check oil NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 54, PDF Size: 1.85 MB

Page 15 of 54

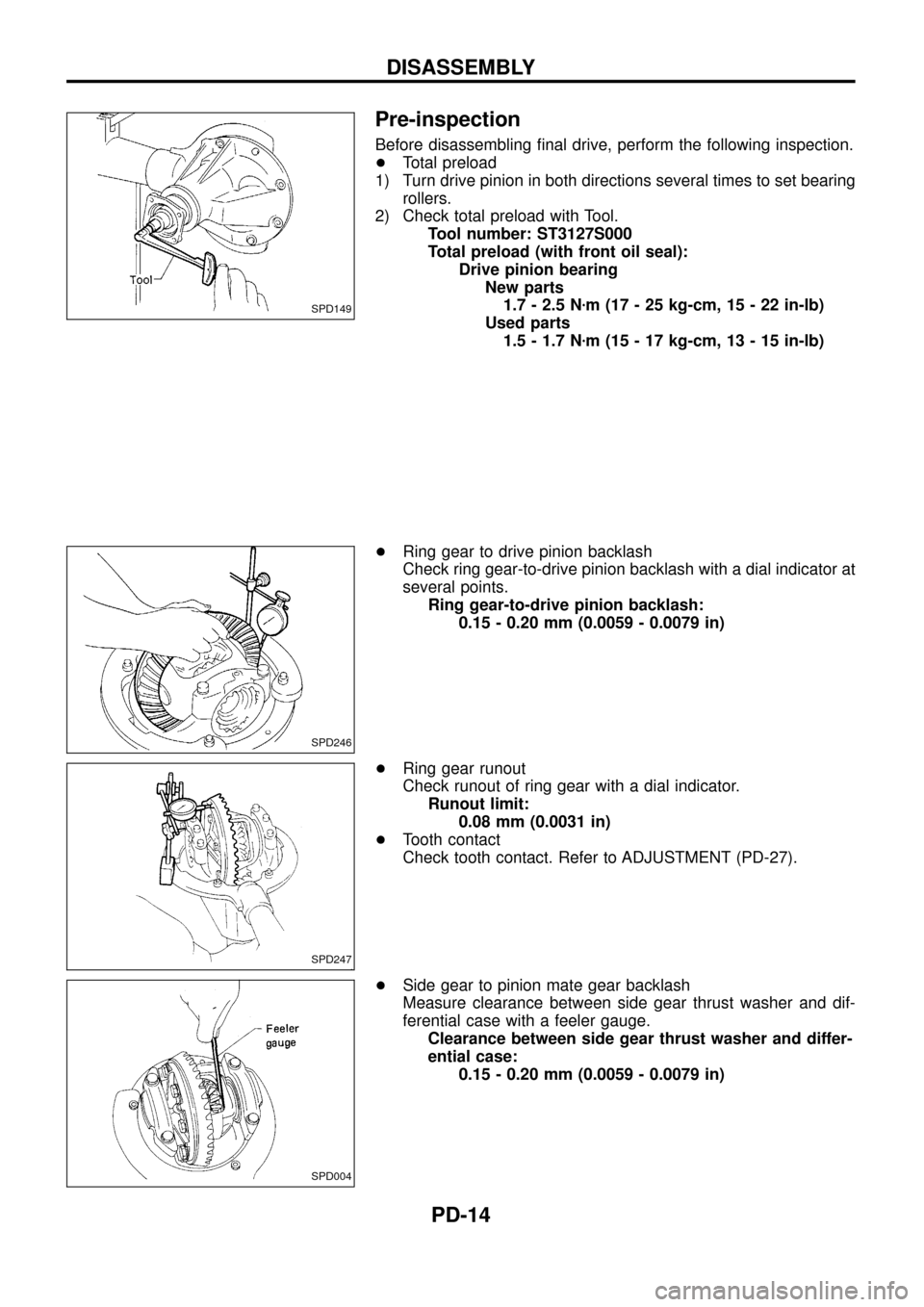

Pre-inspection

Before disassembling ®nal drive, perform the following inspection.

+Total preload

1) Turn drive pinion in both directions several times to set bearing

rollers.

2) Check total preload with Tool.

Tool number: ST3127S000

Total preload (with front oil seal):

Drive pinion bearing

New parts

1.7 - 2.5 Nzm (17 - 25 kg-cm, 15 - 22 in-lb)

Used parts

1.5 - 1.7 Nzm (15 - 17 kg-cm, 13 - 15 in-lb)

+Ring gear to drive pinion backlash

Check ring gear-to-drive pinion backlash with a dial indicator at

several points.

Ring gear-to-drive pinion backlash:

0.15 - 0.20 mm (0.0059 - 0.0079 in)

+Ring gear runout

Check runout of ring gear with a dial indicator.

Runout limit:

0.08 mm (0.0031 in)

+Tooth contact

Check tooth contact. Refer to ADJUSTMENT (PD-27).

+Side gear to pinion mate gear backlash

Measure clearance between side gear thrust washer and dif-

ferential case with a feeler gauge.

Clearance between side gear thrust washer and differ-

ential case:

0.15 - 0.20 mm (0.0059 - 0.0079 in)

SPD149

SPD246

SPD247

SPD004

DISASSEMBLY

PD-14

Page 30 of 54

![NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual Example (H233B):

N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD¢þ S) x 0.01] + 3.05

= 0.30 þ [{2 þ (þ1) þ 0} x 0.01] + 3.05

(1) H ........................................................................ 2 NISSAN PATROL 1998 Y61 / 5.G Propeller Shaft And Differential Carrier Workshop Manual Example (H233B):

N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD¢þ S) x 0.01] + 3.05

= 0.30 þ [{2 þ (þ1) þ 0} x 0.01] + 3.05

(1) H ........................................................................ 2](/img/5/625/w960_625-29.png)

Example (H233B):

N = 0.30

H=2

D¢=þ1

S=0

T=Nþ[(HþD¢þ S) x 0.01] + 3.05

= 0.30 þ [{2 þ (þ1) þ 0} x 0.01] + 3.05

(1) H ........................................................................ 2

þD¢................................................................. þ(þ1)

3

þS ...................................................................... þ0

3

(2) 3

x 0.01

0.03

(3) N ................................................................... 0.30

þ0.03

0.27

(4) 0.27

+3.05

3.32

\T = 3.32

7. Select the proper pinion height washer.

Drive pinion height adjusting washer:

Refer to SDS (PD-0, 53).

If you cannot ®nd the desired thickness of washer, use washer

with thickness closest to the calculated value.

Example (H233B):

Calculated value ... T = 3.32 mm

Used washer ... T = 3.33 mm

Tooth Contact

Gear tooth contact pattern check is necessary to verify correct

relationship between ring gear and drive pinion.

Hypoid gear sets which are not positioned properly in relation to

one another may be noisy, or have short life or both. With a pat-

tern check, the most desirable contact for low noise level and long

life can be assured.

1. Thoroughly clean ring gear and drive pinion teeth.

2. Sparingly apply a mixture of powdered ferric oxide and oil or

equivalent to 3 or 4 teeth of ring gear drive side.

SPD005

ADJUSTMENT

Drive Pinion Height (Cont'd)

PD-29

Page 32 of 54

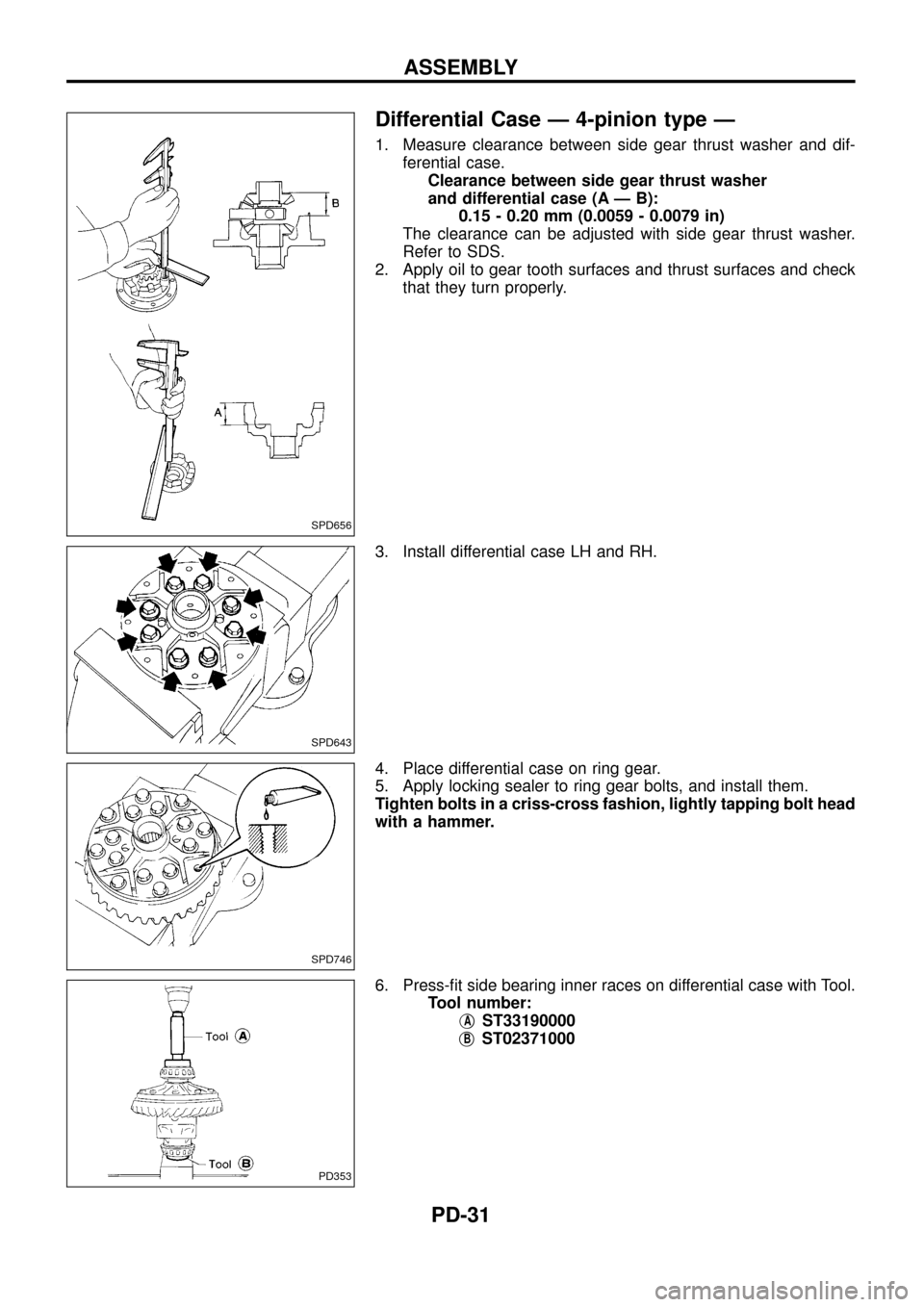

Differential Case Ð 4-pinion type Ð

1. Measure clearance between side gear thrust washer and dif-

ferential case.

Clearance between side gear thrust washer

and differential case (A Ð B):

0.15 - 0.20 mm (0.0059 - 0.0079 in)

The clearance can be adjusted with side gear thrust washer.

Refer to SDS.

2. Apply oil to gear tooth surfaces and thrust surfaces and check

that they turn properly.

3. Install differential case LH and RH.

4. Place differential case on ring gear.

5. Apply locking sealer to ring gear bolts, and install them.

Tighten bolts in a criss-cross fashion, lightly tapping bolt head

with a hammer.

6. Press-®t side bearing inner races on differential case with Tool.

Tool number:

j

AST33190000

j

BST02371000

SPD656

SPD643

SPD746

PD353

ASSEMBLY

PD-31

Page 36 of 54

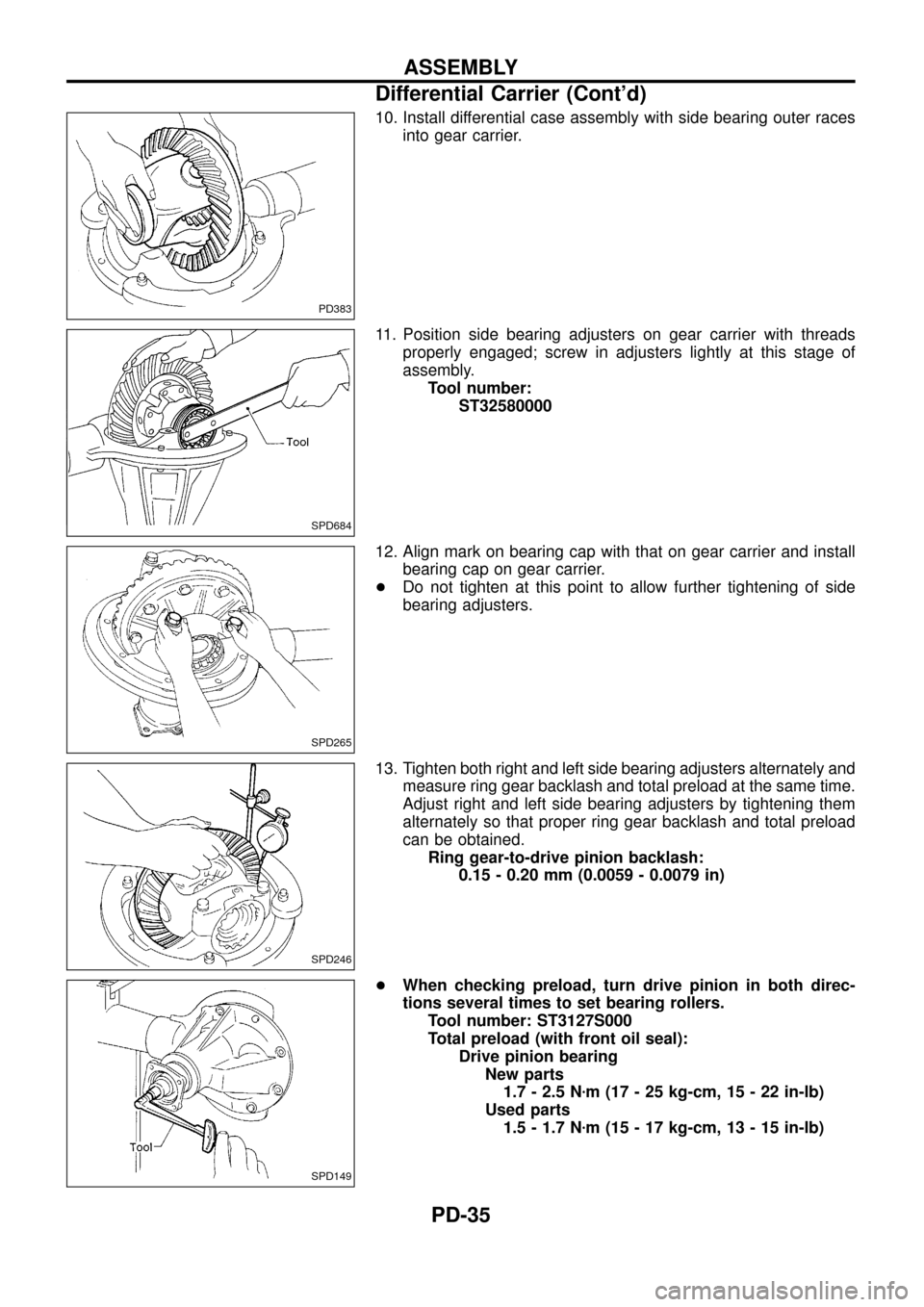

10. Install differential case assembly with side bearing outer races

into gear carrier.

11. Position side bearing adjusters on gear carrier with threads

properly engaged; screw in adjusters lightly at this stage of

assembly.

Tool number:

ST32580000

12. Align mark on bearing cap with that on gear carrier and install

bearing cap on gear carrier.

+Do not tighten at this point to allow further tightening of side

bearing adjusters.

13. Tighten both right and left side bearing adjusters alternately and

measure ring gear backlash and total preload at the same time.

Adjust right and left side bearing adjusters by tightening them

alternately so that proper ring gear backlash and total preload

can be obtained.

Ring gear-to-drive pinion backlash:

0.15 - 0.20 mm (0.0059 - 0.0079 in)

+When checking preload, turn drive pinion in both direc-

tions several times to set bearing rollers.

Tool number: ST3127S000

Total preload (with front oil seal):

Drive pinion bearing

New parts

1.7 - 2.5 Nzm (17 - 25 kg-cm, 15 - 22 in-lb)

Used parts

1.5 - 1.7 Nzm (15 - 17 kg-cm, 13 - 15 in-lb)

PD383

SPD684

SPD265

SPD246

SPD149

ASSEMBLY

Differential Carrier (Cont'd)

PD-35

Page 40 of 54

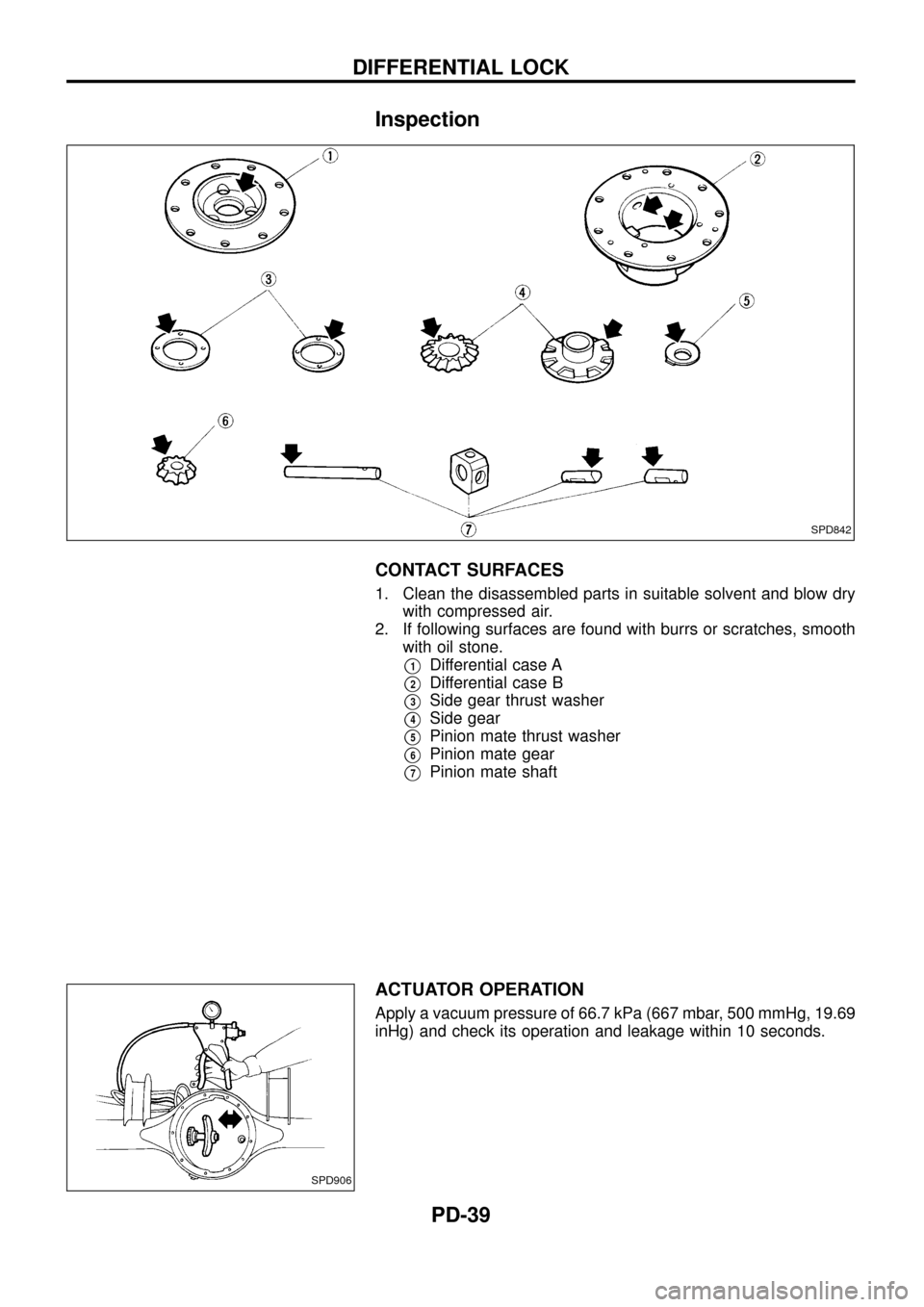

Inspection

CONTACT SURFACES

1. Clean the disassembled parts in suitable solvent and blow dry

with compressed air.

2. If following surfaces are found with burrs or scratches, smooth

with oil stone.

V1Differential case A

V2Differential case B

V3Side gear thrust washer

V4Side gear

V5Pinion mate thrust washer

V6Pinion mate gear

V7Pinion mate shaft

ACTUATOR OPERATION

Apply a vacuum pressure of 66.7 kPa (667 mbar, 500 mmHg, 19.69

inHg) and check its operation and leakage within 10 seconds.

SPD842

SPD906

DIFFERENTIAL LOCK

PD-39