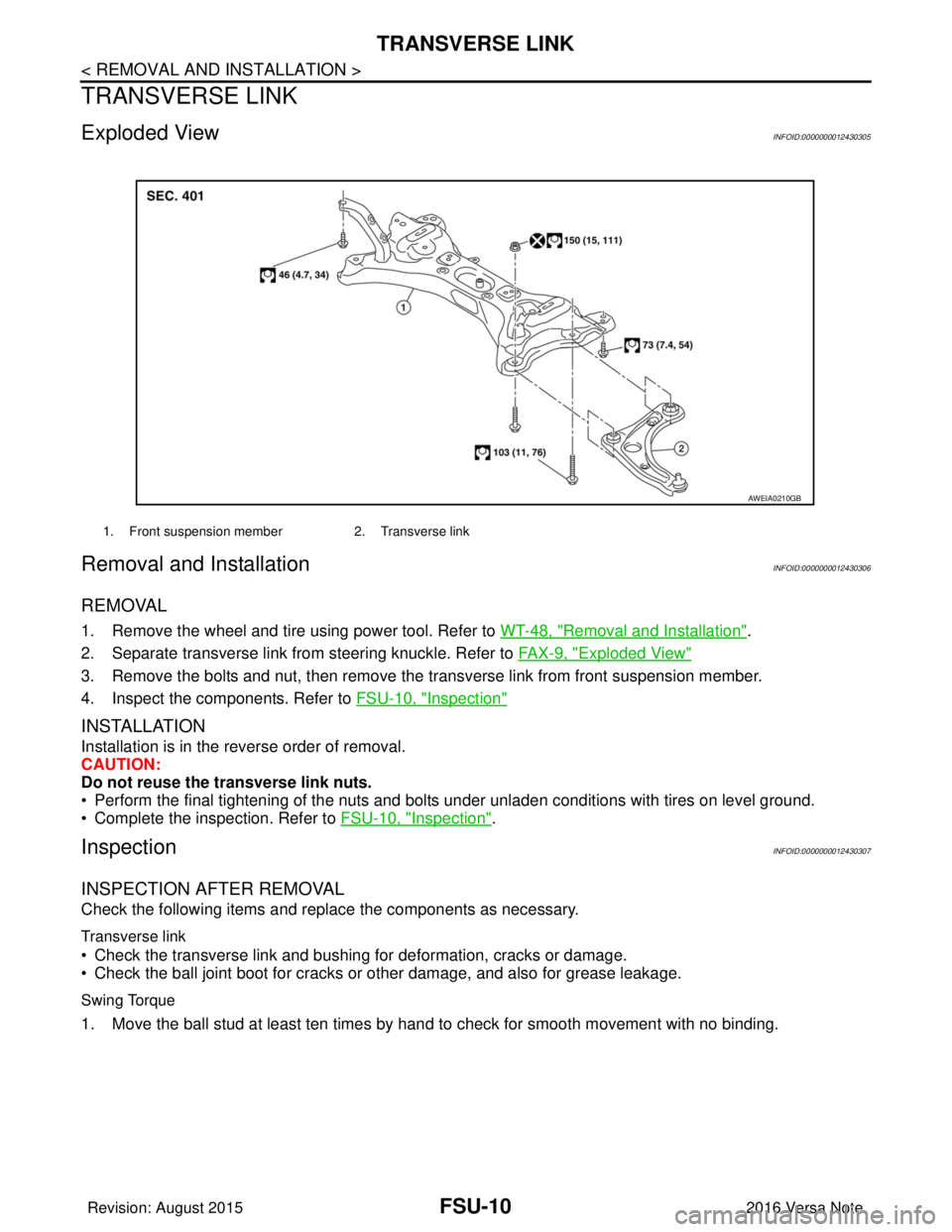

Exploded ViewINFOID:0000000012430305

Removal and InstallationINFOID:0000000012430306

REMOVAL

1. Remove the wheel and tire using power tool. Refer to WT-48, "Removal and Installation".

2. Separate transverse link from steering knuckle. Refer to FA X - 9 , "

Exploded View"

3. Remove the bolts and nut, then remove the transverse link from front suspension member.

4. Inspect the components. Refer to FSU-10, "

Inspection"

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not reuse the transverse link nuts.

• Perform the final tightening of the nuts and bolts under unladen conditions with tires on level ground.

• Complete the inspection. Refer to FSU-10, "

Inspection".

InspectionINFOID:0000000012430307

INSPECTION AFTER REMOVAL

Check the following items and replace the components as necessary.

Transverse link

• Check the transverse link and bushing for deformation, cracks or damage.

• Check the ball joint boot for cracks or other damage, and also for grease leakage.

Swing Torque

1. Move the ball stud at least ten times by hand to check for smooth movement with no binding.

1. Front suspension member2. Transverse link

AWEIA0210GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1856 of 3641

TRANSVERSE LINKFSU-11

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

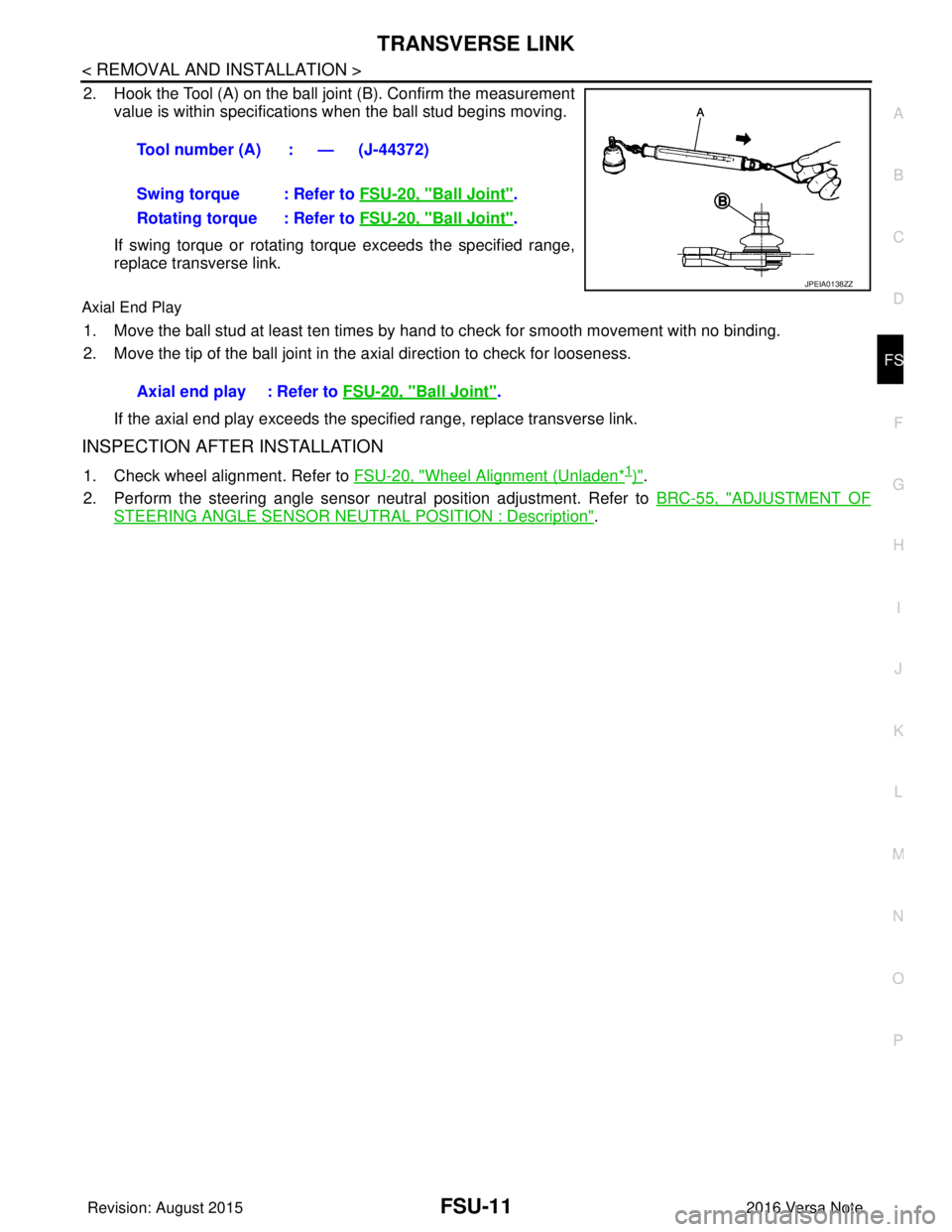

2. Hook the Tool (A) on the ball joint (B). Confirm the measurement value is within specifications when the ball stud begins moving.

If swing torque or rotating torque exceeds the specified range,

replace transverse link.

Axial End Play

1. Move the ball stud at least ten times by hand to check for smooth movement with no binding.

2. Move the tip of the ball joint in the axial direction to check for looseness.

If the axial end play exceeds the specified range, replace transverse link.

INSPECTION AFTER INSTALLATION

1. Check wheel alignment. Refer to FSU-20, "Wheel Alignment (Unladen*1)".

2. Perform the steering angle sensor neutral position adjustment. Refer to BRC-55, "

ADJUSTMENT OF

STEERING ANGLE SENSOR NEUTRAL POSITION : Description".

Tool number (A) : — (J-44372)

Swing torque : Refer to

FSU-20, "

Ball Joint".

Rotating torque : Refer to FSU-20, "

Ball Joint".

JPEIA0138ZZ

Axial end play : Refer to FSU-20, "Ball Joint".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1857 of 3641

FSU-12

< REMOVAL AND INSTALLATION >

FRONT STABILIZER

FRONT STABILIZER

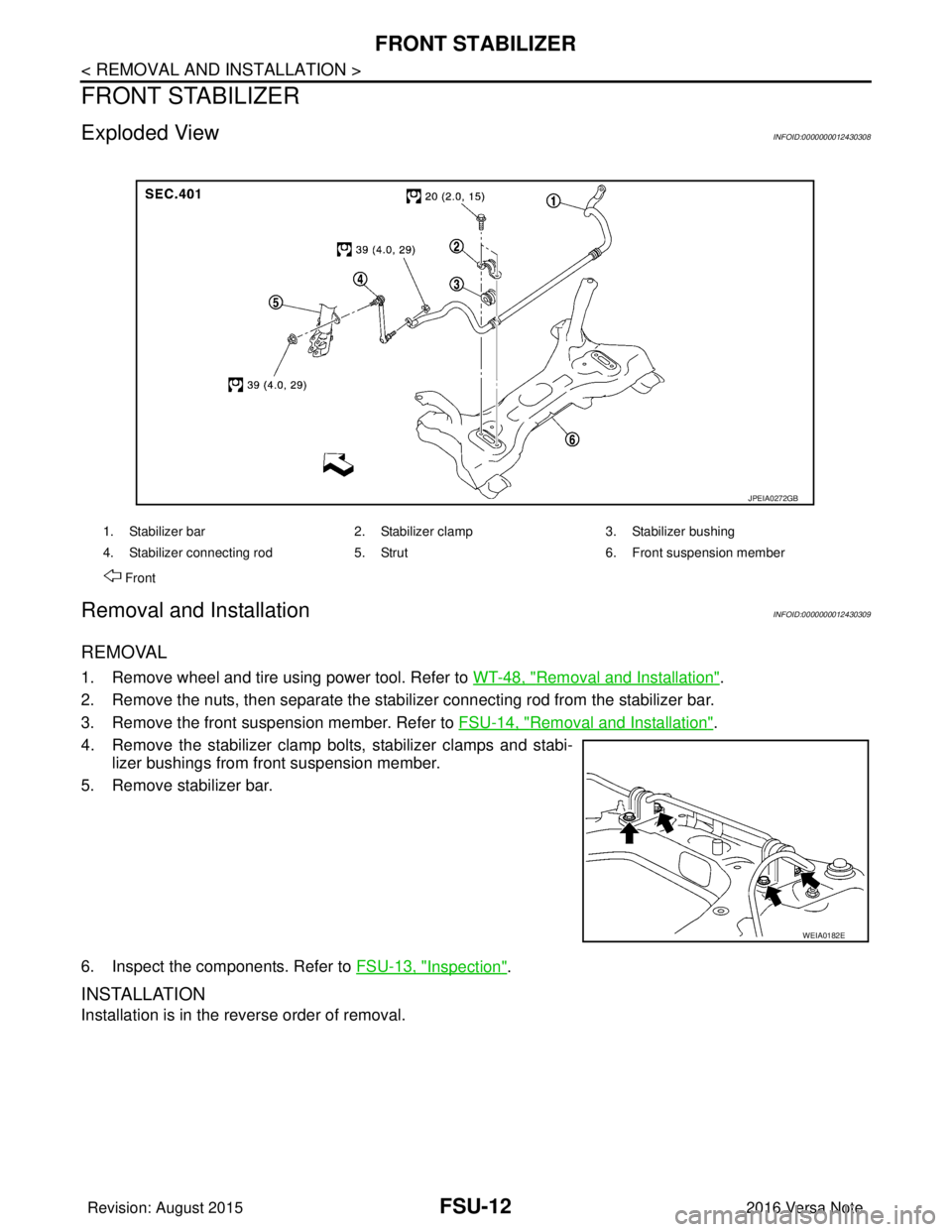

Exploded ViewINFOID:0000000012430308

Removal and InstallationINFOID:0000000012430309

REMOVAL

1. Remove wheel and tire using power tool. Refer to WT-48, "Removal and Installation".

2. Remove the nuts, then separate the stabilizer connecting rod from the stabilizer bar.

3. Remove the front suspension member. Refer to FSU-14, "

Removal and Installation".

4. Remove the stabilizer clamp bolts, stabilizer clamps and stabi- lizer bushings from front suspension member.

5. Remove stabilizer bar.

6. Inspect the components. Refer to FSU-13, "

Inspection".

INSTALLATION

Installation is in the reverse order of removal.

1. Stabilizer bar 2. Stabilizer clamp 3. Stabilizer bushing

4. Stabilizer connecting rod 5. Strut 6. Front suspension member

Front

JPEIA0272GB

WEIA0182E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1858 of 3641

FRONT STABILIZERFSU-13

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

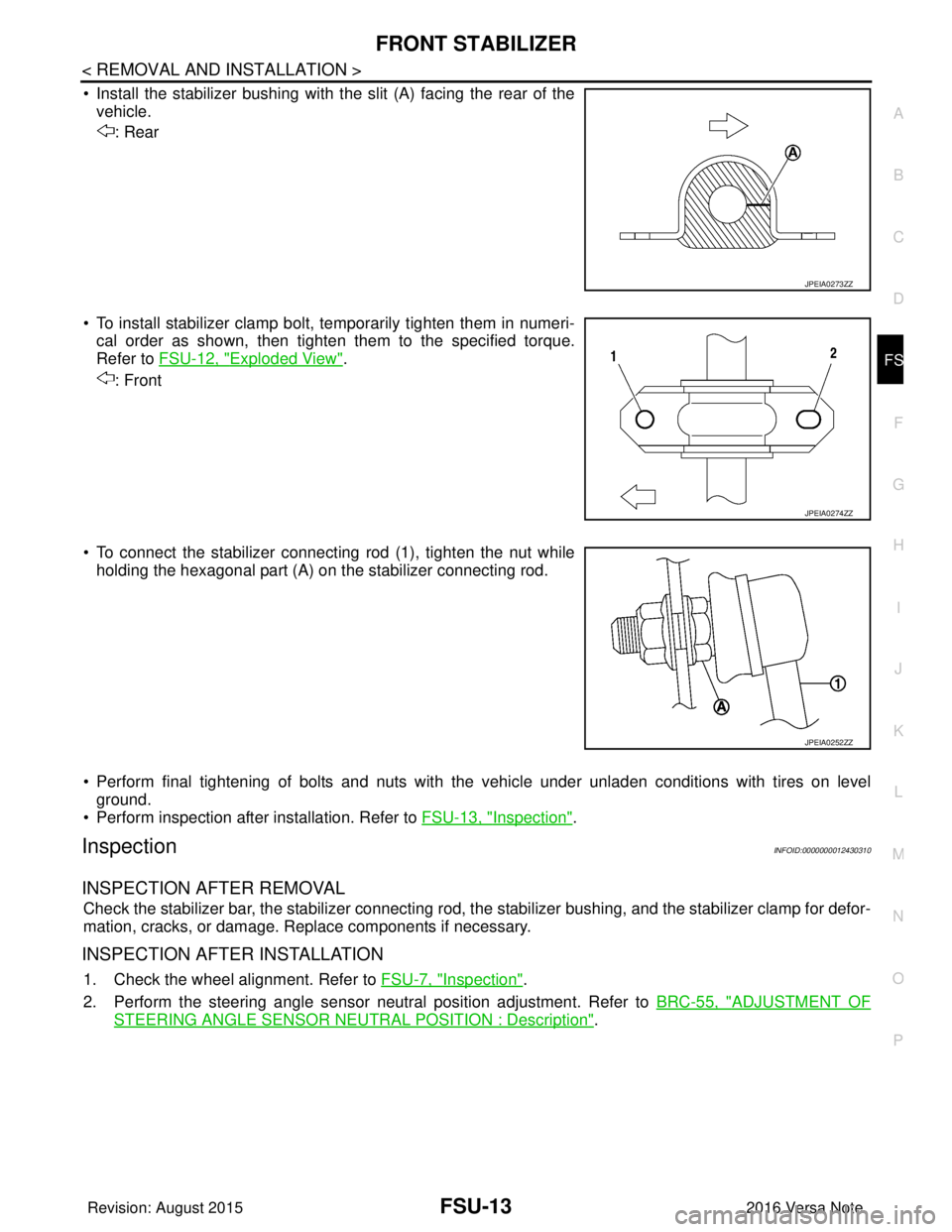

• Install the stabilizer bushing with the slit (A) facing the rear of the vehicle.

: Rear

• To install stabilizer clamp bolt, temporarily tighten them in numeri- cal order as shown, then tighten them to the specified torque.

Refer to FSU-12, "

Exploded View".

: Front

• To connect the stabilizer connecting rod (1), tighten the nut while holding the hexagonal part (A) on the stabilizer connecting rod.

• Perform final tightening of bolts and nuts with the vehicle under unladen conditions with tires on level ground.

• Perform inspection after installation. Refer to FSU-13, "

Inspection".

InspectionINFOID:0000000012430310

INSPECTION AFTER REMOVAL

Check the stabilizer bar, the stabilizer connecting rod, t he stabilizer bushing, and the stabilizer clamp for defor-

mation, cracks, or damage. Replace components if necessary.

INSPECTION AFTER INSTALLATION

1. Check the wheel alignment. Refer to FSU-7, "Inspection".

2. Perform the steering angle sensor neutral position adjustment. Refer to BRC-55, "

ADJUSTMENT OF

STEERING ANGLE SENSOR NEUTRAL POSITION : Description".

JPEIA0273ZZ

JPEIA0274ZZ

JPEIA0252ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1859 of 3641

FSU-14

< UNIT REMOVAL AND INSTALLATION >

FRONT SUSPENSION MEMBER

UNIT REMOVAL AND INSTALLATION

FRONT SUSPENSION MEMBER

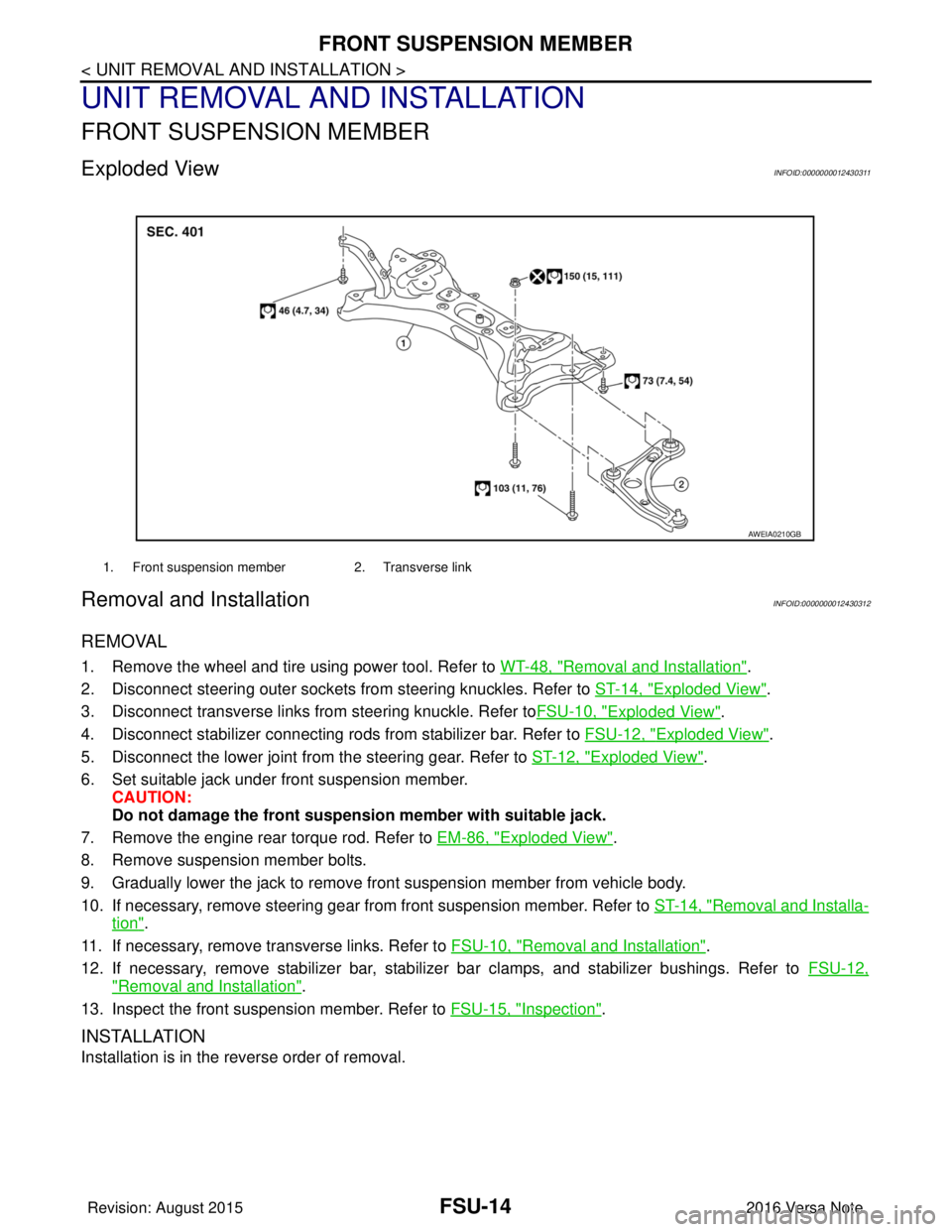

Exploded ViewINFOID:0000000012430311

Removal and InstallationINFOID:0000000012430312

REMOVAL

1. Remove the wheel and tire using power tool. Refer to WT-48, "Removal and Installation".

2. Disconnect steering outer sockets from steering knuckles. Refer to ST-14, "

Exploded View".

3. Disconnect transverse links from steering knuckle. Refer to FSU-10, "

Exploded View".

4. Disconnect stabilizer connecting rods from stabilizer bar. Refer to FSU-12, "

Exploded View".

5. Disconnect the lower joint from the steering gear. Refer to ST-12, "

Exploded View".

6. Set suitable jack under front suspension member. CAUTION:

Do not damage the front suspensi on member with suitable jack.

7. Remove the engine rear torque rod. Refer to EM-86, "

Exploded View".

8. Remove suspension member bolts.

9. Gradually lower the jack to remove front suspension member from vehicle body.

10. If necessary, remove steering gear from front suspension member. Refer to ST-14, "

Removal and Installa-

tion".

11. If necessary, remove transverse links. Refer to FSU-10, "

Removal and Installation".

12. If necessary, remove stabilizer bar, stabilizer bar clamps, and stabilizer bushings. Refer to FSU-12,

"Removal and Installation".

13. Inspect the front suspension member. Refer to FSU-15, "

Inspection".

INSTALLATION

Installation is in the reverse order of removal.

1. Front suspension member2. Transverse link

AWEIA0210GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1860 of 3641

FRONT SUSPENSION MEMBERFSU-15

< UNIT REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

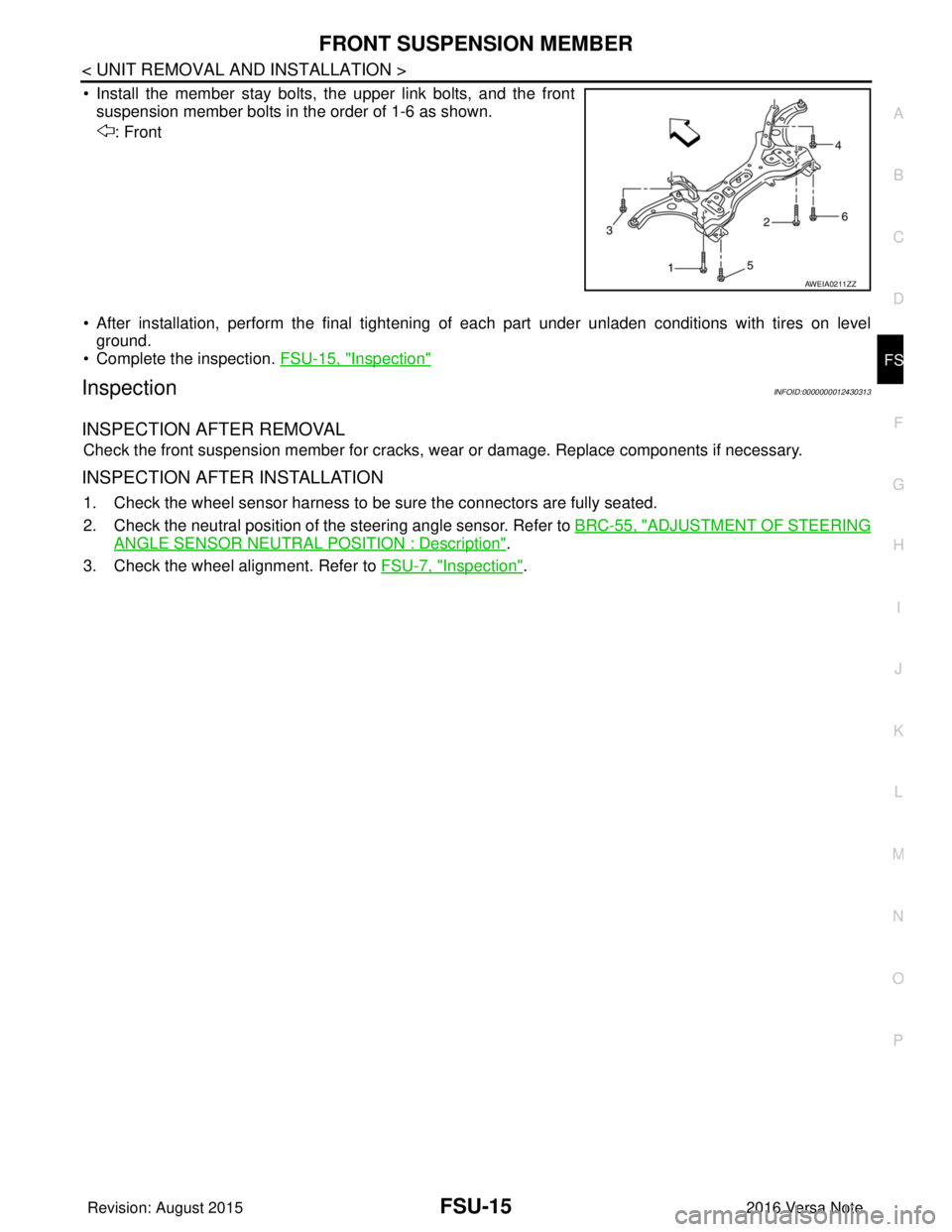

• Install the member stay bolts, the upper link bolts, and the front suspension member bolts in the order of 1-6 as shown.

: Front

• After installation, perform the final tightening of each part under unladen conditions with tires on level

ground.

• Complete the inspection. FSU-15, "

Inspection"

InspectionINFOID:0000000012430313

INSPECTION AFTER REMOVAL

Check the front suspension member for cracks, wear or damage. Replace components if necessary.

INSPECTION AFTER INSTALLATION

1. Check the wheel sensor harness to be sure the connectors are fully seated.

2. Check the neutral position of the steering angle sensor. Refer to BRC-55, "

ADJUSTMENT OF STEERING

ANGLE SENSOR NEUTRAL POSITION : Description".

3. Check the wheel alignment. Refer to FSU-7, "

Inspection".

AWEIA0211ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1864 of 3641

FRONT COIL SPRING AND STRUTFSU-19

< UNIT DISASSEMBLY AND ASSEMBLY >

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

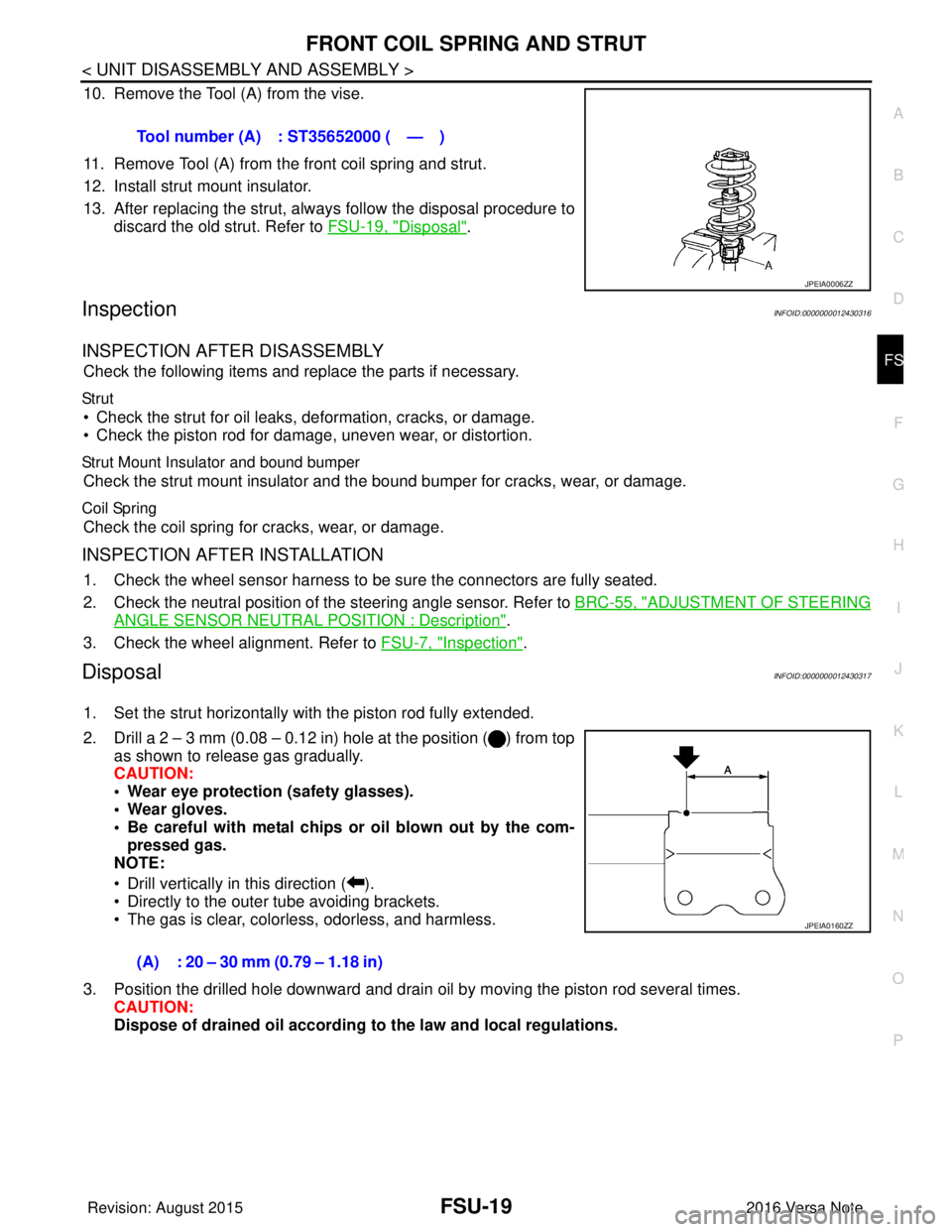

10. Remove the Tool (A) from the vise.

11. Remove Tool (A) from the front coil spring and strut.

12. Install strut mount insulator.

13. After replacing the strut, always follow the disposal procedure to discard the old strut. Refer to FSU-19, "

Disposal".

InspectionINFOID:0000000012430316

INSPECTION AFTER DISASSEMBLY

Check the following items and replace the parts if necessary.

Str ut

• Check the strut for oil leaks, deformation, cracks, or damage.

• Check the piston rod for damage, uneven wear, or distortion.

Strut Mount Insulator and bound bumper

Check the strut mount insulator and t he bound bumper for cracks, wear, or damage.

Coil Spring

Check the coil spring for cracks, wear, or damage.

INSPECTION AFTER INSTALLATION

1. Check the wheel sensor harness to be sure the connectors are fully seated.

2. Check the neutral position of the steering angle sensor. Refer to BRC-55, "

ADJUSTMENT OF STEERING

ANGLE SENSOR NEUTRAL POSITION : Description".

3. Check the wheel alignment. Refer to FSU-7, "

Inspection".

DisposalINFOID:0000000012430317

1. Set the strut horizontally with the piston rod fully extended.

2. Drill a 2 – 3 mm (0.08 – 0.12 in) hole at the position ( ) from top

as shown to release gas gradually.

CAUTION:

• Wear eye protection (safety glasses).

• Wear gloves.

• Be careful with metal chips or oil blown out by the com-

pressed gas.

NOTE:

• Drill vertically in this direction ( ).

• Directly to the outer tube avoiding brackets.

• The gas is clear, colorless, odorless, and harmless.

3. Position the drilled hole downward and drain oil by moving the piston rod several times. CAUTION:

Dispose of drained oil according to the law and local regulations.

Tool number (A) : ST35652000 ( — )

JPEIA0006ZZ

(A) : 20 – 30 mm (0.79 – 1.18 in)

JPEIA0160ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1865 of 3641

FSU-20

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

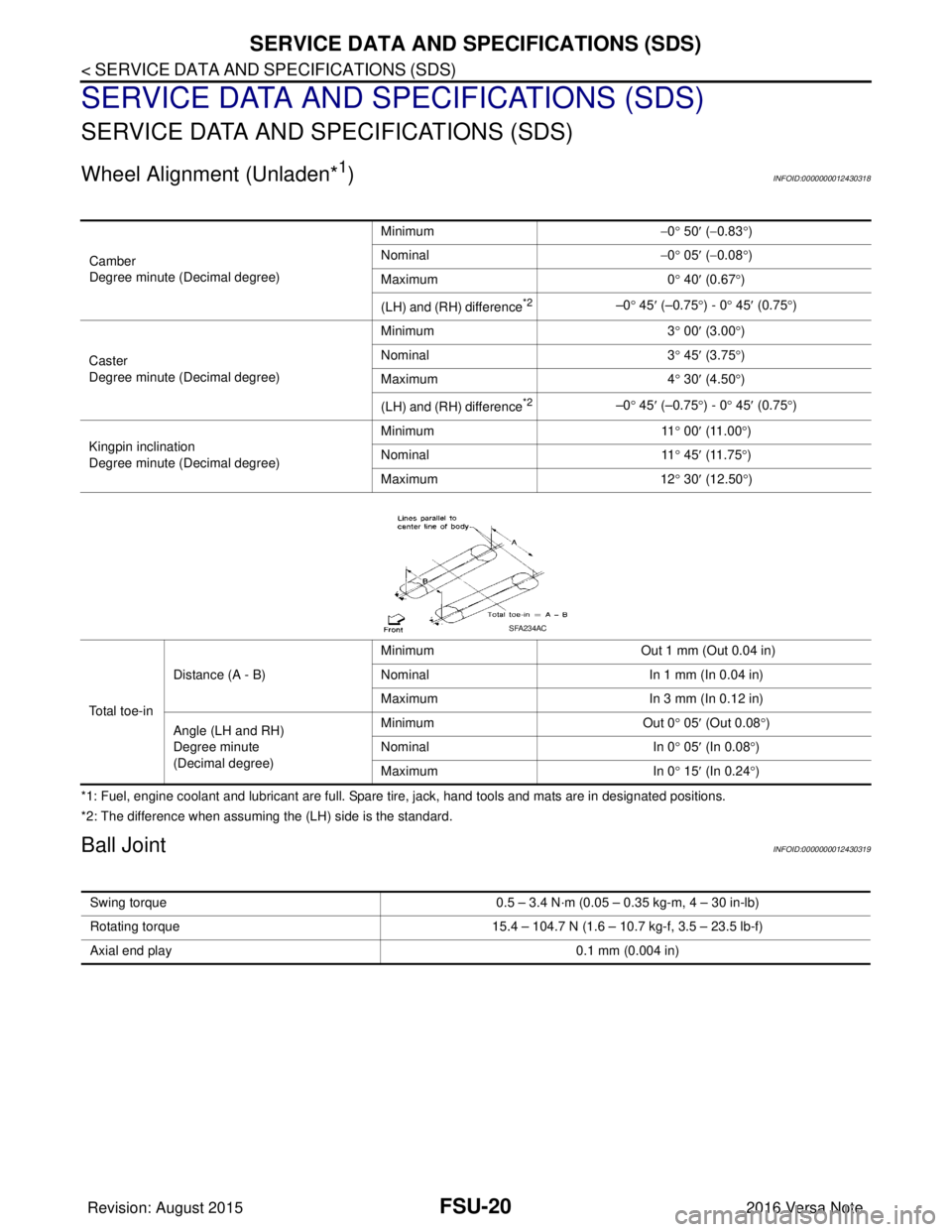

Wheel Alignment (Unladen*1)INFOID:0000000012430318

*1: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and mats are in designated positions.

*2: The difference when assuming the (LH) side is the standard.

Ball JointINFOID:0000000012430319

Camber

Degree minute (Decimal degree)Minimum

−0 ° 50 ′ ( −0.83 °)

Nominal −0 ° 05 ′ ( −0.08 °)

Maximum 0° 40 ′ (0.67 °)

(LH) and (RH) difference

*2–0 ° 45 ′ (–0.75 °) - 0 ° 45 ′ (0.75 °)

Caster

Degree minute (Decimal degree) Minimum

3° 00 ′ (3.00 °)

Nominal 3° 45 ′ (3.75 °)

Maximum 4° 30 ′ (4.50 °)

(LH) and (RH) difference

*2–0 ° 45 ′ (–0.75 °) - 0 ° 45 ′ (0.75 °)

Kingpin inclination

Degree minute (Decimal degree) Minimum

11° 00 ′ (11.00 °)

Nominal 11° 45 ′ (11.75 °)

Maximum 12° 30 ′ (12.50 °)

To t a l t o e - i n Distance (A - B)

Minimum

Out 1 mm (Out 0.04 in)

Nominal In 1 mm (In 0.04 in)

Maximum In 3 mm (In 0.12 in)

Angle (LH and RH)

Degree minute

(Decimal degree) Minimum

Out 0° 05′ (Out 0.08 °)

Nominal In 0° 05 ′ (In 0.08 °)

Maximum In 0° 15′ (In 0.24 °)

SFA234AC

Swing torque 0.5 – 3.4 N·m (0.05 – 0.35 kg-m, 4 – 30 in-lb)

Rotating torque 15.4 – 104.7 N (1.6 – 10.7 kg-f, 3.5 – 23.5 lb-f)

Axial end play 0.1 mm (0.004 in)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1866 of 3641

SERVICE DATA AND SPECIFICATIONS (SDS)FSU-21

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

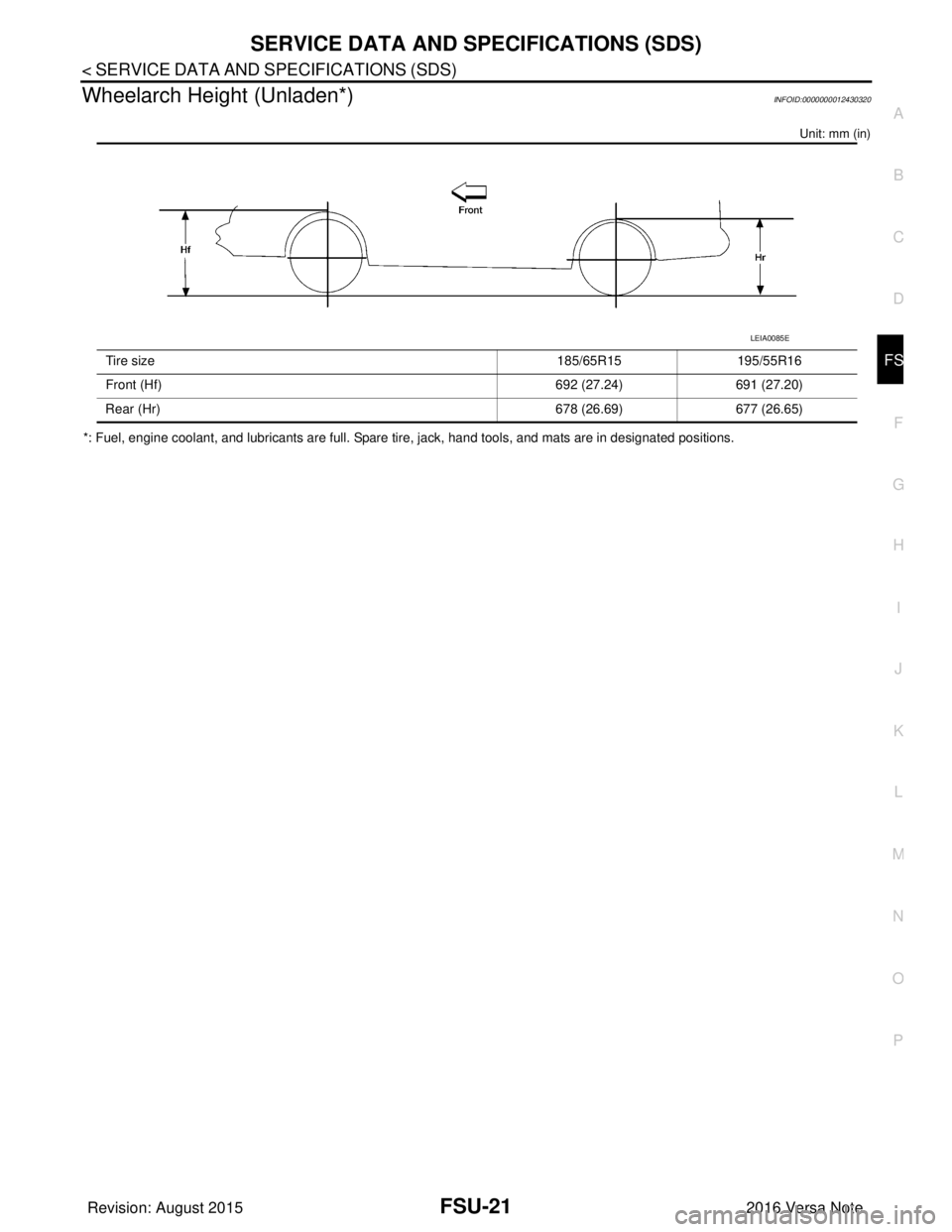

Wheelarch Height (Unladen*)INFOID:0000000012430320

Unit: mm (in)

*: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions. Tire size

185/65R15195/55R16

Front (Hf) 692 (27.24)691 (27.20)

Rear (Hr) 678 (26.69)677 (26.65)

LEIA0085E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1889 of 3641

GI-1

GENERAL INFORMATION

C

DE

F

G H

I

J

K L

M B

GI

SECTION GI

N

O P

CONTENTS

GENERAL INFORMATION

HOW TO USE THIS MANU AL ......................3

HOW TO USE THIS MANUAL ....................... .....3

Description .......................................................... ......3

Terms ........................................................................3

Units ..........................................................................3

Contents ....................................................................3

Relation between Illustrations and Descriptions .......4

Components ..............................................................4

HOW TO FOLLOW TROUBLE DIAGNOSES .....6

Description ................................................................6

How to Follow Test Groups in Trouble Diagnosis ......6

Key to Symbols Signifying Measurements or Pro-

cedures ............................................................... ......

7

HOW TO READ WIRING DIAGRAMS ................9

Connector Symbols ............................................. ......9

Sample/Wiring Diagram -Example- .........................10

Connector Information .............................................12

ABBREVIATIONS .......................................... ....14

Abbreviation List .................................................. ....14

TIGHTENING TORQUE OF STANDARD

BOLTS ................................................................

19

Description .......................................................... ....19

Tightening Torque Table (New Standard Includ-

ed) ...........................................................................

19

RECOMMENDED CHEMICAL PRODUCTS

AND SEALANTS ................................................

22

Recommended Chemical Products and Sealants ....22

PRECAUTION ..............................................23

PRECAUTIONS .............................................. ....23

Description .......................................................... ....23

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

23

Procedures without Cowl Top Cover .......................23

Cautions in Removing Battery Terminal and AV

Control Unit (Models with AV Control Unit) .............

23

General Precautions ............................................ ....24

Three Way Catalyst .................................................25

Fuel ..........................................................................25

Multiport Fuel Injection System or Engine Control

System .....................................................................

26

Hoses ......................................................................26

Engine Oils ..............................................................27

Air Conditioning .......................................................27

LIFTING POINT .................................................28

Special Service Tool ................................................28

Garage Jack and Safety Stand ................................28

2-Pole Lift ................................................................29

Board-on Lift ............................................................30

TOW TRUCK TOWING .....................................31

Tow Truck Towing ...................................................31

Vehicle Recovery (Freeing a Stuck Vehicle) ...........31

VEHICLE INFORMATION ...........................33

IDENTIFICATION INFORMATION ....................33

Model Variation .................................................... ....33

Identification Number ...............................................34

Identification Plate ...................................................35

Engine Serial Number .............................................36

CVT Number ............................................................36

Manual Transaxle Number ......................................36

Dimensions ..............................................................36

Wheels & Tires ........................................................37

BASIC INSPECTION ...................................38

SERVICE INFORMATION FOR ELECTRICAL

INCIDENT ..........................................................

38

Work Flow ............................................................ ....38

Control Units and Electrical Parts ............................38

How to Check Terminal ...........................................39

Intermittent Incident ............................................. ....42

Circuit Inspection .....................................................44

Revision: August 2015 2016 Versa Note

cardiagn.com