differential NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 54, PDF Size: 1.85 MB

Page 1 of 54

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

PROPELLER SHAFT......................................................5

Front Propeller Shaft ...................................................5

Rear Propeller Shaft ....................................................5

On-vehicle Service.......................................................6

Removal and Installation .............................................7

Inspection.....................................................................7

Disassembly.................................................................7

Assembly .....................................................................8

ON-VEHICLE SERVICE (Final Drive)..........................10

Front Oil Seal Replacement ......................................10

REMOVAL AND INSTALLATION.................................. 11

Removal ..................................................................... 11

Installation .................................................................. 11

FRONT FINAL DRIVE...................................................12

REAR FINAL DRIVE.....................................................13

DISASSEMBLY..............................................................14

Pre-inspection ............................................................14

Differential Carrier......................................................15

Differential Case ........................................................17

INSPECTION..................................................................19

Ring Gear and Drive Pinion ......................................19

Differential Case Assembly........................................19Bearing.......................................................................19

LIMITED SLIP DIFFERENTIAL.....................................20

Preparation for Disassembly .....................................20

Disassembly...............................................................21

Inspection...................................................................21

Adjustment .................................................................23

Assembly ...................................................................24

ADJUSTMENT...............................................................27

Drive Pinion Height ....................................................27

Tooth Contact.............................................................29

ASSEMBLY....................................................................31

Differential Case Ð 4-pinion type Ð.........................31

Differential Case Ð 2-pinion type Ð.........................32

Differential Carrier......................................................33

DIFFERENTIAL LOCK..................................................37

Actuator and Fork ......................................................37

Disassembly...............................................................38

Inspection...................................................................39

Assembly ...................................................................40

System Description ....................................................43

Component Parts Location ........................................44

Wiring Diagram Ð DIFF/L Ð/LHD Models ...............45

Wiring Diagram Ð DIFF/L Ð/RHD Models ...............47

Electrical Components Inspection .............................49

SERVICE DATA AND SPECIFICATIONS (SDS)..........51

Propeller Shaft ...........................................................51

Final Drive..................................................................52

PD

Page 2 of 54

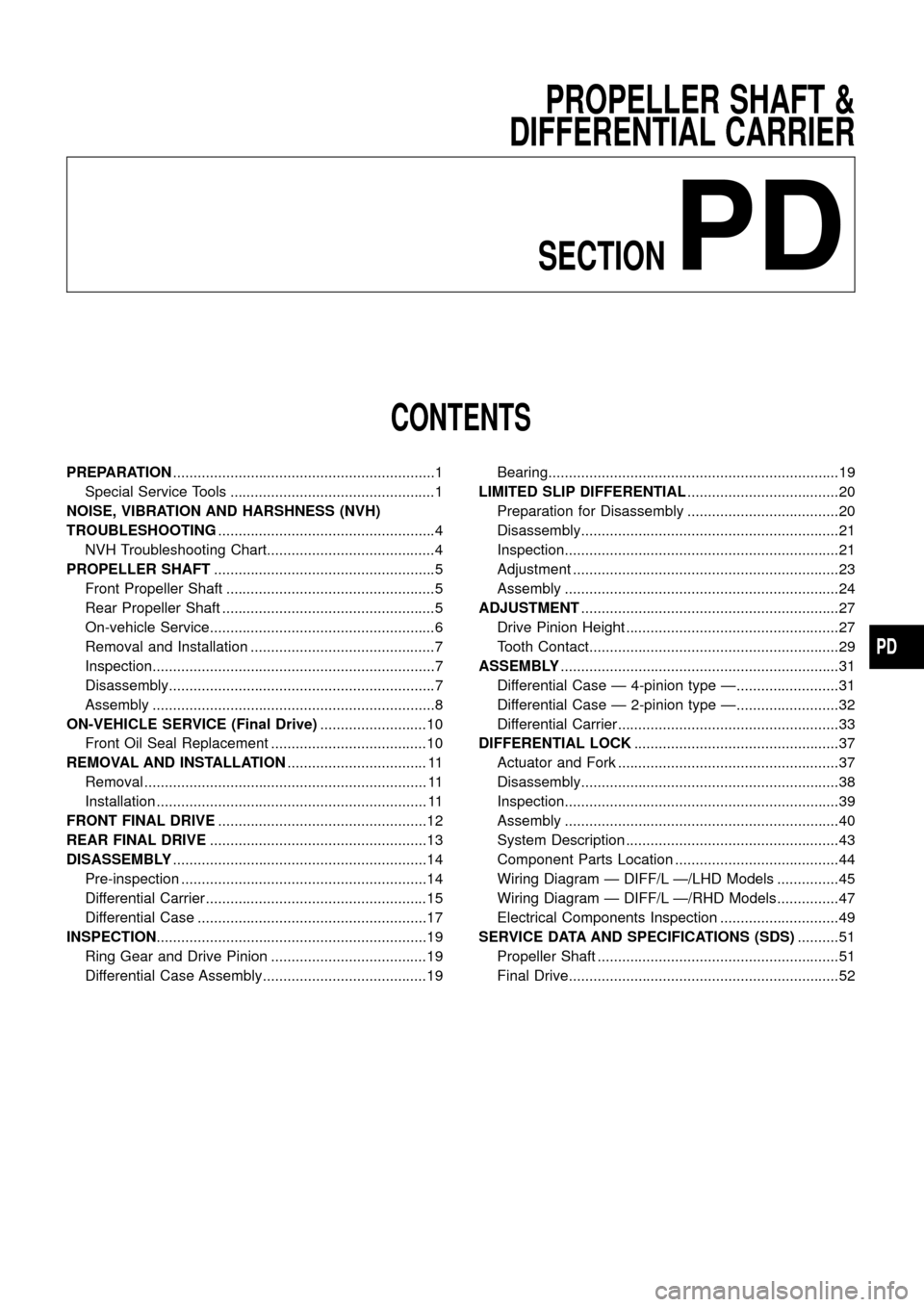

Special Service Tools

*: For front differential carrier only

Tool number

Tool nameDescriptionUnit application

H233B

ST0501S000

Engine stand

V1ST05011000

Engine stand

V2ST05012000

Base

NT042

Mounting differential attach-

ment

X

ST06340000

Differential attachment

NT140

Mounting ®nal drive

X

ST30611000

Drive pinion bearing outer

race drift bar

NT090

Installing pinion rear bearing

outer race

(Use with ST30621000 or

ST30613000)X

ST30613000

Drive pinion front bearing

outer race drift

NT073

Installing pinion front bearing

outer race

(Use with ST30613000)

X

a: 71.5 mm (2.815 in) dia.

b: 47.5 mm (1.870 in) dia.

ST30621000

Drive pinion rear bearing

outer race drift

NT073

Installing pinion rear bearing

outer race

(Use with ST30613000)

X*

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

ST3090S000

Drive pinion rear bearing

inner race puller set

V1ST30031000

Puller

V2ST30911000

Base

NT527

Removing and installing drive

pinion rear inner race

X

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35 mm (1.38 in) dia.

PREPARATION

PD-1

Page 3 of 54

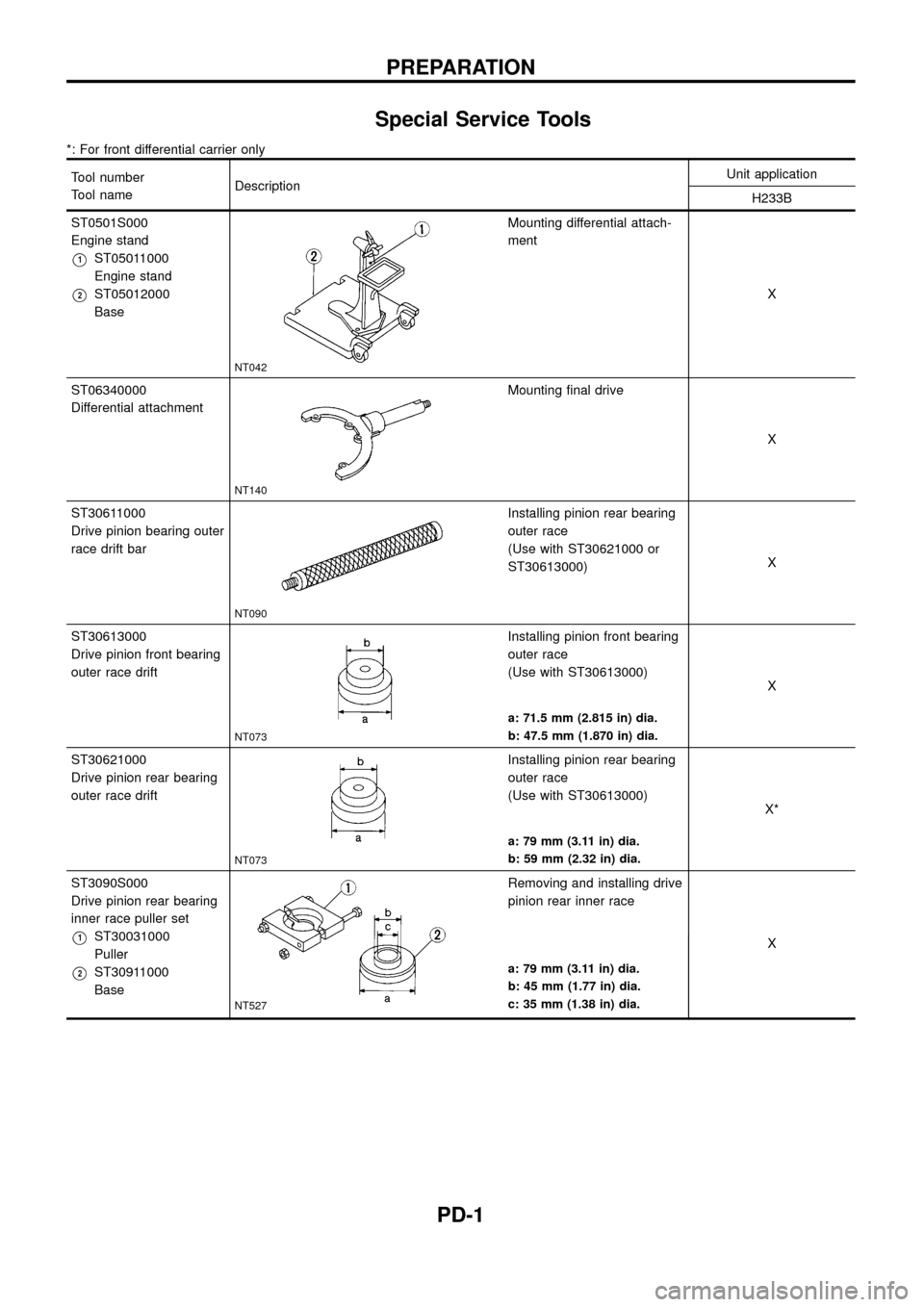

Tool number

Tool nameDescriptionUnit application

H233B

ST3127S000

Preload gauge

V1GG91030000

Torque wrench

V2HT62900000

Socket adapter (1/2²)

V3HT62940000

Socket adapter (3/8²)NT124

Measuring pinion bearing

preload and total preload

X

ST3125S000

Drive pinion setting

gauge set

V1ST31251000

Drive pinion height

gauge

V2ST31181001

Dummy shaft

NT524

Selecting pinion height

adjusting washer

X

KV40104000

Drive pinion ¯ange

wrench

NT113

Removing and installing pro-

peller shaft lock nut and drive

pinion lock nut

X

ST0237S000

Differential side bearing

puller set

V1ST33051001

Puller

V2ST02371000

Adapter

NT072

Removing and installing side

bearing inner race

X

a: 40 mm (1.57 in) dia.

b: 50 mm (1.97 in) dia.

ST33081000

Adapter

NT431

Installing side bearing inner

cone

X

a: 43 mm (1.69 in) dia.

b: 33.5 mm (1.319 in) dia.

ST33190000

Differential side bearing

drift

NT085

Installing side bearing inner

cone

X

a: 52 mm (2.05 in) dia.

b: 45.5 mm (1.791 in) dia.

c: 34 mm (1.34 in) dia.

KV31100300

Fork rod pin punch

NT410

Removing pinion mate shaft

lock pin

X

a: 4.5 mm (0.177 in) dia.

PREPARATION

Special Service Tools (Cont'd)

PD-2

Page 4 of 54

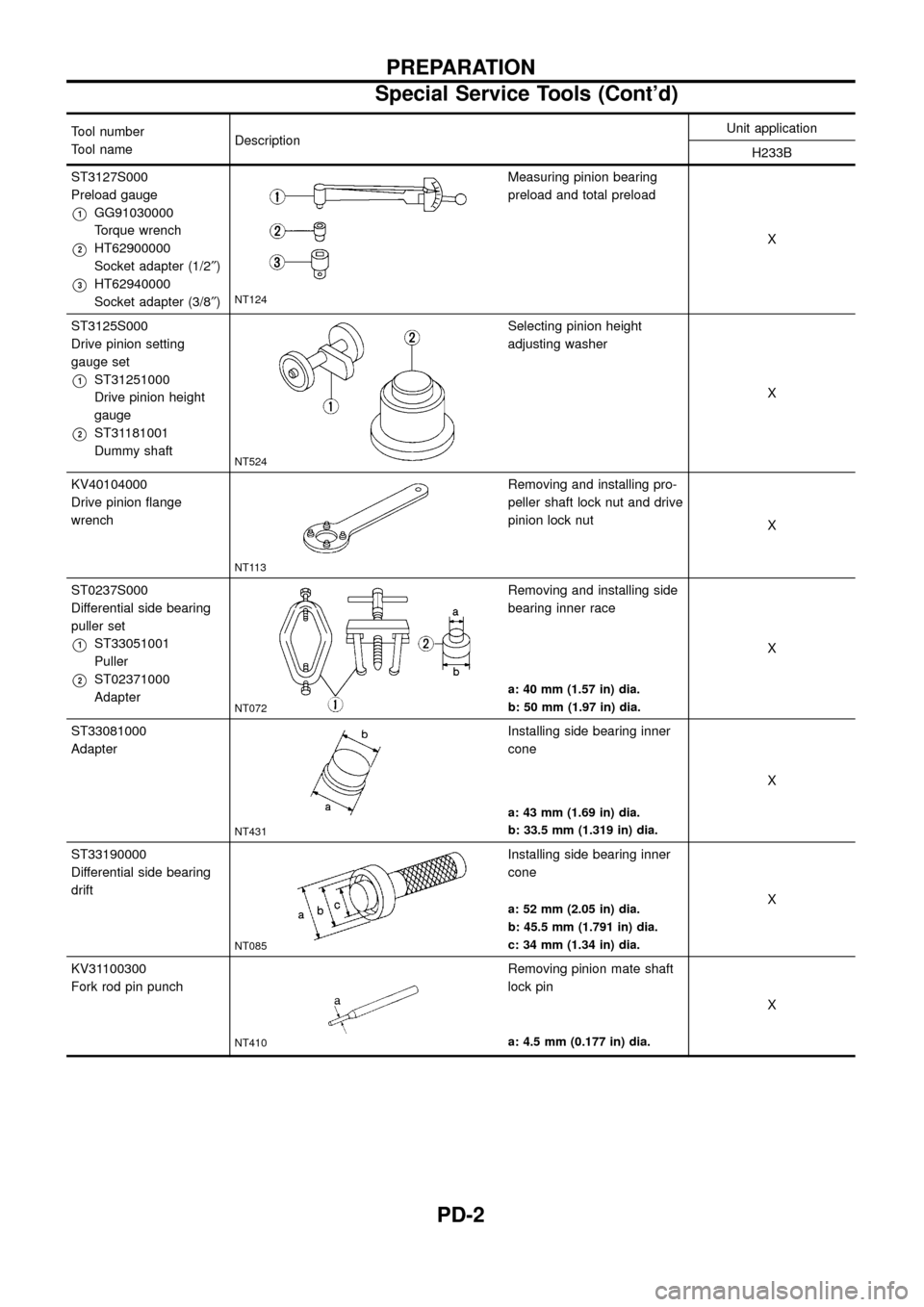

Tool number

Tool nameDescriptionUnit application

H233B

KV381025S0

Oil seal ®tting tool

V1ST30720000

Drift bar

V2KV38102510

Drift

NT525

Installing front oil seal

X

a: 77 mm (3.03 in) dia.

b: 55 mm (2.17 in) dia.

c: 71 mm (2.80 in) dia.

d: 65 mm (2.56 in) dia.

ST32580000

Differential side bearing

adjusting nut wrench

NT141

Adjusting side bearing pre-

load and backlash (ring gear-

drive pinion)

X

PREPARATION

Special Service Tools (Cont'd)

PD-3

Page 5 of 54

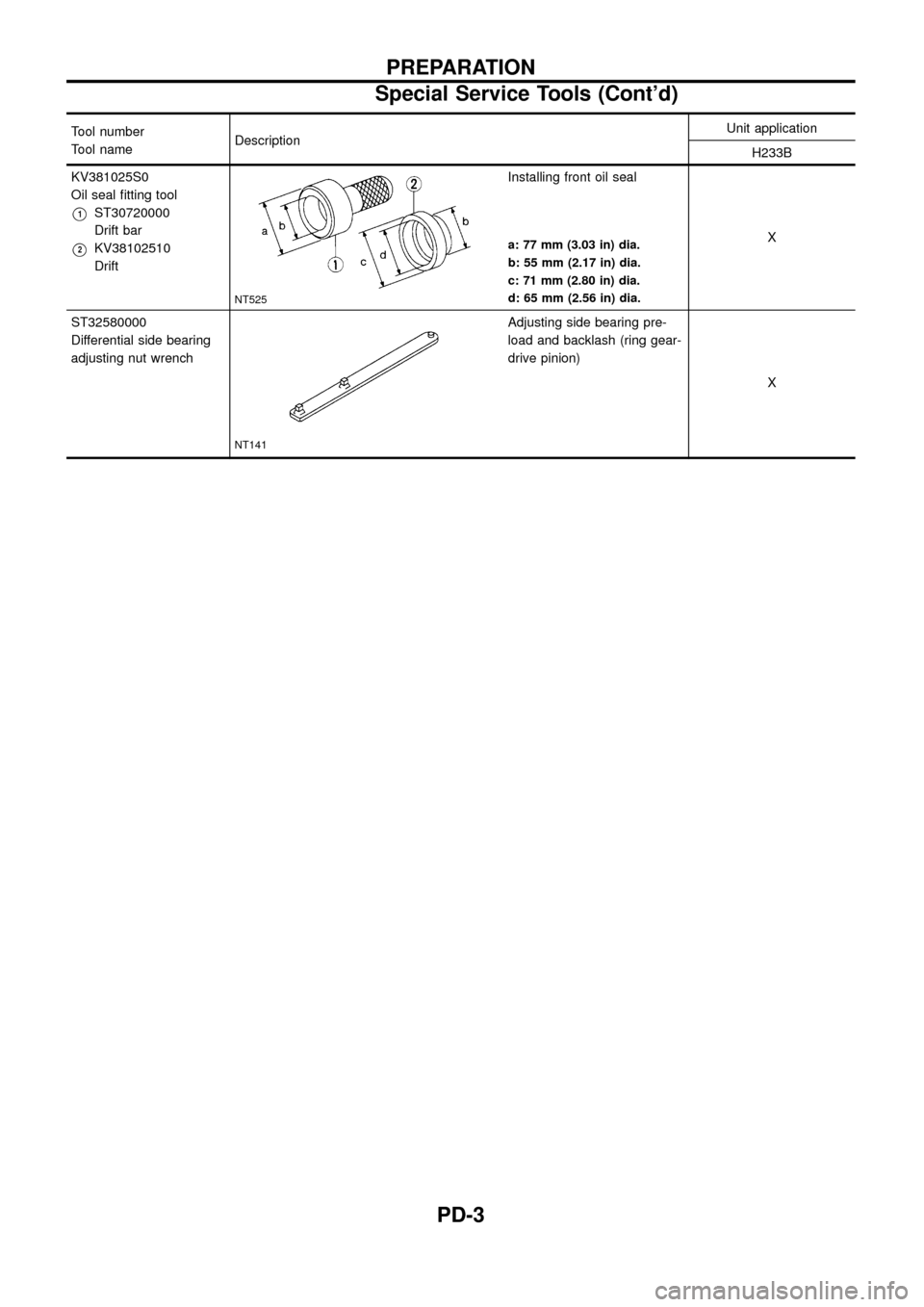

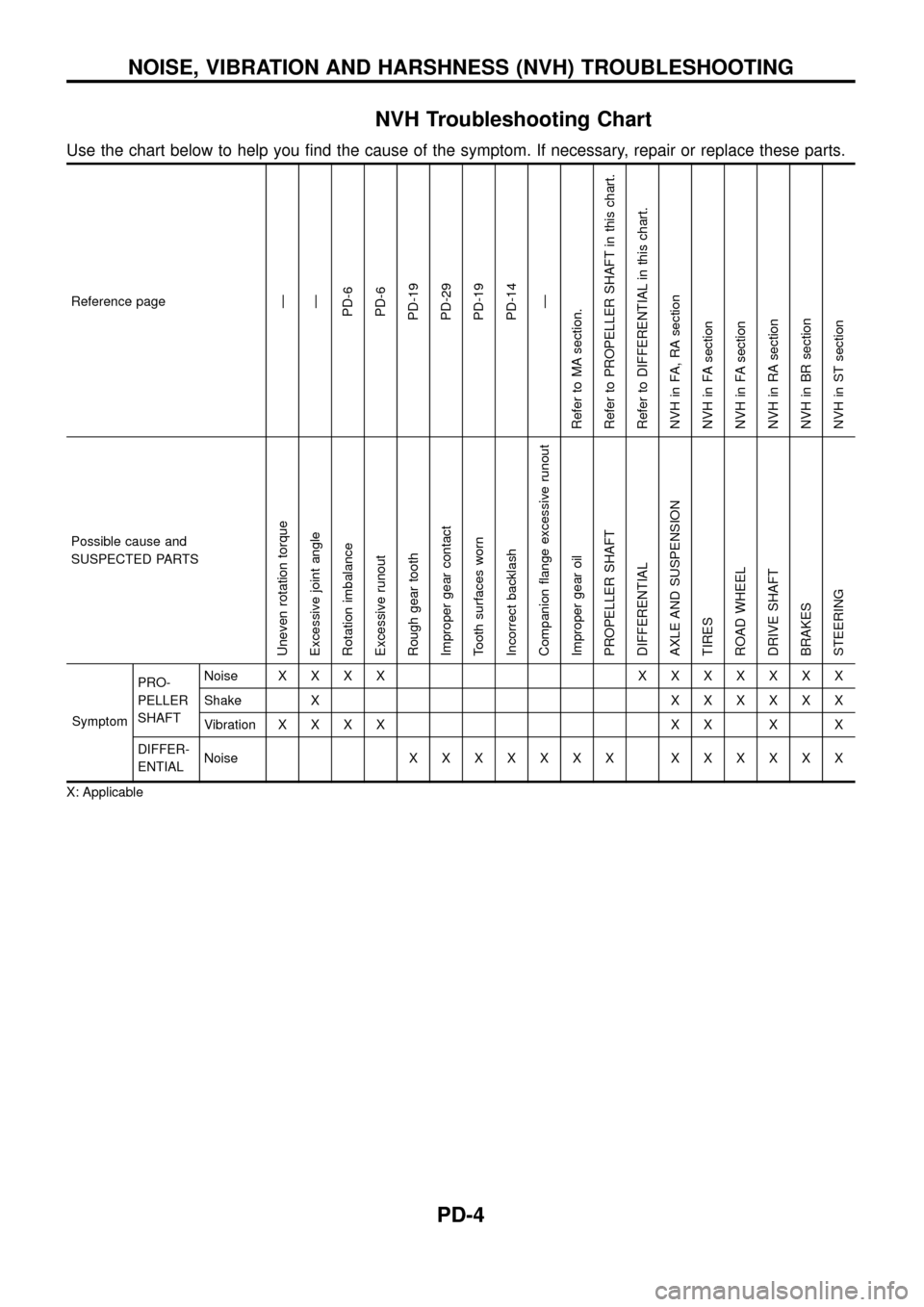

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the symptom. If necessary, repair or replace these parts.

Reference pageÐ

Ð

PD-6

PD-6

PD-19

PD-29

PD-19

PD-14

Ð

Refer to MA section.

Refer to PROPELLER SHAFT in this chart.

Refer to DIFFERENTIAL in this chart.

NVH in FA, RA section

NVH in FA section

NVH in FA section

NVH in RA section

NVH in BR section

NVH in ST section

Possible cause and

SUSPECTED PARTS

Uneven rotation torque

Excessive joint angle

Rotation imbalance

Excessive runout

Rough gear tooth

Improper gear contact

Tooth surfaces worn

Incorrect backlash

Companion ¯ange excessive runout

Improper gear oil

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomPRO-

PELLER

SHAFTNoiseXXXX XXXXXXX

Shake XXXXXXX

VibrationXXXX XX X X

DIFFER-

ENTIALNoiseXXXXXXX XXXXXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PD-4

Page 16 of 54

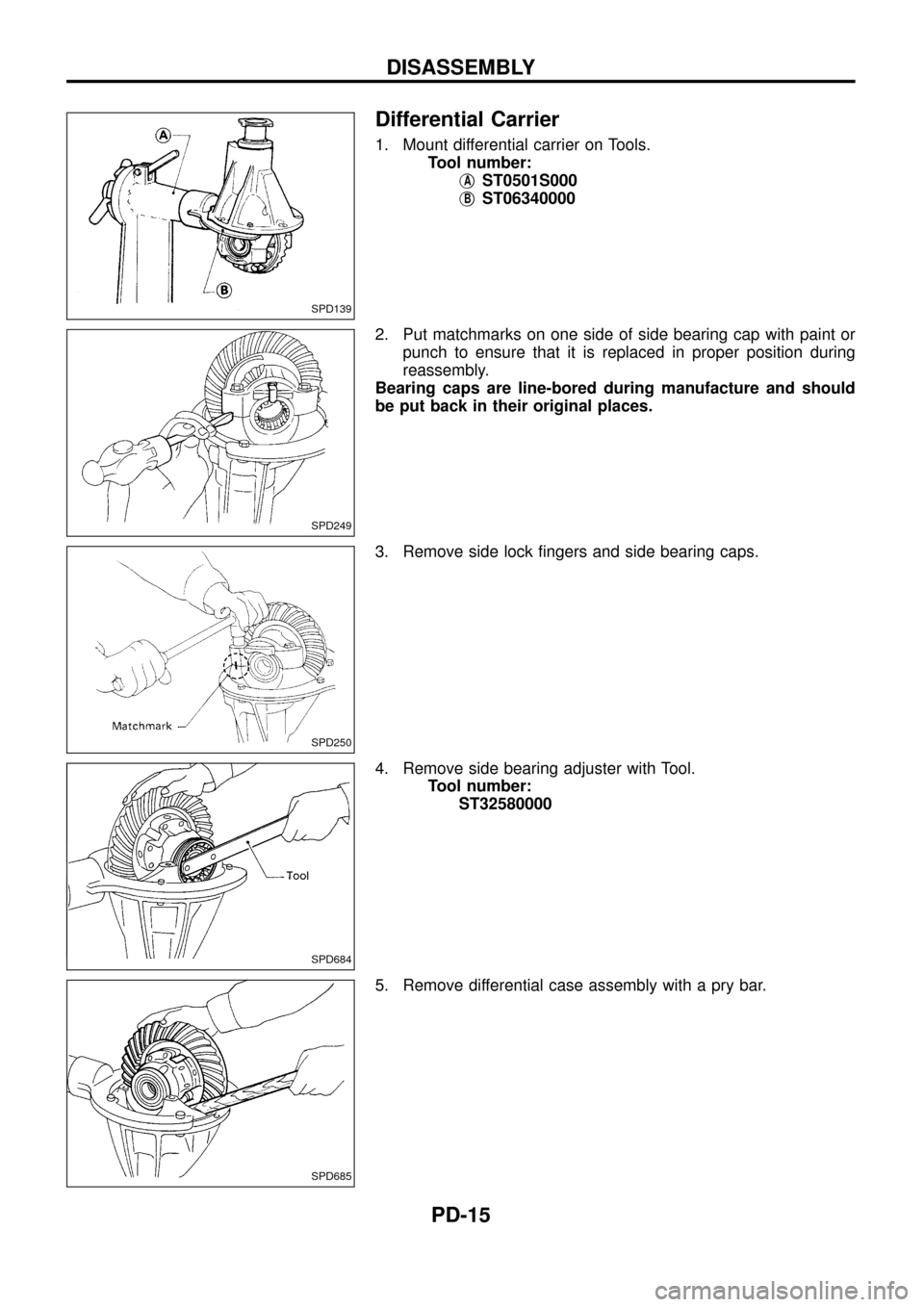

Differential Carrier

1. Mount differential carrier on Tools.

Tool number:

j

AST0501S000

j

BST06340000

2. Put matchmarks on one side of side bearing cap with paint or

punch to ensure that it is replaced in proper position during

reassembly.

Bearing caps are line-bored during manufacture and should

be put back in their original places.

3. Remove side lock ®ngers and side bearing caps.

4. Remove side bearing adjuster with Tool.

Tool number:

ST32580000

5. Remove differential case assembly with a pry bar.

SPD139

SPD249

SPD250

SPD684

SPD685

DISASSEMBLY

PD-15

Page 17 of 54

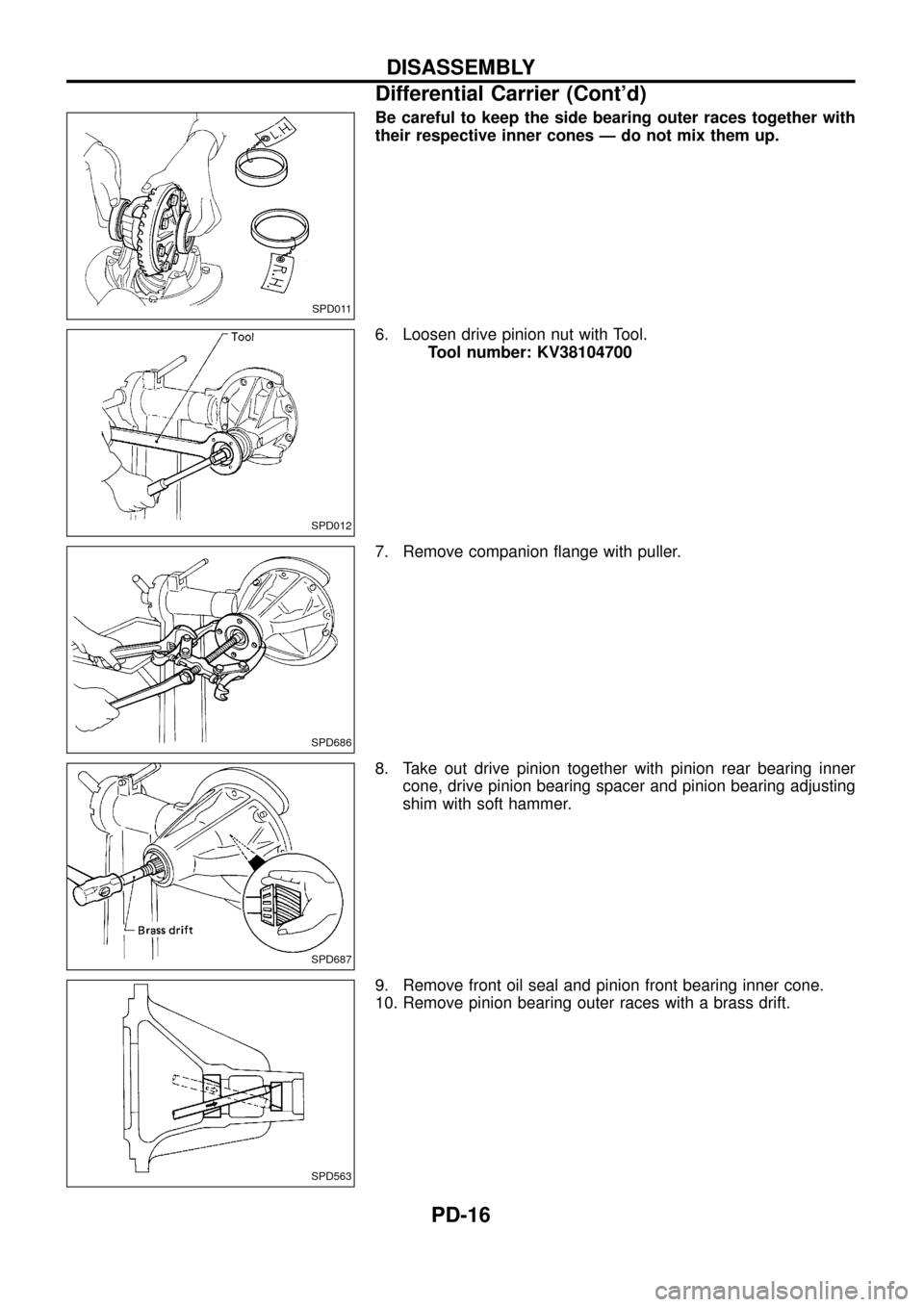

Be careful to keep the side bearing outer races together with

their respective inner cones Ð do not mix them up.

6. Loosen drive pinion nut with Tool.

Tool number: KV38104700

7. Remove companion ¯ange with puller.

8. Take out drive pinion together with pinion rear bearing inner

cone, drive pinion bearing spacer and pinion bearing adjusting

shim with soft hammer.

9. Remove front oil seal and pinion front bearing inner cone.

10. Remove pinion bearing outer races with a brass drift.

SPD011

SPD012

SPD686

SPD687

SPD563

DISASSEMBLY

Differential Carrier (Cont'd)

PD-16

Page 18 of 54

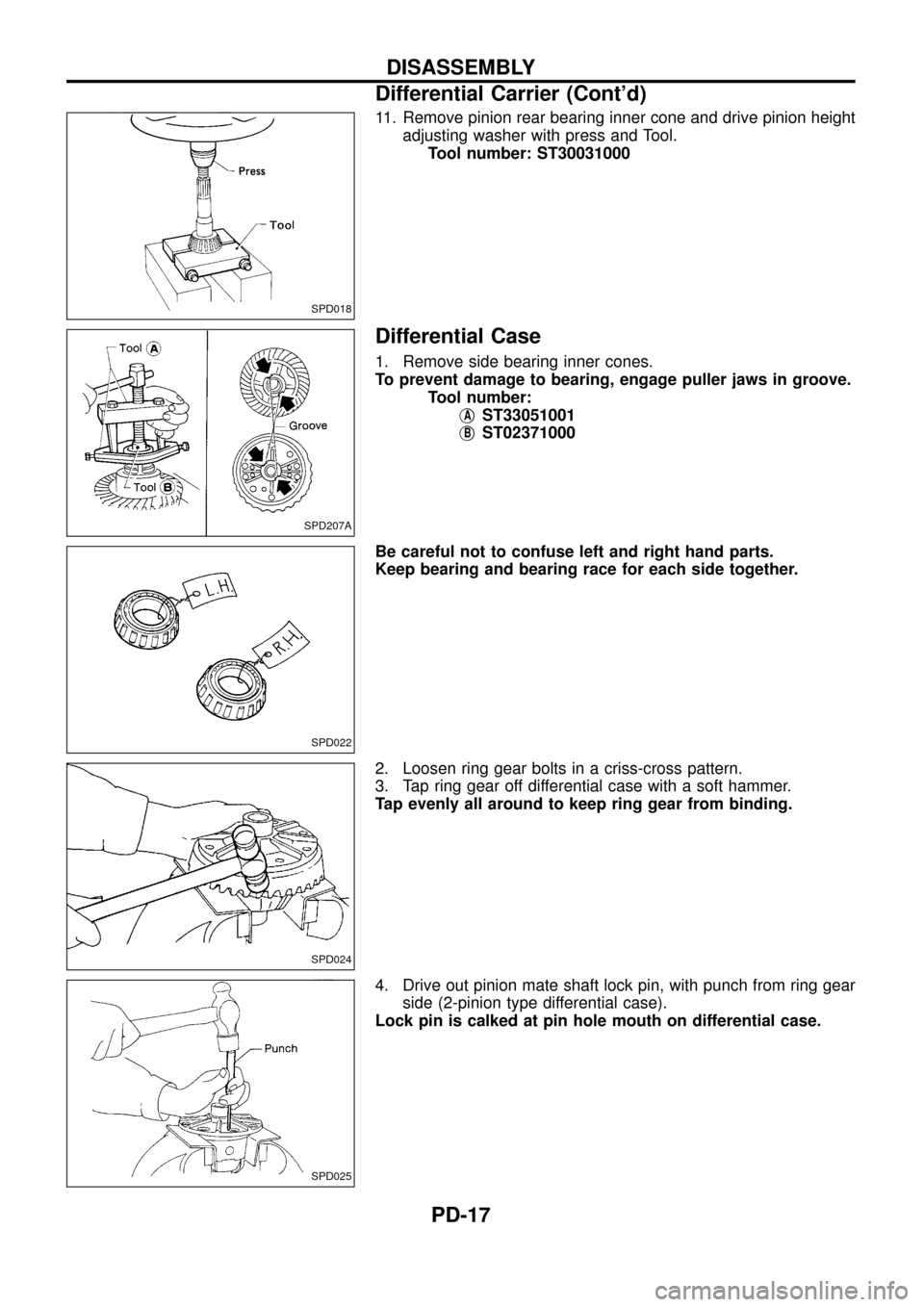

11. Remove pinion rear bearing inner cone and drive pinion height

adjusting washer with press and Tool.

Tool number: ST30031000

Differential Case

1. Remove side bearing inner cones.

To prevent damage to bearing, engage puller jaws in groove.

Tool number:

j

AST33051001

j

BST02371000

Be careful not to confuse left and right hand parts.

Keep bearing and bearing race for each side together.

2. Loosen ring gear bolts in a criss-cross pattern.

3. Tap ring gear off differential case with a soft hammer.

Tap evenly all around to keep ring gear from binding.

4. Drive out pinion mate shaft lock pin, with punch from ring gear

side (2-pinion type differential case).

Lock pin is calked at pin hole mouth on differential case.

SPD018

SPD207A

SPD022

SPD024

SPD025

DISASSEMBLY

Differential Carrier (Cont'd)

PD-17

Page 19 of 54

5. Separate differential case LH and RH (4-pinion type differential

case).

Put matchmarks on both differential case LH and RH sides

prior to separating them.

SPD716

DISASSEMBLY

Differential Case (Cont'd)

PD-18

Page 20 of 54

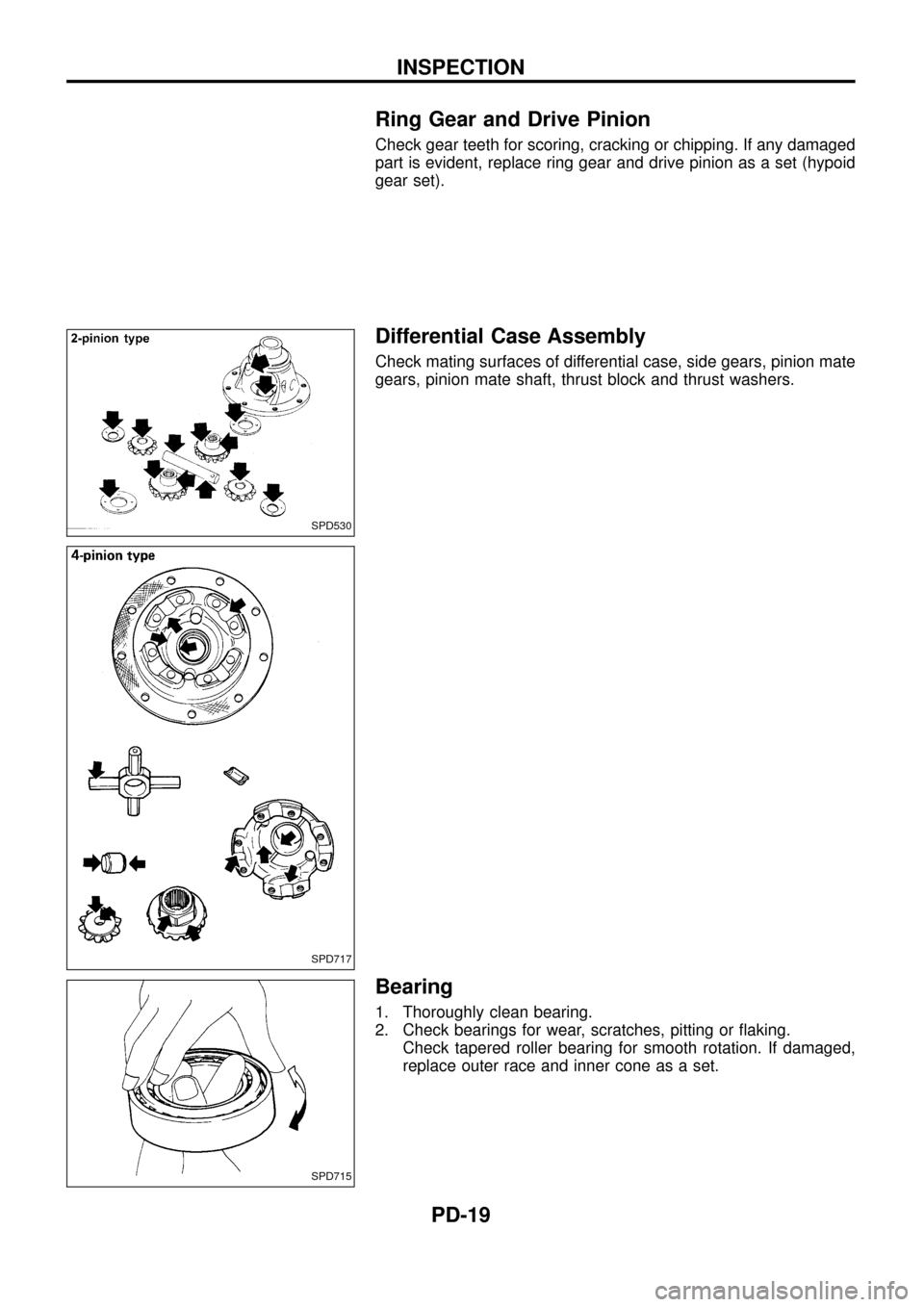

Ring Gear and Drive Pinion

Check gear teeth for scoring, cracking or chipping. If any damaged

part is evident, replace ring gear and drive pinion as a set (hypoid

gear set).

Differential Case Assembly

Check mating surfaces of differential case, side gears, pinion mate

gears, pinion mate shaft, thrust block and thrust washers.

Bearing

1. Thoroughly clean bearing.

2. Check bearings for wear, scratches, pitting or ¯aking.

Check tapered roller bearing for smooth rotation. If damaged,

replace outer race and inner cone as a set.

SPD530

SPD717

SPD715

INSPECTION

PD-19