NISSAN PATHFINDER 1996 R50 / 2.G Owners Manual

Manufacturer: NISSAN, Model Year: 1996, Model line: PATHFINDER, Model: NISSAN PATHFINDER 1996 R50 / 2.GPages: 223, PDF Size: 1.71 MB

Page 131 of 223

installing tire chains. When installing tire

chains, make sure they are of proper size

for the tires on your vehicle and are in-

stalled according to the chain manufactur-

er's suggestions.Use only SAE Class ªSº

chains.Other types may damage your

vehicle. Use chain tensioners when recom-

mended by the tire chain manufacturer to

ensure a tight fit. Loose end links of the tire

chain must be secured or removed to pre-

vent the possibility of whipping action dam-

age to the fenders or underbody. If pos-

sible, avoid fully loading your vehicle when

using tire chains. In addition, drive at a

reduced speed. Otherwise, your vehicle

may be damaged and/or vehicle handling

and performance may be adversely af-

fected.

Do not use the chains on dry roads.

Special winter equipment

It is recommended that the following items be

carried in the vehicle during winter:

1. A scraper and stiff-bristled brush to remove

ice and snow from the windows and wiper

blades.

2. A sturdy, flat board to be placed under the

jack to give it firm support.3. A shovel to dig the vehicle out of snow-

drifts.

4. Extra window washer fluid to refill the res-

ervoir tank.

Driving on snow or ice

IWet ice (32ÉF, 0ÉC and freezing rain), very

cold snow or ice can be slick and very hard

to drive on. The vehicle will have a lot less

traction or ªgripº under these conditions. Try

to avoid driving on wet ice until the road is

salted or sanded.

IWhatever the condition, drive with caution

and accelerate gently. If accelerated too

fast, the drive wheels will spin and will lose

even more traction.

IAllow more stopping distance under these

conditions. Braking should be started

sooner than on dry pavement.

IAllow greater following distances on slip-

pery roads.

IWatch for slippery spots (glare ice). These

may appear on an otherwise clear road in

shaded areas. If a patch of ice is seen

ahead, brake before reaching it. Try not to

brake while actually on the ice, and avoid

any sudden steering maneuvers.

4-26

Z01.2.1/R50-DX

Page 132 of 223

Engine block heater

Do not use your heater with an un-

grounded electrical system or two-

pronged (cheater) adapters. You can be

injured by an electrical shock if you use

an ungrounded connection.

Chemicals used for road surface de-icing are

extremely corrosive and will accelerate corro-

sion and the deterioration of underbody com-

ponents such as the exhaust system, fuel and

brake lines, brake cables, floor pan and fend-

ers.

In winter, the underbody must be cleaned

periodically. For more detailed information

concerning cleaning the exterior to protect

it from corrosion, please refer to the ªAp-

pearance and interior careº section of this

Manual.

For additional protection against rust and cor-

rosion, which may be required in some areas,

consult your local NISSAN dealer.

CORROSION PROTECTION

4-27

Z01.2.1/R50-DX

Page 133 of 223

MEMO

4-28

Z01.2.1/R50-DX

Page 134 of 223

5 In case of emergency

Flat tire ................................................................... 5-2

Jump starting ......................................................... 5-7

Push starting .......................................................... 5-8

If your vehicle overheats ........................................ 5-9

Tow truck towing .................................................. 5-10

Z01.2.1/R50-DX

Page 135 of 223

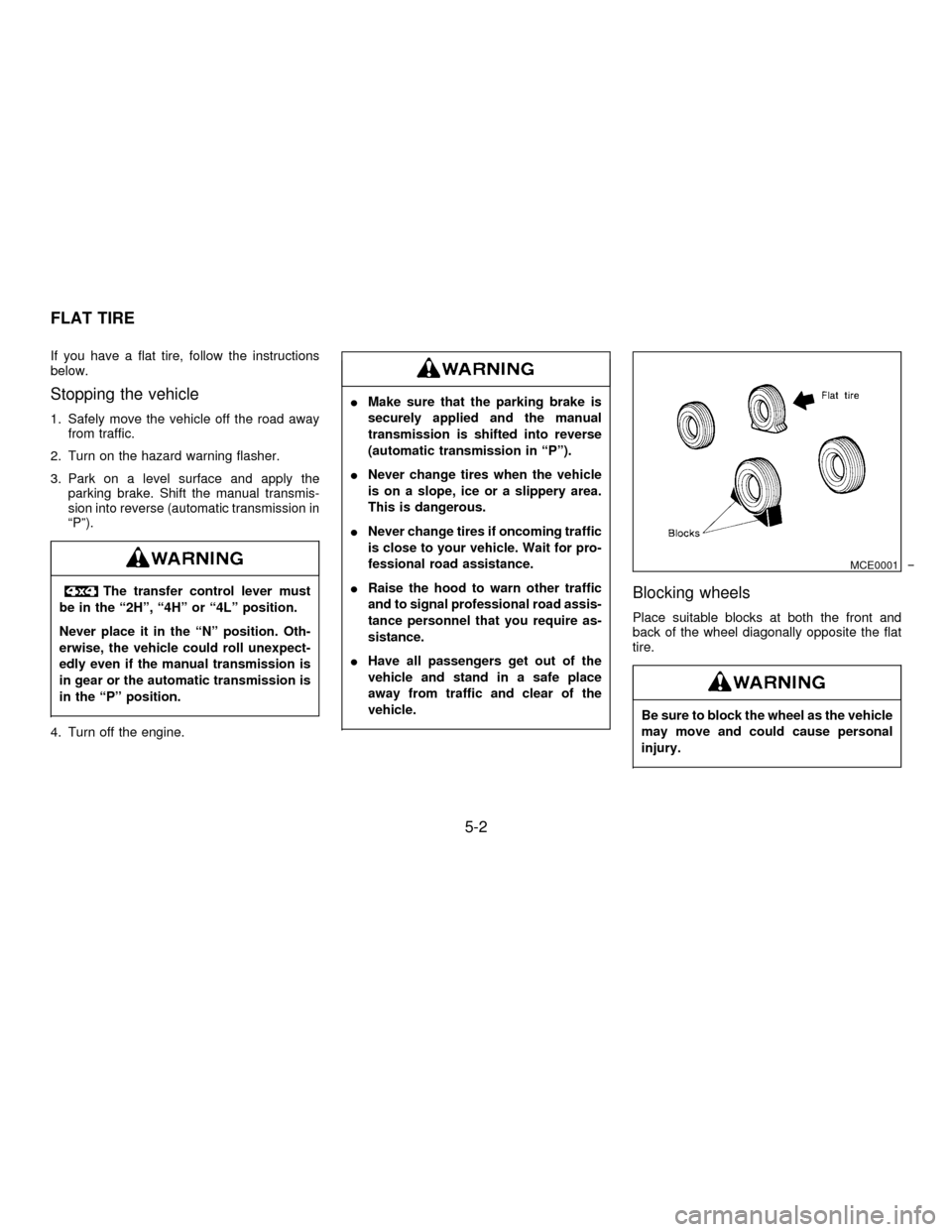

If you have a flat tire, follow the instructions

below.

Stopping the vehicle

1. Safely move the vehicle off the road away

from traffic.

2. Turn on the hazard warning flasher.

3. Park on a level surface and apply the

parking brake. Shift the manual transmis-

sion into reverse (automatic transmission in

ªPº).

The transfer control lever must

be in the ª2Hº, ª4Hº or ª4Lº position.

Never place it in the ªNº position. Oth-

erwise, the vehicle could roll unexpect-

edly even if the manual transmission is

in gear or the automatic transmission is

in the ªPº position.

4. Turn off the engine.

IMake sure that the parking brake is

securely applied and the manual

transmission is shifted into reverse

(automatic transmission in ªPº).

INever change tires when the vehicle

is on a slope, ice or a slippery area.

This is dangerous.

INever change tires if oncoming traffic

is close to your vehicle. Wait for pro-

fessional road assistance.

IRaise the hood to warn other traffic

and to signal professional road assis-

tance personnel that you require as-

sistance.

IHave all passengers get out of the

vehicle and stand in a safe place

away from traffic and clear of the

vehicle.

Blocking wheels

Place suitable blocks at both the front and

back of the wheel diagonally opposite the flat

tire.

Be sure to block the wheel as the vehicle

may move and could cause personal

injury.

MCE0001

FLAT TIRE

5-2

Z01.2.1/R50-DX

Page 136 of 223

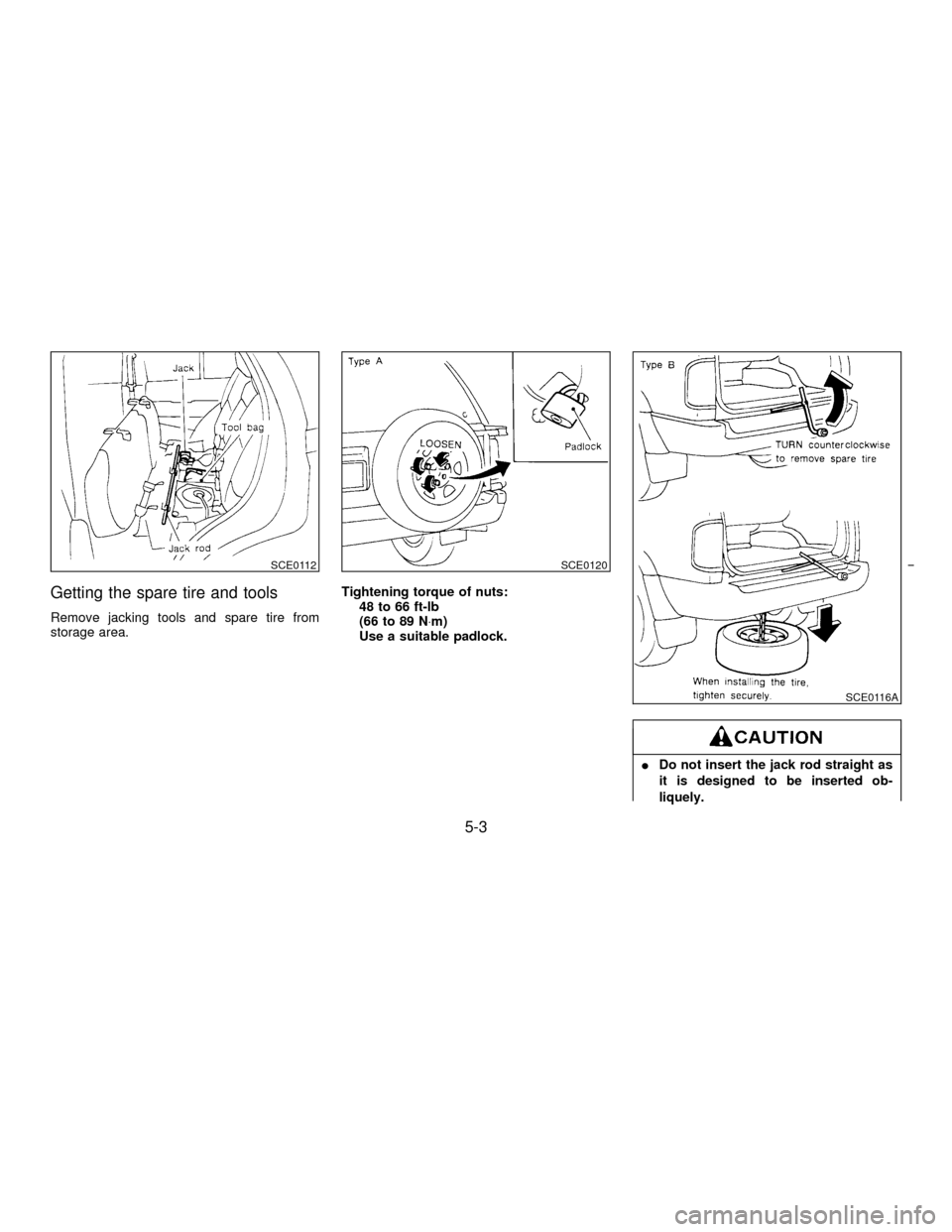

Getting the spare tire and tools

Remove jacking tools and spare tire from

storage area.Tightening torque of nuts:

48 to 66 ft-lb

(66 to 89 N×m)

Use a suitable padlock.

IDo not insert the jack rod straight as

it is designed to be inserted ob-

liquely.

SCE0112SCE0120

SCE0116A

5-3

Z01.2.1/R50-DX

Page 137 of 223

IMake sure the rod tip fits in the fitting

portion of the spare tire hanger and

turn the rod.

IBe sure to center the spare tire sus-

pending plate on the wheel and then

lift the spare tire.

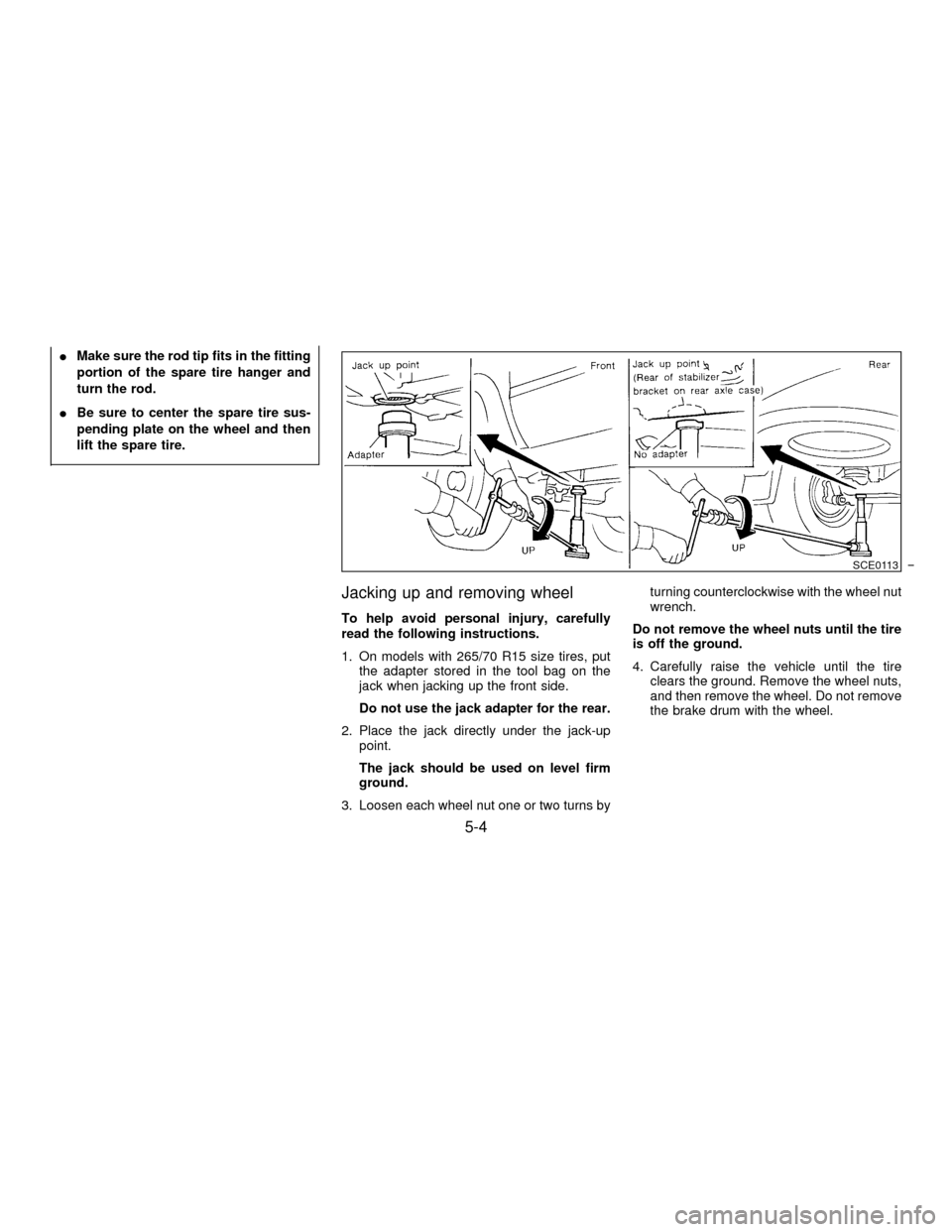

Jacking up and removing wheel

To help avoid personal injury, carefully

read the following instructions.

1. On models with 265/70 R15 size tires, put

the adapter stored in the tool bag on the

jack when jacking up the front side.

Do not use the jack adapter for the rear.

2. Place the jack directly under the jack-up

point.

The jack should be used on level firm

ground.

3. Loosen each wheel nut one or two turns byturning counterclockwise with the wheel nut

wrench.

Do not remove the wheel nuts until the tire

is off the ground.

4. Carefully raise the vehicle until the tire

clears the ground. Remove the wheel nuts,

and then remove the wheel. Do not remove

the brake drum with the wheel.

SCE0113

5-4

Z01.2.1/R50-DX

Page 138 of 223

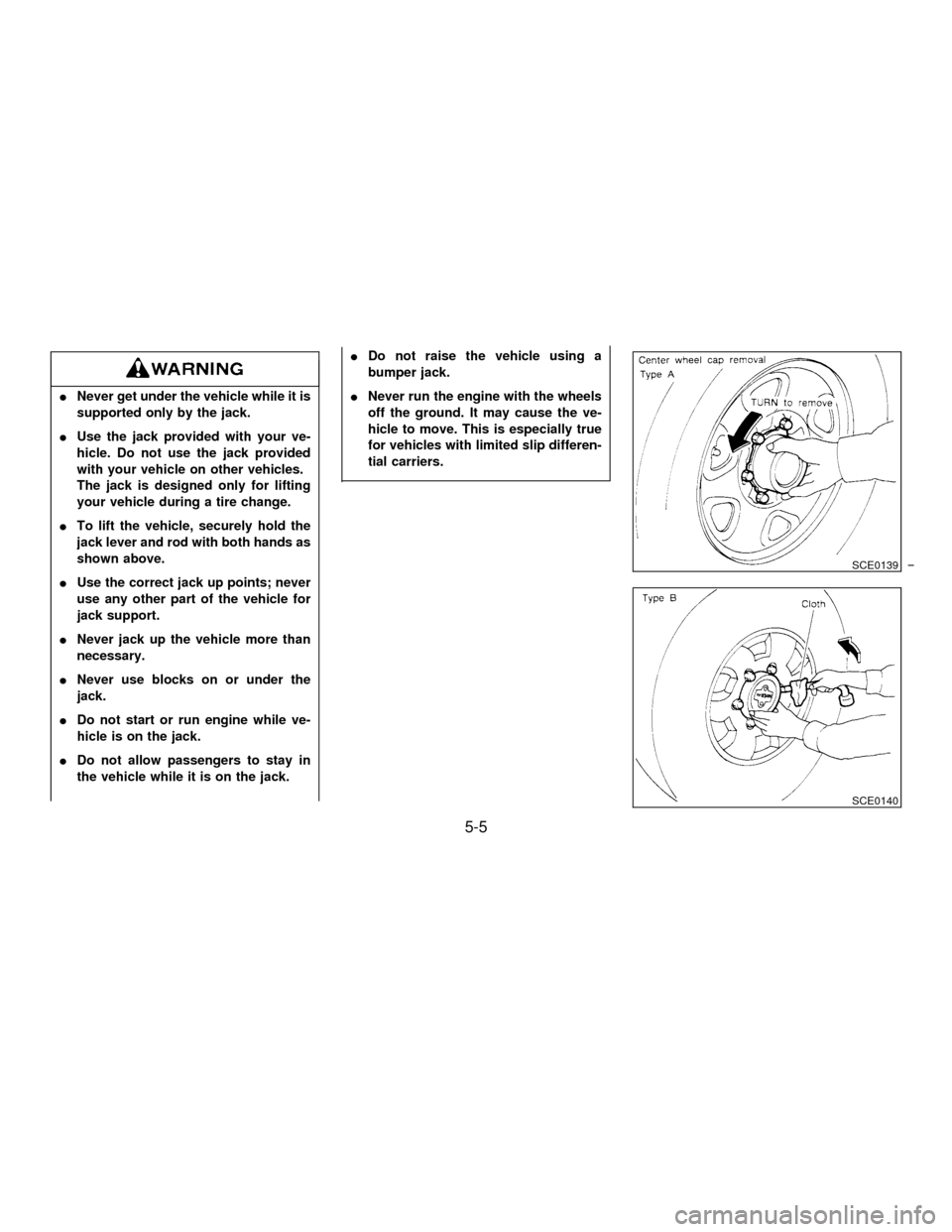

INever get under the vehicle while it is

supported only by the jack.

IUse the jack provided with your ve-

hicle. Do not use the jack provided

with your vehicle on other vehicles.

The jack is designed only for lifting

your vehicle during a tire change.

ITo lift the vehicle, securely hold the

jack lever and rod with both hands as

shown above.

IUse the correct jack up points; never

use any other part of the vehicle for

jack support.

INever jack up the vehicle more than

necessary.

INever use blocks on or under the

jack.

IDo not start or run engine while ve-

hicle is on the jack.

IDo not allow passengers to stay in

the vehicle while it is on the jack.IDo not raise the vehicle using a

bumper jack.

INever run the engine with the wheels

off the ground. It may cause the ve-

hicle to move. This is especially true

for vehicles with limited slip differen-

tial carriers.

SCE0139

SCE0140

5-5

Z01.2.1/R50-DX

Page 139 of 223

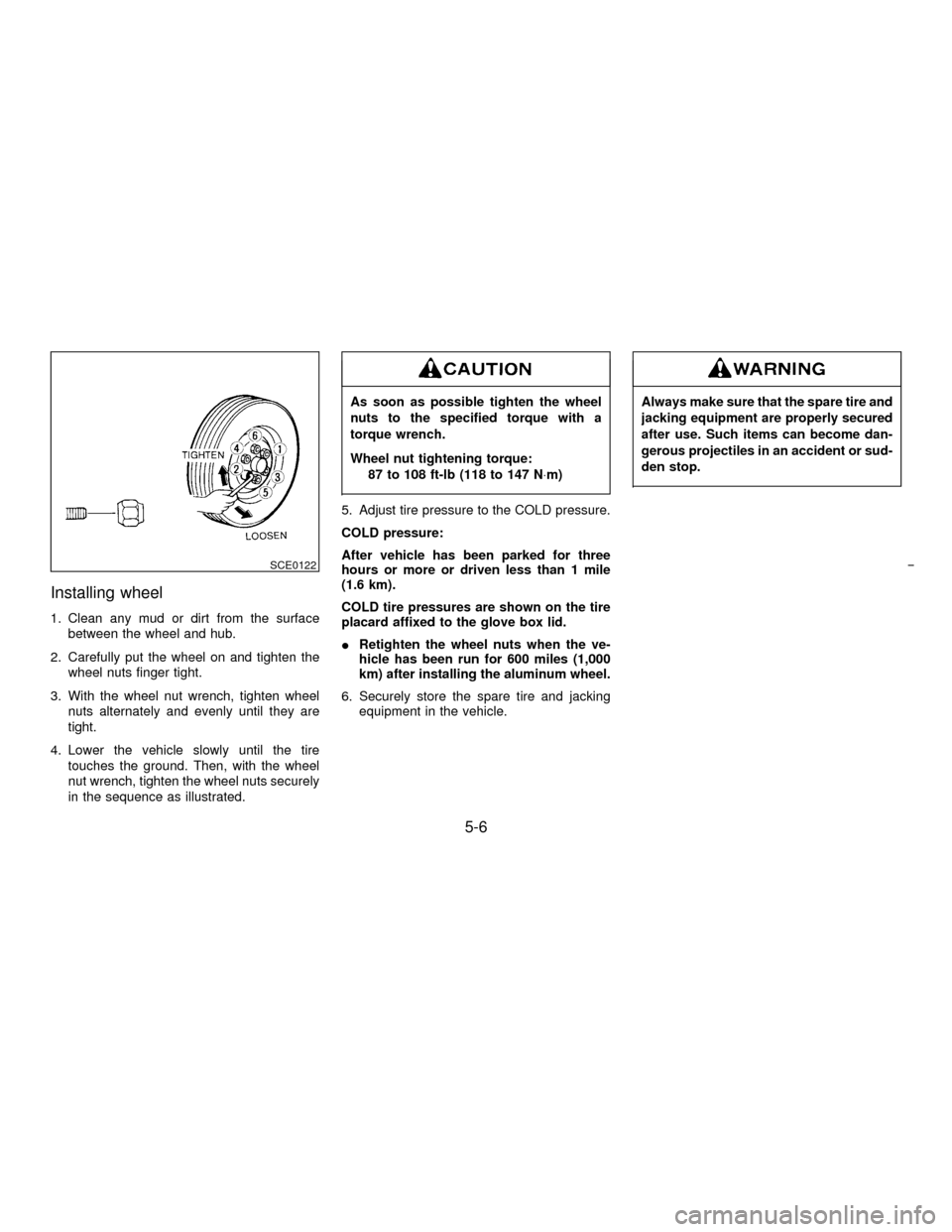

Installing wheel

1. Clean any mud or dirt from the surface

between the wheel and hub.

2. Carefully put the wheel on and tighten the

wheel nuts finger tight.

3. With the wheel nut wrench, tighten wheel

nuts alternately and evenly until they are

tight.

4. Lower the vehicle slowly until the tire

touches the ground. Then, with the wheel

nut wrench, tighten the wheel nuts securely

in the sequence as illustrated.

As soon as possible tighten the wheel

nuts to the specified torque with a

torque wrench.

Wheel nut tightening torque:

87 to 108 ft-lb (118 to 147 N×m)

5. Adjust tire pressure to the COLD pressure.

COLD pressure:

After vehicle has been parked for three

hours or more or driven less than 1 mile

(1.6 km).

COLD tire pressures are shown on the tire

placard affixed to the glove box lid.

IRetighten the wheel nuts when the ve-

hicle has been run for 600 miles (1,000

km) after installing the aluminum wheel.

6. Securely store the spare tire and jacking

equipment in the vehicle.

Always make sure that the spare tire and

jacking equipment are properly secured

after use. Such items can become dan-

gerous projectiles in an accident or sud-

den stop.

SCE0122

5-6

Z01.2.1/R50-DX

Page 140 of 223

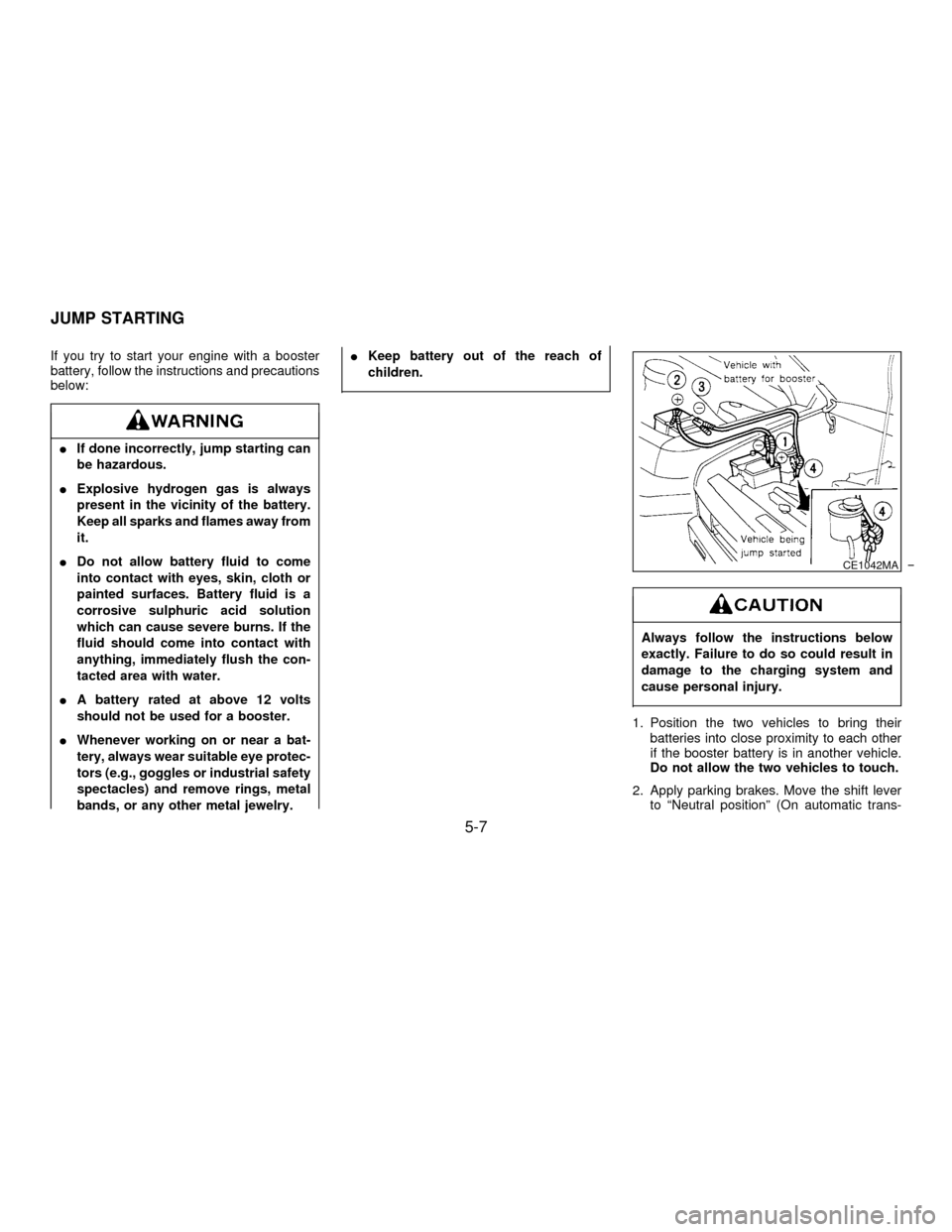

If you try to start your engine with a booster

battery, follow the instructions and precautions

below:

IIf done incorrectly, jump starting can

be hazardous.

IExplosive hydrogen gas is always

present in the vicinity of the battery.

Keep all sparks and flames away from

it.

IDo not allow battery fluid to come

into contact with eyes, skin, cloth or

painted surfaces. Battery fluid is a

corrosive sulphuric acid solution

which can cause severe burns. If the

fluid should come into contact with

anything, immediately flush the con-

tacted area with water.

IA battery rated at above 12 volts

should not be used for a booster.

IWhenever working on or near a bat-

tery, always wear suitable eye protec-

tors (e.g., goggles or industrial safety

spectacles) and remove rings, metal

bands, or any other metal jewelry.IKeep battery out of the reach of

children.

Always follow the instructions below

exactly. Failure to do so could result in

damage to the charging system and

cause personal injury.

1. Position the two vehicles to bring their

batteries into close proximity to each other

if the booster battery is in another vehicle.

Do not allow the two vehicles to touch.

2. Apply parking brakes. Move the shift lever

to ªNeutral positionº (On automatic trans-

CE1042MA

JUMP STARTING

5-7

Z01.2.1/R50-DX