NISSAN PATROL 1998 Y61 / 5.G Steering System User Guide

PATROL 1998 Y61 / 5.G

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/628/w960_628-0.png

NISSAN PATROL 1998 Y61 / 5.G Steering System User Guide

Trending: steering wheel adjustment, light, Removal steering wheel, parking brake, recommended oil, transmission fluid, oil capacity

Page 11 of 24

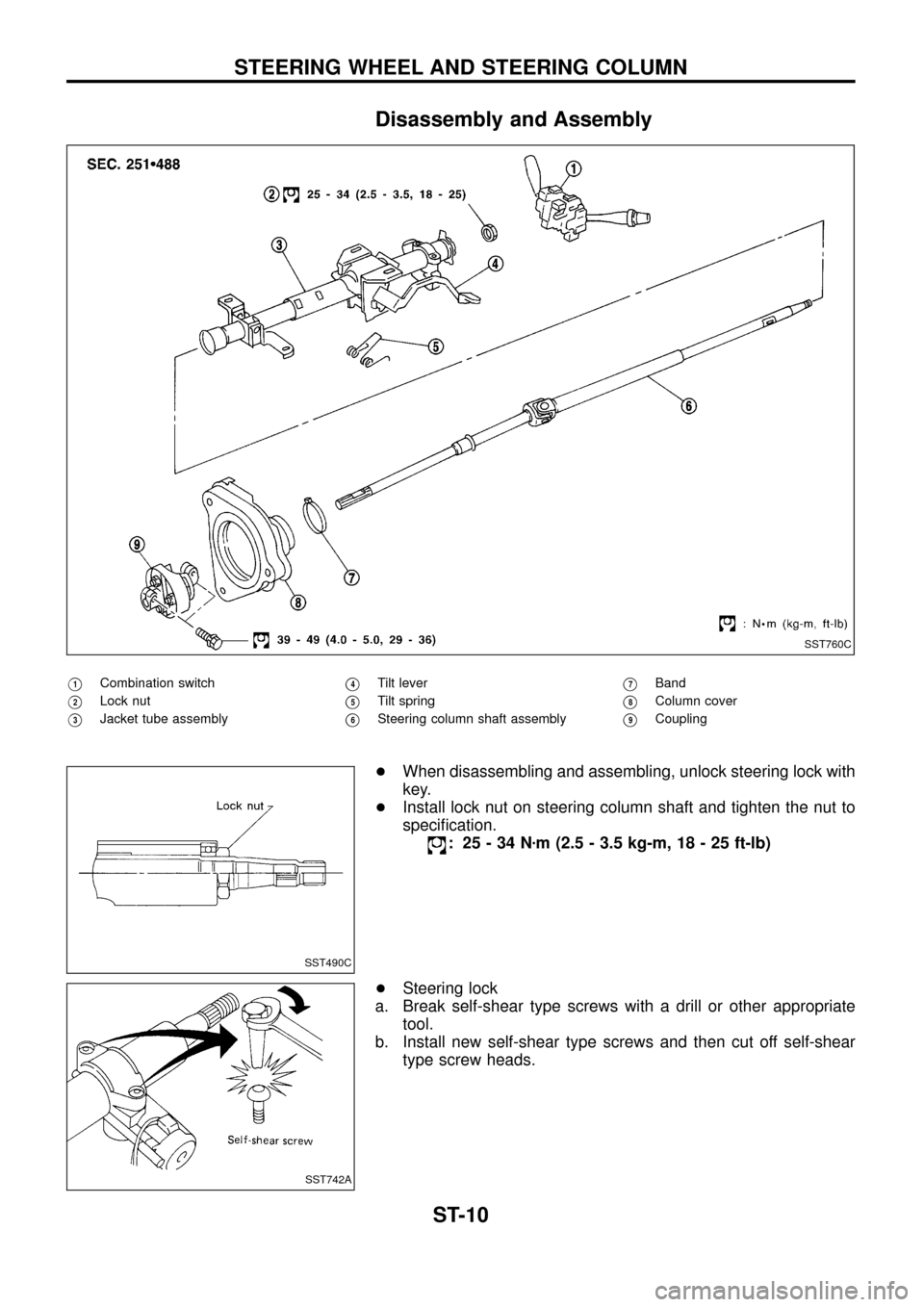

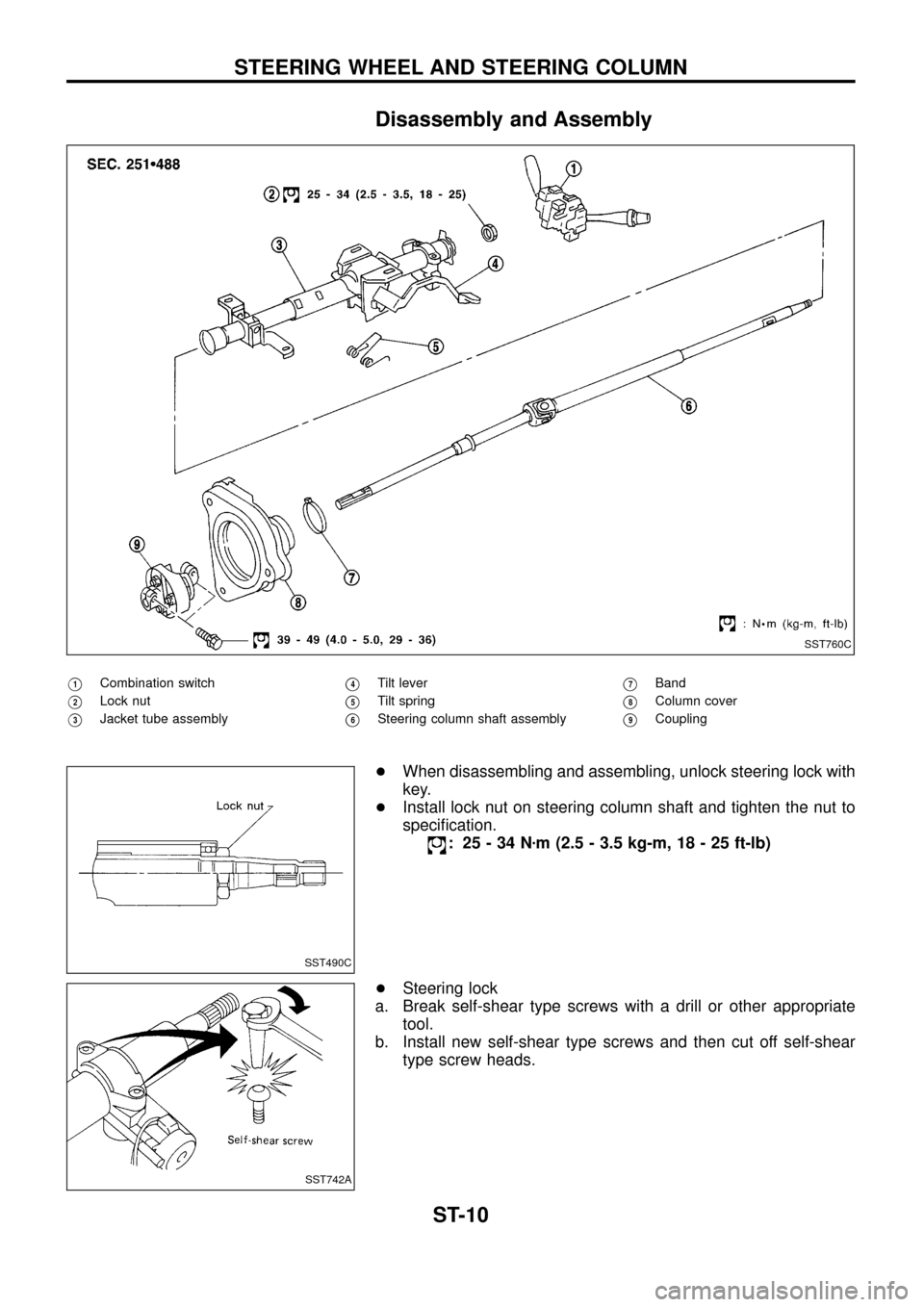

Disassembly and Assembly

V1Combination switch

V2Lock nut

V3Jacket tube assembly

V4Tilt lever

V5Tilt spring

V6Steering column shaft assembly

V7Band

V8Column cover

V9Coupling

+When disassembling and assembling, unlock steering lock with

key.

+Install lock nut on steering column shaft and tighten the nut to

speci®cation.

: 25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

+Steering lock

a. Break self-shear type screws with a drill or other appropriate

tool.

b. Install new self-shear type screws and then cut off self-shear

type screw heads.

SST760C

SST490C

SST742A

STEERING WHEEL AND STEERING COLUMN

ST-10

Page 12 of 24

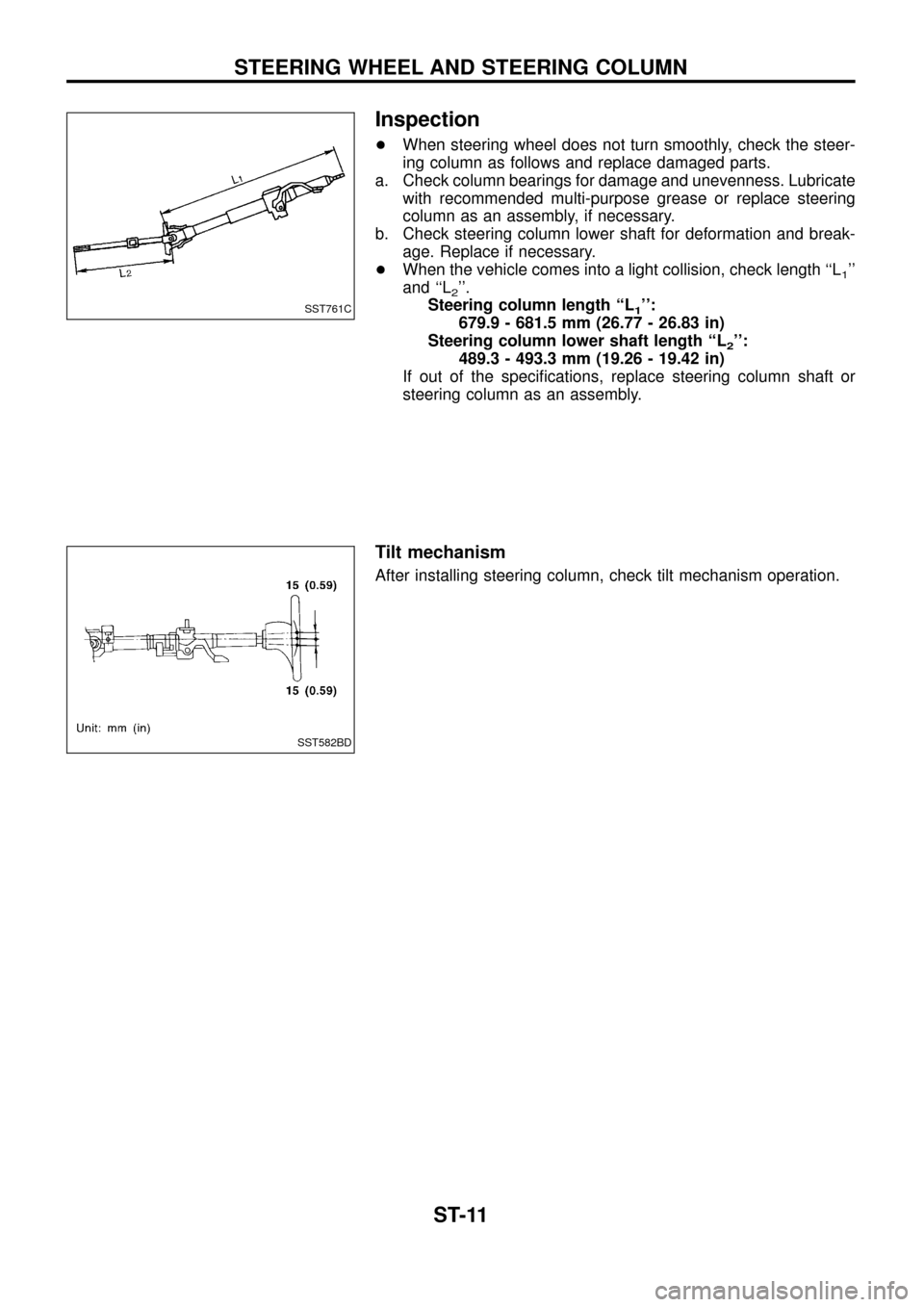

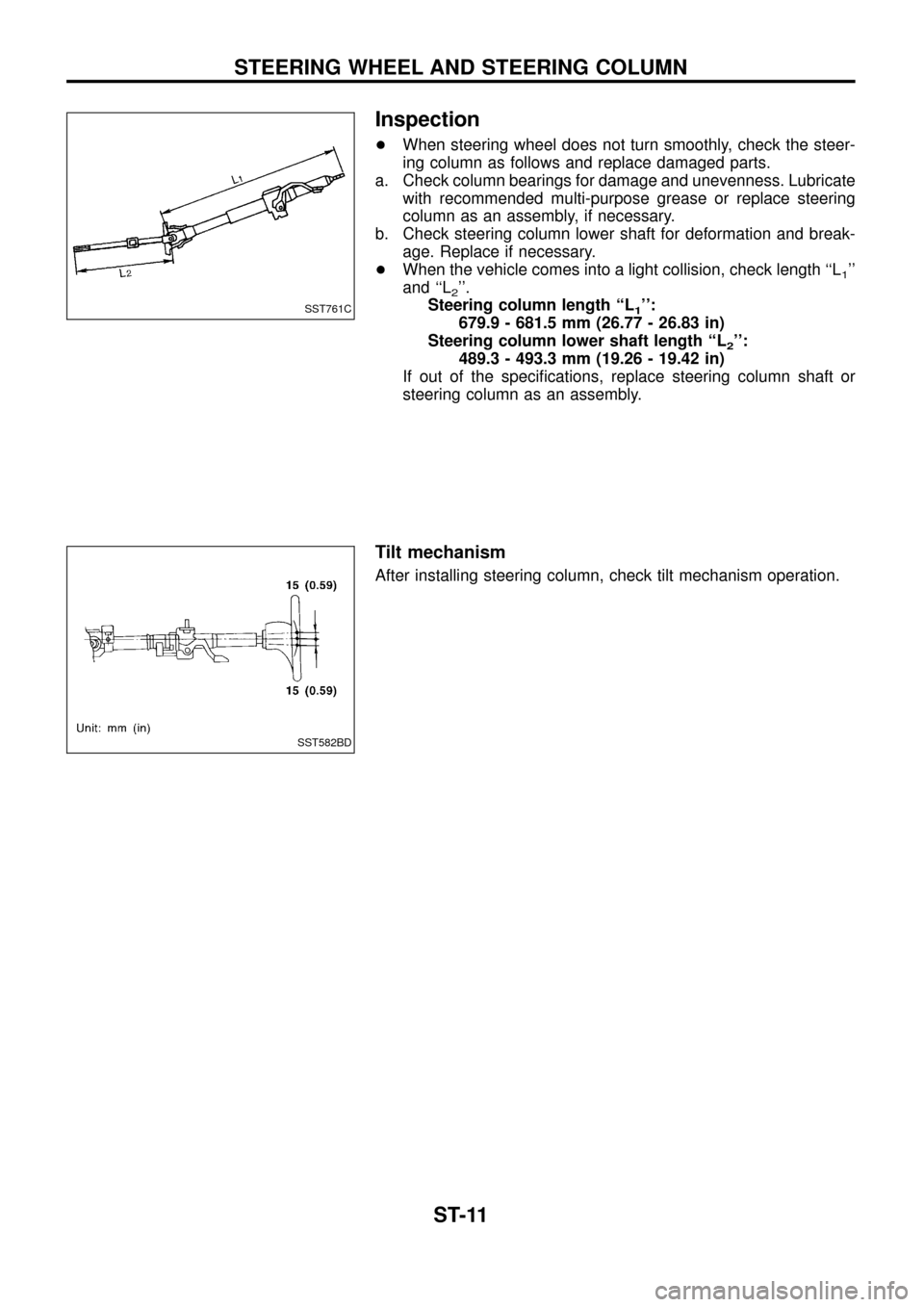

Inspection

+When steering wheel does not turn smoothly, check the steer-

ing column as follows and replace damaged parts.

a. Check column bearings for damage and unevenness. Lubricate

with recommended multi-purpose grease or replace steering

column as an assembly, if necessary.

b. Check steering column lower shaft for deformation and break-

age. Replace if necessary.

+When the vehicle comes into a light collision, check length ``L

1''

and ``L

2''.

Steering column length ``L

1'':

679.9 - 681.5 mm (26.77 - 26.83 in)

Steering column lower shaft length ``L

2'':

489.3 - 493.3 mm (19.26 - 19.42 in)

If out of the speci®cations, replace steering column shaft or

steering column as an assembly.

Tilt mechanism

After installing steering column, check tilt mechanism operation.

SST761C

SST582BD

STEERING WHEEL AND STEERING COLUMN

ST-11

Page 13 of 24

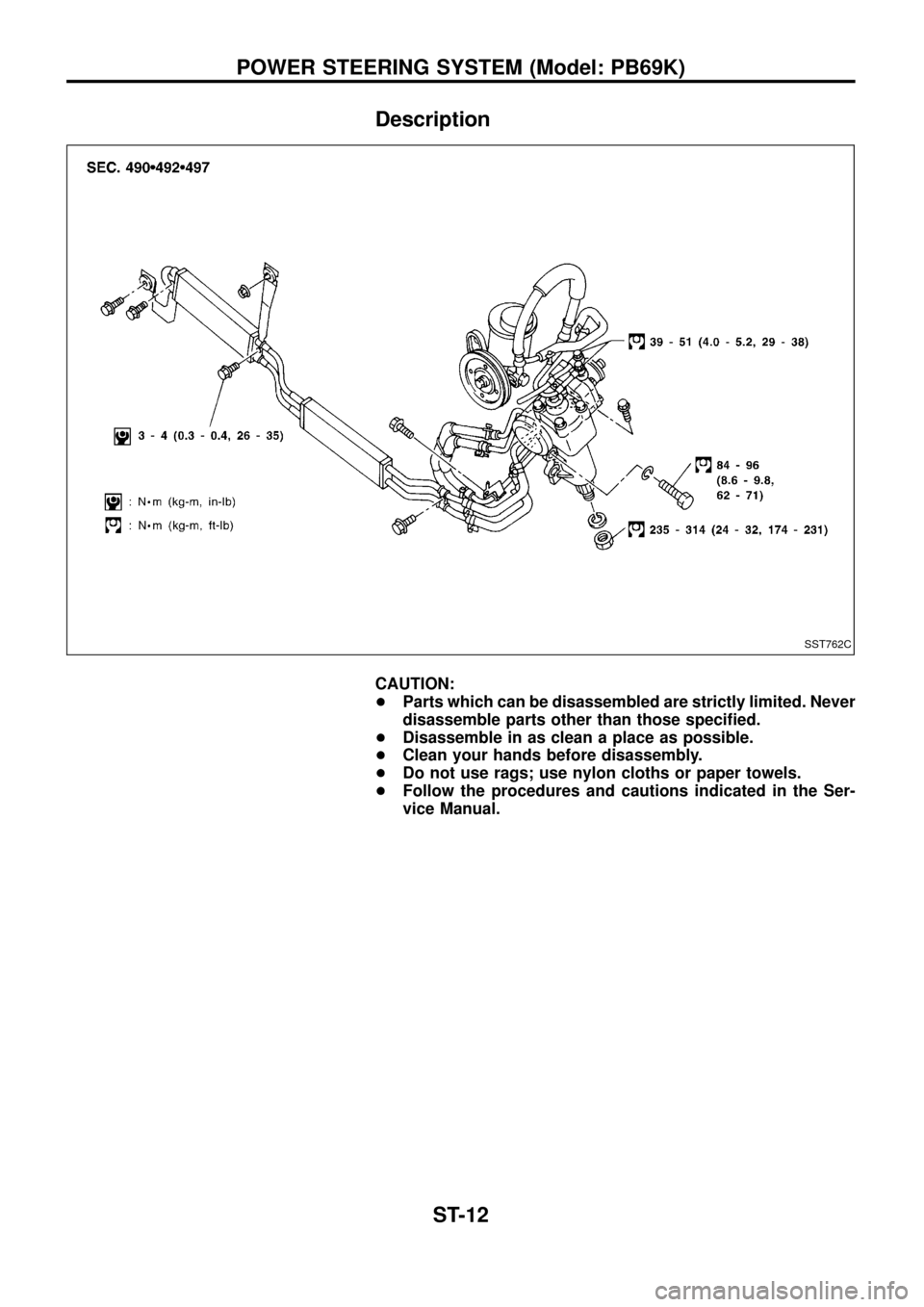

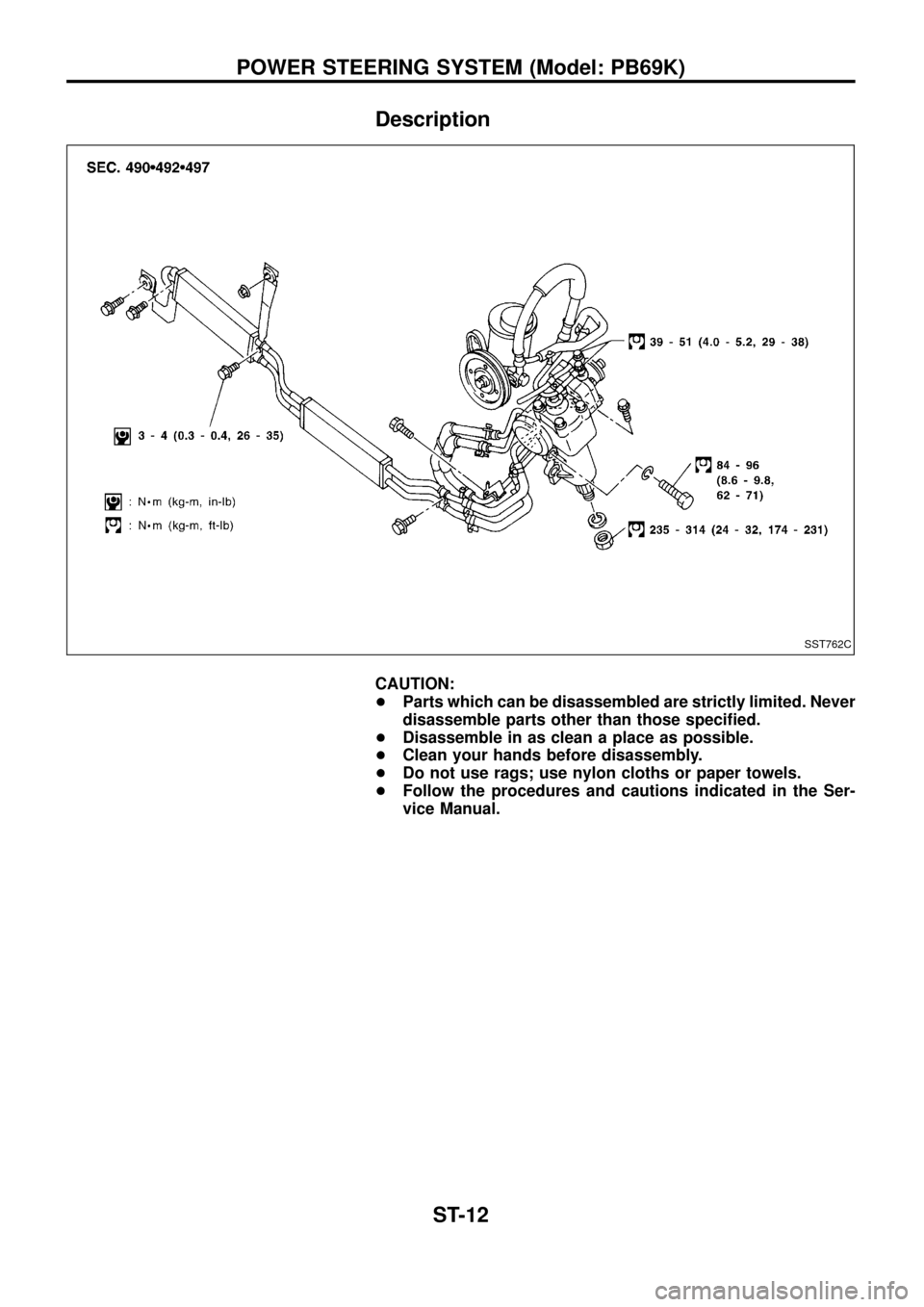

Description

CAUTION:

+Parts which can be disassembled are strictly limited. Never

disassemble parts other than those speci®ed.

+Disassemble in as clean a place as possible.

+Clean your hands before disassembly.

+Do not use rags; use nylon cloths or paper towels.

+Follow the procedures and cautions indicated in the Ser-

vice Manual.

SST762C

POWER STEERING SYSTEM (Model: PB69K)

ST-12

Page 14 of 24

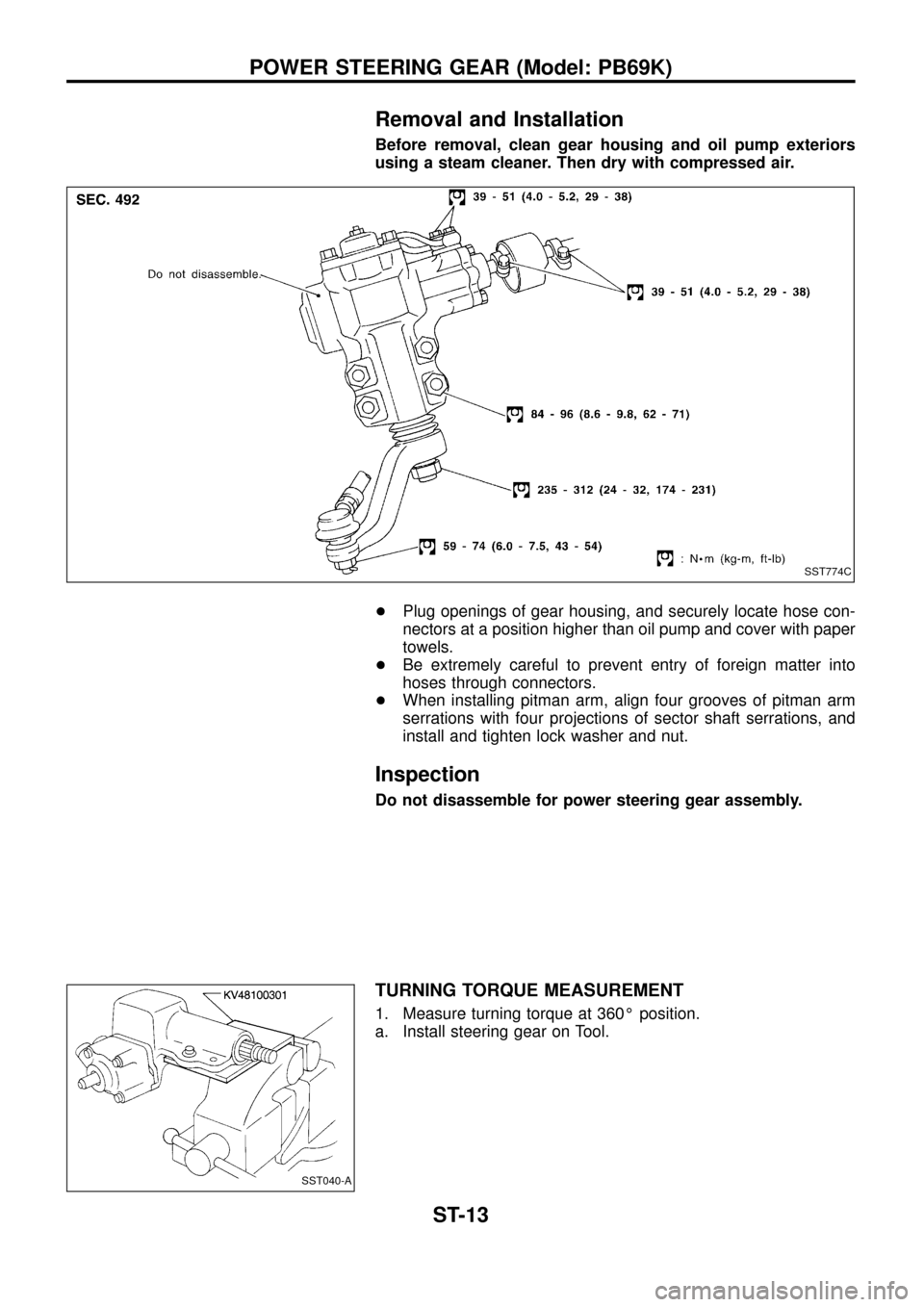

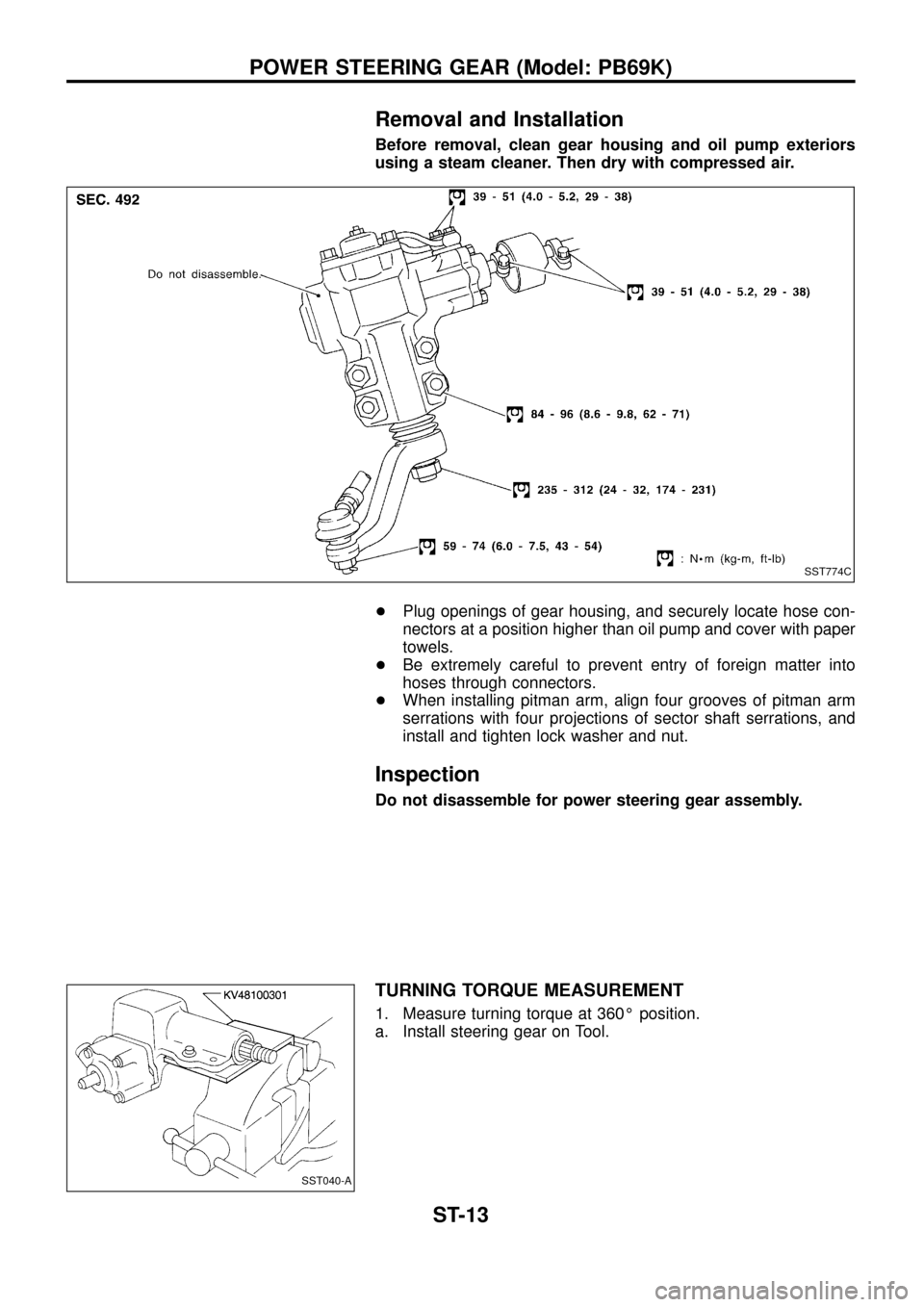

Removal and Installation

Before removal, clean gear housing and oil pump exteriors

using a steam cleaner. Then dry with compressed air.

+Plug openings of gear housing, and securely locate hose con-

nectors at a position higher than oil pump and cover with paper

towels.

+Be extremely careful to prevent entry of foreign matter into

hoses through connectors.

+When installing pitman arm, align four grooves of pitman arm

serrations with four projections of sector shaft serrations, and

install and tighten lock washer and nut.

Inspection

Do not disassemble for power steering gear assembly.

TURNING TORQUE MEASUREMENT

1. Measure turning torque at 360É position.

a. Install steering gear on Tool.

SST774C

SST040-A

POWER STEERING GEAR (Model: PB69K)

ST-13

Page 15 of 24

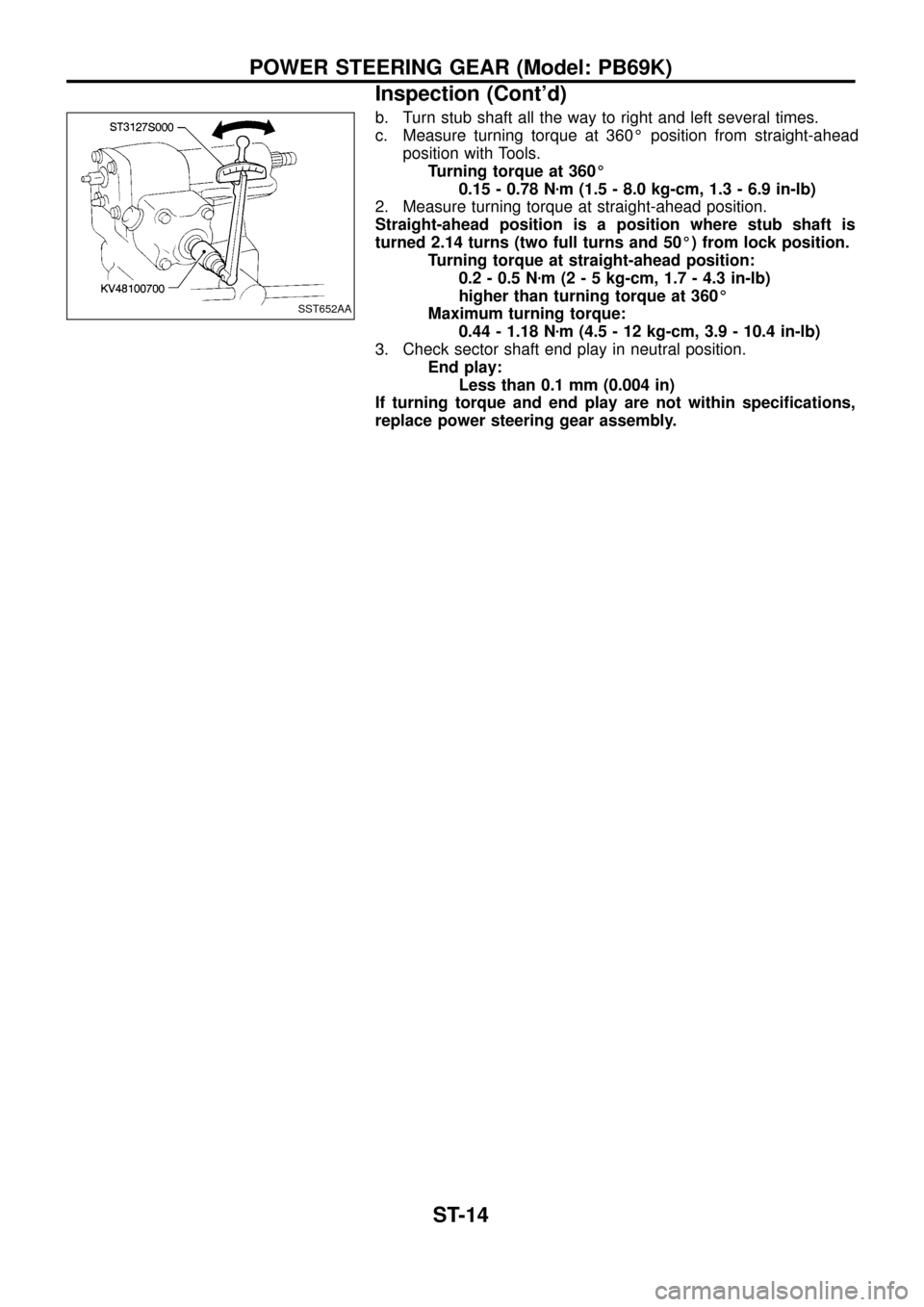

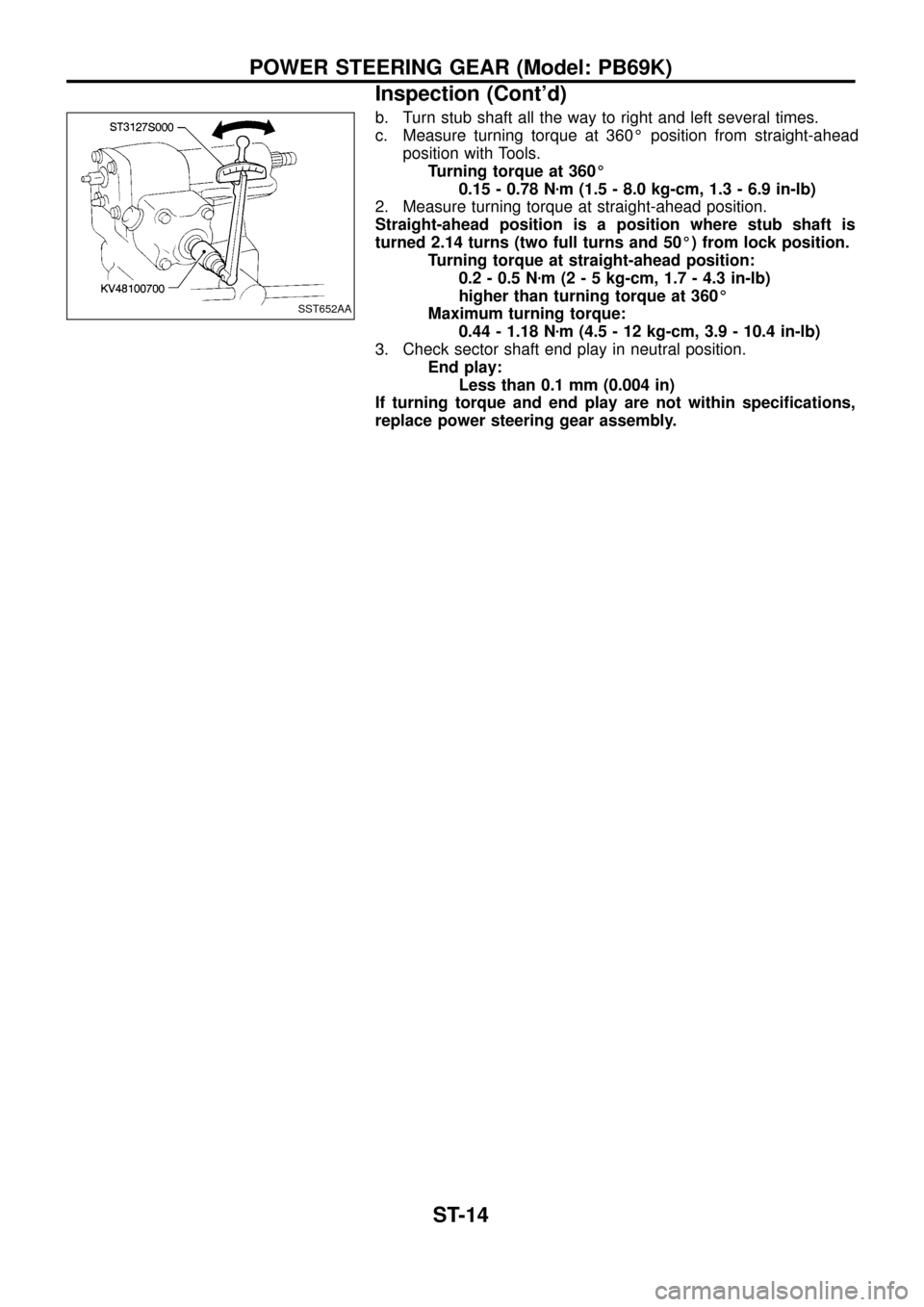

b. Turn stub shaft all the way to right and left several times.

c. Measure turning torque at 360É position from straight-ahead

position with Tools.

Turning torque at 360É

0.15 - 0.78 Nzm (1.5 - 8.0 kg-cm, 1.3 - 6.9 in-lb)

2. Measure turning torque at straight-ahead position.

Straight-ahead position is a position where stub shaft is

turned 2.14 turns (two full turns and 50É) from lock position.

Turning torque at straight-ahead position:

0.2 - 0.5 Nzm (2 - 5 kg-cm, 1.7 - 4.3 in-lb)

higher than turning torque at 360É

Maximum turning torque:

0.44 - 1.18 Nzm (4.5 - 12 kg-cm, 3.9 - 10.4 in-lb)

3. Check sector shaft end play in neutral position.

End play:

Less than 0.1 mm (0.004 in)

If turning torque and end play are not within speci®cations,

replace power steering gear assembly.

SST652AA

POWER STEERING GEAR (Model: PB69K)

Inspection (Cont'd)

ST-14

Page 16 of 24

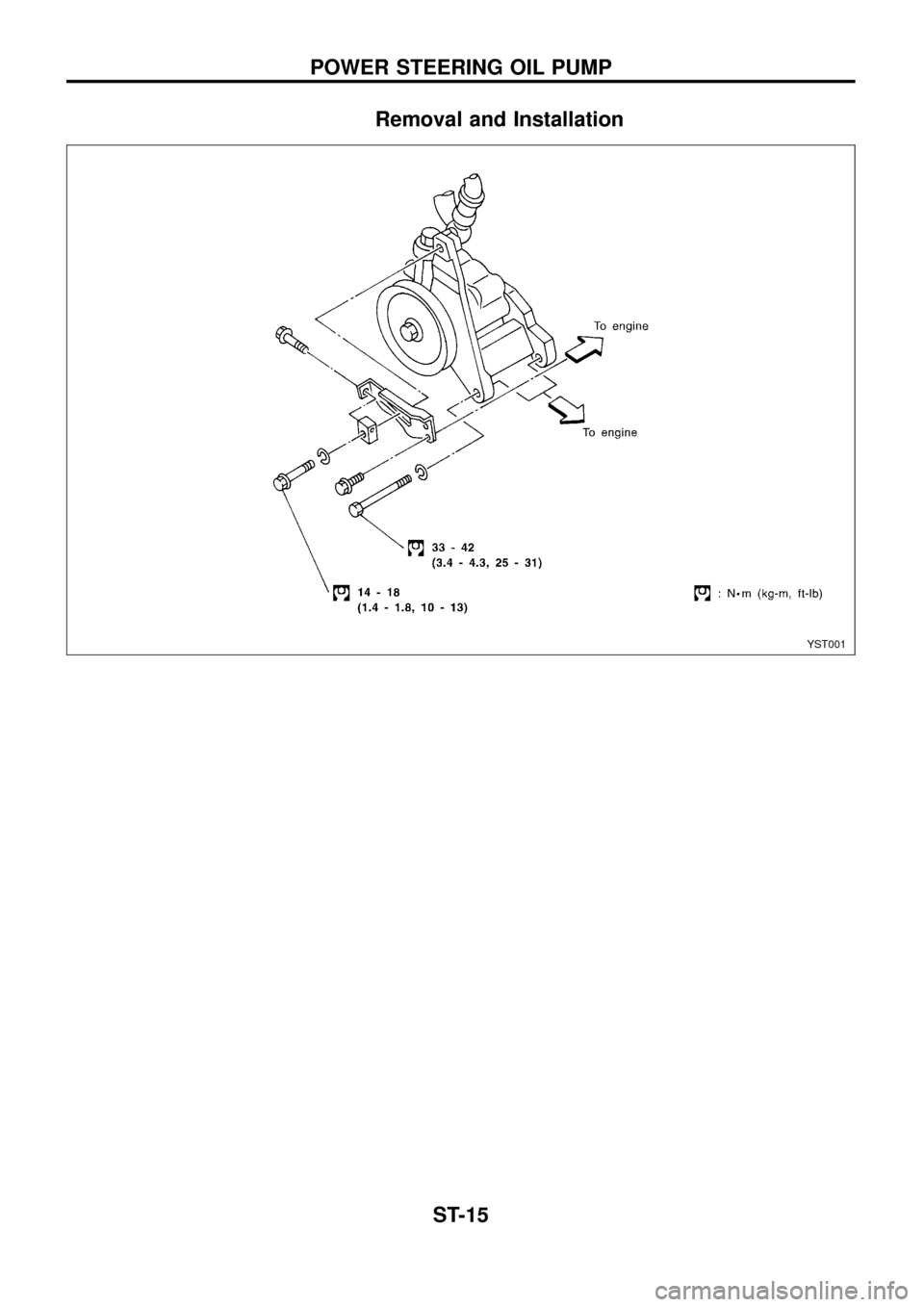

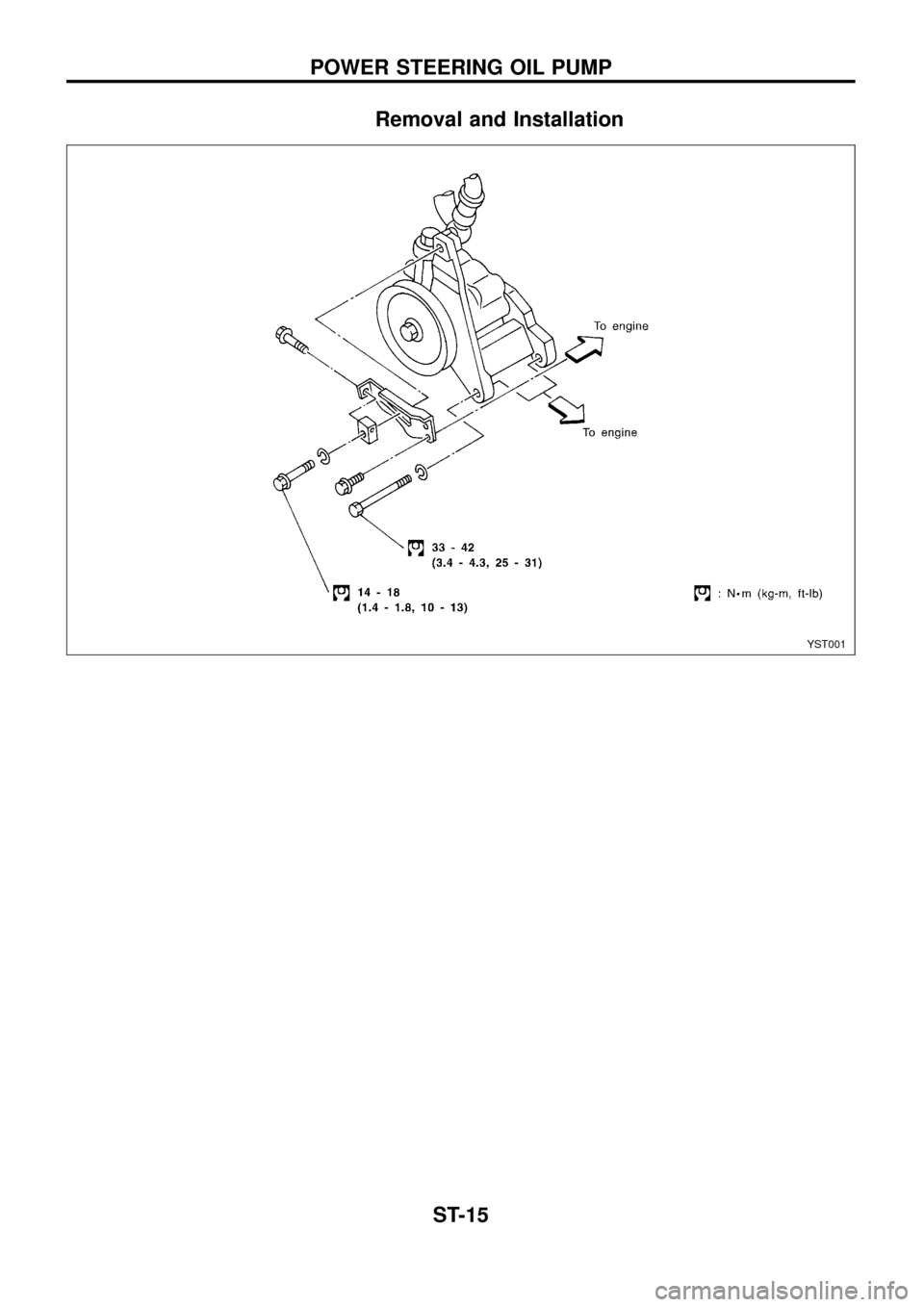

Removal and Installation

YST001

POWER STEERING OIL PUMP

ST-15

Page 17 of 24

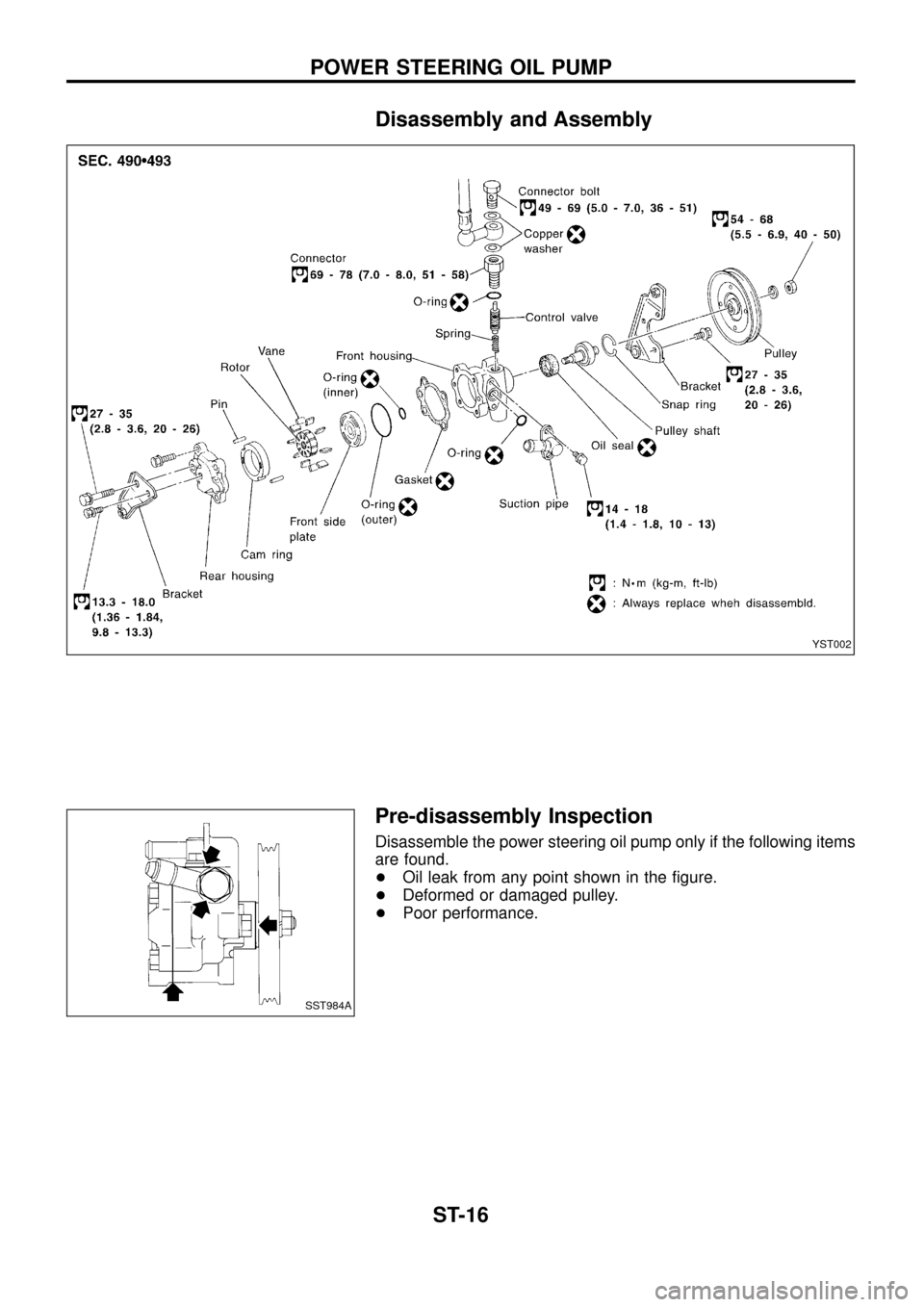

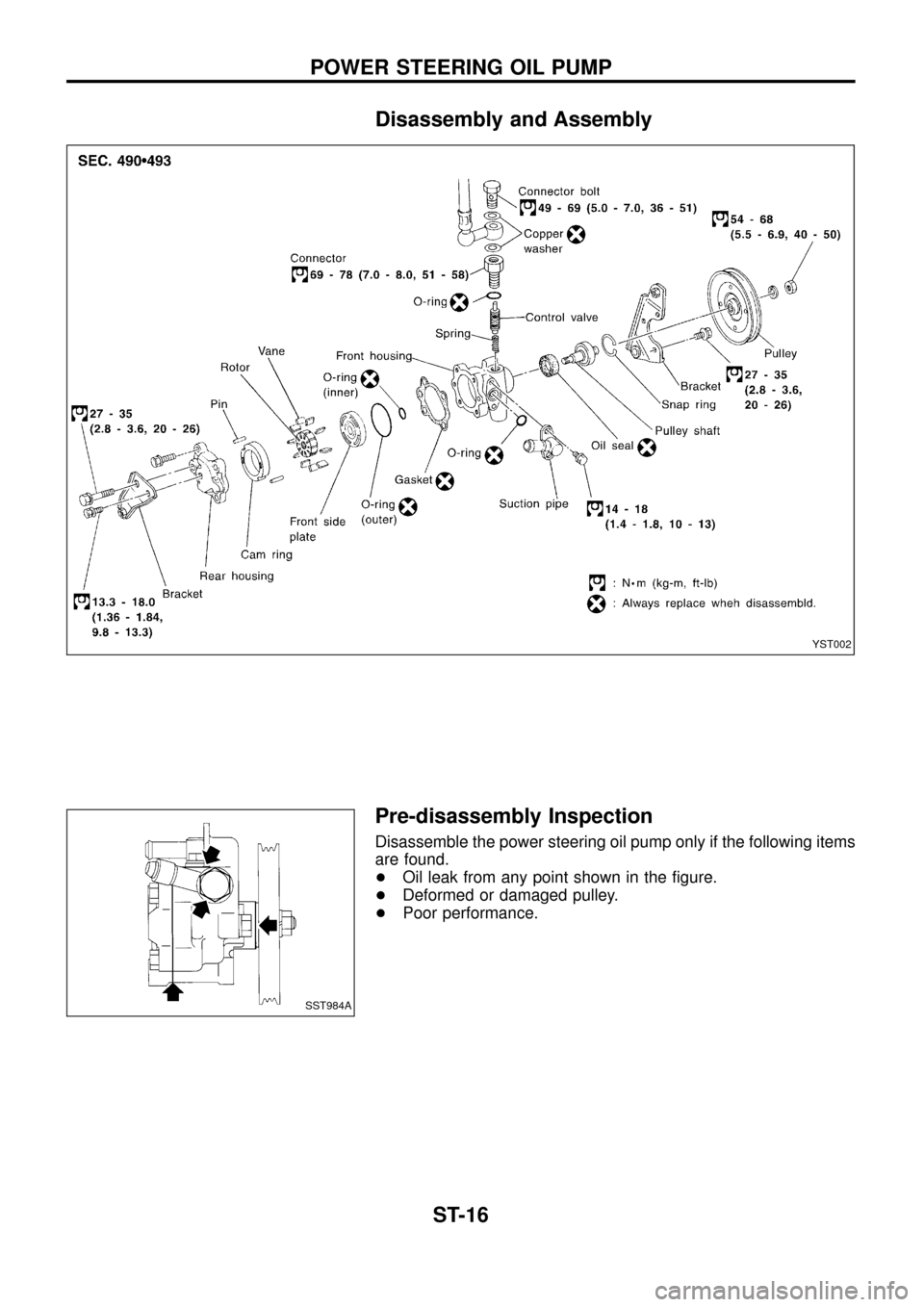

Disassembly and Assembly

Pre-disassembly Inspection

Disassemble the power steering oil pump only if the following items

are found.

+Oil leak from any point shown in the ®gure.

+Deformed or damaged pulley.

+Poor performance.

YST002

SST984A

POWER STEERING OIL PUMP

ST-16

Page 18 of 24

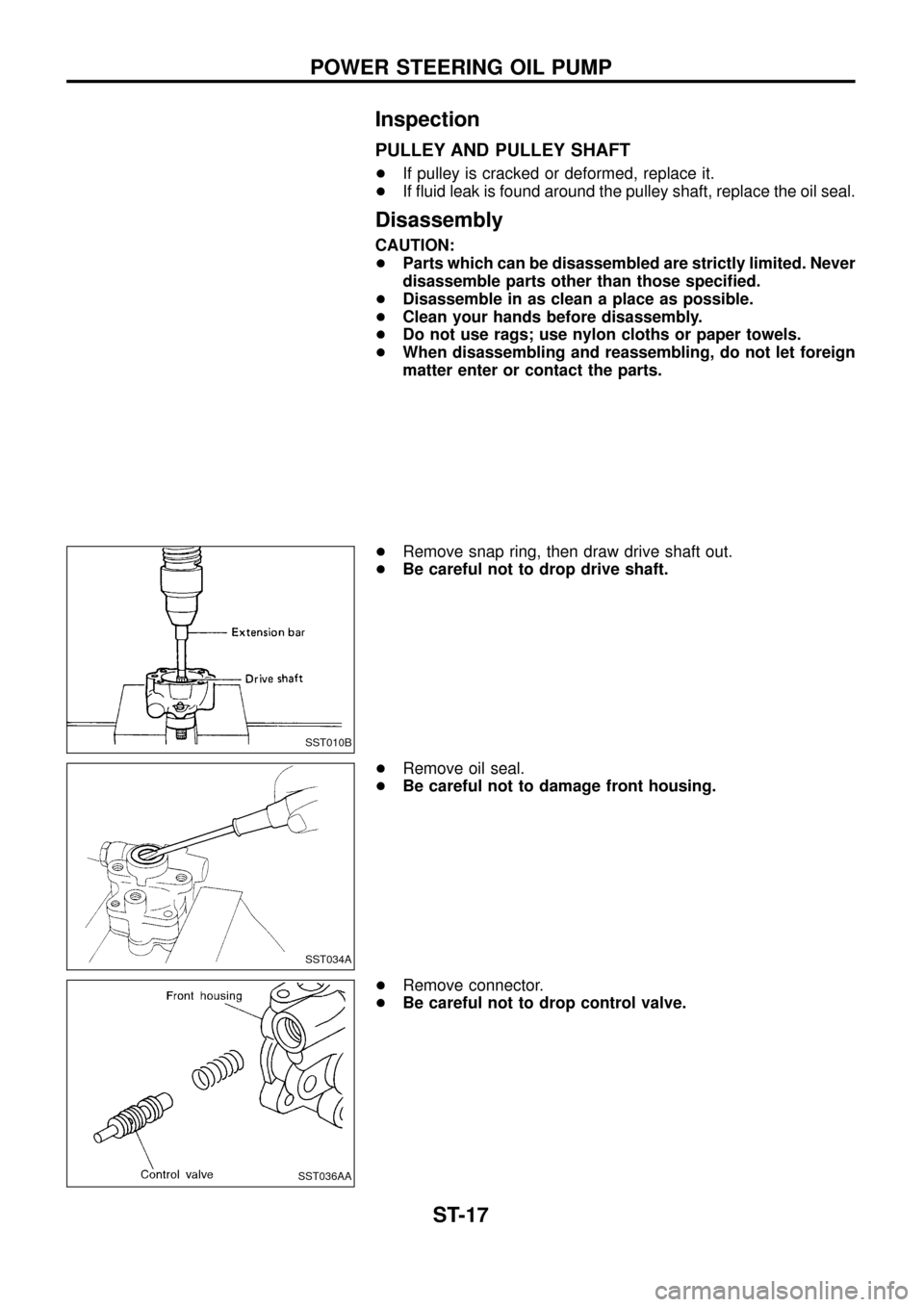

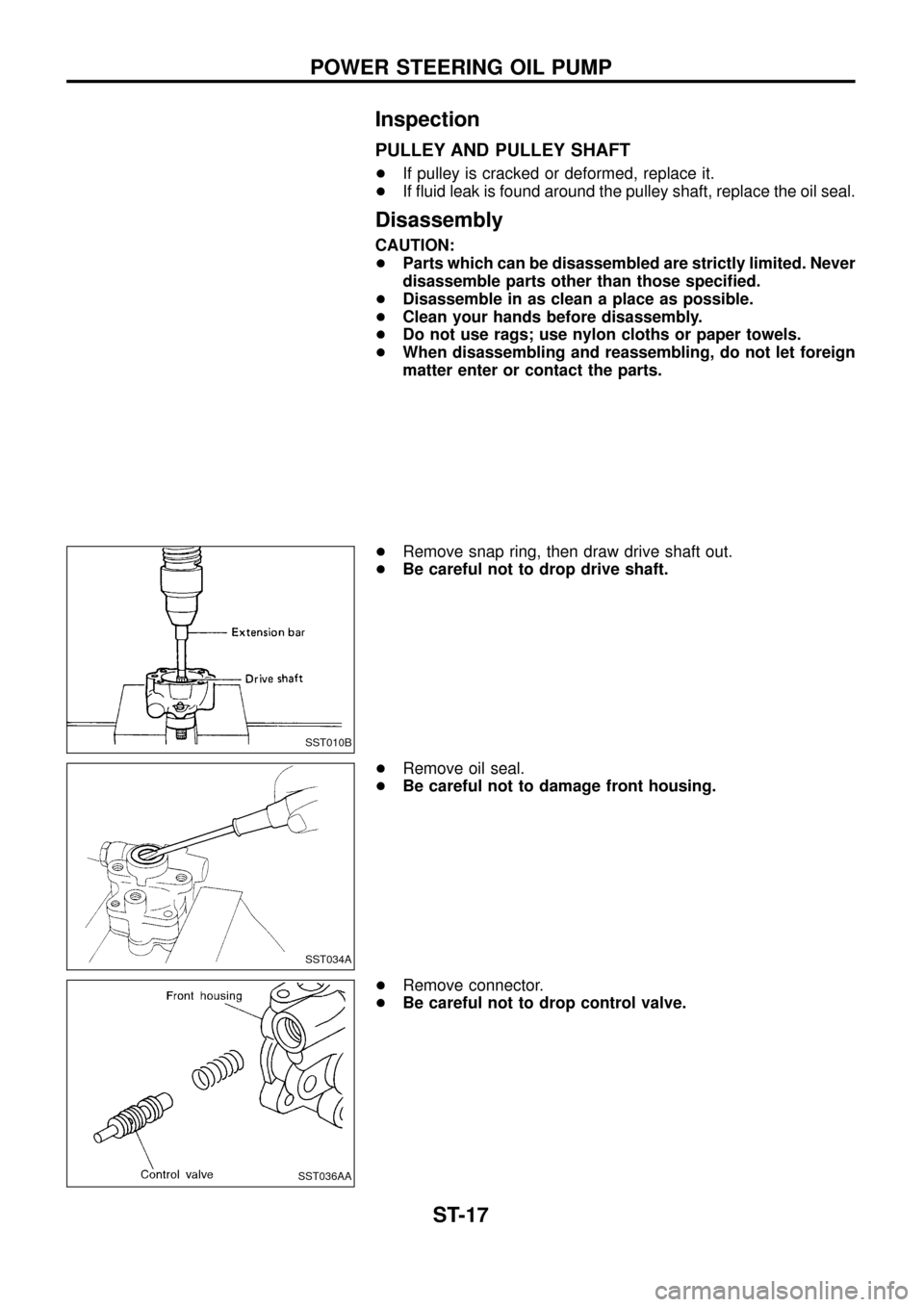

Inspection

PULLEY AND PULLEY SHAFT

+If pulley is cracked or deformed, replace it.

+If ¯uid leak is found around the pulley shaft, replace the oil seal.

Disassembly

CAUTION:

+Parts which can be disassembled are strictly limited. Never

disassemble parts other than those speci®ed.

+Disassemble in as clean a place as possible.

+Clean your hands before disassembly.

+Do not use rags; use nylon cloths or paper towels.

+When disassembling and reassembling, do not let foreign

matter enter or contact the parts.

+Remove snap ring, then draw drive shaft out.

+Be careful not to drop drive shaft.

+Remove oil seal.

+Be careful not to damage front housing.

+Remove connector.

+Be careful not to drop control valve.

SST010B

SST034A

SST036AA

POWER STEERING OIL PUMP

ST-17

Page 19 of 24

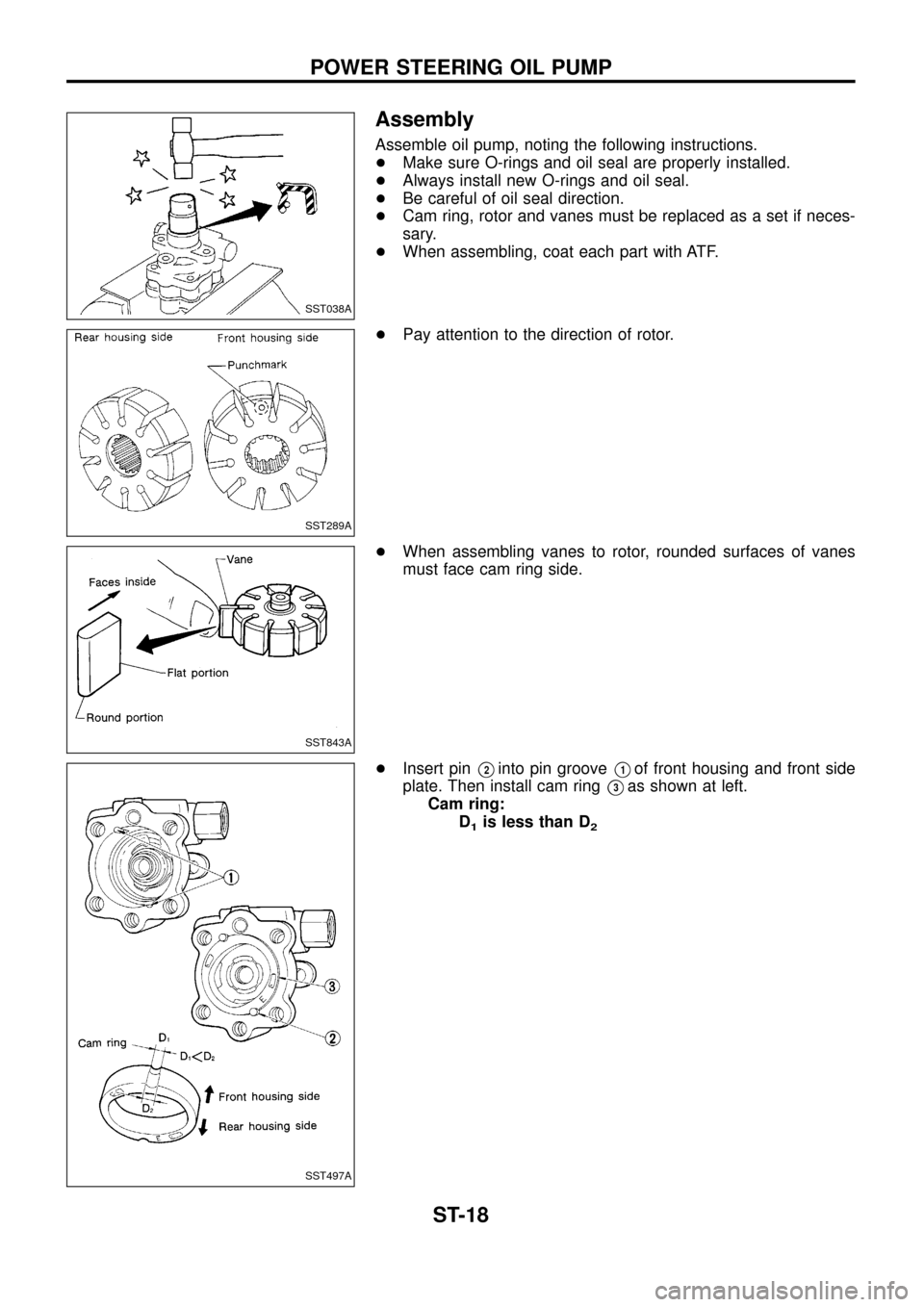

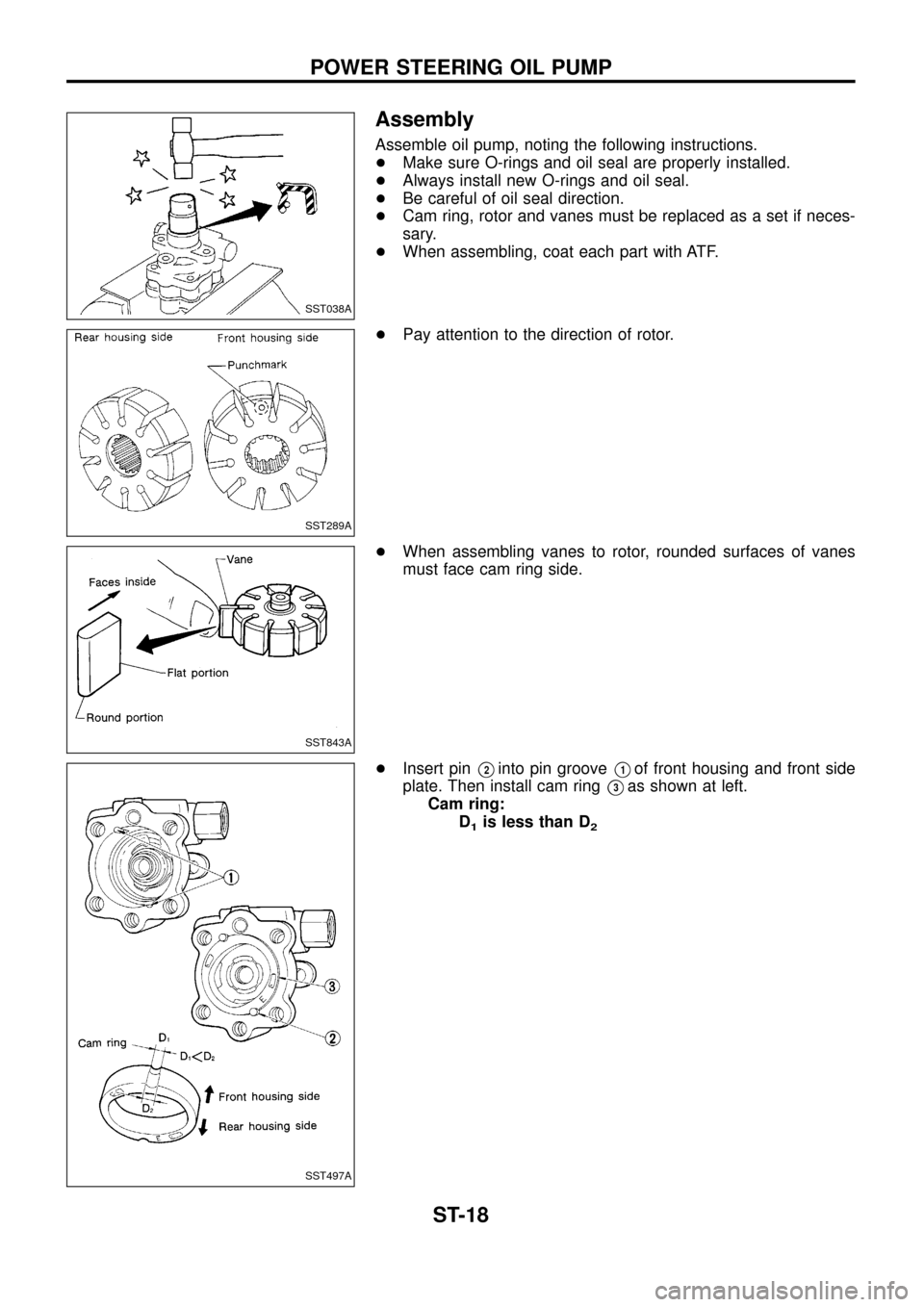

Assembly

Assemble oil pump, noting the following instructions.

+Make sure O-rings and oil seal are properly installed.

+Always install new O-rings and oil seal.

+Be careful of oil seal direction.

+Cam ring, rotor and vanes must be replaced as a set if neces-

sary.

+When assembling, coat each part with ATF.

+Pay attention to the direction of rotor.

+When assembling vanes to rotor, rounded surfaces of vanes

must face cam ring side.

+Insert pin

V2into pin grooveV1of front housing and front side

plate. Then install cam ring

V3as shown at left.

Cam ring:

D

1is less than D2

SST038A

SST289A

SST843A

SST497A

POWER STEERING OIL PUMP

ST-18

Page 20 of 24

Removal and Installation

+Remove pitman arm with tool.

+Remove steering damper.

+Remove tie-rod and drag link with Tool.

SST766C

SST100-B

SST767C

STEERING LINKAGE

ST-19

Trending: air bleeding, tire pressure, oil, check engine, differential, brake, wheel alignment