NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 631 of 1033

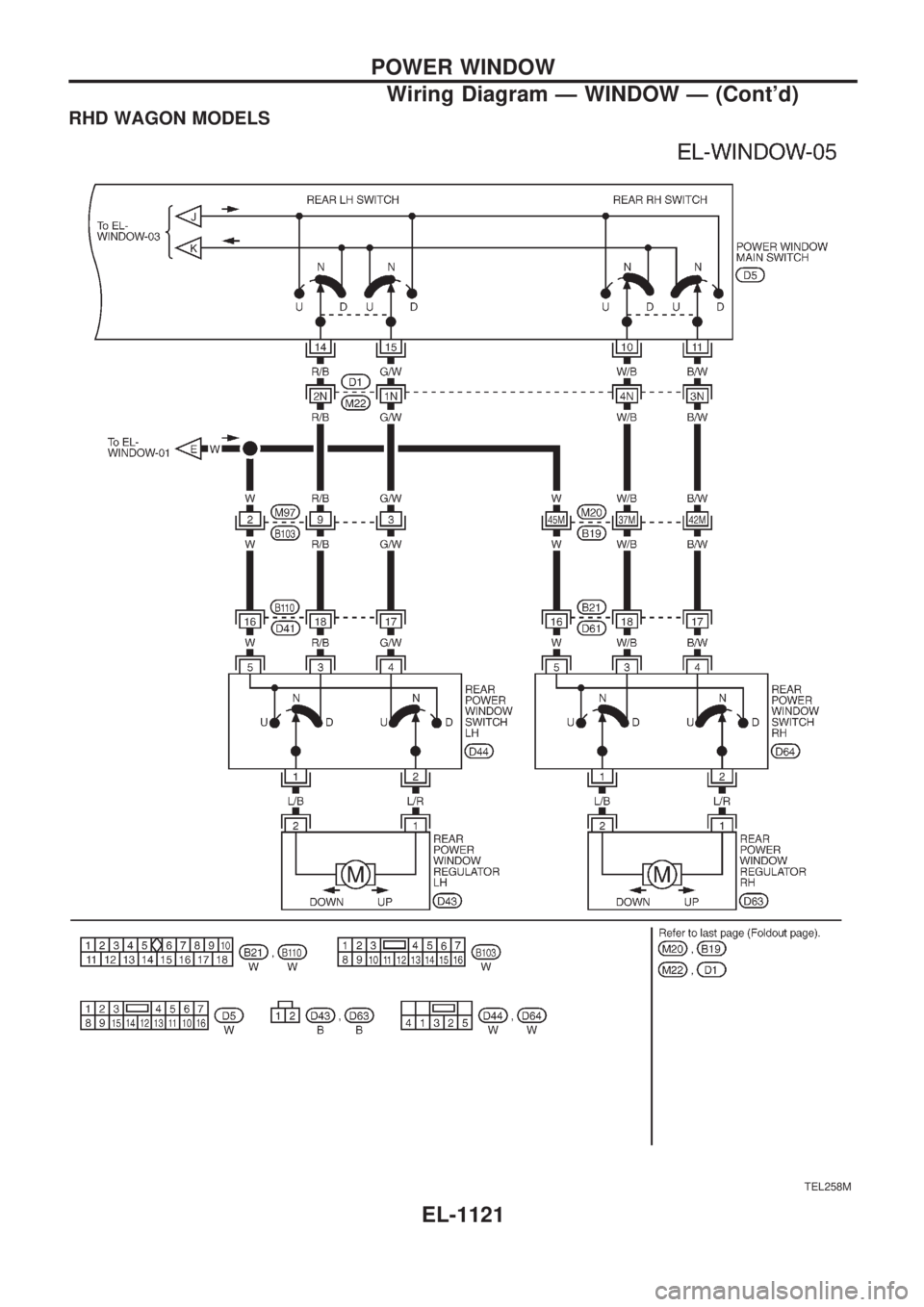

RHD WAGON MODELS

TEL258M

POWER WINDOW

Wiring Diagram Ð WINDOW Ð (Cont'd)

EL-1121

Page 632 of 1033

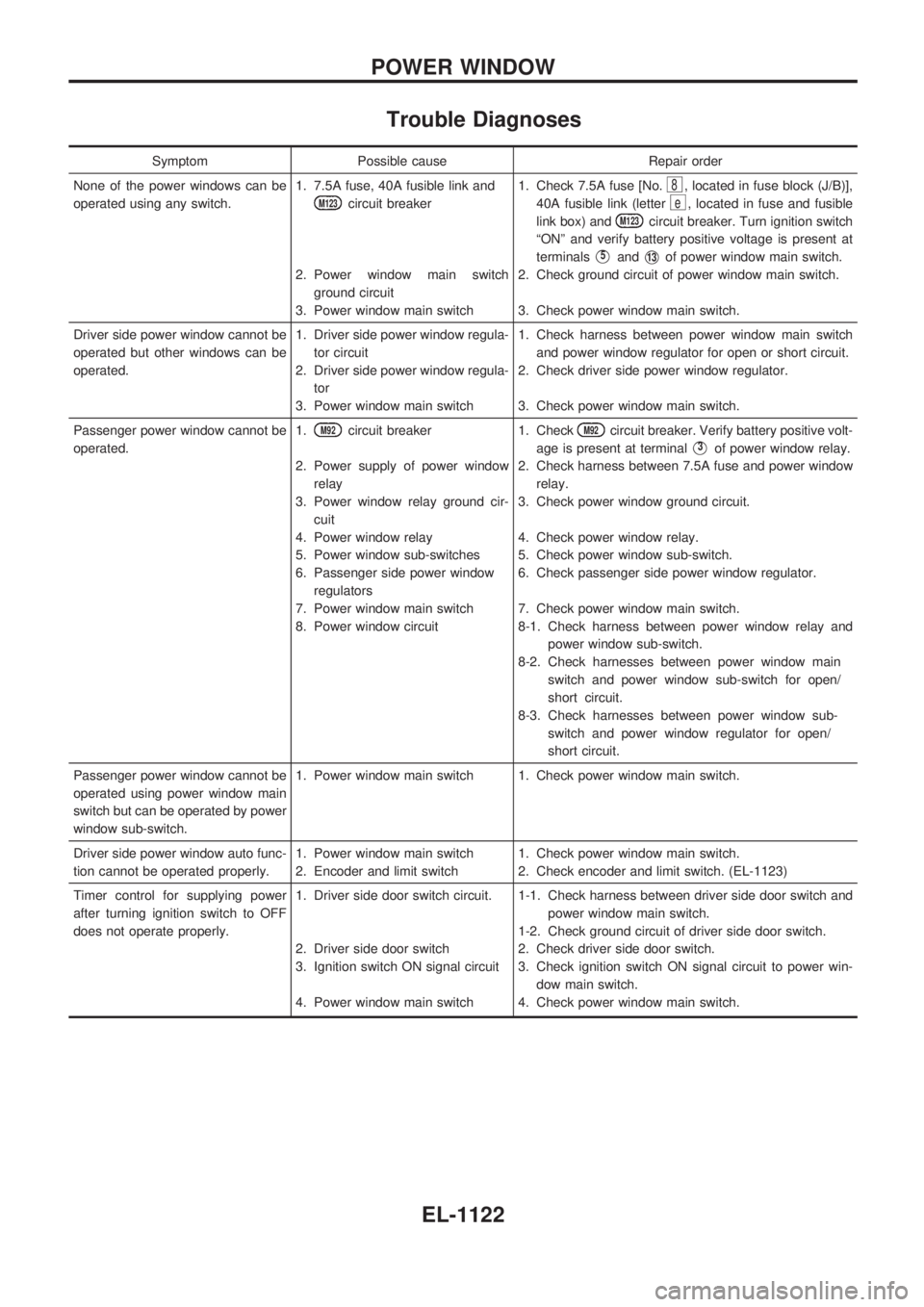

Trouble Diagnoses

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 7.5A fuse, 40A fusible link and

M123circuit breaker

2. Power window main switch

ground circuit

3. Power window main switch1. Check 7.5A fuse [No.

8, located in fuse block (J/B)],

40A fusible link (letter

e, located in fuse and fusible

link box) and

M123circuit breaker. Turn ignition switch

ªONº and verify battery positive voltage is present at

terminals

V5andV13of power window main switch.

2. Check ground circuit of power window main switch.

3. Check power window main switch.

Driver side power window cannot be

operated but other windows can be

operated.1. Driver side power window regula-

tor circuit

2. Driver side power window regula-

tor

3. Power window main switch1. Check harness between power window main switch

and power window regulator for open or short circuit.

2. Check driver side power window regulator.

3. Check power window main switch.

Passenger power window cannot be

operated.1.

M92circuit breaker

2. Power supply of power window

relay

3. Power window relay ground cir-

cuit

4. Power window relay

5. Power window sub-switches

6. Passenger side power window

regulators

7. Power window main switch

8. Power window circuit1. CheckM92circuit breaker. Verify battery positive volt-

age is present at terminal

V3of power window relay.

2. Check harness between 7.5A fuse and power window

relay.

3. Check power window ground circuit.

4. Check power window relay.

5. Check power window sub-switch.

6. Check passenger side power window regulator.

7. Check power window main switch.

8-1. Check harness between power window relay and

power window sub-switch.

8-2. Check harnesses between power window main

switch and power window sub-switch for open/

short circuit.

8-3. Check harnesses between power window sub-

switch and power window regulator for open/

short circuit.

Passenger power window cannot be

operated using power window main

switch but can be operated by power

window sub-switch.1. Power window main switch 1. Check power window main switch.

Driver side power window auto func-

tion cannot be operated properly.1. Power window main switch

2. Encoder and limit switch1. Check power window main switch.

2. Check encoder and limit switch. (EL-1123)

Timer control for supplying power

after turning ignition switch to OFF

does not operate properly.1. Driver side door switch circuit.

2. Driver side door switch

3. Ignition switch ON signal circuit

4. Power window main switch1-1. Check harness between driver side door switch and

power window main switch.

1-2. Check ground circuit of driver side door switch.

2. Check driver side door switch.

3. Check ignition switch ON signal circuit to power win-

dow main switch.

4. Check power window main switch.

POWER WINDOW

EL-1122

Page 633 of 1033

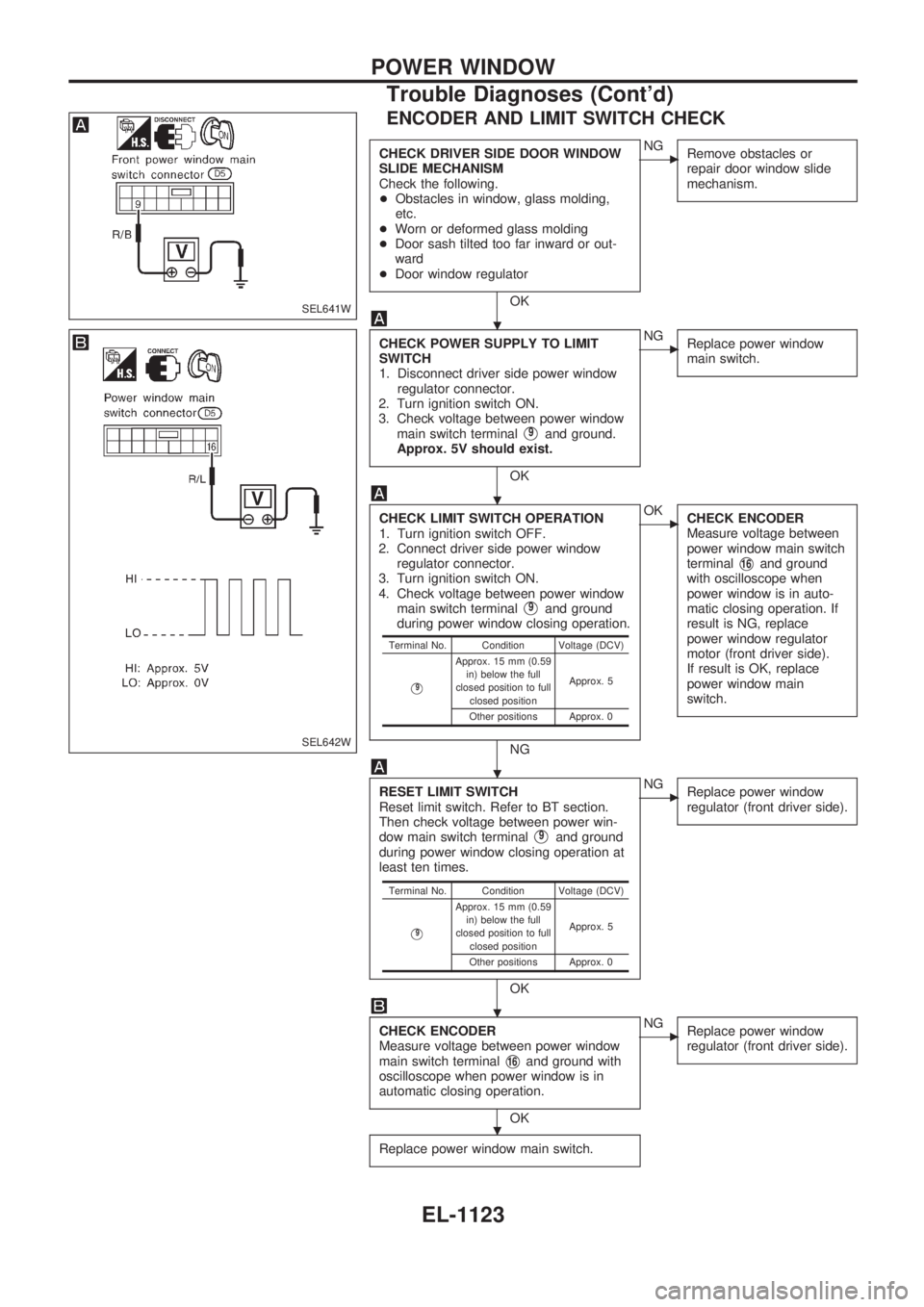

ENCODER AND LIMIT SWITCH CHECK

CHECK DRIVER SIDE DOOR WINDOW

SLIDE MECHANISM

Check the following.

+Obstacles in window, glass molding,

etc.

+Worn or deformed glass molding

+Door sash tilted too far inward or out-

ward

+Door window regulator

OK

cNG

Remove obstacles or

repair door window slide

mechanism.

CHECK POWER SUPPLY TO LIMIT

SWITCH

1. Disconnect driver side power window

regulator connector.

2. Turn ignition switch ON.

3. Check voltage between power window

main switch terminal

V9and ground.

Approx. 5V should exist.

OK

cNG

Replace power window

main switch.

CHECK LIMIT SWITCH OPERATION

1. Turn ignition switch OFF.

2. Connect driver side power window

regulator connector.

3. Turn ignition switch ON.

4. Check voltage between power window

main switch terminal

V9and ground

during power window closing operation.

NG

cOK

CHECK ENCODER

Measure voltage between

power window main switch

terminal

V16and ground

with oscilloscope when

power window is in auto-

matic closing operation. If

result is NG, replace

power window regulator

motor (front driver side).

If result is OK, replace

power window main

switch.

RESET LIMIT SWITCH

Reset limit switch. Refer to BT section.

Then check voltage between power win-

dow main switch terminal

V9and ground

during power window closing operation at

least ten times.

OK

cNG

Replace power window

regulator (front driver side).

CHECK ENCODER

Measure voltage between power window

main switch terminal

V16and ground with

oscilloscope when power window is in

automatic closing operation.

OK

cNG

Replace power window

regulator (front driver side).

Replace power window main switch.

Terminal No. Condition Voltage (DCV)

V9

Approx. 15 mm (0.59

in) below the full

closed position to full

closed positionApprox. 5

Other positions Approx. 0

Terminal No. Condition Voltage (DCV)

V9

Approx. 15 mm (0.59

in) below the full

closed position to full

closed positionApprox. 5

Other positions Approx. 0

SEL641W

SEL642W

.

.

.

.

.

POWER WINDOW

Trouble Diagnoses (Cont'd)

EL-1123

Page 634 of 1033

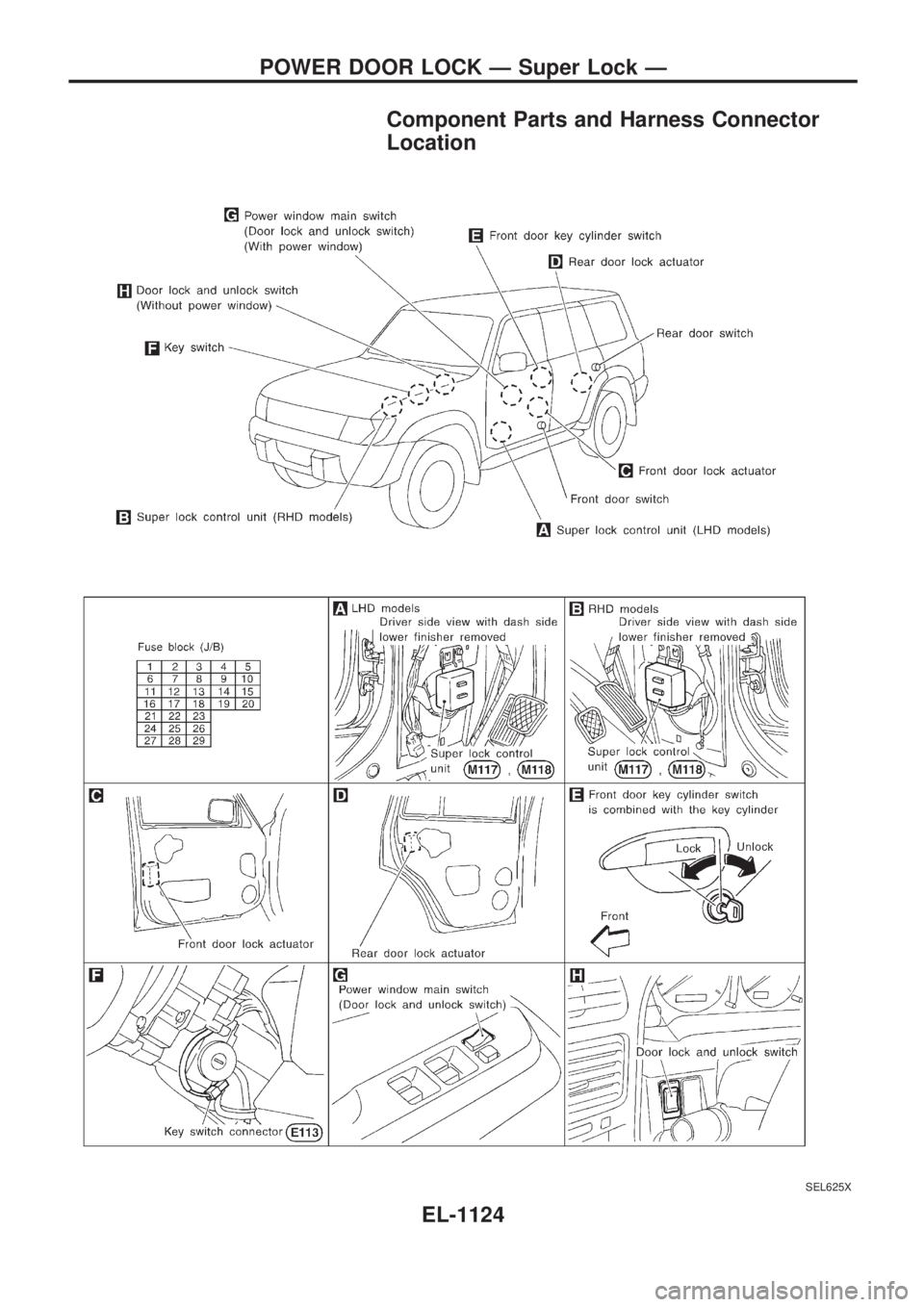

Component Parts and Harness Connector

Location

SEL625X

POWER DOOR LOCK Ð Super Lock Ð

EL-1124

Page 635 of 1033

System Description

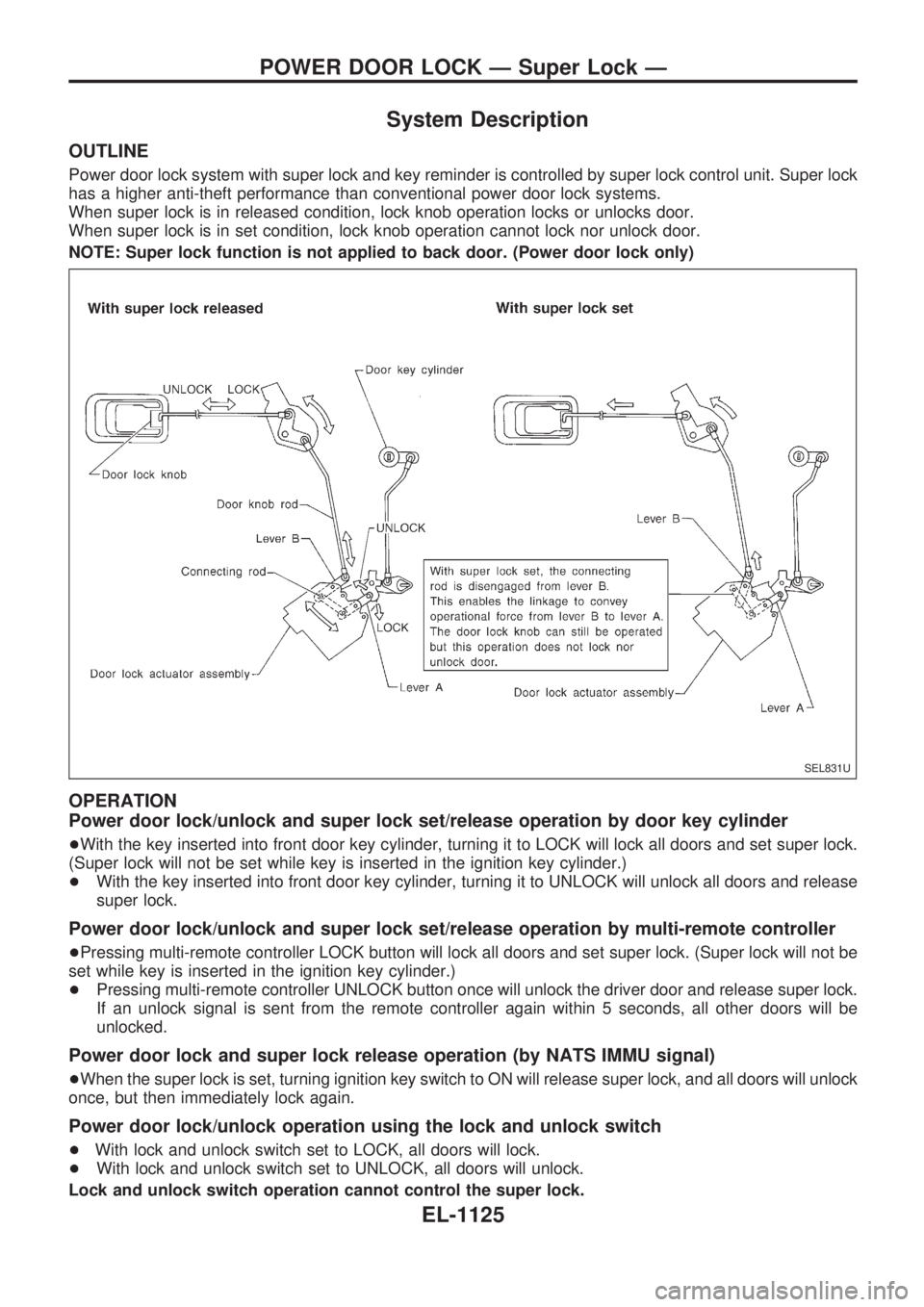

OUTLINE

Power door lock system with super lock and key reminder is controlled by super lock control unit. Super lock

has a higher anti-theft performance than conventional power door lock systems.

When super lock is in released condition, lock knob operation locks or unlocks door.

When super lock is in set condition, lock knob operation cannot lock nor unlock door.

NOTE: Super lock function is not applied to back door. (Power door lock only)

OPERATION

Power door lock/unlock and super lock set/release operation by door key cylinder

+With the key inserted into front door key cylinder, turning it to LOCK will lock all doors and set super lock.

(Super lock will not be set while key is inserted in the ignition key cylinder.)

+With the key inserted into front door key cylinder, turning it to UNLOCK will unlock all doors and release

super lock.

Power door lock/unlock and super lock set/release operation by multi-remote controller

+Pressing multi-remote controller LOCK button will lock all doors and set super lock. (Super lock will not be

set while key is inserted in the ignition key cylinder.)

+Pressing multi-remote controller UNLOCK button once will unlock the driver door and release super lock.

If an unlock signal is sent from the remote controller again within 5 seconds, all other doors will be

unlocked.

Power door lock and super lock release operation (by NATS IMMU signal)

+When the super lock is set, turning ignition key switch to ON will release super lock, and all doors will unlock

once, but then immediately lock again.

Power door lock/unlock operation using the lock and unlock switch

+With lock and unlock switch set to LOCK, all doors will lock.

+With lock and unlock switch set to UNLOCK, all doors will unlock.

Lock and unlock switch operation cannot control the super lock.

SEL831U

POWER DOOR LOCK Ð Super Lock Ð

EL-1125

Page 636 of 1033

Key reminder system

+If the ignition key is in the ignition key cylinder and the driver door is open, setting lock knob on driver door,

key or multi-remote controller to ªLOCKº locks the door once but then immediately unlocks all doors. (Sig-

nal from unlock sensor driver side)

System initialization

+System initialization is required when battery cables are reconnected. Conduct one of the followings to

release super lock once;

Ð insert the key into ignition key cylinder and turn it to ON.

Ð LOCK/UNLOCK operation using door key cylinder or multi-remote controller.

POWER DOOR LOCK Ð Super Lock Ð

System Description (Cont'd)

EL-1126

Page 637 of 1033

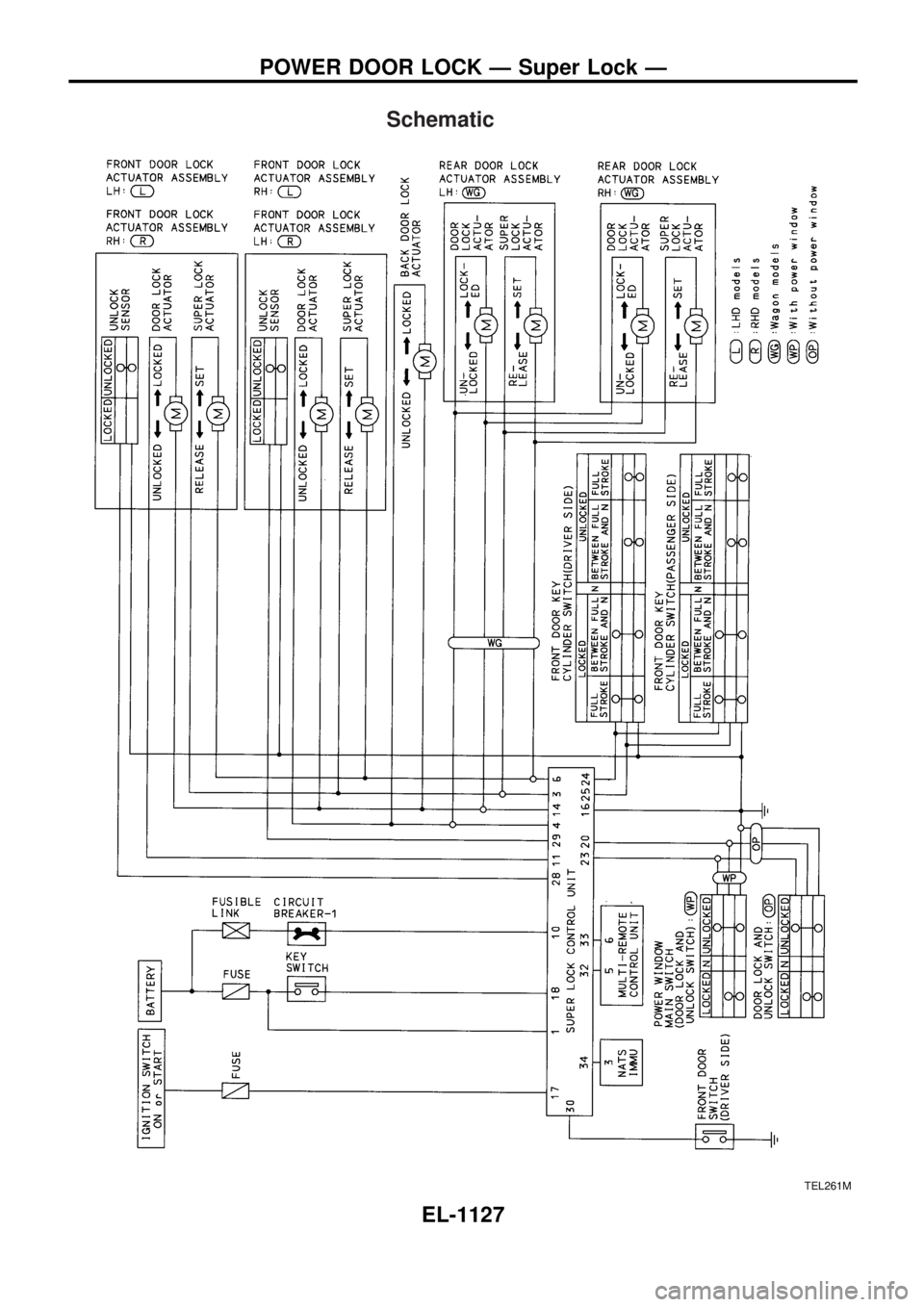

Schematic

TEL261M

POWER DOOR LOCK Ð Super Lock Ð

EL-1127

Page 638 of 1033

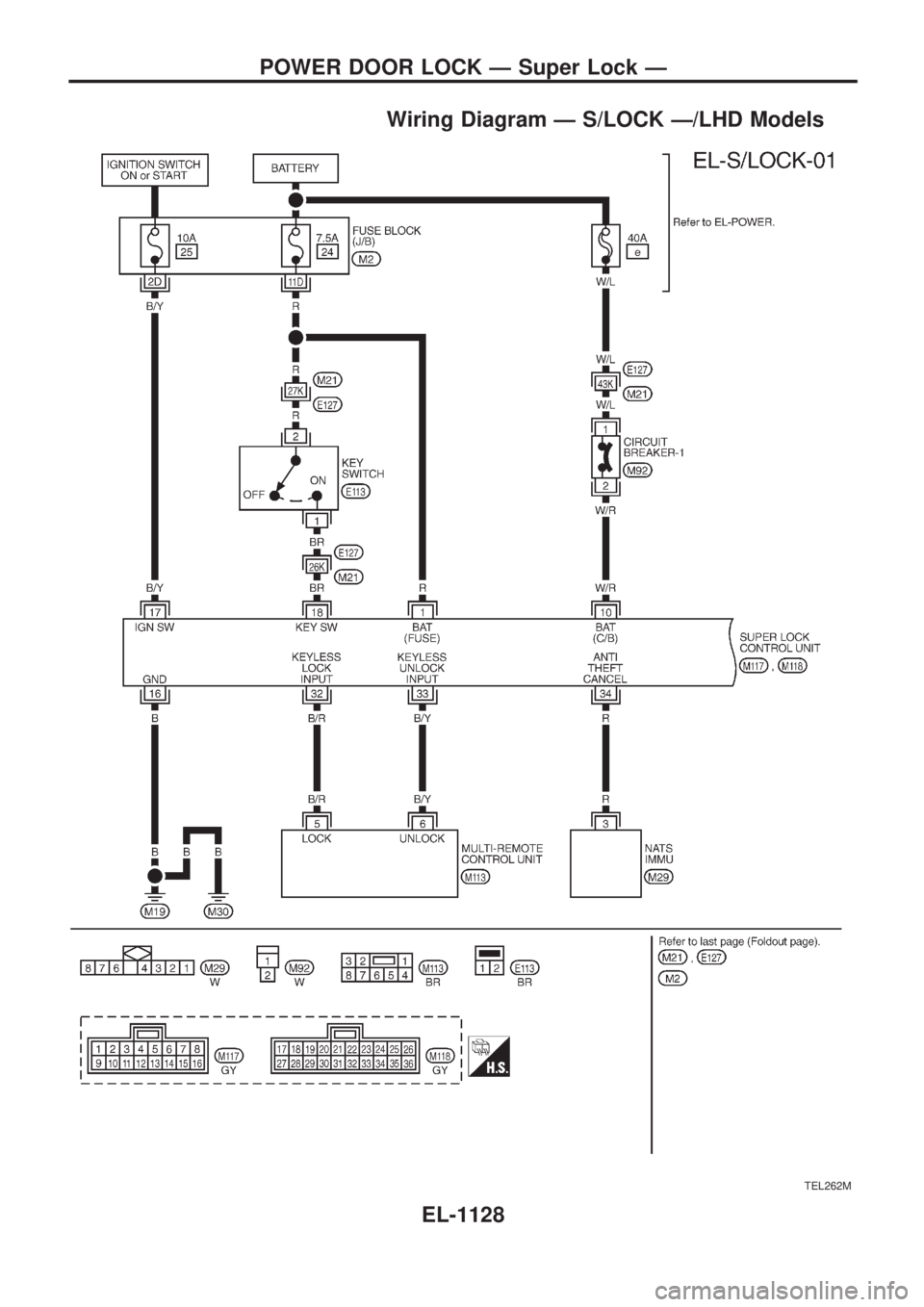

Wiring Diagram Ð S/LOCK Ð/LHD Models

TEL262M

POWER DOOR LOCK Ð Super Lock Ð

EL-1128

Page 639 of 1033

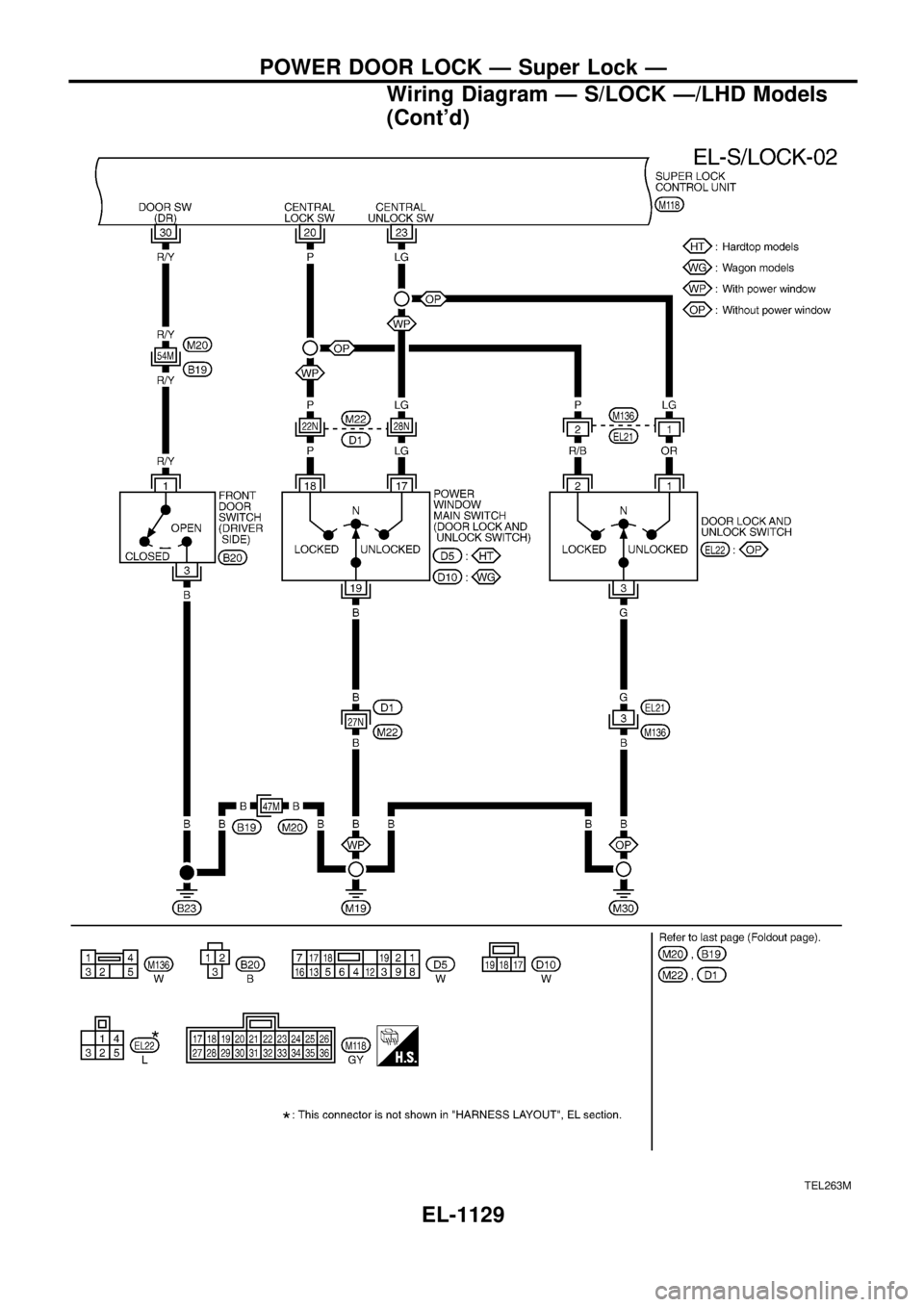

TEL263M

POWER DOOR LOCK Ð Super Lock Ð

Wiring Diagram Ð S/LOCK Ð/LHD Models

(Cont'd)

EL-1129

Page 640 of 1033

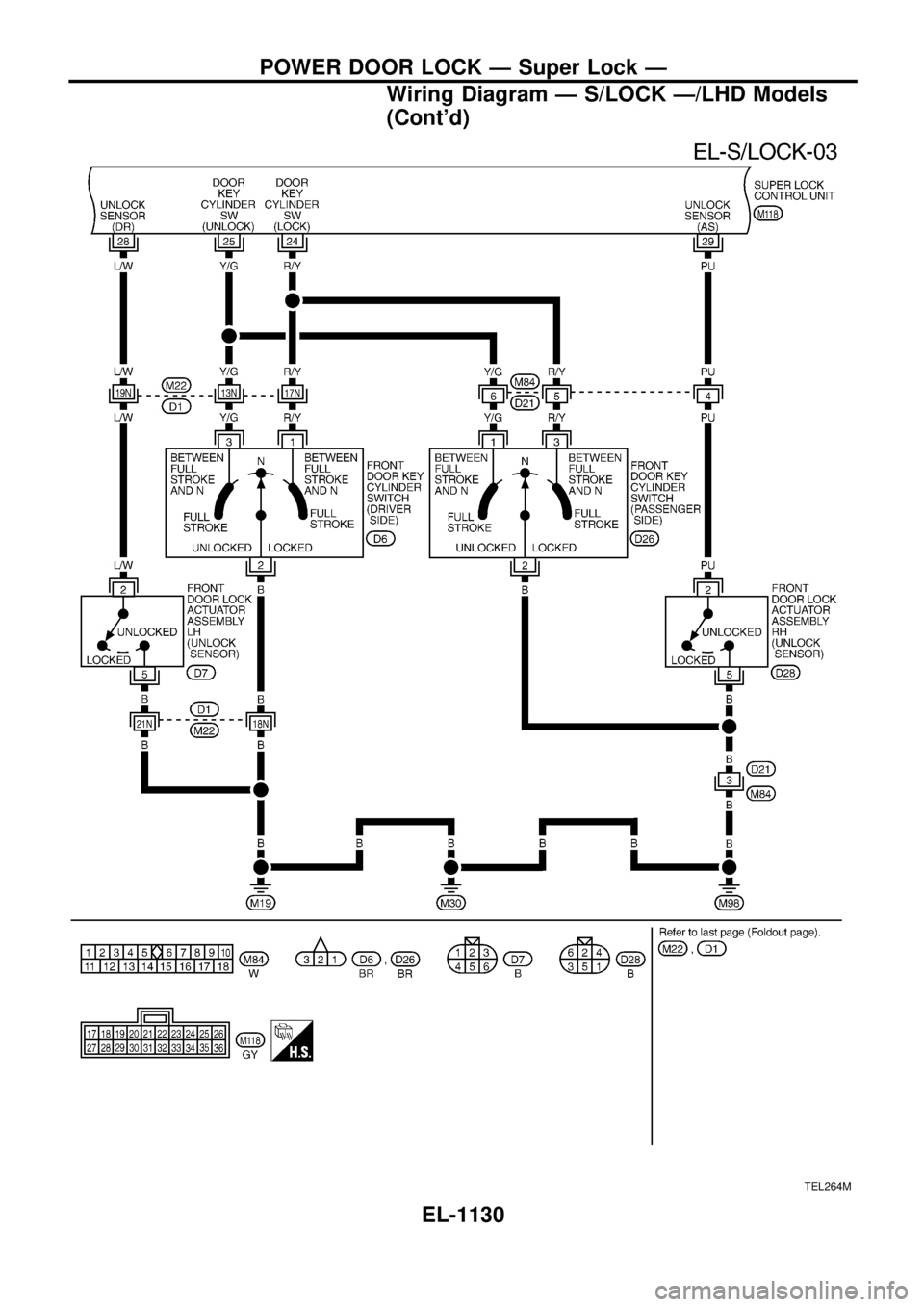

TEL264M

POWER DOOR LOCK Ð Super Lock Ð

Wiring Diagram Ð S/LOCK Ð/LHD Models

(Cont'd)

EL-1130