engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 806 of 1033

Selection Procedure for Selective Part

Combination

Location Selective part combination Item Method

Cylinder block - pistonPiston and piston assembly

(Part No. is given to a piston

and piston pin as a set.)Piston grade (Piston outer

diameter)Refer to ªSelective combination

chartº.

+Identification grade stamped on each part represents initial

dimension of new part. This grade will not be applied to a

reused part.

+Measure correct dimensions of a reused or modified part,

then refer to ªSelective combination chartº in this manual to

identify the grade.

+Refer to the applicable pages for measurement method for

each part, standards for reuse, and selecting method for

selective part combination.

Disassembly

1. Remove engine assembly from vehicle.

Refer to EM-1064, ªENGINE REMOVALº.

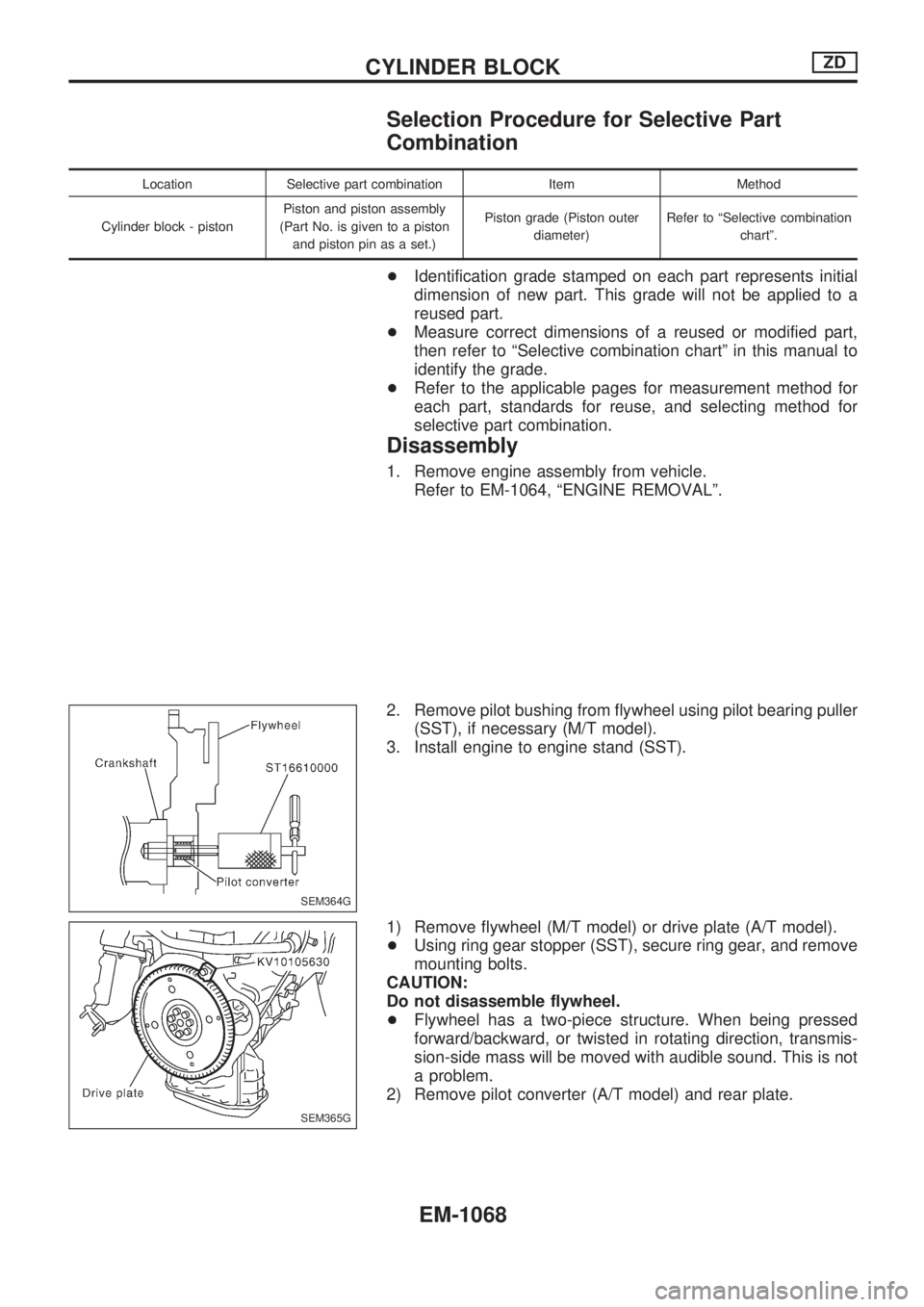

2. Remove pilot bushing from flywheel using pilot bearing puller

(SST), if necessary (M/T model).

3. Install engine to engine stand (SST).

1) Remove flywheel (M/T model) or drive plate (A/T model).

+Using ring gear stopper (SST), secure ring gear, and remove

mounting bolts.

CAUTION:

Do not disassemble flywheel.

+Flywheel has a two-piece structure. When being pressed

forward/backward, or twisted in rotating direction, transmis-

sion-side mass will be moved with audible sound. This is not

a problem.

2) Remove pilot converter (A/T model) and rear plate.

SEM364G

SEM365G

CYLINDER BLOCKZD

EM-1068

Page 807 of 1033

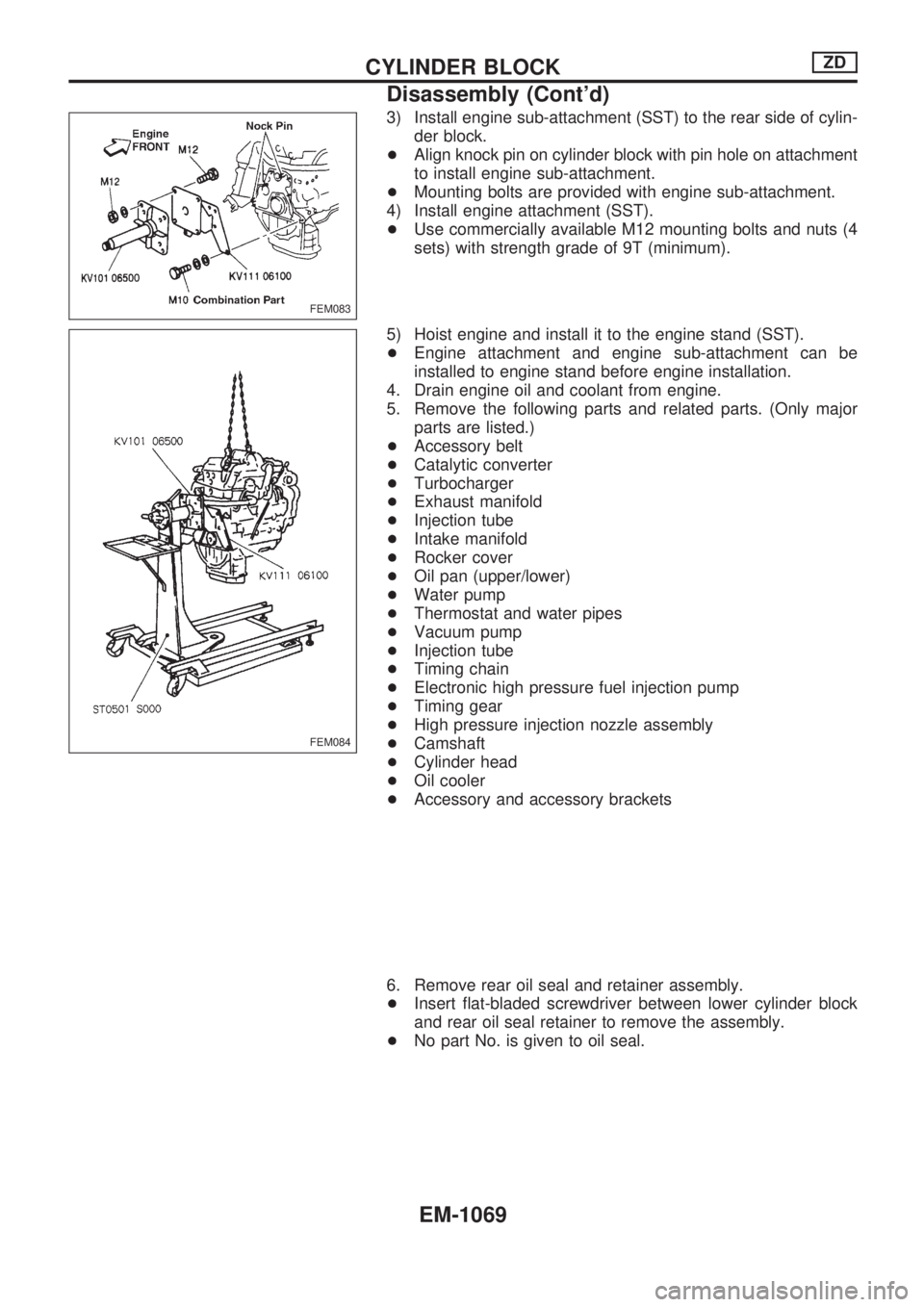

3) Install engine sub-attachment (SST) to the rear side of cylin-

der block.

+Align knock pin on cylinder block with pin hole on attachment

to install engine sub-attachment.

+Mounting bolts are provided with engine sub-attachment.

4) Install engine attachment (SST).

+Use commercially available M12 mounting bolts and nuts (4

sets) with strength grade of 9T (minimum).

5) Hoist engine and install it to the engine stand (SST).

+Engine attachment and engine sub-attachment can be

installed to engine stand before engine installation.

4. Drain engine oil and coolant from engine.

5. Remove the following parts and related parts. (Only major

parts are listed.)

+Accessory belt

+Catalytic converter

+Turbocharger

+Exhaust manifold

+Injection tube

+Intake manifold

+Rocker cover

+Oil pan (upper/lower)

+Water pump

+Thermostat and water pipes

+Vacuum pump

+Injection tube

+Timing chain

+Electronic high pressure fuel injection pump

+Timing gear

+High pressure injection nozzle assembly

+Camshaft

+Cylinder head

+Oil cooler

+Accessory and accessory brackets

6. Remove rear oil seal and retainer assembly.

+Insert flat-bladed screwdriver between lower cylinder block

and rear oil seal retainer to remove the assembly.

+No part No. is given to oil seal.

FEM083

FEM084

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-1069

Page 809 of 1033

3) Using rod with outer diameter of 30 mm (1.18 in), press pis-

ton pins out.

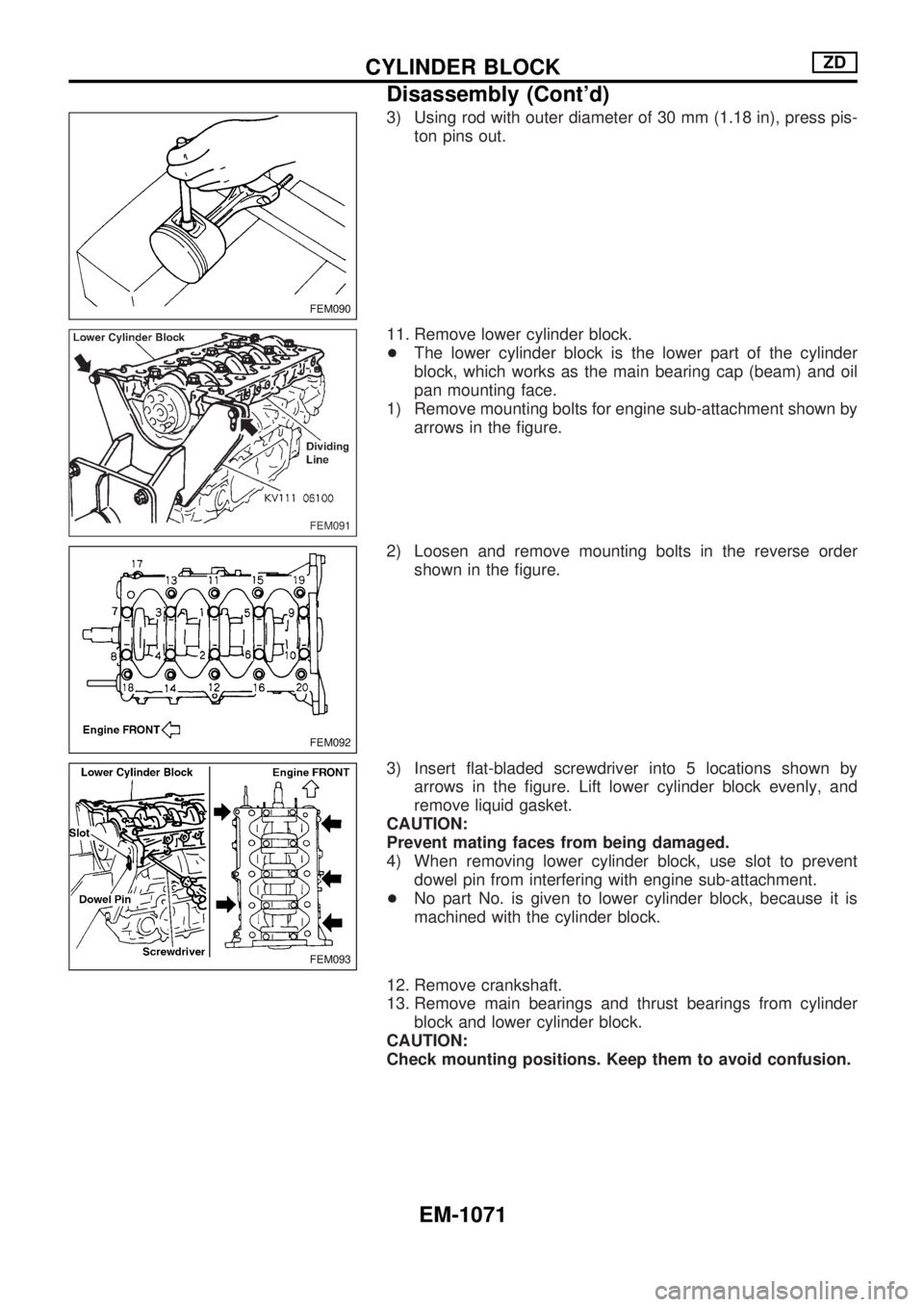

11. Remove lower cylinder block.

+The lower cylinder block is the lower part of the cylinder

block, which works as the main bearing cap (beam) and oil

pan mounting face.

1) Remove mounting bolts for engine sub-attachment shown by

arrows in the figure.

2) Loosen and remove mounting bolts in the reverse order

shown in the figure.

3) Insert flat-bladed screwdriver into 5 locations shown by

arrows in the figure. Lift lower cylinder block evenly, and

remove liquid gasket.

CAUTION:

Prevent mating faces from being damaged.

4) When removing lower cylinder block, use slot to prevent

dowel pin from interfering with engine sub-attachment.

+No part No. is given to lower cylinder block, because it is

machined with the cylinder block.

12. Remove crankshaft.

13. Remove main bearings and thrust bearings from cylinder

block and lower cylinder block.

CAUTION:

Check mounting positions. Keep them to avoid confusion.

FEM090

FEM091

FEM092

FEM093

CYLINDER BLOCKZD

Disassembly (Cont'd)

EM-1071

Page 813 of 1033

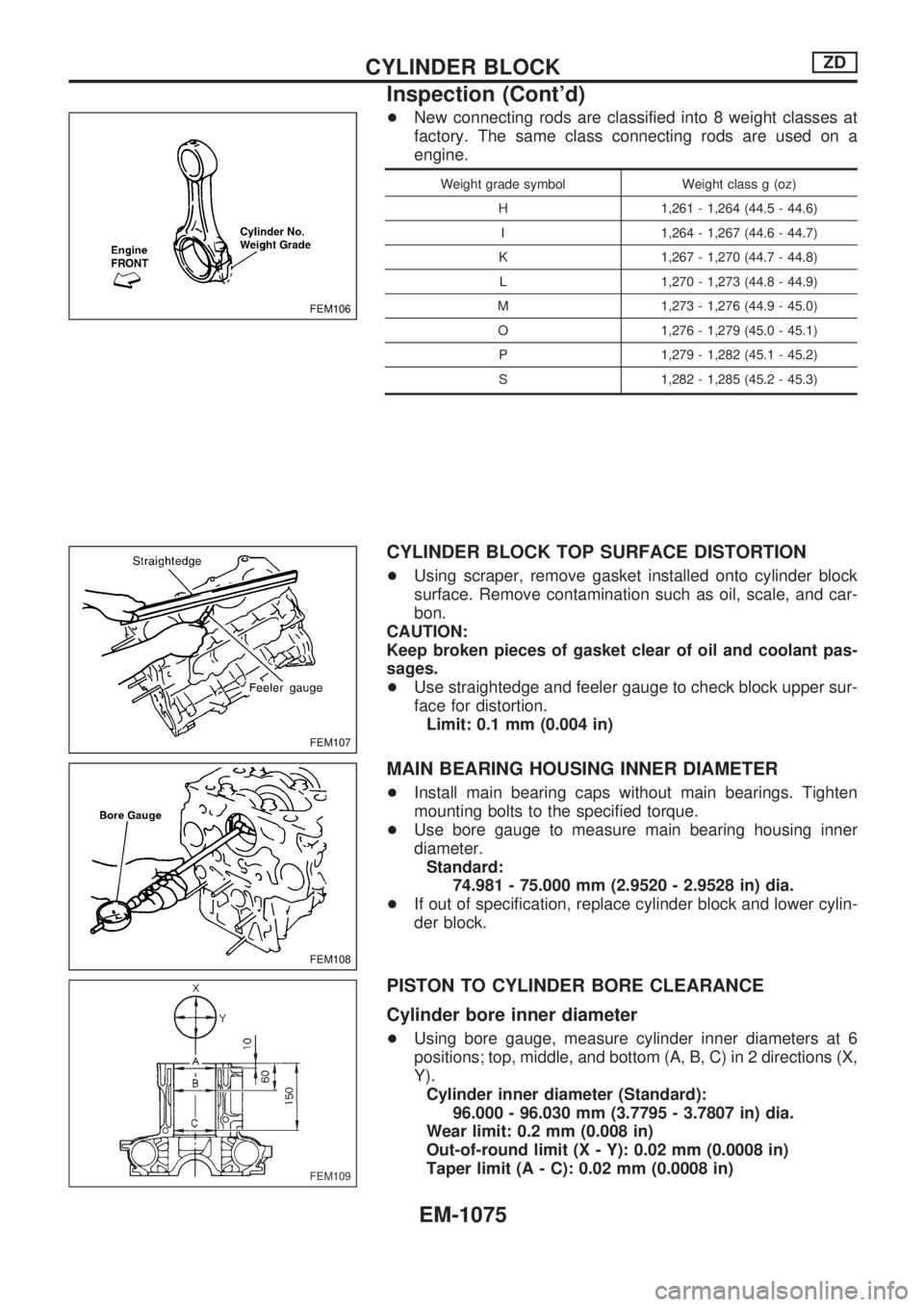

+New connecting rods are classified into 8 weight classes at

factory. The same class connecting rods are used on a

engine.

Weight grade symbol Weight class g (oz)

H 1,261 - 1,264 (44.5 - 44.6)

I 1,264 - 1,267 (44.6 - 44.7)

K 1,267 - 1,270 (44.7 - 44.8)

L 1,270 - 1,273 (44.8 - 44.9)

M 1,273 - 1,276 (44.9 - 45.0)

O 1,276 - 1,279 (45.0 - 45.1)

P 1,279 - 1,282 (45.1 - 45.2)

S 1,282 - 1,285 (45.2 - 45.3)

CYLINDER BLOCK TOP SURFACE DISTORTION

+Using scraper, remove gasket installed onto cylinder block

surface. Remove contamination such as oil, scale, and car-

bon.

CAUTION:

Keep broken pieces of gasket clear of oil and coolant pas-

sages.

+Use straightedge and feeler gauge to check block upper sur-

face for distortion.

Limit: 0.1 mm (0.004 in)

MAIN BEARING HOUSING INNER DIAMETER

+Install main bearing caps without main bearings. Tighten

mounting bolts to the specified torque.

+Use bore gauge to measure main bearing housing inner

diameter.

Standard:

74.981 - 75.000 mm (2.9520 - 2.9528 in) dia.

+If out of specification, replace cylinder block and lower cylin-

der block.

PISTON TO CYLINDER BORE CLEARANCE

Cylinder bore inner diameter

+Using bore gauge, measure cylinder inner diameters at 6

positions; top, middle, and bottom (A, B, C) in 2 directions (X,

Y).

Cylinder inner diameter (Standard):

96.000 - 96.030 mm (3.7795 - 3.7807 in) dia.

Wear limit: 0.2 mm (0.008 in)

Out-of-round limit (X - Y): 0.02 mm (0.0008 in)

Taper limit (A - C): 0.02 mm (0.0008 in)

FEM106

FEM107

FEM108

FEM109

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-1075

Page 815 of 1033

Selective combination chart

Unit: mm (in)

j: Preferable combination

n: Allowable combination

X: NG combinationPiston grade

12

95.950 - 95.960

(3.7776 - 3.7779)95.960 - 95.970

(3.7779 - 3.7783)

Cylinder

bore grade

(Cylinder

block bore

inner

diameter)196.000 - 96.010

(3.7795 - 3.7799)jX

296.010 - 96.020

(3.7799 - 3.7803)nj

396.020 - 96.030

(3.7803 - 3.7807)nj

+Piston grade 3 (95.980/95.970) is applicable at factory only.

+New pistons are classified into 4 weight classes at factory.

The same class pistons are used on a engine.

Weight grade symbol Weight class g (oz)

E 600 - 605 (21.2 - 21.3)

F 605 - 610 (21.3 - 21.5)

G 610 - 615 (21.5 - 21.7)

H 615 - 620 (21.7 - 21.9)

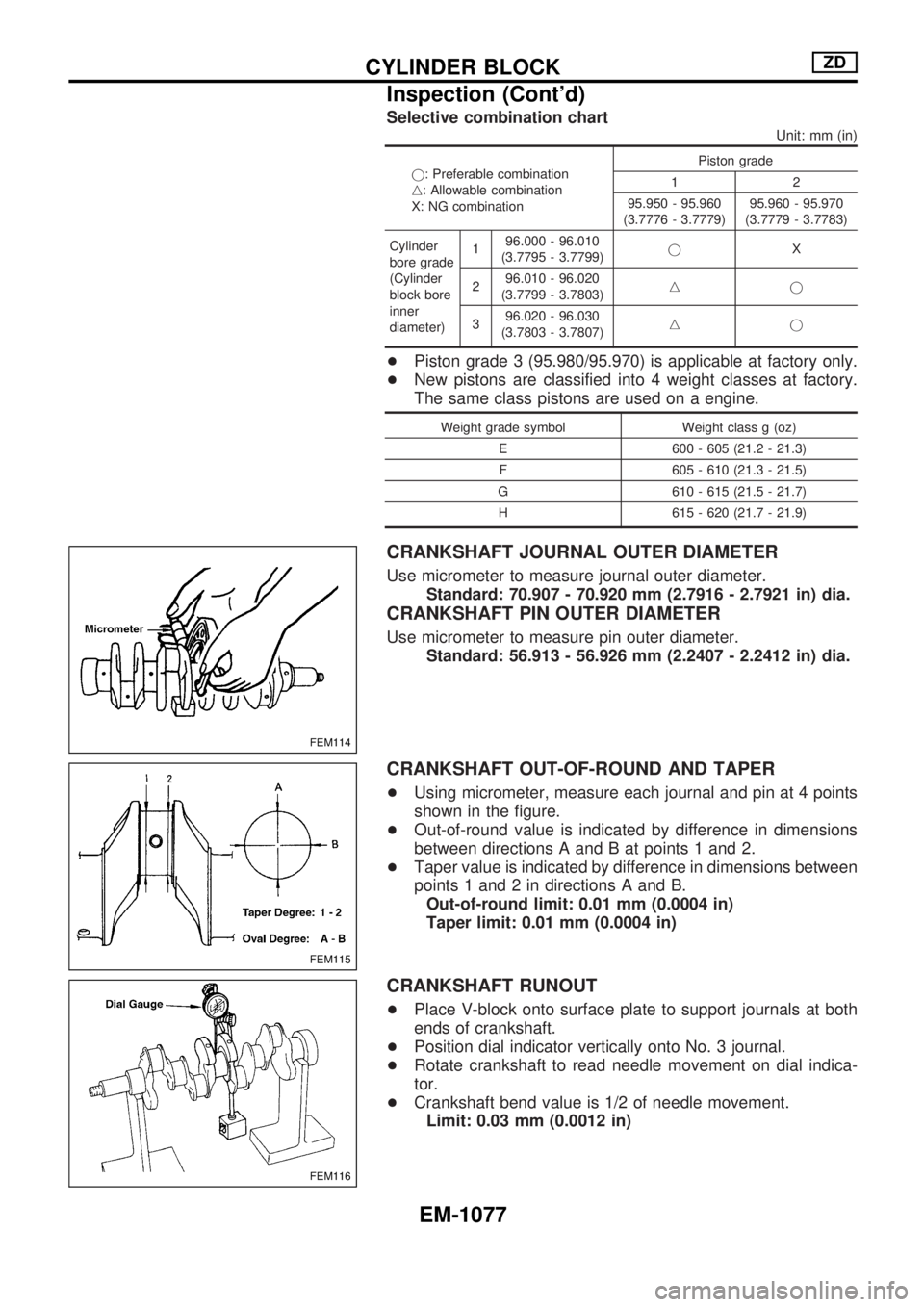

CRANKSHAFT JOURNAL OUTER DIAMETER

Use micrometer to measure journal outer diameter.

Standard: 70.907 - 70.920 mm (2.7916 - 2.7921 in) dia.

CRANKSHAFT PIN OUTER DIAMETER

Use micrometer to measure pin outer diameter.

Standard: 56.913 - 56.926 mm (2.2407 - 2.2412 in) dia.

CRANKSHAFT OUT-OF-ROUND AND TAPER

+Using micrometer, measure each journal and pin at 4 points

shown in the figure.

+Out-of-round value is indicated by difference in dimensions

between directions A and B at points 1 and 2.

+Taper value is indicated by difference in dimensions between

points 1 and 2 in directions A and B.

Out-of-round limit: 0.01 mm (0.0004 in)

Taper limit: 0.01 mm (0.0004 in)

CRANKSHAFT RUNOUT

+Place V-block onto surface plate to support journals at both

ends of crankshaft.

+Position dial indicator vertically onto No. 3 journal.

+Rotate crankshaft to read needle movement on dial indica-

tor.

+Crankshaft bend value is 1/2 of needle movement.

Limit: 0.03 mm (0.0012 in)

FEM114

FEM115

FEM116

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-1077

Page 819 of 1033

Assembly

1. Blow air sufficiently to inside coolant passage, oil passage,

crankcase, and cylinder bore to remove foreign matter.

2. Install main bearings and thrust bearings.

1) Remove contamination, dust and oil from bearing mounting

positions on cylinder block and main bearing caps.

2) Install thrust bearings on both sides of No. 4 housing on cyl-

inder block.

+Install thrust bearings with oil groove facing to crankshaft arm

(outside).

3) Being careful with the direction, install main bearings.

+Install main bearings with the oil holes and grooves onto the

cylinder block side, and those without oil holes and grooves

onto the lower cylinder block side.

+While installing bearings, apply engine oil to bearing surfaces

(inside). Do not apply oil to rear surfaces, but clean them

completely.

+Align stopper notches on bearings to install them.

+Check that the oil holes on the cylinder block body are mated

with the oil hole positions on the bearings.

3. Install crankshaft to cylinder block.

+While rotating crankshaft by hand, check for smooth rotation.

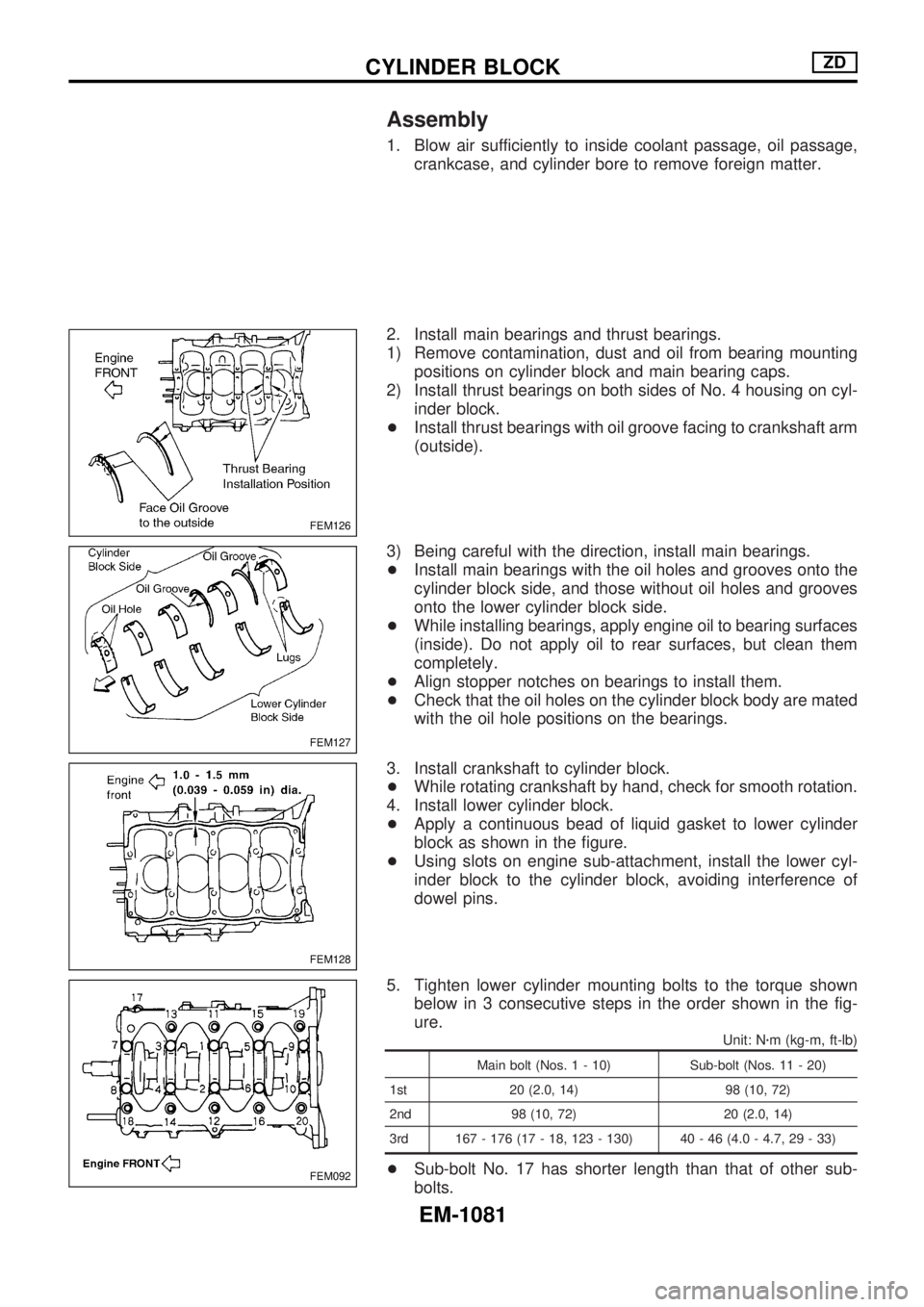

4. Install lower cylinder block.

+Apply a continuous bead of liquid gasket to lower cylinder

block as shown in the figure.

+Using slots on engine sub-attachment, install the lower cyl-

inder block to the cylinder block, avoiding interference of

dowel pins.

5. Tighten lower cylinder mounting bolts to the torque shown

below in 3 consecutive steps in the order shown in the fig-

ure.

Unit: Nzm (kg-m, ft-lb)

Main bolt (Nos. 1 - 10) Sub-bolt (Nos. 11 - 20)

1st 20 (2.0, 14) 98 (10, 72)

2nd 98 (10, 72) 20 (2.0, 14)

3rd 167 - 176 (17 - 18, 123 - 130) 40 - 46 (4.0 - 4.7, 29 - 33)

+Sub-bolt No. 17 has shorter length than that of other sub-

bolts.

FEM126

FEM127

FEM128

FEM092

CYLINDER BLOCKZD

EM-1081

Page 820 of 1033

6. Install mounting bolts for engine sub-attachment shown by

arrows in the figure.

+After tightening bolts to the specified torque, check crank-

shaft for smooth rotation.

+Check crankshaft end play.

Refer to EM-1072, ªCRANKSHAFT END PLAYº.

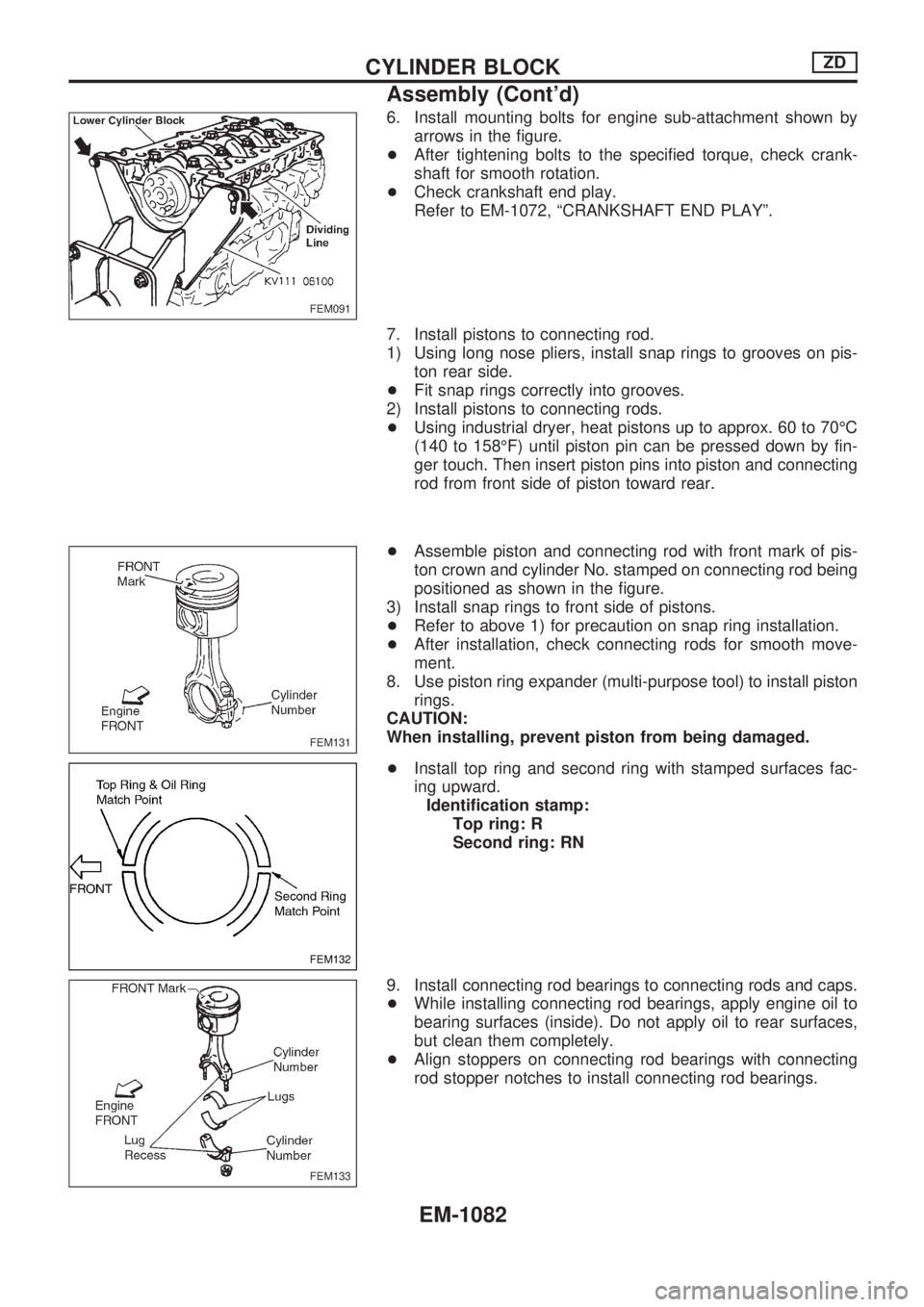

7. Install pistons to connecting rod.

1) Using long nose pliers, install snap rings to grooves on pis-

ton rear side.

+Fit snap rings correctly into grooves.

2) Install pistons to connecting rods.

+Using industrial dryer, heat pistons up to approx. 60 to 70ÉC

(140 to 158ÉF) until piston pin can be pressed down by fin-

ger touch. Then insert piston pins into piston and connecting

rod from front side of piston toward rear.

+Assemble piston and connecting rod with front mark of pis-

ton crown and cylinder No. stamped on connecting rod being

positioned as shown in the figure.

3) Install snap rings to front side of pistons.

+Refer to above 1) for precaution on snap ring installation.

+After installation, check connecting rods for smooth move-

ment.

8. Use piston ring expander (multi-purpose tool) to install piston

rings.

CAUTION:

When installing, prevent piston from being damaged.

+Install top ring and second ring with stamped surfaces fac-

ing upward.

Identification stamp:

Top ring: R

Second ring: RN

9. Install connecting rod bearings to connecting rods and caps.

+While installing connecting rod bearings, apply engine oil to

bearing surfaces (inside). Do not apply oil to rear surfaces,

but clean them completely.

+Align stoppers on connecting rod bearings with connecting

rod stopper notches to install connecting rod bearings.

FEM091

FEM131

FEM132

FEM133

CYLINDER BLOCKZD

Assembly (Cont'd)

EM-1082

Page 821 of 1033

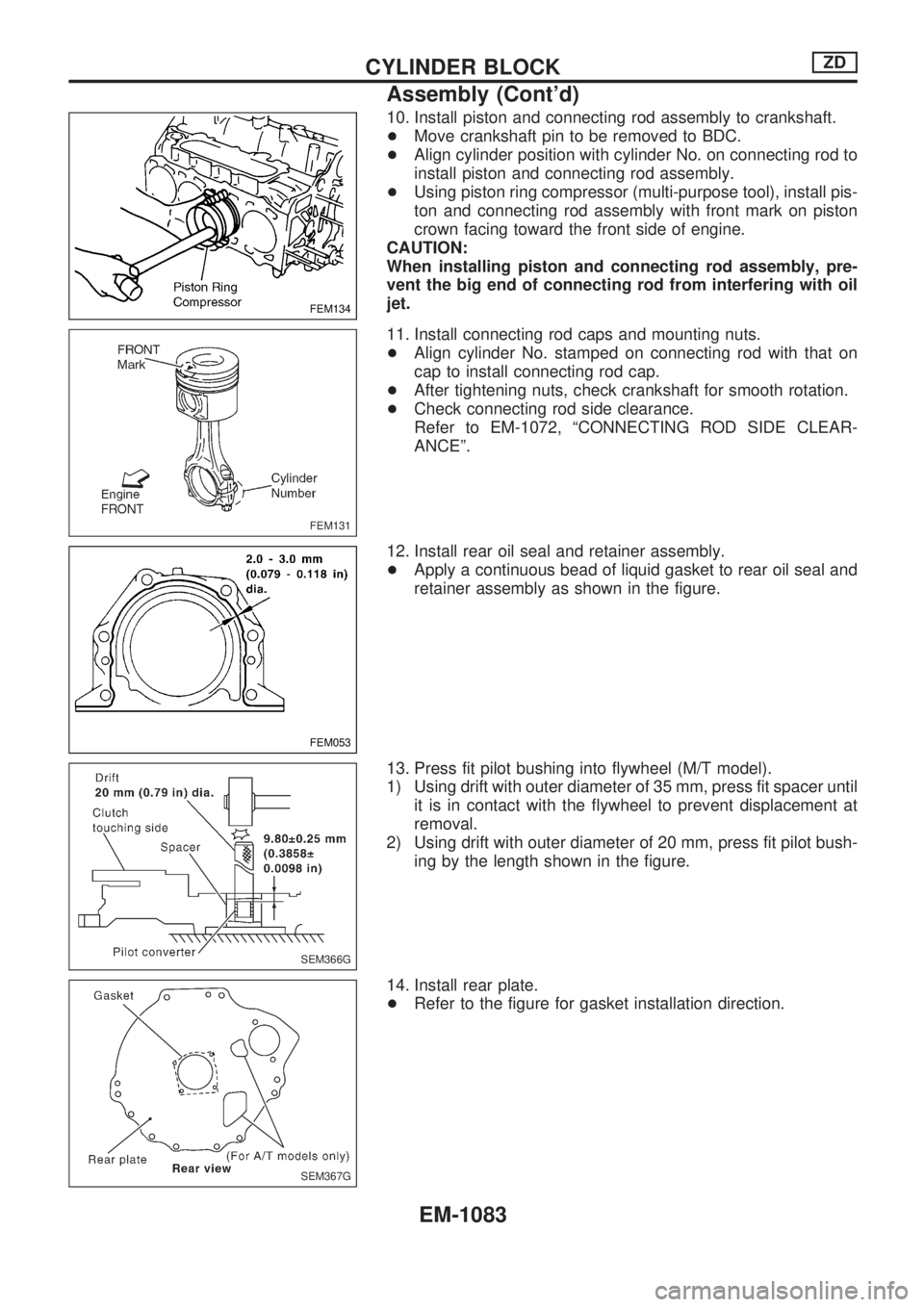

10. Install piston and connecting rod assembly to crankshaft.

+Move crankshaft pin to be removed to BDC.

+Align cylinder position with cylinder No. on connecting rod to

install piston and connecting rod assembly.

+Using piston ring compressor (multi-purpose tool), install pis-

ton and connecting rod assembly with front mark on piston

crown facing toward the front side of engine.

CAUTION:

When installing piston and connecting rod assembly, pre-

vent the big end of connecting rod from interfering with oil

jet.

11. Install connecting rod caps and mounting nuts.

+Align cylinder No. stamped on connecting rod with that on

cap to install connecting rod cap.

+After tightening nuts, check crankshaft for smooth rotation.

+Check connecting rod side clearance.

Refer to EM-1072, ªCONNECTING ROD SIDE CLEAR-

ANCEº.

12. Install rear oil seal and retainer assembly.

+Apply a continuous bead of liquid gasket to rear oil seal and

retainer assembly as shown in the figure.

13. Press fit pilot bushing into flywheel (M/T model).

1) Using drift with outer diameter of 35 mm, press fit spacer until

it is in contact with the flywheel to prevent displacement at

removal.

2) Using drift with outer diameter of 20 mm, press fit pilot bush-

ing by the length shown in the figure.

14. Install rear plate.

+Refer to the figure for gasket installation direction.

FEM134

FEM131

FEM053

SEM366G

SEM367G

CYLINDER BLOCKZD

Assembly (Cont'd)

EM-1083

Page 822 of 1033

15. Install removed parts to engine in the reverse order of disas-

sembly.

16. Remove engine from engine stand.

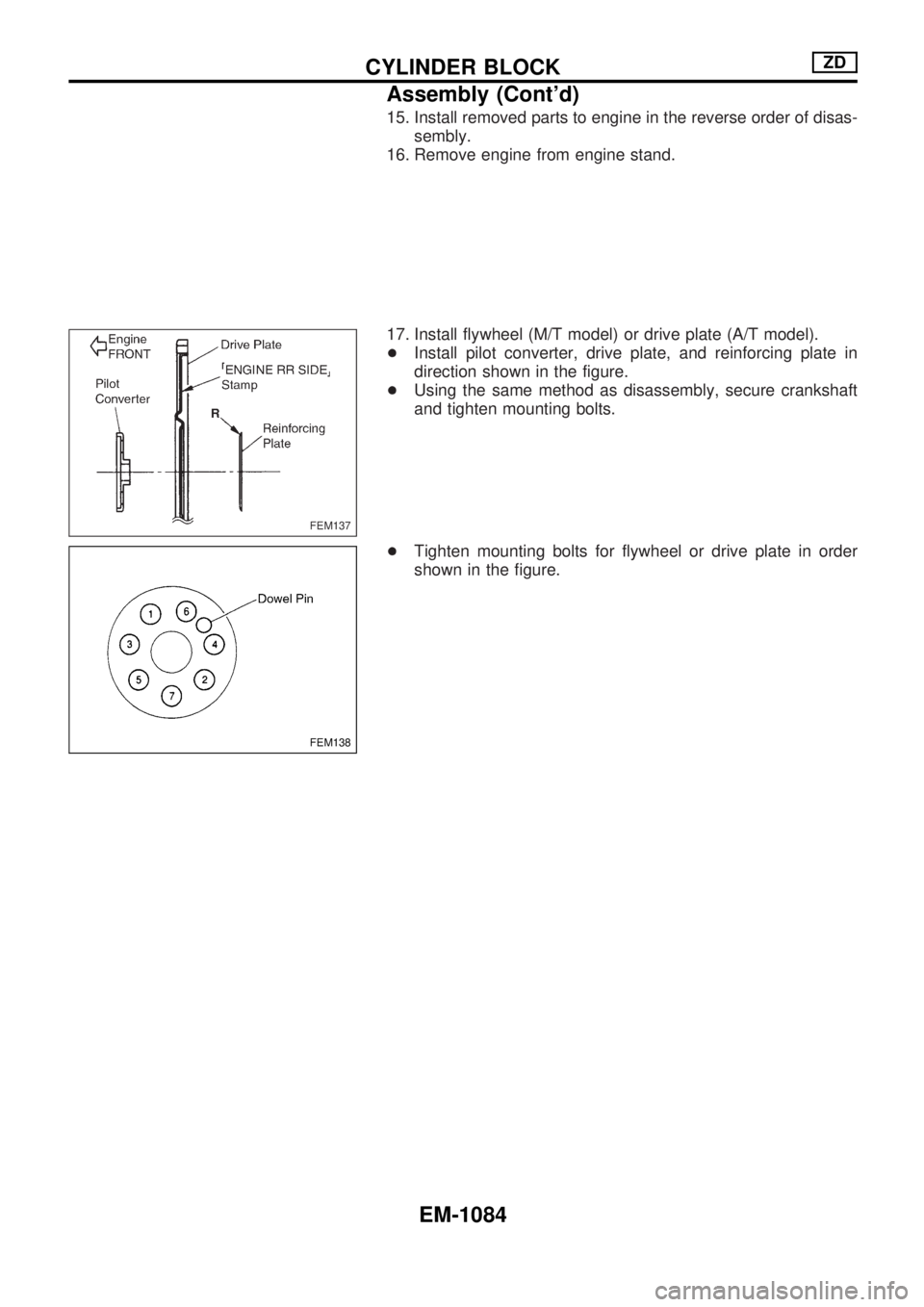

17. Install flywheel (M/T model) or drive plate (A/T model).

+Install pilot converter, drive plate, and reinforcing plate in

direction shown in the figure.

+Using the same method as disassembly, secure crankshaft

and tighten mounting bolts.

+Tighten mounting bolts for flywheel or drive plate in order

shown in the figure.

FEM137

FEM138

CYLINDER BLOCKZD

Assembly (Cont'd)

EM-1084

Page 836 of 1033

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

MODIFICATION NOTICE:

+The circuit diagram and wiring diagram have been changed.

+ZD30DDTi engine has been added.

+The accelerator control system for ZD30DDTi engine models is the same as for RD28ETi engine mod-

els. Refer to FE-3 in Service Manual [SM7E-1Y61G0 (01)].

+The fuel tank and sub-fuel tank for ZD30DDTi engine models are the same as for TD42 engine models.

Refer to FE-22 and FE-25 in Service Manual [SM7E-1Y61G0 (01)].

CONTENTS

TROUBLE DIAGNOSES..................................... 1002

Circuit Diagram ................................................ 1002

Wiring Diagram Ð S/TANK Ð ........................ 1003ZD

EXHAUST SYSTEM............................................ 1007

FE