oil pressure NISSAN PATROL 1998 Y61 / 5.G Engine Mechanical Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 65, PDF Size: 2.4 MB

Page 1 of 65

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS...............................................................1

Parts Requiring Angular Tightening .............................1

Liquid Gasket Application Procedure ..........................1

PREPARATION................................................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart Ð Engine Noise .............7

OUTER COMPONENT PARTS.......................................8

COMPRESSION PRESSURE........................................10

Measurement of Compression Pressure ...................10

OIL PAN.........................................................................13

Removal .....................................................................13

Installation ..................................................................14

TIMING BELT.................................................................15

Removal .....................................................................15

Inspection...................................................................17

Installation ..................................................................18

OIL SEAL REPLACEMENT..........................................20

TURBOCHARGER.........................................................23

Removal and Installation ...........................................23

Inspection...................................................................24CHARGE AIR COOLERS..............................................27

CYLINDER HEAD..........................................................28

Removal .....................................................................29

Disassembly...............................................................30

Inspection...................................................................31

Assembly ...................................................................37

Installation ..................................................................37

VALVE CLEARANCE....................................................40

Checking ....................................................................40

Adjusting ....................................................................41

ENGINE REMOVAL.......................................................43

Removal .....................................................................44

Installation ..................................................................44

CYLINDER BLOCK.......................................................45

Disassembly...............................................................46

Inspection...................................................................46

Assembly ...................................................................53

SERVICE DATA AND SPECIFICATIONS (SDS)..........56

General Speci®cations ...............................................56

Inspection and Adjustment ........................................56

EM

Page 13 of 65

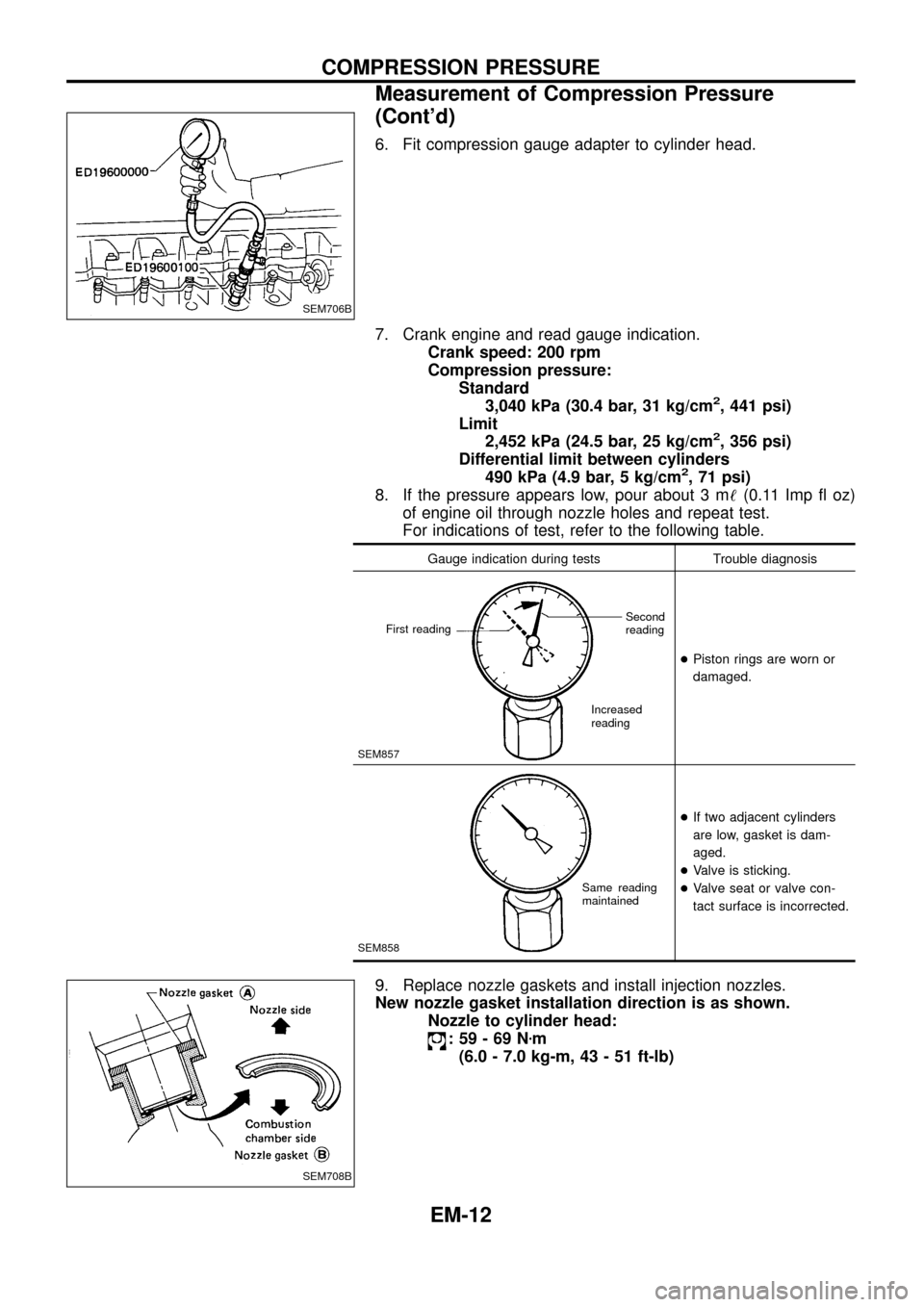

6. Fit compression gauge adapter to cylinder head.

7. Crank engine and read gauge indication.

Crank speed: 200 rpm

Compression pressure:

Standard

3,040 kPa (30.4 bar, 31 kg/cm

2, 441 psi)

Limit

2,452 kPa (24.5 bar, 25 kg/cm

2, 356 psi)

Differential limit between cylinders

490 kPa (4.9 bar, 5 kg/cm

2, 71 psi)

8. If the pressure appears low, pour about 3 m!(0.11 Imp ¯ oz)

of engine oil through nozzle holes and repeat test.

For indications of test, refer to the following table.

Gauge indication during tests Trouble diagnosis

SEM857

+Piston rings are worn or

damaged.

SEM858

+If two adjacent cylinders

are low, gasket is dam-

aged.

+Valve is sticking.

+Valve seat or valve con-

tact surface is incorrected.

9. Replace nozzle gaskets and install injection nozzles.

New nozzle gasket installation direction is as shown.

Nozzle to cylinder head:

:59-69Nzm

(6.0 - 7.0 kg-m, 43 - 51 ft-lb)

SEM706B

SEM708B

COMPRESSION PRESSURE

Measurement of Compression Pressure

(Cont'd)

EM-12

First readingSecond

reading

Increased

reading

Same reading

maintained

Page 58 of 65

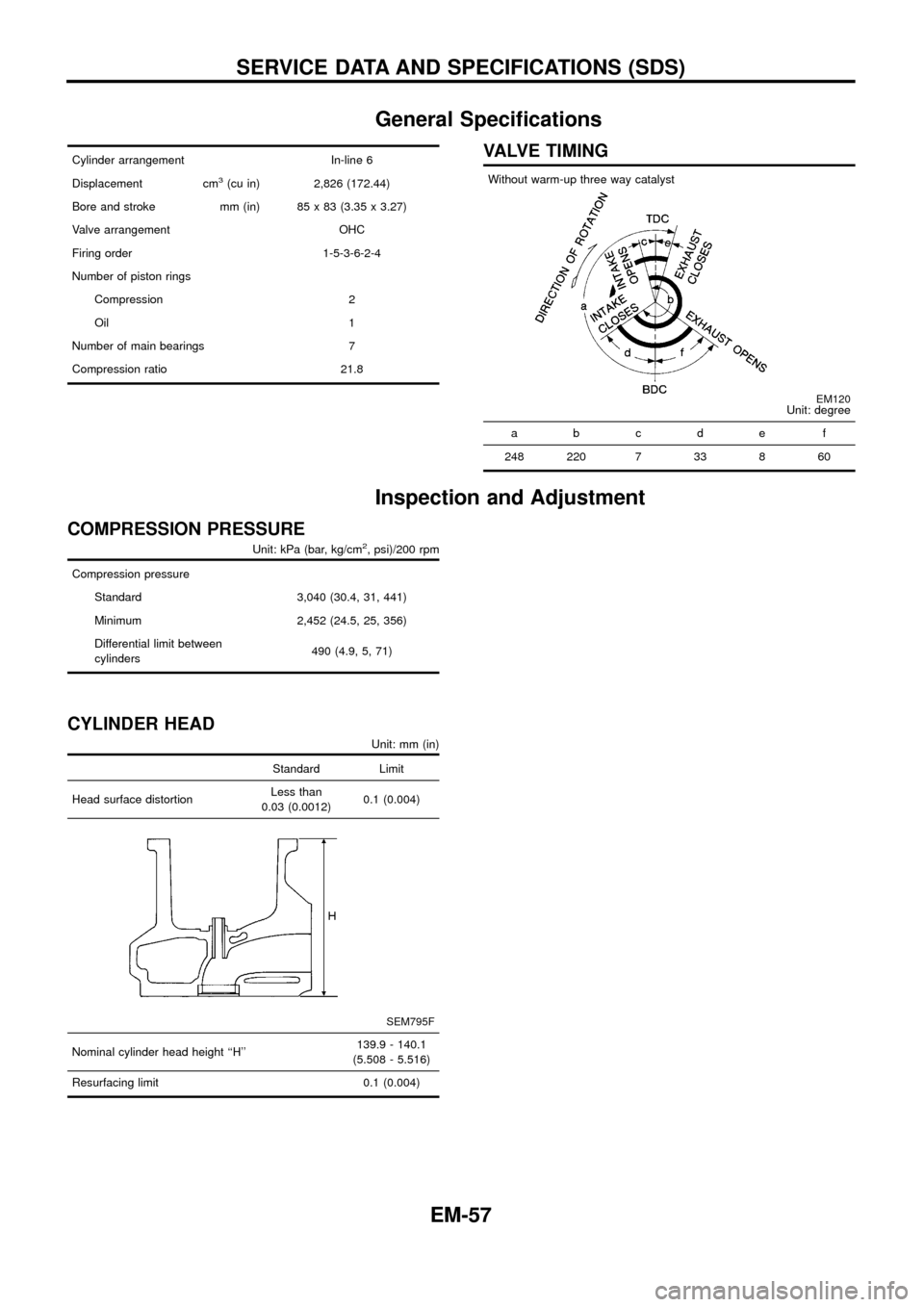

General Speci®cations

Cylinder arrangement In-line 6

Displacement cm

3(cu in) 2,826 (172.44)

Bore and stroke mm (in) 85 x 83 (3.35 x 3.27)

Valve arrangement OHC

Firing order 1-5-3-6-2-4

Number of piston rings

Compression 2

Oil 1

Number of main bearings 7

Compression ratio 21.8

VALVE TIMING

Without warm-up three way catalyst

EM120Unit: degree

abcde f

248 220 7 33 8 60

Inspection and Adjustment

COMPRESSION PRESSURE

Unit: kPa (bar, kg/cm2, psi)/200 rpm

Compression pressure

Standard 3,040 (30.4, 31, 441)

Minimum 2,452 (24.5, 25, 356)

Differential limit between

cylinders490 (4.9, 5, 71)

CYLINDER HEAD

Unit: mm (in)

Standard Limit

Head surface distortionLess than

0.03 (0.0012)0.1 (0.004)

SEM795F

Nominal cylinder head height ``H''139.9 - 140.1

(5.508 - 5.516)

Resurfacing limit 0.1 (0.004)

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-57