dimensions NISSAN PATROL 1998 Y61 / 5.G Engine Mechanical Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 65, PDF Size: 2.4 MB

Page 6 of 65

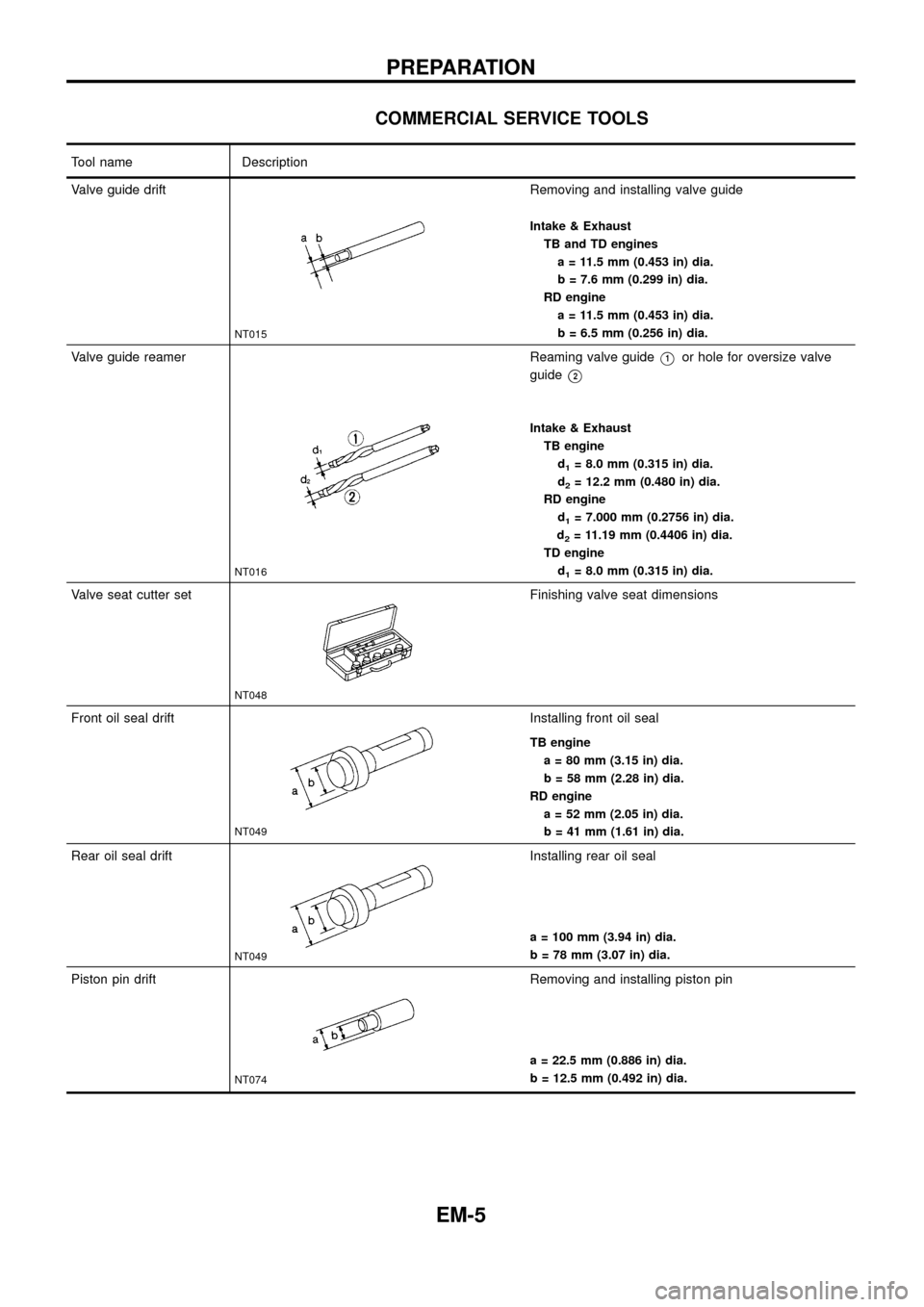

COMMERCIAL SERVICE TOOLS

Tool name Description

Valve guide drift

NT015

Removing and installing valve guide

Intake & Exhaust

TB and TD engines

a = 11.5 mm (0.453 in) dia.

b = 7.6 mm (0.299 in) dia.

RD engine

a = 11.5 mm (0.453 in) dia.

b = 6.5 mm (0.256 in) dia.

Valve guide reamer

NT016

Reaming valve guideV1or hole for oversize valve

guide

V2

Intake & Exhaust

TB engine

d

1= 8.0 mm (0.315 in) dia.

d

2= 12.2 mm (0.480 in) dia.

RD engine

d

1= 7.000 mm (0.2756 in) dia.

d

2= 11.19 mm (0.4406 in) dia.

TD engine

d

1= 8.0 mm (0.315 in) dia.

Valve seat cutter set

NT048

Finishing valve seat dimensions

Front oil seal drift

NT049

Installing front oil seal

TB engine

a = 80 mm (3.15 in) dia.

b = 58 mm (2.28 in) dia.

RD engine

a = 52 mm (2.05 in) dia.

b = 41 mm (1.61 in) dia.

Rear oil seal drift

NT049

Installing rear oil seal

a = 100 mm (3.94 in) dia.

b = 78 mm (3.07 in) dia.

Piston pin drift

NT074

Removing and installing piston pin

a = 22.5 mm (0.886 in) dia.

b = 12.5 mm (0.492 in) dia.

PREPARATION

EM-5

Page 35 of 65

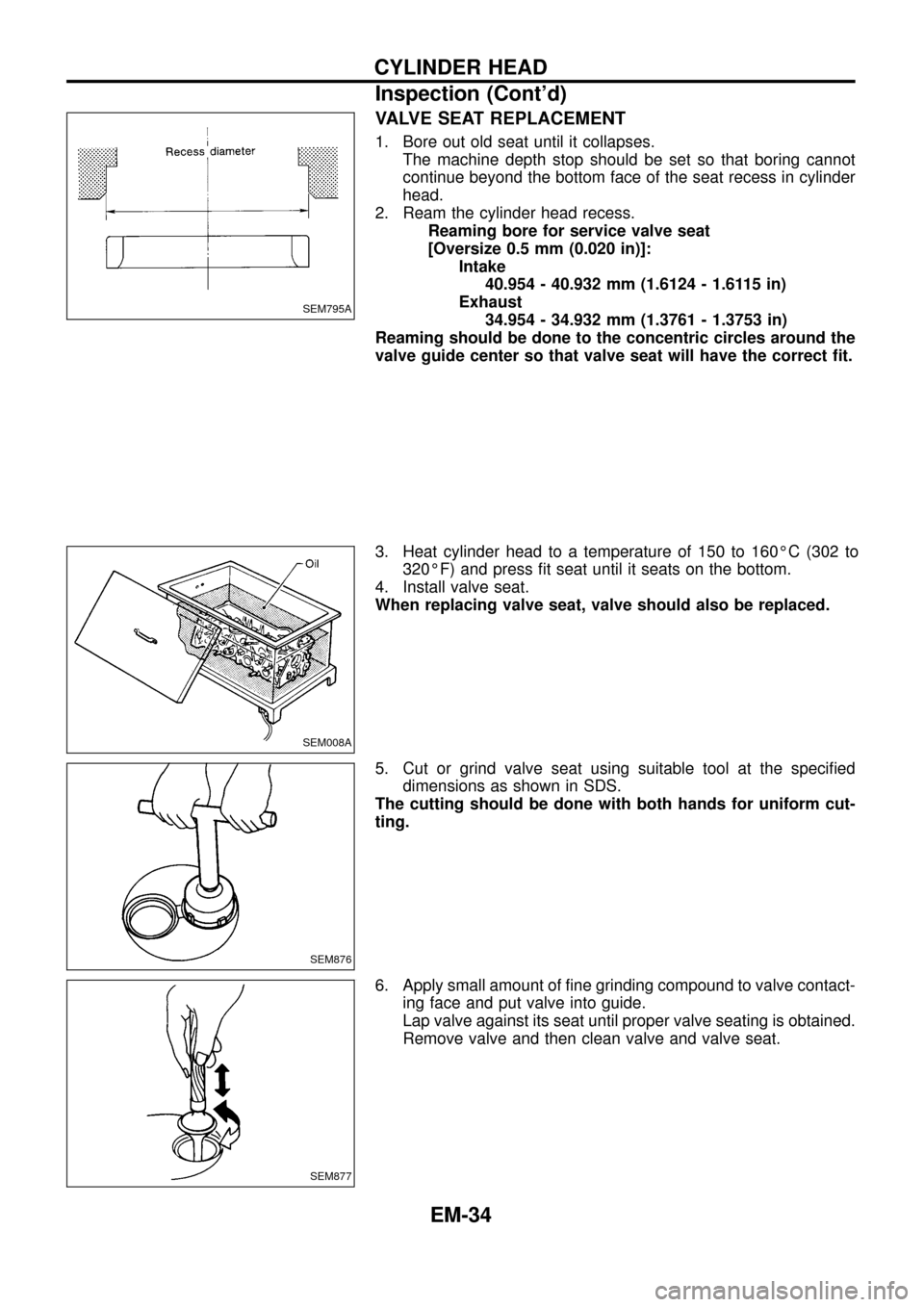

VALVE SEAT REPLACEMENT

1. Bore out old seat until it collapses.

The machine depth stop should be set so that boring cannot

continue beyond the bottom face of the seat recess in cylinder

head.

2. Ream the cylinder head recess.

Reaming bore for service valve seat

[Oversize 0.5 mm (0.020 in)]:

Intake

40.954 - 40.932 mm (1.6124 - 1.6115 in)

Exhaust

34.954 - 34.932 mm (1.3761 - 1.3753 in)

Reaming should be done to the concentric circles around the

valve guide center so that valve seat will have the correct ®t.

3. Heat cylinder head to a temperature of 150 to 160ÉC (302 to

320ÉF) and press ®t seat until it seats on the bottom.

4. Install valve seat.

When replacing valve seat, valve should also be replaced.

5. Cut or grind valve seat using suitable tool at the speci®ed

dimensions as shown in SDS.

The cutting should be done with both hands for uniform cut-

ting.

6. Apply small amount of ®ne grinding compound to valve contact-

ing face and put valve into guide.

Lap valve against its seat until proper valve seating is obtained.

Remove valve and then clean valve and valve seat.

SEM795A

SEM008A

SEM876

SEM877

CYLINDER HEAD

Inspection (Cont'd)

EM-34

Page 36 of 65

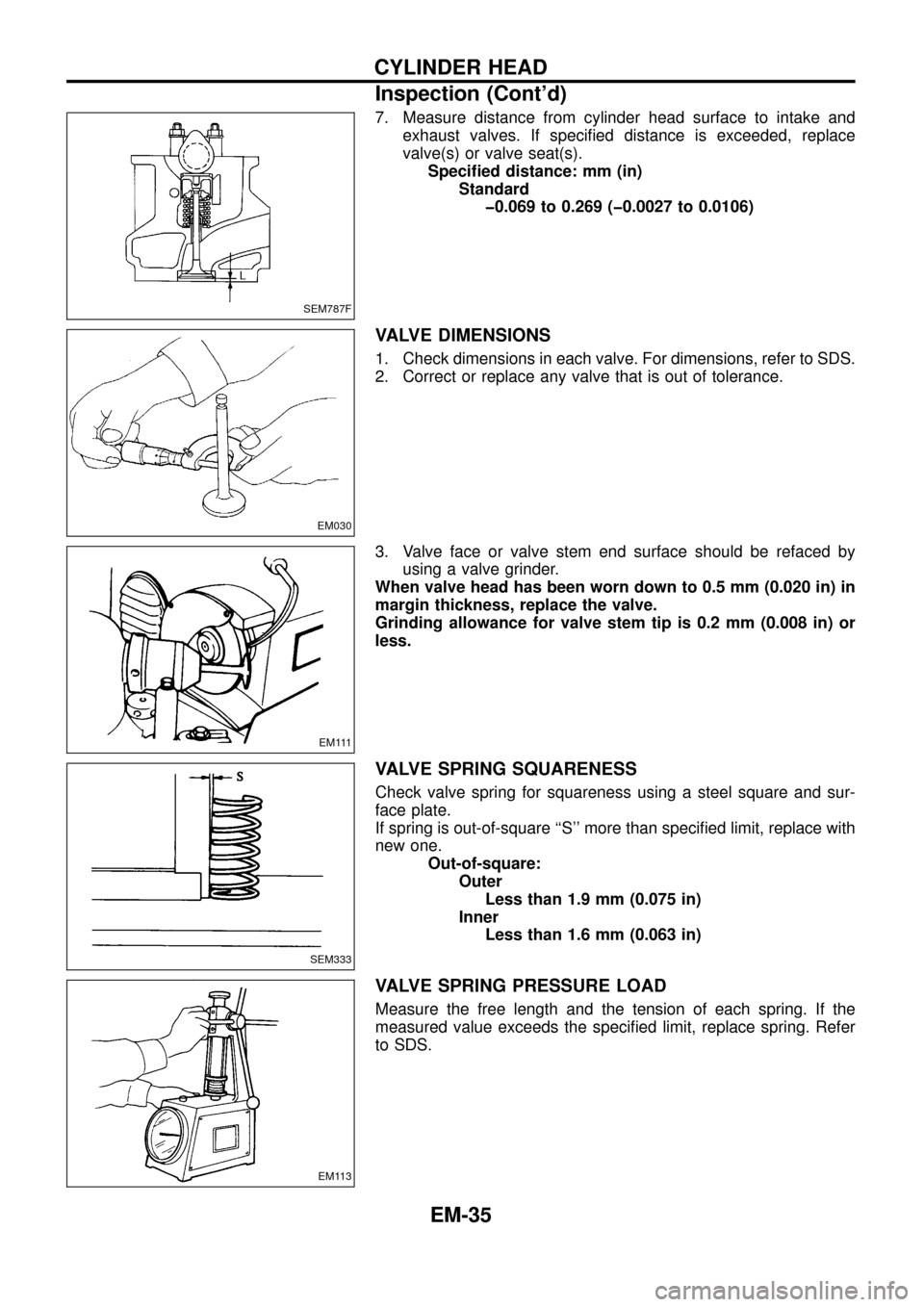

7. Measure distance from cylinder head surface to intake and

exhaust valves. If speci®ed distance is exceeded, replace

valve(s) or valve seat(s).

Speci®ed distance: mm (in)

Standard

þ0.069 to 0.269 (þ0.0027 to 0.0106)

VALVE DIMENSIONS

1. Check dimensions in each valve. For dimensions, refer to SDS.

2. Correct or replace any valve that is out of tolerance.

3. Valve face or valve stem end surface should be refaced by

using a valve grinder.

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace the valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

VALVE SPRING SQUARENESS

Check valve spring for squareness using a steel square and sur-

face plate.

If spring is out-of-square ``S'' more than speci®ed limit, replace with

new one.

Out-of-square:

Outer

Less than 1.9 mm (0.075 in)

Inner

Less than 1.6 mm (0.063 in)

VALVE SPRING PRESSURE LOAD

Measure the free length and the tension of each spring. If the

measured value exceeds the speci®ed limit, replace spring. Refer

to SDS.

SEM787F

EM030

E M 111

SEM333

EM113

CYLINDER HEAD

Inspection (Cont'd)

EM-35