engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 783 of 1033

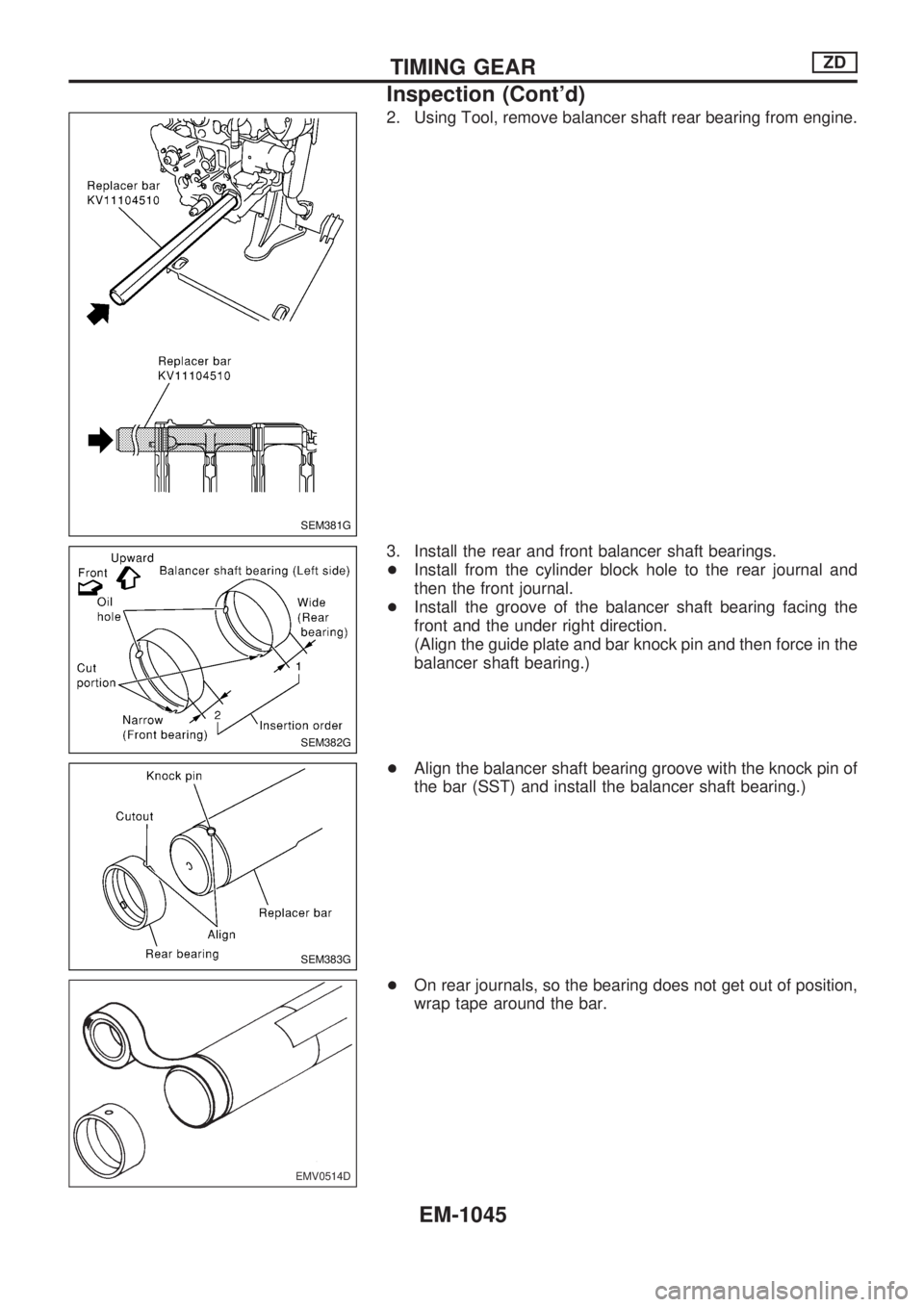

2. Using Tool, remove balancer shaft rear bearing from engine.

3. Install the rear and front balancer shaft bearings.

+Install from the cylinder block hole to the rear journal and

then the front journal.

+Install the groove of the balancer shaft bearing facing the

front and the under right direction.

(Align the guide plate and bar knock pin and then force in the

balancer shaft bearing.)

+Align the balancer shaft bearing groove with the knock pin of

the bar (SST) and install the balancer shaft bearing.)

+On rear journals, so the bearing does not get out of position,

wrap tape around the bar.

SEM381G

SEM382G

SEM383G

EMV0514D

TIMING GEARZD

Inspection (Cont'd)

EM-1045

Page 786 of 1033

![NISSAN PATROL 2000 Electronic Repair Manual 4. Install the front oil seal to the gear case.

+Apply engine oil to the fitting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s NISSAN PATROL 2000 Electronic Repair Manual 4. Install the front oil seal to the gear case.

+Apply engine oil to the fitting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make s](/img/5/57367/w960_57367-785.png)

4. Install the front oil seal to the gear case.

+Apply engine oil to the fitting side.

+Evenly insert the front oil seal using a drift [outer dia.: approx.

64 mm (2.52 in)] completely.

CAUTION:

Make sure the oil seal does not spill off the end side of the

gear case.

5. Install the gear case.

1) Before installing gear case, remove all traces of liquid gas-

ket from mating surface using a scraper.

2) Align gasket with dowel and install.

3) Install the O-rings to the gear case.

+The O-ring at the top position shown in the figure can be

installed in during cylinder head installation.

4) Apply a continuous bead of liquid gasket to gear case and oil

pan (upper).

+Use Genuine Liquid Gasket or equivalent.

a. Coat of liquid gasket should be maintained within the

specified range as shown in the figure.

b. Attach gear case to cylinder block within 5 minutes after

coating.

c. Wait at least 30 minutes before refilling engine oil or

starting engine.

FEM043

FEM044

SEM353G

FEM045

TIMING GEARZD

Installation (Cont'd)

EM-1048

Page 790 of 1033

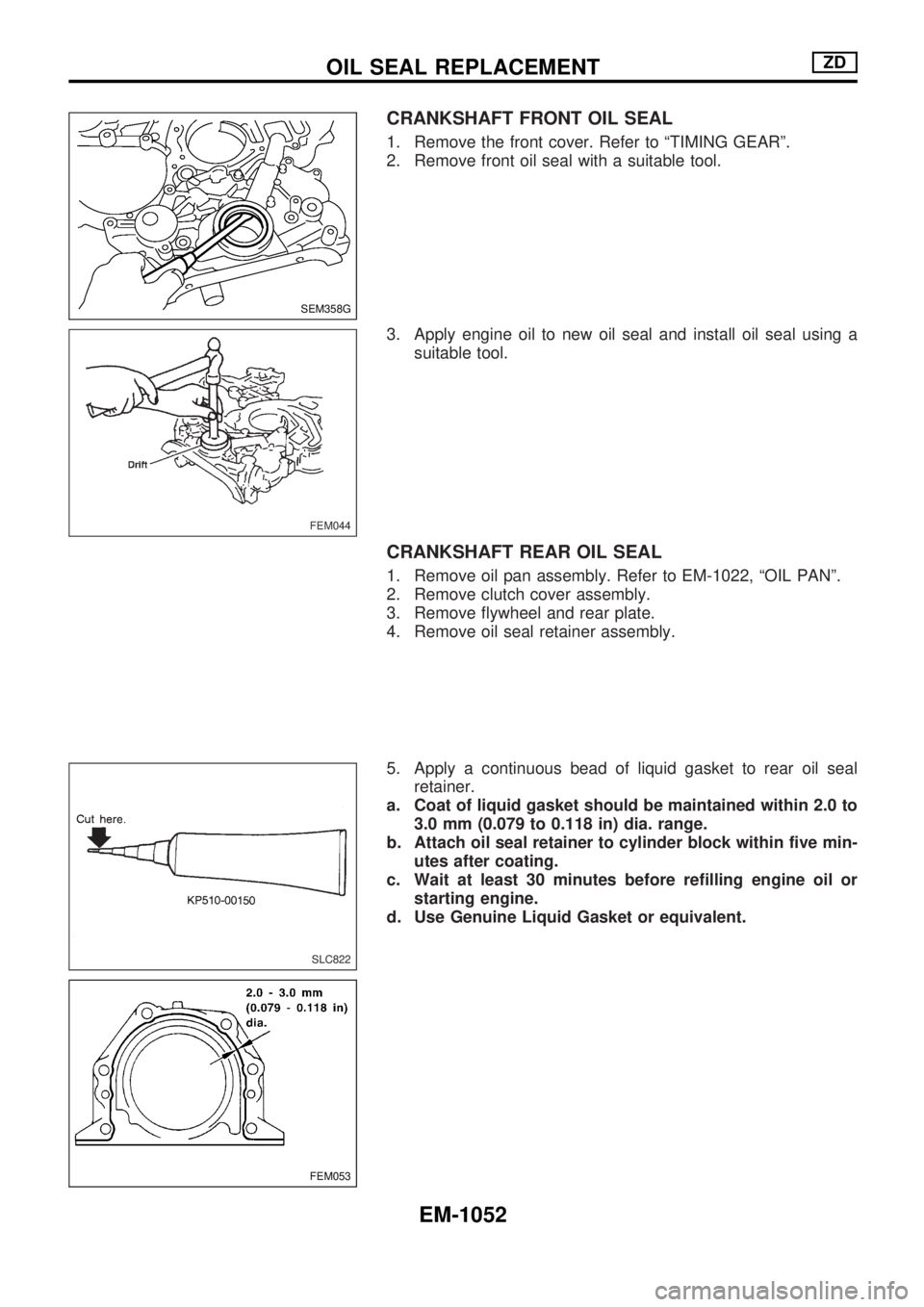

CRANKSHAFT FRONT OIL SEAL

1. Remove the front cover. Refer to ªTIMING GEARº.

2. Remove front oil seal with a suitable tool.

3. Apply engine oil to new oil seal and install oil seal using a

suitable tool.

CRANKSHAFT REAR OIL SEAL

1. Remove oil pan assembly. Refer to EM-1022, ªOIL PANº.

2. Remove clutch cover assembly.

3. Remove flywheel and rear plate.

4. Remove oil seal retainer assembly.

5. Apply a continuous bead of liquid gasket to rear oil seal

retainer.

a. Coat of liquid gasket should be maintained within 2.0 to

3.0 mm (0.079 to 0.118 in) dia. range.

b. Attach oil seal retainer to cylinder block within five min-

utes after coating.

c. Wait at least 30 minutes before refilling engine oil or

starting engine.

d. Use Genuine Liquid Gasket or equivalent.

SEM358G

FEM044

SLC822

FEM053

OIL SEAL REPLACEMENTZD

EM-1052

Page 792 of 1033

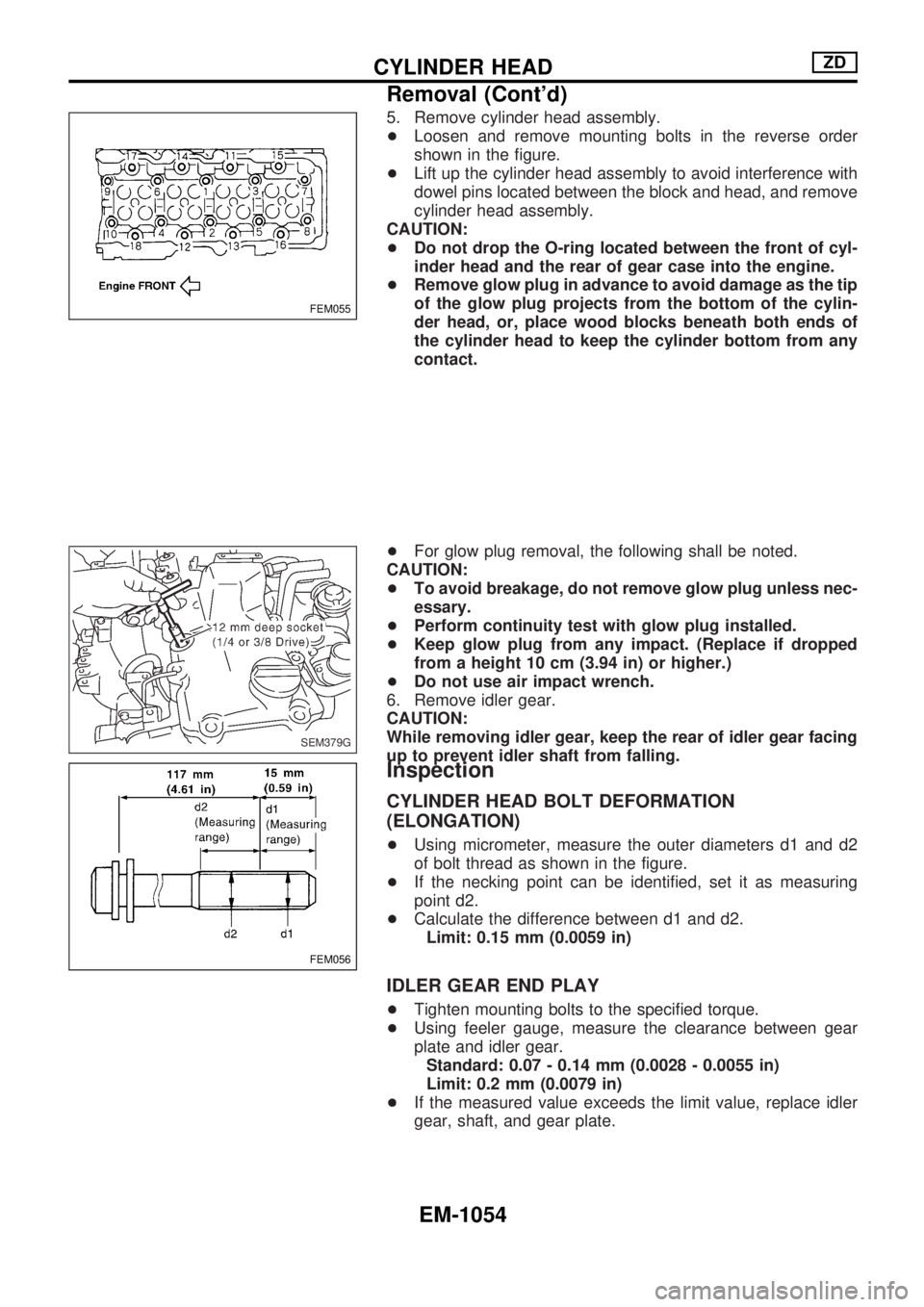

5. Remove cylinder head assembly.

+Loosen and remove mounting bolts in the reverse order

shown in the figure.

+Lift up the cylinder head assembly to avoid interference with

dowel pins located between the block and head, and remove

cylinder head assembly.

CAUTION:

+Do not drop the O-ring located between the front of cyl-

inder head and the rear of gear case into the engine.

+Remove glow plug in advance to avoid damage as the tip

of the glow plug projects from the bottom of the cylin-

der head, or, place wood blocks beneath both ends of

the cylinder head to keep the cylinder bottom from any

contact.

+For glow plug removal, the following shall be noted.

CAUTION:

+To avoid breakage, do not remove glow plug unless nec-

essary.

+Perform continuity test with glow plug installed.

+Keep glow plug from any impact. (Replace if dropped

from a height 10 cm (3.94 in) or higher.)

+Do not use air impact wrench.

6. Remove idler gear.

CAUTION:

While removing idler gear, keep the rear of idler gear facing

up to prevent idler shaft from falling.

Inspection

CYLINDER HEAD BOLT DEFORMATION

(ELONGATION)

+Using micrometer, measure the outer diameters d1 and d2

of bolt thread as shown in the figure.

+If the necking point can be identified, set it as measuring

point d2.

+Calculate the difference between d1 and d2.

Limit: 0.15 mm (0.0059 in)

IDLER GEAR END PLAY

+Tighten mounting bolts to the specified torque.

+Using feeler gauge, measure the clearance between gear

plate and idler gear.

Standard: 0.07 - 0.14 mm (0.0028 - 0.0055 in)

Limit: 0.2 mm (0.0079 in)

+If the measured value exceeds the limit value, replace idler

gear, shaft, and gear plate.

FEM055

SEM379G

FEM056

CYLINDER HEADZD

Removal (Cont'd)

EM-1054

Page 794 of 1033

GradePiston crown

depressionGasket thick-

ness*1No. of notches

1Less than þ0.078

(þ0.0031)*20.65 (0.0256) 1

2More than þ0.078

(þ0.0031)*30.70 (0.0276) 2

*1: Thickness of gasket tightened with head bolts

*2: Indicates values such as þ0.080 mm (þ0.0031 in).

*3: Indicates values such as þ0.075 mm (þ0.0030 in).

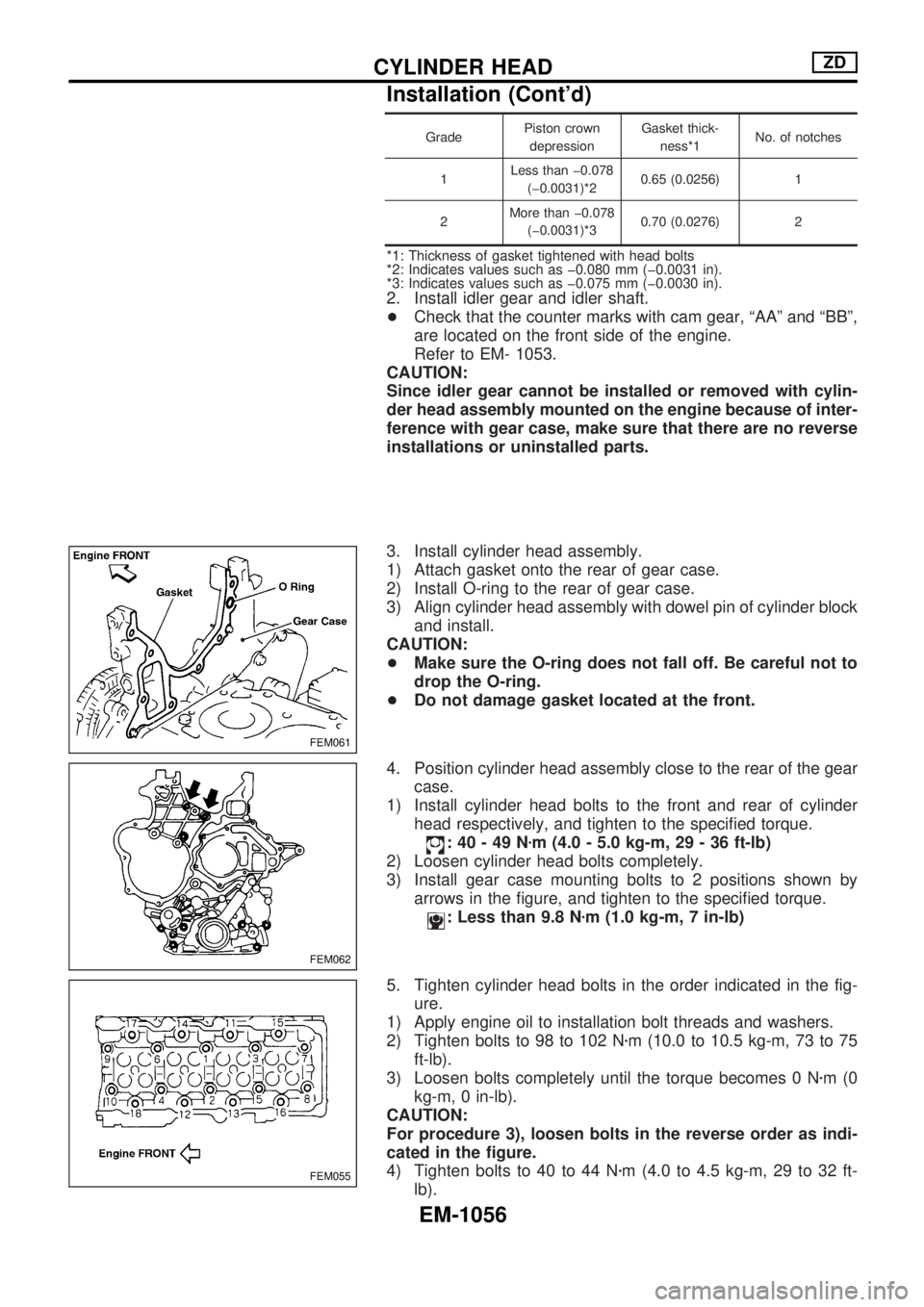

2. Install idler gear and idler shaft.

+Check that the counter marks with cam gear, ªAAº and ªBBº,

are located on the front side of the engine.

Refer to EM- 1053.

CAUTION:

Since idler gear cannot be installed or removed with cylin-

der head assembly mounted on the engine because of inter-

ference with gear case, make sure that there are no reverse

installations or uninstalled parts.

3. Install cylinder head assembly.

1) Attach gasket onto the rear of gear case.

2) Install O-ring to the rear of gear case.

3) Align cylinder head assembly with dowel pin of cylinder block

and install.

CAUTION:

+Make sure the O-ring does not fall off. Be careful not to

drop the O-ring.

+Do not damage gasket located at the front.

4. Position cylinder head assembly close to the rear of the gear

case.

1) Install cylinder head bolts to the front and rear of cylinder

head respectively, and tighten to the specified torque.

:40-49Nzm (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

2) Loosen cylinder head bolts completely.

3) Install gear case mounting bolts to 2 positions shown by

arrows in the figure, and tighten to the specified torque.

: Less than 9.8 Nzm (1.0 kg-m, 7 in-lb)

5. Tighten cylinder head bolts in the order indicated in the fig-

ure.

1) Apply engine oil to installation bolt threads and washers.

2) Tighten bolts to 98 to 102 Nzm (10.0 to 10.5 kg-m, 73 to 75

ft-lb).

3) Loosen bolts completely until the torque becomes 0 Nzm(0

kg-m, 0 in-lb).

CAUTION:

For procedure 3), loosen bolts in the reverse order as indi-

cated in the figure.

4) Tighten bolts to 40 to 44 Nzm (4.0 to 4.5 kg-m, 29 to 32 ft-

lb).

FEM061

FEM062

FEM055

CYLINDER HEADZD

Installation (Cont'd)

EM-1056

Page 795 of 1033

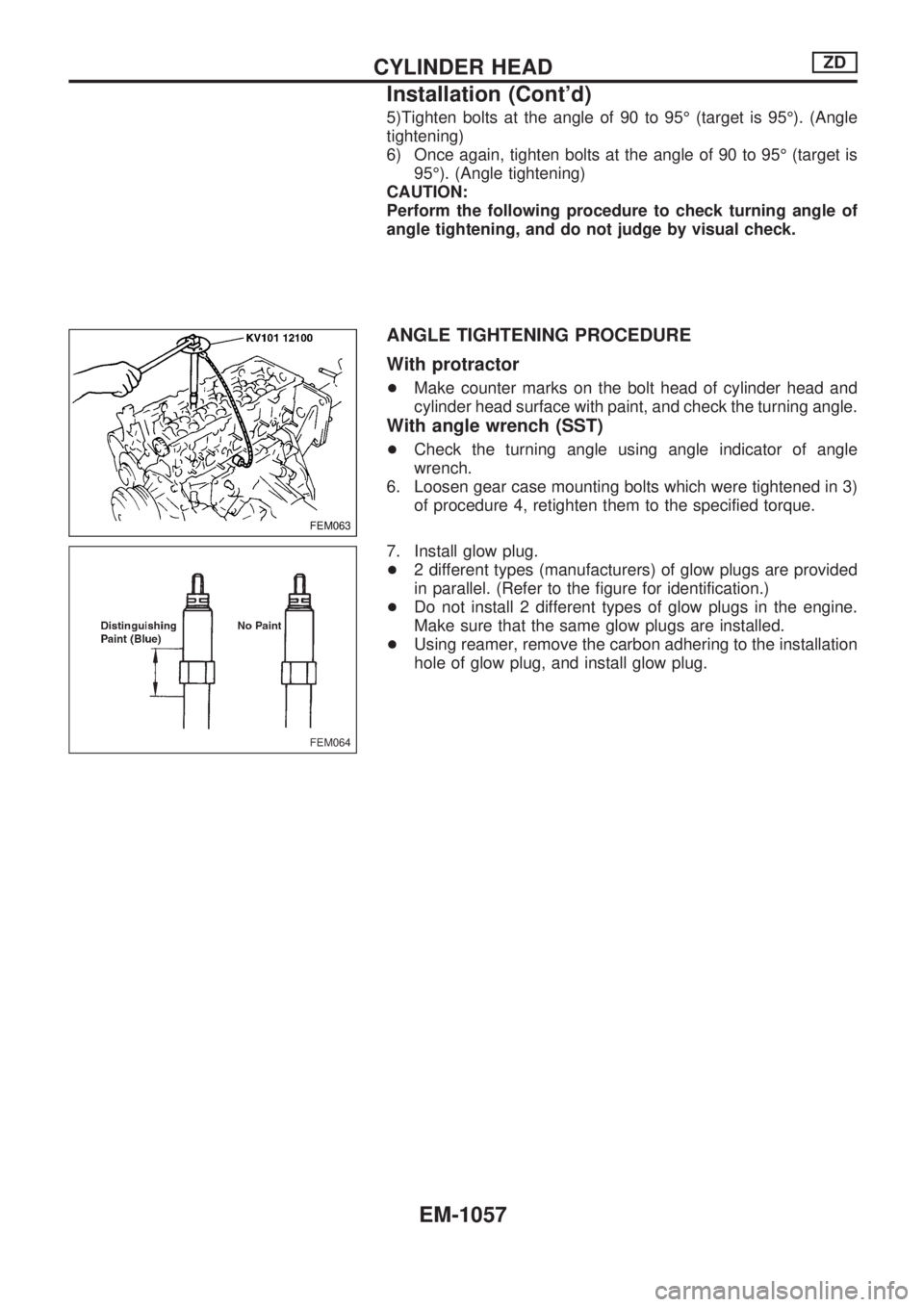

5)Tighten bolts at the angle of 90 to 95É (target is 95É). (Angle

tightening)

6) Once again, tighten bolts at the angle of 90 to 95É (target is

95É). (Angle tightening)

CAUTION:

Perform the following procedure to check turning angle of

angle tightening, and do not judge by visual check.

ANGLE TIGHTENING PROCEDURE

With protractor

+Make counter marks on the bolt head of cylinder head and

cylinder head surface with paint, and check the turning angle.

With angle wrench (SST)

+Check the turning angle using angle indicator of angle

wrench.

6. Loosen gear case mounting bolts which were tightened in 3)

of procedure 4, retighten them to the specified torque.

7. Install glow plug.

+2 different types (manufacturers) of glow plugs are provided

in parallel. (Refer to the figure for identification.)

+Do not install 2 different types of glow plugs in the engine.

Make sure that the same glow plugs are installed.

+Using reamer, remove the carbon adhering to the installation

hole of glow plug, and install glow plug.

FEM063

FEM064

CYLINDER HEADZD

Installation (Cont'd)

EM-1057

Page 800 of 1033

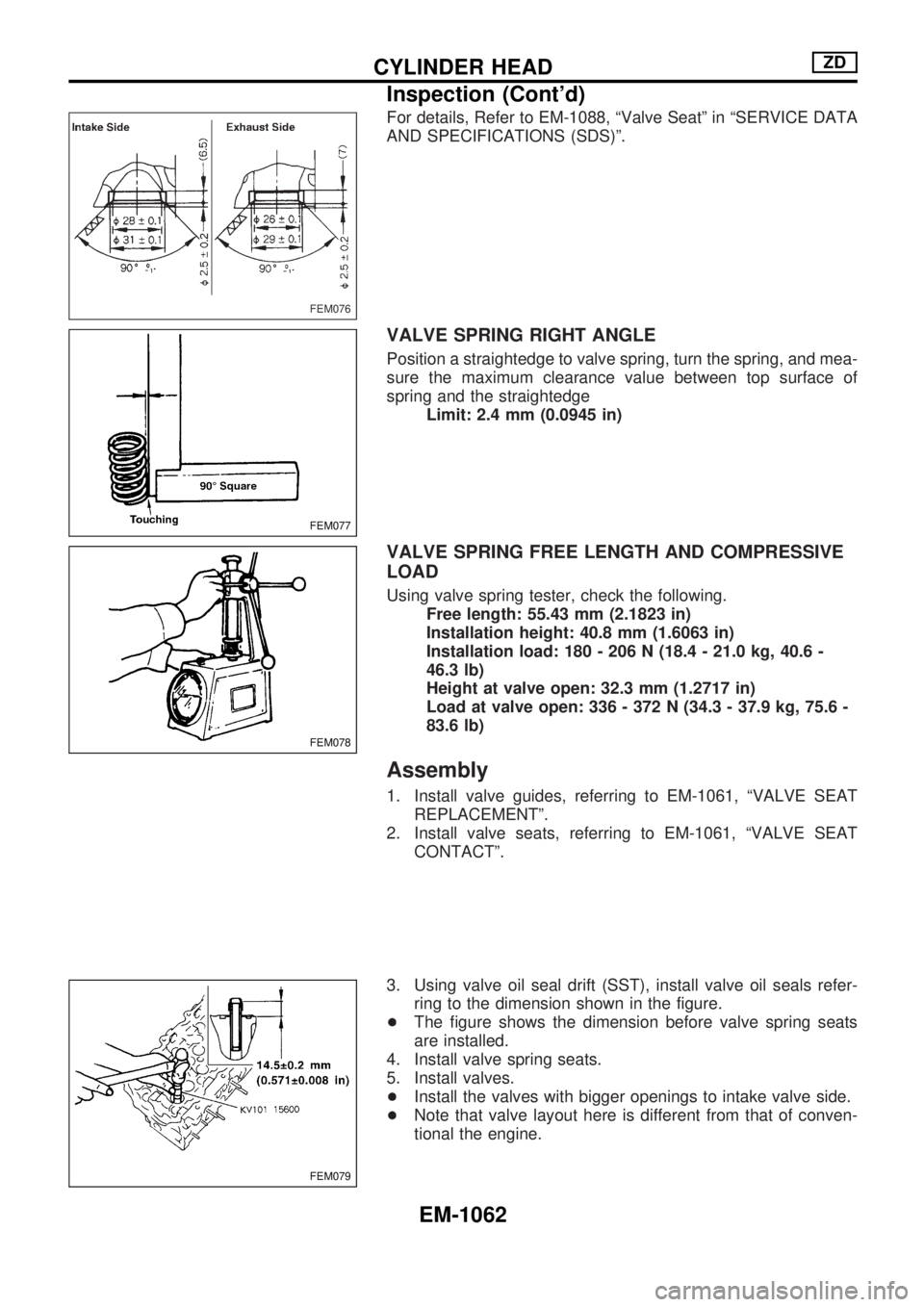

For details, Refer to EM-1088, ªValve Seatº in ªSERVICE DATA

AND SPECIFICATIONS (SDS)º.

VALVE SPRING RIGHT ANGLE

Position a straightedge to valve spring, turn the spring, and mea-

sure the maximum clearance value between top surface of

spring and the straightedge

Limit: 2.4 mm (0.0945 in)

VALVE SPRING FREE LENGTH AND COMPRESSIVE

LOAD

Using valve spring tester, check the following.

Free length: 55.43 mm (2.1823 in)

Installation height: 40.8 mm (1.6063 in)

Installation load: 180 - 206 N (18.4 - 21.0 kg, 40.6 -

46.3 lb)

Height at valve open: 32.3 mm (1.2717 in)

Load at valve open: 336 - 372 N (34.3 - 37.9 kg, 75.6 -

83.6 lb)

Assembly

1. Install valve guides, referring to EM-1061, ªVALVE SEAT

REPLACEMENTº.

2. Install valve seats, referring to EM-1061, ªVALVE SEAT

CONTACTº.

3. Using valve oil seal drift (SST), install valve oil seals refer-

ring to the dimension shown in the figure.

+The figure shows the dimension before valve spring seats

are installed.

4. Install valve spring seats.

5. Install valves.

+Install the valves with bigger openings to intake valve side.

+Note that valve layout here is different from that of conven-

tional the engine.

FEM076

FEM077

FEM078

FEM079

CYLINDER HEADZD

Inspection (Cont'd)

EM-1062

Page 802 of 1033

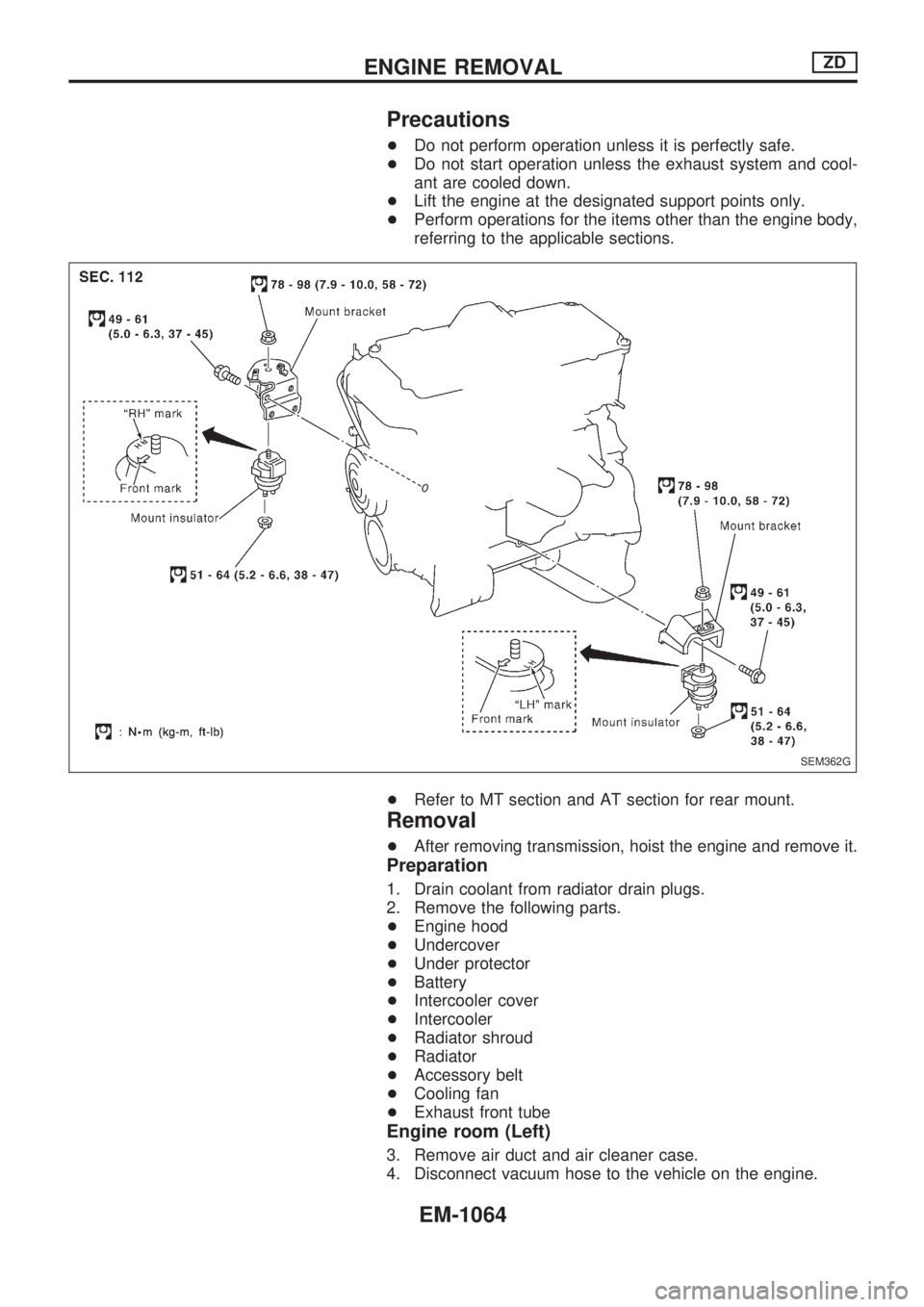

Precautions

+Do not perform operation unless it is perfectly safe.

+Do not start operation unless the exhaust system and cool-

ant are cooled down.

+Lift the engine at the designated support points only.

+Perform operations for the items other than the engine body,

referring to the applicable sections.

+Refer to MT section and AT section for rear mount.

Removal

+After removing transmission, hoist the engine and remove it.

Preparation

1. Drain coolant from radiator drain plugs.

2. Remove the following parts.

+Engine hood

+Undercover

+Under protector

+Battery

+Intercooler cover

+Intercooler

+Radiator shroud

+Radiator

+Accessory belt

+Cooling fan

+Exhaust front tube

Engine room (Left)

3. Remove air duct and air cleaner case.

4. Disconnect vacuum hose to the vehicle on the engine.

SEM362G

ENGINE REMOVALZD

EM-1064

Page 803 of 1033

5. Disconnect harness connectors from alternator and air com-

pressor.

6. Remove alternator.

7. After removing refrigerant, remove pipes of air compressor

and inlet/outlet.

8. Disconnect heating hose, install blank cap to hose to prevent

coolant from leaking.

9. Remove heating pipe.

10. Remove heat insulator.

11. Remove catalytic converter.

Engine room (Right)

12. Remove power steering reservoir tank from bracket, and fix

it to the vehicle with a rope.

CAUTION:

Keep the reservoir tank level when fixing to prevent oil leak.

13. Remove fuel feed and return hoses.

CAUTION:

Install blank caps immediately to avoid fuel leakage.

14. Remove all harness connectors on the engine, and move

harnesses to the side of the vehicle.

Vehicle underfloor

15. Remove starter motor.

16. Detach A/T oil cooler pipes from oil pan. (A/T model)

17. Remove rear propeller shaft.

18. Remove mounting bolts to secure the engine to transmission.

1) Remove torque converter installation bolt. (A/T model)

2) Lift transmission bottom with transmission jack, and remove

rear mount members from the vehicle.

3) Lower transmission with the jack, and remove upper mount-

ing bolts securing the engine to transmission.

4) Lift transmission with the jack, and reinstall rear mount mem-

bers to the vehicle.

5) Position the jack to the front side of transmission.

6) Remove remaining mounting bolts securing the engine to

transmission.

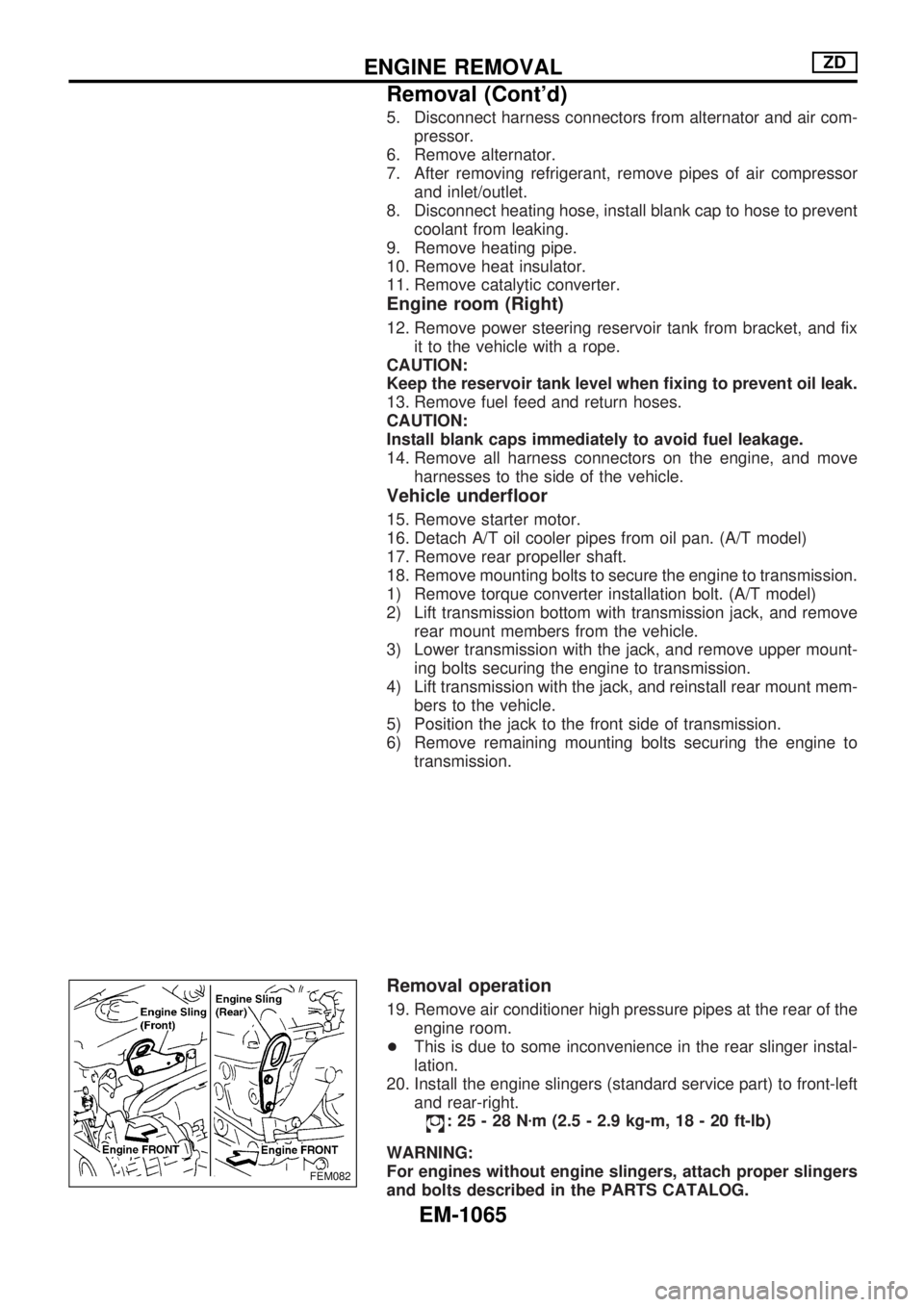

Removal operation

19. Remove air conditioner high pressure pipes at the rear of the

engine room.

+This is due to some inconvenience in the rear slinger instal-

lation.

20. Install the engine slingers (standard service part) to front-left

and rear-right.

:25-28Nzm (2.5 - 2.9 kg-m, 18 - 20 ft-lb)

WARNING:

For engines without engine slingers, attach proper slingers

and bolts described in the PARTS CATALOG.

FEM082

ENGINE REMOVALZD

Removal (Cont'd)

EM-1065

Page 804 of 1033

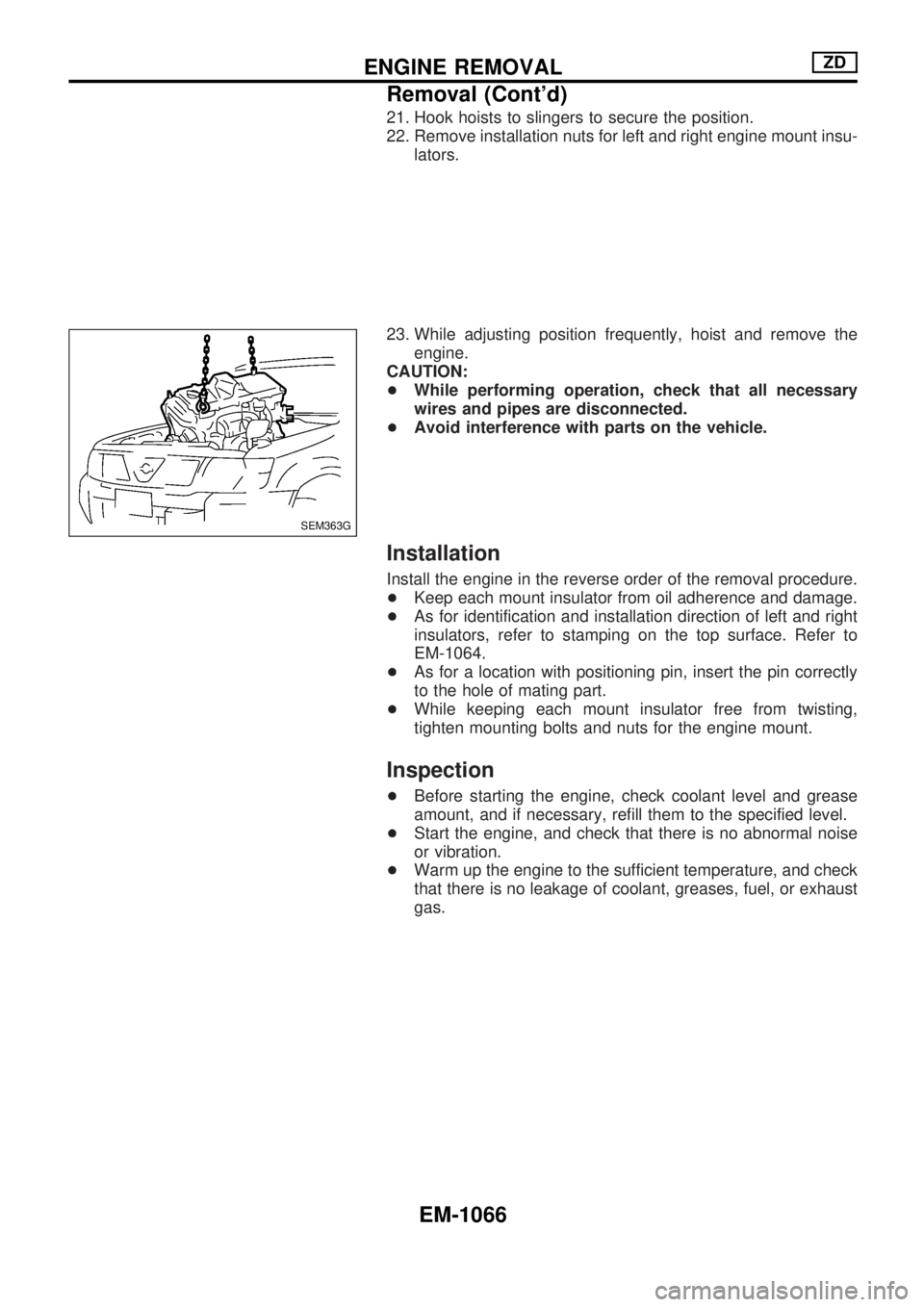

21. Hook hoists to slingers to secure the position.

22. Remove installation nuts for left and right engine mount insu-

lators.

23. While adjusting position frequently, hoist and remove the

engine.

CAUTION:

+While performing operation, check that all necessary

wires and pipes are disconnected.

+Avoid interference with parts on the vehicle.

Installation

Install the engine in the reverse order of the removal procedure.

+Keep each mount insulator from oil adherence and damage.

+As for identification and installation direction of left and right

insulators, refer to stamping on the top surface. Refer to

EM-1064.

+As for a location with positioning pin, insert the pin correctly

to the hole of mating part.

+While keeping each mount insulator free from twisting,

tighten mounting bolts and nuts for the engine mount.

Inspection

+Before starting the engine, check coolant level and grease

amount, and if necessary, refill them to the specified level.

+Start the engine, and check that there is no abnormal noise

or vibration.

+Warm up the engine to the sufficient temperature, and check

that there is no leakage of coolant, greases, fuel, or exhaust

gas.

SEM363G

ENGINE REMOVALZD

Removal (Cont'd)

EM-1066