NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 501 of 1033

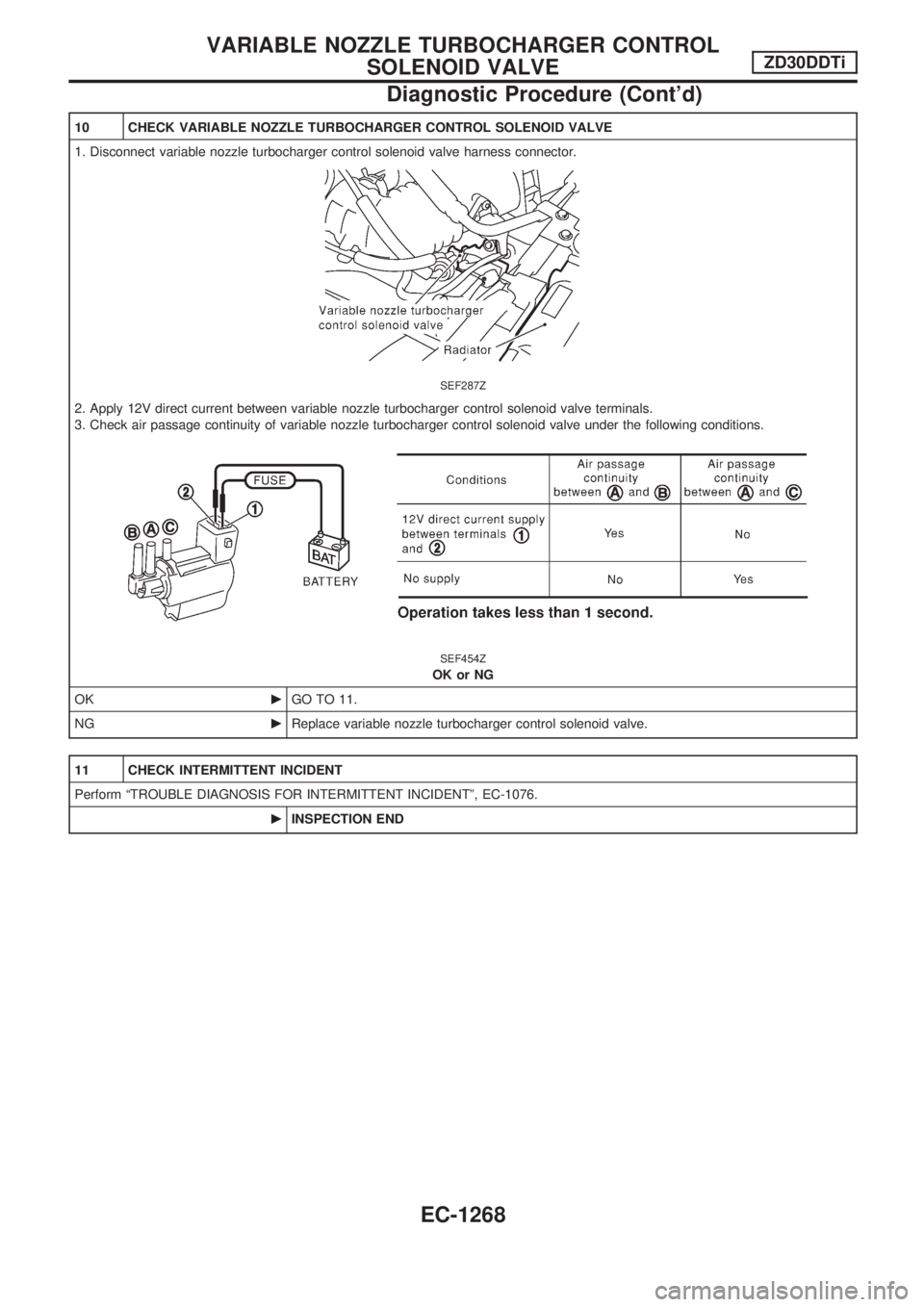

10 CHECK VARIABLE NOZZLE TURBOCHARGER CONTROL SOLENOID VALVE

1. Disconnect variable nozzle turbocharger control solenoid valve harness connector.

SEF287Z

2. Apply 12V direct current between variable nozzle turbocharger control solenoid valve terminals.

3. Check air passage continuity of variable nozzle turbocharger control solenoid valve under the following conditions.

SEF454Z

OK or NG

OKcGO TO 11.

NGcReplace variable nozzle turbocharger control solenoid valve.

11 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

VARIABLE NOZZLE TURBOCHARGER CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1268

Page 502 of 1033

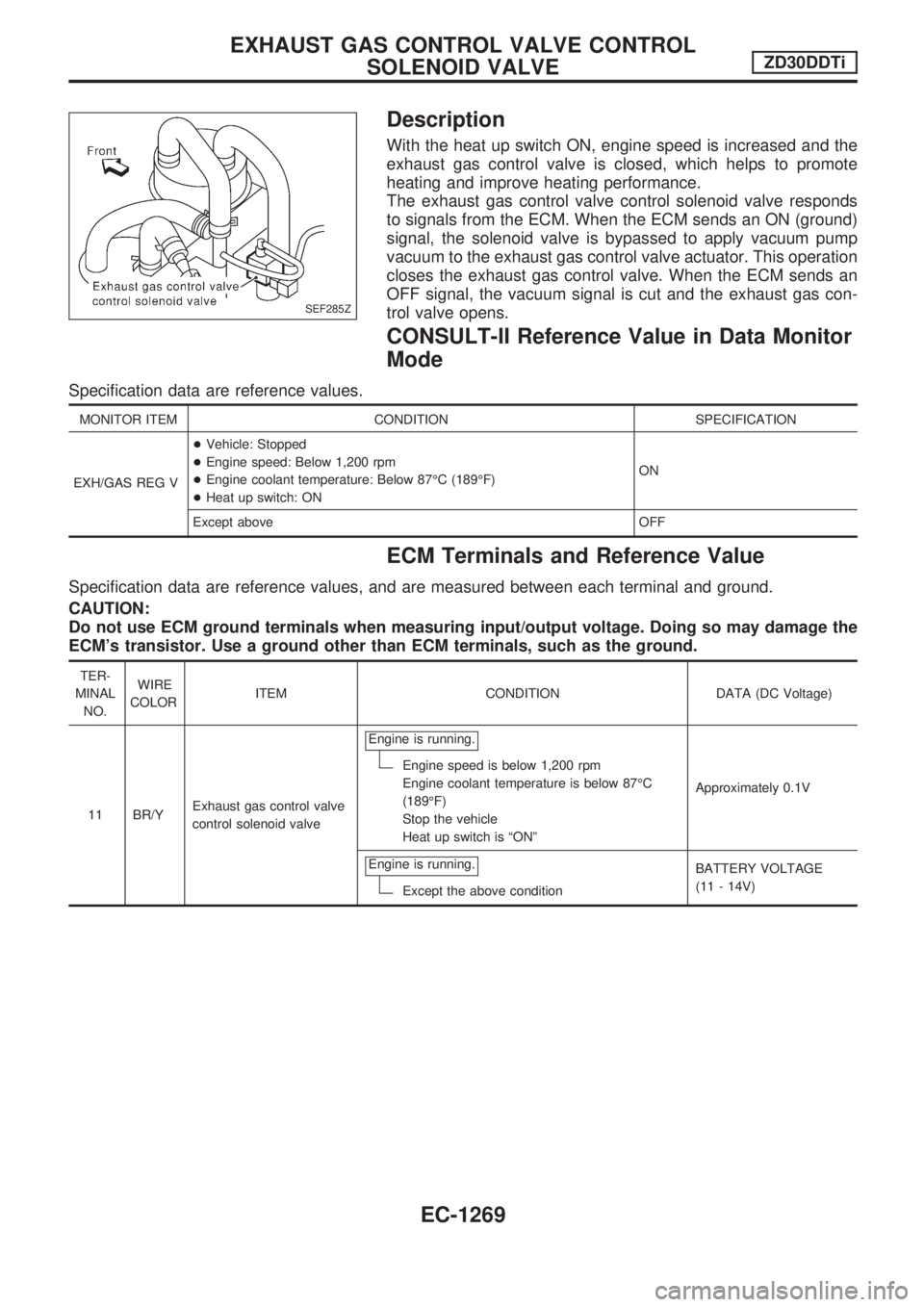

Description

With the heat up switch ON, engine speed is increased and the

exhaust gas control valve is closed, which helps to promote

heating and improve heating performance.

The exhaust gas control valve control solenoid valve responds

to signals from the ECM. When the ECM sends an ON (ground)

signal, the solenoid valve is bypassed to apply vacuum pump

vacuum to the exhaust gas control valve actuator. This operation

closes the exhaust gas control valve. When the ECM sends an

OFF signal, the vacuum signal is cut and the exhaust gas con-

trol valve opens.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

EXH/GAS REG V+Vehicle: Stopped

+Engine speed: Below 1,200 rpm

+Engine coolant temperature: Below 87ÉC (189ÉF)

+Heat up switch: ONON

Except above OFF

ECM Terminals and Reference Value

Specification data are reference values, and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

11 BR/YExhaust gas control valve

control solenoid valveEngine is running.

Engine speed is below 1,200 rpm

Engine coolant temperature is below 87ÉC

(189ÉF)

Stop the vehicle

Heat up switch is ªONºApproximately 0.1V

Engine is running.

Except the above conditionBATTERY VOLTAGE

(11 - 14V)

SEF285Z

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1269

Page 503 of 1033

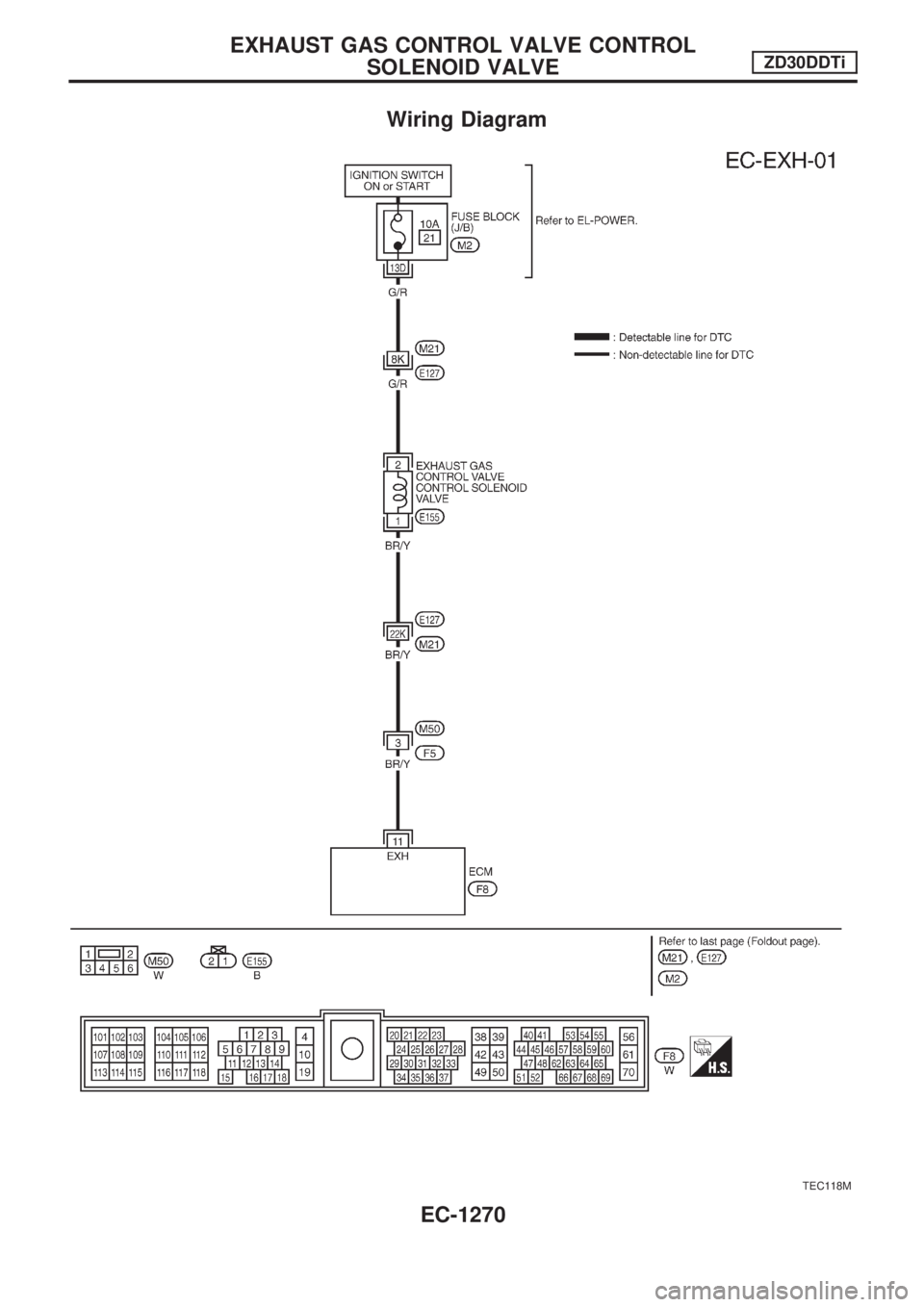

Wiring Diagram

TEC118M

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1270

Page 504 of 1033

Diagnostic Procedure

1 INSPECTION START

Do you have CONSULT-II?

Yes or No

YescGO TO 2.

NocGO TO 3.

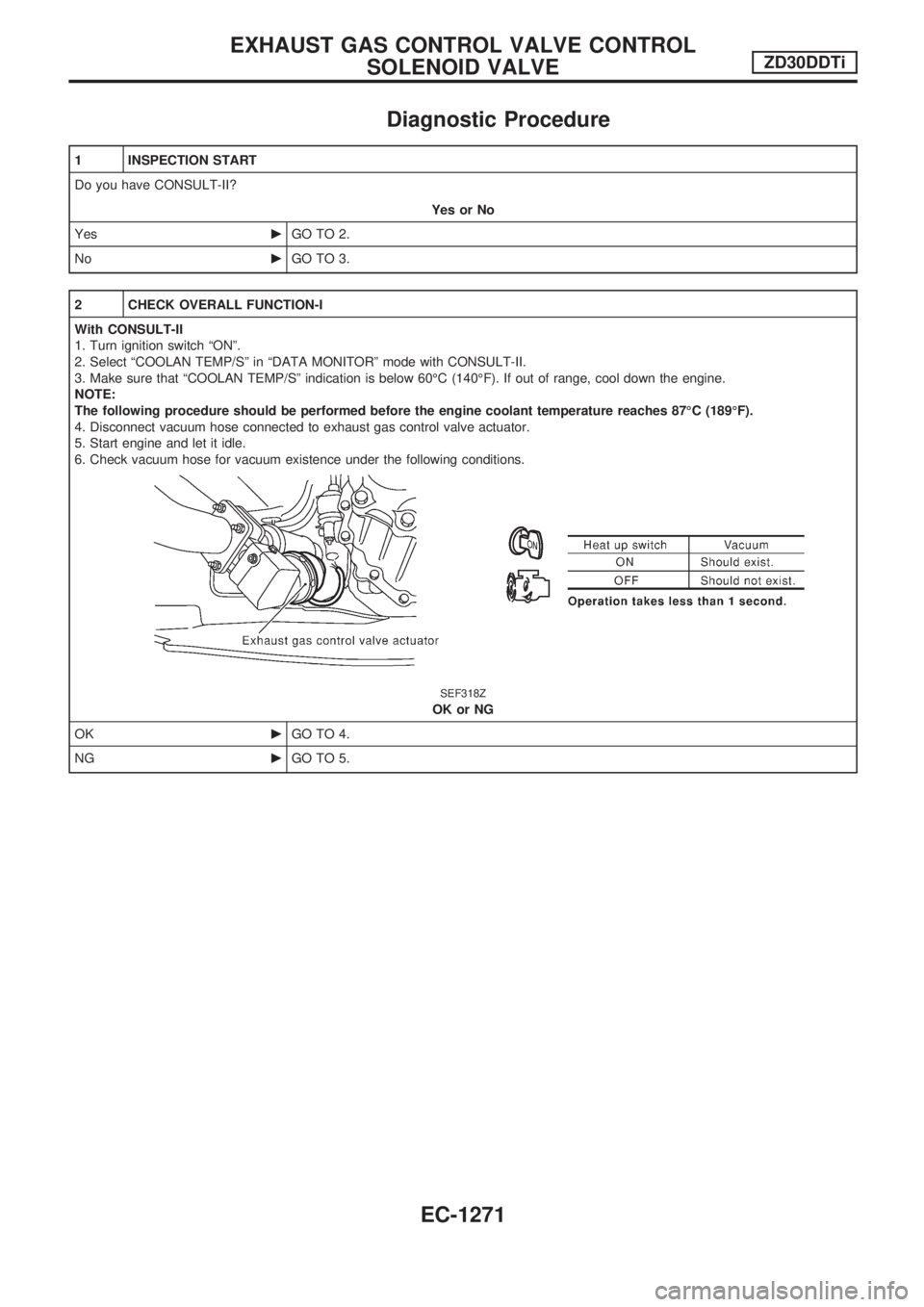

2 CHECK OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with CONSULT-II.

3. Make sure that ªCOOLAN TEMP/Sº indication is below 60ÉC (140ÉF). If out of range, cool down the engine.

NOTE:

The following procedure should be performed before the engine coolant temperature reaches 87ÉC (189ÉF).

4. Disconnect vacuum hose connected to exhaust gas control valve actuator.

5. Start engine and let it idle.

6. Check vacuum hose for vacuum existence under the following conditions.

SEF318Z

OK or NG

OKcGO TO 4.

NGcGO TO 5.

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

EC-1271

Page 505 of 1033

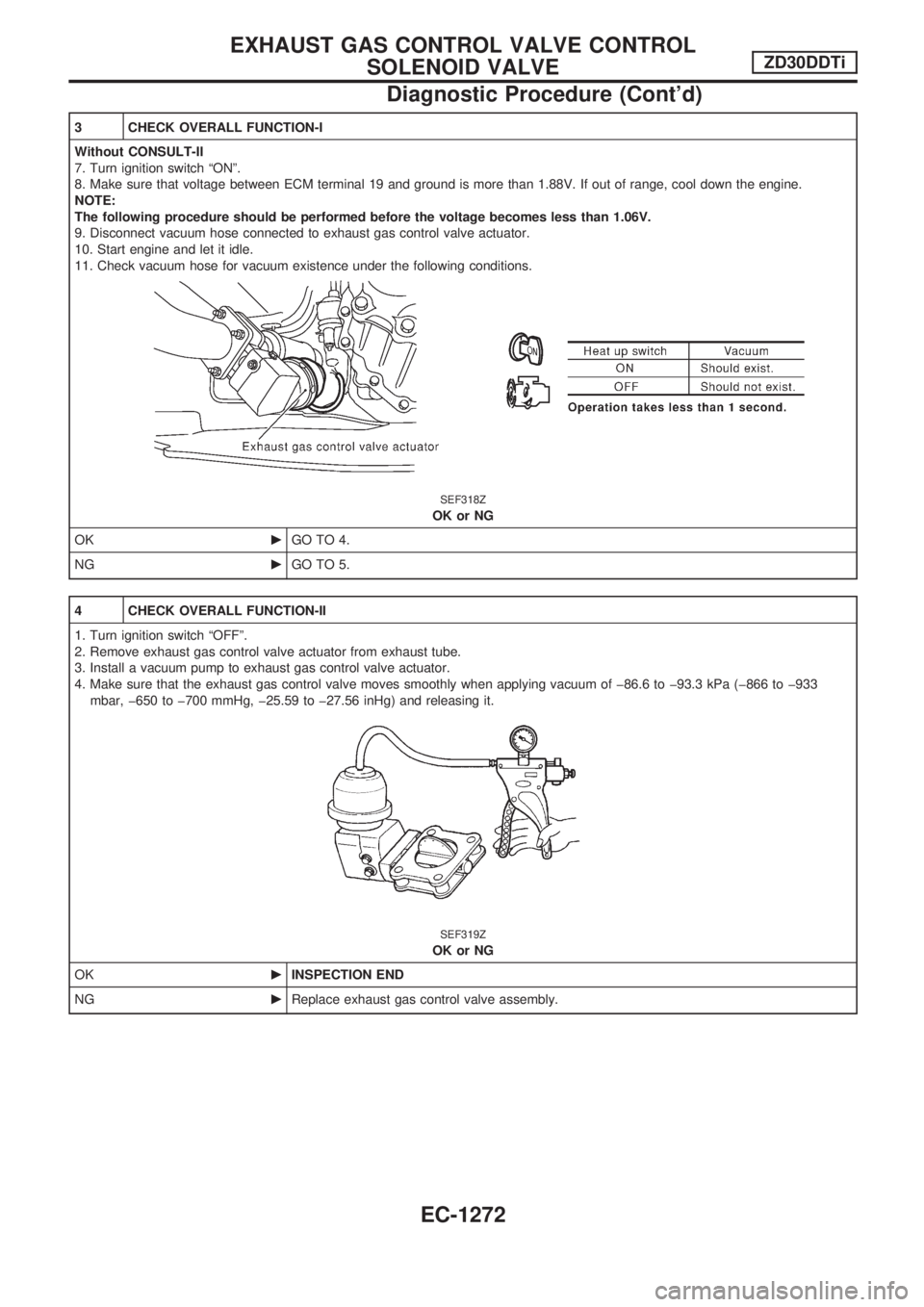

3 CHECK OVERALL FUNCTION-I

Without CONSULT-II

7. Turn ignition switch ªONº.

8. Make sure that voltage between ECM terminal 19 and ground is more than 1.88V. If out of range, cool down the engine.

NOTE:

The following procedure should be performed before the voltage becomes less than 1.06V.

9. Disconnect vacuum hose connected to exhaust gas control valve actuator.

10. Start engine and let it idle.

11. Check vacuum hose for vacuum existence under the following conditions.

SEF318Z

OK or NG

OKcGO TO 4.

NGcGO TO 5.

4 CHECK OVERALL FUNCTION-II

1. Turn ignition switch ªOFFº.

2. Remove exhaust gas control valve actuator from exhaust tube.

3. Install a vacuum pump to exhaust gas control valve actuator.

4. Make sure that the exhaust gas control valve moves smoothly when applying vacuum of þ86.6 to þ93.3 kPa (þ866 to þ933

mbar, þ650 to þ700 mmHg, þ25.59 to þ27.56 inHg) and releasing it.

SEF319Z

OK or NG

OKcINSPECTION END

NGcReplace exhaust gas control valve assembly.

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1272

Page 506 of 1033

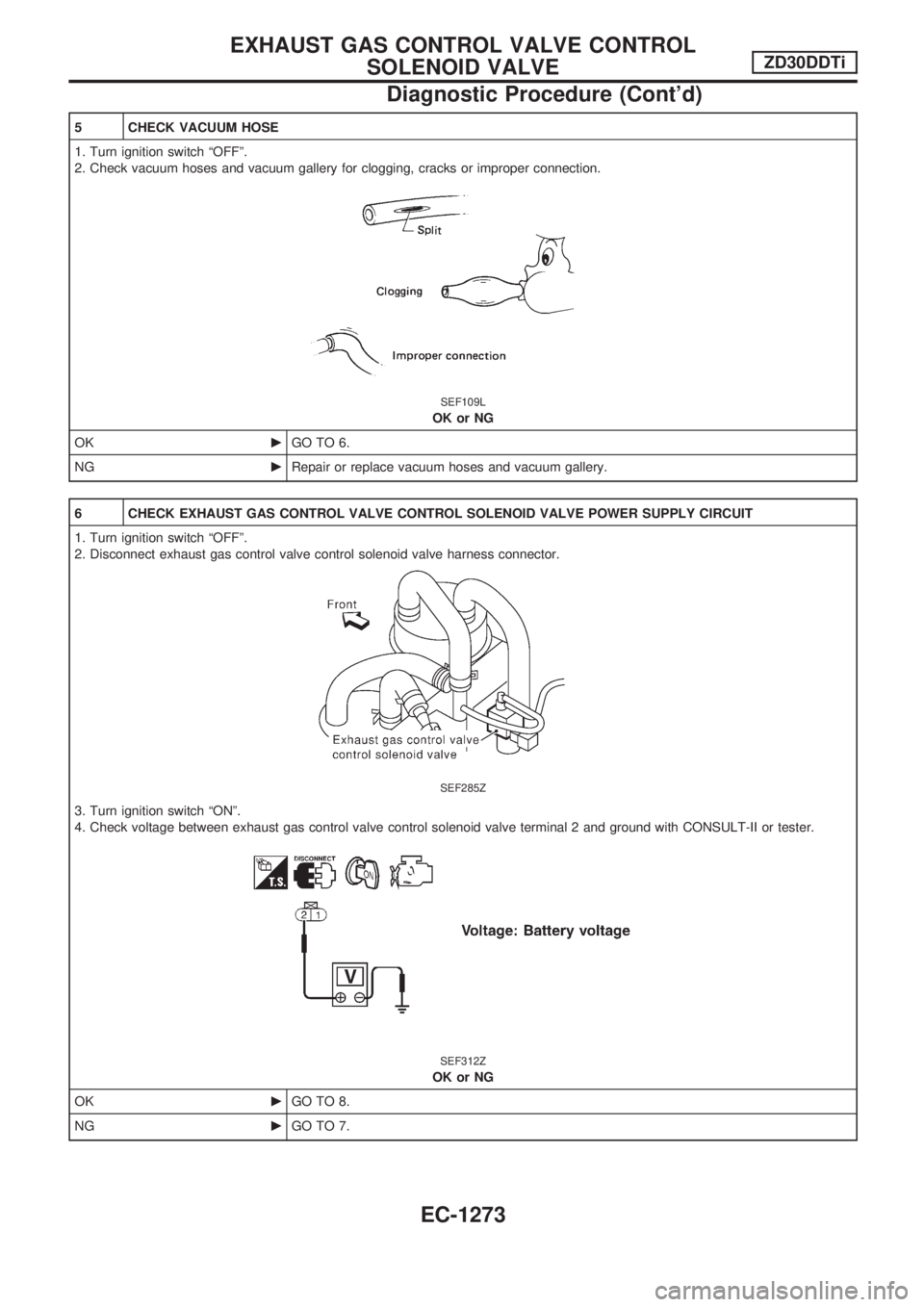

5 CHECK VACUUM HOSE

1. Turn ignition switch ªOFFº.

2. Check vacuum hoses and vacuum gallery for clogging, cracks or improper connection.

SEF109L

OK or NG

OKcGO TO 6.

NGcRepair or replace vacuum hoses and vacuum gallery.

6 CHECK EXHAUST GAS CONTROL VALVE CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect exhaust gas control valve control solenoid valve harness connector.

SEF285Z

3. Turn ignition switch ªONº.

4. Check voltage between exhaust gas control valve control solenoid valve terminal 2 and ground with CONSULT-II or tester.

SEF312Z

OK or NG

OKcGO TO 8.

NGcGO TO 7.

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1273

Page 507 of 1033

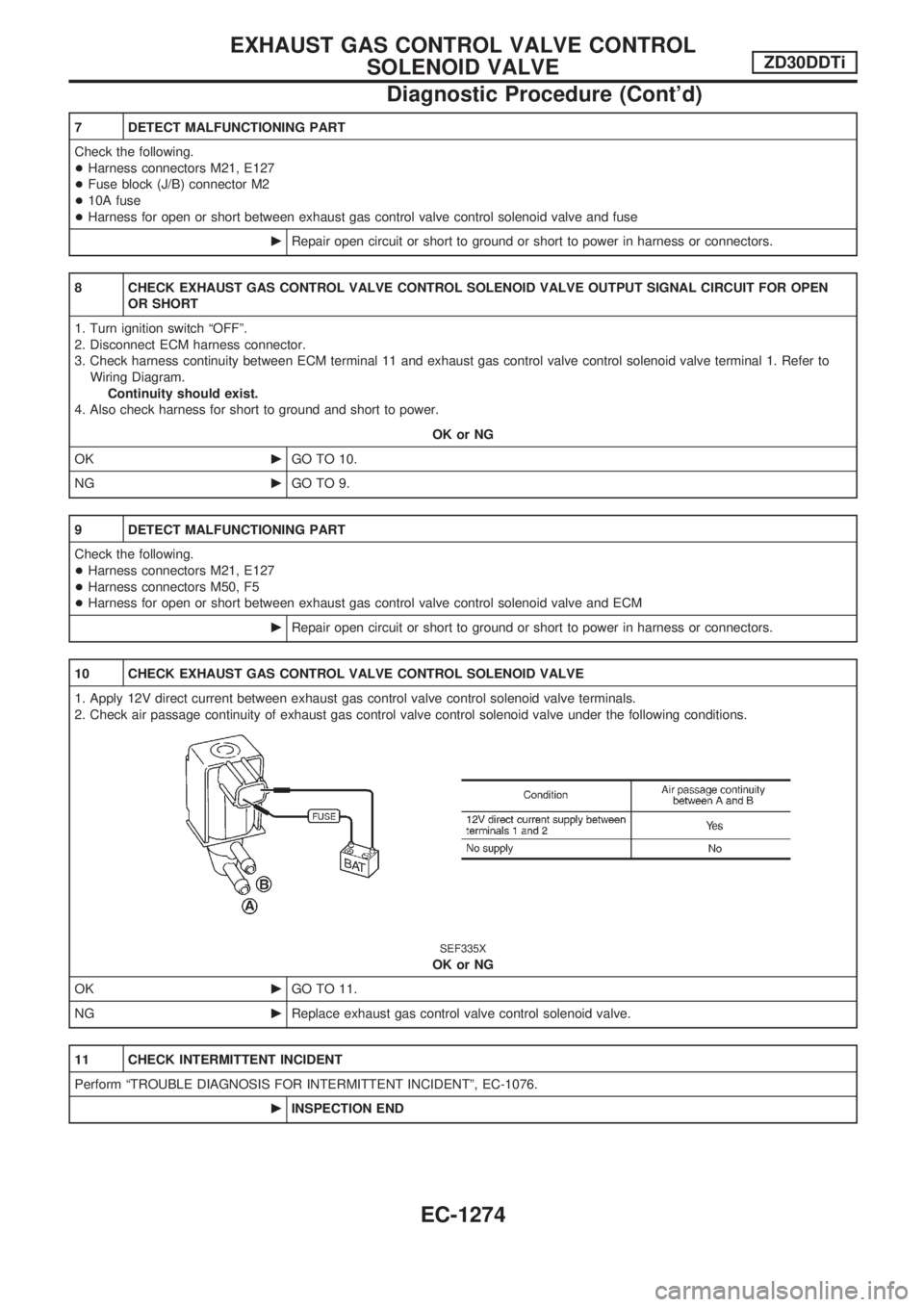

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open or short between exhaust gas control valve control solenoid valve and fuse

cRepair open circuit or short to ground or short to power in harness or connectors.

8 CHECK EXHAUST GAS CONTROL VALVE CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN

OR SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 11 and exhaust gas control valve control solenoid valve terminal 1. Refer to

Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 10.

NGcGO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M21, E127

+Harness connectors M50, F5

+Harness for open or short between exhaust gas control valve control solenoid valve and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

10 CHECK EXHAUST GAS CONTROL VALVE CONTROL SOLENOID VALVE

1. Apply 12V direct current between exhaust gas control valve control solenoid valve terminals.

2. Check air passage continuity of exhaust gas control valve control solenoid valve under the following conditions.

SEF335X

OK or NG

OKcGO TO 11.

NGcReplace exhaust gas control valve control solenoid valve.

11 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

EXHAUST GAS CONTROL VALVE CONTROL

SOLENOID VALVEZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1274

Page 508 of 1033

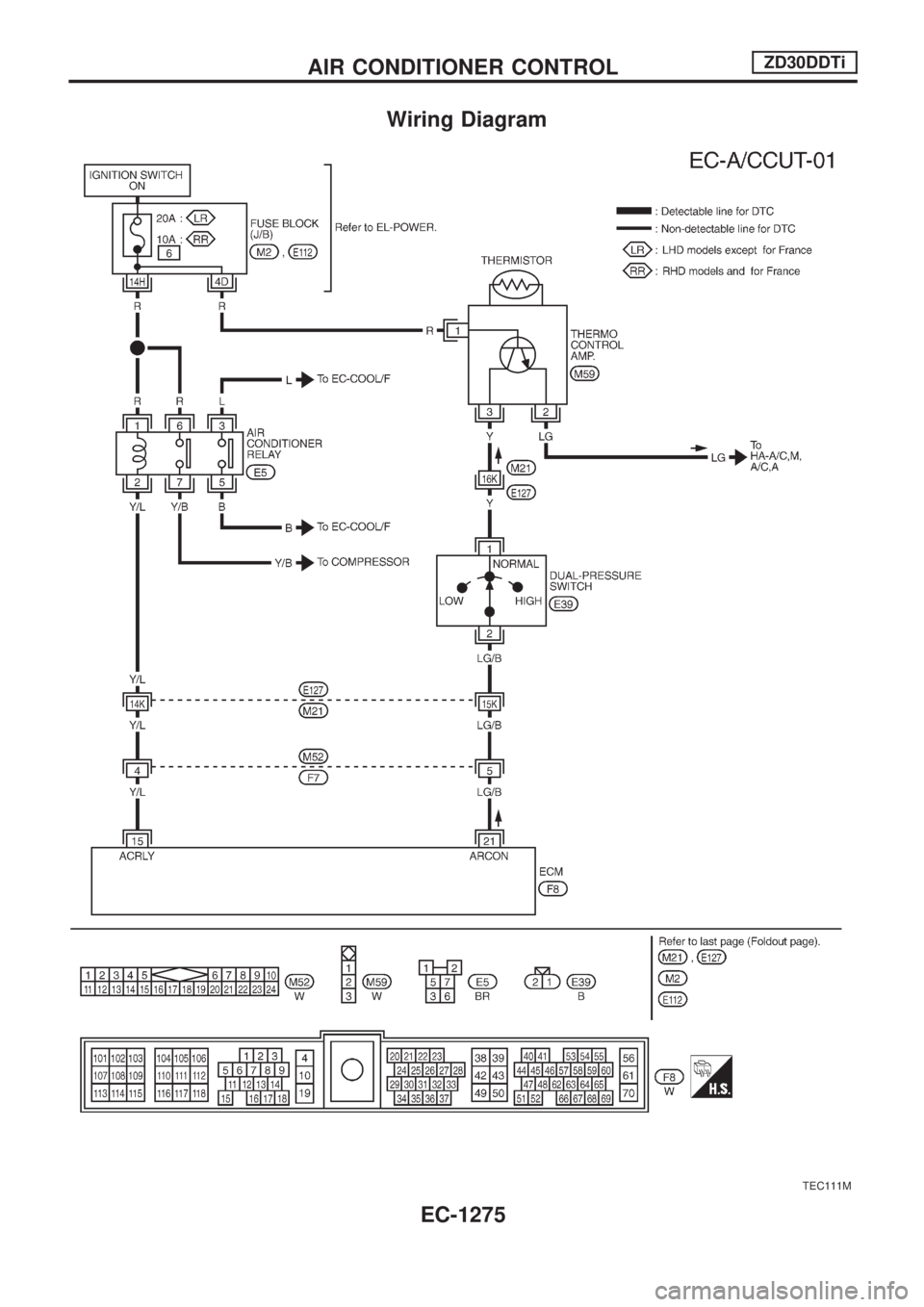

Wiring Diagram

TEC111M

AIR CONDITIONER CONTROLZD30DDTi

EC-1275

Page 509 of 1033

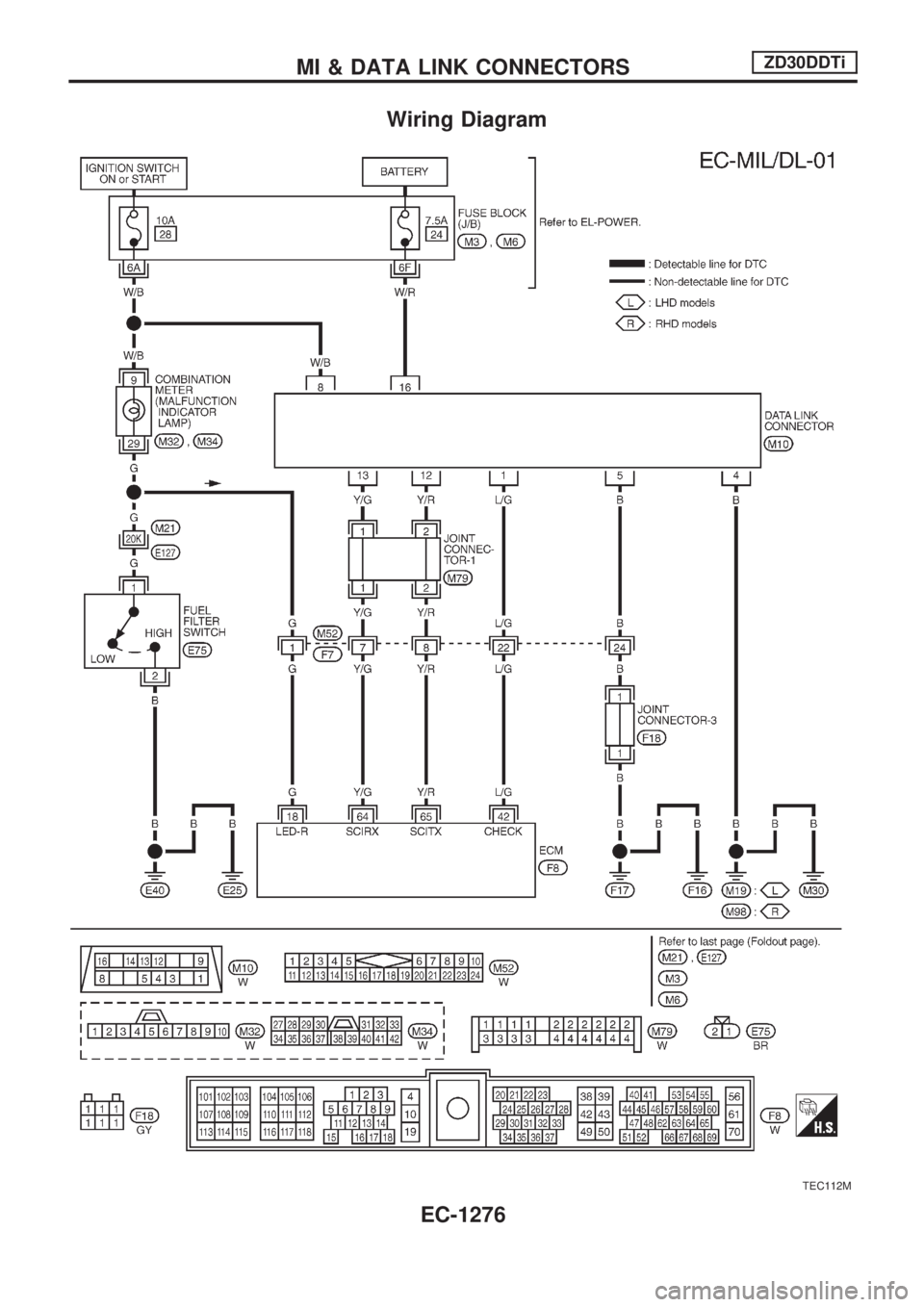

Wiring Diagram

TEC112M

MI & DATA LINK CONNECTORSZD30DDTi

EC-1276

Page 510 of 1033

General Specifications

Unit: rpm

EngineZD30DDTi

Idle speed750 25

Maximum engine speed4,300

Injection Pump Numbers

Engine Part number Pump assembly number

ZD30DDTi 16700 VG100 109342-4023

Injection Nozzle

Unit: kPa (bar, kg/cm2, psi)

Initial injection pressureUsed 19,026 (190.3, 194, 2,759)

New 19,516 - 20,497 (195.2 - 205.0, 199 - 209, 2,830 - 2,972)

Limit 16,182 (161.8, 165, 2,346)

Engine Coolant Temperature Sensor

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Crankshaft Position Sensor (TDC)

Resistance [at 20ÉC (68ÉF)]W1,287 - 1,573

Glow Plug

Resistance [at 20ÉC (68ÉF)]WApproximately 0.5

Accelerator Position Sensor

Throttle valve conditions Resistance between terminals 2 and 3 kW[at 25ÉC (77ÉF)]

Completely closedApproximately 0.5

Partially open0.5-4

Completely openApproximately 4

EGR Volume Control Valve

Resistance [at 25ÉC (77ÉF)]W13-17

SERVICE DATA AND SPECIFICATIONS (SDS)ZD30DDTi

EC-1277