engine NISSAN PATROL 1998 Y61 / 5.G Heather And Air Conditioner User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 128, PDF Size: 3.77 MB

Page 69 of 128

jC

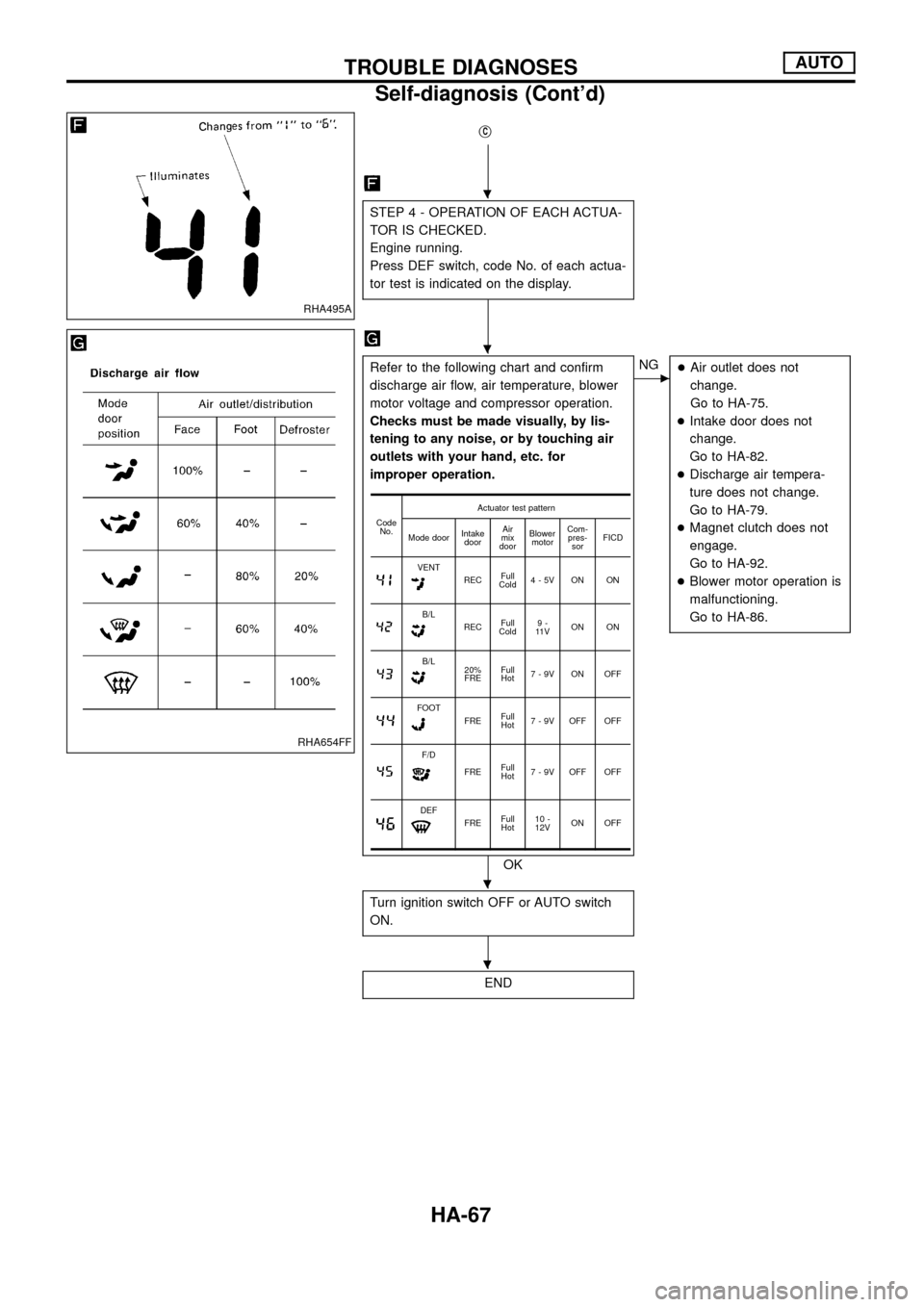

STEP 4 - OPERATION OF EACH ACTUA-

TOR IS CHECKED.

Engine running.

Press DEF switch, code No. of each actua-

tor test is indicated on the display.

Refer to the following chart and con®rm

discharge air ¯ow, air temperature, blower

motor voltage and compressor operation.

Checks must be made visually, by lis-

tening to any noise, or by touching air

outlets with your hand, etc. for

improper operation.

OK

cNG

+Air outlet does not

change.

Go to HA-75.

+Intake door does not

change.

Go to HA-82.

+Discharge air tempera-

ture does not change.

Go to HA-79.

+Magnet clutch does not

engage.

Go to HA-92.

+Blower motor operation is

malfunctioning.

Go to HA-86.

Turn ignition switch OFF or AUTO switch

ON.

END

Code

No.Actuator test pattern

Mode doorIntake

doorAir

mix

doorBlower

motorCom-

pres-

sorFICD

VENTRECFull

Cold4-5V ON ON

B/LRECFull

Cold9-

11 VON ON

B/L20%

FREFull

Hot7-9V ON OFF

FOOTFREFull

Hot7 - 9V OFF OFF

F/D

FREFull

Hot7 - 9V OFF OFF

DEFFREFull

Hot10 -

12VON OFF

RHA495A

RHA654FF

.

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-67

Page 72 of 128

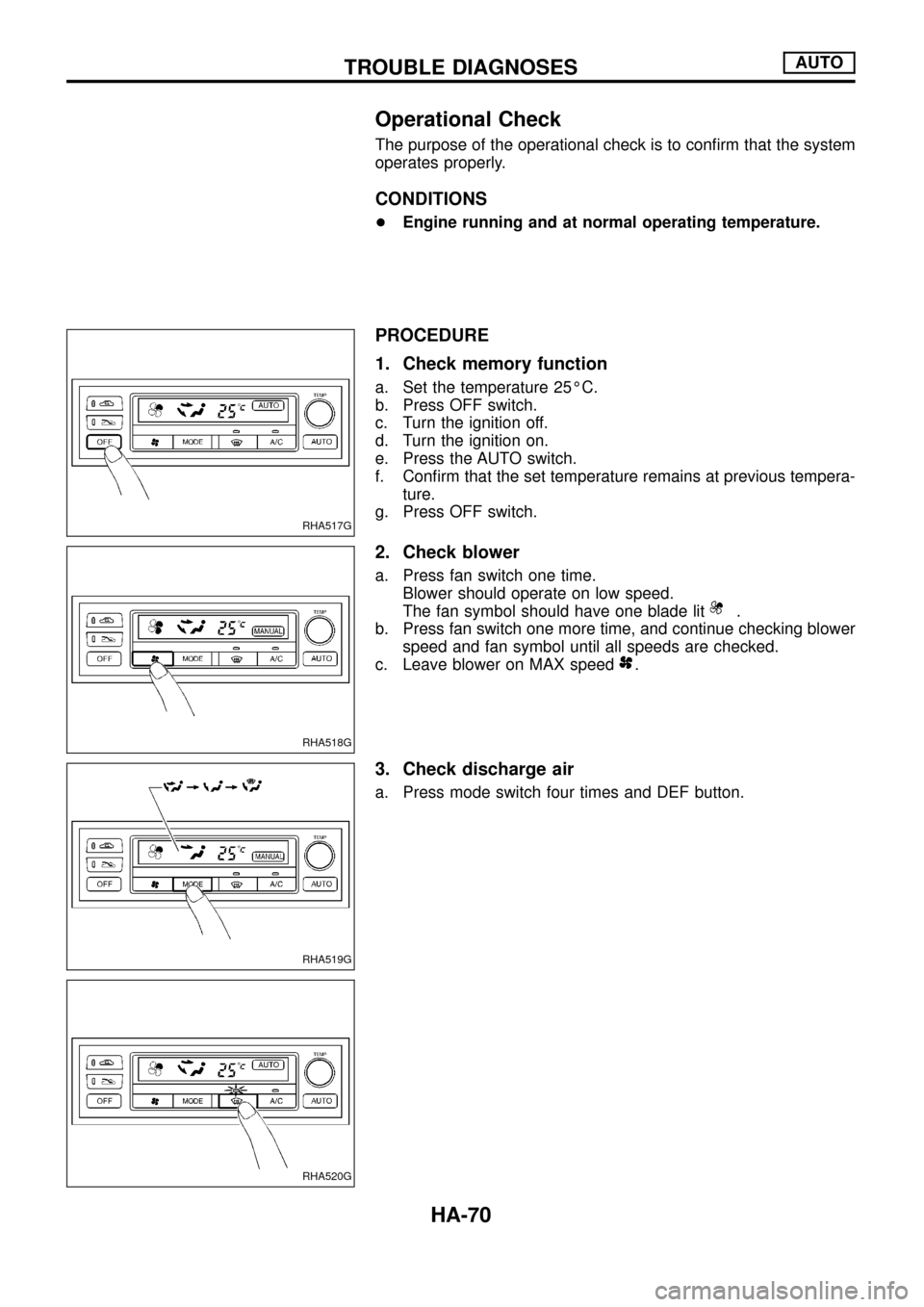

Operational Check

The purpose of the operational check is to con®rm that the system

operates properly.

CONDITIONS

+Engine running and at normal operating temperature.

PROCEDURE

1. Check memory function

a. Set the temperature 25ÉC.

b. Press OFF switch.

c. Turn the ignition off.

d. Turn the ignition on.

e. Press the AUTO switch.

f. Con®rm that the set temperature remains at previous tempera-

ture.

g. Press OFF switch.

2. Check blower

a. Press fan switch one time.

Blower should operate on low speed.

The fan symbol should have one blade lit

.

b. Press fan switch one more time, and continue checking blower

speed and fan symbol until all speeds are checked.

c. Leave blower on MAX speed

.

3. Check discharge air

a. Press mode switch four times and DEF button.

RHA517G

RHA518G

RHA519G

RHA520G

TROUBLE DIAGNOSESAUTO

HA-70

Page 89 of 128

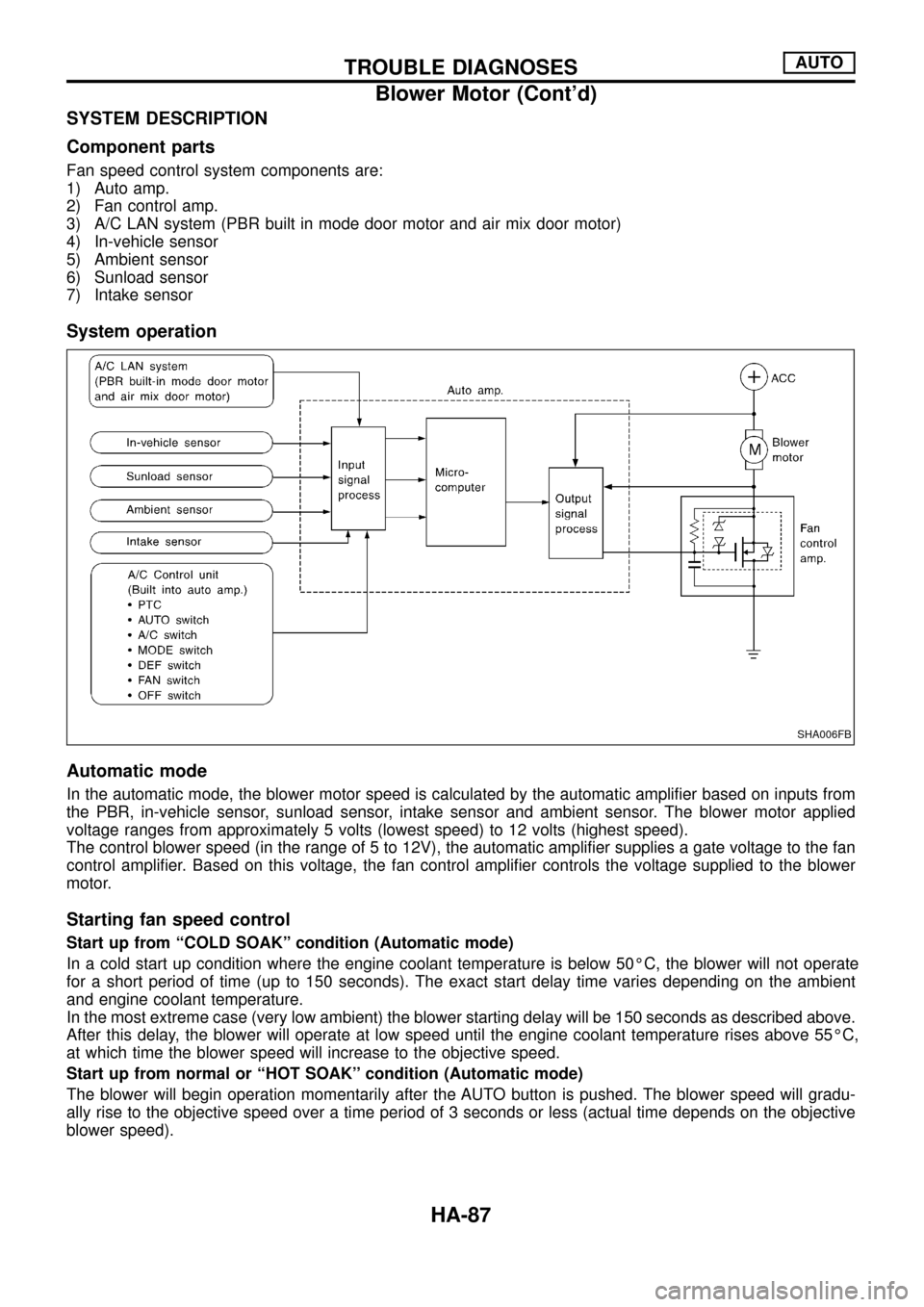

SYSTEM DESCRIPTION

Component parts

Fan speed control system components are:

1) Auto amp.

2) Fan control amp.

3) A/C LAN system (PBR built in mode door motor and air mix door motor)

4) In-vehicle sensor

5) Ambient sensor

6) Sunload sensor

7) Intake sensor

System operation

Automatic mode

In the automatic mode, the blower motor speed is calculated by the automatic ampli®er based on inputs from

the PBR, in-vehicle sensor, sunload sensor, intake sensor and ambient sensor. The blower motor applied

voltage ranges from approximately 5 volts (lowest speed) to 12 volts (highest speed).

The control blower speed (in the range of 5 to 12V), the automatic ampli®er supplies a gate voltage to the fan

control ampli®er. Based on this voltage, the fan control ampli®er controls the voltage supplied to the blower

motor.

Starting fan speed control

Start up from ``COLD SOAK'' condition (Automatic mode)

In a cold start up condition where the engine coolant temperature is below 50ÉC, the blower will not operate

for a short period of time (up to 150 seconds). The exact start delay time varies depending on the ambient

and engine coolant temperature.

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described above.

After this delay, the blower will operate at low speed until the engine coolant temperature rises above 55ÉC,

at which time the blower speed will increase to the objective speed.

Start up from normal or ``HOT SOAK'' condition (Automatic mode)

The blower will begin operation momentarily after the AUTO button is pushed. The blower speed will gradu-

ally rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

SHA006FB

TROUBLE DIAGNOSESAUTO

Blower Motor (Cont'd)

HA-87

Page 96 of 128

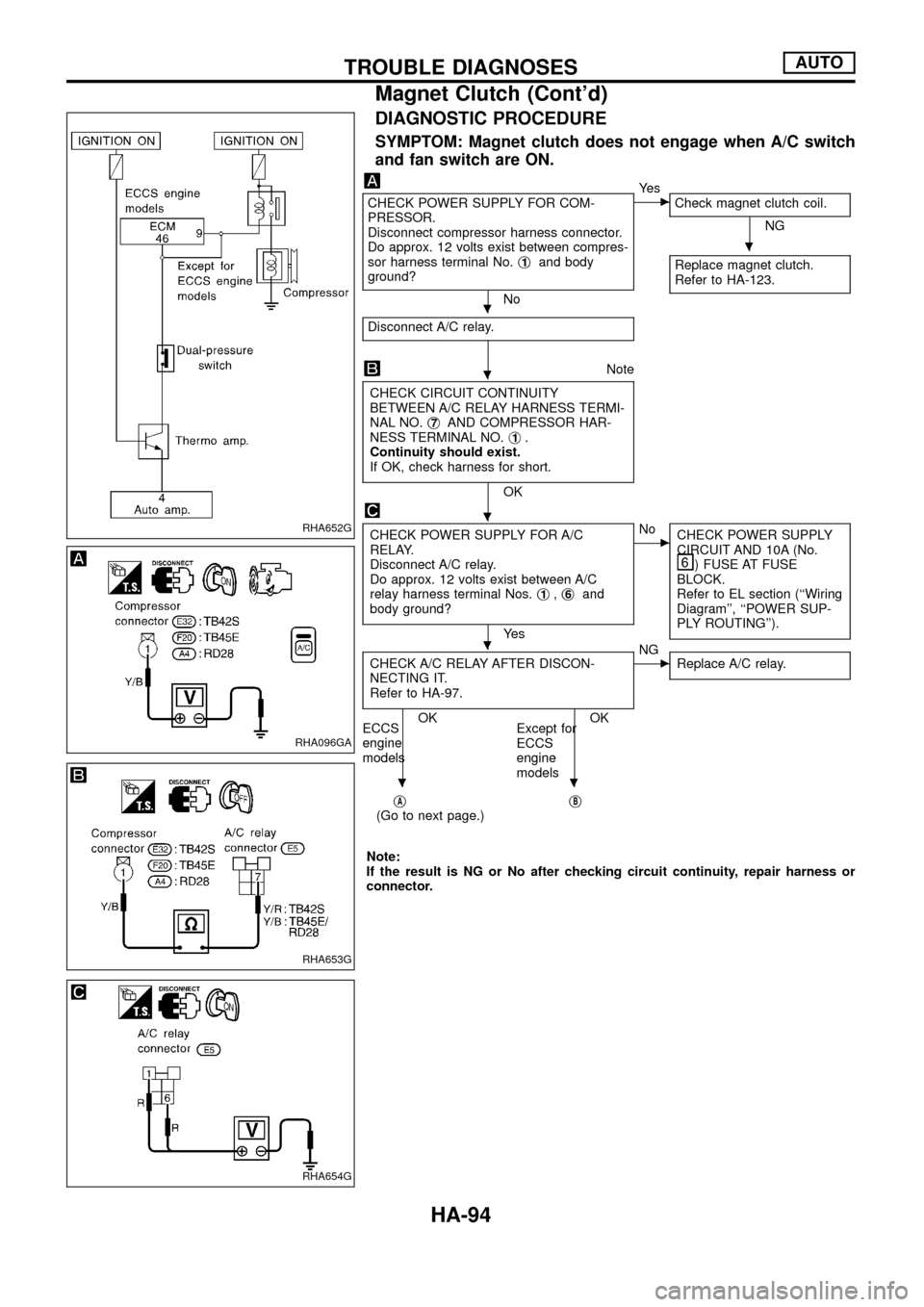

DIAGNOSTIC PROCEDURE

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan switch are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness terminal No.j

1and body

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-123.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS TERMI-

NAL NO.j

7AND COMPRESSOR HAR-

NESS TERMINAL NO.j1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness terminal Nos.j

1,j6and

body ground?

Ye s

cNo

CHECK POWER SUPPLY

CIRCUIT AND 10A (No.

) FUSE AT FUSE

BLOCK.

Refer to EL section (``Wiring

Diagram'', ``POWER SUP-

PLY ROUTING'').

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-97.

OK OK

ECCS

engine

modelsExcept for

ECCS

engine

models

cNG

Replace A/C relay.

jA(Go to next page.)jB

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA652G

RHA096GA

RHA653G

RHA654G

.

.

.

.

.

..

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-94

Page 105 of 128

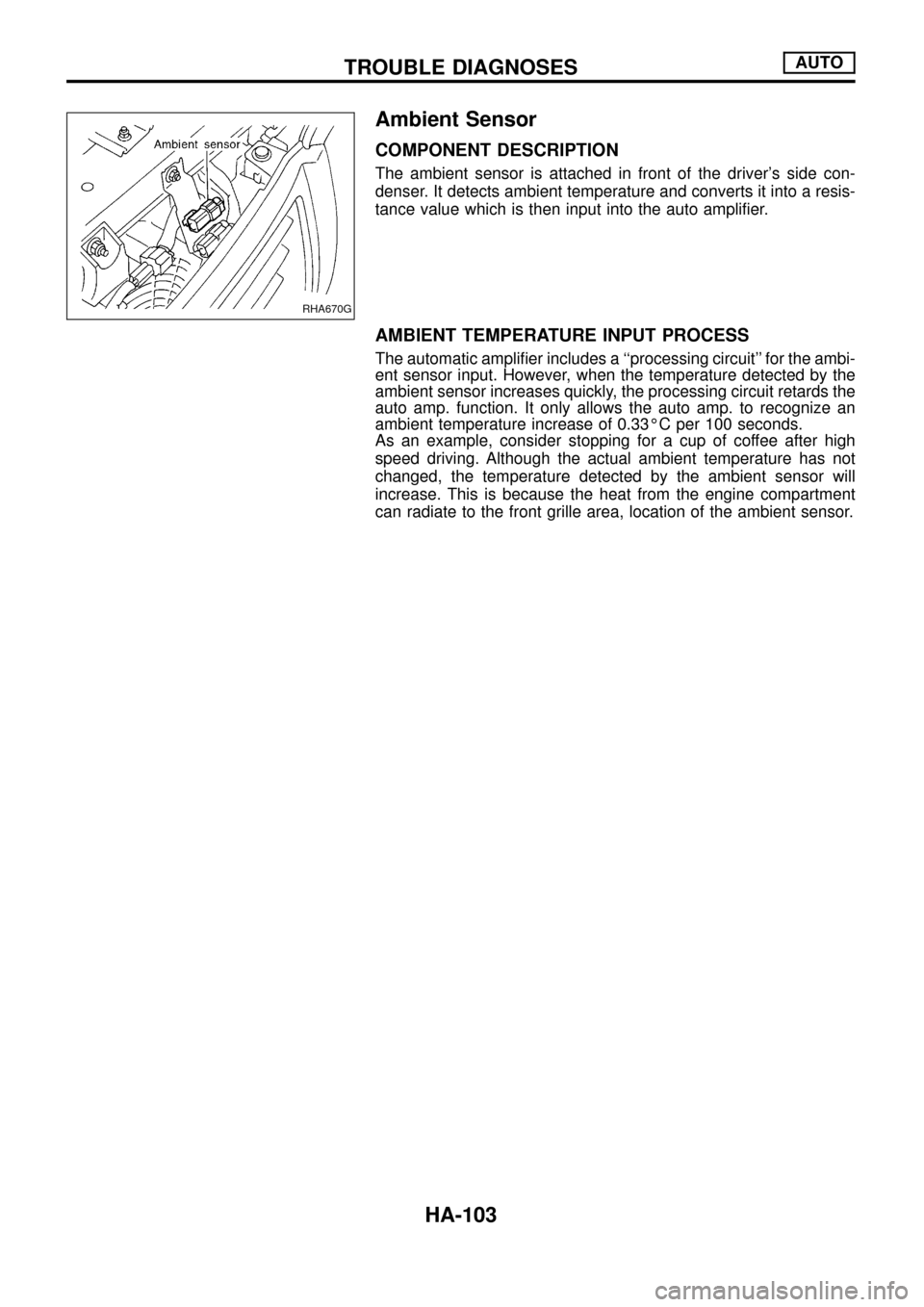

Ambient Sensor

COMPONENT DESCRIPTION

The ambient sensor is attached in front of the driver's side con-

denser. It detects ambient temperature and converts it into a resis-

tance value which is then input into the auto ampli®er.

AMBIENT TEMPERATURE INPUT PROCESS

The automatic ampli®er includes a ``processing circuit'' for the ambi-

ent sensor input. However, when the temperature detected by the

ambient sensor increases quickly, the processing circuit retards the

auto amp. function. It only allows the auto amp. to recognize an

ambient temperature increase of 0.33ÉC per 100 seconds.

As an example, consider stopping for a cup of coffee after high

speed driving. Although the actual ambient temperature has not

changed, the temperature detected by the ambient sensor will

increase. This is because the heat from the engine compartment

can radiate to the front grille area, location of the ambient sensor.

RHA670G

TROUBLE DIAGNOSESAUTO

HA-103

Page 114 of 128

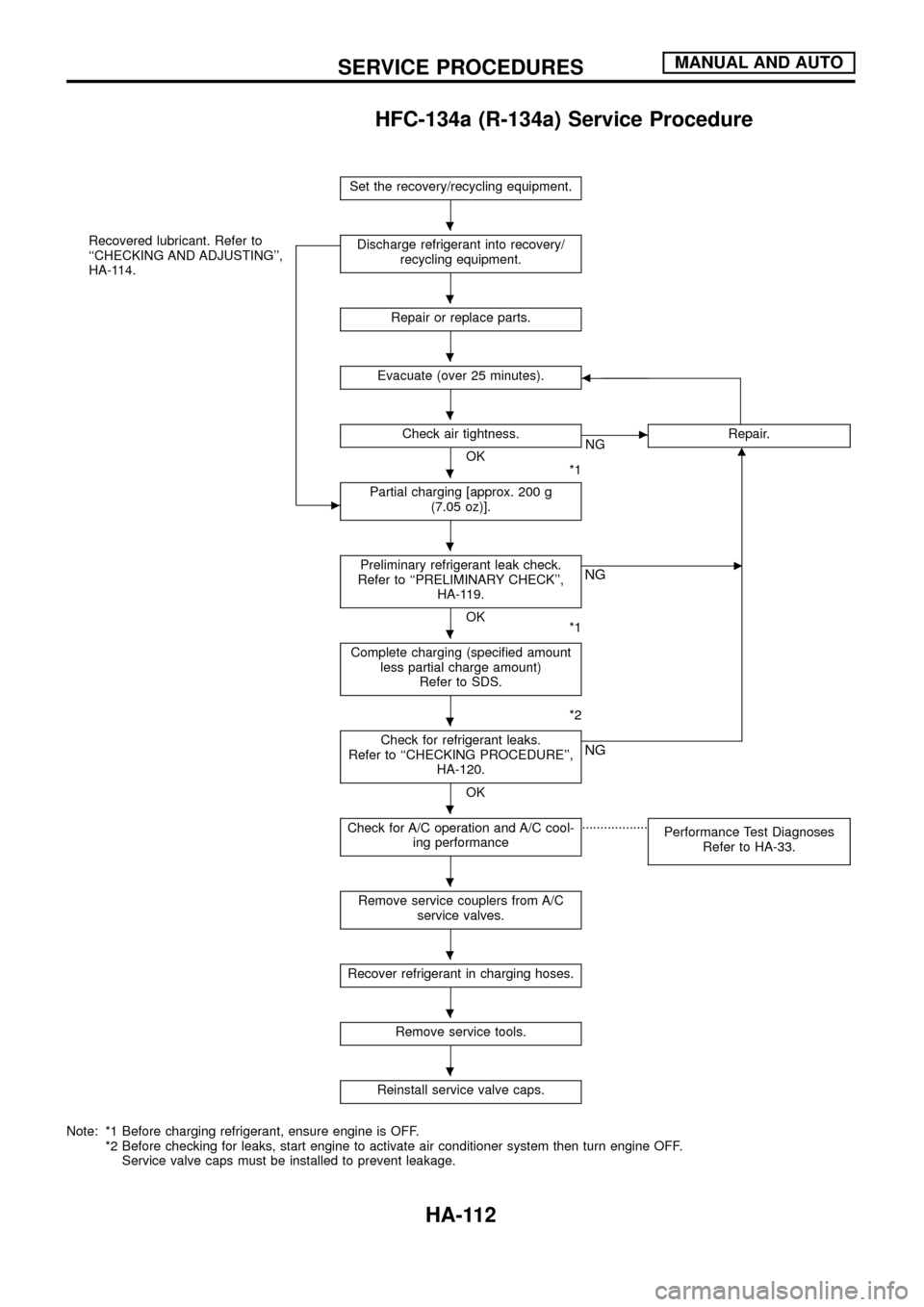

HFC-134a (R-134a) Service Procedure

Set the recovery/recycling equipment.

Recovered lubricant. Refer to

``CHECKING AND ADJUSTING'',

HA-114.

c

Discharge refrigerant into recovery/

recycling equipment.

Repair or replace parts.

Evacuate (over 25 minutes).b

Check air tightness.

OK

*1

cNGRepair.m

Partial charging [approx. 200 g

(7.05 oz)].

Preliminary refrigerant leak check.

Refer to ``PRELIMINARY CHECK'',

HA-119.

OK

*1

cNG

Complete charging (speci®ed amount

less partial charge amount)

Refer to SDS.

*2

Check for refrigerant leaks.

Refer to ``CHECKING PROCEDURE'',

HA-120.

OK

NG

Check for A/C operation and A/C cool-

ing performance..................

Performance Test Diagnoses

Refer to HA-33.

Remove service couplers from A/C

service valves.

Recover refrigerant in charging hoses.

Remove service tools.

Reinstall service valve caps.

Note: *1 Before charging refrigerant, ensure engine is OFF.

*2 Before checking for leaks, start engine to activate air conditioner system then turn engine OFF.

Service valve caps must be installed to prevent leakage.

.

.

.

.

.

.

.

.

.

.

.

.

.

SERVICE PROCEDURESMANUAL AND AUTO

HA-112

Page 116 of 128

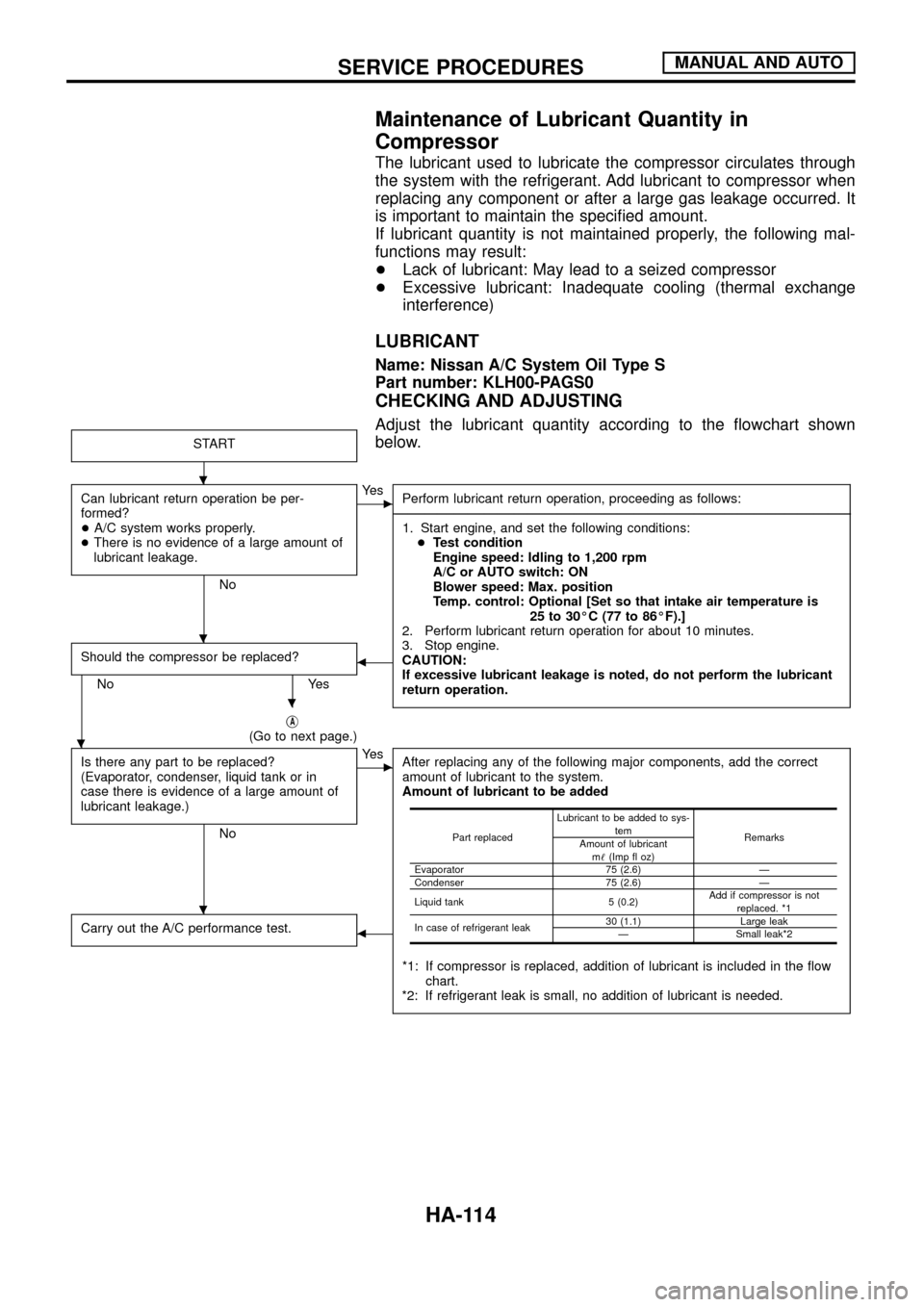

Maintenance of Lubricant Quantity in

Compressor

The lubricant used to lubricate the compressor circulates through

the system with the refrigerant. Add lubricant to compressor when

replacing any component or after a large gas leakage occurred. It

is important to maintain the speci®ed amount.

If lubricant quantity is not maintained properly, the following mal-

functions may result:

+Lack of lubricant: May lead to a seized compressor

+Excessive lubricant: Inadequate cooling (thermal exchange

interference)

LUBRICANT

Name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

CHECKING AND ADJUSTING

Adjust the lubricant quantity according to the ¯owchart shown

below.

START

Can lubricant return operation be per-

formed?

+A/C system works properly.

+There is no evidence of a large amount of

lubricant leakage.

No

cYe s

Perform lubricant return operation, proceeding as follows:

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Start engine, and set the following conditions:

+Test condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is

25 to 30ÉC (77 to 86ÉF).]

2. Perform lubricant return operation for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant

return operation.

Should the compressor be replaced?

No Yes

b

jA(Go to next page.)

Is there any part to be replaced?

(Evaporator, condenser, liquid tank or in

case there is evidence of a large amount of

lubricant leakage.)

No

cYe s

After replacing any of the following major components, add the correct

amount of lubricant to the system.

Amount of lubricant to be added

*1: If compressor is replaced, addition of lubricant is included in the ¯ow

chart.

*2: If refrigerant leak is small, no addition of lubricant is needed.

Carry out the A/C performance test.b

Part replacedLubricant to be added to sys-

tem

Remarks

Amount of lubricant

m!(Imp ¯ oz)

Evaporator 75 (2.6) Ð

Condenser 75 (2.6) Ð

Liquid tank 5 (0.2)Add if compressor is not

replaced. *1

In case of refrigerant leak30 (1.1) Large leak

Ð Small leak*2

.

.

.

.

.

SERVICE PROCEDURESMANUAL AND AUTO

HA-114

Page 119 of 128

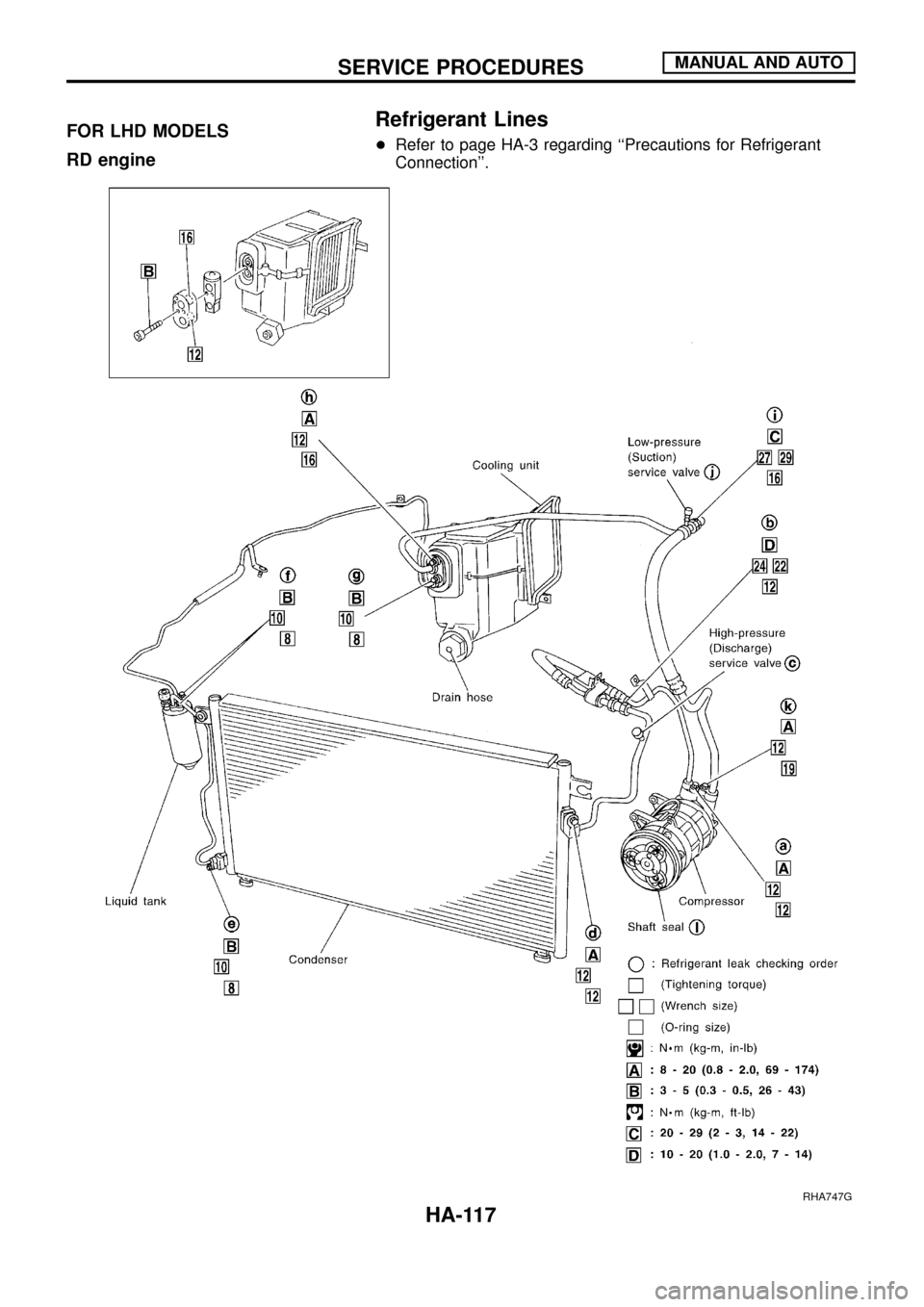

Refrigerant Lines

+Refer to page HA-3 regarding ``Precautions for Refrigerant

Connection''.FOR LHD MODELS

RD engine

RHA747G

SERVICE PROCEDURESMANUAL AND AUTO

HA-117

Page 120 of 128

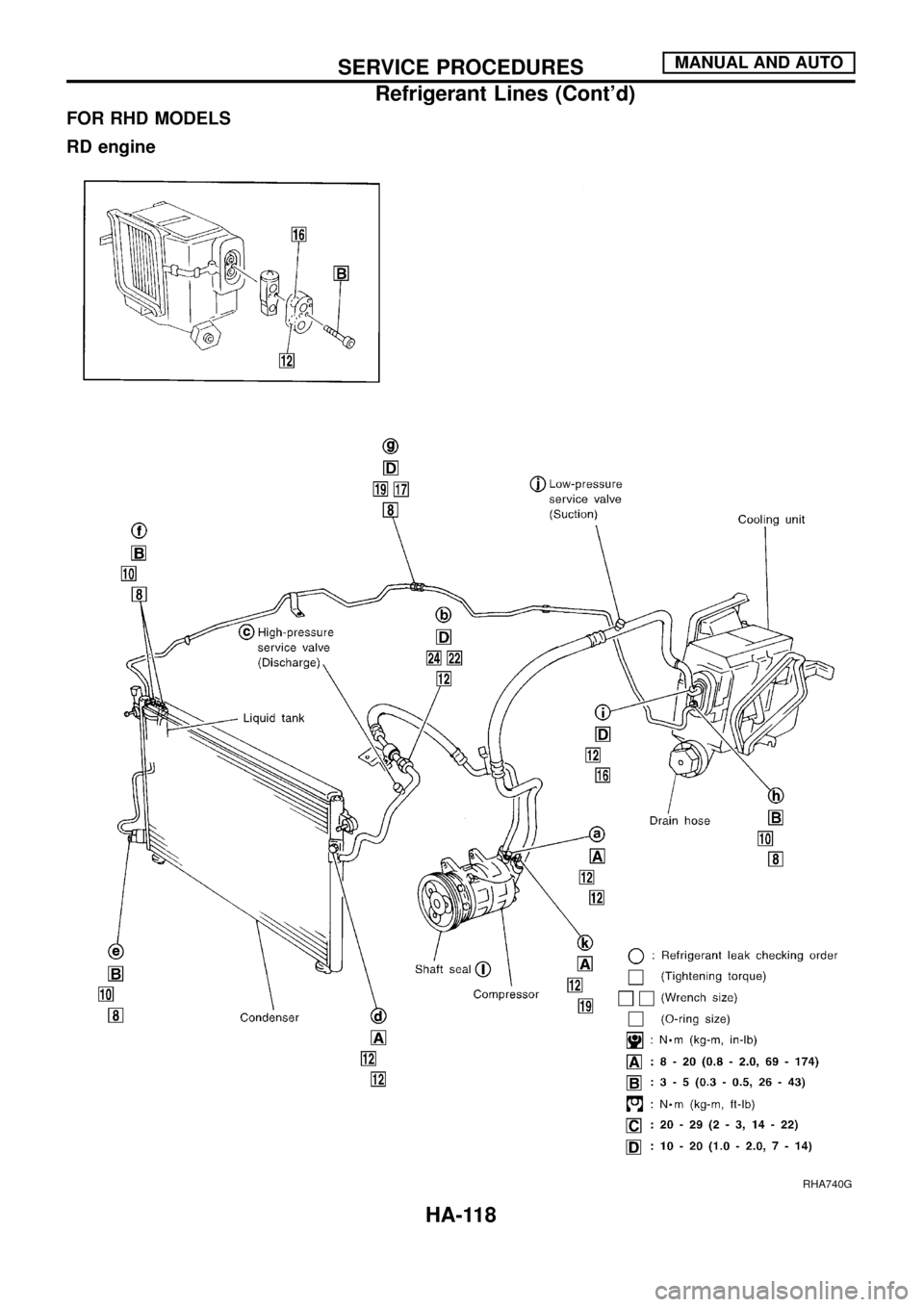

FOR RHD MODELS

RD engine

RHA740G

SERVICE PROCEDURESMANUAL AND AUTO

Refrigerant Lines (Cont'd)

HA-118

Page 122 of 128

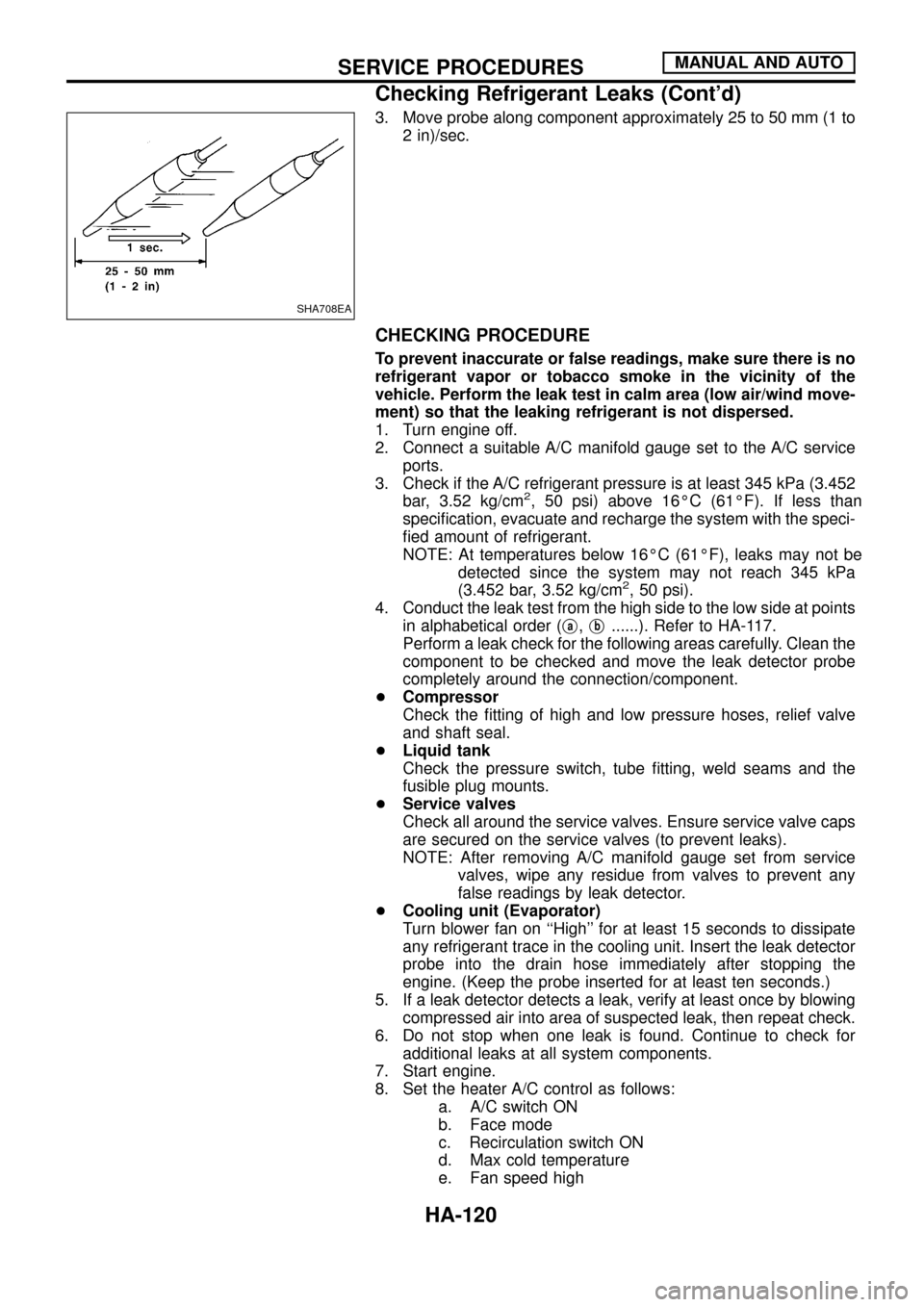

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no

refrigerant vapor or tobacco smoke in the vicinity of the

vehicle. Perform the leak test in calm area (low air/wind move-

ment) so that the leaking refrigerant is not dispersed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C service

ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.452

bar, 3.52 kg/cm

2, 50 psi) above 16ÉC (61ÉF). If less than

speci®cation, evacuate and recharge the system with the speci-

®ed amount of refrigerant.

NOTE: At temperatures below 16ÉC (61ÉF), leaks may not be

detected since the system may not reach 345 kPa

(3.452 bar, 3.52 kg/cm

2, 50 psi).

4. Conduct the leak test from the high side to the low side at points

in alphabetical order (j

a,jb......). Refer to HA-117.

Perform a leak check for the following areas carefully. Clean the

component to be checked and move the leak detector probe

completely around the connection/component.

+Compressor

Check the ®tting of high and low pressure hoses, relief valve

and shaft seal.

+Liquid tank

Check the pressure switch, tube ®tting, weld seams and the

fusible plug mounts.

+Service valves

Check all around the service valves. Ensure service valve caps

are secured on the service valves (to prevent leaks).

NOTE: After removing A/C manifold gauge set from service

valves, wipe any residue from valves to prevent any

false readings by leak detector.

+Cooling unit (Evaporator)

Turn blower fan on ``High'' for at least 15 seconds to dissipate

any refrigerant trace in the cooling unit. Insert the leak detector

probe into the drain hose immediately after stopping the

engine. (Keep the probe inserted for at least ten seconds.)

5. If a leak detector detects a leak, verify at least once by blowing

compressed air into area of suspected leak, then repeat check.

6. Do not stop when one leak is found. Continue to check for

additional leaks at all system components.

7. Start engine.

8. Set the heater A/C control as follows:

a. A/C switch ON

b. Face mode

c. Recirculation switch ON

d. Max cold temperature

e. Fan speed high

SHA708EA

SERVICE PROCEDURESMANUAL AND AUTO

Checking Refrigerant Leaks (Cont'd)

HA-120