NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 491 of 1033

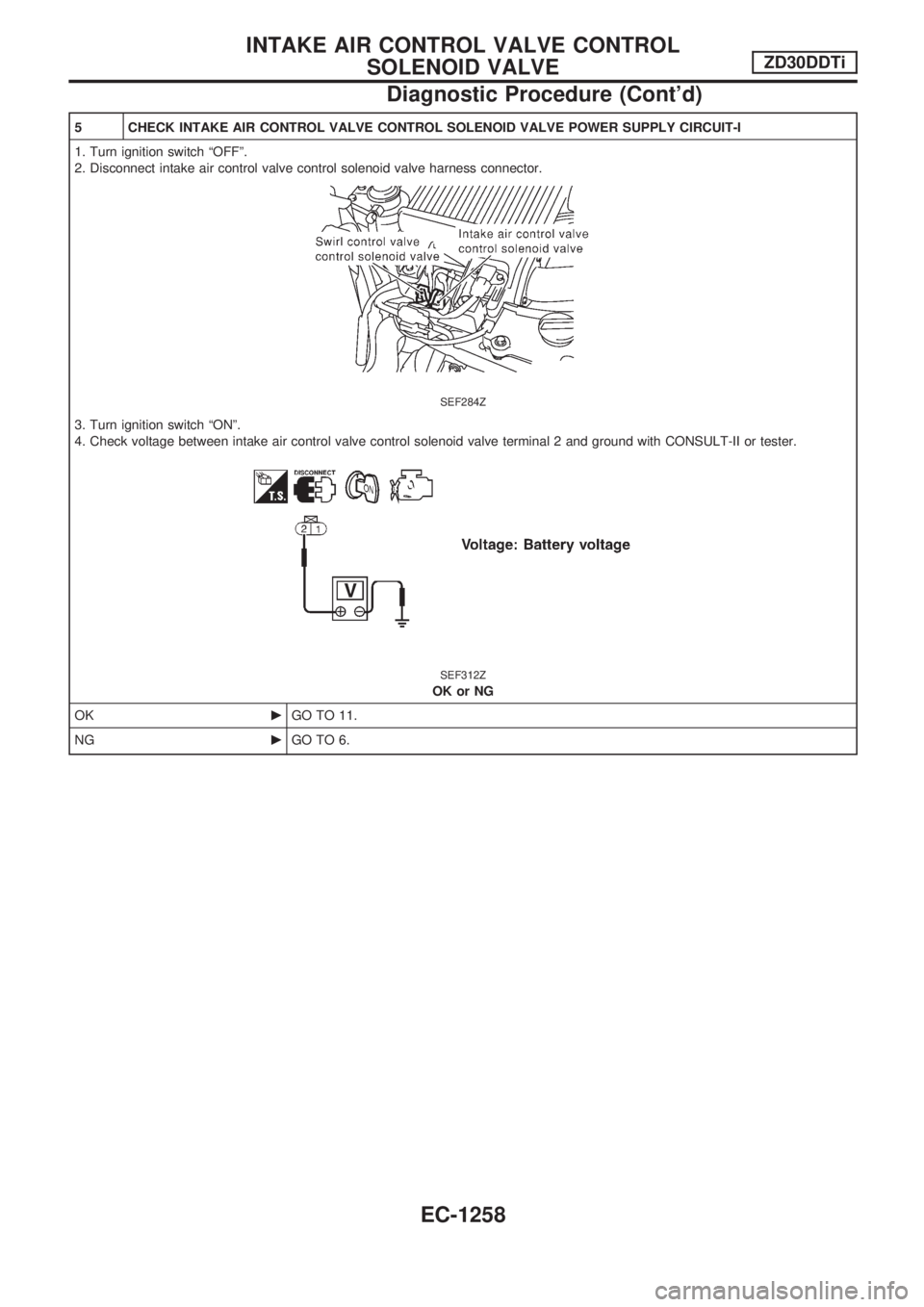

5 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªOFFº.

2. Disconnect intake air control valve control solenoid valve harness connector.

SEF284Z

3. Turn ignition switch ªONº.

4. Check voltage between intake air control valve control solenoid valve terminal 2 and ground with CONSULT-II or tester.

SEF312Z

OK or NG

OKcGO TO 11.

NGcGO TO 6.

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1258

Page 492 of 1033

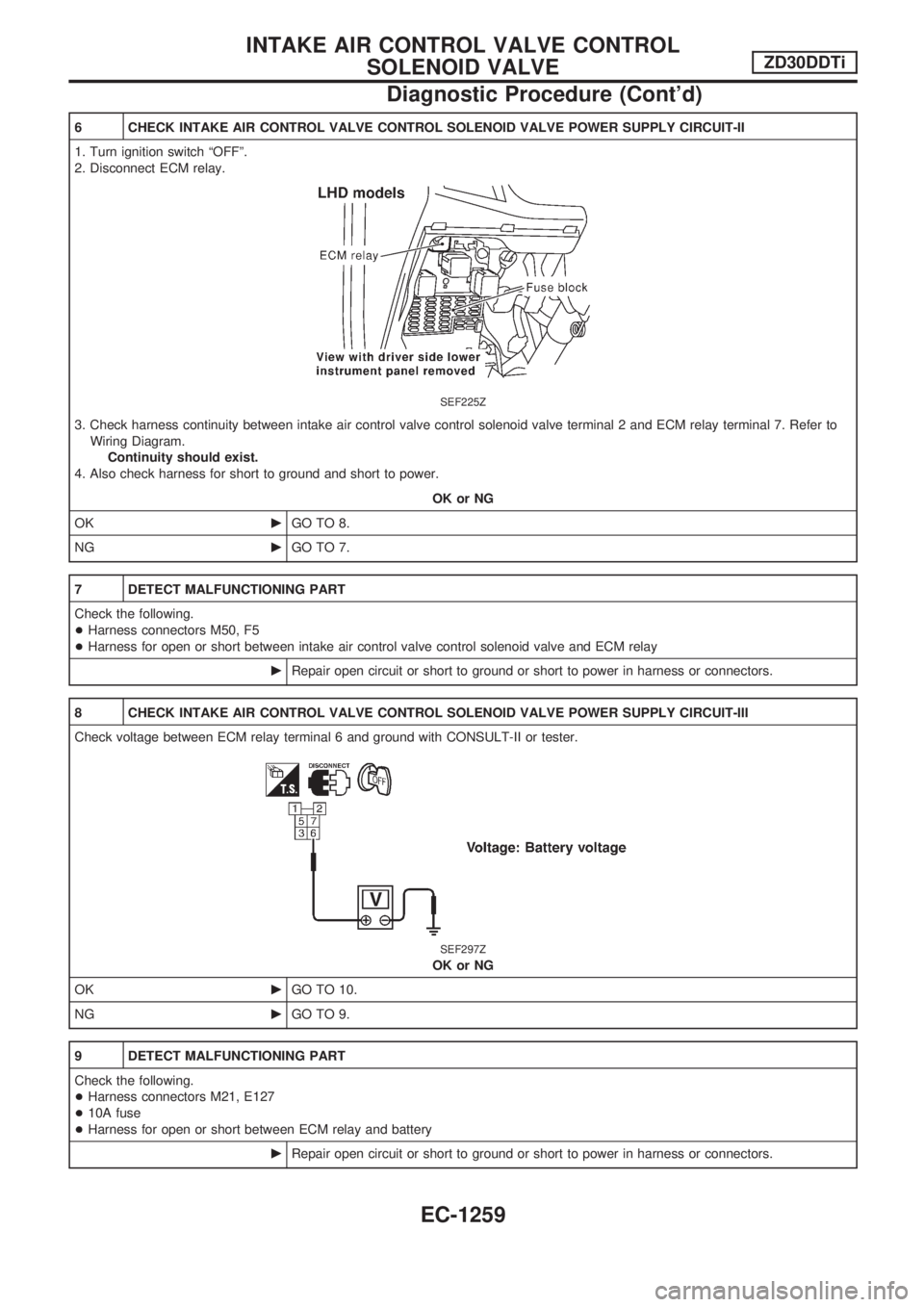

6 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT-II

1. Turn ignition switch ªOFFº.

2. Disconnect ECM relay.

SEF225Z

3. Check harness continuity between intake air control valve control solenoid valve terminal 2 and ECM relay terminal 7. Refer to

Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 8.

NGcGO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F5

+Harness for open or short between intake air control valve control solenoid valve and ECM relay

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT-III

Check voltage between ECM relay terminal 6 and ground with CONSULT-II or tester.

SEF297Z

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+10A fuse

+Harness for open or short between ECM relay and battery

cRepair open circuit or short to ground or short to power in harness or connectors.

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1259

Page 493 of 1033

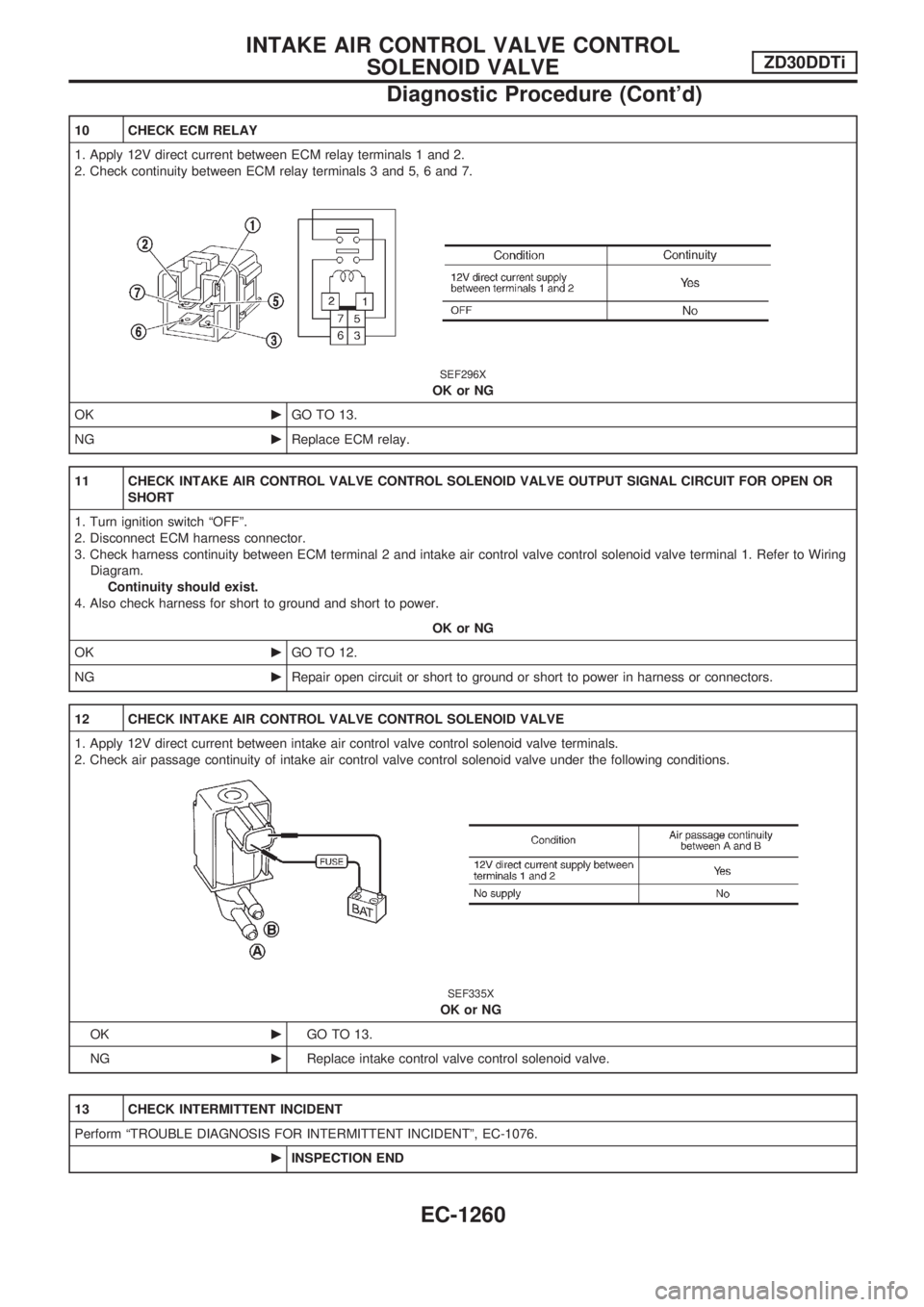

10 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between ECM relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OKcGO TO 13.

NGcReplace ECM relay.

11 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN OR

SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 2 and intake air control valve control solenoid valve terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 12.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

12 CHECK INTAKE AIR CONTROL VALVE CONTROL SOLENOID VALVE

1. Apply 12V direct current between intake air control valve control solenoid valve terminals.

2. Check air passage continuity of intake air control valve control solenoid valve under the following conditions.

SEF335X

OK or NG

OKcGO TO 13.

NGcReplace intake control valve control solenoid valve.

13 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

INTAKE AIR CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1260

Page 494 of 1033

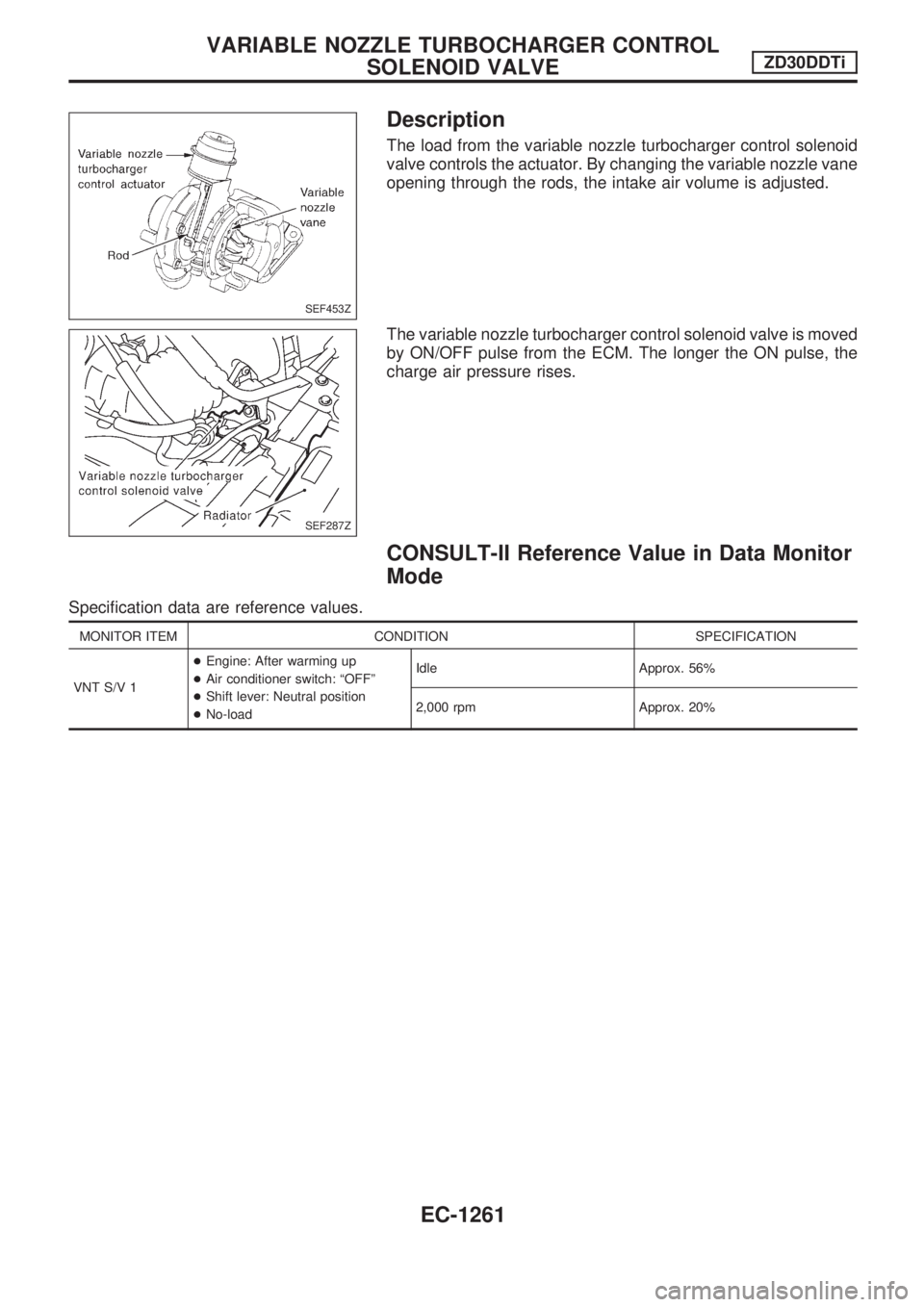

Description

The load from the variable nozzle turbocharger control solenoid

valve controls the actuator. By changing the variable nozzle vane

opening through the rods, the intake air volume is adjusted.

The variable nozzle turbocharger control solenoid valve is moved

by ON/OFF pulse from the ECM. The longer the ON pulse, the

charge air pressure rises.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

VNT S/V 1+Engine: After warming up

+Air conditioner switch: ªOFFº

+Shift lever: Neutral position

+No-loadIdle Approx. 56%

2,000 rpm Approx. 20%

SEF453Z

SEF287Z

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

EC-1261

Page 495 of 1033

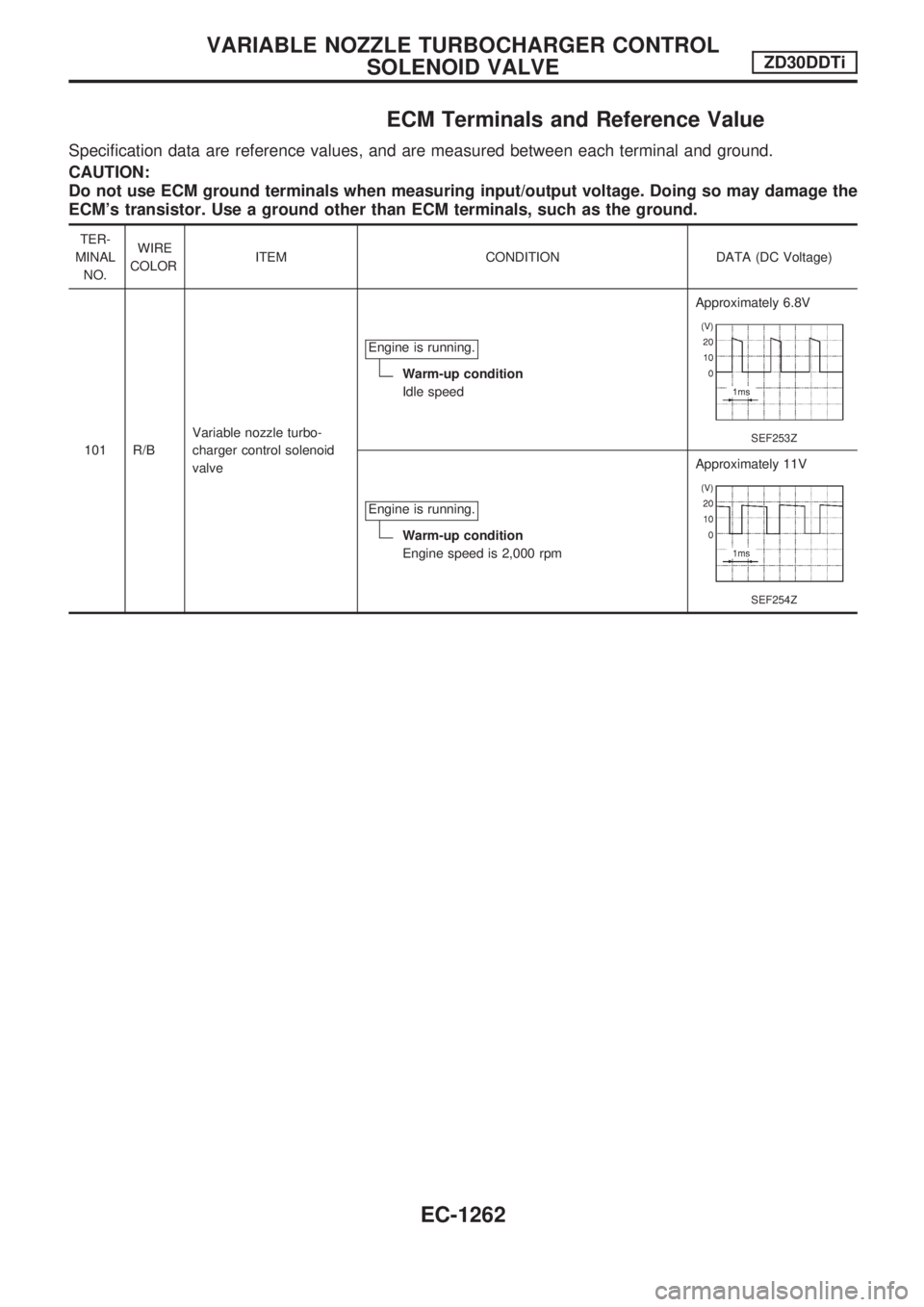

ECM Terminals and Reference Value

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

101 R/BVariable nozzle turbo-

charger control solenoid

valveEngine is running.

Warm-up condition

Idle speedApproximately 6.8V

SEF253Z

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 11V

SEF254Z

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

EC-1262

Page 496 of 1033

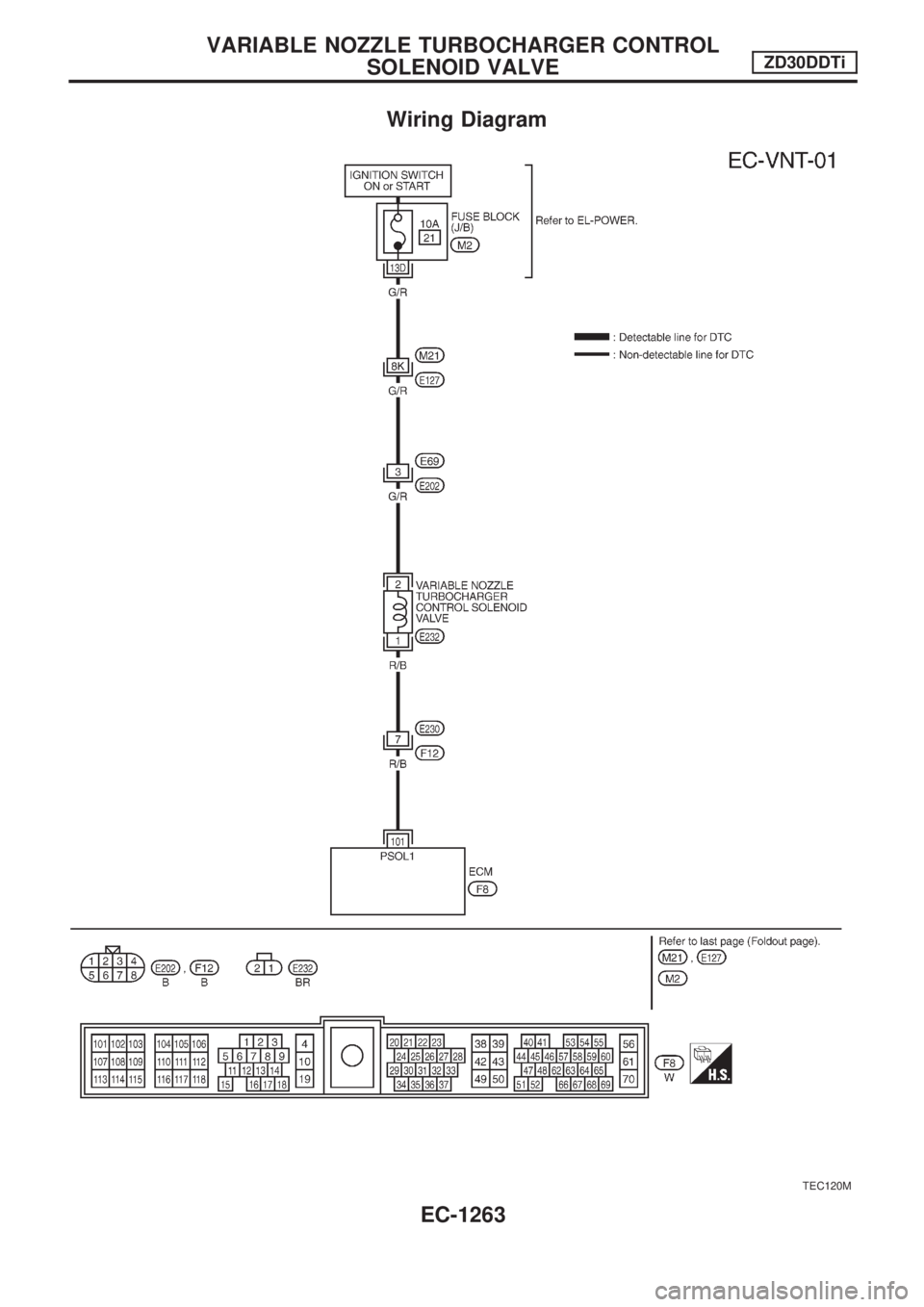

Wiring Diagram

TEC120M

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

EC-1263

Page 497 of 1033

Diagnostic Procedure

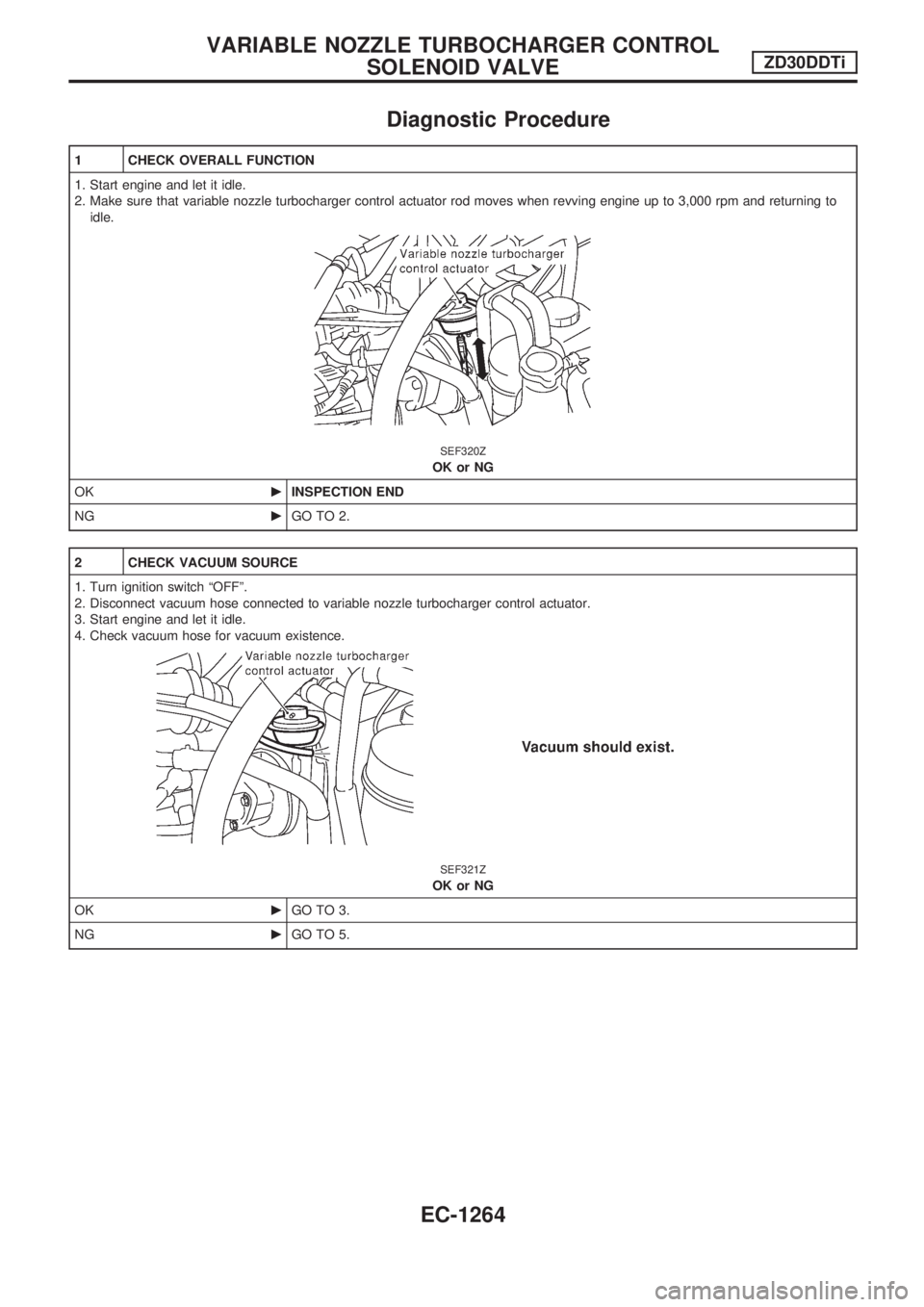

1 CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that variable nozzle turbocharger control actuator rod moves when revving engine up to 3,000 rpm and returning to

idle.

SEF320Z

OK or NG

OKcINSPECTION END

NGcGO TO 2.

2 CHECK VACUUM SOURCE

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to variable nozzle turbocharger control actuator.

3. Start engine and let it idle.

4. Check vacuum hose for vacuum existence.

SEF321Z

OK or NG

OKcGO TO 3.

NGcGO TO 5.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

EC-1264

Page 498 of 1033

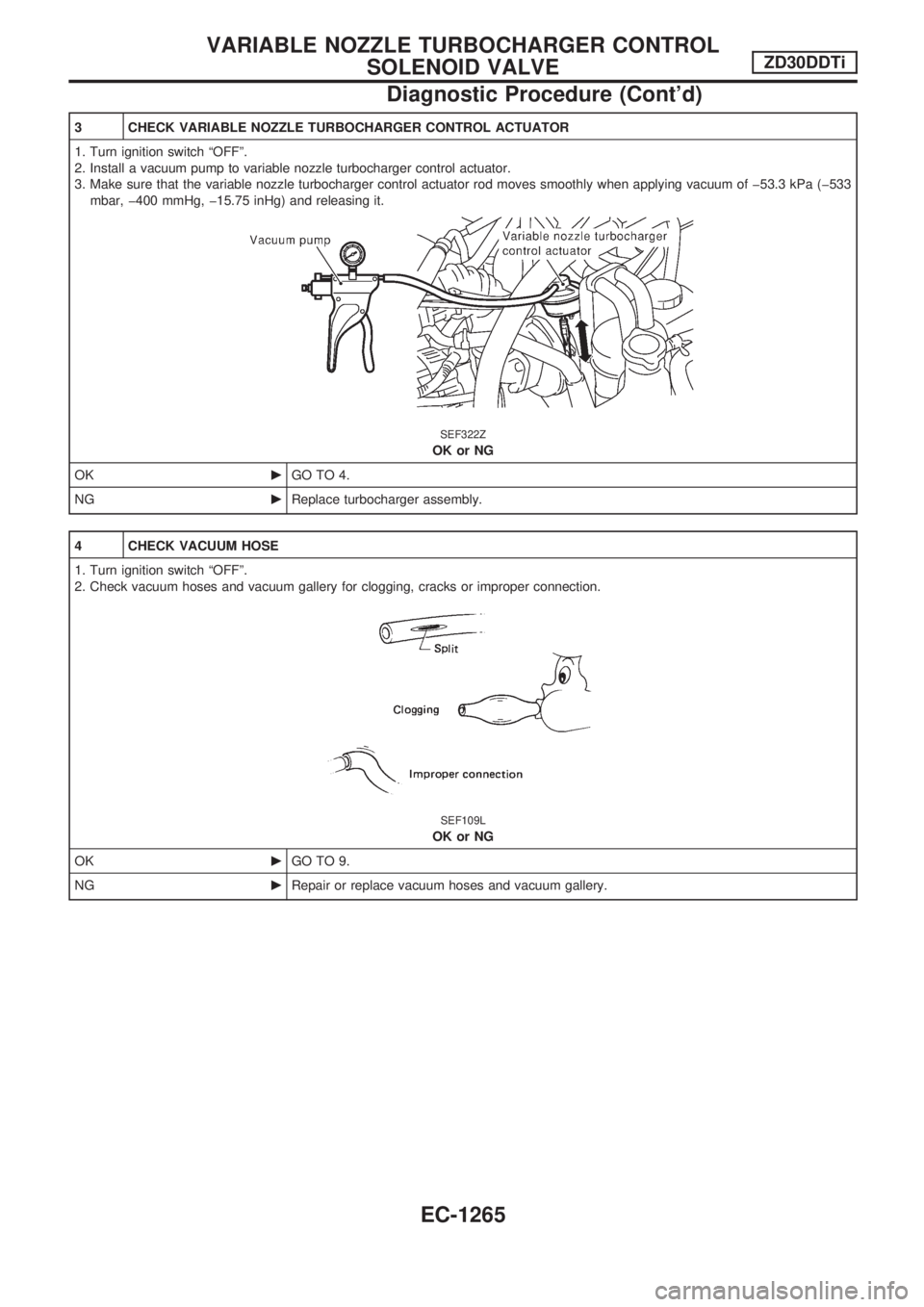

3 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL ACTUATOR

1. Turn ignition switch ªOFFº.

2. Install a vacuum pump to variable nozzle turbocharger control actuator.

3. Make sure that the variable nozzle turbocharger control actuator rod moves smoothly when applying vacuum of þ53.3 kPa (þ533

mbar, þ400 mmHg, þ15.75 inHg) and releasing it.

SEF322Z

OK or NG

OKcGO TO 4.

NGcReplace turbocharger assembly.

4 CHECK VACUUM HOSE

1. Turn ignition switch ªOFFº.

2. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

SEF109L

OK or NG

OKcGO TO 9.

NGcRepair or replace vacuum hoses and vacuum gallery.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1265

Page 499 of 1033

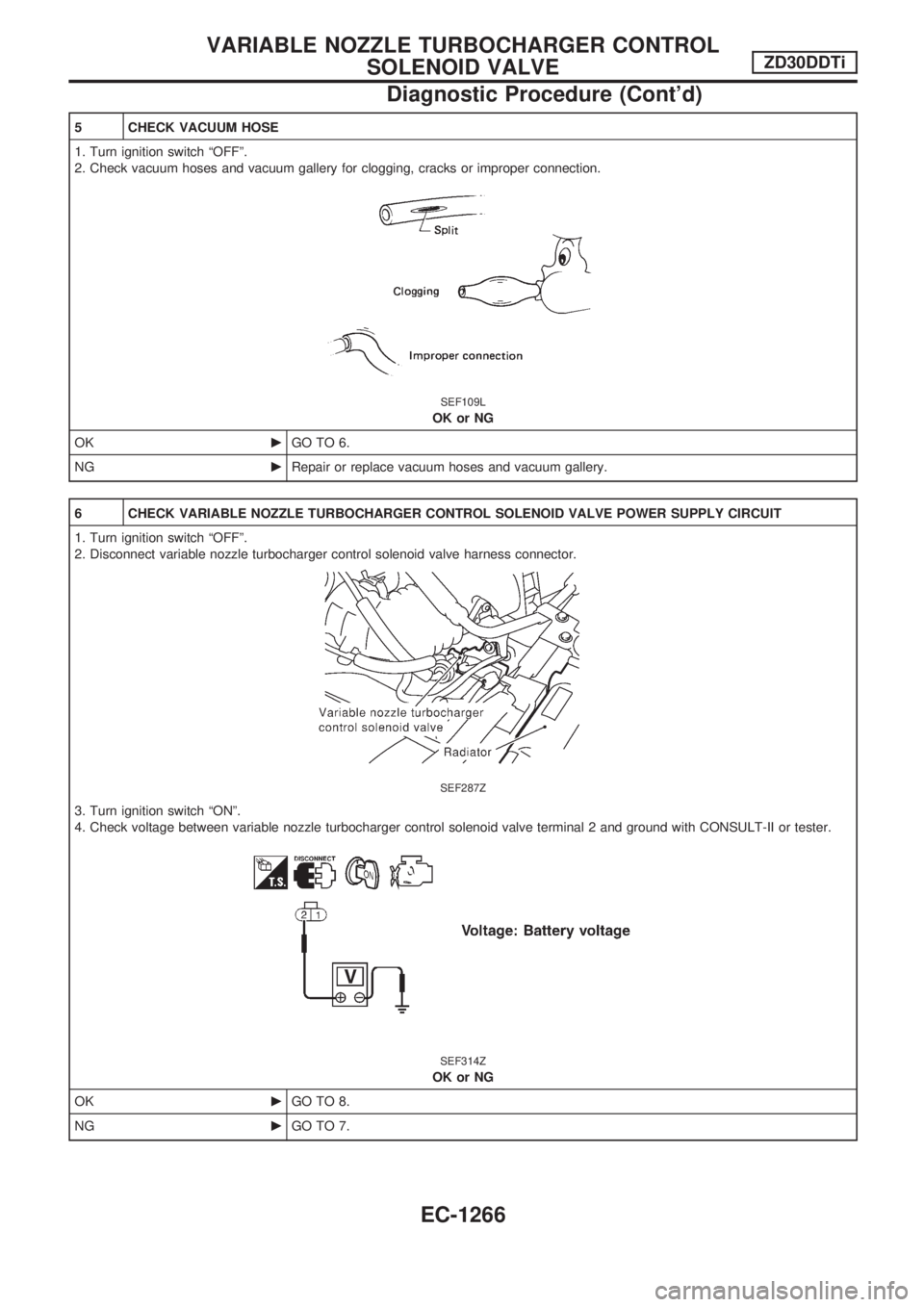

5 CHECK VACUUM HOSE

1. Turn ignition switch ªOFFº.

2. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

SEF109L

OK or NG

OKcGO TO 6.

NGcRepair or replace vacuum hoses and vacuum gallery.

6 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect variable nozzle turbocharger control solenoid valve harness connector.

SEF287Z

3. Turn ignition switch ªONº.

4. Check voltage between variable nozzle turbocharger control solenoid valve terminal 2 and ground with CONSULT-II or tester.

SEF314Z

OK or NG

OKcGO TO 8.

NGcGO TO 7.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1266

Page 500 of 1033

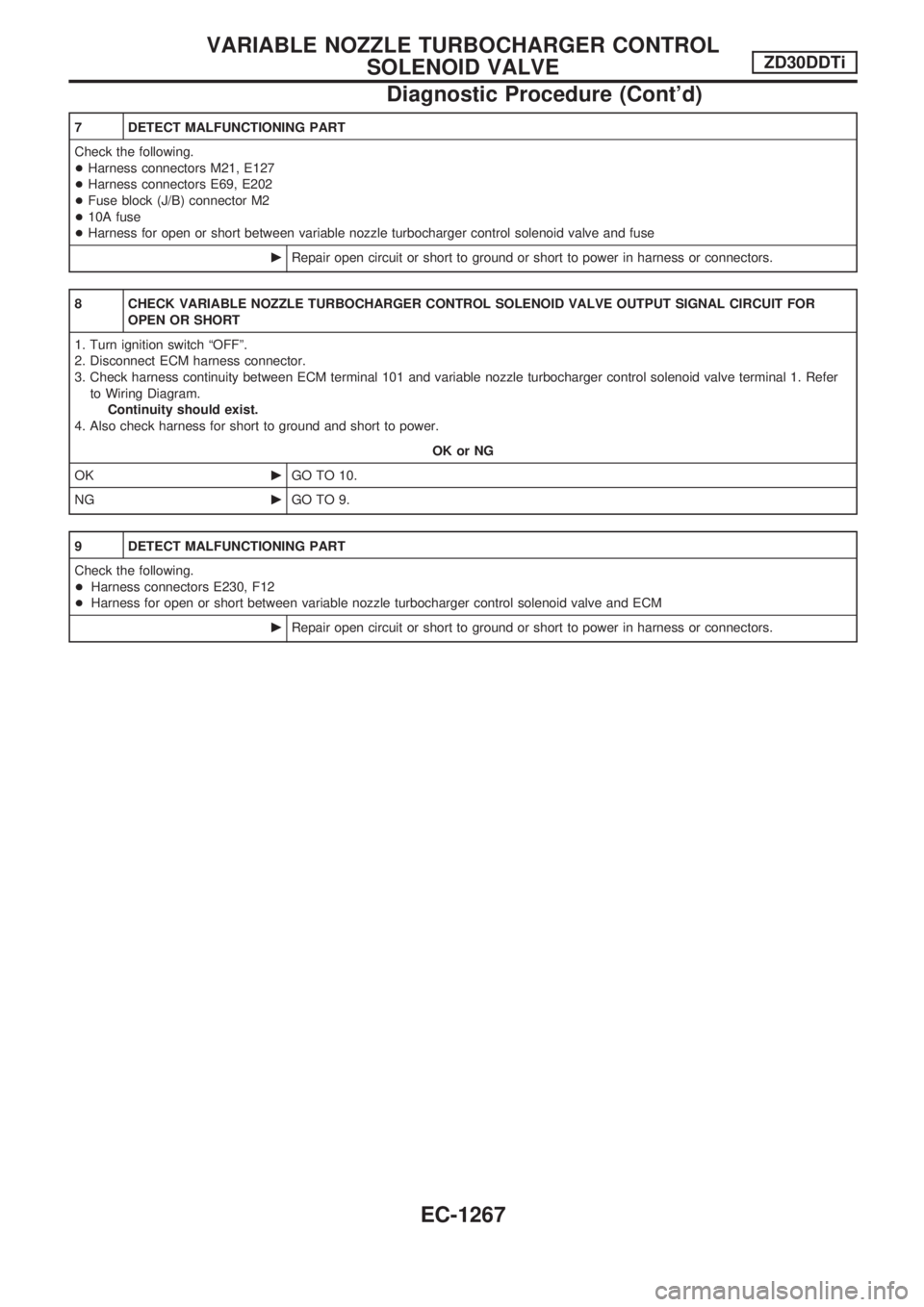

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+Harness connectors E69, E202

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open or short between variable nozzle turbocharger control solenoid valve and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR

OPEN OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 101 and variable nozzle turbocharger control solenoid valve terminal 1. Refer

to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E230, F12

+Harness for open or short between variable nozzle turbocharger control solenoid valve and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1267