diagram NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 2698 of 3641

POWER WINDOW MOTORPWC-37

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

Is the inspection result normal?

YES >> Replace rear power window switch LH. Refer to PWC-57, "Removal and Installation".

NO >> Repair or replace harness.

REAR RH

REAR RH : Component Function CheckINFOID:0000000012431825

1. CHECK FUNCTION

Check rear power window motor RH operation with main power window and door lock/unlock switch or rear

power window switch RH.

Is the inspection result normal?

YES >> Inspection End.

NO >> Refer to PWC-37, "

REAR RH : Diagnosis Procedure".

REAR RH : Diagnosis ProcedureINFOID:0000000012431826

Regarding Wiring Diagram information, refer to PWC-16, "Wiring Diagram".

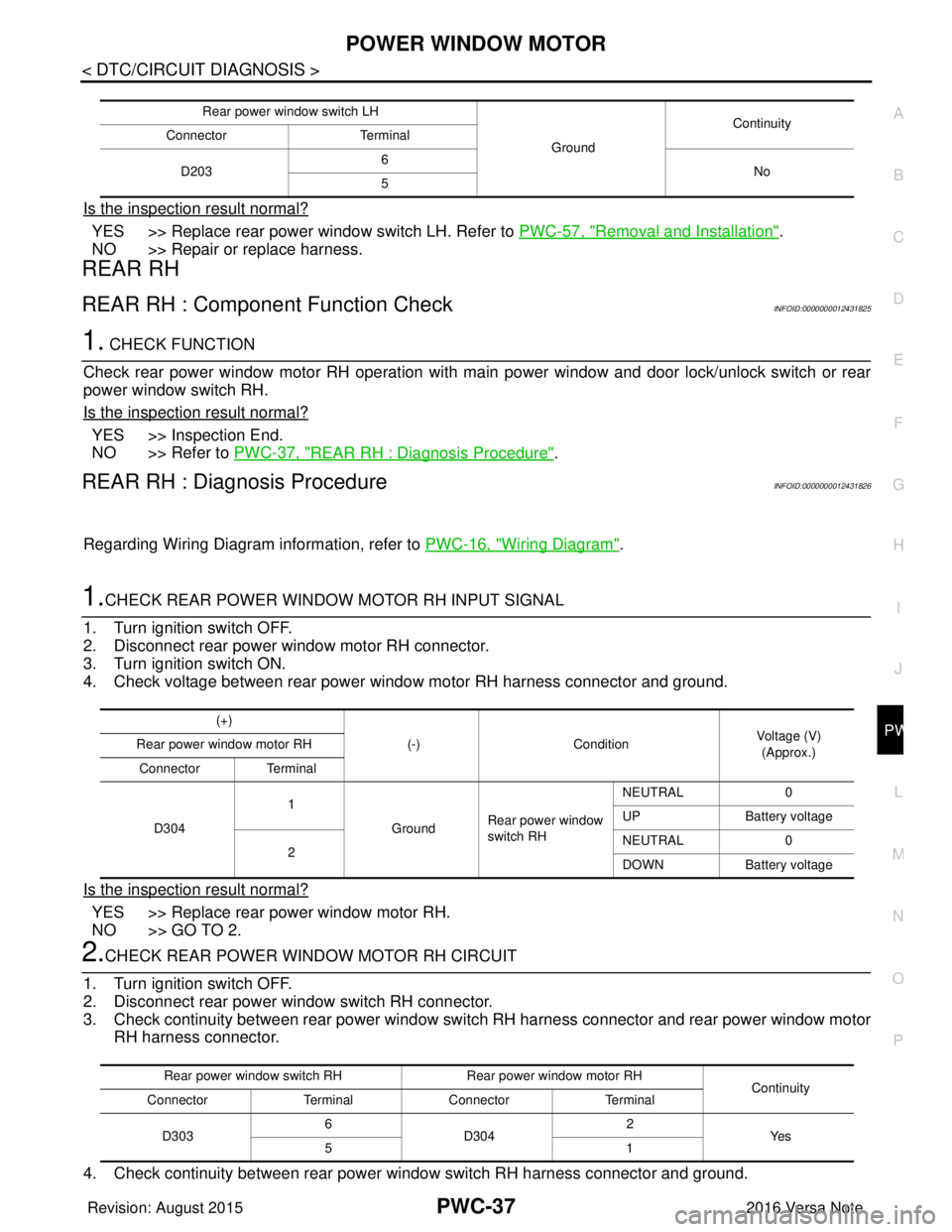

1.CHECK REAR POWER WINDOW MOTOR RH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear power window motor RH connector.

3. Turn ignition switch ON.

4. Check voltage between rear power window motor RH harness connector and ground.

Is the inspection result normal?

YES >> Replace rear power window motor RH.

NO >> GO TO 2.

2.CHECK REAR POWER WINDOW MOTOR RH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear power window switch RH connector.

3. Check continuity between rear power window swit ch RH harness connector and rear power window motor

RH harness connector.

4. Check continuity between rear power window switch RH harness connector and ground.

Rear power window switch LH GroundContinuity

Connector Terminal

D203 6

No

5

(+)

(-)Condition Voltage (V)

(Approx.)

Rear power window motor RH

Connector Terminal

D304 1

GroundRear power window

switch RH NEUTRAL

0

UP Battery voltage

2 NEUTRAL

0

DOWN Battery voltage

Rear power window switch RH Rear power window motor RH

Continuity

Connector TerminalConnector Terminal

D303 6

D304 2

Ye s

51

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2700 of 3641

DOOR SWITCHPWC-39

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

DOOR SWITCH

WITH INTELLIGENT KEY SYSTEM

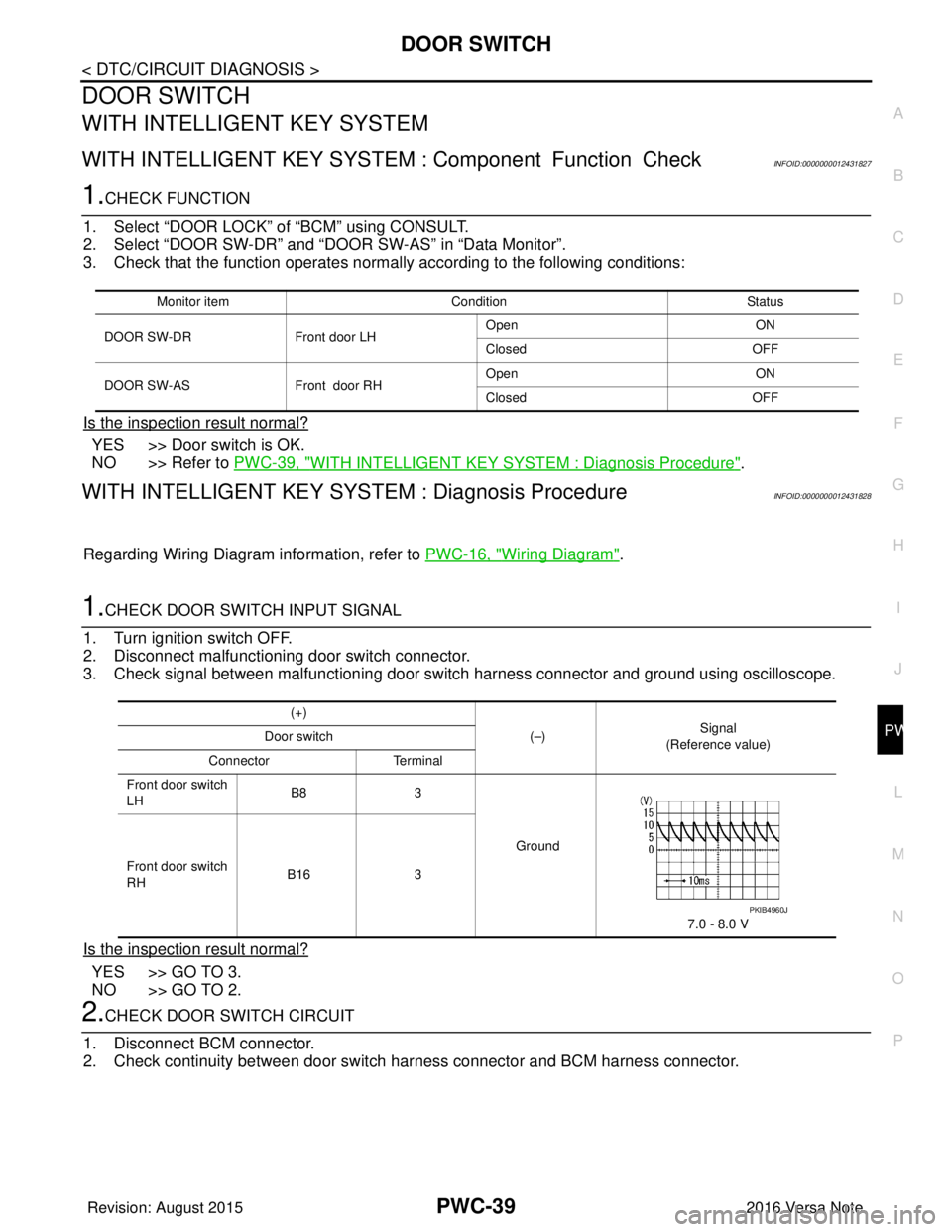

WITH INTELLIGENT KEY SYST EM : Component Function CheckINFOID:0000000012431827

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT.

2. Select “DOOR SW-DR” and “DOOR SW-AS” in “Data Monitor”.

3. Check that the function operates normall y according to the following conditions:

Is the inspection result normal?

YES >> Door switch is OK.

NO >> Refer to PWC-39, "

WITH INTELLIGENT KEY SYSTEM : Diagnosis Procedure".

WITH INTELLIGENT KEY SYST EM : Diagnosis ProcedureINFOID:0000000012431828

Regarding Wiring Diagram information, refer to PWC-16, "Wiring Diagram".

1.CHECK DOOR SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect malfunctioning door switch connector.

3. Check signal between malfunctioning door switch harness connector and ground using oscilloscope.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK DOOR SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between door switch harness connector and BCM harness connector.

Monitor item Condition Status

DOOR SW-DR Front door LH Open

ON

Closed OFF

DOOR SW-AS Front door RHOpen

ON

Closed OFF

(+)

(–)Signal

(Reference value)

Door switch

Connector Terminal

Front door switch

LH B8

3

Ground

7.0 - 8.0 V

Front door switch

RH

B16

3

PKIB4960J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2702 of 3641

DOOR SWITCHPWC-41

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

L

M A

B

PWC

N

O P

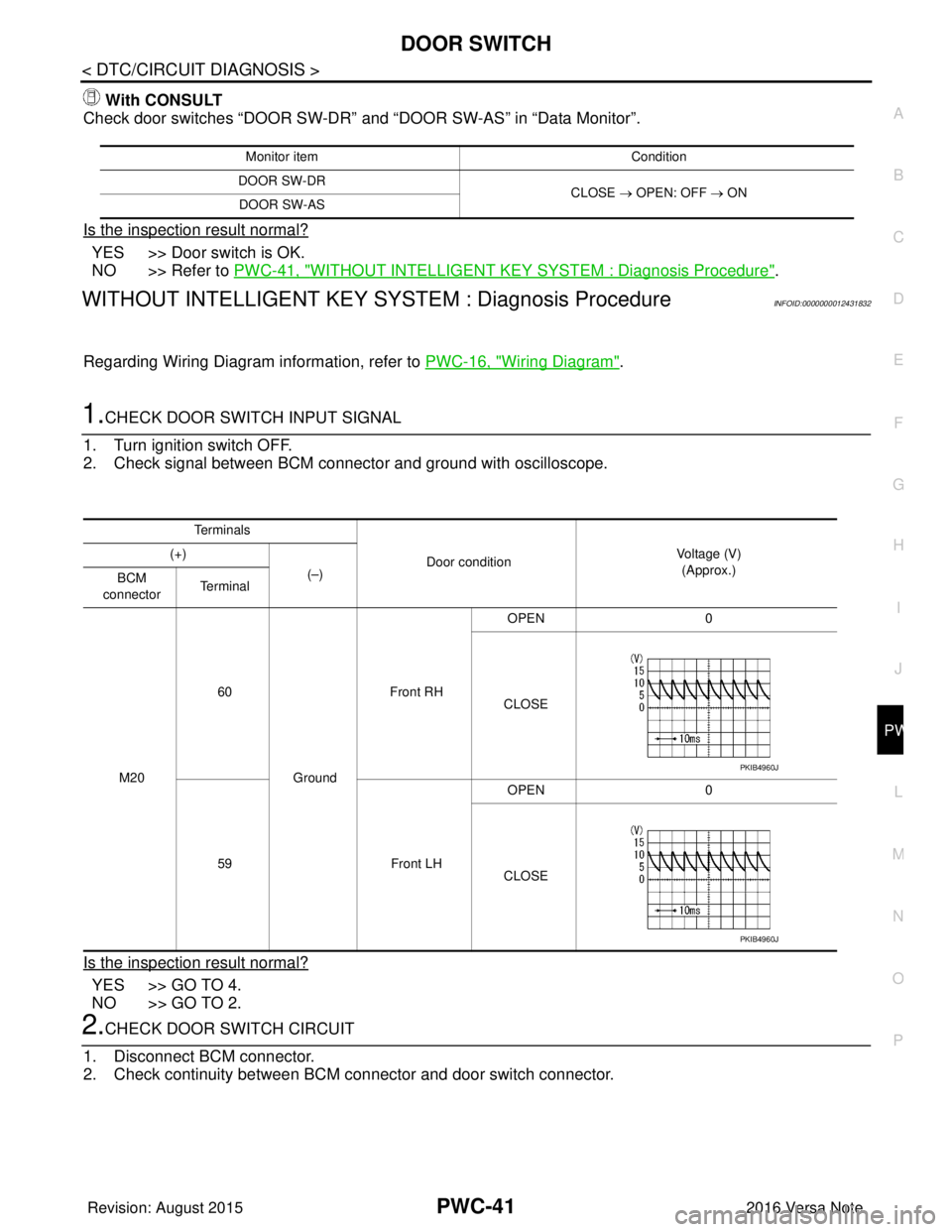

With CONSULT

Check door switches “DOOR SW-DR” and “DOOR SW-AS” in “Data Monitor”.

Is the inspection result normal?

YES >> Door switch is OK.

NO >> Refer to PWC-41, "

WITHOUT INTELLIGENT KEY SY STEM : Diagnosis Procedure".

WITHOUT INTELLIGENT KEY SYSTEM : Diagnosis ProcedureINFOID:0000000012431832

Regarding Wiring Diagram information, refer to PWC-16, "Wiring Diagram".

1.CHECK DOOR SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Check signal between BCM connector and ground with oscilloscope.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK DOOR SWITCH CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM connector and door switch connector.

Monitor item Condition

DOOR SW-DR CLOSE → OPEN: OFF → ON

DOOR SW-AS

Te r m i n a l s

Door condition Voltage (V)

(Approx.)

(+)

(–)

BCM

connector Te r m i n a l

M20 60

Ground Front RH

OPEN

0

CLOSE

59 Front LHOPEN

0

CLOSE

PKIB4960J

PKIB4960J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2744 of 3641

WT-1

SUSPENSION

C

DF

G H

I

J

K L

M

SECTION WT

A

B

WT

N

O PCONTENTS

ROAD WHEELS & TIRES

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Service Notice and Precautions for TPMS ................3

Service Notice and Precautions for Road Wheel ......3

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYSTEM DESCRIPTION ..............................6

COMPONENT PARTS ................................... .....6

Component Parts Location .................................. ......6

Component Description .............................................6

BCM ..........................................................................6

Remote Keyless Entry Receiver ...............................6

Transmitter ................................................................7

Low Tire Pressure Warning Lamp .............................7

SYSTEM ......................................................... .....8

TIRE PRESSURE MONITORING SYSTEM .......... ......8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Diagram ..............................................................

8

TIRE PRESSURE MONITORING SYSTEM : Sys-

tem Description .........................................................

8

TIRE PRESSURE MONITORING SYSTEM :

Easy Fill Tire Alert Function ......................................

8

DIAGNOSIS SYSTEM (BCM) ............................10

WITH INTELLIGENT KEY ..................................... ....10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - COMMON ITEM) ........................................

10

WITH INTELLIGENT KEY : CONSULT Function

(BCM - AIR PRESSURE MONITOR) ......................

11

WITHOUT INTELLIGENT KEY .............................. ....11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - COMMON ITEM) ..................................

11

WITHOUT INTELLIGENT KEY : CONSULT Func-

tion (BCM - AIR PRESSURE MONITOR) ...............

12

ECU DIAGNOSIS INFORMATION ..............14

BCM ...................................................................14

List of ECU Reference ......................................... ....14

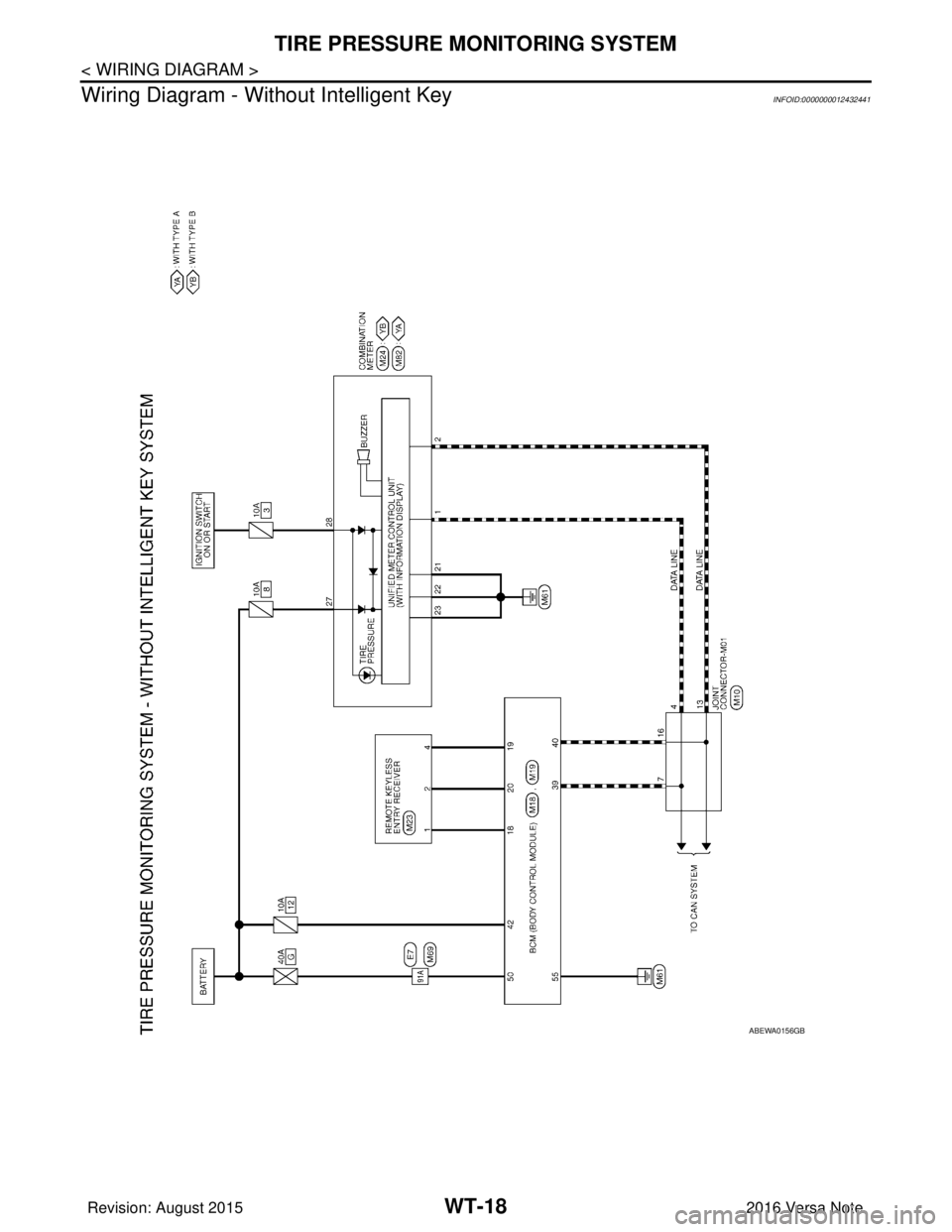

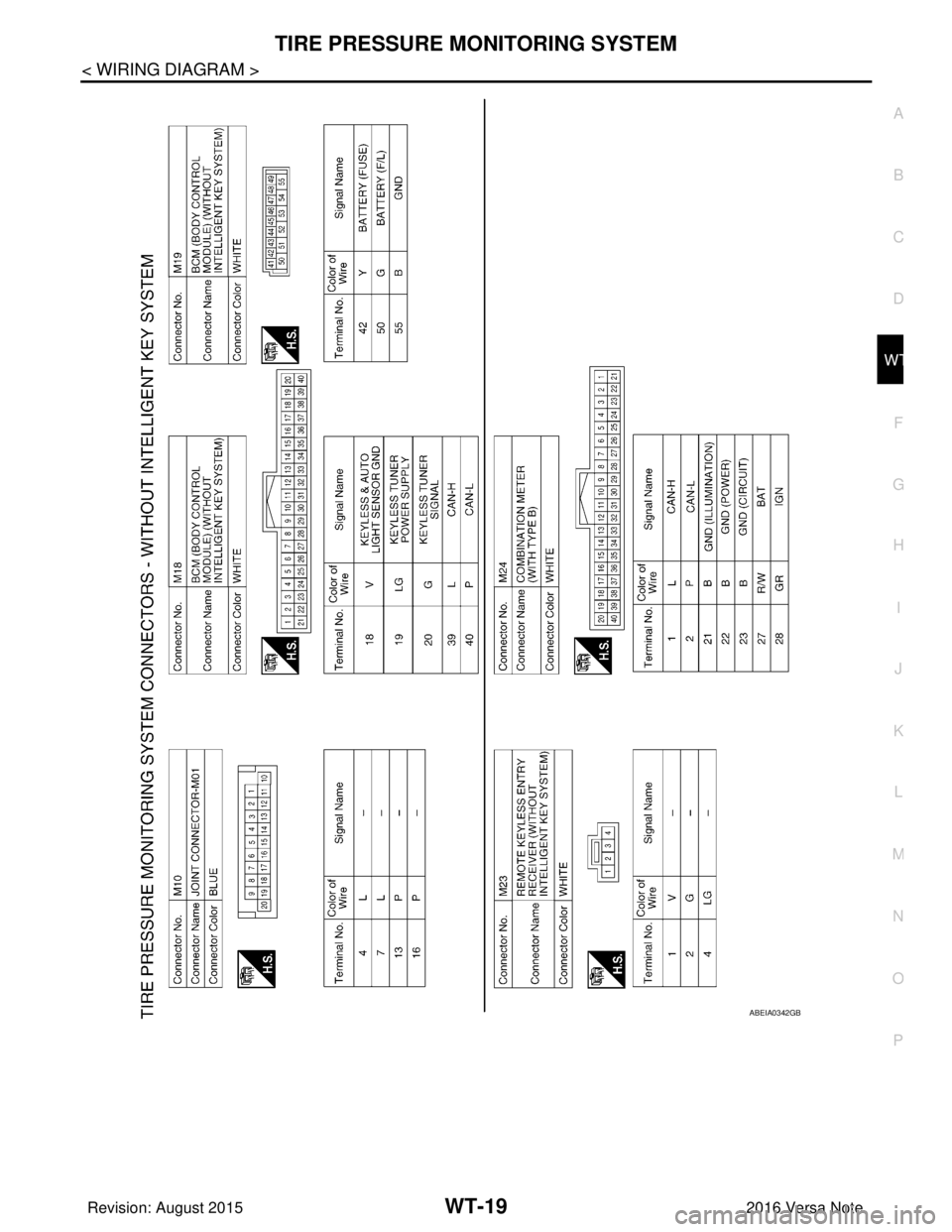

WIRING DIAGRAM ......................................15

TIRE PRESSURE MONITORING SYSTEM ......15

Wiring Diagram - With Inte lligent Key ......................15

Wiring Diagram - Without Intelligent Ke y .................18

BASIC INSPECTION ....... ............................21

DIAGNOSIS AND REPAIR WORK FLOW .......21

Work Flow ............................................................ ....21

ID REGISTRATION PROCEDURE ...................22

Description ...............................................................22

Work Procedure .......................................................22

DTC/CIRCUIT DIAGNOSIS .........................25

C1704, C1705, C1706, C1707 LOW TIRE

PRESSURE .......................................................

25

DTC Logic ............................................................ ....25

Diagnosis Procedure ...............................................25

C1708, C1709, C1710, C1711 TRANSMITTER

(NO DATA) ........................................................

27

DTC Logic ............................................................ ....27

Diagnosis Procedure ...............................................27

C1716, C1717, C1718, C1719 TRANSMITTER

(PRESSURE DATA) ..........................................

30

DTC Logic ............................................................ ....30

Diagnosis Procedure ...............................................30

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2751 of 3641

WT-8

< SYSTEM DESCRIPTION >

SYSTEM

SYSTEM

TIRE PRESSURE MONITORING SYSTEM

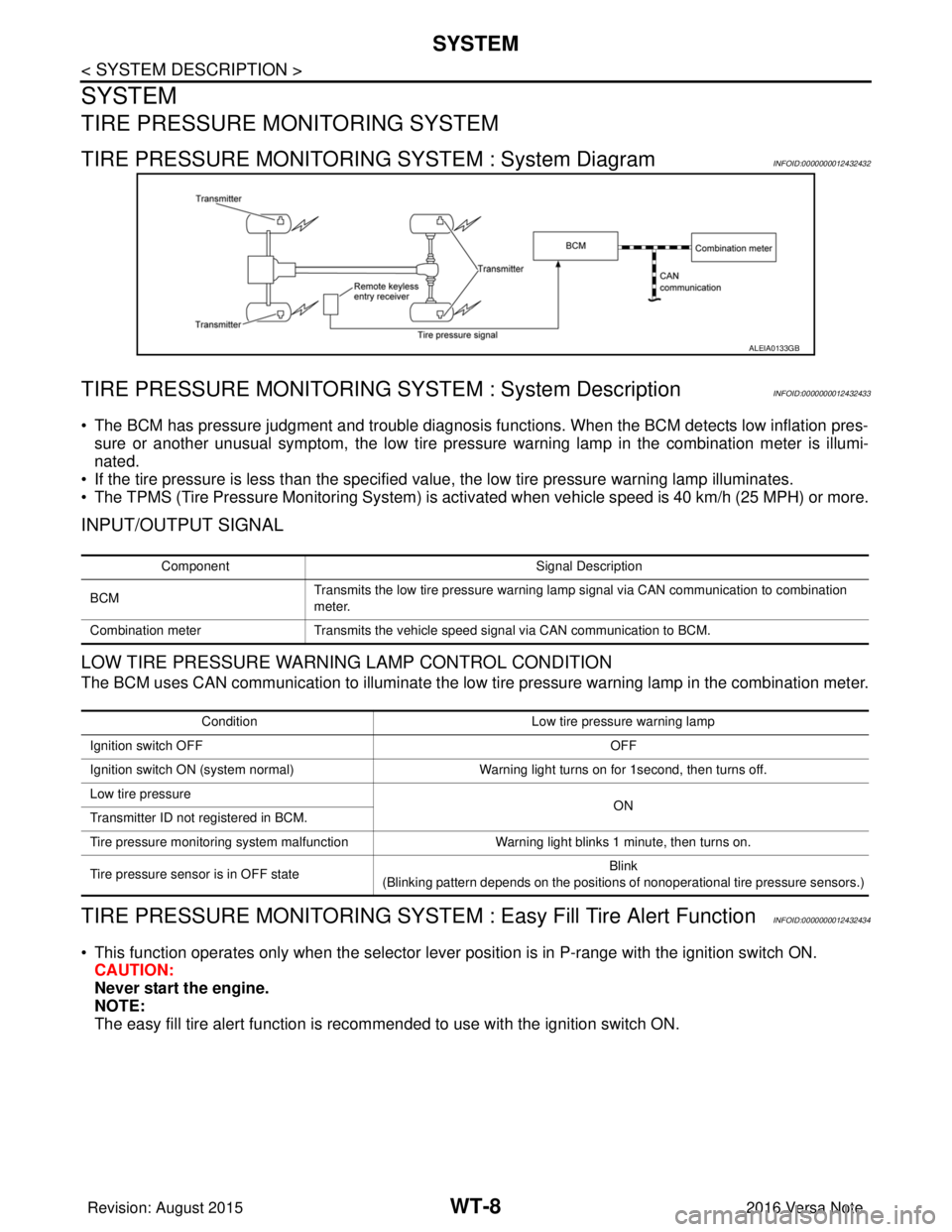

TIRE PRESSURE MONITORING SYSTEM : System DiagramINFOID:0000000012432432

TIRE PRESSURE MONITORING SY STEM : System DescriptionINFOID:0000000012432433

• The BCM has pressure judgment and trouble diagnosis functions. When the BCM detects low inflation pres-

sure or another unusual symptom, the low tire pressure warning lamp in the combination meter is illumi-

nated.

• If the tire pressure is less than the specified value, the low tire pressure warning lamp illuminates.

• The TPMS (Tire Pressure Monitoring System) is activated when vehicle s peed is 40 km/h (25 MPH) or more.

INPUT/OUTPUT SIGNAL

LOW TIRE PRESSURE WARNING LAMP CONTROL CONDITION

The BCM uses CAN communication to illuminate the low tire pressure warning lamp in the combination meter.

TIRE PRESSURE MONITORING SYSTEM : Easy Fill Tire Alert FunctionINFOID:0000000012432434

• This function operates only when the selector lever position is in P-range with the ignition switch ON.

CAUTION:

Never start the engine.

NOTE:

The easy fill tire alert function is reco mmended to use with the ignition switch ON.

ALEIA0133GB

Component Signal Description

BCM Transmits the low tire pressure warning lamp signal via CAN communication to combination

meter.

Combination meter Transmits the vehicle speed signal via CAN communication to BCM.

Condition Low tire pressure warning lamp

Ignition switch OFF OFF

Ignition switch ON (system normal) Warning light turns on for 1second, then turns off.

Low tire pressure ON

Transmitter ID not registered in BCM.

Tire pressure monitoring system malfunction Warning light blinks 1 minute, then turns on.

Tire pressure sensor is in OFF state Blink

(Blinking pattern depends on the positions of nonoperational tire pressure sensors.)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2758 of 3641

TIRE PRESSURE MONITORING SYSTEMWT-15

< WIRING DIAGRAM >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

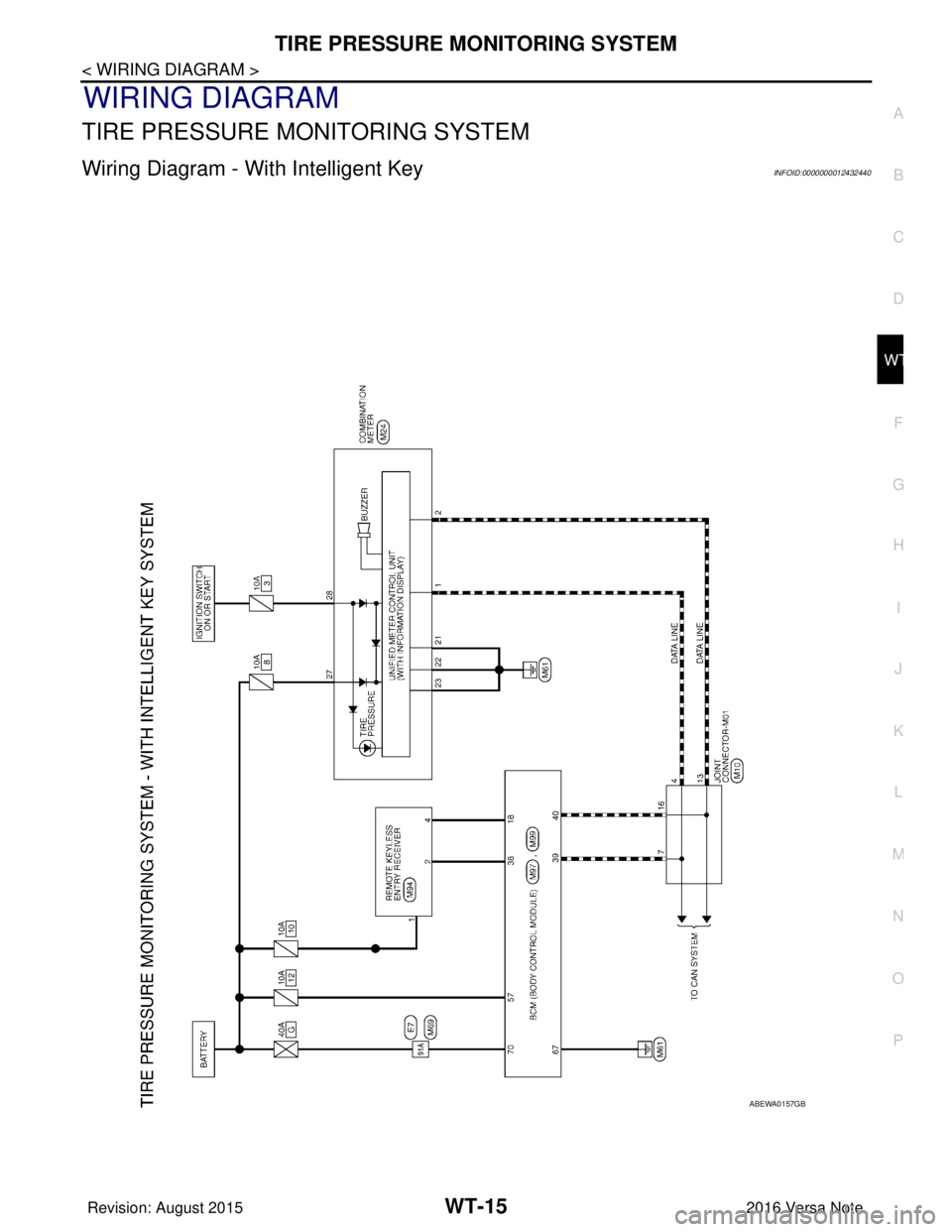

WIRING DIAGRAM

TIRE PRESSURE MO NITORING SYSTEM

Wiring Diagram - With Intelligent KeyINFOID:0000000012432440

ABEWA0157GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2759 of 3641

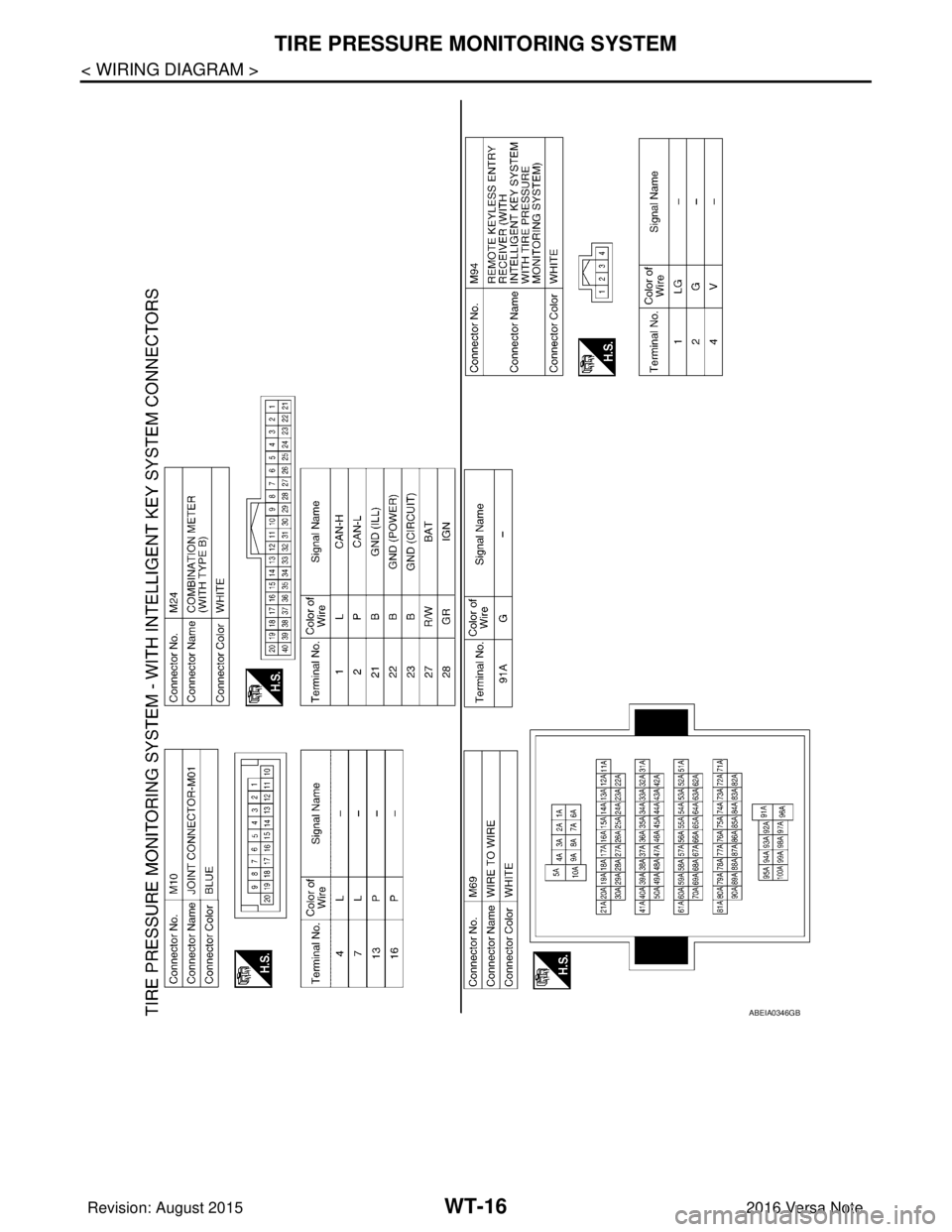

WT-16

< WIRING DIAGRAM >

TIRE PRESSURE MONITORING SYSTEM

ABEIA0346GB

Revision: August 20152016 Versa Note

cardiagn.com

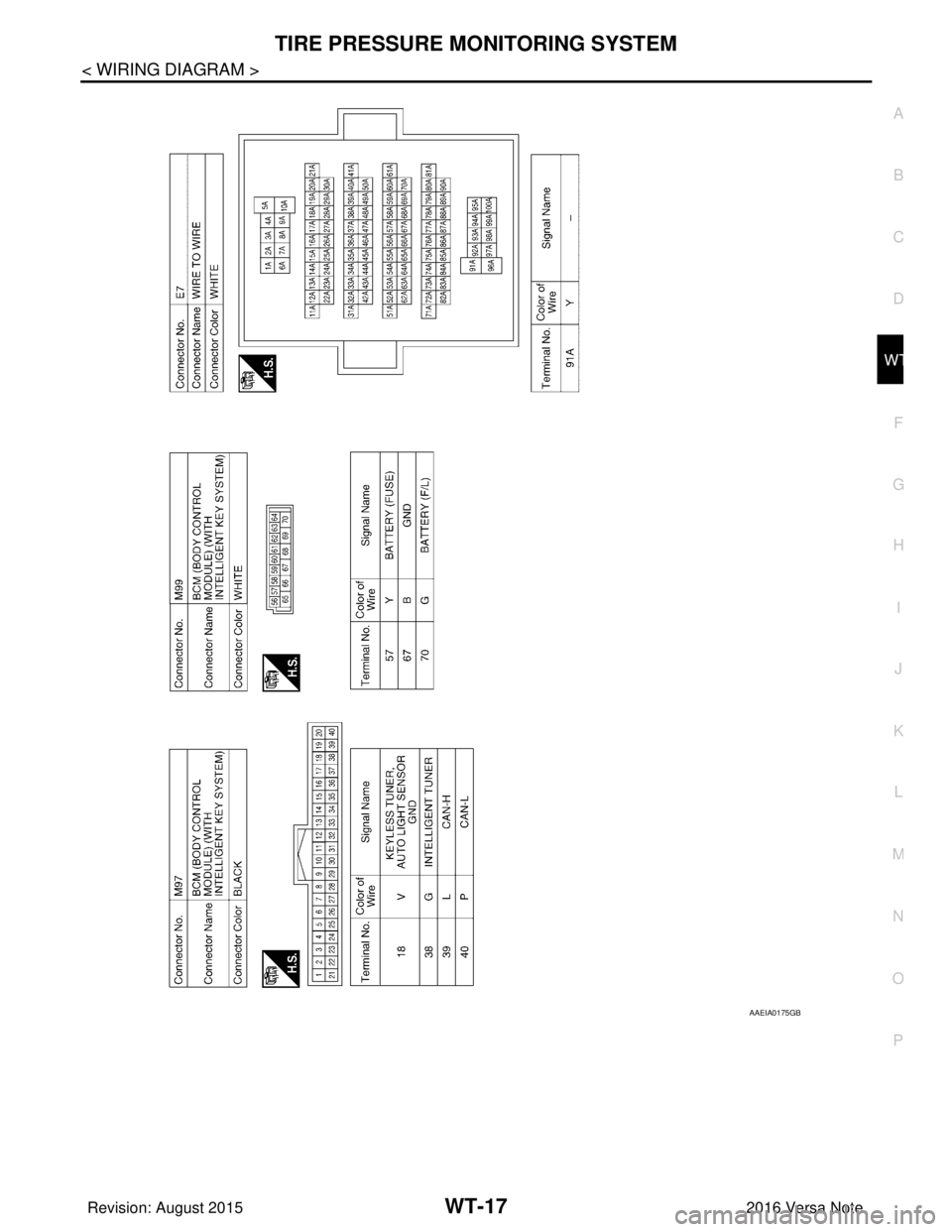

Page 2760 of 3641

TIRE PRESSURE MONITORING SYSTEMWT-17

< WIRING DIAGRAM >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

AAEIA0175GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2761 of 3641

WT-18

< WIRING DIAGRAM >

TIRE PRESSURE MONITORING SYSTEM

Wiring Diagram - With out Intelligent Key

INFOID:0000000012432441

ABEWA0156GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2762 of 3641

TIRE PRESSURE MONITORING SYSTEMWT-19

< WIRING DIAGRAM >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

ABEIA0342GB

Revision: August 2015 2016 Versa Note

cardiagn.com