engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 747 of 1033

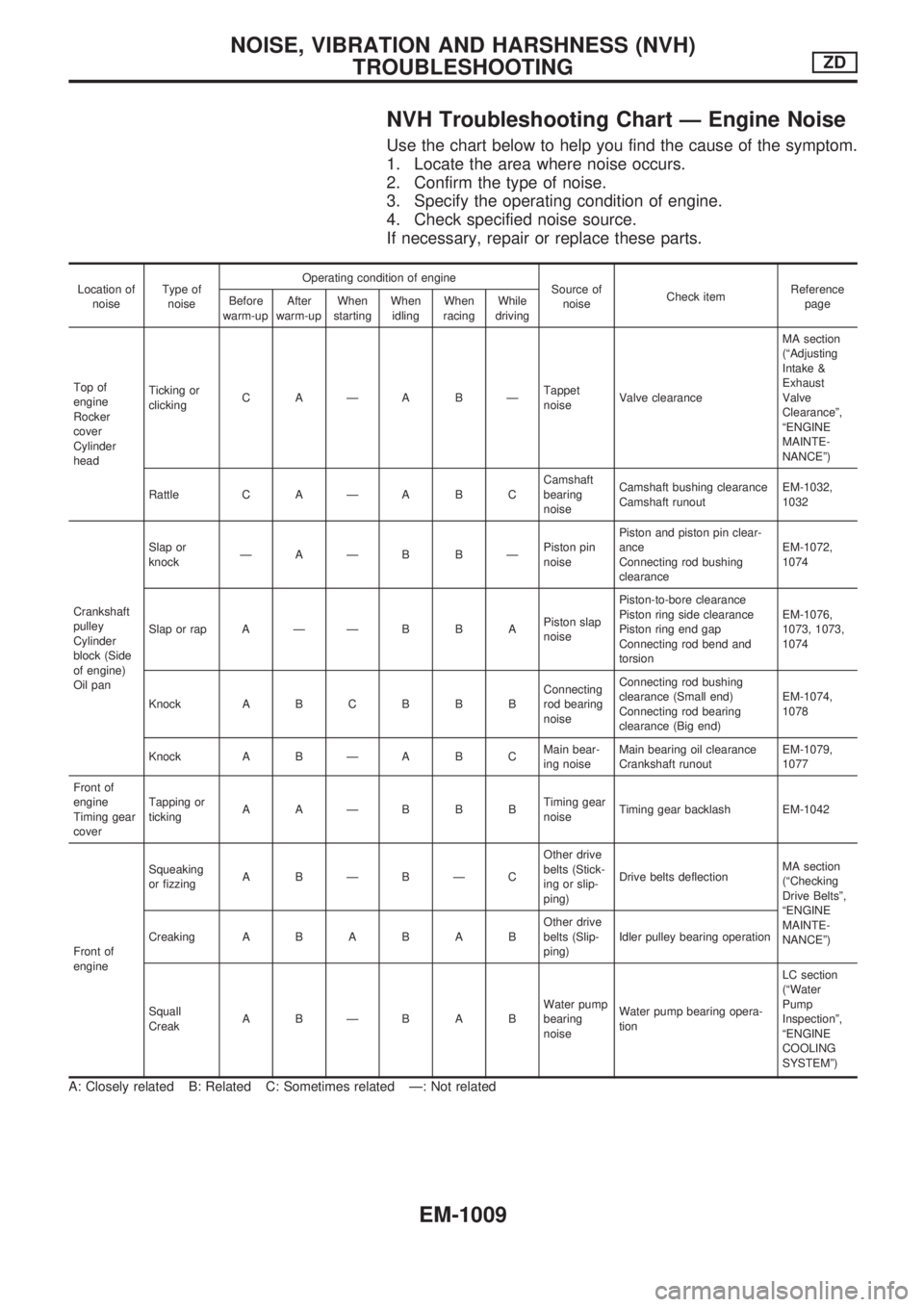

NVH Troubleshooting Chart Ð Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

Top of

engine

Rocker

cover

Cylinder

headTicking or

clickingCAÐABÐTappet

noiseValve clearanceMA section

(ªAdjusting

Intake &

Exhaust

Valve

Clearanceº,

ªENGINE

MAINTE-

NANCEº)

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft bushing clearance

Camshaft runoutEM-1032,

1032

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil panSlap or

knockÐAÐB BÐPiston pin

noisePiston and piston pin clear-

ance

Connecting rod bushing

clearanceEM-1072,

1074

Slap or rap A Ð Ð B B APiston slap

noisePiston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsionEM-1076,

1073, 1073,

1074

Knock A B C B B BConnecting

rod bearing

noiseConnecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)EM-1074,

1078

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clearance

Crankshaft runoutEM-1079,

1077

Front of

engine

Timing gear

coverTapping or

tickingAAÐBBBTiming gear

noiseTiming gear backlash EM-1042

Front of

engineSqueaking

or fizzingABÐBÐCOther drive

belts (Stick-

ing or slip-

ping)Drive belts deflectionMA section

(ªChecking

Drive Beltsº,

ªENGINE

MAINTE-

NANCEº) CreakingABABABOther drive

belts (Slip-

ping)Idler pulley bearing operation

Squall

CreakABÐBABWater pump

bearing

noiseWater pump bearing opera-

tionLC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTINGZD

EM-1009

Page 748 of 1033

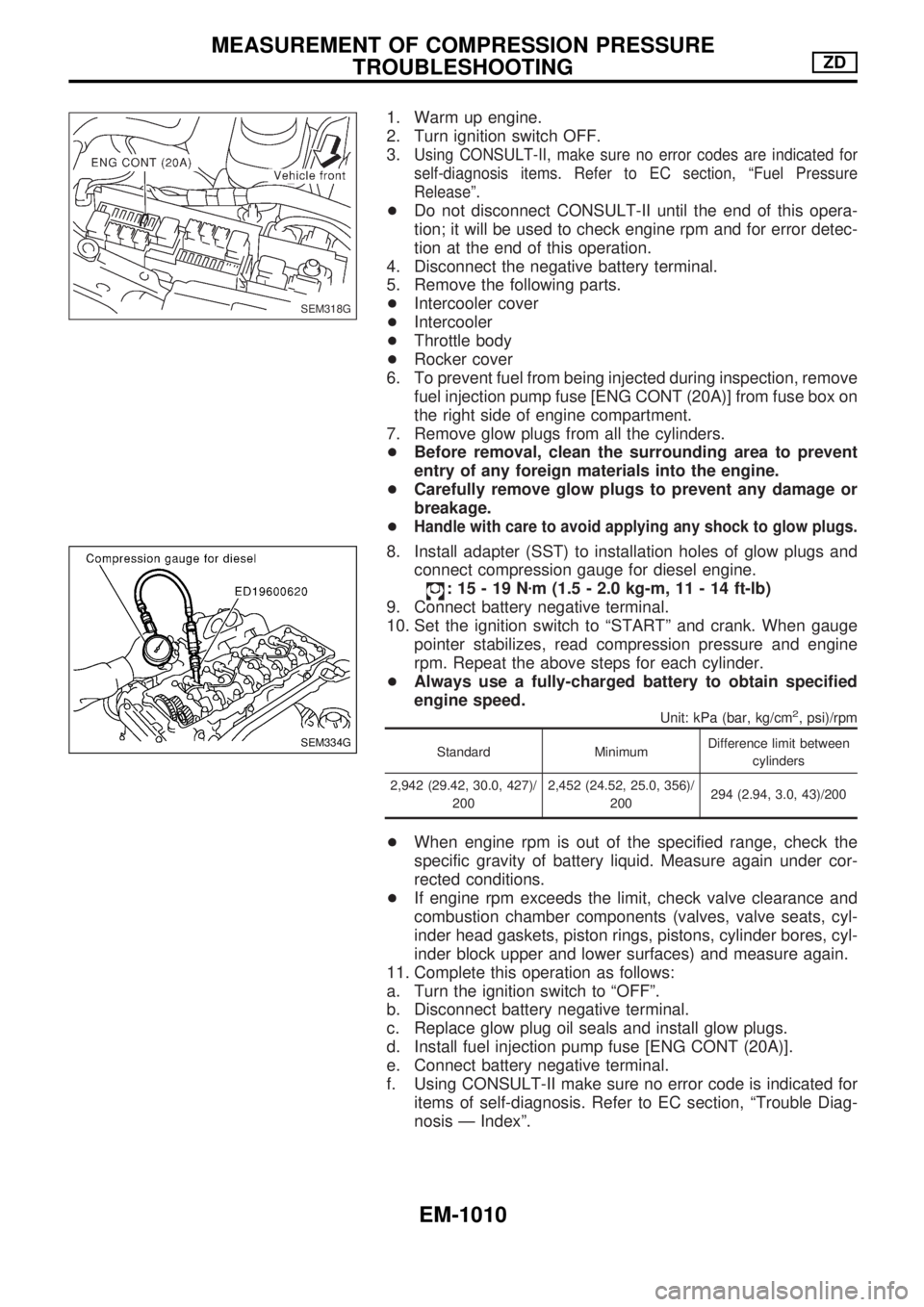

1. Warm up engine.

2. Turn ignition switch OFF.

3.

Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC section, ªFuel Pressure

Releaseº.

+Do not disconnect CONSULT-II until the end of this opera-

tion; it will be used to check engine rpm and for error detec-

tion at the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

+Intercooler cover

+Intercooler

+Throttle body

+Rocker cover

6. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT (20A)] from fuse box on

the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

+Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

+Carefully remove glow plugs to prevent any damage or

breakage.

+

Handle with care to avoid applying any shock to glow plugs.

8. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

:15-19Nzm (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to ªSTARTº and crank. When gauge

pointer stabilizes, read compression pressure and engine

rpm. Repeat the above steps for each cylinder.

+Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

2,942 (29.42, 30.0, 427)/

2002,452 (24.52, 25.0, 356)/

200294 (2.94, 3.0, 43)/200

+When engine rpm is out of the specified range, check the

specific gravity of battery liquid. Measure again under cor-

rected conditions.

+If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cyl-

inder head gaskets, piston rings, pistons, cylinder bores, cyl-

inder block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to ªOFFº.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT (20A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self-diagnosis. Refer to EC section, ªTrouble Diag-

nosis Ð Indexº.

SEM318G

SEM334G

MEASUREMENT OF COMPRESSION PRESSURE

TROUBLESHOOTINGZD

EM-1010

Page 750 of 1033

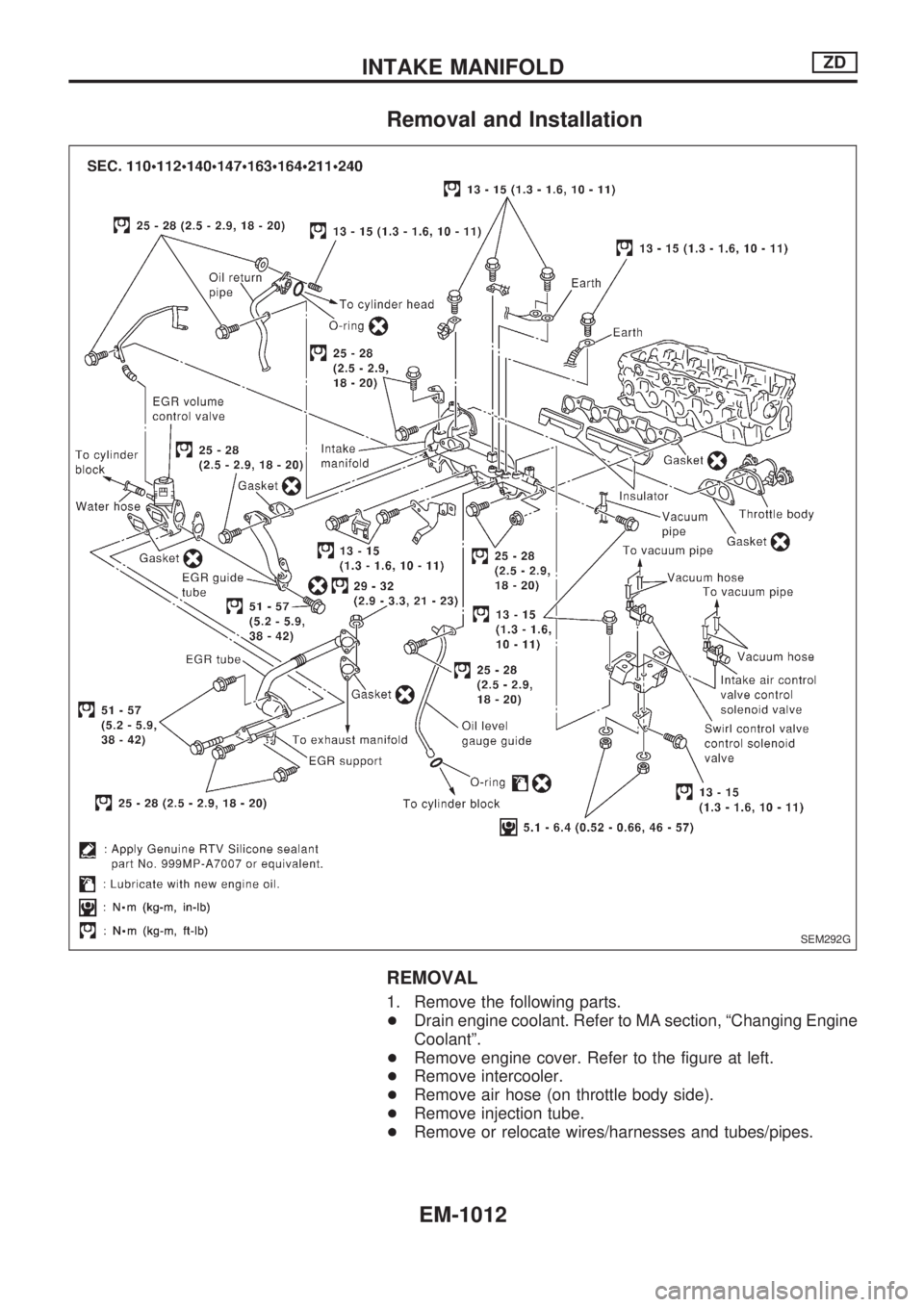

Removal and Installation

REMOVAL

1. Remove the following parts.

+Drain engine coolant. Refer to MA section, ªChanging Engine

Coolantº.

+Remove engine cover. Refer to the figure at left.

+Remove intercooler.

+Remove air hose (on throttle body side).

+Remove injection tube.

+Remove or relocate wires/harnesses and tubes/pipes.

SEM292G

INTAKE MANIFOLDZD

EM-1012

Page 752 of 1033

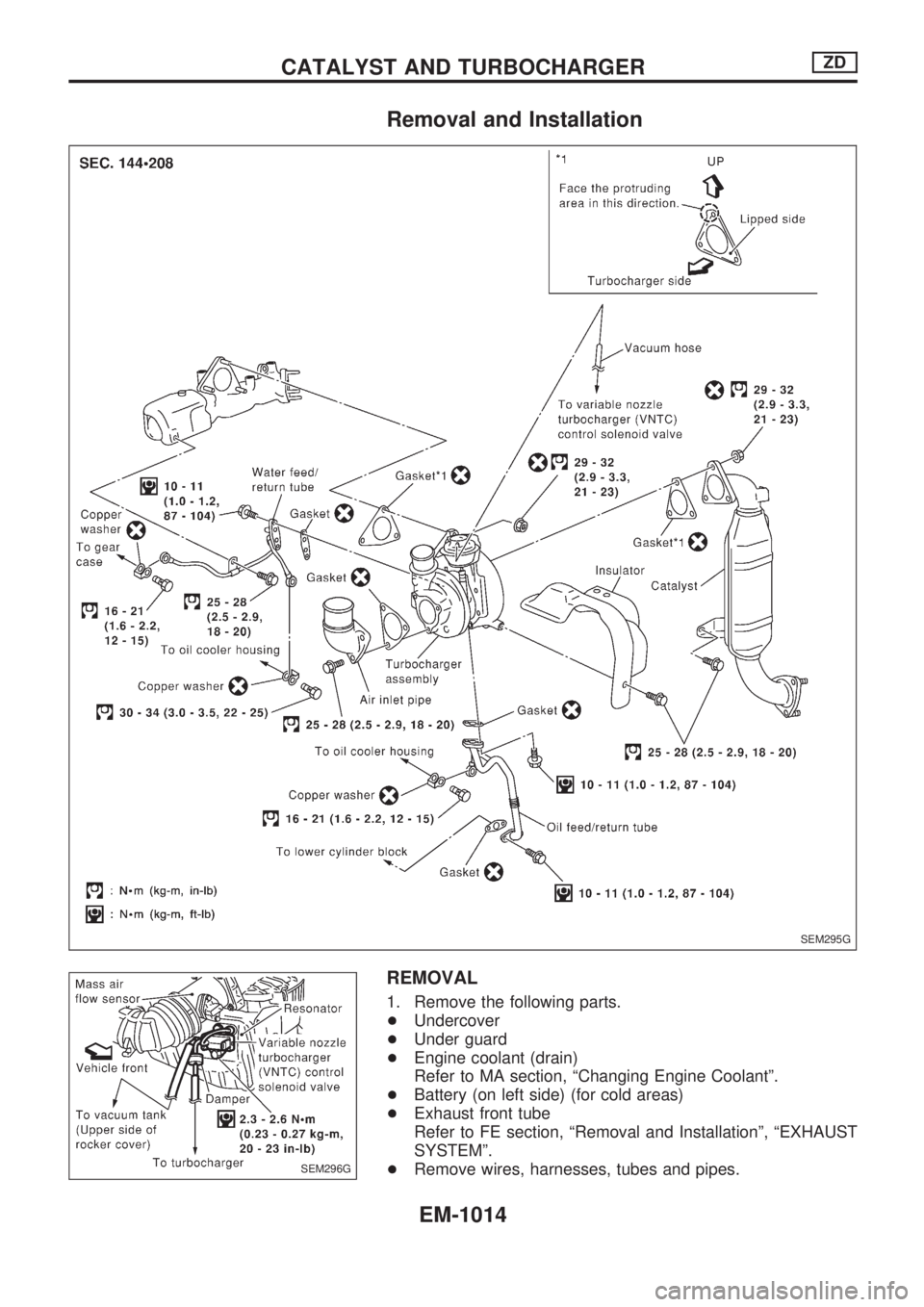

Removal and Installation

REMOVAL

1. Remove the following parts.

+Undercover

+Under guard

+Engine coolant (drain)

Refer to MA section, ªChanging Engine Coolantº.

+Battery (on left side) (for cold areas)

+Exhaust front tube

Refer to FE section, ªRemoval and Installationº, ªEXHAUST

SYSTEMº.

+Remove wires, harnesses, tubes and pipes.

SEM295G

SEM296G

CATALYST AND TURBOCHARGERZD

EM-1014

Page 755 of 1033

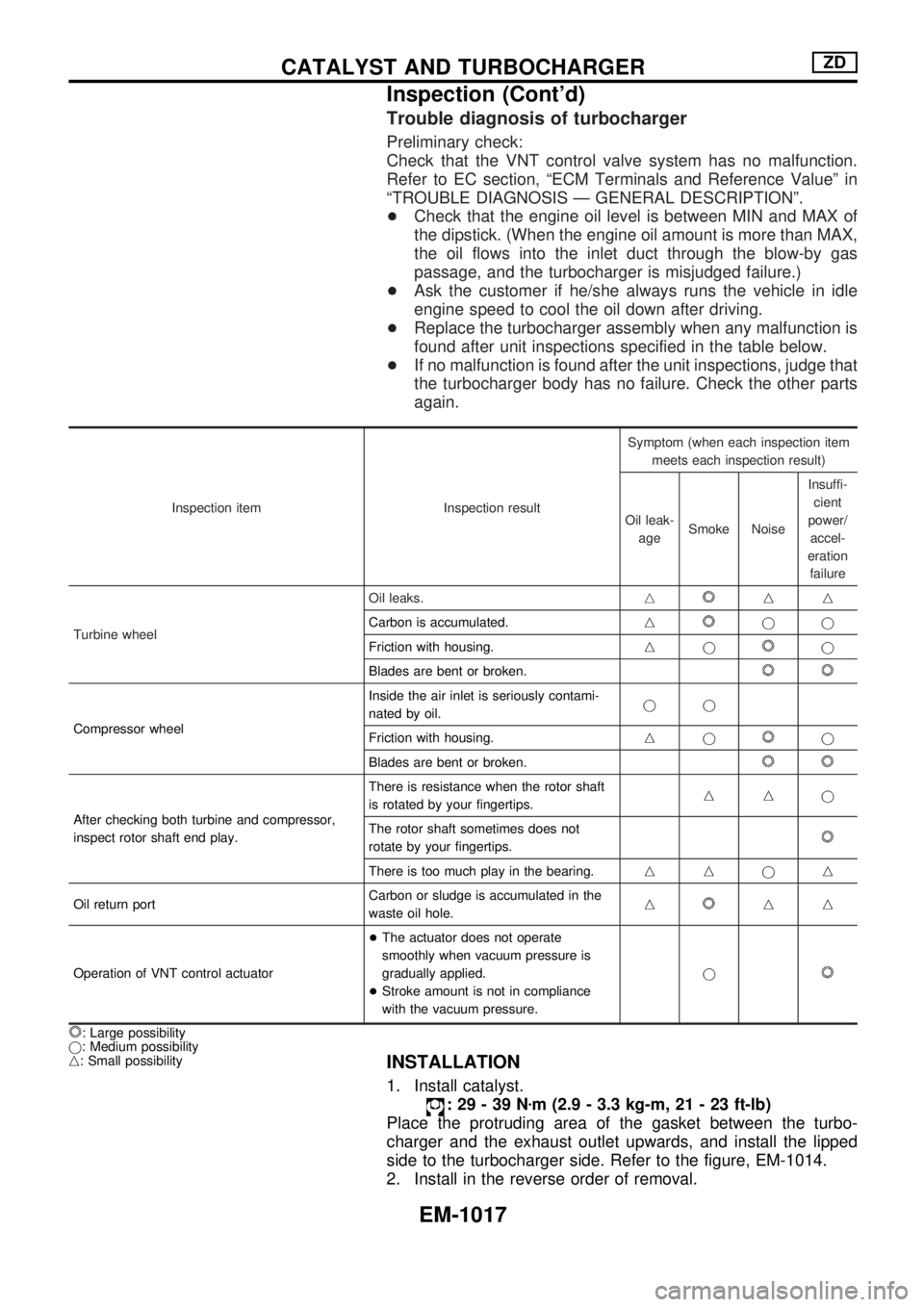

Trouble diagnosis of turbocharger

Preliminary check:

Check that the VNT control valve system has no malfunction.

Refer to EC section, ªECM Terminals and Reference Valueº in

ªTROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONº.

+Check that the engine oil level is between MIN and MAX of

the dipstick. (When the engine oil amount is more than MAX,

the oil flows into the inlet duct through the blow-by gas

passage, and the turbocharger is misjudged failure.)

+Ask the customer if he/she always runs the vehicle in idle

engine speed to cool the oil down after driving.

+Replace the turbocharger assembly when any malfunction is

found after unit inspections specified in the table below.

+If no malfunction is found after the unit inspections, judge that

the turbocharger body has no failure. Check the other parts

again.

Inspection item Inspection resultSymptom (when each inspection item

meets each inspection result)

Oil leak-

ageSmoke NoiseInsuffi-

cient

power/

accel-

eration

failure

Turbine wheelOil leaks.n

nn

Carbon is accumulated.n

jj

Friction with housing.nj

j

Blades are bent or broken.

Compressor wheelInside the air inlet is seriously contami-

nated by oil.jj

Friction with housing.njj

Blades are bent or broken.

After checking both turbine and compressor,

inspect rotor shaft end play.There is resistance when the rotor shaft

is rotated by your fingertips.nnj

The rotor shaft sometimes does not

rotate by your fingertips.

There is too much play in the bearing.nnjn

Oil return portCarbon or sludge is accumulated in the

waste oil hole.n

nn

Operation of VNT control actuator+The actuator does not operate

smoothly when vacuum pressure is

gradually applied.

+Stroke amount is not in compliance

with the vacuum pressure.j

: Large possibility

j: Medium possibility

n: Small possibility

INSTALLATION

1. Install catalyst.

:29-39Nzm (2.9 - 3.3 kg-m, 21 - 23 ft-lb)

Place the protruding area of the gasket between the turbo-

charger and the exhaust outlet upwards, and install the lipped

side to the turbocharger side. Refer to the figure, EM-1014.

2. Install in the reverse order of removal.

CATALYST AND TURBOCHARGERZD

Inspection (Cont'd)

EM-1017

Page 758 of 1033

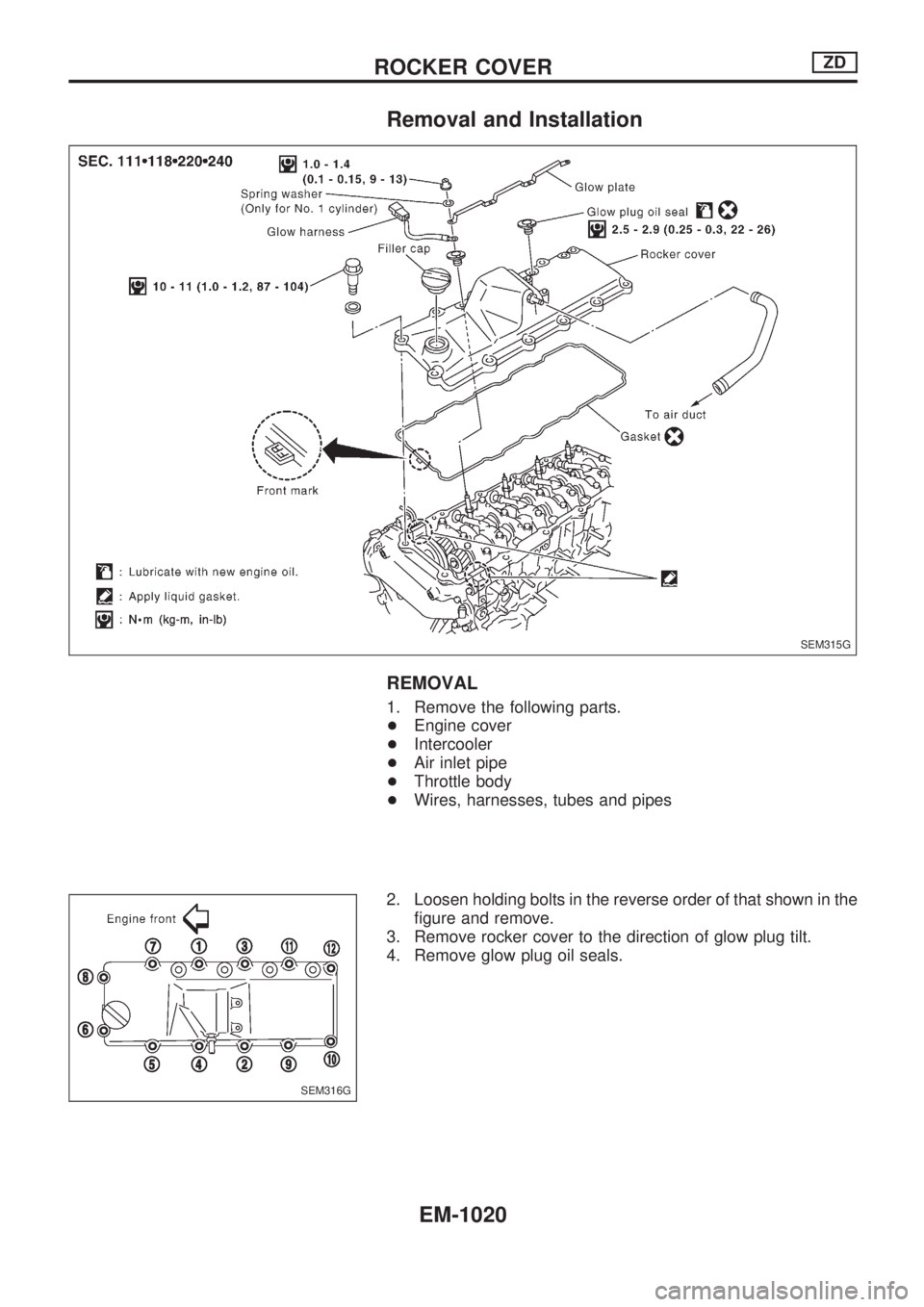

Removal and Installation

REMOVAL

1. Remove the following parts.

+Engine cover

+Intercooler

+Air inlet pipe

+Throttle body

+Wires, harnesses, tubes and pipes

2. Loosen holding bolts in the reverse order of that shown in the

figure and remove.

3. Remove rocker cover to the direction of glow plug tilt.

4. Remove glow plug oil seals.

SEM315G

SEM316G

ROCKER COVERZD

EM-1020

Page 759 of 1033

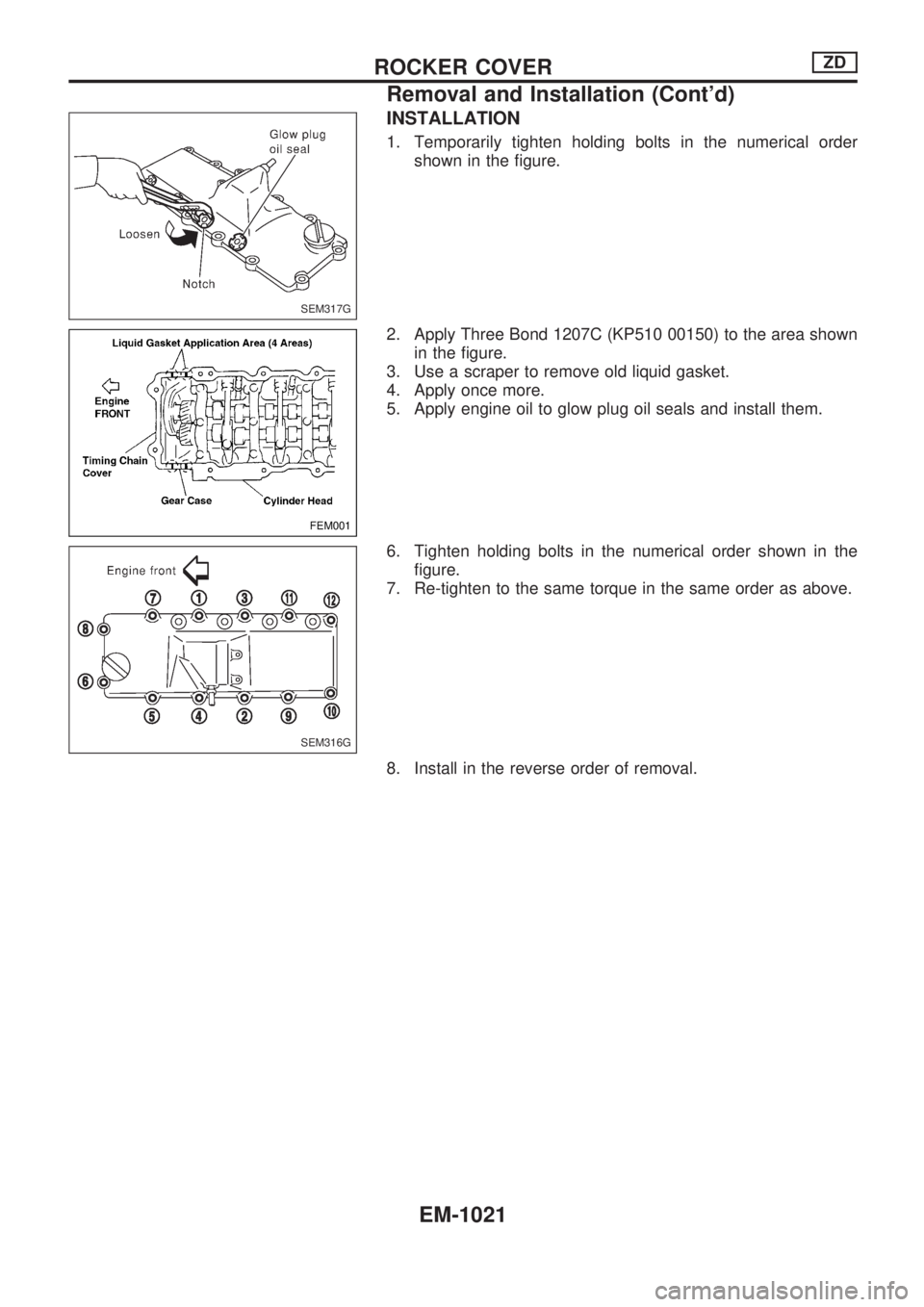

INSTALLATION

1. Temporarily tighten holding bolts in the numerical order

shown in the figure.

2. Apply Three Bond 1207C (KP510 00150) to the area shown

in the figure.

3. Use a scraper to remove old liquid gasket.

4. Apply once more.

5. Apply engine oil to glow plug oil seals and install them.

6. Tighten holding bolts in the numerical order shown in the

figure.

7. Re-tighten to the same torque in the same order as above.

8. Install in the reverse order of removal.

SEM317G

FEM001

SEM316G

ROCKER COVERZD

Removal and Installation (Cont'd)

EM-1021

Page 760 of 1033

![NISSAN PATROL 2000 Electronic Repair Manual Removal and Installation

REMOVAL [OIL PAN (LOWER)]

1. Remove the following parts.

+Remove undercover.

+Extract the engine oil.

2. Loosen the installation bolts in the reverse order of that

shown in th NISSAN PATROL 2000 Electronic Repair Manual Removal and Installation

REMOVAL [OIL PAN (LOWER)]

1. Remove the following parts.

+Remove undercover.

+Extract the engine oil.

2. Loosen the installation bolts in the reverse order of that

shown in th](/img/5/57367/w960_57367-759.png)

Removal and Installation

REMOVAL [OIL PAN (LOWER)]

1. Remove the following parts.

+Remove undercover.

+Extract the engine oil.

2. Loosen the installation bolts in the reverse order of that

shown in the figure and then remove.

3. Using a seal cutter (SST), cut the liquid gasket to separate

it.

SEM319G

SEM341G

OIL PAN & OIL STRAINERZD

EM-1022

Page 761 of 1033

![NISSAN PATROL 2000 Electronic Repair Manual INSTALLATION [OIL PAN (LOWER)]

1. Install oil pan (Lower).

a. Use a scraper to remove all traces of liquid gasket from

mating surfaces.

+Also remove traces of liquid gasket from mating surface of oil

NISSAN PATROL 2000 Electronic Repair Manual INSTALLATION [OIL PAN (LOWER)]

1. Install oil pan (Lower).

a. Use a scraper to remove all traces of liquid gasket from

mating surfaces.

+Also remove traces of liquid gasket from mating surface of oil](/img/5/57367/w960_57367-760.png)

INSTALLATION [OIL PAN (LOWER)]

1. Install oil pan (Lower).

a. Use a scraper to remove all traces of liquid gasket from

mating surfaces.

+Also remove traces of liquid gasket from mating surface of oil

pan (Upper).

+Remove old liquid gasket from the bolt hole and thread.

b. Apply a continuous bead of liquid gasket to mating surface

of oil pan (Lower).

+Use Genuine Liquid Gasket or equivalent.

+Apply liquid gasket to the groove on the mating surface.

+Allow 7 mm (0.28 in) clearance around bolt holes.

c. Apply liquid gasket to inner sealing surface as shown in fig-

ure.

+Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in).

+Attaching should be done within 5 minutes after coating.

2. Tighten the installation bolts in the order shown in the figure.

3. Install in the reverse order of removal.

REMOVAL [OIL PAN (UPPER) AND OIL STRAINER]

1. Remove the following parts.

+Engine cover

+Under covers

+Stabilizer; Refer to FA section in original Service Manual.

+Exhaust front tube and its bracket; Refer to FE section in

original Service Manual.

+Front propeller shaft and rear propeller shaft; Refer to PD

section in original Service Manual.

+Starter motor; Refer to EL section in original Service Manual.

+A/T or M/T assembly with transfer; Refer to AT section or MT

section in original Service Manual.

NOTE:

As there is a converter/clutch housing side oil pan (upper)

installation bolt as well, the transmission will also need to

be removed.

2. Loosen the installation bolts in the reverse order of that

shown in the figure and then remove.

3.

Using a seal cutter (SST), cut the liquid gasket to separate it.

4. Remove oil strainer

INSTALLATION [OIL PAN (UPPER) AND OIL STRAINER]

1. Clean oil strainer if any object is attached, and install oil

strainer.

2. Install oil pan (Upper).

a. Use a scraper to remove all traces of liquid gasket from

mating surfaces.

+Also remove traces of liquid gasket from mating surface of

cylinder block, front cover and oil pan (Lower).

+Remove old liquid gasket from the bolt hole and thread.

b. Apply a continuous bead of liquid gasket to mating surface

of oil pan (Upper).

SEM159F

SEM345GA

SEM346G

SEM159F

SEM347GA

OIL PAN & OIL STRAINERZD

Removal and Installation (Cont'd)

EM-1023

Page 763 of 1033

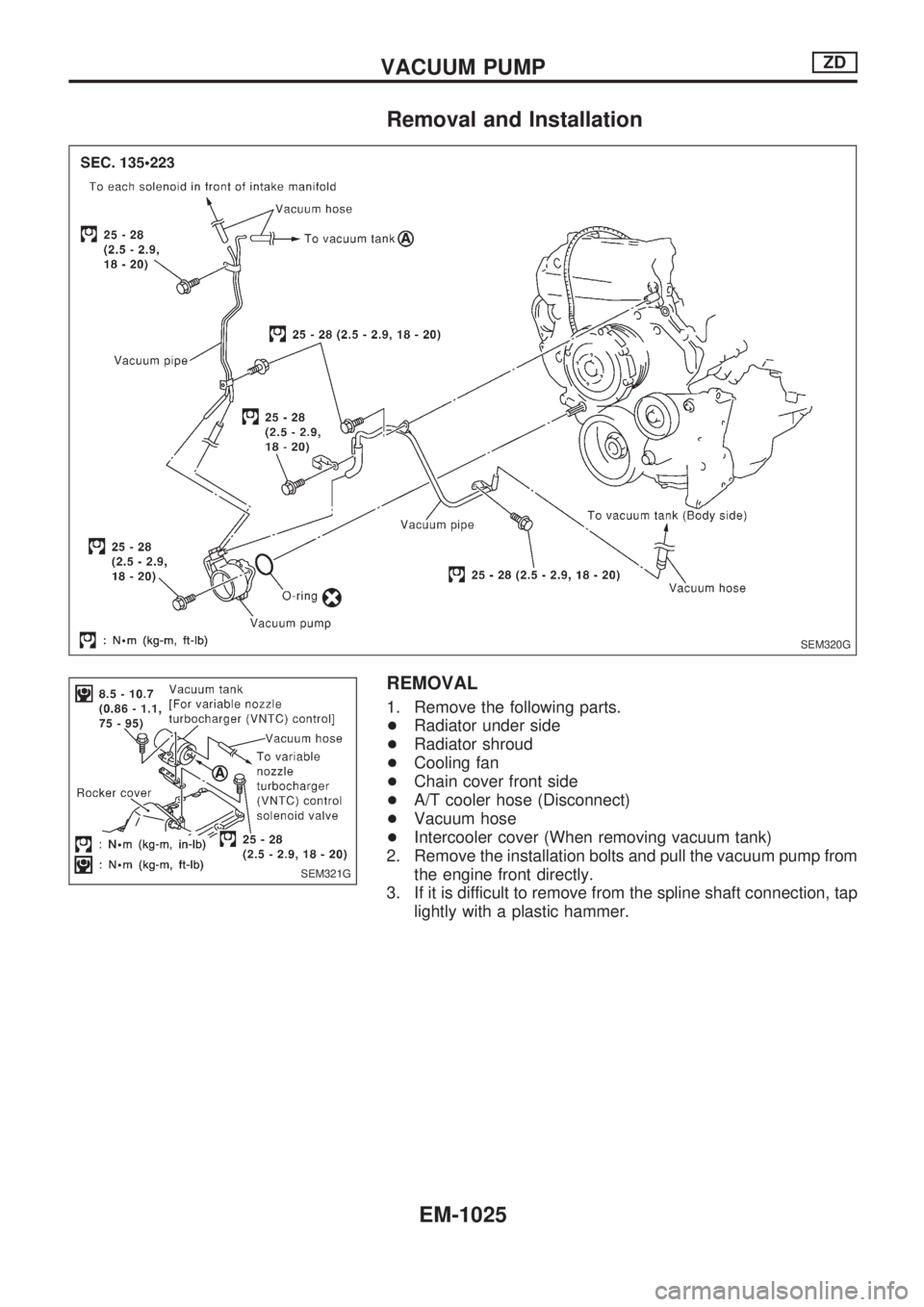

Removal and Installation

REMOVAL

1. Remove the following parts.

+Radiator under side

+Radiator shroud

+Cooling fan

+Chain cover front side

+A/T cooler hose (Disconnect)

+Vacuum hose

+Intercooler cover (When removing vacuum tank)

2. Remove the installation bolts and pull the vacuum pump from

the engine front directly.

3. If it is difficult to remove from the spline shaft connection, tap

lightly with a plastic hammer.

SEM320G

SEM321G

VACUUM PUMPZD

EM-1025