length NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1832 of 3641

FRONT DRIVE SHAFT BOOTFAX-15

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

WHEEL SIDE : Removal and InstallationINFOID:0000000012431895

REMOVAL

1. Remove the wheel and tire using power tool. Refer to WT-48, "Removal and Installation".

2. Remove the brake caliper torque member bolts, leav ing the brake hose attached. Position the brake cali-

per aside with wire. Refer to BR-37, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

CAUTION:

Do not depress the brake pedal while the brake caliper is removed.

3. Put alignment marks on the disc brake rotor and on the wheel hub. Remove the disc brake rotor.

CAUTION:

Do not drop the disc brake rotor.

4. Remove the wheel sensor bolt. Position the wheel sensor and the wheel sensor harness aside. Refer to

BRC-140, "

FRONT WHEEL SENSOR : Removal and Installation".

5. Remove the cotter pin from the drive shaft.

6. Hold the wheel hub using Tool. Loosen the wheel hub lock nut.

7. Using a piece of wood and a suitable tool, tap on the wheel hub lock nut to disengage the drive shaft from the wheel hub.

CAUTION:

• Do not place the drive shaft joint at an extreme angle. Also be careful not to overextend slide

joint.

• Do not allow the drive shaft to hang down without support.

NOTE:

Use a suitable puller if the drive shaft cannot be separated from the wheel hub even after performing the

above procedure.

8. Remove the wheel hub lock nut.

9. Remove the nut and bolt from the lower ball joint. Disconnect the steering knuckle from the transverse

link.

10. Remove the drive shaft from the wheel hub.

11. Remove the boot bands.

12. Separate the boot from the joint sub-assembly.

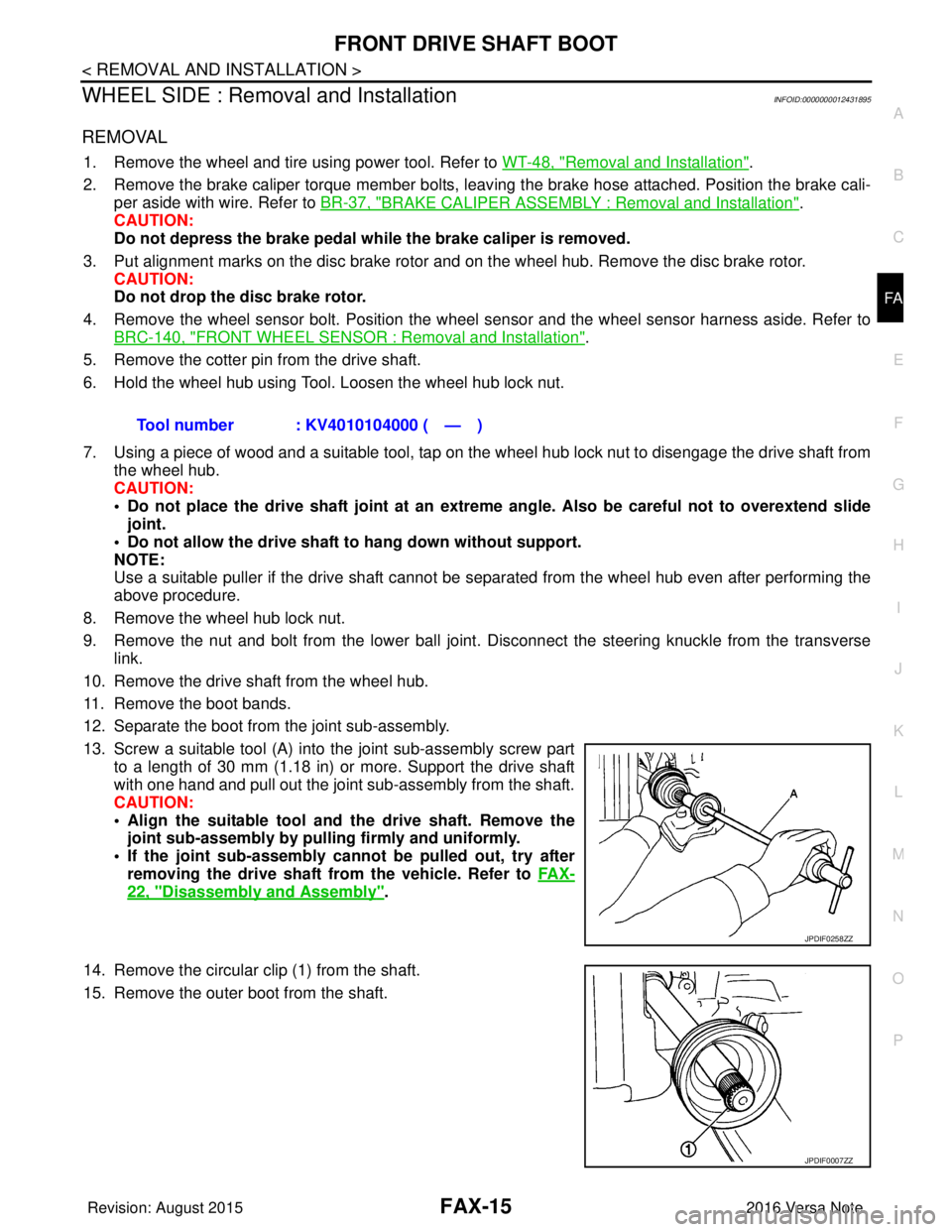

13. Screw a suitable tool (A) into the joint sub-assembly screw part to a length of 30 mm (1.18 in) or more. Support the drive shaft

with one hand and pull out the joint sub-assembly from the shaft.

CAUTION:

• Align the suitable tool an d the drive shaft. Remove the

joint sub-assembly by pull ing firmly and uniformly.

• If the joint sub-assembly cannot be pulled out, try after removing the drive shaft from the vehicle. Refer to FA X -

22, "Disassembly and Assembly".

14. Remove the circular clip (1) from the shaft.

15. Remove the outer boot from the shaft. Tool number : KV4010104000 ( — )

JPDIF0258ZZ

JPDIF0007ZZ

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1834 of 3641

FRONT DRIVE SHAFT BOOTFAX-17

< REMOVAL AND INSTALLATION >

CEF

G H

I

J

K L

M A

B

FA X

N

O P

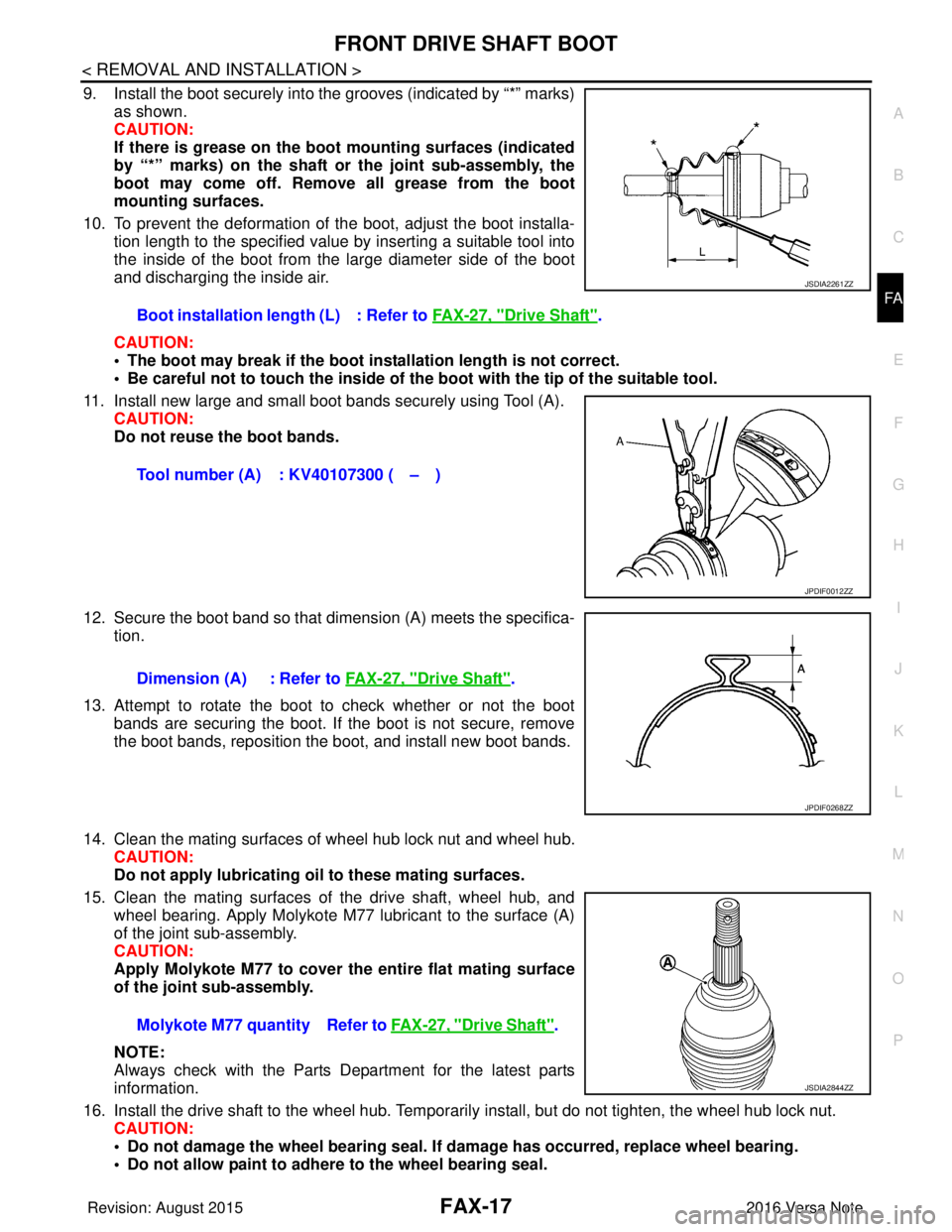

9. Install the boot securely into the grooves (indicated by “*” marks) as shown.

CAUTION:

If there is grease on the bo ot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remo ve all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot in stallation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

11. Install new large and small boot bands securely using Tool (A). CAUTION:

Do not reuse the boot bands.

12. Secure the boot band so that dimension (A) meets the specifica- tion.

13. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

14. Clean the mating surfaces of wheel hub lock nut and wheel hub. CAUTION:

Do not apply lubricating oil to these mating surfaces.

15. Clean the mating surfaces of the drive shaft, wheel hub, and wheel bearing. Apply Molykote M77 lubricant to the surface (A)

of the joint sub-assembly.

CAUTION:

Apply Molykote M77 to cover the entire flat mating surface

of the joint sub-assembly.

NOTE:

Always check with the Parts Department for the latest parts

information.

16. Install the drive shaft to the wheel hub. Temporaril y install, but do not tighten, the wheel hub lock nut.

CAUTION:

• Do not damage the wheel bearing seal. If damage has occurred, replace wheel bearing.

• Do not allow paint to adhere to the wheel bearing seal.

Boot installation length (L) : Refer to

FAX-27, "

Drive Shaft".

Tool number (A) : KV40107300 ( – )

JSDIA2261ZZ

JPDIF0012ZZ

Dimension (A) : Refer to FAX-27, "Drive Shaft".

JPDIF0268ZZ

Molykote M77 quantity Refer to FAX-27, "Drive Shaft".

JSDIA2844ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1839 of 3641

FAX-22

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

Disassembly and Assembly

INFOID:0000000012431901

DISASSEMBLY (WHEEL SIDE)

1. Mount the drive shaft in a vise. CAUTION:

When mounting the drive shaft in a vise, always use aluminum or copper plates between the vise

and the drive shaft.

2. Remove the boot bands and slide the boot back.

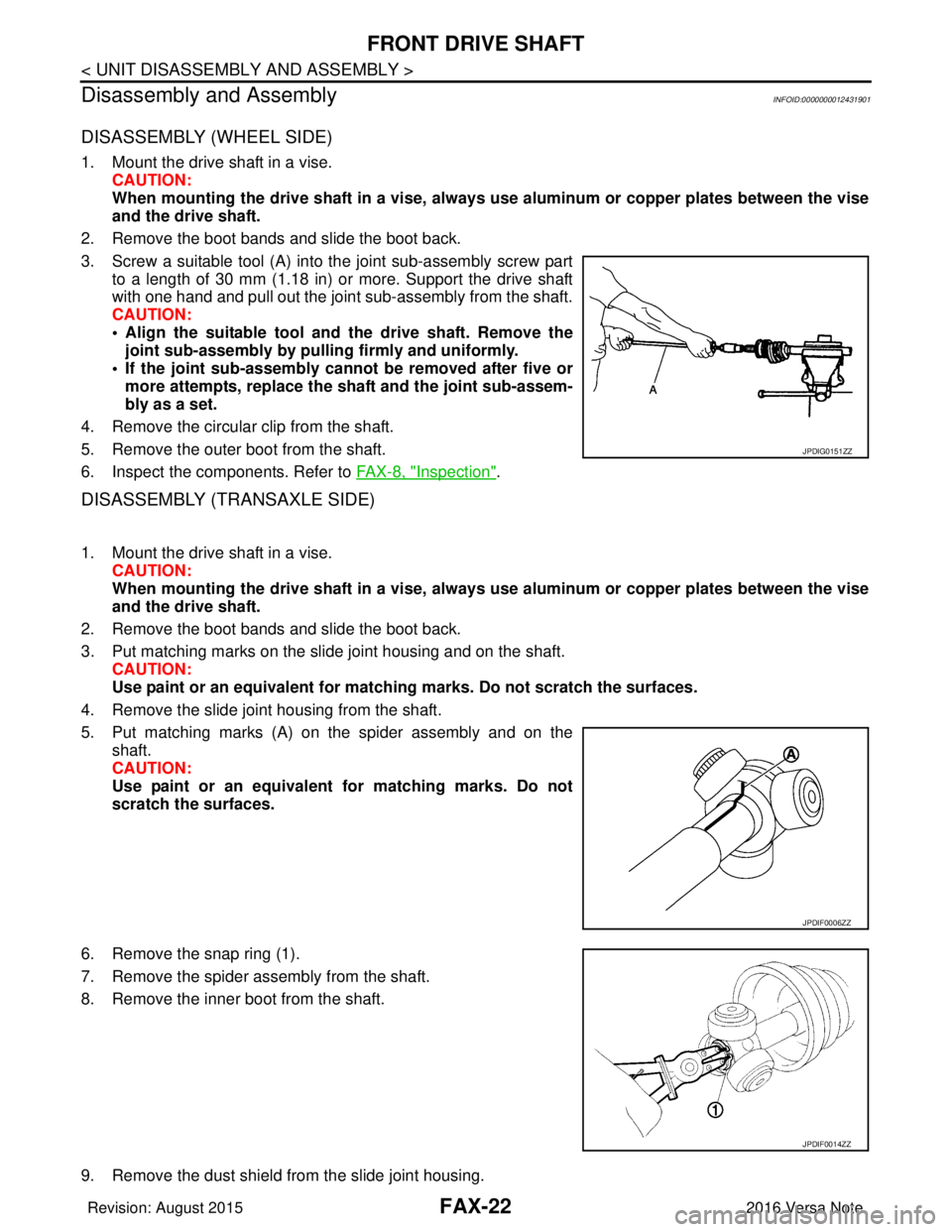

3. Screw a suitable tool (A) into the joint sub-assembly screw part to a length of 30 mm (1.18 in) or more. Support the drive shaft

with one hand and pull out the joint sub-assembly from the shaft.

CAUTION:

• Align the suitable tool and the drive shaft. Remove thejoint sub-assembly by pulli ng firmly and uniformly.

• If the joint sub-assembly cannot be removed after five or more attempts, replace the shaft and the joint sub-assem-

bly as a set.

4. Remove the circular clip from the shaft.

5. Remove the outer boot from the shaft.

6. Inspect the components. Refer to FAX-8, "

Inspection".

DISASSEMBLY (TRANSAXLE SIDE)

1. Mount the drive shaft in a vise. CAUTION:

When mounting the drive shaft in a vise, always use aluminum or copper plates between the vise

and the drive shaft.

2. Remove the boot bands and slide the boot back.

3. Put matching marks on the slide joint housing and on the shaft. CAUTION:

Use paint or an equivalent for matchi ng marks. Do not scratch the surfaces.

4. Remove the slide joint housing from the shaft.

5. Put matching marks (A) on the spider assembly and on the shaft.

CAUTION:

Use paint or an equivalent fo r matching marks. Do not

scratch the surfaces.

6. Remove the snap ring (1).

7. Remove the spider assembly from the shaft.

8. Remove the inner boot from the shaft.

9. Remove the dust shield from the slide joint housing.

JPDIG0151ZZ

JPDIF0006ZZ

JPDIF0014ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1841 of 3641

FAX-24

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

Always check with the Parts Department for the latest parts information.

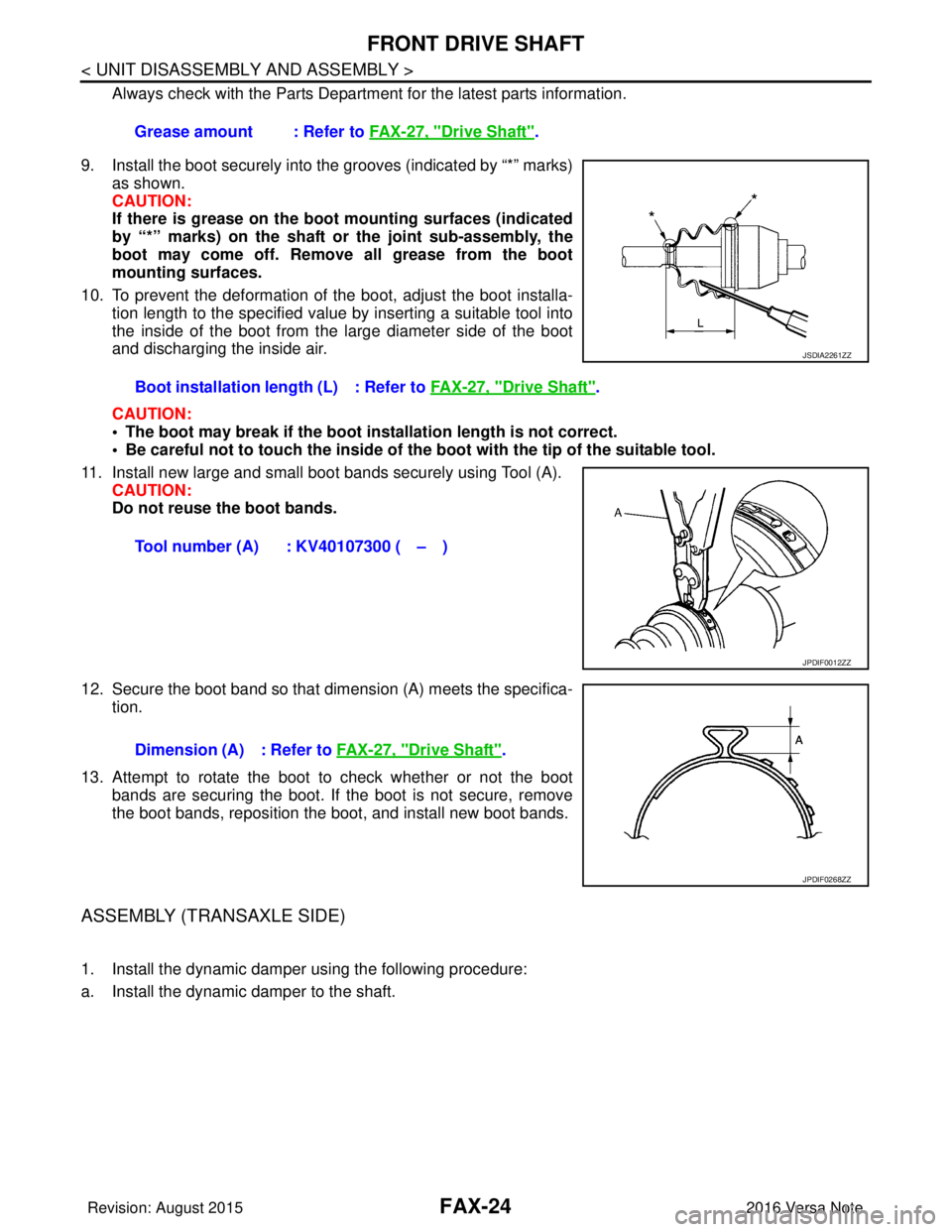

9. Install the boot securely into the grooves (indicated by “*” marks) as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remove all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot installation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

11. Install new large and small boot bands securely using Tool (A). CAUTION:

Do not reuse the boot bands.

12. Secure the boot band so that dimension (A) meets the specifica- tion.

13. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

ASSEMBLY (TRANSAXLE SIDE)

1. Install the dynamic damper using the following procedure:

a. Install the dynamic damper to the shaft. Grease amount : Refer to

FAX-27, "

Drive Shaft".

Boot installation length (L) : Refer to FAX-27, "

Drive Shaft".

Tool number (A) : KV40107300 ( – )

JSDIA2261ZZ

JPDIF0012ZZ

Dimension (A) : Refer to FAX-27, "Drive Shaft".

JPDIF0268ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1843 of 3641

FAX-26

< UNIT DISASSEMBLY AND ASSEMBLY >

FRONT DRIVE SHAFT

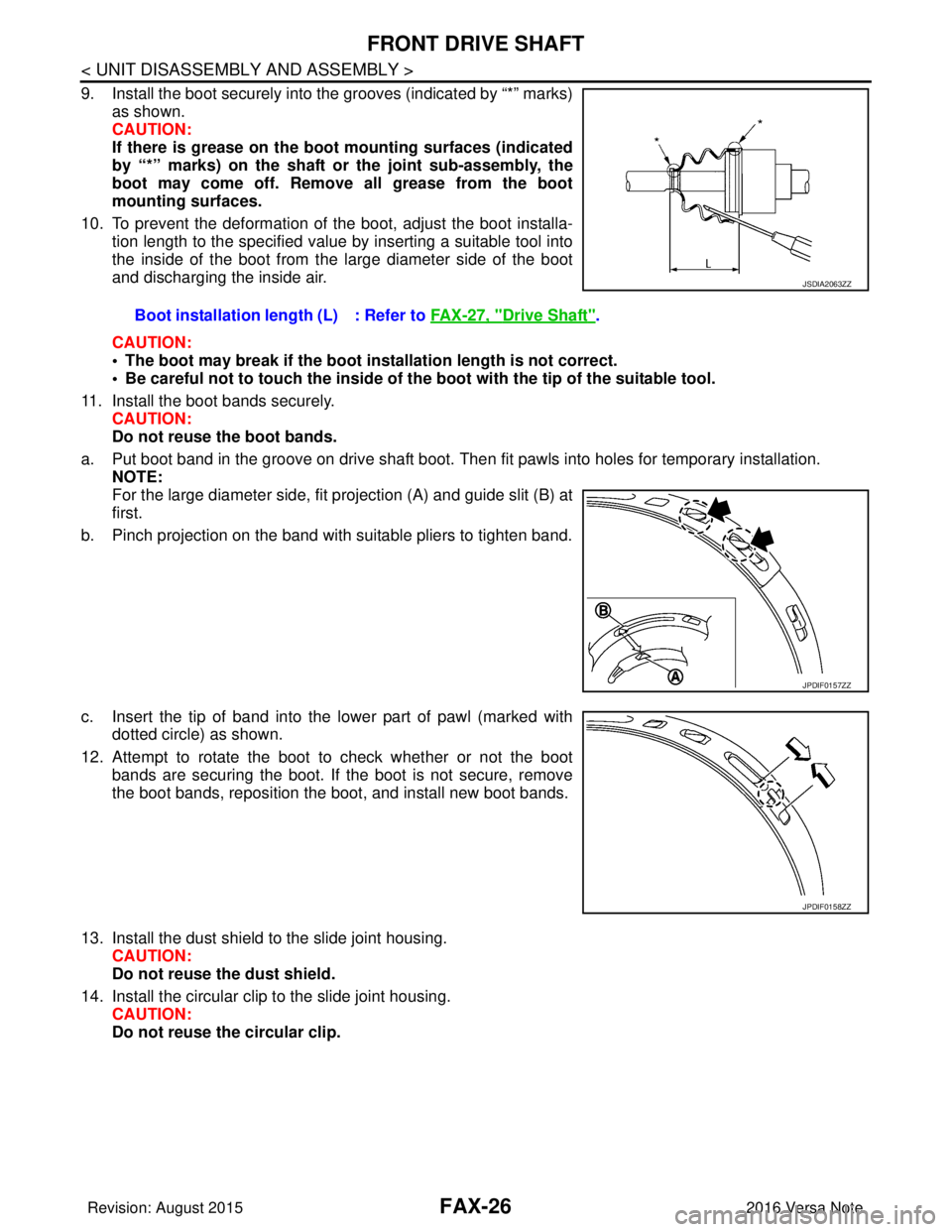

9. Install the boot securely into the grooves (indicated by “*” marks)as shown.

CAUTION:

If there is grease on the boot mounting surfaces (indicated

by “*” marks) on the shaft or the joint sub-assembly, the

boot may come off. Remove all grease from the boot

mounting surfaces.

10. To prevent the deformation of the boot, adjust the boot installa- tion length to the specified value by inserting a suitable tool into

the inside of the boot from the large diameter side of the boot

and discharging the inside air.

CAUTION:

• The boot may break if the boot installation length is not correct.

• Be careful not to touch the inside of the boot with the tip of the suitable tool.

11. Install the boot bands securely. CAUTION:

Do not reuse the boot bands.

a. Put boot band in the groove on drive shaft boot. Then fit pawls into holes for temporary installation. NOTE:

For the large diameter side, fit projection (A) and guide slit (B) at

first.

b. Pinch projection on the band with suitable pliers to tighten band.

c. Insert the tip of band into the lower part of pawl (marked with dotted circle) as shown.

12. Attempt to rotate the boot to check whether or not the boot bands are securing the boot. If the boot is not secure, remove

the boot bands, reposition the boot, and install new boot bands.

13. Install the dust shield to the slide joint housing. CAUTION:

Do not reuse the dust shield.

14. Install the circular clip to the slide joint housing. CAUTION:

Do not reuse the circular clip.Boot installation length (L) : Refer to

FAX-27, "

Drive Shaft".

JSDIA2063ZZ

JPDIF0157ZZ

JPDIF0158ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1844 of 3641

SERVICE DATA AND SPECIFICATIONS (SDS)FAX-27

< SERVICE DATA AND SPECIFICATIONS (SDS)

CEF

G H

I

J

K L

M A

B

FA X

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel BearingINFOID:0000000012431902

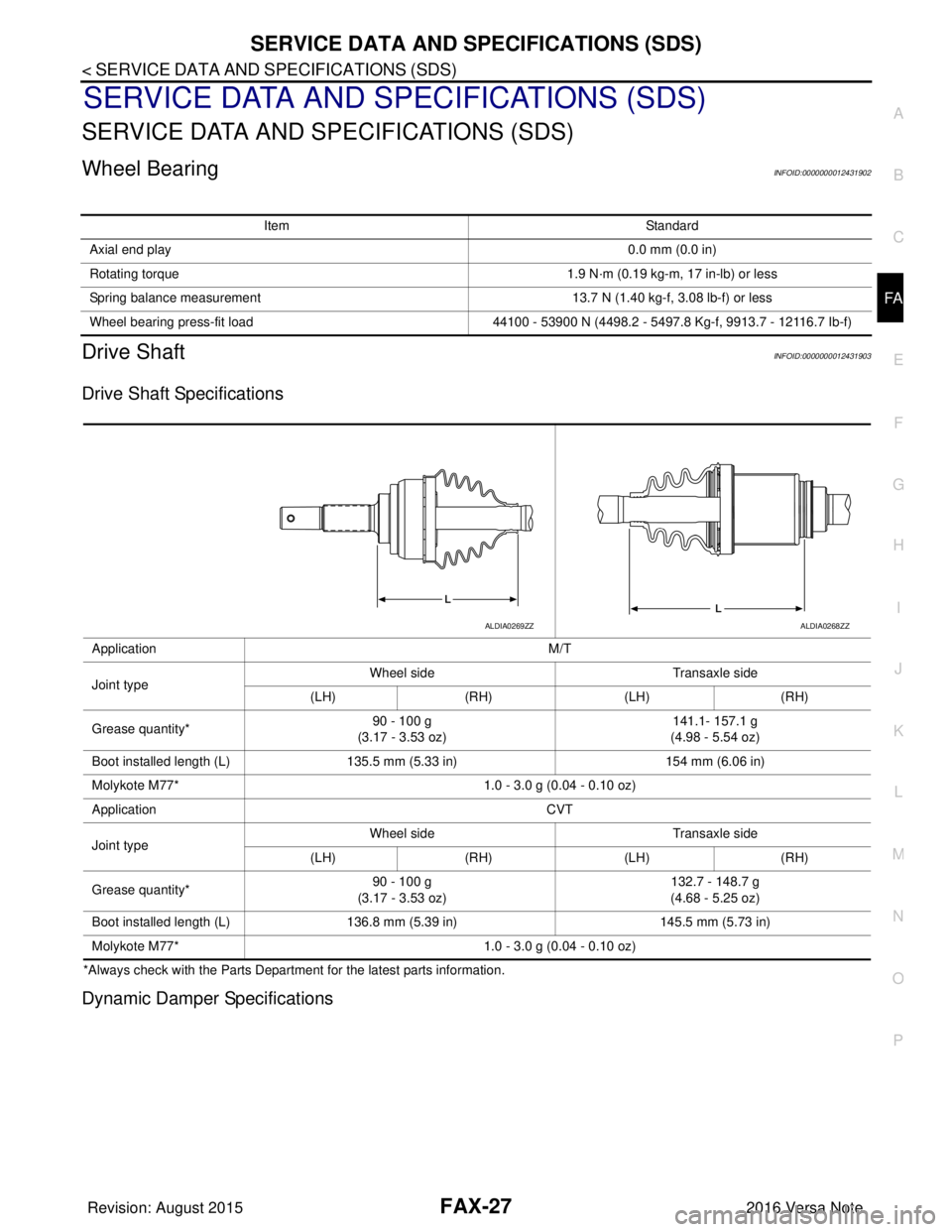

Drive ShaftINFOID:0000000012431903

Drive Shaft Specifications

*Always check with the Parts Departme nt for the latest parts information.

Dynamic Damper Specifications

Item Standard

Axial end play 0.0 mm (0.0 in)

Rotating torque 1.9 N·m (0.19 kg-m, 17 in-lb) or less

Spring balance measurement 13.7 N (1.40 kg-f, 3.08 lb-f) or less

Wheel bearing press-fit load 44100 - 53900 N (4498.2 - 5497.8 Kg-f, 9913.7 - 12116.7 Ib-f)

Application M/T

Joint type Wheel side

Transaxle side

(LH) (RH) (LH)(RH)

Grease quantity* 90 - 100 g

(3.17 - 3.53 oz) 141.1- 157.1 g

(4.98 - 5.54 oz)

Boot installed length (L) 135.5 mm (5.33 in) 154 mm (6.06 in)

Molykote M77* 1.0 - 3.0 g (0.04 - 0.10 oz)

Application CVT

Joint type Wheel side

Transaxle side

(LH) (RH) (LH)(RH)

Grease quantity* 90 - 100 g

(3.17 - 3.53 oz) 132.7 - 148.7 g

(4.68 - 5.25 oz)

Boot installed length (L) 136.8 mm (5.39 in) 145.5 mm (5.73 in)

Molykote M77* 1.0 - 3.0 g (0.04 - 0.10 oz)

ALDIA0269ZZALDIA0268ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1853 of 3641

FSU-8

< PERIODIC MAINTENANCE >

WHEEL ALIGNMENT

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in fr ont of vehicle before pushing it.

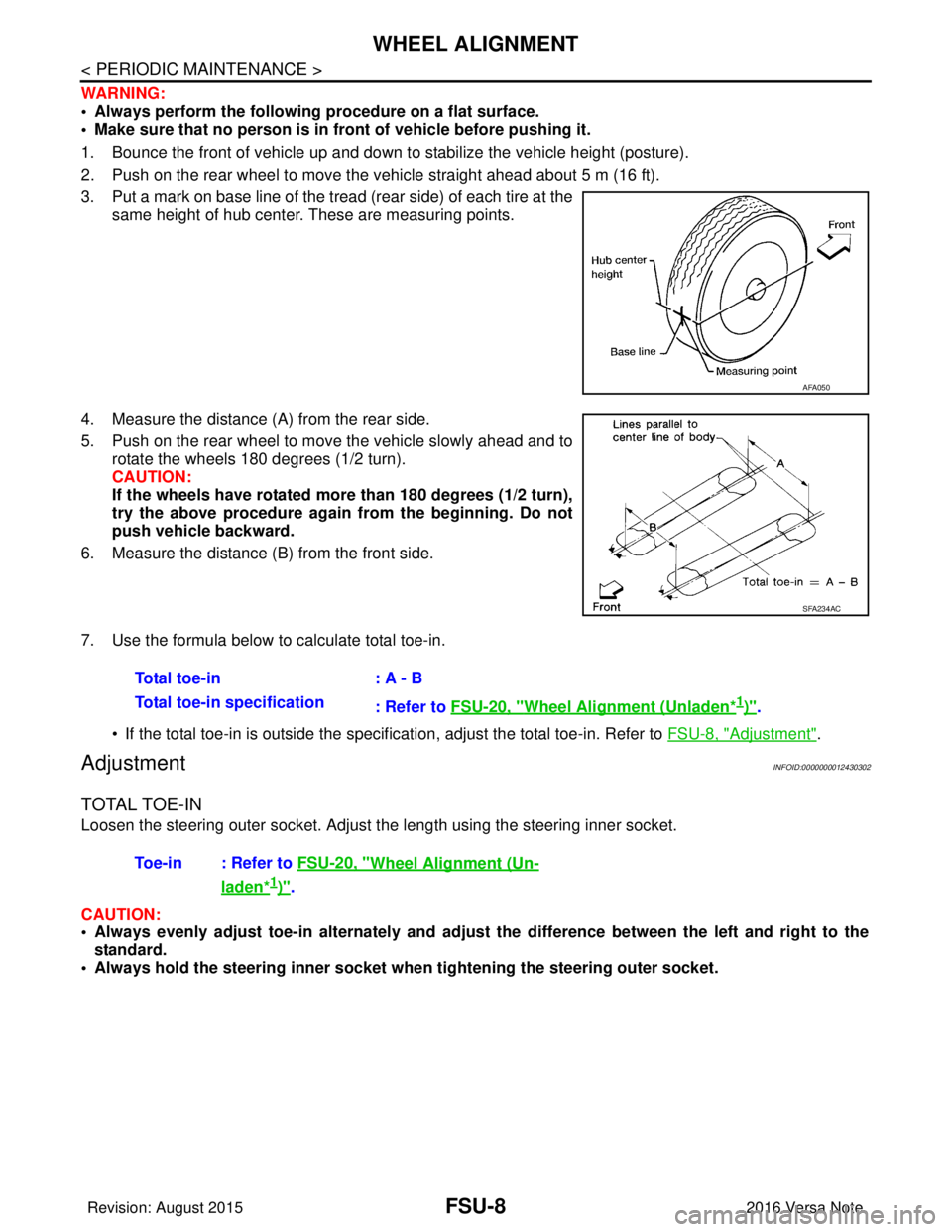

1. Bounce the front of vehicle up and down to stabilize the vehicle height (posture).

2. Push on the rear wheel to move the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of each tire at the same height of hub center. These are measuring points.

4. Measure the distance (A) from the rear side.

5. Push on the rear wheel to move the vehicle slowly ahead and to rotate the wheels 180 degrees (1/2 turn).

CAUTION:

If the wheels have rotated more than 180 degrees (1/2 turn),

try the above procedure again from the beginning. Do not

push vehicle backward.

6. Measure the distance (B) from the front side.

7. Use the formula below to calculate total toe-in.

• If the total toe-in is outside the specification, adjust the total toe-in. Refer to FSU-8, "

Adjustment".

AdjustmentINFOID:0000000012430302

TOTAL TOE-IN

Loosen the steering outer socket. Adjust the length using the steering inner socket.

CAUTION:

• Always evenly adjust toe-in alternately and adjust the difference be tween the left and right to the

standard.

• Always hold the steering inner socket wh en tightening the steering outer socket.

AFA050

SFA234AC

Total toe-in: A - B

Total toe-in specification : Refer to FSU-20, "

Wheel Alignment (Unladen*1)".

Toe-in : Refer to FSU-20, "

Wheel Alignment (Un-

laden*1)".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1879 of 3641

FUEL TANKFL-13

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

FL

NP

O

17. If replacing the fuel tank, remove the fuel level sensor unit, fuel filter and fuel pump assembly to transfer to

the new fuel tank.

CAUTION:

Do not reuse O-ring.

INSTALLATION

Installation is in the reverse order of removal.

Fuel Filler Hose

• Insert fuel filler hose to the length below.

• Be sure hose clamp is not placed on swelled area of fuel filler tube.

• Install fuel filler hose to fuel t ank, paying attention to install mark.

EVAP Hose

1. Check connections for damage or foreign material.

2. Align the matching side connection part with the center of shaft, and insert connector straight until a "click"

sound is heard.

InspectionINFOID:0000000012432114

INSPECTION AFTER INSTALLATION

Use the following procedure to check for fuel leaks.

1. Turn ignition switch “ON” (with engine stopped), then check fuel system connections for leaks by applying

fuel pressure to fuel piping.

2. Start engine and let it idle and check there are no fuel leaks at the fuel system connections.

Fuel filler hose : 35 mm (1.38 in)

Vent hose : 25 mm (0.98 in)

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1914 of 3641

GI-26

< PRECAUTION >

PRECAUTIONS

• U.S. government regulations require ethanol dispensing pumps to be identified by a small, square,

orange and black label with the common abbreviation or the appropriate percentage for that region.

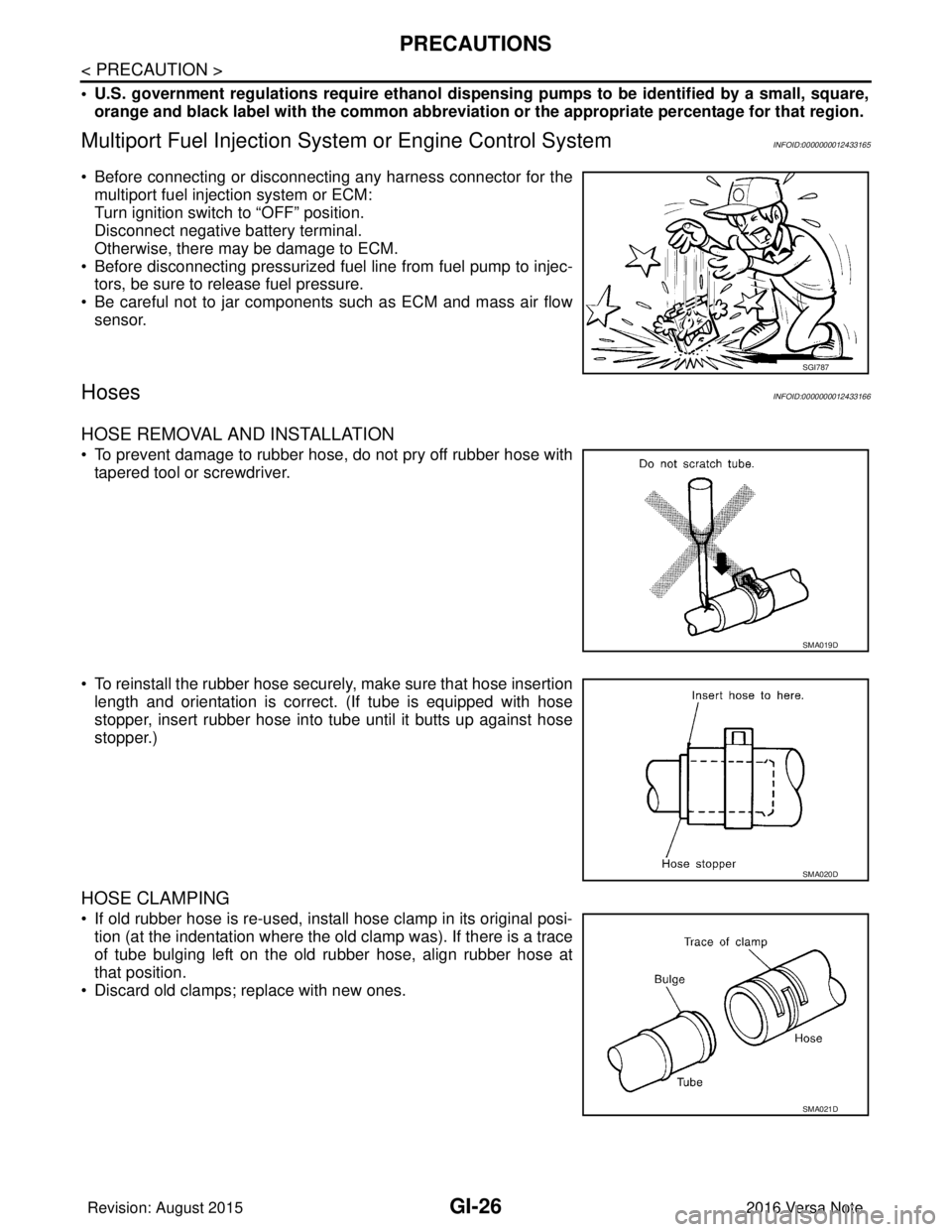

Multiport Fuel Injection System or Engine Control SystemINFOID:0000000012433165

• Before connecting or disconnecting any harness connector for the

multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

• Before disconnecting pressurized fuel line from fuel pump to injec- tors, be sure to release fuel pressure.

• Be careful not to jar components such as ECM and mass air flow sensor.

HosesINFOID:0000000012433166

HOSE REMOVAL AND INSTALLATION

• To prevent damage to rubber hose, do not pry off rubber hose withtapered tool or screwdriver.

• To reinstall the rubber hose securely, make sure that hose insertion length and orientation is correct. (If tube is equipped with hose

stopper, insert rubber hose into tube until it butts up against hose

stopper.)

HOSE CLAMPING

• If old rubber hose is re-used, install hose clamp in its original posi-tion (at the indentation where the old clamp was). If there is a trace

of tube bulging left on the old rubber hose, align rubber hose at

that position.

• Discard old clamps; replace with new ones.

SGI787

SMA019D

SMA020D

SMA021D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1924 of 3641

GI-36

< VEHICLE INFORMATION >

IDENTIFICATION INFORMATION

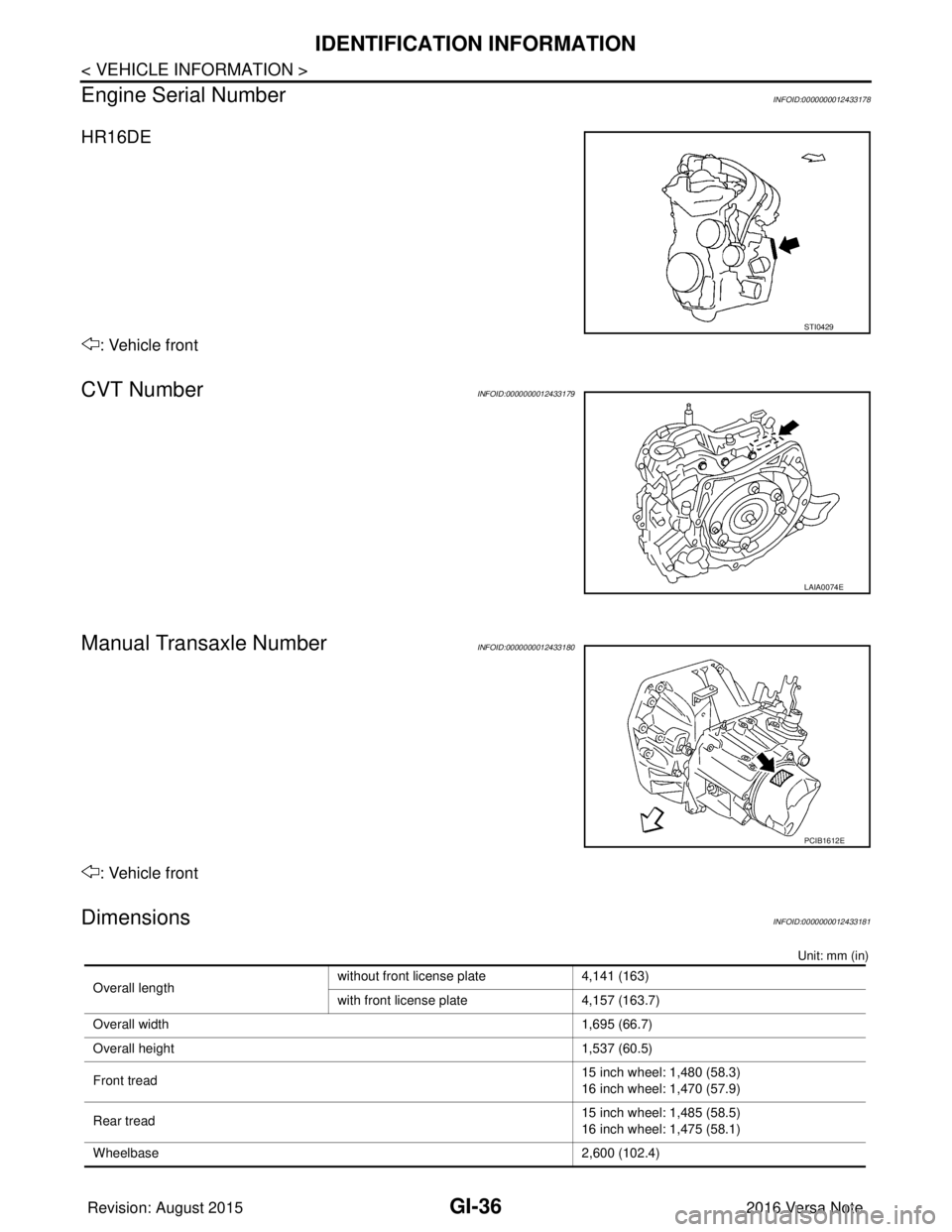

Engine Serial Number

INFOID:0000000012433178

HR16DE

: Vehicle front

CVT NumberINFOID:0000000012433179

Manual Transaxle NumberINFOID:0000000012433180

: Vehicle front

DimensionsINFOID:0000000012433181

Unit: mm (in)

STI0429

LAIA0074E

PCIB1612E

Overall length without front license plate 4,141 (163)

with front license plate

4,157 (163.7)

Overall width 1,695 (66.7)

Overall height 1,537 (60.5)

Front tread 15 inch wheel: 1,480 (58.3)

16 inch wheel: 1,470 (57.9)

Rear tread 15 inch wheel: 1,485 (58.5)

16 inch wheel: 1,475 (58.1)

Wheelbase 2,600 (102.4)

Revision: August 2015 2016 Versa Note

cardiagn.com