cvt NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1086 of 3641

![NISSAN NOTE 2016 Service Owners Manual CYLINDER HEADEM-85

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine NISSAN NOTE 2016 Service Owners Manual CYLINDER HEADEM-85

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine](/img/5/57363/w960_57363-1085.png)

CYLINDER HEADEM-85

< REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaks Leaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1087 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-86

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Exploded ViewINFOID:0000000012431731

CAUTION:

Check that the stud bolt (*2) is tight at th NISSAN NOTE 2016 Service Owners Manual EM-86

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Exploded ViewINFOID:0000000012431731

CAUTION:

Check that the stud bolt (*2) is tight at th](/img/5/57363/w960_57363-1086.png)

EM-86

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

UNIT REMOVAL AND INSTALLATION

ENGINE ASSEMBLY

Exploded ViewINFOID:0000000012431731

CAUTION:

Check that the stud bolt (*2) is tight at the specified torque before tightening the nut (*1) shown. [Stud

bolt (*2) may be loosened after loosening the nut (*1)]

1. Engine mounting (RH) stay 2. Engine mount (RH) stay

3. Engine mounting insulator (RH)

4. Rear engine mounting bracket 5. Rear torque rod 6. Engine mounting bracket (LH)

7. Engine mounting bracket (LH) 8. Engine mounting insulator (LH) 9. Mass damper

A. Front mark B. Transaxle (lower) C. CVT models

AWBIA1586ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1089 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-88

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the

transaxle.

REMOVAL

1. Release fu NISSAN NOTE 2016 Service Owners Manual EM-88

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the

transaxle.

REMOVAL

1. Release fu](/img/5/57363/w960_57363-1088.png)

EM-88

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Remove the engine and the transaxle assembly from the vehicle downward. Separate the engine and the

transaxle.

REMOVAL

1. Release fuel pressure. Refer to EC-137, "Work Procedure".

2. Drain engine coolant from radiator. Refer to CO-8, "

Draining Engine Coolant".

CAUTION:

• Perform this step when the engine is cold.

• Do not spill engine coolant on drive belts.

3. Remove the following parts: • Front wheels and tires (RH/LH). Refer to WT-48, "

Removal and Installation".

• Front fender protector (RH/LH). Refer to EXT-38, "

Exploded View".

• Drive belt. Refer to EM-16, "

Removal and Installation".

• Battery and battery tray. Refer to PG-70, "

Exploded View".

• Air duct (inlet), air duct, and air cleaner case assembly. Refer to EM-26, "

Removal and Installation".

• Radiator hose (upper and lower). Refer to CO-13, "

Exploded View".

• Exhaust front tube. Refer to EX-5, "

Exploded View".

4. Disconnect engine room harness connector at the ECM and CVT (if equipped). CAUTION:

Protect connectors against foreign materials during the operation by wrapping in a plastic bag.

5. Disconnect heater hoses. Refer to CO-13, "

Exploded View".

6. Disconnect fuel feed hose at engine side. Refer to EM-40, "

Exploded View".

7. Disconnect control linkage cable from transaxle. Refer to TM-20, "

Exploded View" (M/T models) and TM-

234, "Exploded View" (CVT models).

8. Disconnect clutch tube on transaxle side from clutch damper (M/T models). Refer to CL-15, "

Exploded

View".

9. Remove generator. Refer to CHG-29, "

Exploded View".

10. Disconnect vacuum hose at engine side.

11. Remove EVAP hoses at engine side.

12. Remove A/C compressor from the engine with the piping connected. Temporarily position the A/C com-

pressor on the vehicle side with a rope without placing a heavy load on the piping.

13. Remove ground cable at transaxle side.

14. Remove drive shafts (RH/LH). Refer to FAX-19, "

Removal and Installation".

15. Remove rear torque rod (1).

16. When engine can be hoisted, install engine slinger to cylinder head front left side (A) and rear right side (B) and support the

engine position with a suitable tool.

(2) : Rear engine mounting bracket

: Front

JSBIA0643ZZ

: Engine front

Slinger (A) bolts : 65 N·m (6.6 kg-m, 48 ft-lb)

Slinger (B) bolts : 25 N·m (2.6 kg-m, 18 ft-lb)

AWBIA1134GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1090 of 3641

![NISSAN NOTE 2016 Service Owners Manual ENGINE ASSEMBLYEM-89

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

17. Use a suitable jack (A) to securely support the bottom of the

engine and the transaxle assembly.

CAU NISSAN NOTE 2016 Service Owners Manual ENGINE ASSEMBLYEM-89

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

17. Use a suitable jack (A) to securely support the bottom of the

engine and the transaxle assembly.

CAU](/img/5/57363/w960_57363-1089.png)

ENGINE ASSEMBLYEM-89

< UNIT REMOVAL AND INSTALLATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

17. Use a suitable jack (A) to securely support the bottom of the

engine and the transaxle assembly.

CAUTION:

Put a piece of wood or an equivalent as the supporting sur-

face and secure in a stable condition.

18. Remove engine mounting insulator (RH) (1).

19. Remove engine through bolt-securing nut (C).

20. Carefully lower suitable jack, or raise lift to remove the engine and the transaxle assembly. Observe the following cautions:

CAUTION:

• Check that no part interferes with the vehicle side.

• Before and during lifting, always check if any harnesses are left connected.

• During removal, always be careful to prevent the vehic le from falling off the lift due to changes in

the center of gravity.

• If necessary, support the vehicle by setting jack or suitable tool at the rear.

21. Remove starter motor. Refer to STR-31, "

Exploded View".

22. Lift with a hoist and separate the engine from the transaxle assembly. Refer to TM-24, "

Exploded View"

(M/T models) and TM-259, "Exploded View" (CVT models).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mount-

ing insulator.

• Check that each mounting insulator is seated properly, and tighten nuts and bolts.

• When installation directions are specified, instal l parts according to the direction marks on them,

referring to the figure of components. Refer to EM-86, "

Exploded View".

• Inspect vehicle alignment and adjust (If necessary). Refer to FSU-8, "

Adjustment".

Engine Mounting Insulator (RH)

• Tighten bolts include spec table showing installation torque for

engine mounting bracket in the numerical order as shown.

INSPECTION AFTER INSTALLATION

PBIC3223J

(2) : Engine mounting insulator (LH)

(A) : Engine front side

(B) : Transaxle side

JSBIA1223ZZ

: Front

JPBIA2809ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1091 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the NISSAN NOTE 2016 Service Owners Manual EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the](/img/5/57363/w960_57363-1090.png)

EM-90

< UNIT REMOVAL AND INSTALLATION >[HR16DE]

ENGINE ASSEMBLY

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-11, "

Fluids and Lubricants".

• Use procedure below to check for fuel leaks.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leaks

at connection points.

• Start engine. With engine speed increased, che ck again for fuel leaks at connection points.

• Run engine to check for unusual noise and vibration. NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after engine start. However, this is normal. Noise will stop

after hydraulic pressure rises.

• Warm up engine thoroughly to make sure there are no l eaks of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeaks Level

Engine oil LevelLeaks Level

Transmission/

transaxle fluid CVT Models

LeaksLevel/Leaks Leaks

M/T Models Level/Leaks LeaksLevel/Leaks

Other oils and fluids* LevelLeaks Level

Fuel LeaksLeaksLeaks

Exhaust gas —Leaks —

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1092 of 3641

![NISSAN NOTE 2016 Service Owners Manual ENGINE UNITEM-91

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE UNIT

SettingINFOID:0000000012431733

NOTE:

The following procedures expl NISSAN NOTE 2016 Service Owners Manual ENGINE UNITEM-91

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE UNIT

SettingINFOID:0000000012431733

NOTE:

The following procedures expl](/img/5/57363/w960_57363-1091.png)

ENGINE UNITEM-91

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

UNIT DISASSEMBLY AND ASSEMBLY

ENGINE UNIT

SettingINFOID:0000000012431733

NOTE:

The following procedures explain how to disassemble the engine with the engine stand fastened to the bell

housing. Some steps may be different if using a different type of engine stand.

1. Install engine to engine stand:

a. On (M/T models), remove flywheel.

• Secure flywheel using suitable tool and remove bolts.

CAUTION:

• Do not disassemble flywheel.

• Do not place flywheel with signal plate facing down.

• When handling signal plate, take care not to damage or scratch it.

• Handle signal plate in a manner that prevents it from becoming magnetized.

b. On (CVT models), remove driveplate. • Secure driveplate using suitable tool and remove bolts.

CAUTION:

• Do not disassemble flywheel.

• Do not place flywheel or drive plat e with signal plate facing down.

• When handling signal plate, take care not to damage or scratch it.

• Handle signal plate in a manner that prevents it from becoming magnetized.

c. Lift the engine with a hoist to install it onto a widely used engine stand. CAUTION:

• Use the engine stand that has a load capacity approximately 150 kg (331 lb) or more large

enough for supporting the engine weight.

• If the load capacity of stand is not adequate, remove the following parts beforehand to reduce the poten- tial risk of overturning stand.

- Intake manifold. Refer to EM-28, "

Exploded View".

- Exhaust manifold. Refer to EM-31, "

Removal and Installation".

- Rocker cover. Refer to EM-48, "

Exploded View".

CAUTION:

Before removing the hanging chains, check the engine stand is stable and there is no risk of over-

turning.

NOTE:

The figure shows an example of widely used engine stand (A)

that can support the mating surface of transaxle with flywheel

removed.

2. Drain engine oil. Refer to LU-8, "

Draining".

CAUTION:

• Be sure to clean drain plug and in stall with new drain plug washer.

• Do not reuse drain plug washer. Tool number : KV11105210 (J-44716)

Tool number : KV11105210 (J-44716)

PBIC3227J

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1095 of 3641

![NISSAN NOTE 2016 Service Owners Manual EM-94

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

Disassembly and Assembly

INFOID:0000000012431737

DISASSEMBLY

NOTE:

The following procedures explain how to disassem ble the engine with t NISSAN NOTE 2016 Service Owners Manual EM-94

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

Disassembly and Assembly

INFOID:0000000012431737

DISASSEMBLY

NOTE:

The following procedures explain how to disassem ble the engine with t](/img/5/57363/w960_57363-1094.png)

EM-94

< UNIT DISASSEMBLY AND ASSEMBLY >[HR16DE]

CYLINDER BLOCK

Disassembly and Assembly

INFOID:0000000012431737

DISASSEMBLY

NOTE:

The following procedures explain how to disassem ble the engine with the engine stand fastened to the bell

housing. Some steps may be different if using a different type of engine stand.

1. Remove cylinder head. Refer to EM-76, "

Exploded View".

2. Remove knock sensor. CAUTION:

Carefully handle knock sensor avoiding shocks.

3. Remove the crankshaft position sensor cover (3), and then crankshaft position sensor (POS) (2).

CAUTION:

• Avoid impacts such as a dropping.

• Do not disassemble.

• Keep sensor away from metal particles.

• Do not place the sensor in a location where it is exposed

to magnetism.

• Do not reuse O-ring.

4. Remove oil pan (upper and lower). Refer to EM-34

.

5. Remove piston and connecting rod assembly: • Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer toEM-102, "

Inspection".

a. Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center.

b. Remove connecting rod cap.

c. Using a hammer handle or similar tool, push piston and connect- ing rod assembly out through the cylinder head side.

CAUTION:

• Do not damage mating surface with connecting rod cap.

• Do not damage the cylinder wall or crankshaft pin.

6. Remove connecting rod bearings. CAUTION:

Identify original positions for installation, an d store the bearings without mixing them up.

10. Oil temperature sensor 11. Oil pressure sensor12. Oil jet

13. Top ring 14. Second ring15. Oil rings

16. Piston 17. Piston pin18. Connecting rod

19. Connecting rod bearing (upper) 20. Main bearing (upper) 21. Thrust bearing

22. Crankshaft key 23. Connecting rod bolt24. Connecting rod cap

25. Connecting rod bearing (lower) 26. Main bearing (lower) 27. Crankshaft

28. Pilot converter (CVT models) 29. Signal plate30. Rear oil seal

31. Drive plate (CVT models) 32. Reinforce plate (CVT models) 33. Flywheel (M/T models)

34. Main bearing cap 35. Main bearing cap bolt A. Refer to ASSEMBLY

B. Chamfered Crankshaft side

(1) O-ring

(4) Cylinder block

: Engine front

JPBIA4202ZZ

KBIA3365J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1102 of 3641

![NISSAN NOTE 2016 Service Owners Manual CYLINDER BLOCKEM-101

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install the rear oil seal after installing the oil pan (upper).

17. Install rear oil seal. Refer to EM- NISSAN NOTE 2016 Service Owners Manual CYLINDER BLOCKEM-101

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install the rear oil seal after installing the oil pan (upper).

17. Install rear oil seal. Refer to EM-](/img/5/57363/w960_57363-1101.png)

CYLINDER BLOCKEM-101

< UNIT DISASSEMBLY AND ASSEMBLY > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EM

NP

O

Install the rear oil seal after installing the oil pan (upper).

17. Install rear oil seal. Refer to EM-74, "

REAR OIL SEAL : Removal and Installation".

18. Install flywheel (M/T models) or drive plate (CVT models).

M/T models

• Secure crankshaft with a stopper plate and tighten bolts crosswise over several times.

CVT models

• Secure crankshaft with a stopper plate and tighten bolts crosswise over several times.

CAUTION:

Do not damage or scratch and contact surface for clutch disc of flywheel.

19. Install knock sensor (1).

• Install connectors so that they are positioned toward the rearof the engine.

CAUTION:

• Do not tighten bolt while holding the connector.

• If any impact by dropping is applied to knock sensor,

replace it with a new one.

NOTE:

• Check that there is no foreign material on the cylinder block

mating surface and the back surface of knock sensor.

• Check that knock sensor does not interfere with other parts.

20. Install crankshaft position sensor (POS) (2) and O-ring (1) and then install the crankshaft position sensor cover (3) on the cylin-

der block (4).

• Tighten bolts with sensor inserted completely.

CAUTION:

• Avoid impacts such as a dropping.

• Do not disassemble.

• Keep sensor away from metal particles.

• Do not place the sensor in a location where it is exposedto magnetism.

• Do not reuse O-ring.

21. For the oil level gauge guide (1), secure in position (B) shown to the water inlet clip (A) after inserting to the cylinder block side.

22. Assembly of the remaining components is in the reverse order of disassembly.

Tool number : KV11105210 (J-44716)

Tool number : KV11105210 (J-44716)

: Engine front

: Engine front

PBIC3754E

JPBIA4202ZZ

PBIC3755E

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 1128 of 3641

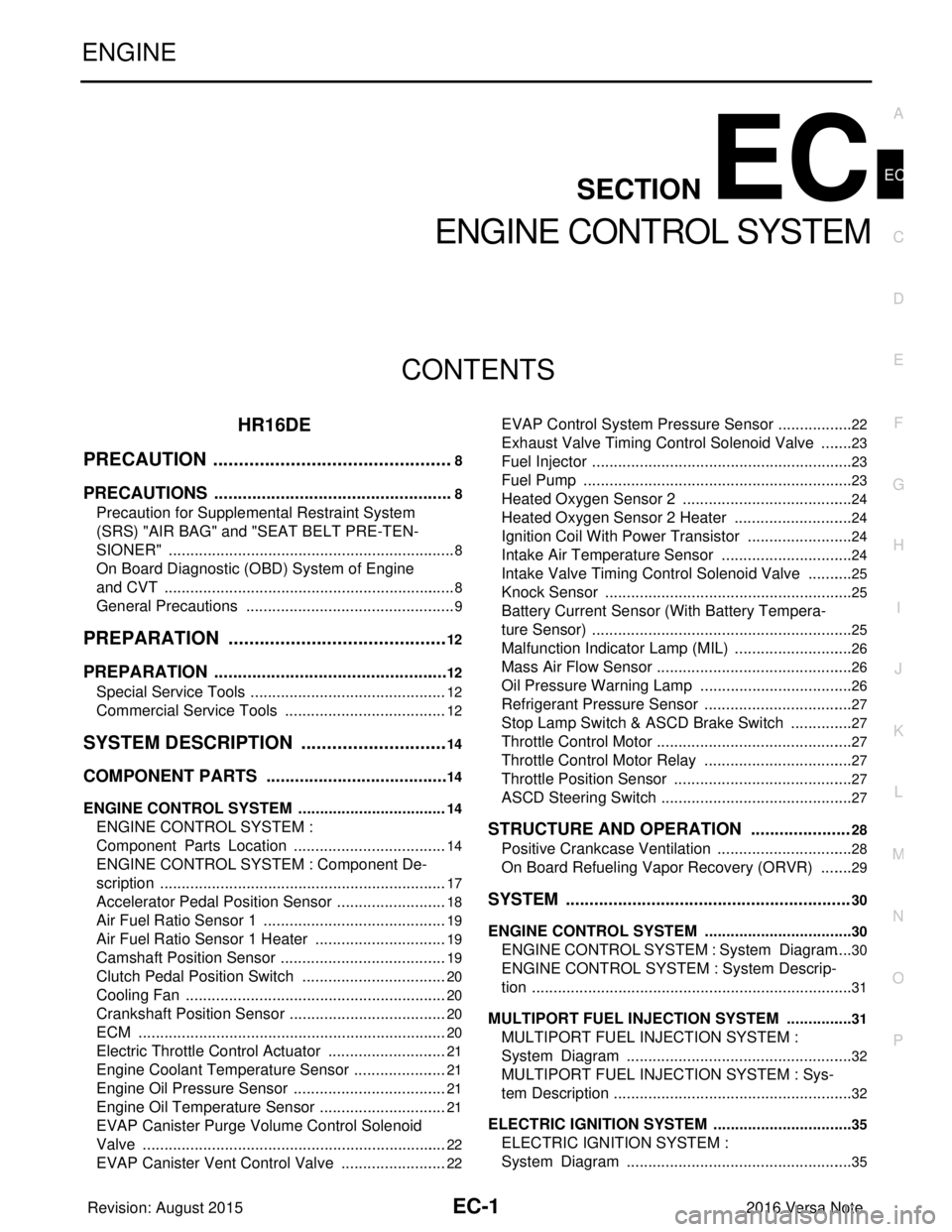

EC-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EC

A

EC

N

O P

CONTENTS

ENGINE CONTROL SYSTEM

HR16DE

PRECAUTION ....... ........................................

8

PRECAUTIONS .............................................. .....8

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

8

On Board Diagnostic (OBD) System of Engine

and CVT ....................................................................

8

General Precautions .................................................9

PREPARATION ...........................................12

PREPARATION .............................................. ....12

Special Service Tools .......................................... ....12

Commercial Service Tools ......................................12

SYSTEM DESCRIPTION .............................14

COMPONENT PARTS ................................... ....14

ENGINE CONTROL SYSTEM ............................... ....14

ENGINE CONTROL SYSTEM :

Component Parts Location ....................................

14

ENGINE CONTROL SYSTEM : Component De-

scription ............................................................... ....

17

Accelerator Pedal Position Sensor ..........................18

Air Fuel Ratio Sensor 1 ...........................................19

Air Fuel Ratio Sensor 1 Heater ...............................19

Camshaft Position Sensor .......................................19

Clutch Pedal Position Switch ..................................20

Cooling Fan .............................................................20

Crankshaft Position Sensor .....................................20

ECM .................................................................... ....20

Electric Throttle Control Actuator ............................21

Engine Coolant Temperature Sensor ......................21

Engine Oil Pressure Sensor ....................................21

Engine Oil Temperature Sensor ..............................21

EVAP Canister Purge Volume Control Solenoid

Valve ................................................................... ....

22

EVAP Canister Vent Control Valve .........................22

EVAP Control System Pressure Sensor ..................22

Exhaust Valve Timing Cont rol Solenoid Valve ........23

Fuel Injector ......................................................... ....23

Fuel Pump ...............................................................23

Heated Oxygen Sensor 2 ........................................24

Heated Oxygen Sensor 2 Heater ............................24

Ignition Coil With Power Transistor .........................24

Intake Air Temperature Sensor ...............................24

Intake Valve Timing Control Solenoid Valve ...........25

Knock Sensor ...................................................... ....25

Battery Current Sensor (With Battery Tempera-

ture Sensor) .............................................................

25

Malfunction Indicator Lamp (MIL) ............................26

Mass Air Flow Sensor ..............................................26

Oil Pressure Warning Lamp ....................................26

Refrigerant Pressure Sensor ............................... ....27

Stop Lamp Switch & ASCD Brake Switch ...............27

Throttle Control Motor .......................................... ....27

Throttle Control Motor Relay ...................................27

Throttle Position Sensor ..........................................27

ASCD Steering Switch .............................................27

STRUCTURE AND OPERATION .....................28

Positive Crankcase Ventilation ................................28

On Board Refueling Vapor Recovery (ORVR) ........29

SYSTEM ............................................................30

ENGINE CONTROL SYSTEM ........................ ...........30

ENGINE CONTROL SYSTEM : System Diagram ....30

ENGINE CONTROL SYSTEM : System Descrip-

tion ...........................................................................

31

MULTIPORT FUEL INJECTION SYSTEM ................31

MULTIPORT FUEL INJECTION SYSTEM :

System Diagram ................................................. ....

32

MULTIPORT FUEL INJECTION SYSTEM : Sys-

tem Description ........................................................

32

ELECTRIC IGNITION SYSTEM .................................35

ELECTRIC IGNITION SYSTEM :

System Diagram ................................................. ....

35

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1135 of 3641

![NISSAN NOTE 2016 Service Owners Manual EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res NISSAN NOTE 2016 Service Owners Manual EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Res](/img/5/57363/w960_57363-1134.png)

EC-8

< PRECAUTION >[HR16DE]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012431263

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

On Board Diagnosti c (OBD) System of Engine and CVTINFOID:0000000012431265

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the negative battery cable before any repair

or inspection work. The open/short circuit of re lated switches, sensors, solenoid valves, etc. will

cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock- ing type harness connector. For descripti on and how to disconnect, refer to PG-9, "

Harness Connec-

tor".

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction info rmation (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

Revision: August 2015 2016 Versa Note

cardiagn.com