battery NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3463 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-222

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F11A]

SHIFT LOCK SYSTEM

4.CHECK CVT SHIFT SELECTOR POWER CIRCUIT

Check voltage between CVT shift selector connector M38 terminal 5 and ground.

Is the inspectio NISSAN NOTE 2016 Service Repair Manual TM-222

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F11A]

SHIFT LOCK SYSTEM

4.CHECK CVT SHIFT SELECTOR POWER CIRCUIT

Check voltage between CVT shift selector connector M38 terminal 5 and ground.

Is the inspectio](/img/5/57363/w960_57363-3462.png)

TM-222

< DTC/CIRCUIT DIAGNOSIS >[CVT: RE0F11A]

SHIFT LOCK SYSTEM

4.CHECK CVT SHIFT SELECTOR POWER CIRCUIT

Check voltage between CVT shift selector connector M38 terminal 5 and ground.

Is the inspection result normal?

YES >> Replace CVT shift selector. Refer to TM-231, "Removal and Installation".

NO >> Repair or replace power circuit.

CVT shift selector GroundBrake pedal Voltage

Connector Terminal

M38 5Ground AppliedBattery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3475 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-234

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CONTROL CABLE

CONTROL CABLE

Exploded ViewINFOID:0000000012431179

Removal and InstallationINFOID:0000000012431180

CAUTION:

Always apply the parking bra NISSAN NOTE 2016 Service Repair Manual TM-234

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CONTROL CABLE

CONTROL CABLE

Exploded ViewINFOID:0000000012431179

Removal and InstallationINFOID:0000000012431180

CAUTION:

Always apply the parking bra](/img/5/57363/w960_57363-3474.png)

TM-234

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

CONTROL CABLE

CONTROL CABLE

Exploded ViewINFOID:0000000012431179

Removal and InstallationINFOID:0000000012431180

CAUTION:

Always apply the parking brake before performing removal

and installation.

REMOVAL

1. Remove the battery negative terminal. Refer to PG-70, "Exploded View".

2. Remove the TCM and bracket. Refer to TM-239, "

Removal and Installation".

3. Remove the IPDM E/R. Refer to PCS-30, "

Removal and Installation".

4. Remove the battery tray and bracket.

5. Remove instrument lower panel LH. Refer to IP-24, "

Removal and Installation".

6. Remove the center console assembly. Refer to IP-18, "

Removal and Installation".

7. Remove the control cable from the shift selector assembly.

8. Disengage the pawls (B) of the grommet (A), and pull downward to remove.

9. Remove the control cable nut from the manual lever.

1. Bracket B 2. Lock plate3. Transaxle assembly

4. Bracket A 5. Control cable6. Shift selector assembly

A: Manual lever B: Grommet

JSDIA1921GB

JSDIA1809ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3480 of 3641

![NISSAN NOTE 2016 Service Repair Manual TCM

TM-239

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TCM

Exploded ViewINFOID:0000000012431185

Removal and InstallationINFOID:0000000012431186

CAUTION:

• When replac NISSAN NOTE 2016 Service Repair Manual TCM

TM-239

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TCM

Exploded ViewINFOID:0000000012431185

Removal and InstallationINFOID:0000000012431186

CAUTION:

• When replac](/img/5/57363/w960_57363-3479.png)

TCM

TM-239

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

TCM

Exploded ViewINFOID:0000000012431185

Removal and InstallationINFOID:0000000012431186

CAUTION:

• When replacing TCM, note the “CVTF DETERIORATION DATE” value displayed on CONSULT “CON- FORM CVTF DETERIORATION” in MAINTENANCE BOOKLET, before starting the operation.

• When replacing TCM, perform "ADDITIONAL SERVICE WHEN REPLACING TCM". Refer to TM-125,

"Description".

• When replacing TCM and transaxle assembly simultaneously, replace transaxle assembly first and then replace TCM.

REMOVAL

1. Remove the battery. Refer to PG-70, "Removal and Installation (Battery)".

2. Disconnect the harness connector from the TCM.

3. Remove the TCM and bracket as an assembly.

4. Remove the TCM from the bracket (if necessary).

INSTALLATION

Installation is in the reverse order of removal.

AdjustmentINFOID:0000000012431187

ADJUSTMENT AFTER INSTALLATION

Perform "ADDITIONAL SERVICE WHEN REPLACING TCM". Refer to TM-125, "Description".

1. TCM2. Bracket3. Clip

Front

AWBIA1482ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3482 of 3641

![NISSAN NOTE 2016 Service Repair Manual G SENSORTM-241

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

G SENSOR

Exploded ViewINFOID:0000000012431189

Removal and InstallationINFOID:0000000012431190

CAUTION:

• Do NISSAN NOTE 2016 Service Repair Manual G SENSORTM-241

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

G SENSOR

Exploded ViewINFOID:0000000012431189

Removal and InstallationINFOID:0000000012431190

CAUTION:

• Do](/img/5/57363/w960_57363-3481.png)

G SENSORTM-241

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

G SENSOR

Exploded ViewINFOID:0000000012431189

Removal and InstallationINFOID:0000000012431190

CAUTION:

• Do not drop or strike G sensor, because it may be damaged by impact.

• Do not use a power tool.

REMOVAL

1. Disconnect the battery negative terminal. Refer to PG-70, "Exploded View".

2. Remove center console assembly. Refer to IP-18, "

Removal and Installation".

3. Disconnect the harness connector from G sensor.

4. Remove G sensor.

INSTALLATION

Installation is in the reverse order of removal.

AdjustmentINFOID:0000000012431191

ADJUSTMENT AFTER INSTALLATION

Perform “G SENSOR CALIBRATION”. Refer to TM-130, "Description".

1. G sensor Front

JSDIA1922GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3483 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-242

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

OIL PAN, CONTROL VALVE

Exploded ViewINFOID:0000000012431192

Removal and InstallationINFOID:0000000012431193

REMOVAL

1. Disconne NISSAN NOTE 2016 Service Repair Manual TM-242

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

OIL PAN, CONTROL VALVE

Exploded ViewINFOID:0000000012431192

Removal and InstallationINFOID:0000000012431193

REMOVAL

1. Disconne](/img/5/57363/w960_57363-3482.png)

TM-242

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

OIL PAN, CONTROL VALVE

OIL PAN, CONTROL VALVE

Exploded ViewINFOID:0000000012431192

Removal and InstallationINFOID:0000000012431193

REMOVAL

1. Disconnect battery negative terminal.

1. Transaxle assembly

2. O-ring 3. Control valve

4. Manual plate 5. Washer 6. O-ring

7. Strainer 8. Oil pan gasket9. Magnet

10. Oil pan 11. Drain plug gasket 12. Drain plug

13. Overflow tube : Apply petroleum jelly

: Always replace after every disassembly.

: Apply CVT fluid

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

JSDIA6707GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3486 of 3641

![NISSAN NOTE 2016 Service Repair Manual OIL PAN, CONTROL VALVETM-245

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

4. Install the strainer , and then tighten the strainer bolts to the specitied torque.

5. In NISSAN NOTE 2016 Service Repair Manual OIL PAN, CONTROL VALVETM-245

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

4. Install the strainer , and then tighten the strainer bolts to the specitied torque.

5. In](/img/5/57363/w960_57363-3485.png)

OIL PAN, CONTROL VALVETM-245

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

4. Install the strainer , and then tighten the strainer bolts to the specitied torque.

5. Install oil pan (with oil pan gasket) to transaxle case and tempo- rarily tighten oil pan bolts ( ).

CAUTION:

Never reuse oil pan gasket.

6. Tighten the oil pan bolts to specification in the order shown.

7. Tighten the overflow tube to the specitied torque. CAUTION:

If it is not tightened to the specified torque, the tube may be

damaged.

8. Connect the CVT unit harness connector.

9. Connect battery negative terminal.

10. Fill with CVT fluid from overflow tube to the specified level. Refer to TM-228, "

Replacement".

11. Install the drain plug and drain plug gasket to oil pan. CAUTION:

Never reuse drain plug gasket.

Inspection and AdjustmentINFOID:0000000012431194

INSPECTION AFTER REMOVAL

Check oil pan for foreign material.

• If a large amount of worn material is found, clutch plate may be worn.

• If iron powder is found, bearings, gears, or clutch plates may be worn.

• If aluminum powder is found, bushing may be worn, or ch ips or burrs of aluminum casting parts may enter.

Check points where wear is found in all cases.

ADJUSTMENT AFTER INSTALLATION

Erase the CVT fluid deterioration data.

INSPECTION AFTER INSTALLATION

• When replacing control valve, perform "ADDITION AL SERVICE WHEN REPLACING CONTROL VALVE OR

TRANSAXLE ASSEMBLY". Refer to TM-127, "

Work Procedure".

• Check the CVT fluid level, condition and leakage.

JSDIA6594ZZ

: Vehicle front

JSDIA1874ZZ

: Vehicle front

JSDIA1884ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3488 of 3641

![NISSAN NOTE 2016 Service Repair Manual SECONDARY SPEED SENSORTM-247

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SECONDARY SPEED SENSOR

Exploded ViewINFOID:0000000012431198

Removal and InstallationINFOID:0000 NISSAN NOTE 2016 Service Repair Manual SECONDARY SPEED SENSORTM-247

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SECONDARY SPEED SENSOR

Exploded ViewINFOID:0000000012431198

Removal and InstallationINFOID:0000](/img/5/57363/w960_57363-3487.png)

SECONDARY SPEED SENSORTM-247

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SECONDARY SPEED SENSOR

Exploded ViewINFOID:0000000012431198

Removal and InstallationINFOID:0000000012431199

REMOVAL

1. Remove battery tray. Refer to PG-71, "Removal and Installation (Battery Tray)".

2. Remove IPDM/ER. Refer to PCS-30, "

Removal and Installation".

3. Disconnect the harness connector from secondary speed sensor.

4. Remove the secondary speed sensor.

5. Remove the O-ring from the secondary speed sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not reuse O-ring.

• Apply Genuine NISSAN CVT Fluid NS-3 to the O-ring.

Inspection and AdjustmentINFOID:0000000012431200

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage. Refer to TM-228, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Adjust the CVT fluid level. Refer to TM-229, "Adjustment".

1. Transaxle assembly 2. O-ring3. Secondary speed sensor

Front : Genuine NISSAN CVT Fluid NS-3

JSDIA1881GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3508 of 3641

VTL-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430544

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for WorkINFOID:0000000012430545

• When removing or disassembling each component, be careful not to damage or deform it. If a component may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3515 of 3641

FRONT BLOWER MOTORVTL-9

< REMOVAL AND INSTALLATION >

C

DE

F

G H

J

K L

M A

B

VTL

N

O P

FRONT BLOWER MOTOR

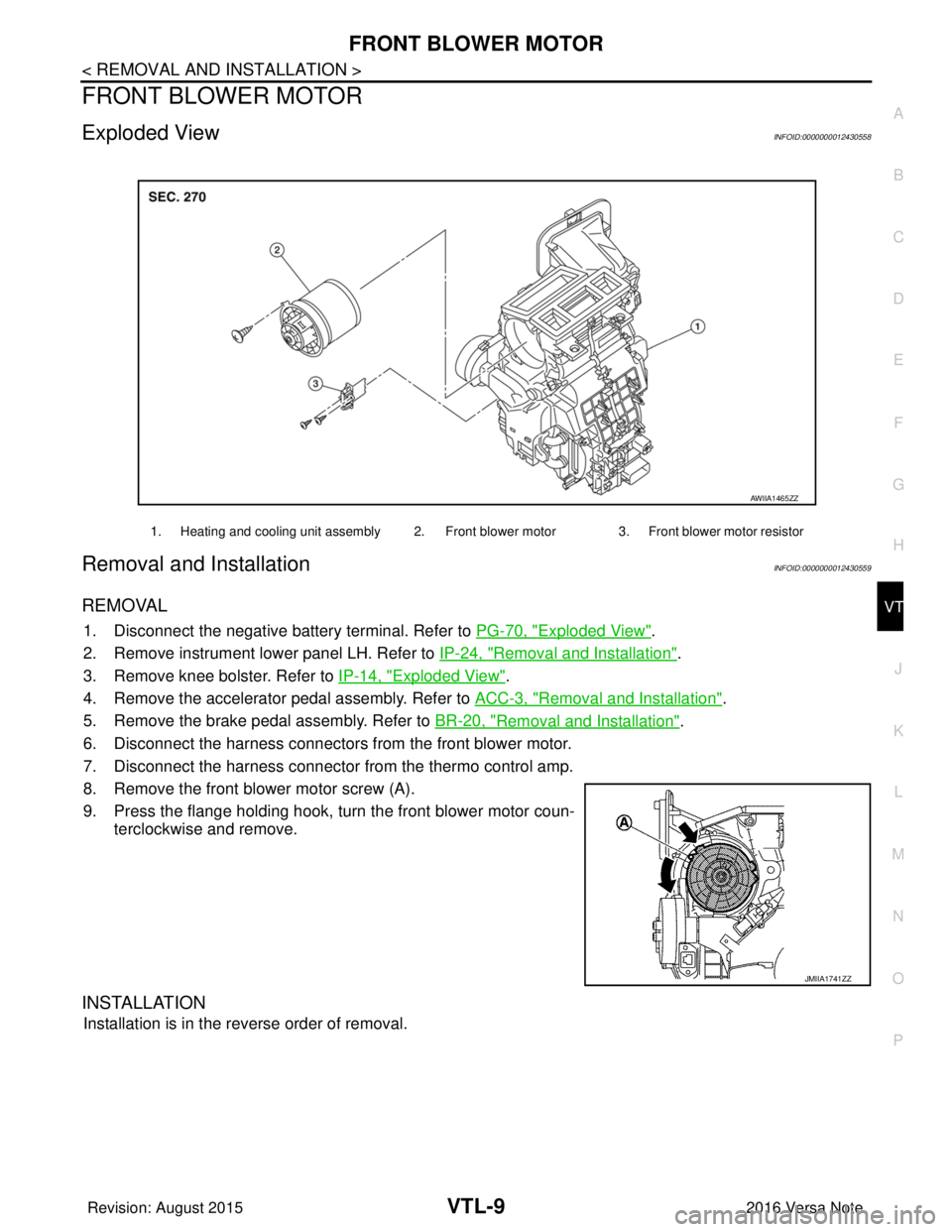

Exploded ViewINFOID:0000000012430558

Removal and InstallationINFOID:0000000012430559

REMOVAL

1. Disconnect the negative battery terminal. Refer to PG-70, "Exploded View".

2. Remove instrument lower panel LH. Refer to IP-24, "

Removal and Installation".

3. Remove knee bolster. Refer to IP-14, "

Exploded View".

4. Remove the accelerator pedal assembly. Refer to ACC-3, "

Removal and Installation".

5. Remove the brake pedal assembly. Refer to BR-20, "

Removal and Installation".

6. Disconnect the harness connectors from the front blower motor.

7. Disconnect the harness connector from the thermo control amp.

8. Remove the front blower motor screw (A).

9. Press the flange holding hook, turn the front blower motor coun- terclockwise and remove.

INSTALLATION

Installation is in the reverse order of removal.

1. Heating and cooling unit assembly 2. Front blower motor 3. Front blower motor resistor

AWIIA1465ZZ

JMIIA1741ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3519 of 3641

WCS-4

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012542981

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Revision: August 2015 2016 Versa Note

cardiagn.com