differential NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 54, PDF Size: 1.85 MB

Page 21 of 54

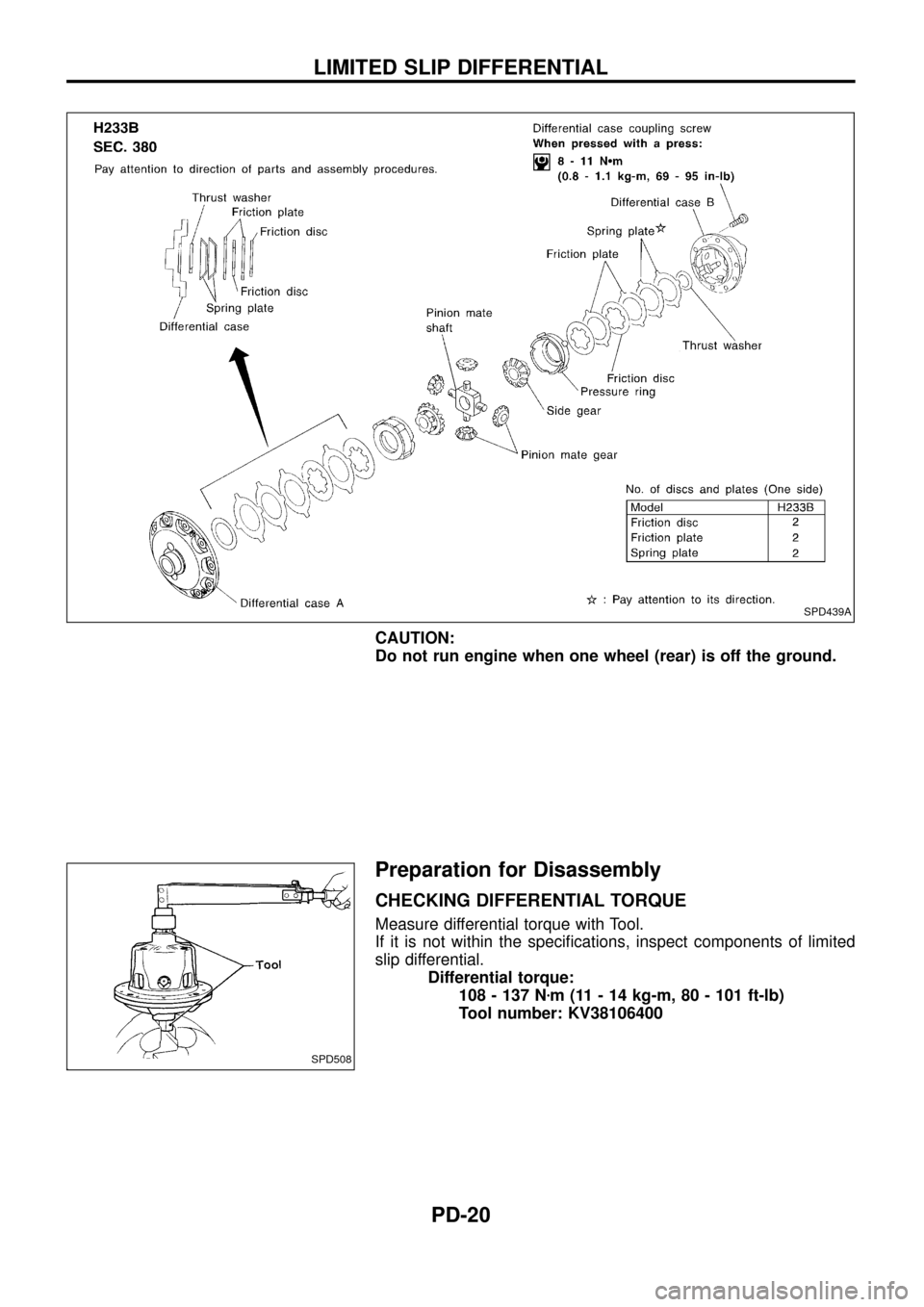

CAUTION:

Do not run engine when one wheel (rear) is off the ground.

Preparation for Disassembly

CHECKING DIFFERENTIAL TORQUE

Measure differential torque with Tool.

If it is not within the speci®cations, inspect components of limited

slip differential.

Differential torque:

108 - 137 Nzm (11 - 14 kg-m, 80 - 101 ft-lb)

Tool number: KV38106400

SPD439A

SPD508

LIMITED SLIP DIFFERENTIAL

PD-20

Page 22 of 54

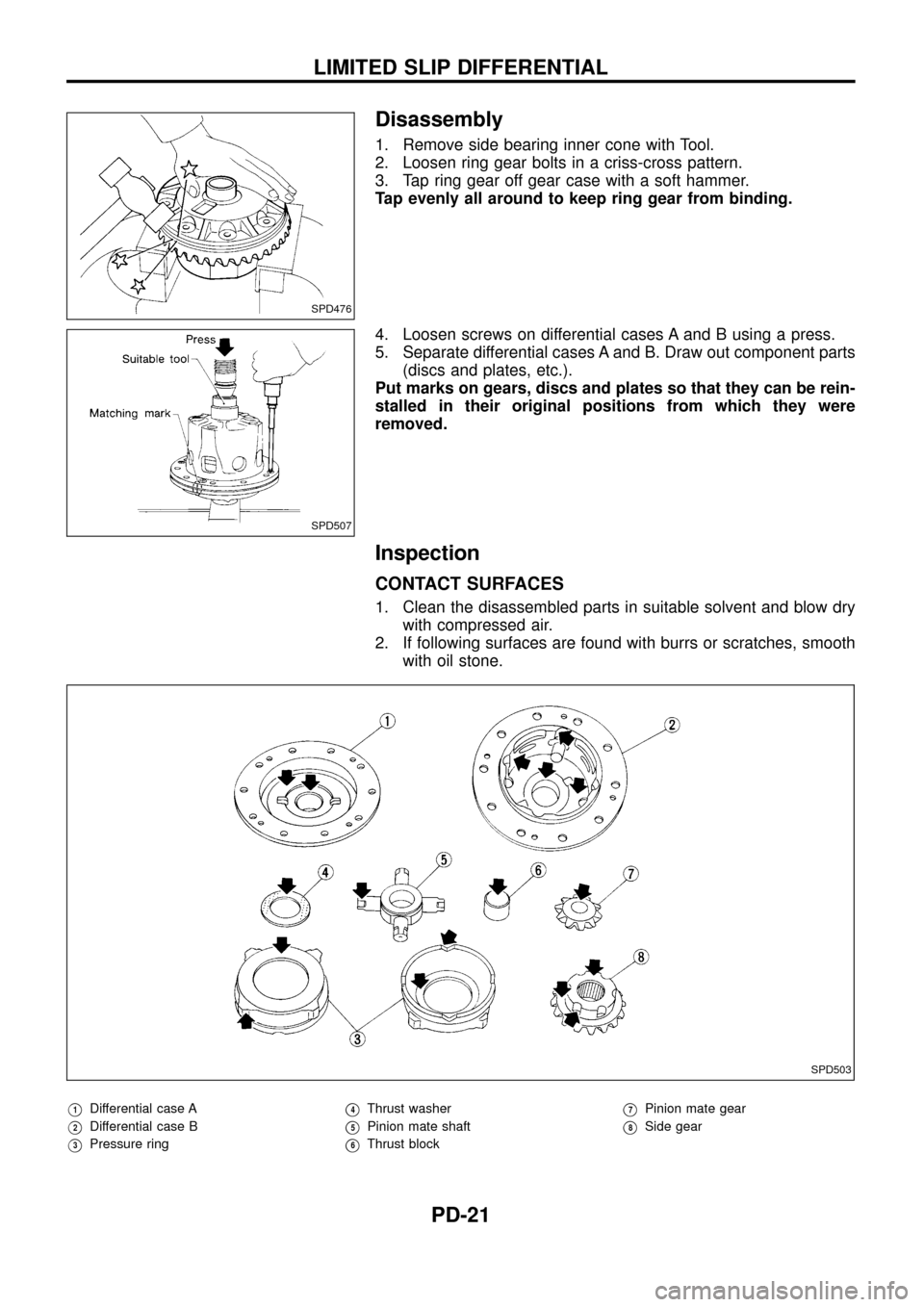

Disassembly

1. Remove side bearing inner cone with Tool.

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off gear case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

4. Loosen screws on differential cases A and B using a press.

5. Separate differential cases A and B. Draw out component parts

(discs and plates, etc.).

Put marks on gears, discs and plates so that they can be rein-

stalled in their original positions from which they were

removed.

Inspection

CONTACT SURFACES

1. Clean the disassembled parts in suitable solvent and blow dry

with compressed air.

2. If following surfaces are found with burrs or scratches, smooth

with oil stone.

V1Differential case A

V2Differential case B

V3Pressure ring

V4Thrust washer

V5Pinion mate shaft

V6Thrust block

V7Pinion mate gear

V8Side gear

SPD476

SPD507

SPD503

LIMITED SLIP DIFFERENTIAL

PD-21

Page 23 of 54

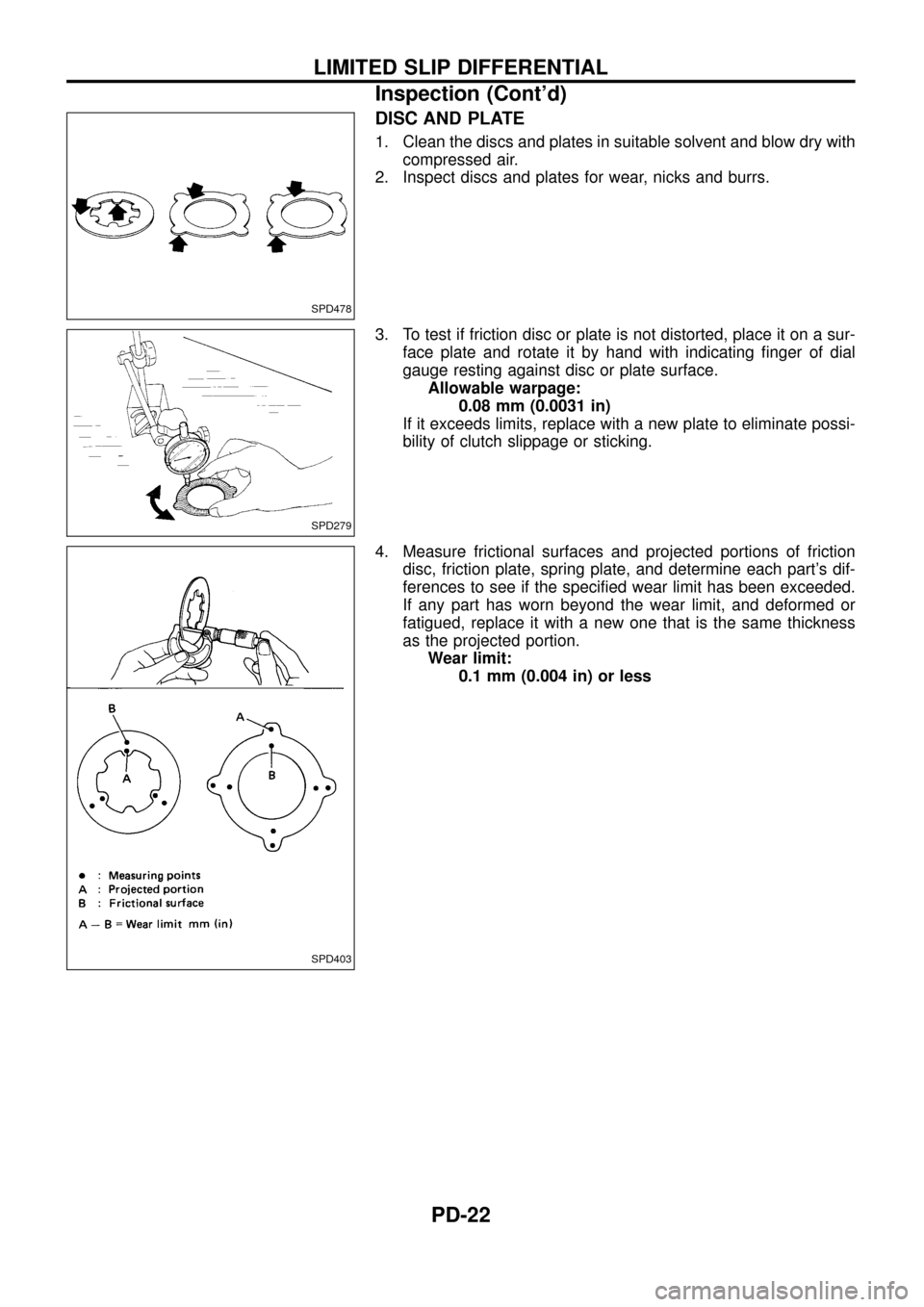

DISC AND PLATE

1. Clean the discs and plates in suitable solvent and blow dry with

compressed air.

2. Inspect discs and plates for wear, nicks and burrs.

3. To test if friction disc or plate is not distorted, place it on a sur-

face plate and rotate it by hand with indicating ®nger of dial

gauge resting against disc or plate surface.

Allowable warpage:

0.08 mm (0.0031 in)

If it exceeds limits, replace with a new plate to eliminate possi-

bility of clutch slippage or sticking.

4. Measure frictional surfaces and projected portions of friction

disc, friction plate, spring plate, and determine each part's dif-

ferences to see if the speci®ed wear limit has been exceeded.

If any part has worn beyond the wear limit, and deformed or

fatigued, replace it with a new one that is the same thickness

as the projected portion.

Wear limit:

0.1 mm (0.004 in) or less

SPD478

SPD279

SPD403

LIMITED SLIP DIFFERENTIAL

Inspection (Cont'd)

PD-22

Page 24 of 54

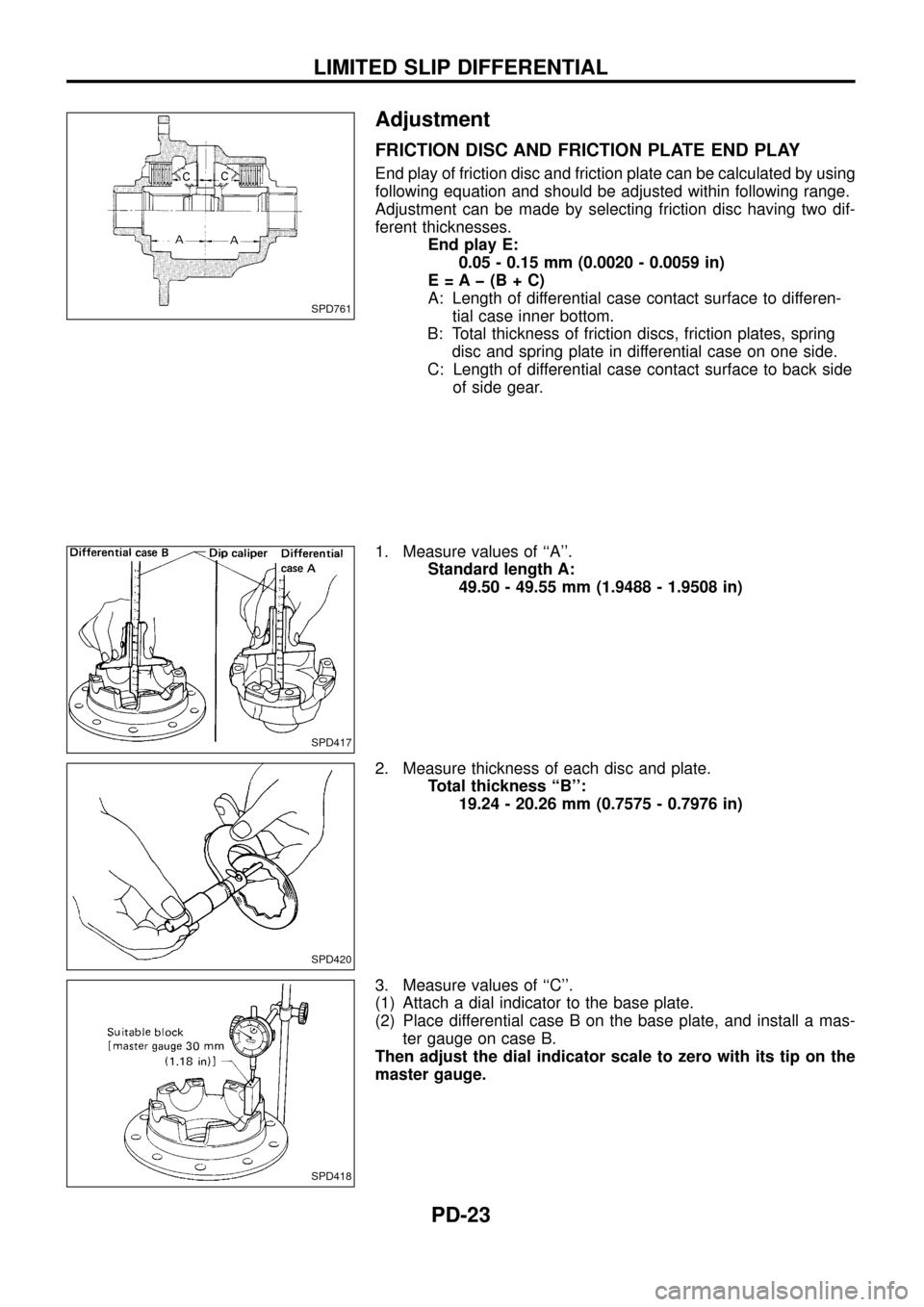

Adjustment

FRICTION DISC AND FRICTION PLATE END PLAY

End play of friction disc and friction plate can be calculated by using

following equation and should be adjusted within following range.

Adjustment can be made by selecting friction disc having two dif-

ferent thicknesses.

End play E:

0.05 - 0.15 mm (0.0020 - 0.0059 in)

E=Aþ(B+C)

A: Length of differential case contact surface to differen-

tial case inner bottom.

B: Total thickness of friction discs, friction plates, spring

disc and spring plate in differential case on one side.

C: Length of differential case contact surface to back side

of side gear.

1. Measure values of ``A''.

Standard length A:

49.50 - 49.55 mm (1.9488 - 1.9508 in)

2. Measure thickness of each disc and plate.

Total thickness ``B'':

19.24 - 20.26 mm (0.7575 - 0.7976 in)

3. Measure values of ``C''.

(1) Attach a dial indicator to the base plate.

(2) Place differential case B on the base plate, and install a mas-

ter gauge on case B.

Then adjust the dial indicator scale to zero with its tip on the

master gauge.

SPD761

SPD417

SPD420

SPD418

LIMITED SLIP DIFFERENTIAL

PD-23

Page 25 of 54

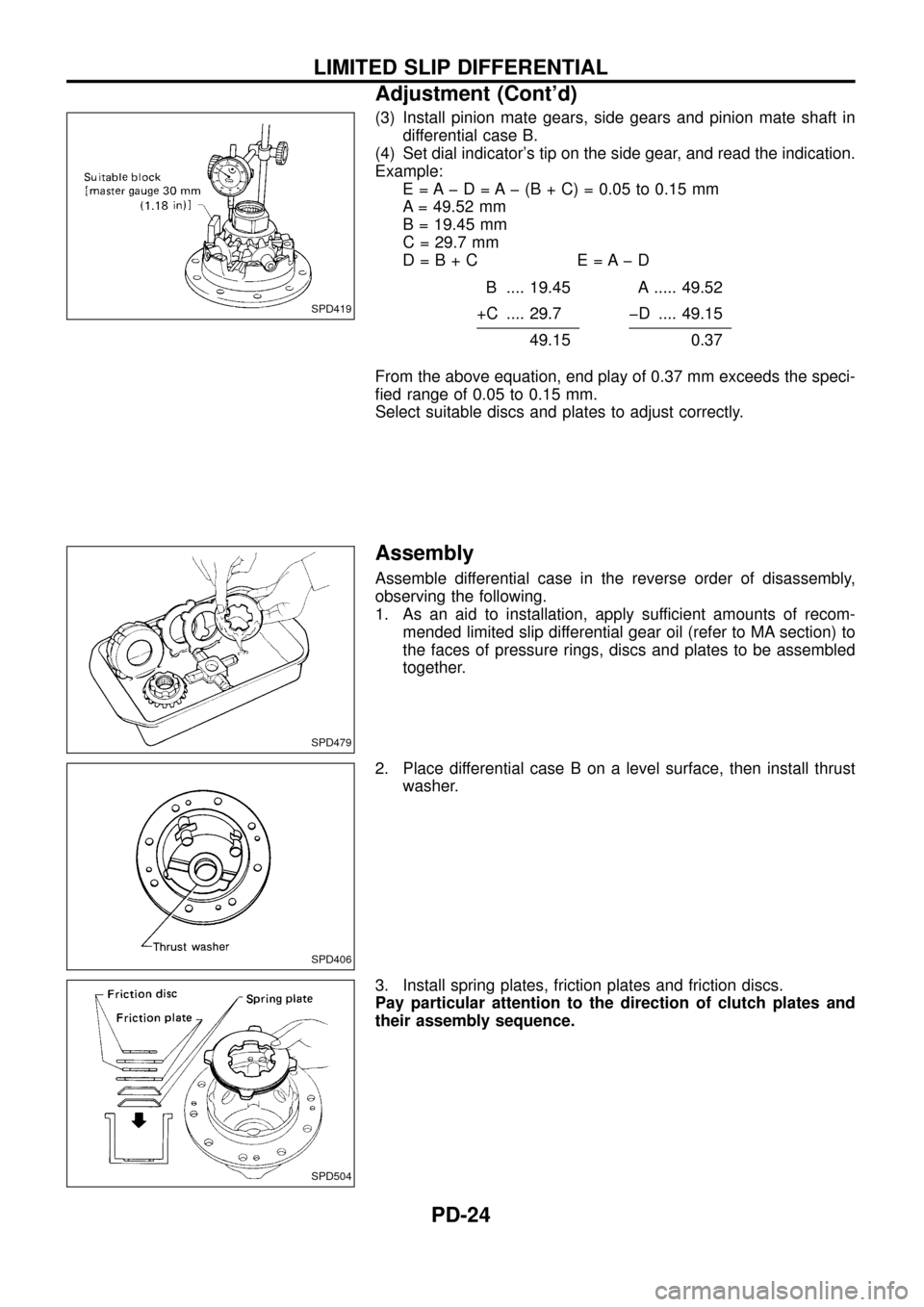

(3) Install pinion mate gears, side gears and pinion mate shaft in

differential case B.

(4) Set dial indicator's tip on the side gear, and read the indication.

Example:

E = A þ D = A þ (B + C) = 0.05 to 0.15 mm

A = 49.52 mm

B = 19.45 mm

C = 29.7 mm

D=B+C E=AþD

B .... 19.45 A ..... 49.52

+C .... 29.7 þD .... 49.15

49.150.37

From the above equation, end play of 0.37 mm exceeds the speci-

®ed range of 0.05 to 0.15 mm.

Select suitable discs and plates to adjust correctly.

Assembly

Assemble differential case in the reverse order of disassembly,

observing the following.

1. As an aid to installation, apply sufficient amounts of recom-

mended limited slip differential gear oil (refer to MA section) to

the faces of pressure rings, discs and plates to be assembled

together.

2. Place differential case B on a level surface, then install thrust

washer.

3. Install spring plates, friction plates and friction discs.

Pay particular attention to the direction of clutch plates and

their assembly sequence.

SPD419

SPD479

SPD406

SPD504

LIMITED SLIP DIFFERENTIAL

Adjustment (Cont'd)

PD-24

Page 26 of 54

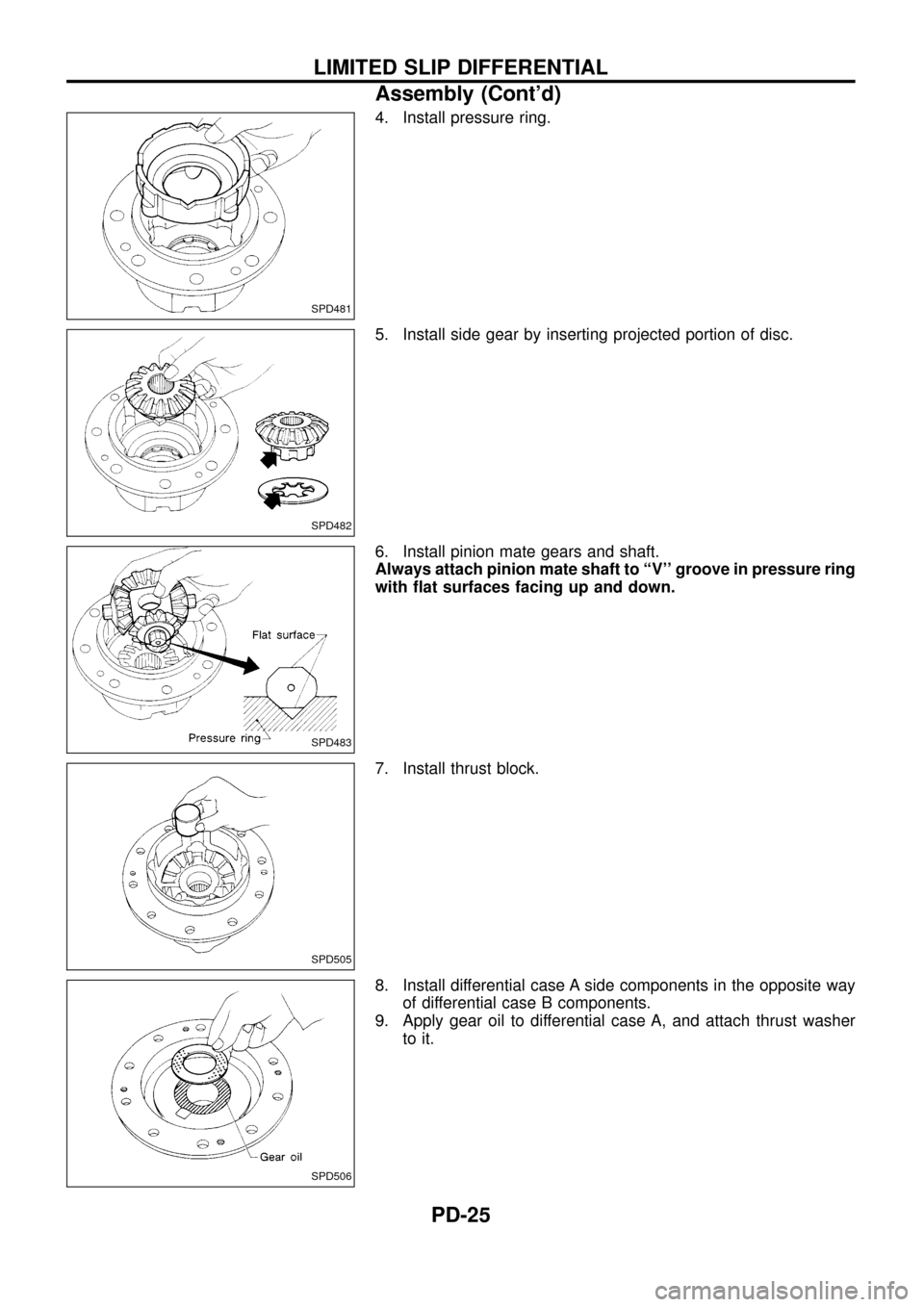

4. Install pressure ring.

5. Install side gear by inserting projected portion of disc.

6. Install pinion mate gears and shaft.

Always attach pinion mate shaft to ``V'' groove in pressure ring

with ¯at surfaces facing up and down.

7. Install thrust block.

8. Install differential case A side components in the opposite way

of differential case B components.

9. Apply gear oil to differential case A, and attach thrust washer

to it.

SPD481

SPD482

SPD483

SPD505

SPD506

LIMITED SLIP DIFFERENTIAL

Assembly (Cont'd)

PD-25

Page 27 of 54

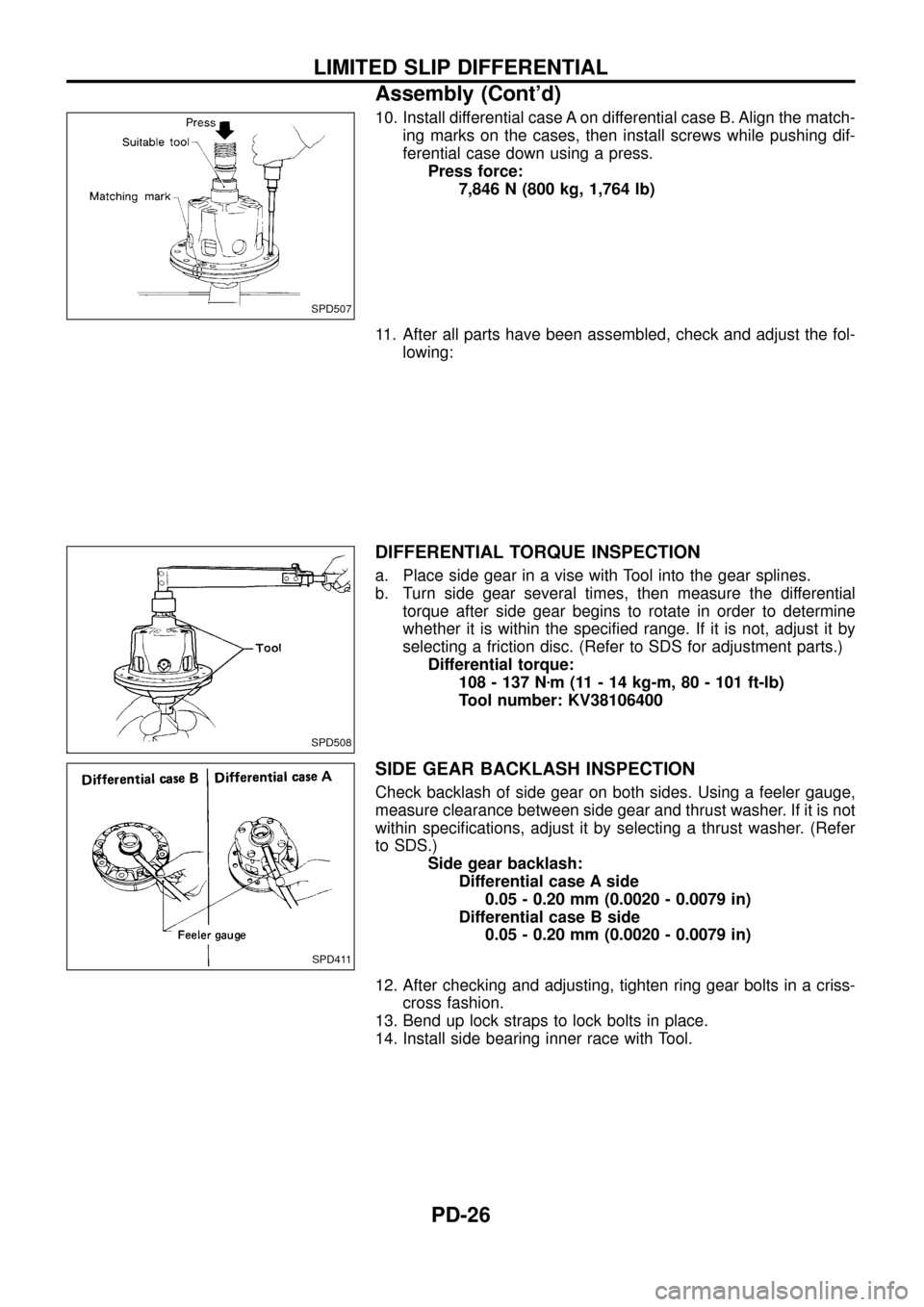

10. Install differential case A on differential case B. Align the match-

ing marks on the cases, then install screws while pushing dif-

ferential case down using a press.

Press force:

7,846 N (800 kg, 1,764 lb)

11. After all parts have been assembled, check and adjust the fol-

lowing:

DIFFERENTIAL TORQUE INSPECTION

a. Place side gear in a vise with Tool into the gear splines.

b. Turn side gear several times, then measure the differential

torque after side gear begins to rotate in order to determine

whether it is within the speci®ed range. If it is not, adjust it by

selecting a friction disc. (Refer to SDS for adjustment parts.)

Differential torque:

108 - 137 Nzm (11 - 14 kg-m, 80 - 101 ft-lb)

Tool number: KV38106400

SIDE GEAR BACKLASH INSPECTION

Check backlash of side gear on both sides. Using a feeler gauge,

measure clearance between side gear and thrust washer. If it is not

within speci®cations, adjust it by selecting a thrust washer. (Refer

to SDS.)

Side gear backlash:

Differential case A side

0.05 - 0.20 mm (0.0020 - 0.0079 in)

Differential case B side

0.05 - 0.20 mm (0.0020 - 0.0079 in)

12. After checking and adjusting, tighten ring gear bolts in a criss-

cross fashion.

13. Bend up lock straps to lock bolts in place.

14. Install side bearing inner race with Tool.

SPD507

SPD508

SPD411

LIMITED SLIP DIFFERENTIAL

Assembly (Cont'd)

PD-26

Page 32 of 54

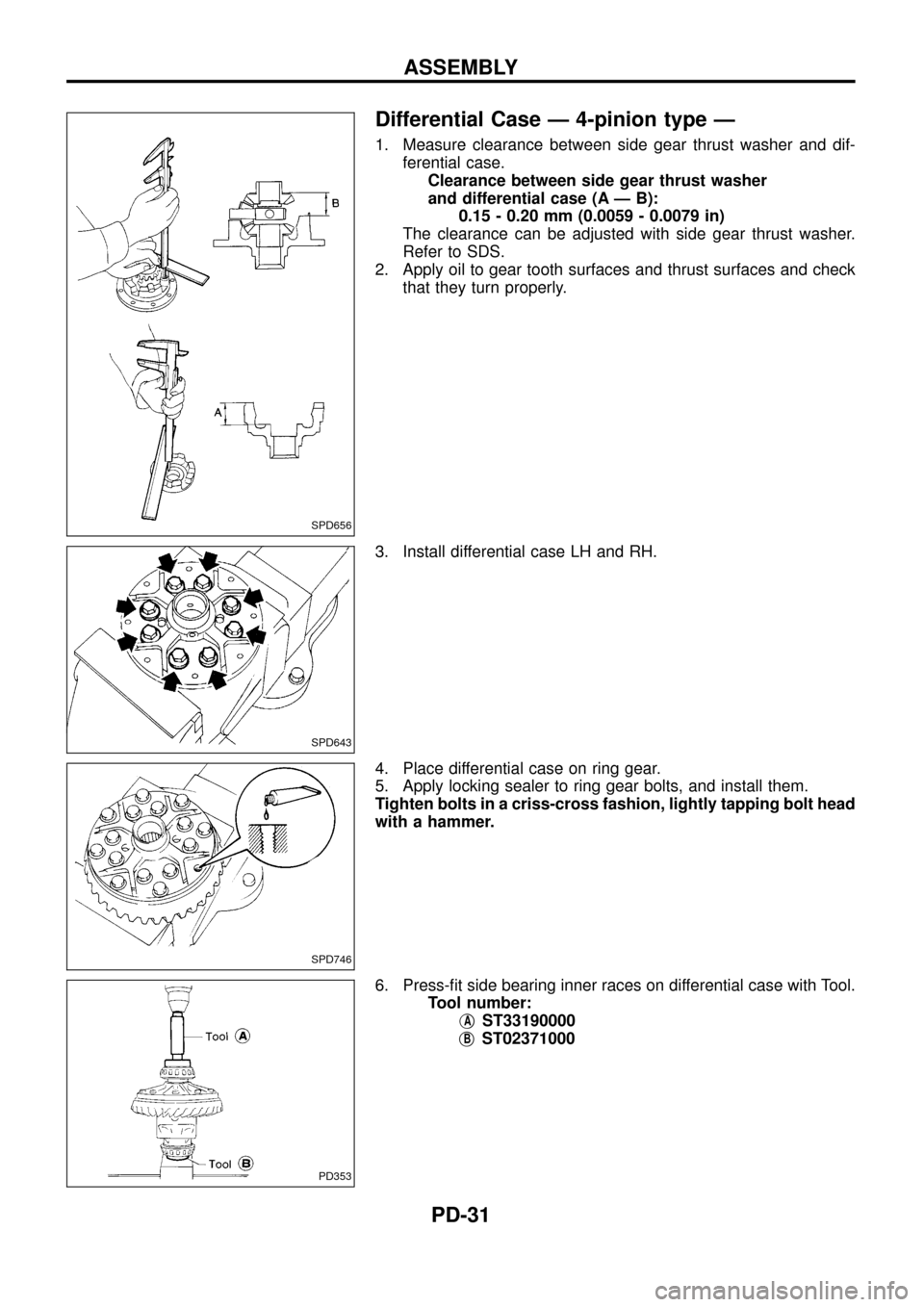

Differential Case Ð 4-pinion type Ð

1. Measure clearance between side gear thrust washer and dif-

ferential case.

Clearance between side gear thrust washer

and differential case (A Ð B):

0.15 - 0.20 mm (0.0059 - 0.0079 in)

The clearance can be adjusted with side gear thrust washer.

Refer to SDS.

2. Apply oil to gear tooth surfaces and thrust surfaces and check

that they turn properly.

3. Install differential case LH and RH.

4. Place differential case on ring gear.

5. Apply locking sealer to ring gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

6. Press-®t side bearing inner races on differential case with Tool.

Tool number:

j

AST33190000

j

BST02371000

SPD656

SPD643

SPD746

PD353

ASSEMBLY

PD-31

Page 33 of 54

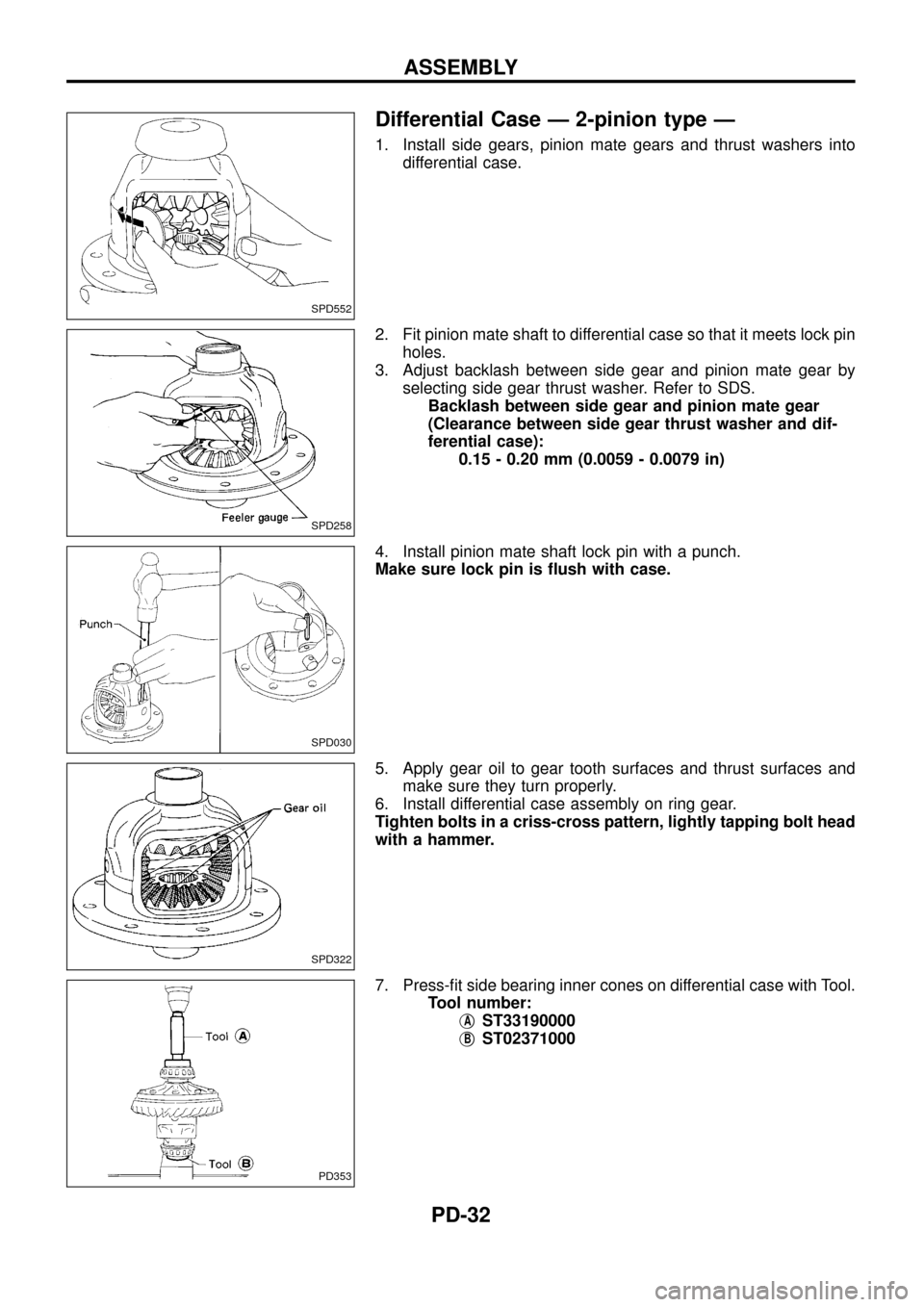

Differential Case Ð 2-pinion type Ð

1. Install side gears, pinion mate gears and thrust washers into

differential case.

2. Fit pinion mate shaft to differential case so that it meets lock pin

holes.

3. Adjust backlash between side gear and pinion mate gear by

selecting side gear thrust washer. Refer to SDS.

Backlash between side gear and pinion mate gear

(Clearance between side gear thrust washer and dif-

ferential case):

0.15 - 0.20 mm (0.0059 - 0.0079 in)

4. Install pinion mate shaft lock pin with a punch.

Make sure lock pin is ¯ush with case.

5. Apply gear oil to gear tooth surfaces and thrust surfaces and

make sure they turn properly.

6. Install differential case assembly on ring gear.

Tighten bolts in a criss-cross pattern, lightly tapping bolt head

with a hammer.

7. Press-®t side bearing inner cones on differential case with Tool.

Tool number:

j

AST33190000

j

BST02371000

SPD552

SPD258

SPD030

SPD322

PD353

ASSEMBLY

PD-32

Page 34 of 54

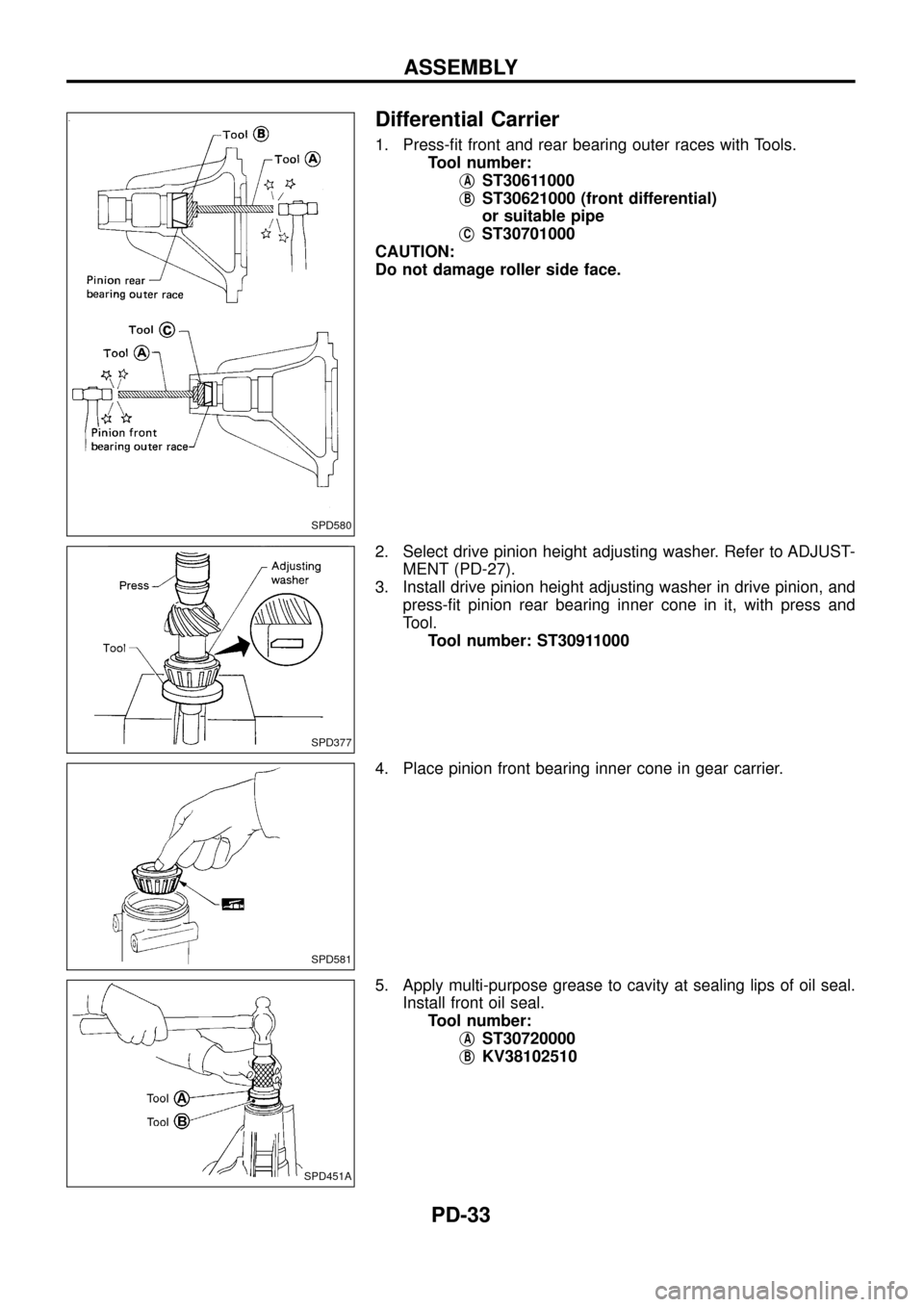

Differential Carrier

1. Press-®t front and rear bearing outer races with Tools.

Tool number:

j

AST30611000

j

BST30621000 (front differential)

or suitable pipe

j

CST30701000

CAUTION:

Do not damage roller side face.

2. Select drive pinion height adjusting washer. Refer to ADJUST-

MENT (PD-27).

3. Install drive pinion height adjusting washer in drive pinion, and

press-®t pinion rear bearing inner cone in it, with press and

Tool.

Tool number: ST30911000

4. Place pinion front bearing inner cone in gear carrier.

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Install front oil seal.

Tool number:

j

AST30720000

j

BKV38102510

SPD580

SPD377

SPD581

SPD451A

ASSEMBLY

PD-33