engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 764 of 1033

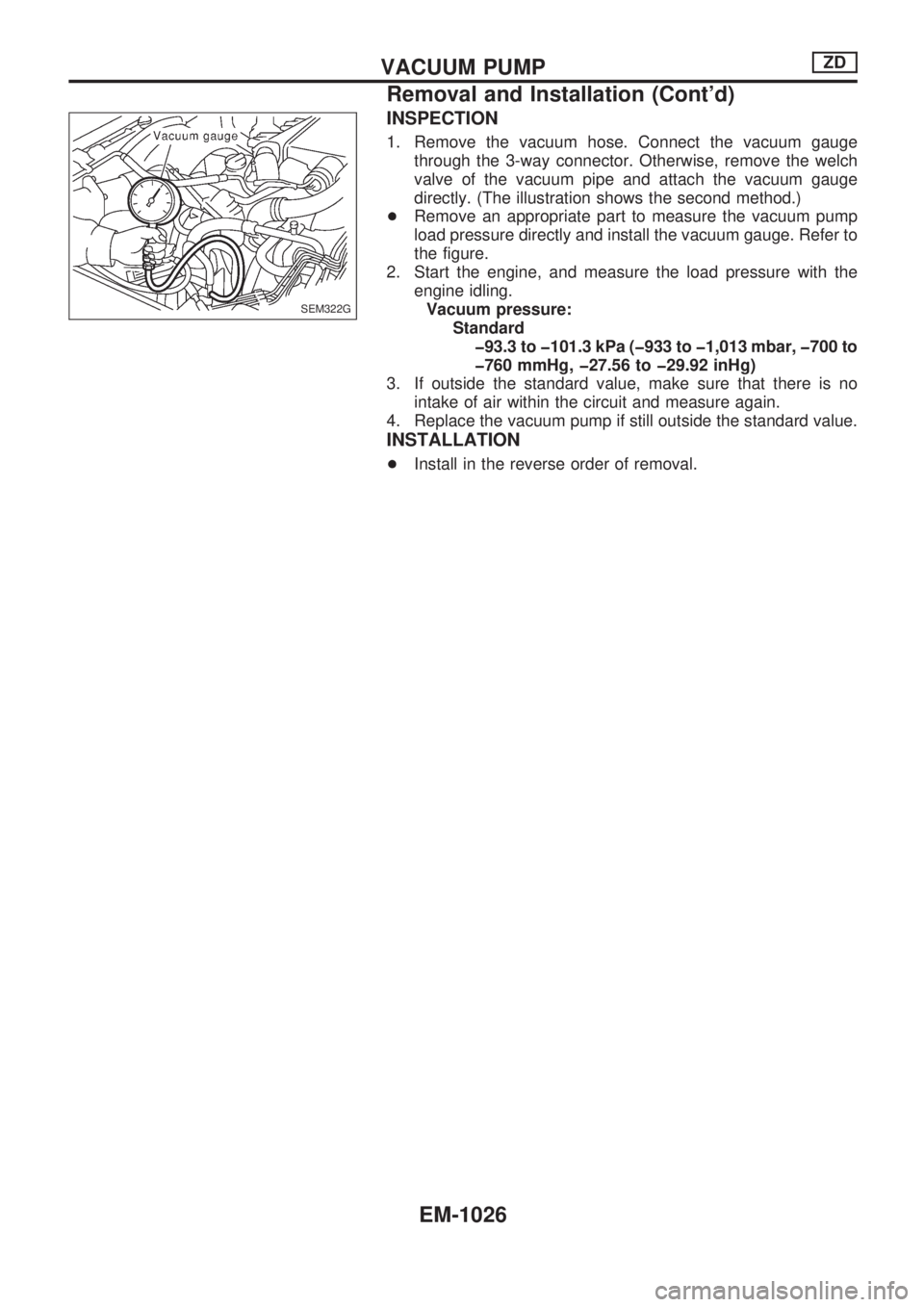

INSPECTION

1. Remove the vacuum hose. Connect the vacuum gauge

through the 3-way connector. Otherwise, remove the welch

valve of the vacuum pipe and attach the vacuum gauge

directly. (The illustration shows the second method.)

+Remove an appropriate part to measure the vacuum pump

load pressure directly and install the vacuum gauge. Refer to

the figure.

2. Start the engine, and measure the load pressure with the

engine idling.

Vacuum pressure:

Standard

þ93.3 to þ101.3 kPa (þ933 to þ1,013 mbar, þ700 to

þ760 mmHg, þ27.56 to þ29.92 inHg)

3. If outside the standard value, make sure that there is no

intake of air within the circuit and measure again.

4. Replace the vacuum pump if still outside the standard value.

INSTALLATION

+Install in the reverse order of removal.

SEM322G

VACUUM PUMPZD

Removal and Installation (Cont'd)

EM-1026

Page 765 of 1033

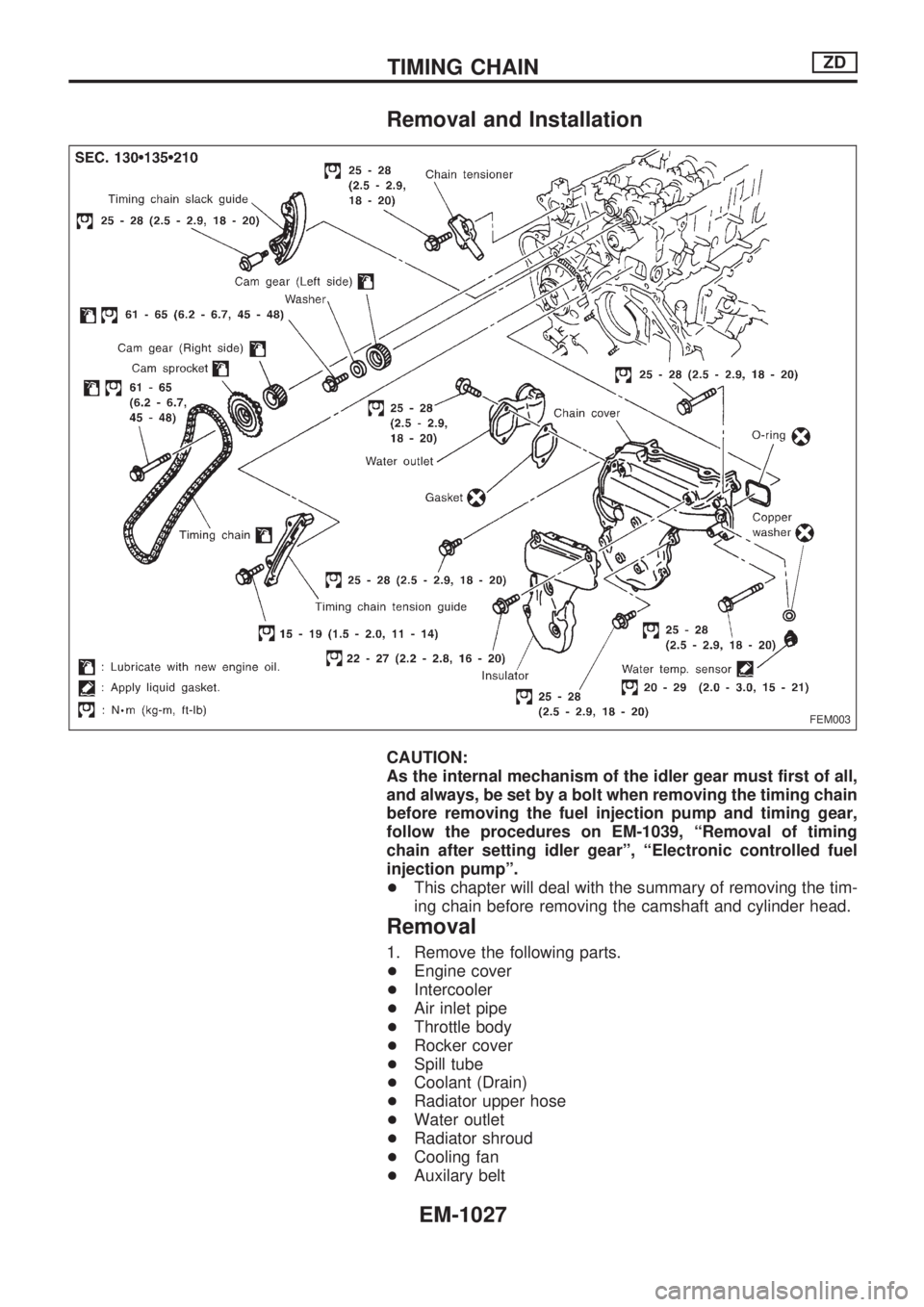

Removal and Installation

CAUTION:

As the internal mechanism of the idler gear must first of all,

and always, be set by a bolt when removing the timing chain

before removing the fuel injection pump and timing gear,

follow the procedures on EM-1039, ªRemoval of timing

chain after setting idler gearº, ªElectronic controlled fuel

injection pumpº.

+This chapter will deal with the summary of removing the tim-

ing chain before removing the camshaft and cylinder head.

Removal

1. Remove the following parts.

+Engine cover

+Intercooler

+Air inlet pipe

+Throttle body

+Rocker cover

+Spill tube

+Coolant (Drain)

+Radiator upper hose

+Water outlet

+Radiator shroud

+Cooling fan

+Auxilary belt

FEM003

TIMING CHAINZD

EM-1027

Page 767 of 1033

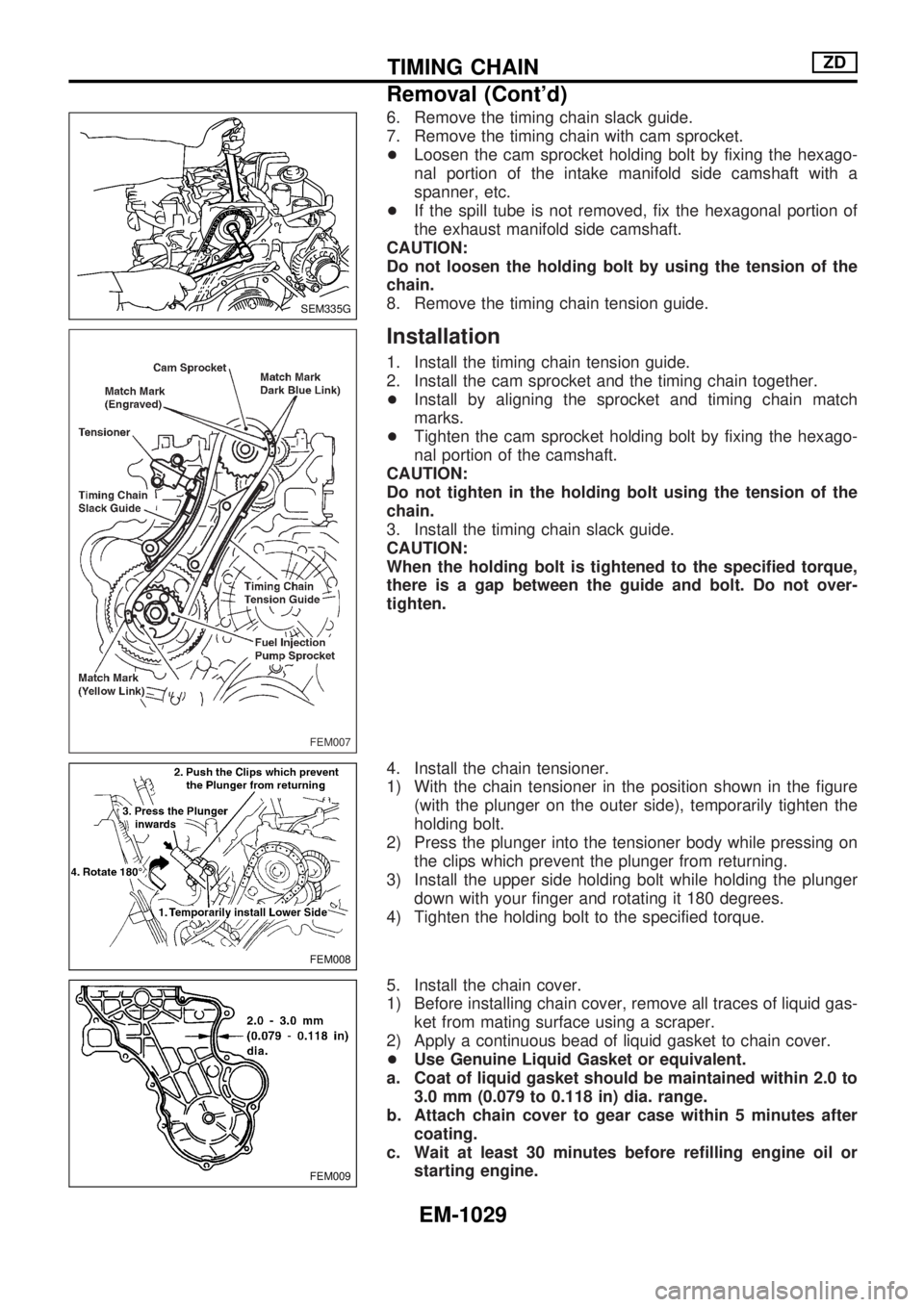

6. Remove the timing chain slack guide.

7. Remove the timing chain with cam sprocket.

+Loosen the cam sprocket holding bolt by fixing the hexago-

nal portion of the intake manifold side camshaft with a

spanner, etc.

+If the spill tube is not removed, fix the hexagonal portion of

the exhaust manifold side camshaft.

CAUTION:

Do not loosen the holding bolt by using the tension of the

chain.

8. Remove the timing chain tension guide.

Installation

1. Install the timing chain tension guide.

2. Install the cam sprocket and the timing chain together.

+Install by aligning the sprocket and timing chain match

marks.

+Tighten the cam sprocket holding bolt by fixing the hexago-

nal portion of the camshaft.

CAUTION:

Do not tighten in the holding bolt using the tension of the

chain.

3. Install the timing chain slack guide.

CAUTION:

When the holding bolt is tightened to the specified torque,

there is a gap between the guide and bolt. Do not over-

tighten.

4. Install the chain tensioner.

1) With the chain tensioner in the position shown in the figure

(with the plunger on the outer side), temporarily tighten the

holding bolt.

2) Press the plunger into the tensioner body while pressing on

the clips which prevent the plunger from returning.

3) Install the upper side holding bolt while holding the plunger

down with your finger and rotating it 180 degrees.

4) Tighten the holding bolt to the specified torque.

5. Install the chain cover.

1) Before installing chain cover, remove all traces of liquid gas-

ket from mating surface using a scraper.

2) Apply a continuous bead of liquid gasket to chain cover.

+Use Genuine Liquid Gasket or equivalent.

a. Coat of liquid gasket should be maintained within 2.0 to

3.0 mm (0.079 to 0.118 in) dia. range.

b. Attach chain cover to gear case within 5 minutes after

coating.

c. Wait at least 30 minutes before refilling engine oil or

starting engine.

SEM335G

FEM007

FEM008

FEM009

TIMING CHAINZD

Removal (Cont'd)

EM-1029

Page 769 of 1033

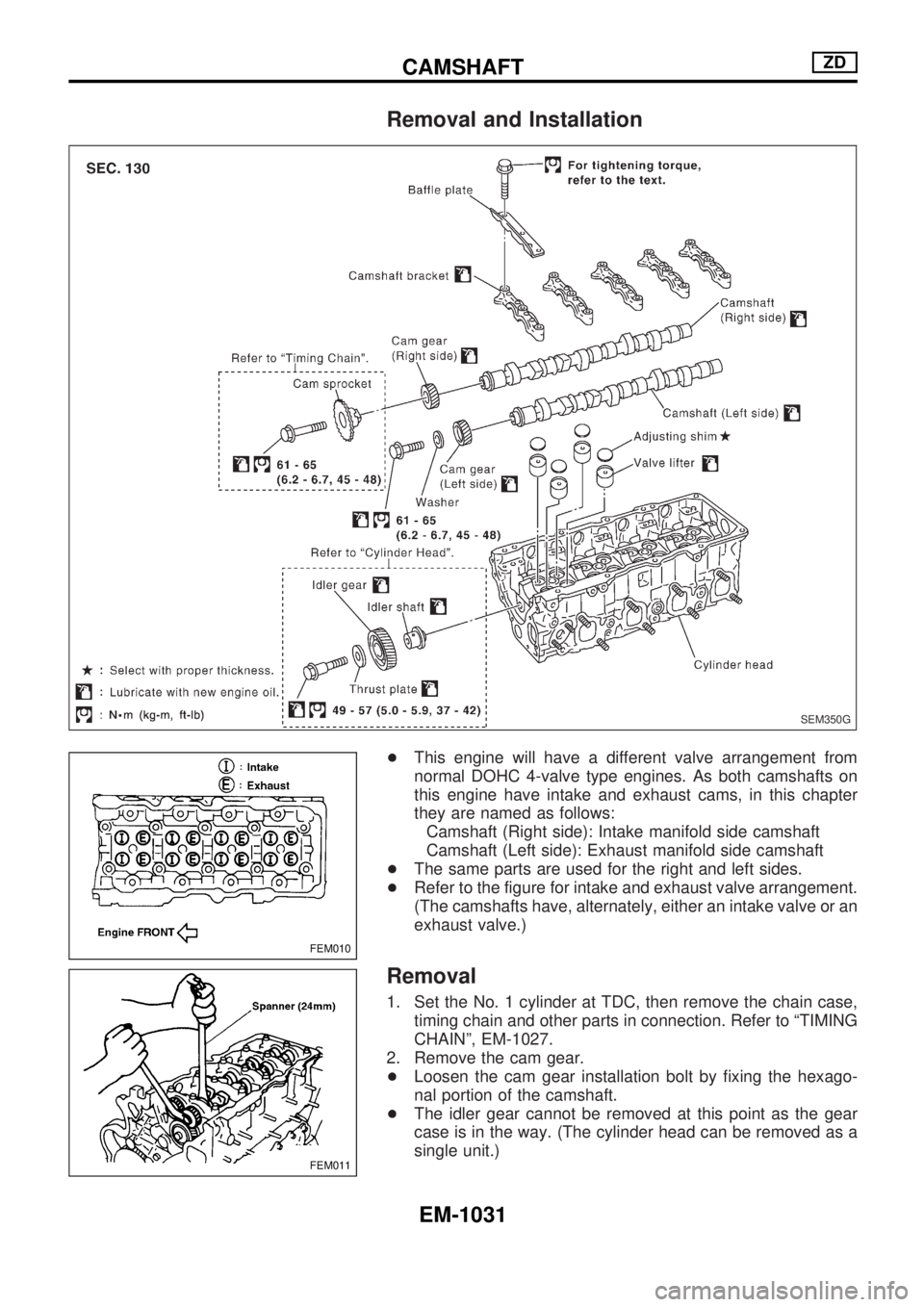

Removal and Installation

+This engine will have a different valve arrangement from

normal DOHC 4-valve type engines. As both camshafts on

this engine have intake and exhaust cams, in this chapter

they are named as follows:

Camshaft (Right side): Intake manifold side camshaft

Camshaft (Left side): Exhaust manifold side camshaft

+The same parts are used for the right and left sides.

+Refer to the figure for intake and exhaust valve arrangement.

(The camshafts have, alternately, either an intake valve or an

exhaust valve.)

Removal

1. Set the No. 1 cylinder at TDC, then remove the chain case,

timing chain and other parts in connection. Refer to ªTIMING

CHAINº, EM-1027.

2. Remove the cam gear.

+Loosen the cam gear installation bolt by fixing the hexago-

nal portion of the camshaft.

+The idler gear cannot be removed at this point as the gear

case is in the way. (The cylinder head can be removed as a

single unit.)

SEM350G

FEM010

FEM011

CAMSHAFTZD

EM-1031

Page 770 of 1033

3. Remove injection tube and injection nozzle assembly. Refer

to EC section, ªInjection Tube and Injection Nozzleº in

ªBASIC SERVICE PROCEDUREº.

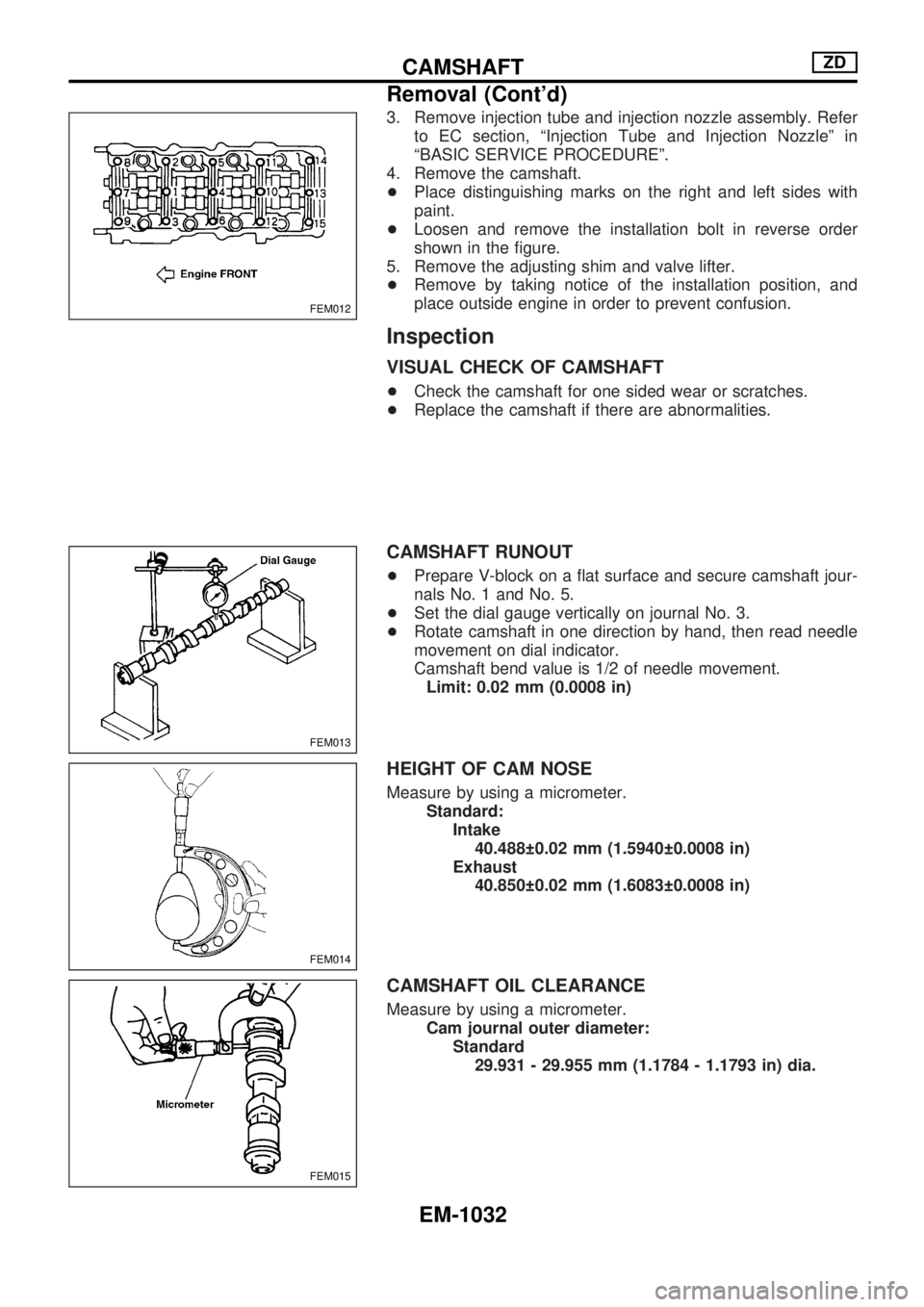

4. Remove the camshaft.

+Place distinguishing marks on the right and left sides with

paint.

+Loosen and remove the installation bolt in reverse order

shown in the figure.

5. Remove the adjusting shim and valve lifter.

+Remove by taking notice of the installation position, and

place outside engine in order to prevent confusion.

Inspection

VISUAL CHECK OF CAMSHAFT

+Check the camshaft for one sided wear or scratches.

+Replace the camshaft if there are abnormalities.

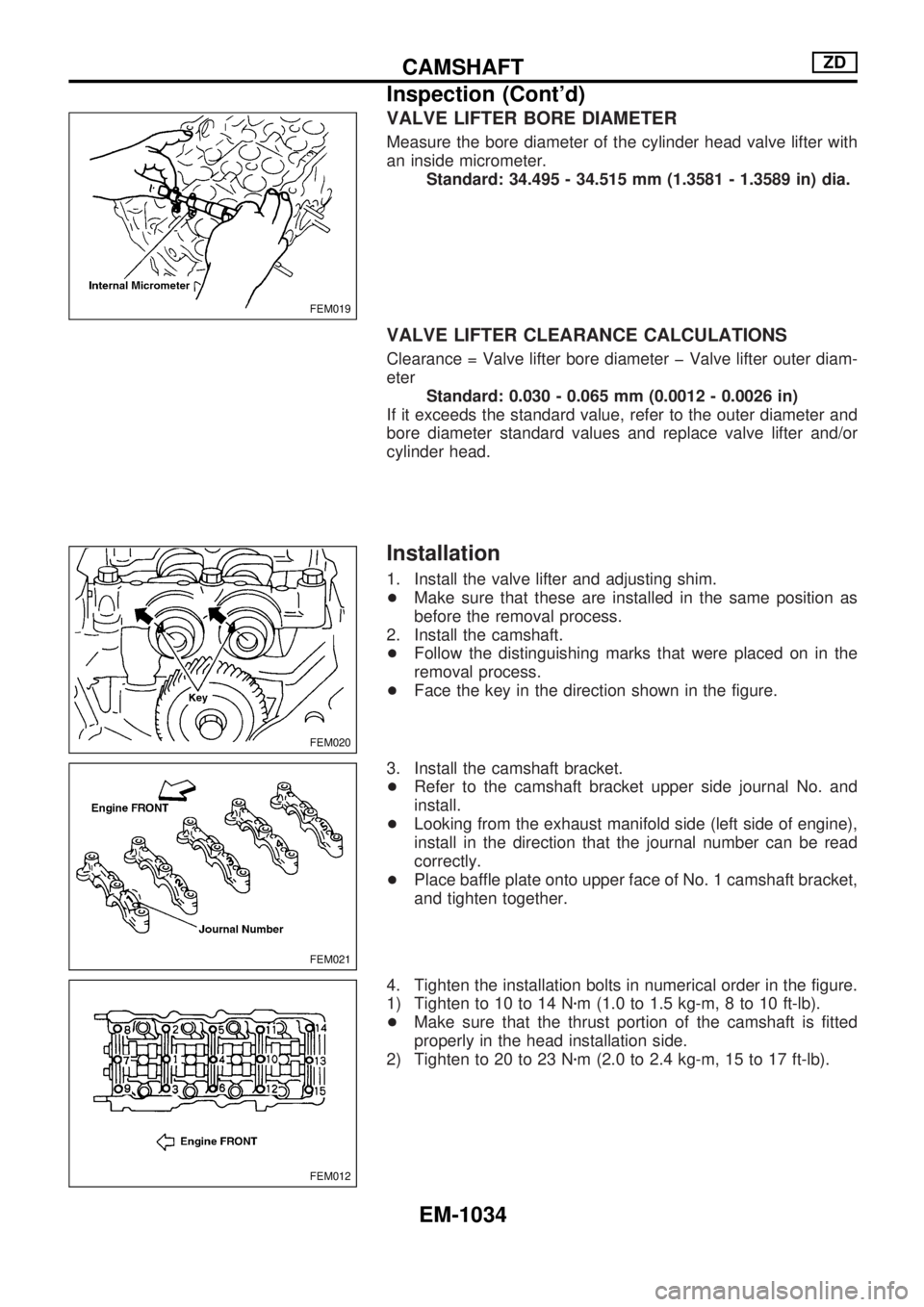

CAMSHAFT RUNOUT

+Prepare V-block on a flat surface and secure camshaft jour-

nals No. 1 and No. 5.

+Set the dial gauge vertically on journal No. 3.

+Rotate camshaft in one direction by hand, then read needle

movement on dial indicator.

Camshaft bend value is 1/2 of needle movement.

Limit: 0.02 mm (0.0008 in)

HEIGHT OF CAM NOSE

Measure by using a micrometer.

Standard:

Intake

40.488 0.02 mm (1.5940 0.0008 in)

Exhaust

40.850 0.02 mm (1.6083 0.0008 in)

CAMSHAFT OIL CLEARANCE

Measure by using a micrometer.

Cam journal outer diameter:

Standard

29.931 - 29.955 mm (1.1784 - 1.1793 in) dia.

FEM012

FEM013

FEM014

FEM015

CAMSHAFTZD

Removal (Cont'd)

EM-1032

Page 772 of 1033

VALVE LIFTER BORE DIAMETER

Measure the bore diameter of the cylinder head valve lifter with

an inside micrometer.

Standard: 34.495 - 34.515 mm (1.3581 - 1.3589 in) dia.

VALVE LIFTER CLEARANCE CALCULATIONS

Clearance = Valve lifter bore diameter þ Valve lifter outer diam-

eter

Standard: 0.030 - 0.065 mm (0.0012 - 0.0026 in)

If it exceeds the standard value, refer to the outer diameter and

bore diameter standard values and replace valve lifter and/or

cylinder head.

Installation

1. Install the valve lifter and adjusting shim.

+Make sure that these are installed in the same position as

before the removal process.

2. Install the camshaft.

+Follow the distinguishing marks that were placed on in the

removal process.

+Face the key in the direction shown in the figure.

3. Install the camshaft bracket.

+Refer to the camshaft bracket upper side journal No. and

install.

+Looking from the exhaust manifold side (left side of engine),

install in the direction that the journal number can be read

correctly.

+Place baffle plate onto upper face of No. 1 camshaft bracket,

and tighten together.

4. Tighten the installation bolts in numerical order in the figure.

1) Tighten to 10 to 14 Nzm (1.0 to 1.5 kg-m, 8 to 10 ft-lb).

+Make sure that the thrust portion of the camshaft is fitted

properly in the head installation side.

2) Tighten to 20 to 23 Nzm (2.0 to 2.4 kg-m, 15 to 17 ft-lb).

FEM019

FEM020

FEM021

FEM012

CAMSHAFTZD

Inspection (Cont'd)

EM-1034

Page 774 of 1033

Inspection

+When the camshaft or parts in connection with valves are

removed or replaced, and a fault has occurred (poor starting,

idling, or other faults) due to the misadjustment of the valve

clearance, inspect as follows.

+Inspect and adjust when the engine is cool (at normal tem-

perature).

+Be careful of the intake and exhaust valve arrangement. (The

valve arrangement is different from that in a normal engine.)

(The camshafts have, alternately, either an intake valve or an

exhaust valve.)

1. Remove the following parts.

+Intercooler cover

+Intercooler

+Rocker cover

2. Set the No. 1 cylinder at TDC.

1) Rotate the crankshaft pulley clockwise, and align the TDC

mark of the crankshaft pulley with the timing indicator of the

TDC sensor bracket.

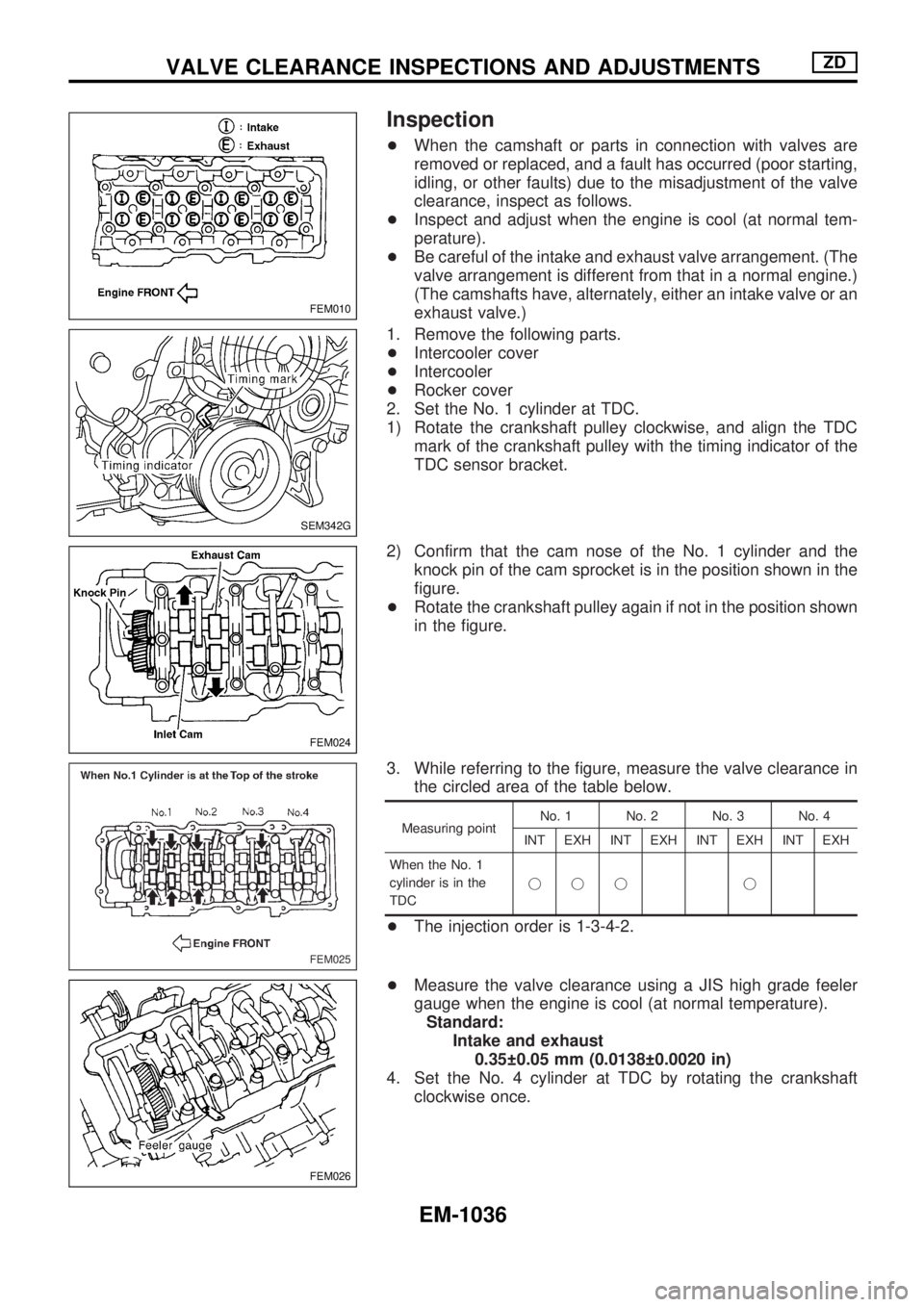

2) Confirm that the cam nose of the No. 1 cylinder and the

knock pin of the cam sprocket is in the position shown in the

figure.

+Rotate the crankshaft pulley again if not in the position shown

in the figure.

3. While referring to the figure, measure the valve clearance in

the circled area of the table below.

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 1

cylinder is in the

TDCjjj j

+The injection order is 1-3-4-2.

+Measure the valve clearance using a JIS high grade feeler

gauge when the engine is cool (at normal temperature).

Standard:

Intake and exhaust

0.35 0.05 mm (0.0138 0.0020 in)

4. Set the No. 4 cylinder at TDC by rotating the crankshaft

clockwise once.

FEM010

SEM342G

FEM024

FEM025

FEM026

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

EM-1036

Page 775 of 1033

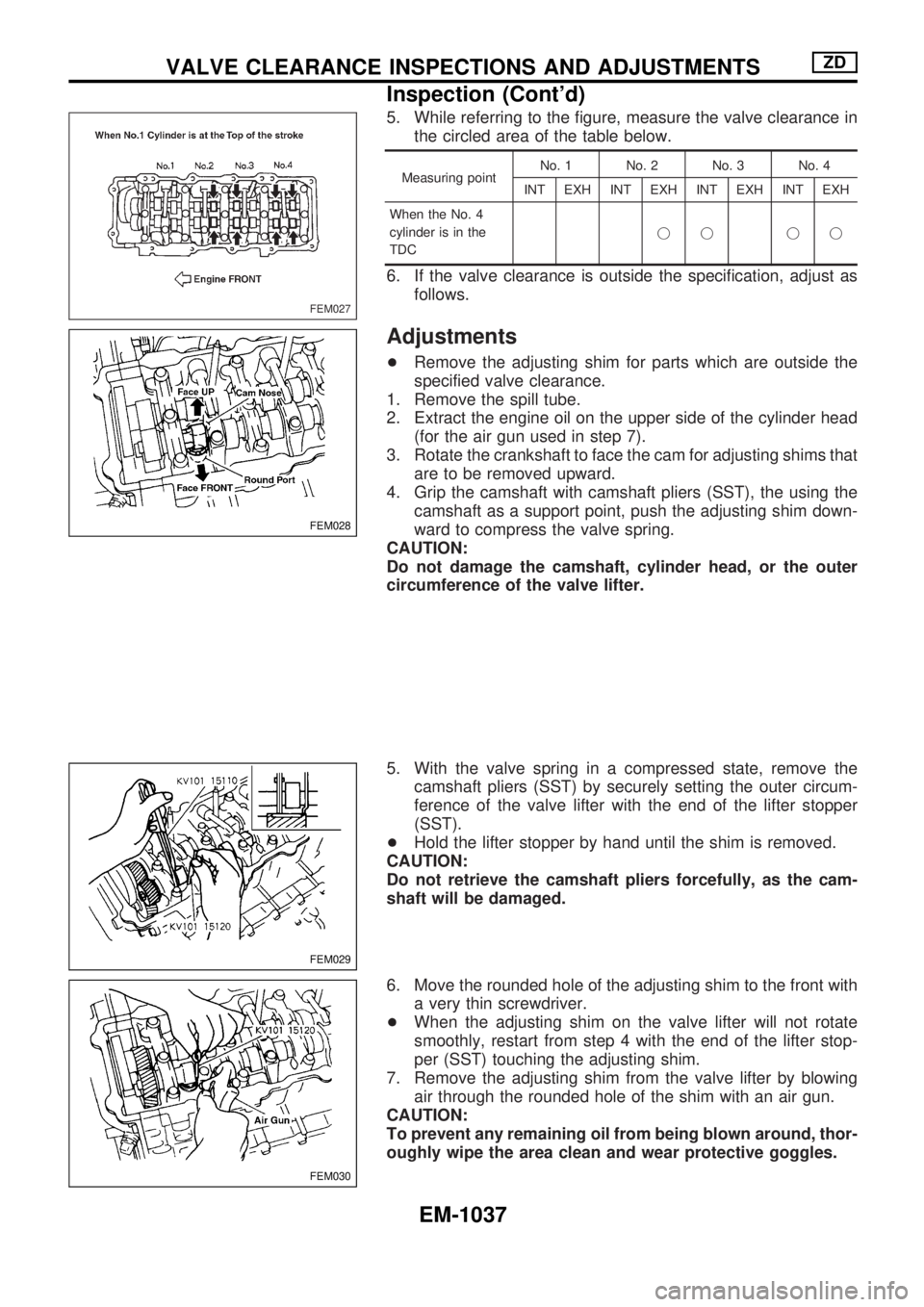

5. While referring to the figure, measure the valve clearance in

the circled area of the table below.

Measuring pointNo. 1 No. 2 No. 3 No. 4

INT EXH INT EXH INT EXH INT EXH

When the No. 4

cylinder is in the

TDCjj jj

6. If the valve clearance is outside the specification, adjust as

follows.

Adjustments

+Remove the adjusting shim for parts which are outside the

specified valve clearance.

1. Remove the spill tube.

2. Extract the engine oil on the upper side of the cylinder head

(for the air gun used in step 7).

3. Rotate the crankshaft to face the cam for adjusting shims that

are to be removed upward.

4. Grip the camshaft with camshaft pliers (SST), the using the

camshaft as a support point, push the adjusting shim down-

ward to compress the valve spring.

CAUTION:

Do not damage the camshaft, cylinder head, or the outer

circumference of the valve lifter.

5. With the valve spring in a compressed state, remove the

camshaft pliers (SST) by securely setting the outer circum-

ference of the valve lifter with the end of the lifter stopper

(SST).

+Hold the lifter stopper by hand until the shim is removed.

CAUTION:

Do not retrieve the camshaft pliers forcefully, as the cam-

shaft will be damaged.

6. Move the rounded hole of the adjusting shim to the front with

a very thin screwdriver.

+When the adjusting shim on the valve lifter will not rotate

smoothly, restart from step 4 with the end of the lifter stop-

per (SST) touching the adjusting shim.

7. Remove the adjusting shim from the valve lifter by blowing

air through the rounded hole of the shim with an air gun.

CAUTION:

To prevent any remaining oil from being blown around, thor-

oughly wipe the area clean and wear protective goggles.

FEM027

FEM028

FEM029

FEM030

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

Inspection (Cont'd)

EM-1037

Page 776 of 1033

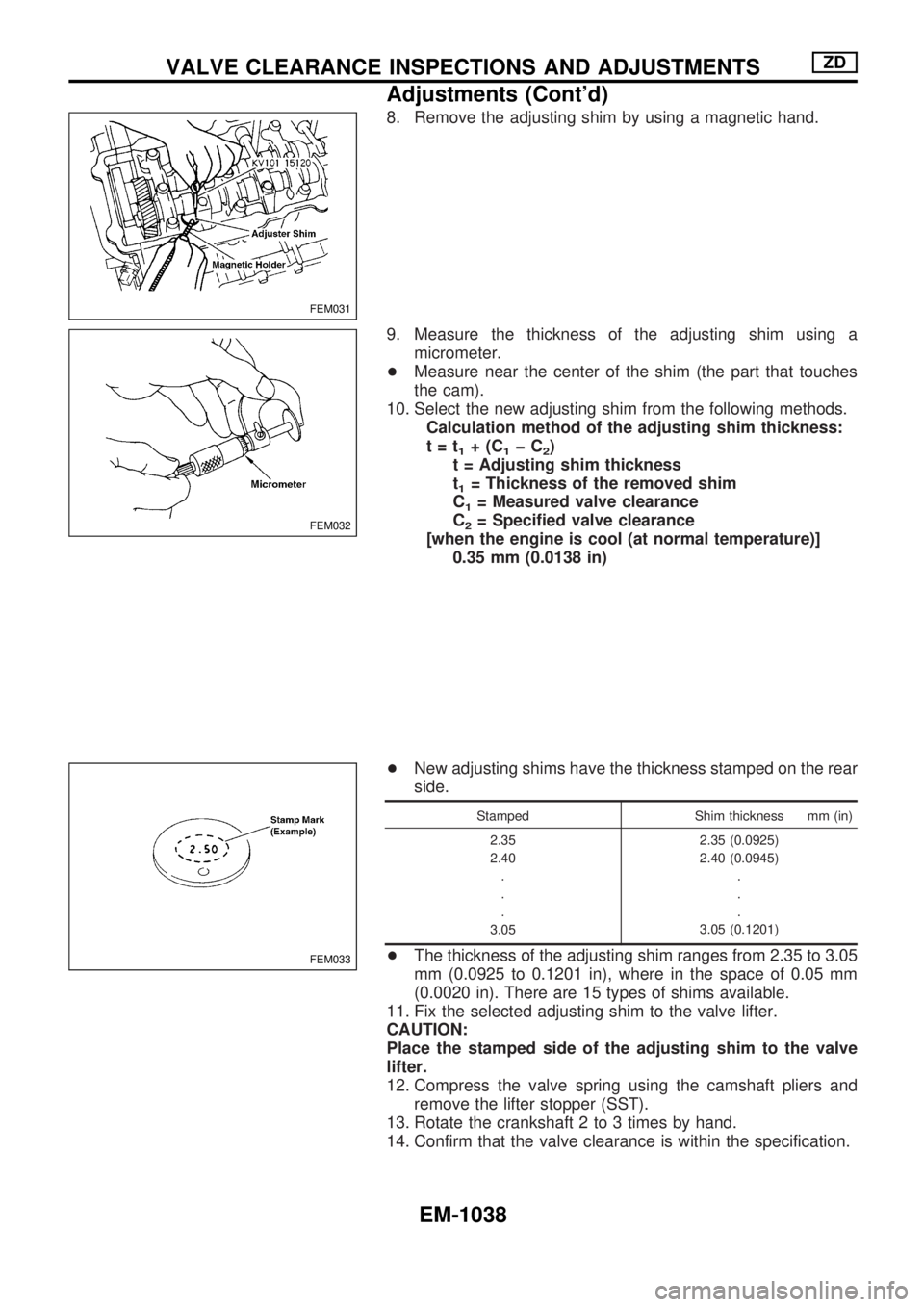

8. Remove the adjusting shim by using a magnetic hand.

9. Measure the thickness of the adjusting shim using a

micrometer.

+Measure near the center of the shim (the part that touches

the cam).

10. Select the new adjusting shim from the following methods.

Calculation method of the adjusting shim thickness:

t=t

1+(C1þC2)

t = Adjusting shim thickness

t

1= Thickness of the removed shim

C

1= Measured valve clearance

C

2= Specified valve clearance

[when the engine is cool (at normal temperature)]

0.35 mm (0.0138 in)

+New adjusting shims have the thickness stamped on the rear

side.

Stamped Shim thickness mm (in)

2.35

2.40

.

.

.

3.052.35 (0.0925)

2.40 (0.0945)

.

.

.

3.05 (0.1201)

+The thickness of the adjusting shim ranges from 2.35 to 3.05

mm (0.0925 to 0.1201 in), where in the space of 0.05 mm

(0.0020 in). There are 15 types of shims available.

11. Fix the selected adjusting shim to the valve lifter.

CAUTION:

Place the stamped side of the adjusting shim to the valve

lifter.

12. Compress the valve spring using the camshaft pliers and

remove the lifter stopper (SST).

13. Rotate the crankshaft 2 to 3 times by hand.

14. Confirm that the valve clearance is within the specification.

FEM031

FEM032

FEM033

VALVE CLEARANCE INSPECTIONS AND ADJUSTMENTSZD

Adjustments (Cont'd)

EM-1038

Page 778 of 1033

Removal

1. Remove the following parts.

+Undercover

+Engine oil (Drain)

+Engine coolant (Drain)

+Engine cover

+Intercooler

+Air inlet pipe

+Air cleaner case

+Throttle body

+Swirl and intake air control valve control solenoid valve and

bracket

+Vacuum tank

+Glow plate

+Rocker cover

+Spill tube

+Radiator shrouds (Rear and Lower)

+Cooling fan

+Radiator hose (Upper and Lower)

+Auxiliary belt and auto tensioner.

2. Remove the alternator.

3. Remove the A/C compressor and bracket with piping con-

nected. Move and support it at the LH side of engine bay with

a rope to avoid putting load on piping.

Refer to HA section in Nissan Service Manual (Supplement

I: Publication No. SM0E-Y61AE0E.)

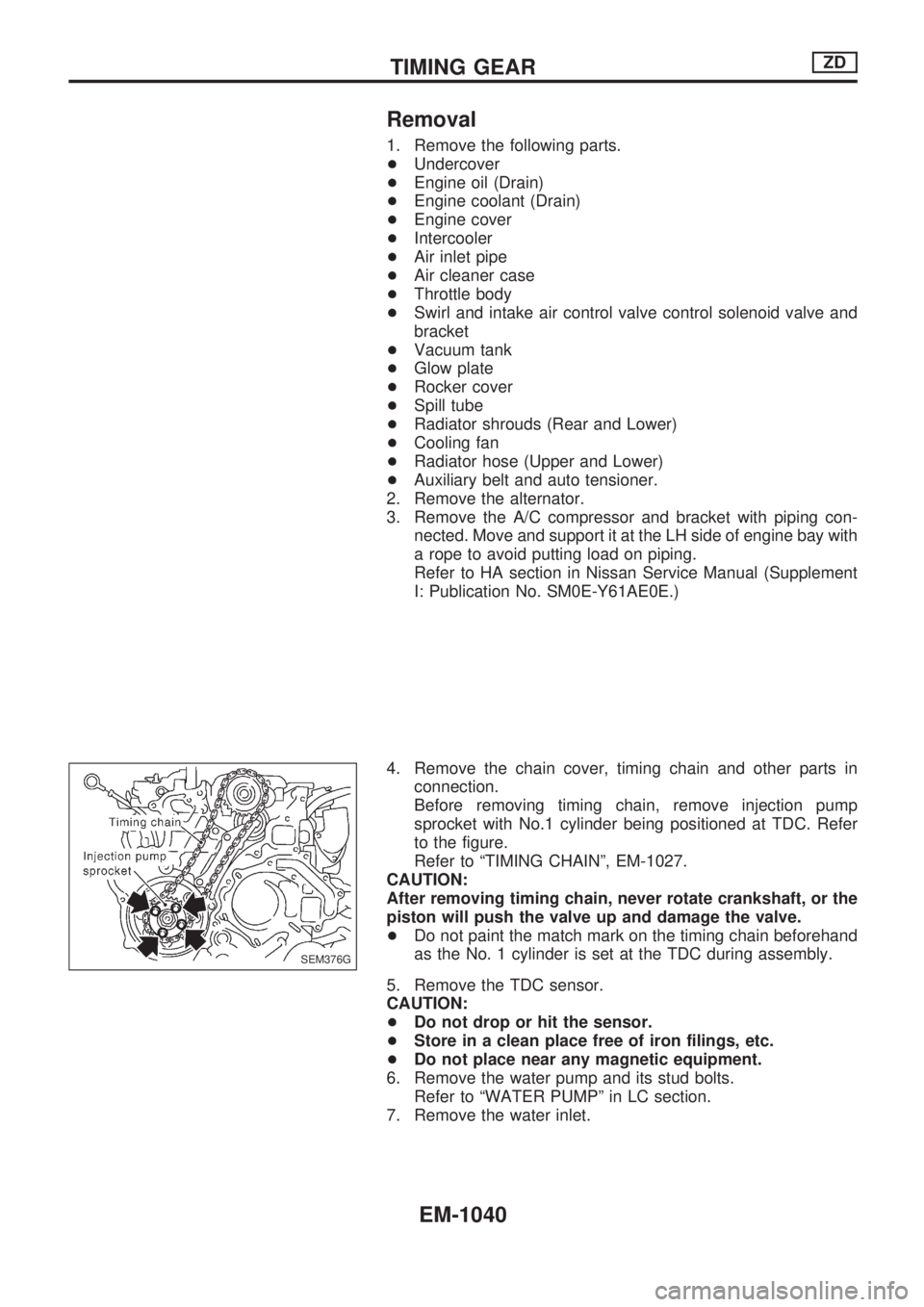

4. Remove the chain cover, timing chain and other parts in

connection.

Before removing timing chain, remove injection pump

sprocket with No.1 cylinder being positioned at TDC. Refer

to the figure.

Refer to ªTIMING CHAINº, EM-1027.

CAUTION:

After removing timing chain, never rotate crankshaft, or the

piston will push the valve up and damage the valve.

+Do not paint the match mark on the timing chain beforehand

as the No. 1 cylinder is set at the TDC during assembly.

5. Remove the TDC sensor.

CAUTION:

+Do not drop or hit the sensor.

+Store in a clean place free of iron filings, etc.

+Do not place near any magnetic equipment.

6. Remove the water pump and its stud bolts.

Refer to ªWATER PUMPº in LC section.

7. Remove the water inlet.

SEM376G

TIMING GEARZD

EM-1040