roof NISSAN NOTE 2016 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1930 of 3641

GI-42

< BASIC INSPECTION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

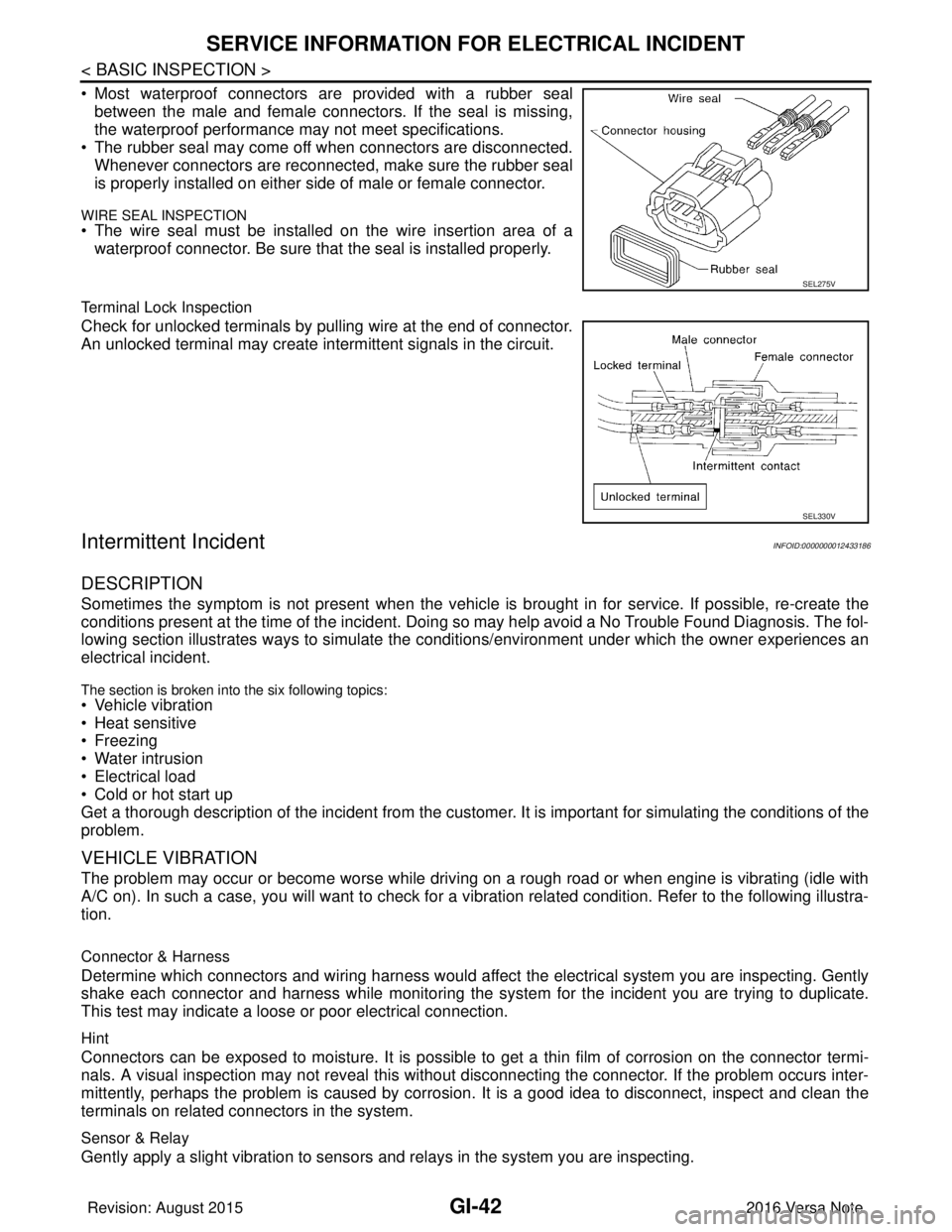

• Most waterproof connectors are provided with a rubber sealbetween the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected. Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

• The wire seal must be installed on the wire insertion area of awaterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

Intermittent IncidentINFOID:0000000012433186

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doi ng so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the condi tions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vi bration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the sy stem for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

SEL275V

SEL330V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1941 of 3641

GW-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION GW

A

B

GW

N

O P

CONTENTS

GLASS & WINDOW SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Handling for Adhesive and Primer ............................2

Precaution for Work ..................................................2

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................4

SYMPTOM DIAGNOSIS ...............................5

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ........................ ........................................

5

Work Flow ........................................................... ......5

Generic Squeak and Rattle Troubleshooting ............6

Diagnostic Worksheet ...............................................9

REMOVAL AND INSTALLATION ...............11

WINDSHIELD GLASS .................................... ....11

Exploded View .................................................... ....11

Removal and Installation ..................................... ....12

OPERA WINDOW .............................................14

Exploded View .........................................................14

Removal and Installation .........................................14

SIDE WINDOW GLASS ....................................16

Exploded View .........................................................16

Removal and Installation .........................................17

BACK DOOR WINDOW GLASS ......................19

Exploded View ..................................................... ....19

Removal and Installation .........................................19

FRONT DOOR GLASS AND REGULATOR .....21

Exploded View .........................................................21

Removal and Installation .........................................21

FRONT POWER WINDOW MOTOR .................24

Removal and Installation .........................................24

REAR DOOR GLASS AND REGULATOR .......25

Exploded View .........................................................25

Removal and Installation .........................................25

REAR POWER WINDOW MOTOR ...................28

Removal and Installation .........................................28

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1947 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESGW-7

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

GW

N

O P

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1952 of 3641

GW-12

< REMOVAL AND INSTALLATION >

WINDSHIELD GLASS

Removal and Installation

INFOID:0000000012430531

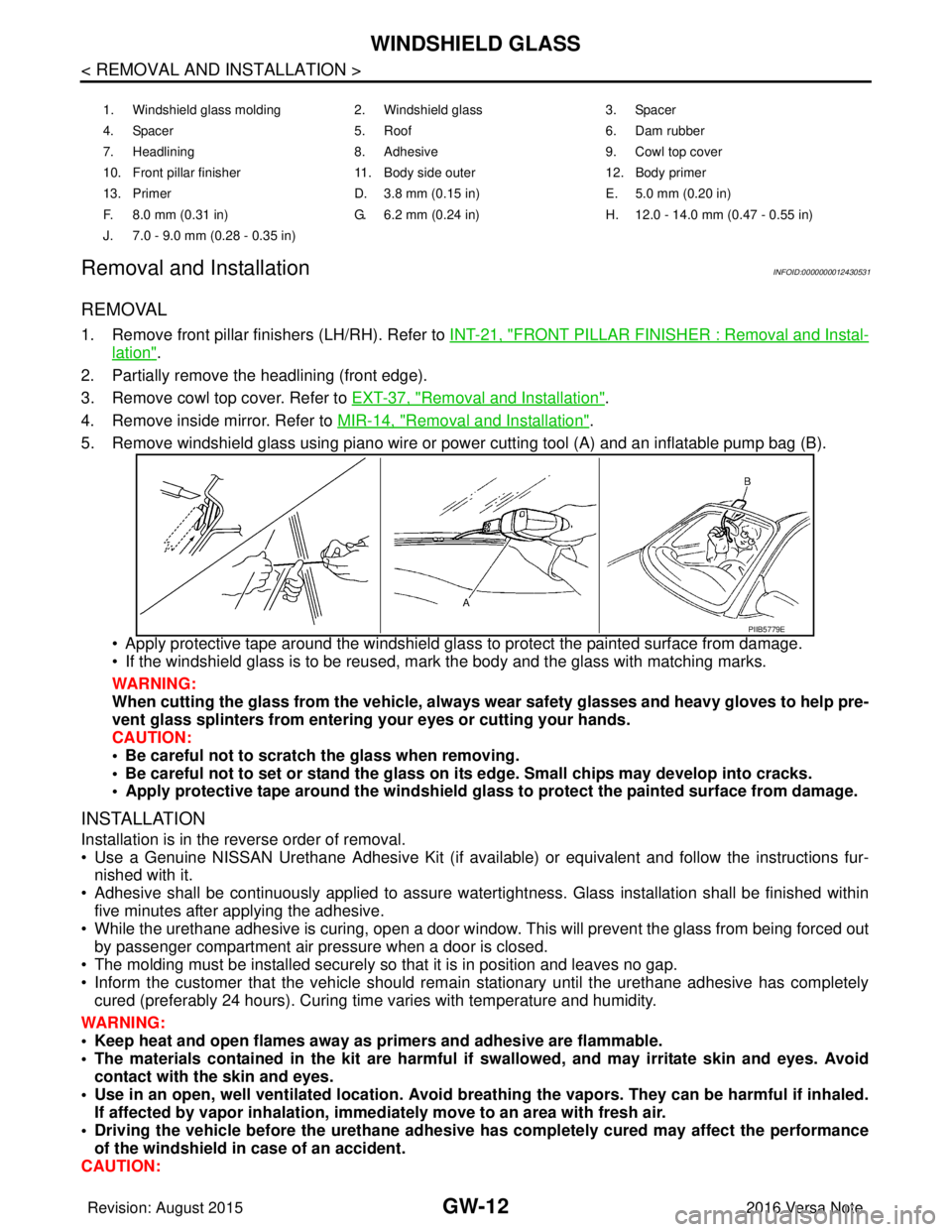

REMOVAL

1. Remove front pillar finishers (LH/RH). Refer to INT-21, "FRONT PILLAR FINISHER : Removal and Instal-

lation".

2. Partially remove the headlining (front edge).

3. Remove cowl top cover. Refer to EXT-37, "

Removal and Installation".

4. Remove inside mirror. Refer to MIR-14, "

Removal and Installation".

5. Remove windshield glass using piano wire or pow er cutting tool (A) and an inflatable pump bag (B).

• Apply protective tape around the windshield gla ss to protect the painted surface from damage.

• If the windshield glass is to be reused, mark the body and the glass with matching marks.

WARNING:

When cutting the glass from the vehicle, always wear safety glasses and heavy gloves to help pre-

vent glass splinters from entering your eyes or cutting your hands.

CAUTION:

• Be careful not to scratch the glass when removing.

• Be careful not to set or stand the glass on its edge. Small chips may develop into cracks.

• Apply protective tape around th e windshield glass to protect the painted surface from damage.

INSTALLATION

Installation is in the reverse order of removal.

• Use a Genuine NISSAN Urethane Adhesive Kit (if availabl e) or equivalent and follow the instructions fur-

nished with it.

• Adhesive shall be continuously applied to assure watert ightness. Glass installation shall be finished within

five minutes after applying the adhesive.

• While the urethane adhesive is curing, open a door window . This will prevent the glass from being forced out

by passenger compartment air pressure when a door is closed.

• The molding must be installed securely so that it is in position and leaves no gap.

• Inform the customer that the vehicle should remain stationary until the urethane adhesive has completely

cured (preferably 24 hours). Curing time varies with temperature and humidity.

WARNING:

• Keep heat and open flames away as primers and adhesive are flammable.

• The materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid

contact with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing the vapors. They can be harmful if inhaled. If affected by vapor inhalation, imme diately move to an area with fresh air.

• Driving the vehicle before the urethane adhesive has completely cured may affect the performance

of the windshield in case of an accident.

CAUTION:

1. Windshield glass molding 2. Windshield glass 3. Spacer

4. Spacer 5. Roof 6. Dam rubber

7. Headlining 8. Adhesive 9. Cowl top cover

10. Front pillar finisher 11. Body side outer 12. Body primer

13. Primer D. 3.8 mm (0.15 in) E. 5.0 mm (0.20 in)

F. 8.0 mm (0.31 in) G. 6.2 mm (0.24 in) H. 12.0 - 14.0 mm (0.47 - 0.55 in)

J. 7.0 - 9.0 mm (0.28 - 0.35 in)

PIIB5779E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2078 of 3641

IP-10

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2162 of 3641

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-11

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noi se. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or ra ttle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the ar eas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2182 of 3641

HEADLININGINT-31

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

Removal and InstallationINFOID:0000000012431874

REMOVAL

1. Remove front pillar finishers (LH/RH). Refer to INT-21, "FRONT PILLAR FINISHER : Removal and Instal-

lation".

2. Remove sun visor screws and sun visors (LH/RH).

3. Remove map lamp. Refer to INL-51, "

Removal and Installation".

4. Remove interior room lamp. Refer to INL-53, "

Removal and Installation".

5. Remove microphone (if equipped). Refer to AV-59, "

Removal and Installation".

6. Remove center pillar upper finishers (LH/RH). Refer to INT-25, "

CENTER PILLAR UPPER FINISHER :

Removal and Installation".

7. Remove luggage side upper finishers (LH/RH). Refer to INT-35, "

LUGGAGE SIDE UPPER FINISHER :

Removal and Installation".

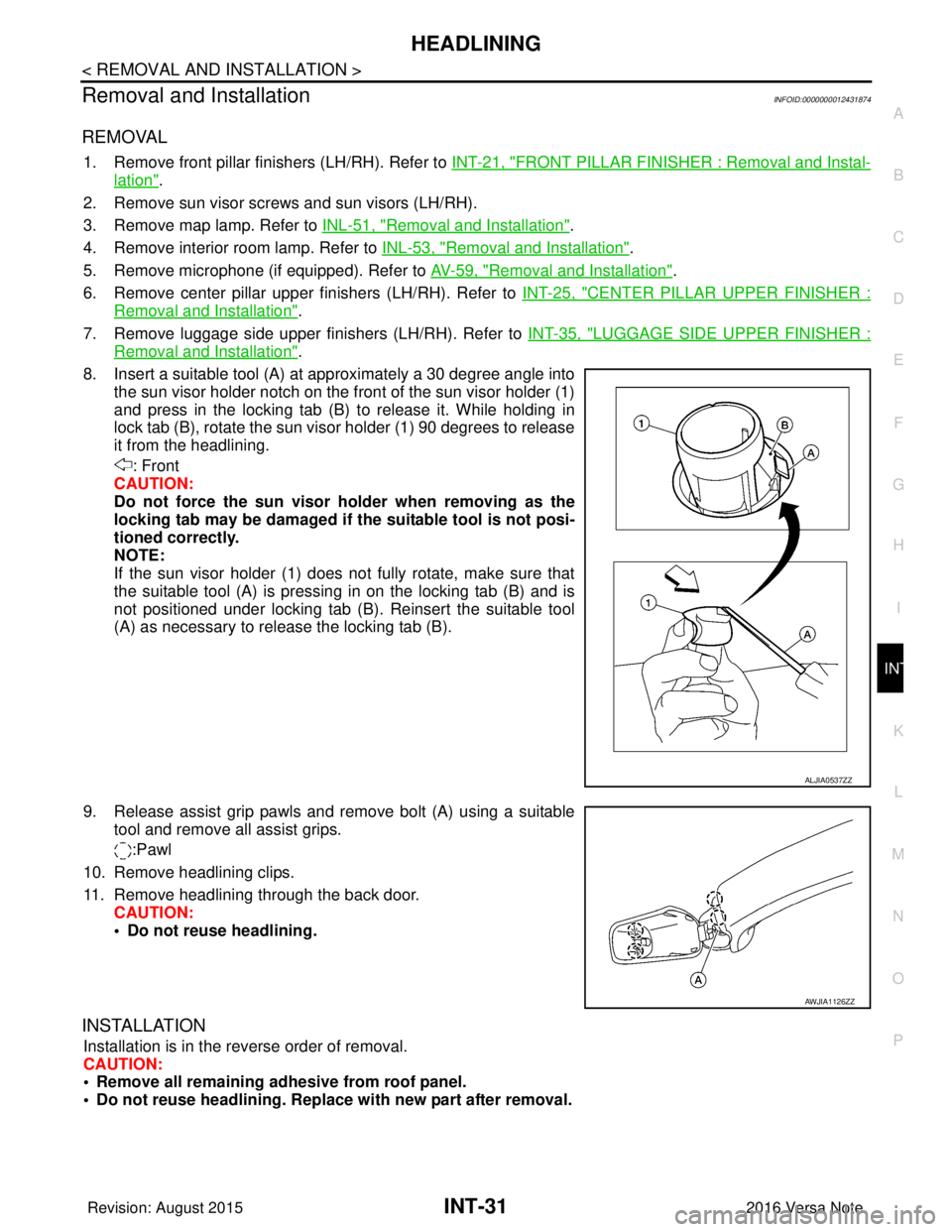

8. Insert a suitable tool (A) at approximately a 30 degree angle into the sun visor holder notch on the front of the sun visor holder (1)

and press in the locking tab (B) to release it. While holding in

lock tab (B), rotate the sun visor holder (1) 90 degrees to release

it from the headlining.

: Front

CAUTION:

Do not force the sun visor ho lder when removing as the

locking tab may be damaged if the suitable tool is not posi-

tioned correctly.

NOTE:

If the sun visor holder (1) does not fully rotate, make sure that

the suitable tool (A) is pressing in on the locking tab (B) and is

not positioned under locking tab (B). Reinsert the suitable tool

(A) as necessary to release the locking tab (B).

9. Release assist grip pawls and remove bolt (A) using a suitable tool and remove all assist grips.

:Pawl

10. Remove headlining clips.

11. Remove headlining through the back door. CAUTION:

• Do not reuse headlining.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Remove all remaining adhesive from roof panel.

• Do not reuse headlini ng. Replace with new part after removal.

ALJIA0537ZZ

AWJIA1126ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2484 of 3641

MIR-10

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2662 of 3641

PWC-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION PWC

A

B

PWC

N

O P

CONTENTS

POWER WINDOW CONTROL SYSTEM

PRECAUTION ....... ........................................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution for Work ..................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Main Power Window And Door Lock/Unlock

Switch ........................................................................

7

Power Window Switch ...............................................7

Power Window Motor ................................................7

SYSTEM ..............................................................8

System Description ............................................. ......8

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) ..........................................

9

COMMON ITEM ..................................................... ......9

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .......................................................

9

RETAINED PWR .......................................................10

RETAINED PWR : CONSULT Function (BCM -

RETAINED PWR) ...................................................

10

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) ...............................

11

COMMON ITEM ..................................................... ....11

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

11

RETAINED PWR .................................................... ....12

RETAINED PWR : CONSULT Function (BCM -

RETAINED PWR) ....................................................

12

ECU DIAGNOSIS INFORMATION ..............13

BCM ...................................................................13

List of ECU Reference ......................................... ....13

POWER WINDOW MAIN SWITCH ...................14

Reference Value ......................................................14

Fail Safe ..................................................................15

WIRING DIAGRAM ......................................16

POWER WINDOW SYSTEM .............................16

Wiring Diagram .................................................... ....16

BASIC INSPECTION ...................................23

DIAGNOSIS AND REPAIR WORK FLOW .......23

Work Flow ............................................................ ....23

DTC/CIRCUIT DIAGNOSIS .........................25

POWER SUPPLY AND GROUND CIRCUIT . ...25

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) ........

.....................................

25

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) : Diagnosis Procedure .. ....

25

BCM (BODY CONTROL SYSTEM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .................................. ....

25

BCM (BODY CONTROL SYSTEM) (WITHOUT

INTELLIGENT KEY SYSTEM) : Diagnosis Proce-

dure ..................................................................... ....

25

POWER WINDOW MAIN SWITCH ........................ ....26

POWER WINDOW MAIN SWITCH : Diagnosis

Procedure ................................................................

26

FRONT POWER WINDOW SWITCH (PASSEN-

GER SIDE) .................................................................

27

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2823 of 3641

SE-10

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. Cluster lid A and the instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar finisher

4. Instrument panel to windshield

5. Instrument panel pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the ar ea with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shift selector assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them wh ile driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-50397) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headlining and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

Revision: August 2015 2016 Versa Note

cardiagn.com