width NISSAN NOTE 2016 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1122 of 3641

![NISSAN NOTE 2016 Service User Guide SERVICE DATA AND SPECIFICATIONS (SDS)EM-121

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*1: Diameter made by intersection point of conic angles

α1 and α2

*

2 NISSAN NOTE 2016 Service User Guide SERVICE DATA AND SPECIFICATIONS (SDS)EM-121

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*1: Diameter made by intersection point of conic angles

α1 and α2

*

2](/img/5/57363/w960_57363-1121.png)

SERVICE DATA AND SPECIFICATIONS (SDS)EM-121

< SERVICE DATA AND SPECIFICATIONS (SDS) [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*1: Diameter made by intersection point of conic angles

α1 and α2

*

2: Diameter made by intersection point of conic angles α2 and α3

*

3: Machining data

VALVE SPRING

Cylinder BlockINFOID:0000000012431748

CYLINDER BLOCK

Unit: mm (in)

Angle “ α2” Intake 88

°45 ′ - 90 °15 ′

Exhaust 88°45 ′ - 90 °15 ′

Angle “ α3” Intake

120°

Exhaust 120°

Contacting width “W”*

3Intake 1.44 - 2.1 (0.0567 - .0827)

Exhaust 1.1 - 1.9 (.0433 - .0748) or 0.9 - 2.1 (.0354 - .0827)

Height “h” Intake

4.7 (0.185) 4.15 (0.163)

Exhaust 6.0 (0.236) 5.43 (0.213)

Depth “H” Intake

4.7 (0.185)

Exhaust 6.0 (0.236)

Free height 46.73 mm (1.8398 in)

Installation height 32.40 mm (1.2756 in)

Installation load 136 - 154 N (13.9 - 15.7 kg, 30.6 - 34.6 lb)

Height during valve open 23.96 mm (0.9433 in)

Load with valve open 242 - 272 N (24.7 - 27.7 kg, 54.4 - 61.1 lb)

Surface distortionLimit 0.1 (0.004)

Cylinder bore Inner diameter Standard 78.000 - 78.015 (3.0709 - 3.0715)

Wear limit —

Out-of-round (Difference between “X” and “Y”) Limit 0.015 (0.0006)

Taper (Difference between “A” and “C”) 0.010 (0.0004)

PBIC3924E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1150 of 3641

![NISSAN NOTE 2016 Service User Guide COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is NISSAN NOTE 2016 Service User Guide COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is](/img/5/57363/w960_57363-1149.png)

COMPONENT PARTSEC-23

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

Exhaust Valve Timing Control Solenoid ValveINFOID:0000000012431286

Exhaust valve timing control solenoi

d valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The exhaust valve timing control solenoid valve changes the oil

amount and direction of flow through exhaust valve timing control

unit or stops oil flow.

The longer pulse width retards valve angle.

The shorter pulse width advances valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the exhaust valve angle at the control

position.

Fuel InjectorINFOID:0000000012431287

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

Fuel PumpINFOID:0000000012431288

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for a few seconds after the ignition switch is turned ON to improve engine

start ability. If the ECM receives a engine speed signal from the crankshaft position sensor (POS) and cam-

shaft position sensor (PHASE), it knows that the engi ne is rotating, and causes the pump to operate. If the

engine speed signal is not received when the ignition s witch is ON, the engine stalls. The ECM stops pump

operation and prevents battery discharging, thereby improving safety. The EC M does not directly drive the fuel

pump. It controls the ON/OFF fuel pump rela y, which in turn controls the fuel pump.

JSBIA0652ZZ

JSBIA0742ZZ

SensorInput signal to ECMECM functionActuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE) Engine speed*

Fuel pump controlFuel pump relay

↓

Fuel pump

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and cranking Operates.

When engine is stopped Stops in 1.5 seconds.

Except as shown above Sto ps .

Revision: August 20152016 Versa Note

cardiagn.com

Page 1152 of 3641

![NISSAN NOTE 2016 Service User Guide COMPONENT PARTSEC-25

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Intake Valve Timing Con NISSAN NOTE 2016 Service User Guide COMPONENT PARTSEC-25

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

<Reference data>

*: These data are reference values and are measured between ECM terminals.

Intake Valve Timing Con](/img/5/57363/w960_57363-1151.png)

COMPONENT PARTSEC-25

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

*: These data are reference values and are measured between ECM terminals.

Intake Valve Timing Control Solenoid ValveINFOID:0000000012431293

Intake valve timing control solenoid valve is activated by ON/OFF

pulse duty (ratio) signals from the ECM.

The intake valve timing control solenoid valve changes the oil

amount and direction of flow through intake valve timing control unit

or stops oil flow.

The longer pulse width advances valve angle.

The shorter pulse width retards valve angle.

When ON and OFF pulse widths become equal, the solenoid valve

stops oil pressure flow to fix the intake valve angle at the control

position.

Knock SensorINFOID:0000000012431294

The knock sensor is attached to t

he cylinder block. It senses engine

knocking using a piezoelectric el ement. A knocking vibration from

the cylinder block is sensed as vibrational pressure. This pressure is

converted into a voltage signal and sent to the ECM.

Battery Current Sensor (With Battery Temperature Sensor)INFOID:0000000012431295

OUTLINE

The power generation voltage variable control enables fuel con-

sumption to be decreased by reducing the engine load which is

caused by the power generation of the generator.

Based on sensor signals, ECM judges whether or not the power

generation voltage variable contro l is performed. When performing

the power generation voltage variable control, ECM calculates the

target power generation voltage based on the sensor signal. And

ECM sends the calculated value as the power generation command

value to IPDM E/R. For the details of the power generation voltage

variable control, refer to CHG-8, "

System Description".

CAUTION:

Never connect the electrical co mponent or the ground wire

directly to the battery terminal. The connection cau ses the malfunction of the power generation volt-

age variable control, and then the battery discharge may occur.

BATTERY CURRENT SENSOR

The battery current sensor is installed to the battery negative cable. The sensor measures the charging/dis-

charging current of the battery.

Intake air temperature [ °C ( °F)] Voltage* (V) Resistance (k Ω)

25 (77) 3.31.800 - 2.200

80 (176) 1.20.283 - 0.359

SEF012P

PBIB1842E

JSBIA0284ZZ

JPBIA3262ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1161 of 3641

![NISSAN NOTE 2016 Service User Guide EC-34

< SYSTEM DESCRIPTION >[HR16DE]

SYSTEM

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback sys

tem provides the best air-fuel mixture ra tio for drivability and emissi NISSAN NOTE 2016 Service User Guide EC-34

< SYSTEM DESCRIPTION >[HR16DE]

SYSTEM

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback sys

tem provides the best air-fuel mixture ra tio for drivability and emissi](/img/5/57363/w960_57363-1160.png)

EC-34

< SYSTEM DESCRIPTION >[HR16DE]

SYSTEM

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback sys

tem provides the best air-fuel mixture ra tio for drivability and emission control.

The three way catalyst (manifold) can better reduce CO, HC and NOx emissions. This system uses A/F sen-

sor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The ECM adjusts the

injection pulse width according to the sensor voltage signal. For more information about A/F sensor 1, refer to

EC-19, "

Air Fuel Ratio Sensor 1". This maintains the mixture ratio within the range of stoichiometric (ideal air-

fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of A/F sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal from heated

oxygen sensor 2.

• Open Loop Control The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

- Deceleration and acceleration

- High-load, high-speed operation

- Malfunction of A/F sensor 1 or its circuit

- Insufficient activation of heated sensor 1 at low engine coolant temperature

- High engine coolant temperature

- During warm-up

- After shifting from N to D (CVT models)

- When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors t he mixture ratio signal transmitted from A/F sensor 1.

This feedback signal is then sent to the ECM. The ECM c ontrols the basic mixture ratio as close to the theoret-

ical mixture ratio as possible. However, the basic mi xture ratio is not necessarily controlled as originally

designed. Both manufacturing differences (i.e., mass ai r flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes “short-term fuel trim” and “long-term fuel trim”.

“Short-term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from A/F sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the the-

oretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an increase in

fuel volume if it is lean.

“Long-term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation

of the “short-term fuel trim” from the central value. Such deviation will occur due to individual engine differ-

ences, wear over time and changes in the usage environment.

PBIB2793E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1162 of 3641

![NISSAN NOTE 2016 Service User Guide SYSTEMEC-35

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL INJECTION TIMING

Two types of systems are used.

• Sequential Multiport Fuel Injection System

Fuel is injected into ea NISSAN NOTE 2016 Service User Guide SYSTEMEC-35

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL INJECTION TIMING

Two types of systems are used.

• Sequential Multiport Fuel Injection System

Fuel is injected into ea](/img/5/57363/w960_57363-1161.png)

SYSTEMEC-35

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

FUEL INJECTION TIMING

Two types of systems are used.

• Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycl e according to the firing order. This system is used

when the engine is running.

• Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals

of the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speeds.

ELECTRIC IGNITION SYSTEM

ELECTRIC IGNITION SYSTEM : System DiagramINFOID:0000000012431311

ELECTRIC IGNITION SYSTEM : System DescriptionINFOID:0000000012431312

INPUT/OUTPUT SIGNAL CHART

SEF337W

JPBIA4883GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1163 of 3641

![NISSAN NOTE 2016 Service User Guide EC-36

< SYSTEM DESCRIPTION >[HR16DE]

SYSTEM

*1: M/T models

*2: CVT models

*3: ECM determines the start signal status

by the signals of engine speed and battery voltage.

*4: This signal is sent to the NISSAN NOTE 2016 Service User Guide EC-36

< SYSTEM DESCRIPTION >[HR16DE]

SYSTEM

*1: M/T models

*2: CVT models

*3: ECM determines the start signal status

by the signals of engine speed and battery voltage.

*4: This signal is sent to the](/img/5/57363/w960_57363-1162.png)

EC-36

< SYSTEM DESCRIPTION >[HR16DE]

SYSTEM

*1: M/T models

*2: CVT models

*3: ECM determines the start signal status

by the signals of engine speed and battery voltage.

*4: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

Firing order: 1 - 3 - 4 - 2

The ignition timing is controlled by the ECM to maintain the best air-fuel ratio for every running condition of the

engine. The ignition timing data is stored in the ECM.

The ECM receives information such as the injection pulse width and camshaft position sensor signal. Comput-

ing this information, ignition signals are transmitted to the power transistor.

During the following conditions, the ignition timing is re vised by the ECM according to the other data stored in

the ECM.

• At starting

• During warm-up

• At idle

• At low battery voltage

• During acceleration

The knock sensor retard system is designed only for emergencies. The basic ignition timing is programmed

within the anti-knocking zone, if recommended fuel is used under dry conditions. The retard system does not

operate under normal driving conditions. If engine knocking occurs, the \

knock sensor monitors the condition.

The signal is transmitted to the ECM. The ECM retards the ignition timing to eliminate the knocking condition.

AIR CONDITIONING CUT CONTROL

SensorInput signal to ECM ECM function Actuator

Crankshaft position sensor (POS) Engine speed

*3

Piston position

Ignition timing control Ignition coil (with power transistor)

Camshaft position sensor (PHASE)

Mass air flow sensor

Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch

*1

PNP signal

Transmission range switch*2

Battery Battery voltage*3

Knock sensorEngine knocking

Combination meter Vehicle speed

*4

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1189 of 3641

![NISSAN NOTE 2016 Service User Guide EC-62

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

MAS A/F SE-B1

VThe signal voltage of the mass air flow sensor is dis-

played. • When the engine is stopped, a certain

value is indicated. NISSAN NOTE 2016 Service User Guide EC-62

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

MAS A/F SE-B1

VThe signal voltage of the mass air flow sensor is dis-

played. • When the engine is stopped, a certain

value is indicated.](/img/5/57363/w960_57363-1188.png)

EC-62

< SYSTEM DESCRIPTION >[HR16DE]

DIAGNOSIS SYSTEM (ECM)

MAS A/F SE-B1

VThe signal voltage of the mass air flow sensor is dis-

played. • When the engine is stopped, a certain

value is indicated.

• When engine is running, specification range is indica ted in “SPEC”.

B/FUEL SCHDL ms“Base fuel schedule” indicates the fuel injection

pulse width programmed into ECM, prior to any

learned on board correction. When engine is running, specification

range is indicated in “SPEC”.

A/F ALPHA-B1 %The mean value of the air-fuel ratio feedback cor-

rection factor per cycle is indicated. • When the engine is stopped, a certain

value is indicated.

• When engine is running, specification

range is indica ted in “SPEC”.

• This data also includes the data for the air-fuel ratio learning control.

COOLAN TEMP/S °C or °F The engine coolant temperature (determined by the

signal voltage of the engine coolant temperature

sensor) is displayed. When the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine cool-

ant temperature determined by the ECM

is displayed.

A/F SEN1 (B1) VThe A/F signal computed from the input signal of

the air fuel ratio (A/F) sensor 1 is displayed.

HO2S2 (B1) VThe signal voltage of the heated oxygen sensor 2 is

displayed.

HO2S2 MNTR(B1) RICH/LEAN • Display of heated oxygen sensor 2 signal.

- RICH: means the amount of oxygen after three

way catalyst is relatively small.

- LEAN: means the amount of oxygen after three

way catalyst is relatively large. When the engine is stopped, a certain

value is indicated.

VHCL SPEED SE km/h or mph The vehicle speed computed from the vehicle

speed signal sent from combination meter is dis-

played.

BATTERY VOLT V The power supply voltage of ECM is displayed.

ACCEL SEN 1 VThe accelerator pedal position sensor signal volt-

age is displayed. ACCEL SEN 2 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

ACCEL SEN 2

TP SEN 1-B1

VThe throttle position sensor signal voltage is dis-

played. TP SEN 2-B1 signal is converted by

ECM internally. Thus, it differs from

ECM terminal voltage signal.

TP SEN 2-B1

FUEL T/TMP SE

°C or °F The fuel temperature (determined by the signal volt-

age of the fuel tank temperature sensor) is dis-

played.

EVAP SYS PRES VThe signal voltage of EVAP control system pres-

sure sensor is displayed.

FUEL LEVEL SE VThe signal voltage of the fuel level sensor is dis-

played.

START SIGNAL ON/OFF Indicates start signal status [ON/OFF] computed by

the ECM according to the signals of engine speed

and battery voltage. After starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS ON/OFF Indicates idle position [ON/OFF] computed by ECM

according to the accelerator pedal position sensor

signal.

AIR COND SIG ON/OFF Indicates [ON/OFF] condition of the air conditioner

switch as determined by the air conditioner signal.

PW/ST SIGNAL ON/OFF [ON/OFF] condition of the power steering system

(determined by the signal sent from EPS control

unit) is indicated.

Monitored item Unit

DescriptionRemarks

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1190 of 3641

![NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (ECM)EC-63

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

• Indicates [ON/OFF] condition of the electrical

lode signal.

- ON: Rear window defogge NISSAN NOTE 2016 Service User Guide DIAGNOSIS SYSTEM (ECM)EC-63

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

• Indicates [ON/OFF] condition of the electrical

lode signal.

- ON: Rear window defogge](/img/5/57363/w960_57363-1189.png)

DIAGNOSIS SYSTEM (ECM)EC-63

< SYSTEM DESCRIPTION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

OLOAD SIGNAL ON/OFF

• Indicates [ON/OFF] condition of the electrical

lode signal.

- ON: Rear window defogger switch is ON and/or lighting switch is 2nd position.

- OFF: Both rear window defogger switch and light-

ing switch are OFF.

IGNITION SW ON/OFFIndicates [ON/OFF] condition from ignition switch

signal.

HEATER FAN SW ON/OFF Indicates [ON/OFF] condition from the heater fan

switch signal.

BRAKE SW ON/OFFIndicates [ON/OFF] condition from the stop lamp

switch signal.

INJ PULSE-B1 msecIndicates the actual fuel injection pulse width com-

pensated by ECM according to the input signals. When the engine is stopped, a certain

computed value is indicated.

IGN TIMING BTDCIndicates the ignition timing computed by ECM ac-

cording to the input signals. When the engine is stopped, a certain

value is indicated.

CAL/LD VALUE %“Calculated load value” indicates the value of the

current air flow divided by peak air flow.

MASS AIRFLOW g/sIndicates the mass air flow computed by ECM ac-

cording to the signal voltage of the mass air flow

sensor.

PURG VOL C/V %• Indicates the EVAP canister purge volume con-

trol solenoid valve control value computed by the

ECM according to the input signals.

• The opening becomes larger as the value in-

creases.

INT/V TIM(B1) °CA Indicates [ °CA] of intake camshaft advance angle.

EXH/V TIM B1 °CA Indicates [ °CA] of exhaust camshaft retard angle.

INT/V SOL(B1) %• The control value of the intake valve timing con-

trol solenoid valve (determined by ECM accord-

ing to the input signals) is indicated.

• The advance angle becomes larger as the value increases.

AIR COND RLY ON/OFF The air conditioner relay control condition (deter-

mined by ECM according to the input signals) is in-

dicated.

FUEL PUMP RLY ON/OFF Indicates the fuel pump relay control condition de-

termined by ECM according to the input signals.

VENT CONT/V ON/OFF • The control condition of the EVAP canister vent

control valve (determined by ECM according to

the input signals) is displayed.

- ON: Closed

-OFF: Open

THRTL RELAY ON/OFF Indicates the throttle control motor relay control

condition determined by the ECM according to the

input signals.

COOLING FAN HI/LOW/OFF • Indicates the condition of the cooling fan (deter-

mined by ECM according to the input signals).

- HI: High speed operation

- LOW: Low speed operation

-OFF: Stop

HO2S2 HTR (B1) ON/OFF Indicates [ON/OFF] condition of heated oxygen

sensor 2 heater determined by ECM according to

the input signals.

Monitored item Unit

DescriptionRemarks

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1278 of 3641

![NISSAN NOTE 2016 Service User Guide TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000 NISSAN NOTE 2016 Service User Guide TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000](/img/5/57363/w960_57363-1277.png)

TROUBLE DIAGNOSIS - SPECIFICATION VALUEEC-151

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

DTC/CIRCUIT DIAGNOSIS

TROUBLE DIAGNOSIS - SPECIFICATION VALUE

DescriptionINFOID:0000000012431370

The specification (SP) value indicates the tolerance of

the value that is displayed in “SPEC” of “DATA MONI-

TOR” mode of CONSULT during normal operation of the Engine Control System. When the value in “SPEC” of

“DATA MONITOR” mode is within the SP value, the Engine Control System is confirmed OK. When the value

in “SPEC” of “DATA MONITOR” mode is NOT within the SP value, the Engine Control System may have one

or more malfunctions.

The SP value is used to detect malfunctions that may af fect the Engine Control System, but will not light the

MIL.

The SP value will be displayed for the following three items:

• B/FUEL SCHDL (The fuel injection pulse width programmed into ECM prior to any learned on board correc- tion)

• A/F ALPHA-B1 (The mean value of air-fuel ratio feedback correction factor per cycle)

• MAS A/F SE-B1 (The signal voltage of the mass air flow sensor)

Component Function CheckINFOID:0000000012431371

1.START

Make sure that all of the following conditions are satisfied.

• Vehicle driven distance: More than 5,000 km (3,107 miles)

• Barometric pressure: 98.3 - 104.3 kPa (1.003 - 1.064 kg/cm

2, 14.25 - 15.12 psi)

• Atmospheric temperature: 20 - 30 °C (68 - 86° F)

• Engine coolant temperature: 75 - 95 °C (167 - 203° F)

• Transmission: Warmed-up

- CVT models: After the engine is warmed up to normal operating temperature, drive vehicle until “FLUID TEMP SE” (CVT fluid temperature sensor signal) indicates more than 60 °C (140° F).

- M/T models: After the engine is warmed up to normal operating temperature, drive vehicle for 5 minutes.

• Electrical load: Not applied

- Rear window defogger switch, air conditioner switch, lighting switch are OFF. Steering wheel is straight

ahead.

• Engine speed: Idle

>> GO TO 2.

2.PERFORM “SPEC” OF “DATA MONITOR” MODE

With CONSULT

NOTE:

Perform “SPEC” in “DATA MONITOR” mode in maximum scale display.

1. Perform EC-133, "

Work Procedure".

2. Select “B/FUEL SCHDL”, “A/F ALPHA-B1” and “MAS A/F SE-B1” in “SPEC” of “DATA MONITOR” mode

with CONSULT.

3. Make sure that monitor items are within the SP value.

Is the inspection result normal?

YES >> END

NO >> Go to EC-152, "

Diagnosis Procedure".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1905 of 3641

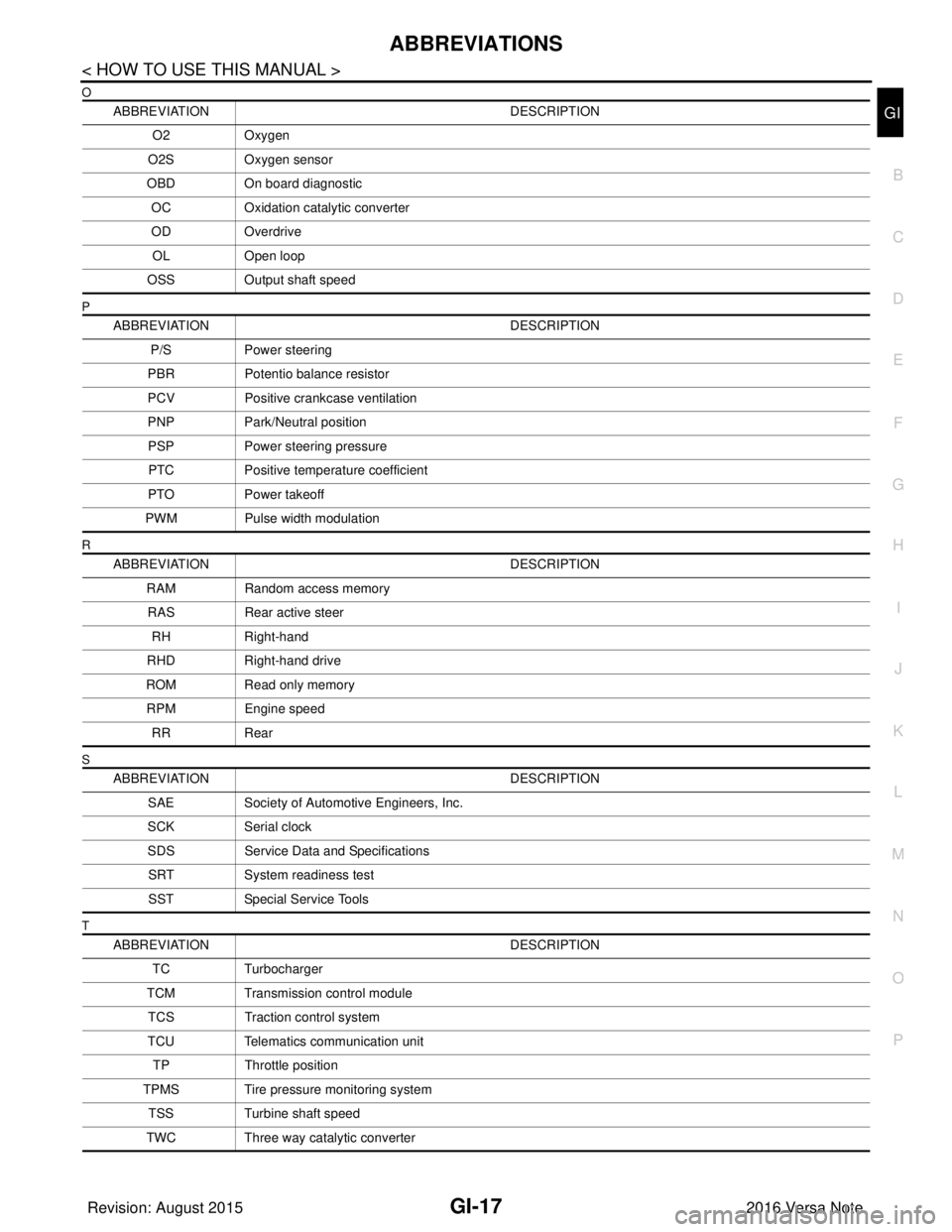

ABBREVIATIONSGI-17

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

O

P

R

S

T

ABBREVIATION DESCRIPTION

O2 Oxygen

O2S Oxygen sensor

OBD On board diagnostic

OC Oxidation catalytic converter

OD Overdrive

OL Open loop

OSS Output shaft speed

ABBREVIATION DESCRIPTION

P/S Power steering

PBR Potentio balance resistor

PCV Positive crankcase ventilation

PNP Park/Neutral position

PSP Power steering pressure

PTC Positive temperature coefficient

PTO Power takeoff

PWM Pulse width modulation

ABBREVIATION DESCRIPTION

RAM Random access memory

RAS Rear active steer

RH Right-hand

RHD Right-hand drive

ROM Read only memory

RPM Engine speed

RR Rear

ABBREVIATION DESCRIPTION

SAE Society of Automoti ve Engineers, Inc.

SCK Serial clock

SDS Service Data and Specifications

SRT System readiness test

SST Special Service Tools

ABBREVIATION DESCRIPTION

TC Turbocharger

TCM Transmission control module

TCS Traction control system

TCU Telematics communication unit

TP Throttle position

TPMS Tire pressure monitoring system TSS Turbine shaft speed

TWC Three way catalytic converter

Revision: August 2015 2016 Versa Note

cardiagn.com