gauge NISSAN PATROL 1998 Y61 / 5.G Electrical System Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 326, PDF Size: 11.36 MB

Page 2 of 326

Wiring Diagram Ð H/AIM Ð .....................................71

PARKING, LICENSE AND TAIL LAMPS......................73

Wiring Diagram Ð TAIL/L Ð/Type A .........................73

Wiring Diagram Ð TAIL/L Ð/Type B.........................75

STOP LAMP..................................................................77

Wiring Diagram Ð STOP/L Ð/Type A ......................77

BACK-UP LAMP............................................................78

Wiring Diagram Ð BACK/L Ð/LHD Models..............78

Wiring Diagram Ð BACK/L Ð/RHD Models .............79

REAR FOG LAMP.........................................................80

Wiring Diagram Ð R/FOG Ð ....................................80

TURN SIGNAL AND HAZARD WARNING LAMPS.....81

Wiring Diagram Ð TURN Ð/Type A .........................81

Wiring Diagram Ð TURN Ð/Type B .........................83

Trouble Diagnoses.....................................................85

Electrical Components Inspection .............................85

ILLUMINATION..............................................................86

Schematic ..................................................................86

Wiring Diagram Ð ILL Ð ..........................................87

INTERIOR ROOM LAMP Ð With Timer Ð.................93

System Description ....................................................93

Schematic ..................................................................94

Wiring Diagram Ð ROOM/L Ð/LHD Models ............95

Wiring Diagram Ð ROOM/L Ð/RHD Models............98

Trouble Diagnoses...................................................100

MAP AND VANITY MIRROR LAMPS.........................101

Wiring Diagram Ð INT/L Ð.....................................101

METER AND GAUGES...............................................102

System Description ..................................................102

Combination Meter ..................................................103

Wiring Diagram Ð METER Ð/LHD Models............104

Wiring Diagram Ð METER Ð/RHD Models ...........106

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode ........................108

Flexible Print Circuit (FPC) ......................................109

Trouble Diagnoses................................................... 110

Electrical Components Inspection ........................... 114

COMPASS AND THERMOMETER............................. 116

System Description .................................................. 116

Wiring Diagram Ð COMPAS Ð .............................. 117

Trouble Diagnoses................................................... 118

Calibration Procedure For Compass ....................... 119

WARNING LAMPS......................................................121

Schematic ................................................................121

Wiring Diagram Ð WARN Ð ..................................123

Electrical Components Inspection ...........................134

WARNING CHIME.......................................................135

System Description ..................................................135

Wiring Diagram Ð CHIME Ð/LHD Models.............136

Wiring Diagram Ð CHIME Ð/RHD Models ............137

Trouble Diagnoses...................................................138

Electrical Components Inspection ...........................140FRONT WIPER AND WASHER..................................141

System Description ..................................................141

Wiring Diagram Ð WIPER Ð/With Intermittent

Wiper........................................................................142

Removal and Installation .........................................143

Washer Nozzle Adjustment .....................................144

Washer Tube Layout ...............................................144

REAR WIPER AND WASHER....................................145

System Description ..................................................145

Wiring Diagram Ð WIP/R Ð/LHD Models ..............146

Wiring Diagram Ð WIP/R Ð/RHD Models .............148

Trouble Diagnoses...................................................150

Removal and Installation .........................................151

Washer Nozzle Adjustment .....................................151

Washer Tube Layout ...............................................152

Check Valve .............................................................152

HEADLAMP WIPER AND WASHER..........................153

Wiring Diagram Ð HLC Ð ......................................153

Electrical Components Inspection ...........................154

Removal and Installation .........................................154

Washer Tube Layout ...............................................154

Check Valve .............................................................154

HORN...........................................................................155

Wiring Diagram Ð HORN Ð...................................155

CIGARETTE LIGHTER................................................156

Wiring Diagram Ð CIGAR Ð ..................................156

CLOCK.........................................................................157

Wiring Diagram Ð CLOCK Ð .................................157

REAR WINDOW DEFOGGER.....................................158

System Description ..................................................158

Wiring Diagram Ð DEF Ð/LHD Models .................159

Wiring Diagram Ð DEF Ð/RHD Models ................161

Trouble Diagnoses...................................................163

Electrical Components Inspection ...........................164

Filament Check ........................................................164

Filament Repair .......................................................165

WIPER DEICER...........................................................166

System Description ..................................................166

Wiring Diagram Ð DEICER Ð................................167

AUDIO..........................................................................168

Wiring Diagram Ð AUDIO Ð/LHD Models .............168

Wiring Diagram Ð AUDIO Ð/RHD Models ............170

Trouble Diagnoses...................................................172

CATS (Code) System/RHD .....................................173

NATS Audio Link/LHD .............................................174

AUDIO Ð CD AUTO CHANGER Ð...........................176

Wiring Diagram Ð CD/CHG Ð/LHD Wagon ..........176

Wiring Diagram Ð CD/CHG Ð/LHD Hardtop .........177

Wiring Diagram Ð CD/CHG Ð/RHD Wagon ..........178

Wiring Diagram Ð CD/CHG Ð/RHD Hardtop ........179

Trouble Diagnoses...................................................180

AUDIO ANTENNA.......................................................181

Page 106 of 326

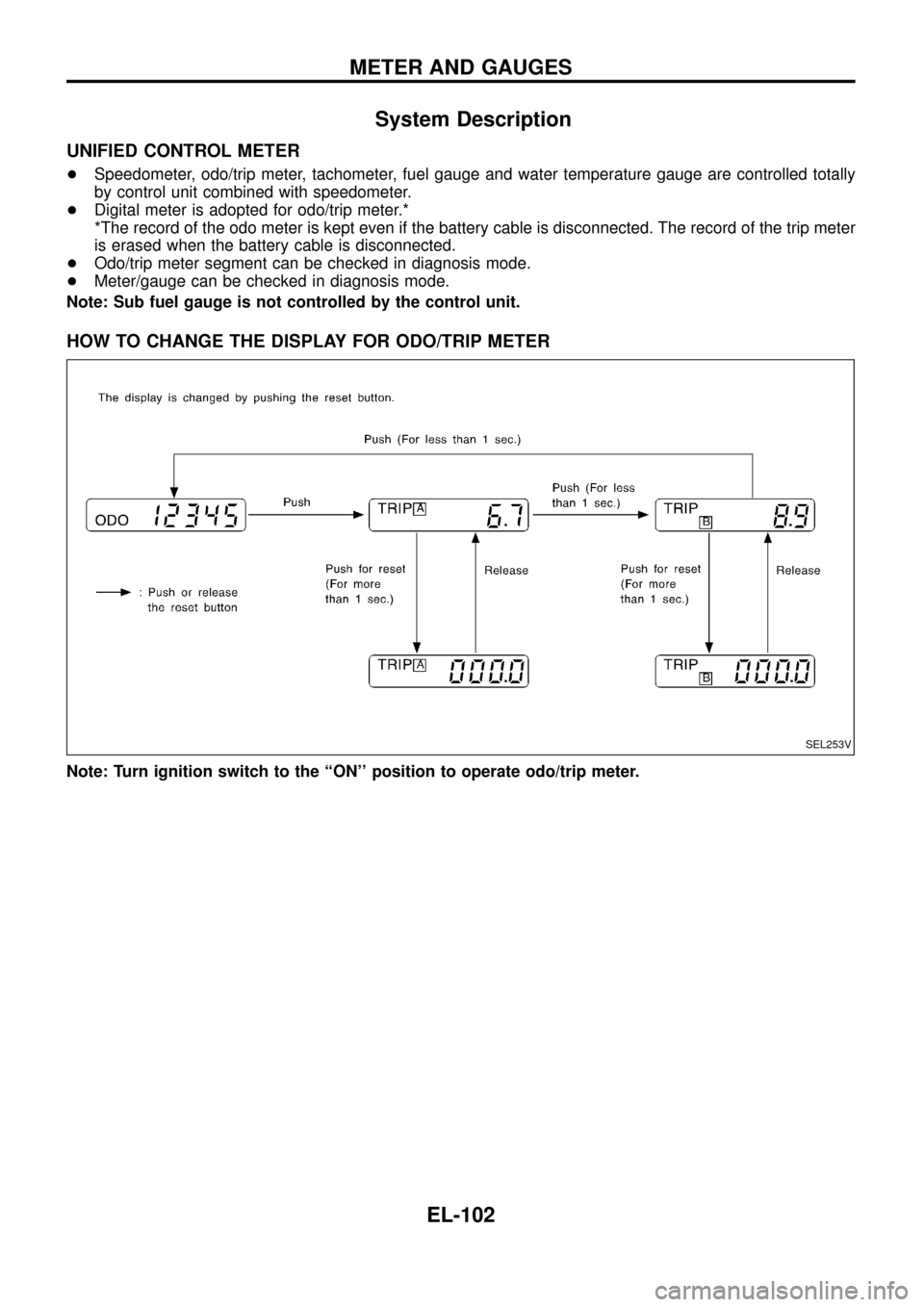

System Description

UNIFIED CONTROL METER

+Speedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled totally

by control unit combined with speedometer.

+Digital meter is adopted for odo/trip meter.*

*The record of the odo meter is kept even if the battery cable is disconnected. The record of the trip meter

is erased when the battery cable is disconnected.

+Odo/trip meter segment can be checked in diagnosis mode.

+Meter/gauge can be checked in diagnosis mode.

Note: Sub fuel gauge is not controlled by the control unit.

HOW TO CHANGE THE DISPLAY FOR ODO/TRIP METER

Note: Turn ignition switch to the ``ON'' position to operate odo/trip meter.

SEL253V

METER AND GAUGES

EL-102

Page 107 of 326

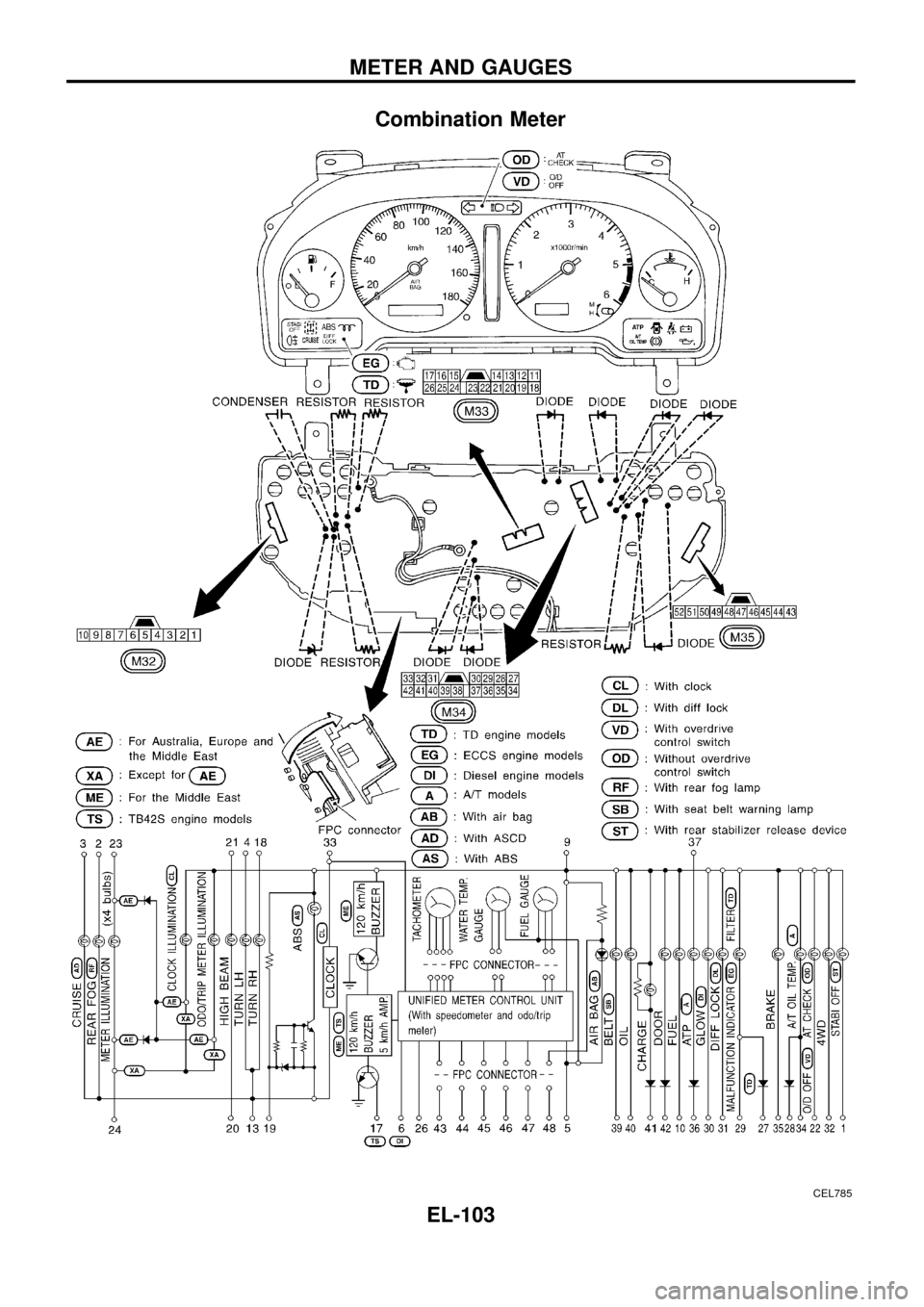

Combination Meter

CEL785

METER AND GAUGES

EL-103

Page 108 of 326

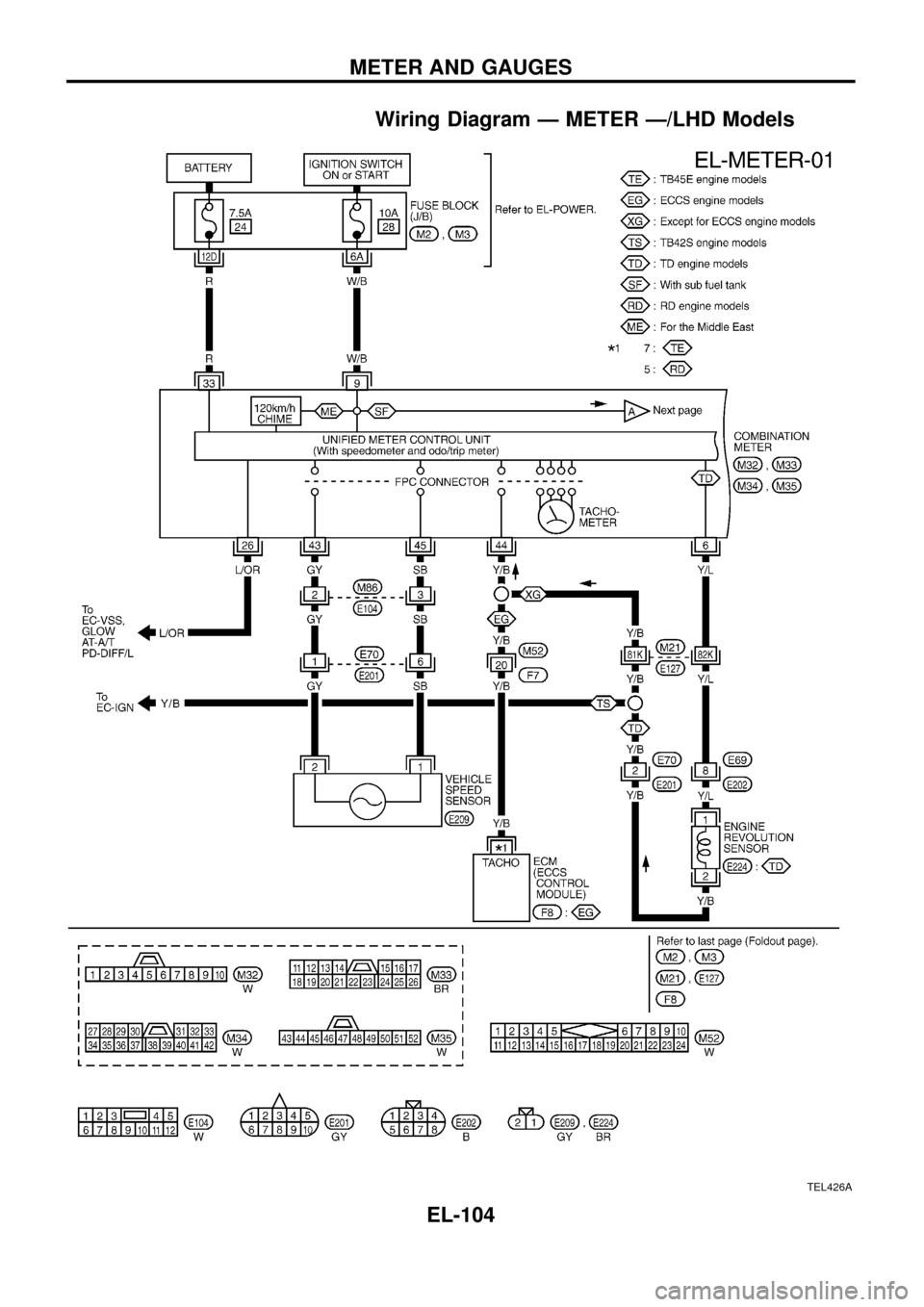

Wiring Diagram Ð METER Ð/LHD Models

TEL426A

METER AND GAUGES

EL-104

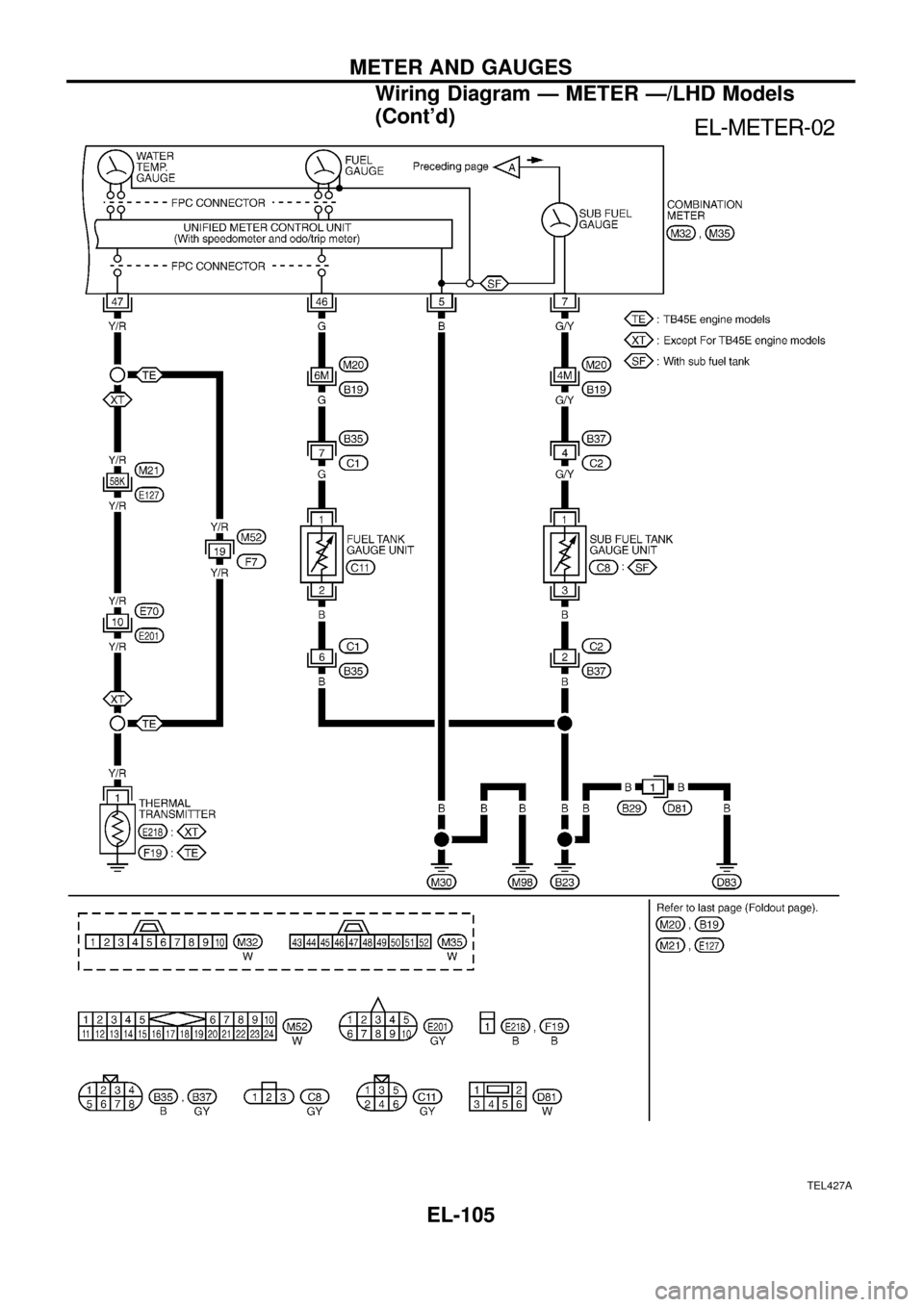

Page 109 of 326

TEL427A

METER AND GAUGES

Wiring Diagram Ð METER Ð/LHD Models

(Cont'd)

EL-105

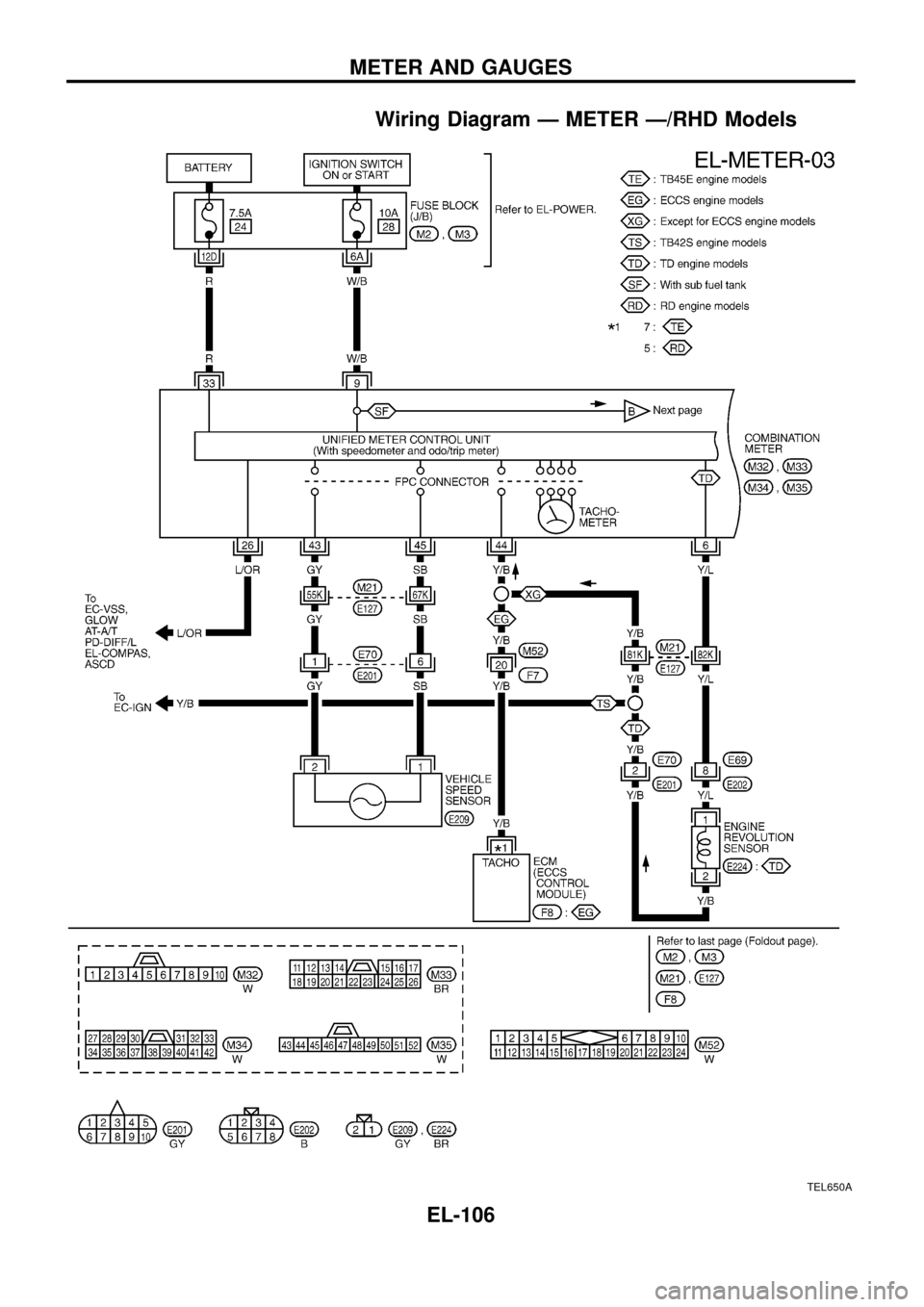

Page 110 of 326

Wiring Diagram Ð METER Ð/RHD Models

TEL650A

METER AND GAUGES

EL-106

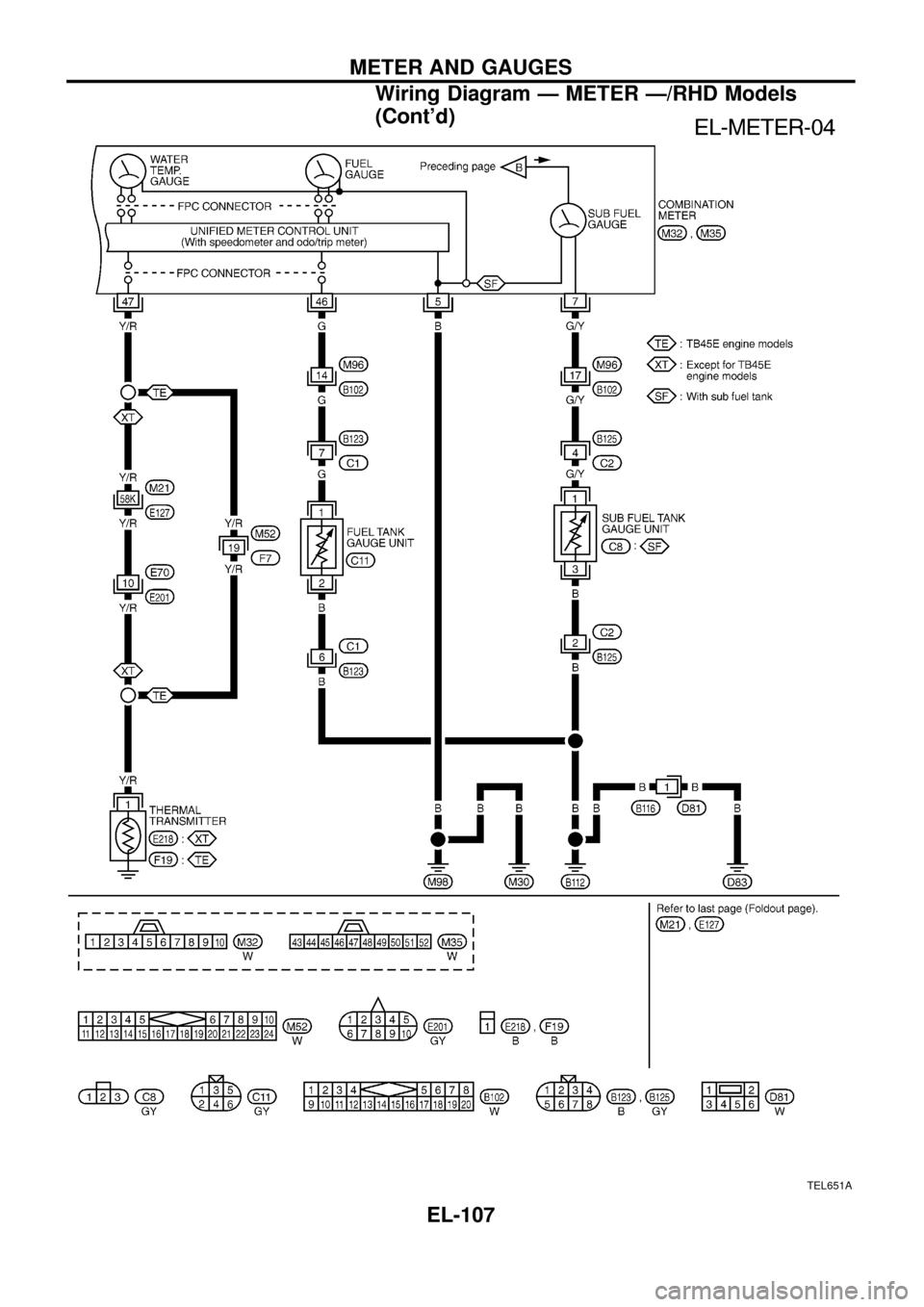

Page 111 of 326

TEL651A

METER AND GAUGES

Wiring Diagram Ð METER Ð/RHD Models

(Cont'd)

EL-107

Page 112 of 326

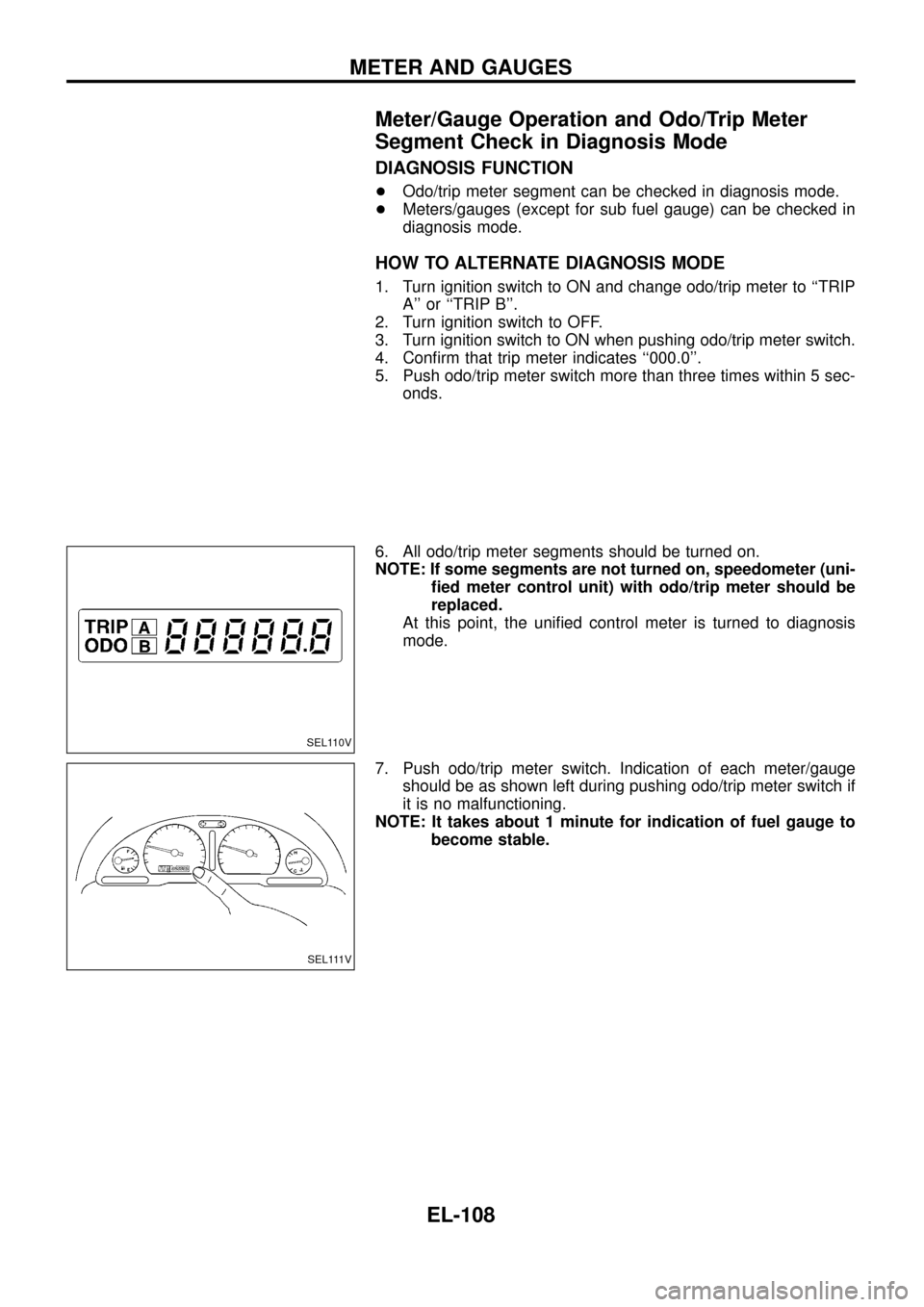

Meter/Gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode

DIAGNOSIS FUNCTION

+Odo/trip meter segment can be checked in diagnosis mode.

+Meters/gauges (except for sub fuel gauge) can be checked in

diagnosis mode.

HOW TO ALTERNATE DIAGNOSIS MODE

1. Turn ignition switch to ON and change odo/trip meter to ``TRIP

A'' or ``TRIP B''.

2. Turn ignition switch to OFF.

3. Turn ignition switch to ON when pushing odo/trip meter switch.

4. Con®rm that trip meter indicates ``000.0''.

5. Push odo/trip meter switch more than three times within 5 sec-

onds.

6. All odo/trip meter segments should be turned on.

NOTE: If some segments are not turned on, speedometer (uni-

®ed meter control unit) with odo/trip meter should be

replaced.

At this point, the uni®ed control meter is turned to diagnosis

mode.

7. Push odo/trip meter switch. Indication of each meter/gauge

should be as shown left during pushing odo/trip meter switch if

it is no malfunctioning.

NOTE: It takes about 1 minute for indication of fuel gauge to

become stable.

SEL110V

SEL111V

METER AND GAUGES

EL-108

Page 113 of 326

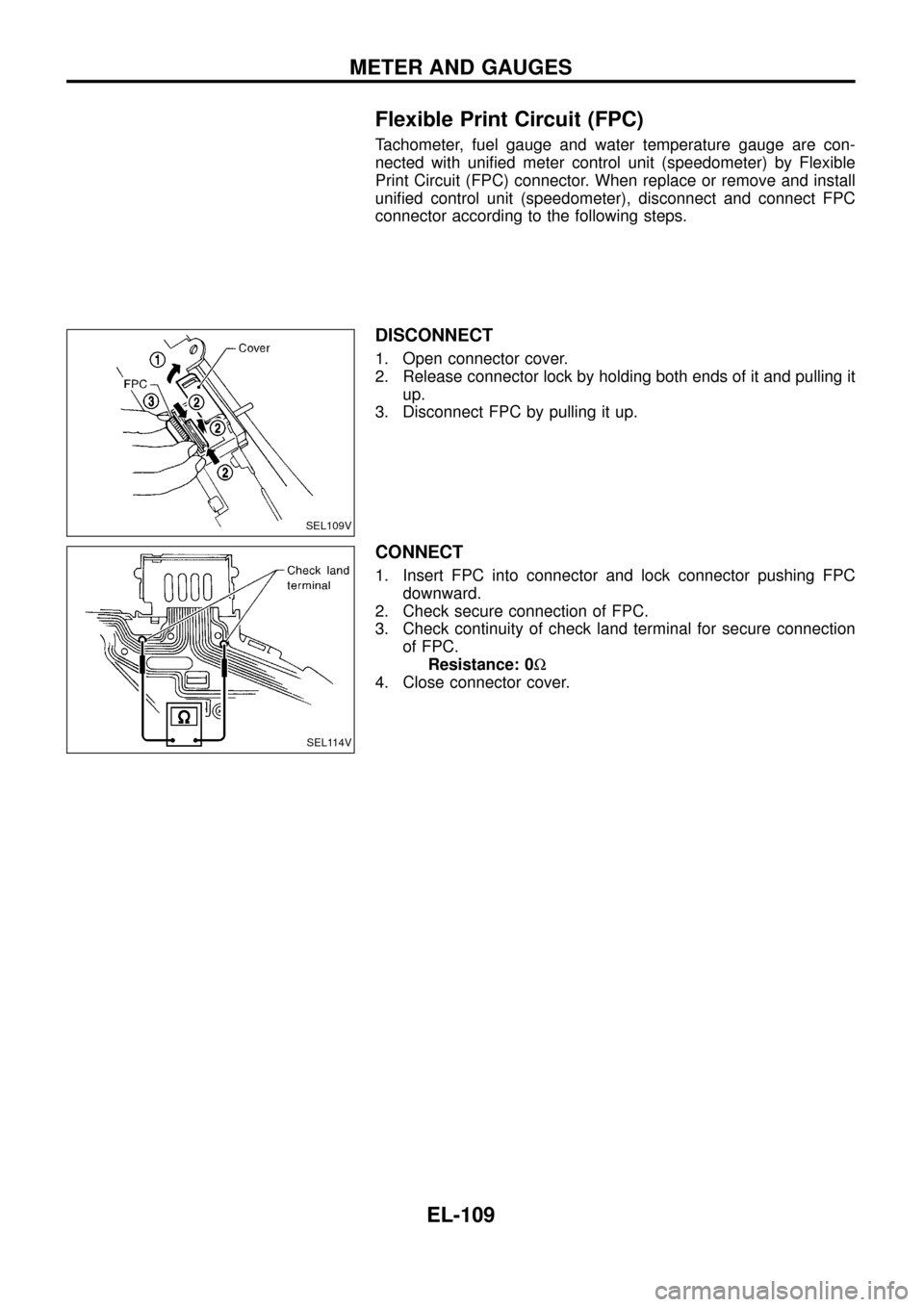

Flexible Print Circuit (FPC)

Tachometer, fuel gauge and water temperature gauge are con-

nected with uni®ed meter control unit (speedometer) by Flexible

Print Circuit (FPC) connector. When replace or remove and install

uni®ed control unit (speedometer), disconnect and connect FPC

connector according to the following steps.

DISCONNECT

1. Open connector cover.

2. Release connector lock by holding both ends of it and pulling it

up.

3. Disconnect FPC by pulling it up.

CONNECT

1. Insert FPC into connector and lock connector pushing FPC

downward.

2. Check secure connection of FPC.

3. Check continuity of check land terminal for secure connection

of FPC.

Resistance: 0W

4. Close connector cover.

SEL109V

SEL114V

METER AND GAUGES

EL-109

Page 114 of 326

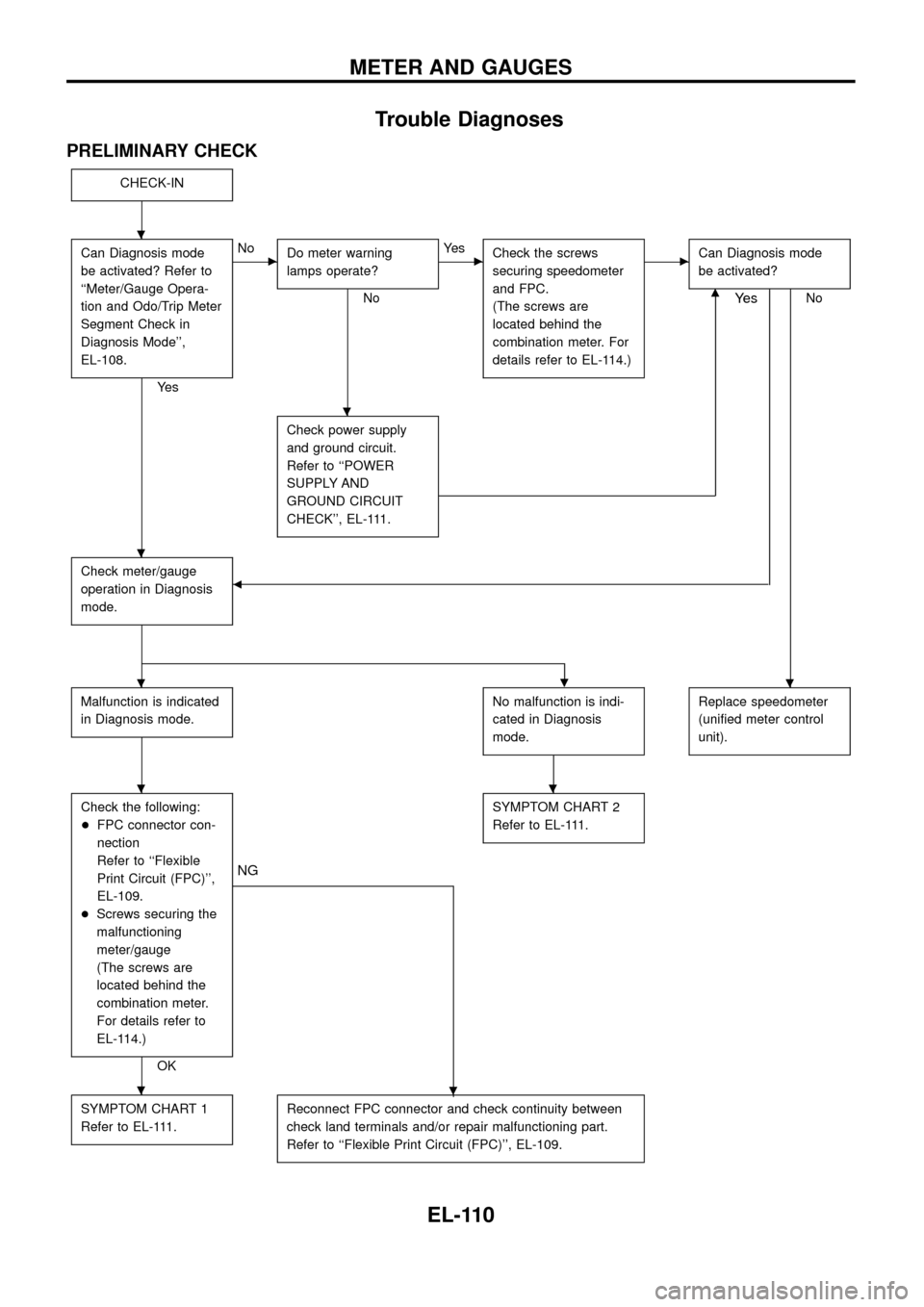

Trouble Diagnoses

PRELIMINARY CHECK

CHECK-IN

Can Diagnosis mode

be activated? Refer to

``Meter/Gauge Opera-

tion and Odo/Trip Meter

Segment Check in

Diagnosis Mode'',

EL-108.

Ye s

cNo

Do meter warning

lamps operate?

No

cYe s

Check the screws

securing speedometer

and FPC.

(The screws are

located behind the

combination meter. For

details refer to EL-114.)cCan Diagnosis mode

be activated?

Nom

Check power supply

and ground circuit.

Refer to ``POWER

SUPPLY AND

GROUND CIRCUIT

CHECK'', EL-111.

Check meter/gauge

operation in Diagnosis

mode.b

Ye s

.

Malfunction is indicated

in Diagnosis mode.No malfunction is indi-

cated in Diagnosis

mode.Replace speedometer

(uni®ed meter control

unit).

Check the following:

+FPC connector con-

nection

Refer to ``Flexible

Print Circuit (FPC)'',

EL-109.

+Screws securing the

malfunctioning

meter/gauge

(The screws are

located behind the

combination meter.

For details refer to

EL-114.)

OK

.

NG

SYMPTOM CHART 2

Refer to EL-111.

SYMPTOM CHART 1

Refer to EL-111.Reconnect FPC connector and check continuity between

check land terminals and/or repair malfunctioning part.

Refer to ``Flexible Print Circuit (FPC)'', EL-109.

.

.

.

..

..

.

METER AND GAUGES

EL-110