belt NISSAN PATROL 1998 Y61 / 5.G Restraint System User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PATROL, Model: NISSAN PATROL 1998 Y61 / 5.GPages: 47, PDF Size: 1.15 MB

Page 12 of 47

Maintenance Items

CAUTION:

Do not use a circuit tester to check SRS circuit.

1. Check operation of ``AIR BAG'' warning lamp.

After turning ignition key to ``ON'' position, both warning lamps

illuminate. The ``AIR BAG'' warning lamp will go off after about

7 seconds if no malfunction is detected.

If any of the following warning lamp conditions occur, immedi-

ately check the air bag or seat belt pre-tensioner system. Refer

to RS-30 for details.

+The ``AIR BAG'' warning lamp does not illuminate when the

ignition switch is turned ``ON''.

+The ``AIR BAG'' warning lamp does not go off about 7 seconds

after the ignition switch is turned ``ON''.

+The ``AIR BAG'' warning lamp blinks about 7 seconds after the

ignition switch is turned ``ON''.

2. Visually check SRS components.

(1) Diagnosis sensor unit

+Check diagnosis sensor unit and bracket for dents, cracks or

deformities.

+Check connectors for damage, and terminals for deformities.

(2) Air bag module and steering wheel

+Remove air bag module from steering wheel or instrument

panel. Check harness cover and connectors for damage, ter-

minals for deformities, and harness for binding.

+Install driver air bag module to steering wheel to check ®t or

alignment with the wheel.

+Check steering wheel for excessive free play.

+For dual air bag system, install passenger air bag module to

instrument panel to check ®t or alignment with the instrument

panel.

(3) Spiral cable

+Check spiral cable for dents, cracks, or deformities.

+Check connectors and protective tape for damage.

+Check steering wheel for noise, binding or heavy operation.

(4) Harness related to SRS

+Check connectors for poor connections, damage, and terminals

for deformities.

+Check harnesses for binding, cha®ng or cut.

(5) Seat belt pre-tensioner

+Check harness cover and connectors for damage, terminals for

deformities, and harness for binding.

+Check belts for damage and anchors for loose mounting.

+Check retractor for smooth operation.

+Perform self-diagnosis for seat belt pre-tensioner using

bulb or CONSULT. Refer to ``SRS Operation Check'' for details.

(RS-30)

CAUTION:

Replace previously used special bolts, ground bolt and anchor

bolt with new ones.

SRS451

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-11

Page 13 of 47

Removal and Installation Ð Diagnosis Sensor

Unit and Seat Belt Pre-tensioner

CAUTION:

+Before servicing SRS, turn the ignition switch off, disconnect both battery cables and wait for at

least 3 minutes.

+The special bolts are coated with bonding agent while the other bolt is for ground. Do not use old

bolts after removal; replace with new ones.

+Check diagnosis sensor unit and seat belt pre-tensioner for proper installation.

+Check diagnosis sensor unit to ensure they are free of deformities, dents, cracks or rust. If they

show any visible signs of damage, replace them with new ones.

+Check diagnosis sensor unit brackets to ensure they are free of deformities or rust.

+Replace diagnosis sensor unit and seat belt pre-tensioner if they have been dropped or sustained

an impact.

+After replacement of diagnosis sensor unit and seat belt pre-tensioner, check SRS function and

perform self-diagnosis for SRS. Refer to ``SRS Operation Check'' for details (RS-30).

+Do not attempt to disassemble diagnosis sensor unit and seat belt pre-tensioner.

+Do not expose seat belt pre-tensioner to temperatures exceeding 80ÉC (176ÉF).

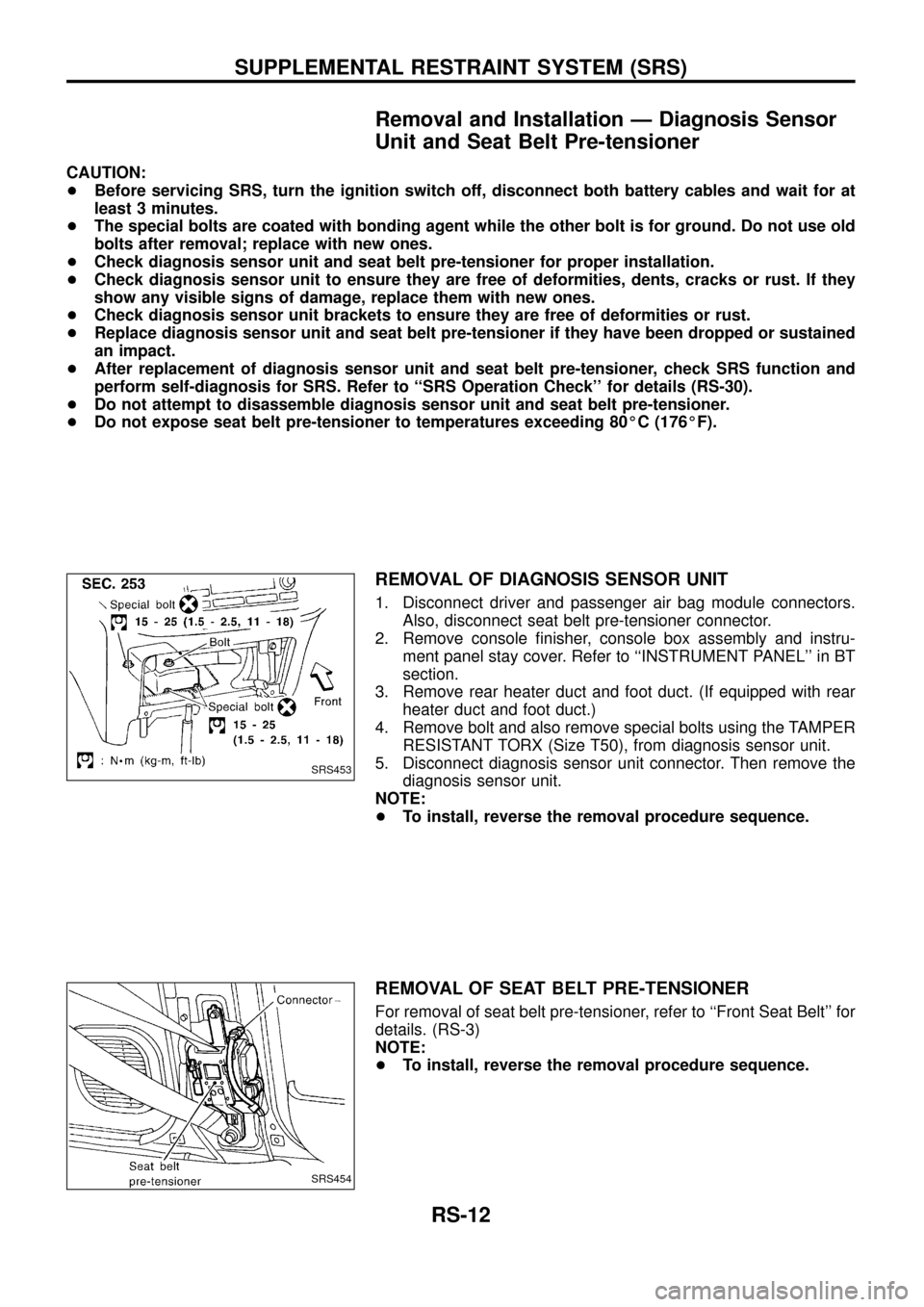

REMOVAL OF DIAGNOSIS SENSOR UNIT

1. Disconnect driver and passenger air bag module connectors.

Also, disconnect seat belt pre-tensioner connector.

2. Remove console ®nisher, console box assembly and instru-

ment panel stay cover. Refer to ``INSTRUMENT PANEL'' in BT

section.

3. Remove rear heater duct and foot duct. (If equipped with rear

heater duct and foot duct.)

4. Remove bolt and also remove special bolts using the TAMPER

RESISTANT TORX (Size T50), from diagnosis sensor unit.

5. Disconnect diagnosis sensor unit connector. Then remove the

diagnosis sensor unit.

NOTE:

+To install, reverse the removal procedure sequence.

REMOVAL OF SEAT BELT PRE-TENSIONER

For removal of seat belt pre-tensioner, refer to ``Front Seat Belt'' for

details. (RS-3)

NOTE:

+To install, reverse the removal procedure sequence.

SRS453

SRS454

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-12

Page 18 of 47

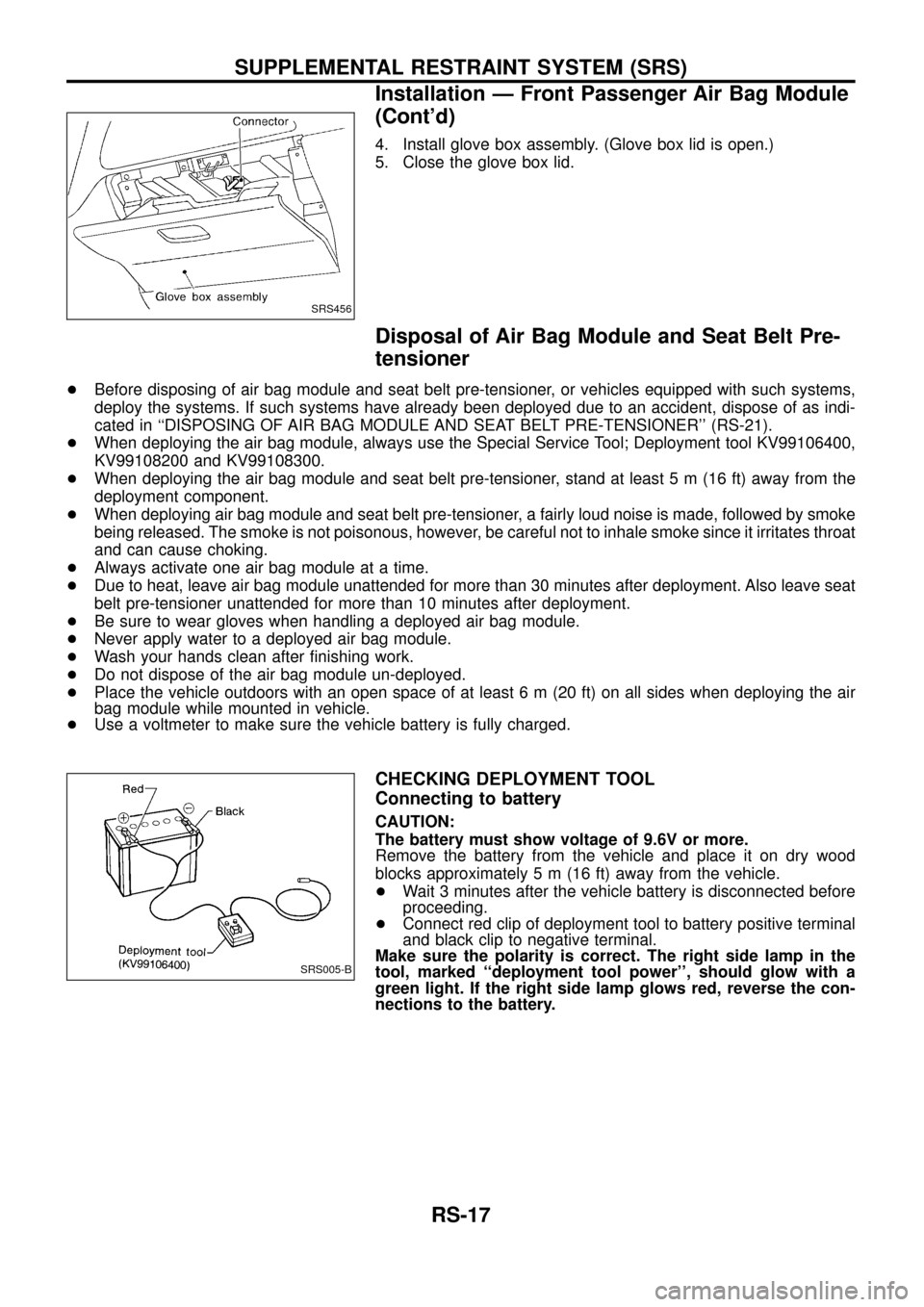

4. Install glove box assembly. (Glove box lid is open.)

5. Close the glove box lid.

Disposal of Air Bag Module and Seat Belt Pre-

tensioner

+Before disposing of air bag module and seat belt pre-tensioner, or vehicles equipped with such systems,

deploy the systems. If such systems have already been deployed due to an accident, dispose of as indi-

cated in ``DISPOSING OF AIR BAG MODULE AND SEAT BELT PRE-TENSIONER'' (RS-21).

+When deploying the air bag module, always use the Special Service Tool; Deployment tool KV99106400,

KV99108200 and KV99108300.

+When deploying the air bag module and seat belt pre-tensioner, stand at least 5 m (16 ft) away from the

deployment component.

+When deploying air bag module and seat belt pre-tensioner, a fairly loud noise is made, followed by smoke

being released. The smoke is not poisonous, however, be careful not to inhale smoke since it irritates throat

and can cause choking.

+Always activate one air bag module at a time.

+Due to heat, leave air bag module unattended for more than 30 minutes after deployment. Also leave seat

belt pre-tensioner unattended for more than 10 minutes after deployment.

+Be sure to wear gloves when handling a deployed air bag module.

+Never apply water to a deployed air bag module.

+Wash your hands clean after ®nishing work.

+Do not dispose of the air bag module un-deployed.

+Place the vehicle outdoors with an open space of at least 6 m (20 ft) on all sides when deploying the air

bag module while mounted in vehicle.

+Use a voltmeter to make sure the vehicle battery is fully charged.

CHECKING DEPLOYMENT TOOL

Connecting to battery

CAUTION:

The battery must show voltage of 9.6V or more.

Remove the battery from the vehicle and place it on dry wood

blocks approximately 5 m (16 ft) away from the vehicle.

+Wait 3 minutes after the vehicle battery is disconnected before

proceeding.

+Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

Make sure the polarity is correct. The right side lamp in the

tool, marked ``deployment tool power'', should glow with a

green light. If the right side lamp glows red, reverse the con-

nections to the battery.

SRS456

SRS005-B

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Installation Ð Front Passenger Air Bag Module

(Cont'd)

RS-17

Page 19 of 47

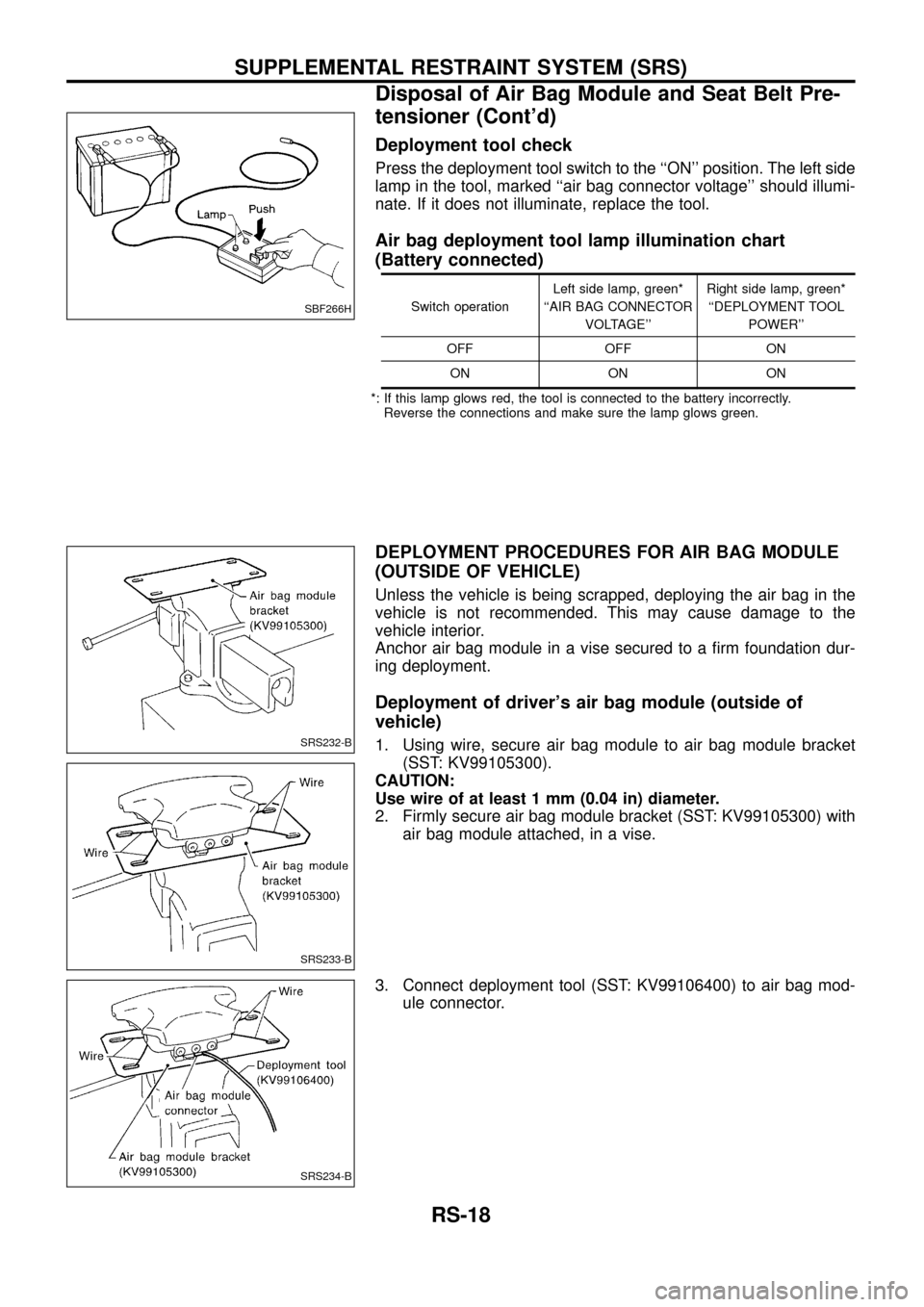

Deployment tool check

Press the deployment tool switch to the ``ON'' position. The left side

lamp in the tool, marked ``air bag connector voltage'' should illumi-

nate. If it does not illuminate, replace the tool.

Air bag deployment tool lamp illumination chart

(Battery connected)

Switch operationLeft side lamp, green*

``AIR BAG CONNECTOR

VOLTAGE''Right side lamp, green*

``DEPLOYMENT TOOL

POWER''

OFF OFF ON

ON ON ON

*: If this lamp glows red, the tool is connected to the battery incorrectly.

Reverse the connections and make sure the lamp glows green.

DEPLOYMENT PROCEDURES FOR AIR BAG MODULE

(OUTSIDE OF VEHICLE)

Unless the vehicle is being scrapped, deploying the air bag in the

vehicle is not recommended. This may cause damage to the

vehicle interior.

Anchor air bag module in a vise secured to a ®rm foundation dur-

ing deployment.

Deployment of driver's air bag module (outside of

vehicle)

1. Using wire, secure air bag module to air bag module bracket

(SST: KV99105300).

CAUTION:

Use wire of at least 1 mm (0.04 in) diameter.

2. Firmly secure air bag module bracket (SST: KV99105300) with

air bag module attached, in a vise.

3. Connect deployment tool (SST: KV99106400) to air bag mod-

ule connector.

SBF266H

SRS232-B

SRS233-B

SRS234-B

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-

tensioner (Cont'd)

RS-18

Page 20 of 47

4. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

5. The lamp on the right side of the tool, marked ``deployment tool

power'', should glow green, not red.

6. Press the button on the deployment tool. The left side lamp on

the tool, marked ``air bag connector voltage'', will illuminate and

the air bag module will deploy.

CAUTION:

When deploying the air bag module, stand at least 5 m (16 ft)

away from the air bag module.

Deployment of passenger air bag module (outside of

vehicle)

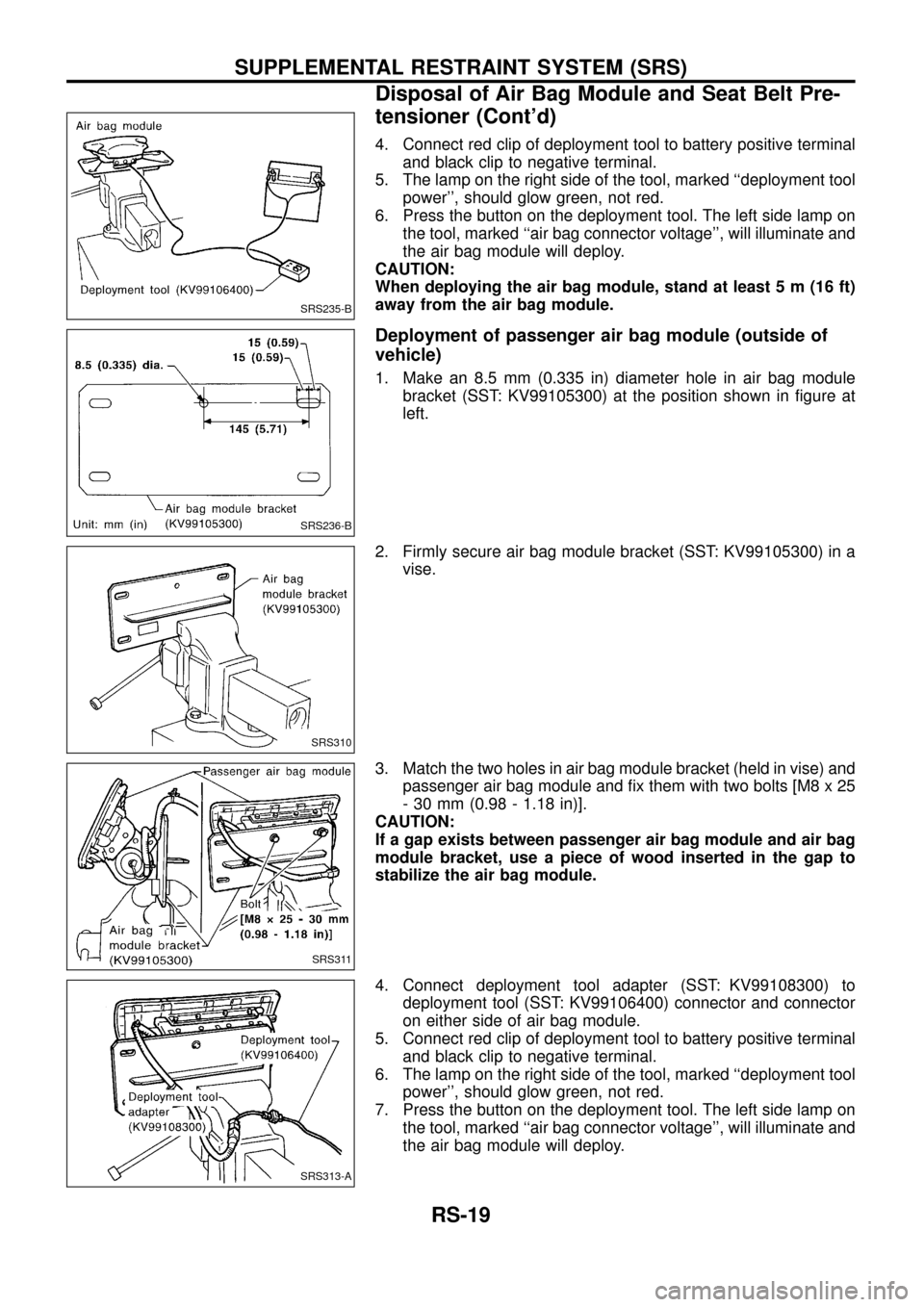

1. Make an 8.5 mm (0.335 in) diameter hole in air bag module

bracket (SST: KV99105300) at the position shown in ®gure at

left.

2. Firmly secure air bag module bracket (SST: KV99105300) in a

vise.

3. Match the two holes in air bag module bracket (held in vise) and

passenger air bag module and ®x them with two bolts [M8 x 25

- 30 mm (0.98 - 1.18 in)].

CAUTION:

If a gap exists between passenger air bag module and air bag

module bracket, use a piece of wood inserted in the gap to

stabilize the air bag module.

4. Connect deployment tool adapter (SST: KV99108300) to

deployment tool (SST: KV99106400) connector and connector

on either side of air bag module.

5. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

6. The lamp on the right side of the tool, marked ``deployment tool

power'', should glow green, not red.

7. Press the button on the deployment tool. The left side lamp on

the tool, marked ``air bag connector voltage'', will illuminate and

the air bag module will deploy.

SRS235-B

SRS236-B

SRS310

SRS311

SRS313-A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-

tensioner (Cont'd)

RS-19

Page 21 of 47

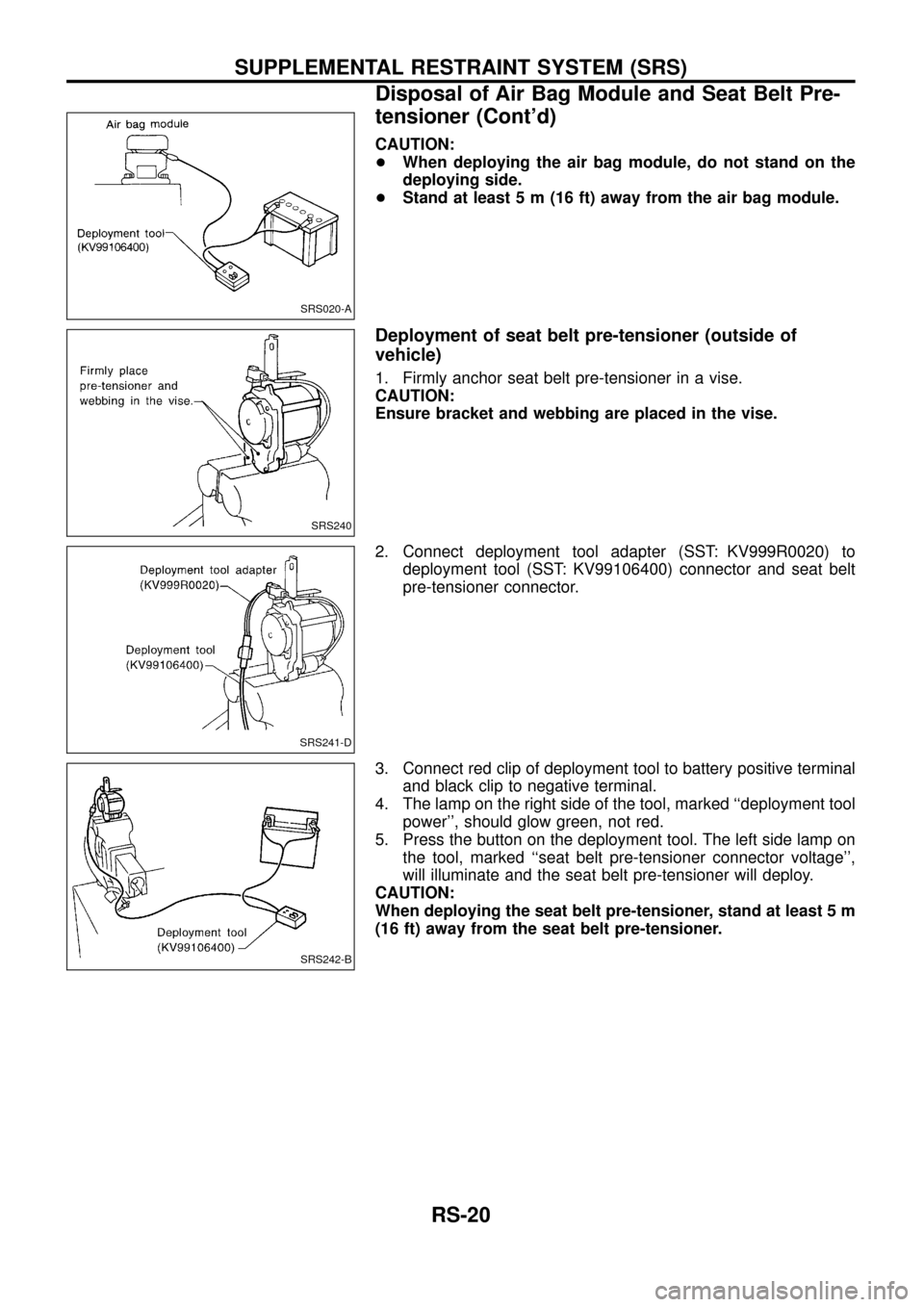

CAUTION:

+When deploying the air bag module, do not stand on the

deploying side.

+Stand at least 5 m (16 ft) away from the air bag module.

Deployment of seat belt pre-tensioner (outside of

vehicle)

1. Firmly anchor seat belt pre-tensioner in a vise.

CAUTION:

Ensure bracket and webbing are placed in the vise.

2. Connect deployment tool adapter (SST: KV999R0020) to

deployment tool (SST: KV99106400) connector and seat belt

pre-tensioner connector.

3. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

4. The lamp on the right side of the tool, marked ``deployment tool

power'', should glow green, not red.

5. Press the button on the deployment tool. The left side lamp on

the tool, marked ``seat belt pre-tensioner connector voltage'',

will illuminate and the seat belt pre-tensioner will deploy.

CAUTION:

When deploying the seat belt pre-tensioner, stand at least 5 m

(16 ft) away from the seat belt pre-tensioner.

SRS020-A

SRS240

SRS241-D

SRS242-B

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-

tensioner (Cont'd)

RS-20

Page 22 of 47

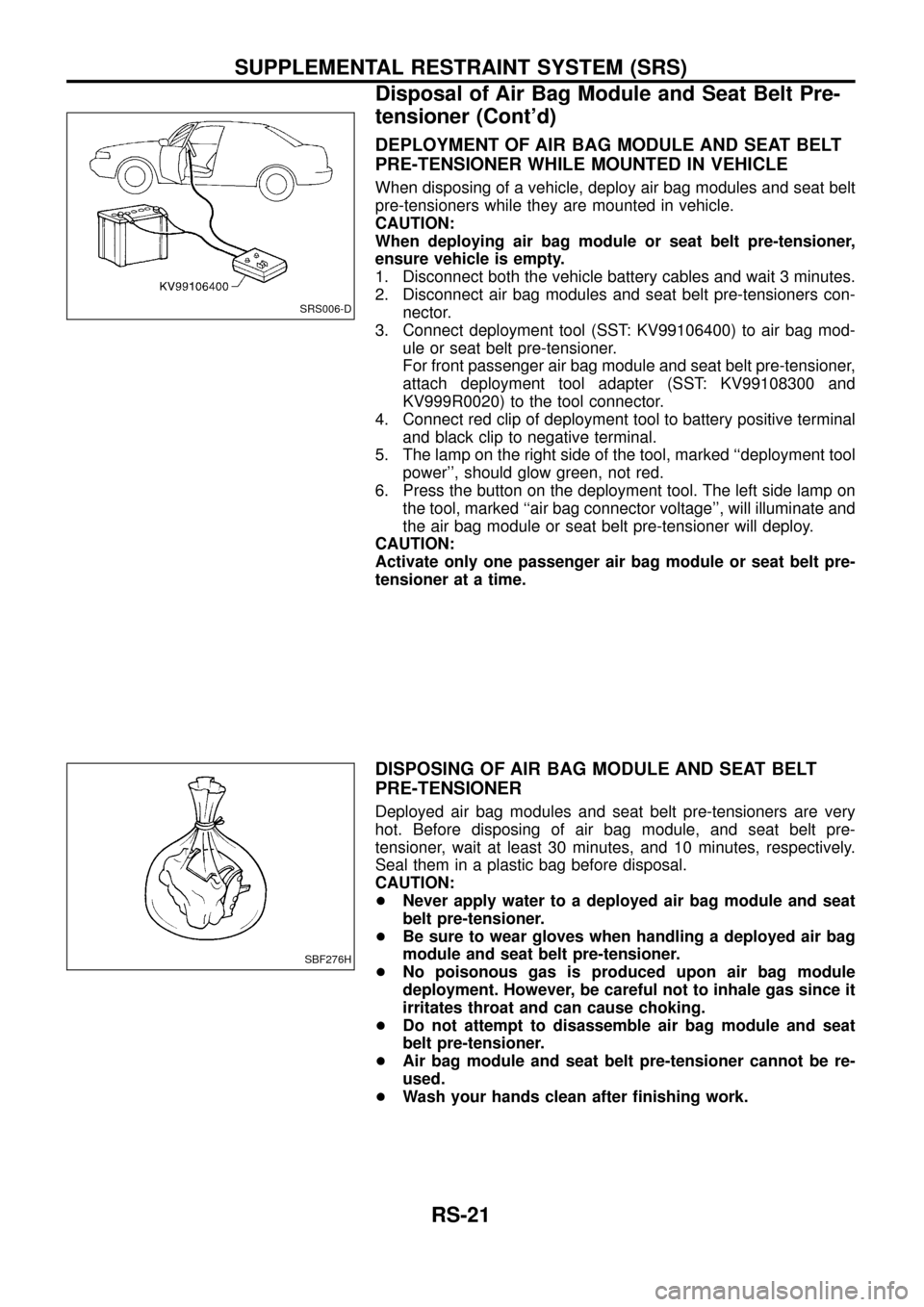

DEPLOYMENT OF AIR BAG MODULE AND SEAT BELT

PRE-TENSIONER WHILE MOUNTED IN VEHICLE

When disposing of a vehicle, deploy air bag modules and seat belt

pre-tensioners while they are mounted in vehicle.

CAUTION:

When deploying air bag module or seat belt pre-tensioner,

ensure vehicle is empty.

1. Disconnect both the vehicle battery cables and wait 3 minutes.

2. Disconnect air bag modules and seat belt pre-tensioners con-

nector.

3. Connect deployment tool (SST: KV99106400) to air bag mod-

ule or seat belt pre-tensioner.

For front passenger air bag module and seat belt pre-tensioner,

attach deployment tool adapter (SST: KV99108300 and

KV999R0020) to the tool connector.

4. Connect red clip of deployment tool to battery positive terminal

and black clip to negative terminal.

5. The lamp on the right side of the tool, marked ``deployment tool

power'', should glow green, not red.

6. Press the button on the deployment tool. The left side lamp on

the tool, marked ``air bag connector voltage'', will illuminate and

the air bag module or seat belt pre-tensioner will deploy.

CAUTION:

Activate only one passenger air bag module or seat belt pre-

tensioner at a time.

DISPOSING OF AIR BAG MODULE AND SEAT BELT

PRE-TENSIONER

Deployed air bag modules and seat belt pre-tensioners are very

hot. Before disposing of air bag module, and seat belt pre-

tensioner, wait at least 30 minutes, and 10 minutes, respectively.

Seal them in a plastic bag before disposal.

CAUTION:

+Never apply water to a deployed air bag module and seat

belt pre-tensioner.

+Be sure to wear gloves when handling a deployed air bag

module and seat belt pre-tensioner.

+No poisonous gas is produced upon air bag module

deployment. However, be careful not to inhale gas since it

irritates throat and can cause choking.

+Do not attempt to disassemble air bag module and seat

belt pre-tensioner.

+Air bag module and seat belt pre-tensioner cannot be re-

used.

+Wash your hands clean after ®nishing work.

SRS006-D

SBF276H

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Disposal of Air Bag Module and Seat Belt Pre-

tensioner (Cont'd)

RS-21

Page 23 of 47

Trouble Diagnoses Introduction

CAUTION:

+Do not use a circuit tester to check SRS harness connectors unless instructed to in this Service

Manual. SRS wiring harnesses except for ``SEAT BELT PRE-TENSIONER'' can be identi®ed with

yellow harness protector or yellow insulation tape before the harness connectors.

+Do not attempt to repair, splice or modify the SRS wiring harness. If the harness is damaged,

replace it with a new one.

+Keep ground portion clean.

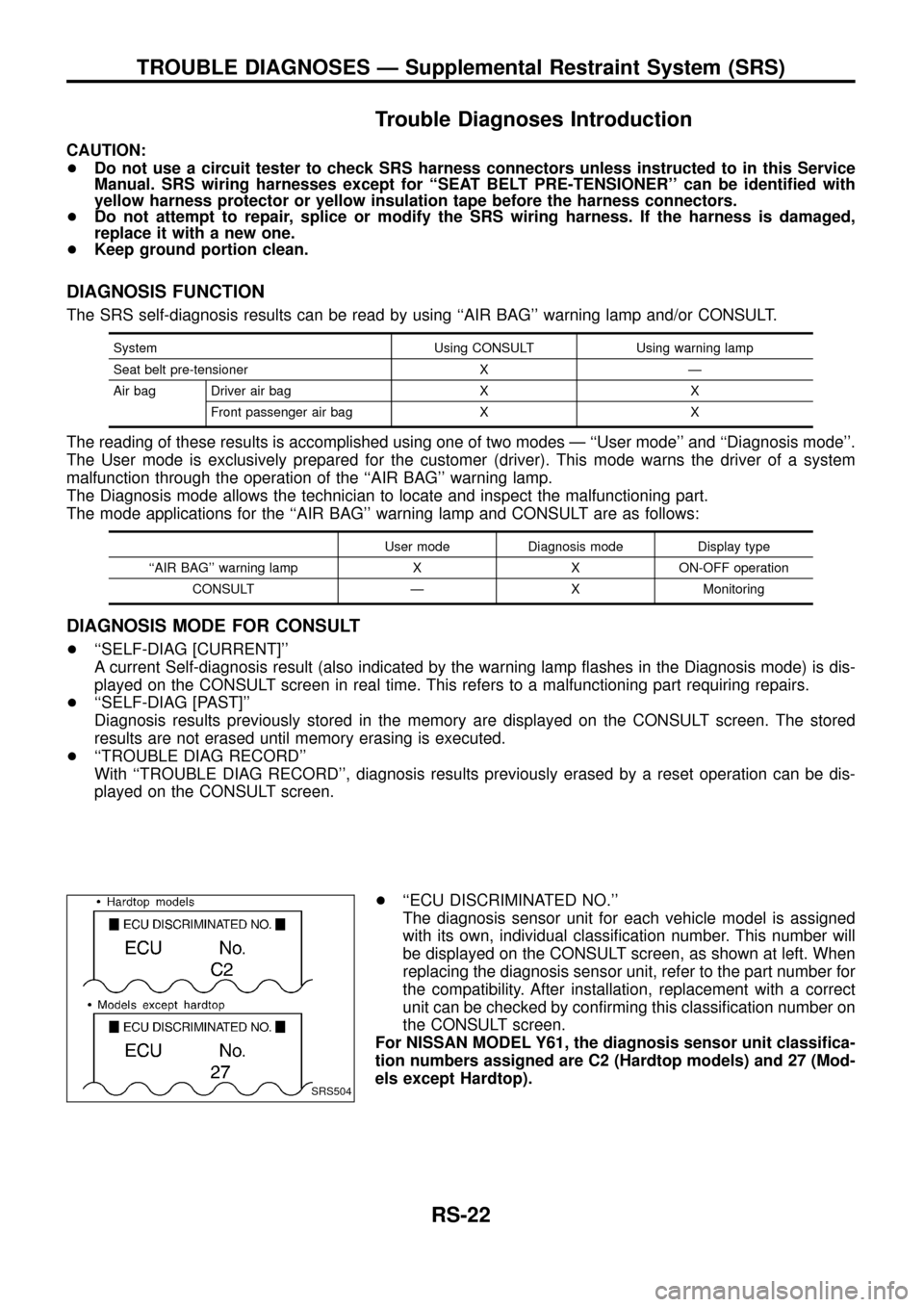

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by using ``AIR BAG'' warning lamp and/or CONSULT.

System Using CONSULT Using warning lamp

Seat belt pre-tensioner X Ð

Air bag Driver air bag X X

Front passenger air bag X X

The reading of these results is accomplished using one of two modes Ð ``User mode'' and ``Diagnosis mode''.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system

malfunction through the operation of the ``AIR BAG'' warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the ``AIR BAG'' warning lamp and CONSULT are as follows:

User mode Diagnosis mode Display type

``AIR BAG'' warning lamp X X ON-OFF operation

CONSULT Ð X Monitoring

DIAGNOSIS MODE FOR CONSULT

+``SELF-DIAG [CURRENT]''

A current Self-diagnosis result (also indicated by the warning lamp ¯ashes in the Diagnosis mode) is dis-

played on the CONSULT screen in real time. This refers to a malfunctioning part requiring repairs.

+``SELF-DIAG [PAST]''

Diagnosis results previously stored in the memory are displayed on the CONSULT screen. The stored

results are not erased until memory erasing is executed.

+``TROUBLE DIAG RECORD''

With ``TROUBLE DIAG RECORD'', diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT screen.

+``ECU DISCRIMINATED NO.''

The diagnosis sensor unit for each vehicle model is assigned

with its own, individual classi®cation number. This number will

be displayed on the CONSULT screen, as shown at left. When

replacing the diagnosis sensor unit, refer to the part number for

the compatibility. After installation, replacement with a correct

unit can be checked by con®rming this classi®cation number on

the CONSULT screen.

For NISSAN MODEL Y61, the diagnosis sensor unit classi®ca-

tion numbers assigned are C2 (Hardtop models) and 27 (Mod-

els except Hardtop).

SRS504

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

RS-22

Page 26 of 47

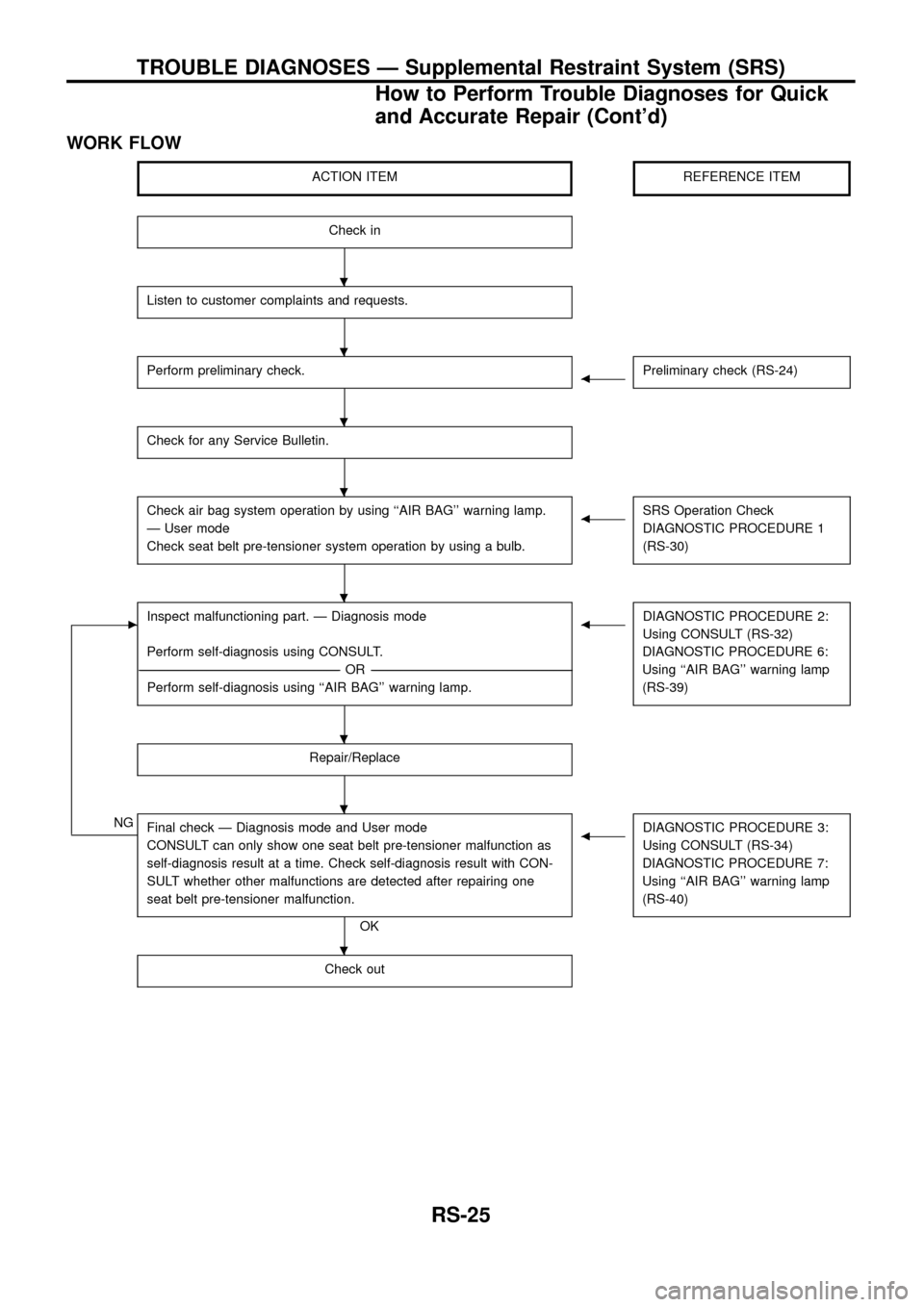

WORK FLOW

ACTION ITEMREFERENCE ITEM

Check in

Listen to customer complaints and requests.

Perform preliminary check.bPreliminary check (RS-24)

Check for any Service Bulletin.

Check air bag system operation by using ``AIR BAG'' warning lamp.

Ð User mode

Check seat belt pre-tensioner system operation by using a bulb.bSRS Operation Check

DIAGNOSTIC PROCEDURE 1

(RS-30)

cInspect malfunctioning part. Ð Diagnosis mode

Perform self-diagnosis using CONSULT.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR ----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Perform self-diagnosis using ``AIR BAG'' warning lamp.bDIAGNOSTIC PROCEDURE 2:

Using CONSULT (RS-32)

DIAGNOSTIC PROCEDURE 6:

Using ``AIR BAG'' warning lamp

(RS-39)

Repair/Replace

NGFinal check Ð Diagnosis mode and User mode

CONSULT can only show one seat belt pre-tensioner malfunction as

self-diagnosis result at a time. Check self-diagnosis result with CON-

SULT whether other malfunctions are detected after repairing one

seat belt pre-tensioner malfunction.

OK

bDIAGNOSTIC PROCEDURE 3:

Using CONSULT (RS-34)

DIAGNOSTIC PROCEDURE 7:

Using ``AIR BAG'' warning lamp

(RS-40)

Check out

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

How to Perform Trouble Diagnoses for Quick

and Accurate Repair (Cont'd)

RS-25

Page 32 of 47

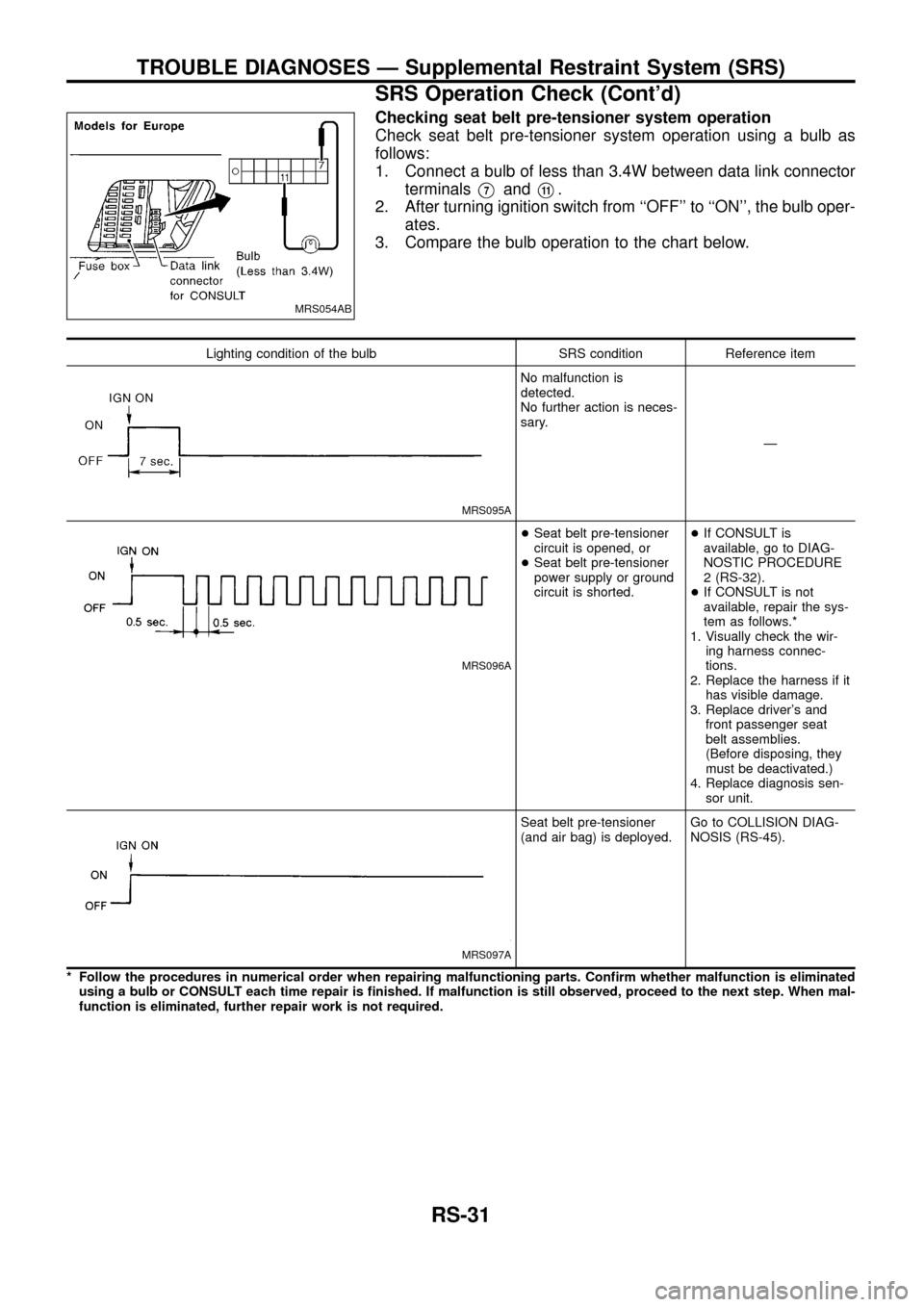

Checking seat belt pre-tensioner system operation

Check seat belt pre-tensioner system operation using a bulb as

follows:

1. Connect a bulb of less than 3.4W between data link connector

terminals

V7andV11.

2. After turning ignition switch from ``OFF'' to ``ON'', the bulb oper-

ates.

3. Compare the bulb operation to the chart below.

Lighting condition of the bulb SRS condition Reference item

MRS095A

No malfunction is

detected.

No further action is neces-

sary.

Ð

MRS096A

+Seat belt pre-tensioner

circuit is opened, or

+Seat belt pre-tensioner

power supply or ground

circuit is shorted.+If CONSULT is

available, go to DIAG-

NOSTIC PROCEDURE

2 (RS-32).

+If CONSULT is not

available, repair the sys-

tem as follows.*

1. Visually check the wir-

ing harness connec-

tions.

2. Replace the harness if it

has visible damage.

3. Replace driver's and

front passenger seat

belt assemblies.

(Before disposing, they

must be deactivated.)

4. Replace diagnosis sen-

sor unit.

MRS097A

Seat belt pre-tensioner

(and air bag) is deployed.Go to COLLISION DIAG-

NOSIS (RS-45).

* Follow the procedures in numerical order when repairing malfunctioning parts. Con®rm whether malfunction is eliminated

using a bulb or CONSULT each time repair is ®nished. If malfunction is still observed, proceed to the next step. When mal-

function is eliminated, further repair work is not required.

MRS054AB

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

SRS Operation Check (Cont'd)

RS-31