NISSAN PATROL 2000 Electronic Manual Online

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 81 of 1033

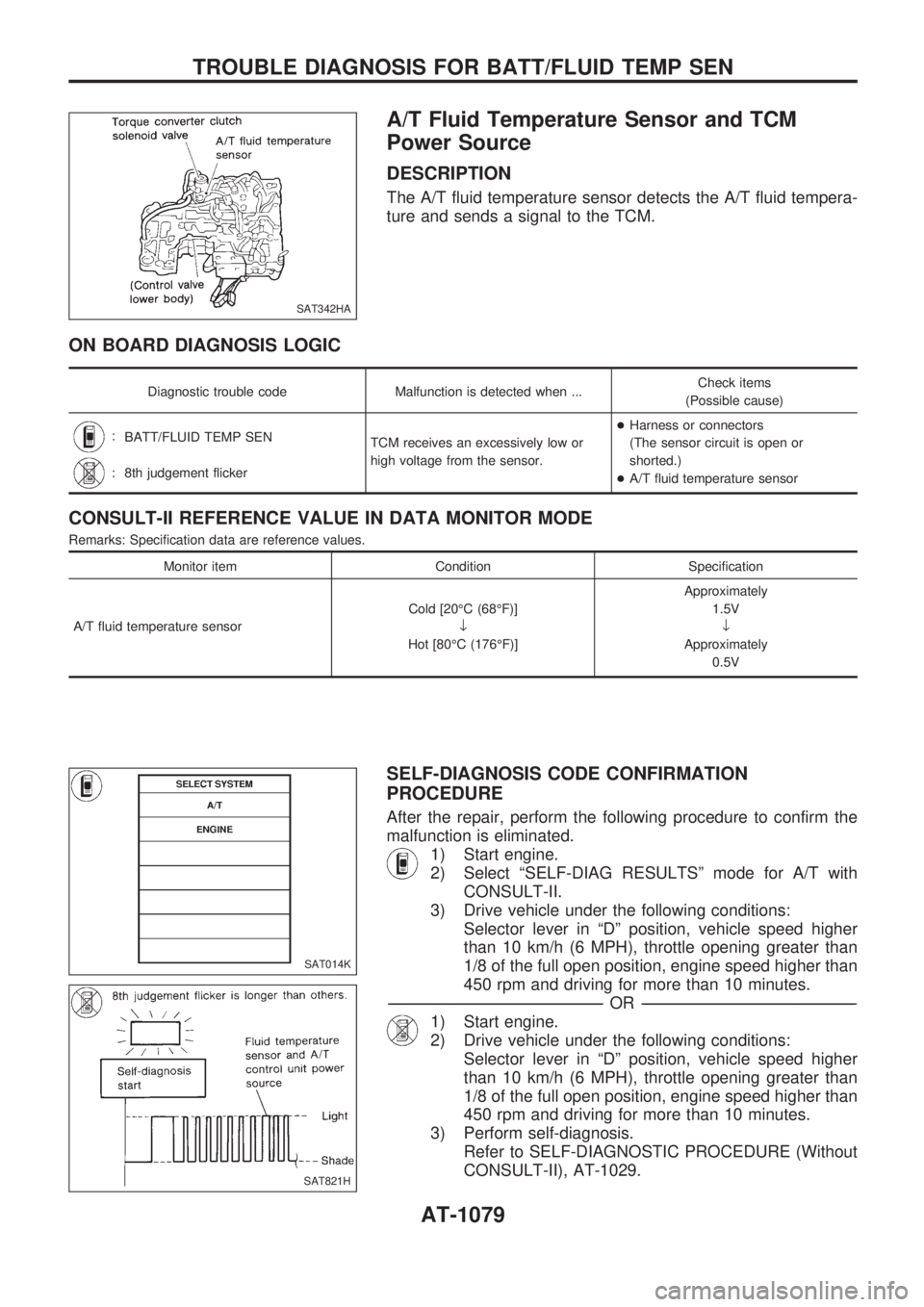

A/T Fluid Temperature Sensor and TCM

Power Source

DESCRIPTION

The A/T fluid temperature sensor detects the A/T fluid tempera-

ture and sends a signal to the TCM.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

:

BATT/FLUID TEMP SEN

TCM receives an excessively low or

high voltage from the sensor.+Harness or connectors

(The sensor circuit is open or

shorted.)

+A/T fluid temperature sensor

: 8th judgement flicker

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

Monitor item Condition Specification

A/T fluid temperature sensorCold [20ÉC (68ÉF)]

¯

Hot [80ÉC (176ÉF)]Approximately

1.5V

¯

Approximately

0.5V

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/8 of the full open position, engine speed higher than

450 rpm and driving for more than 10 minutes.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/8 of the full open position, engine speed higher than

450 rpm and driving for more than 10 minutes.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT342HA

SAT014K

SAT821H

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

AT-1079

Page 82 of 1033

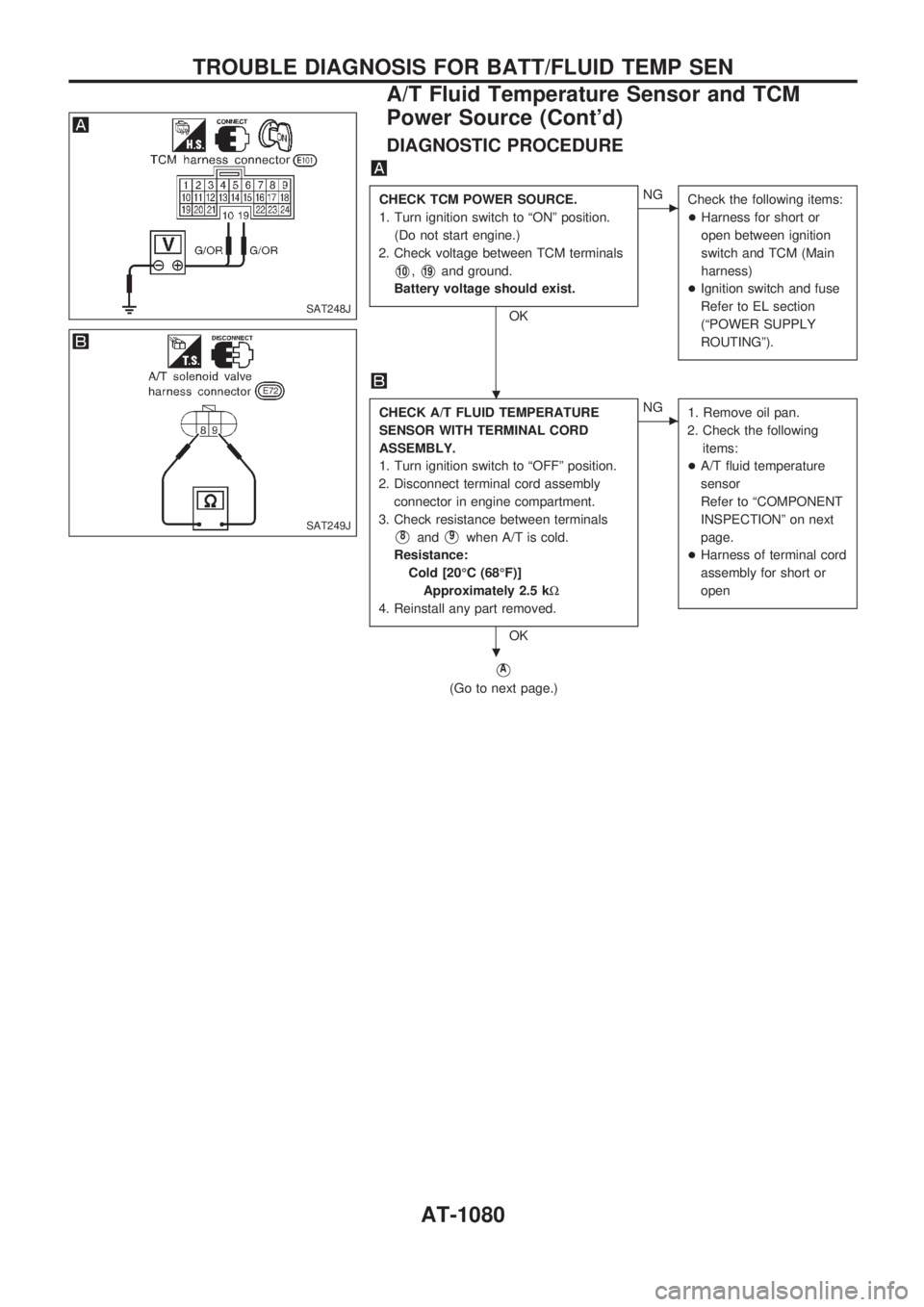

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

V10,V19and ground.

Battery voltage should exist.

OK

cNG

Check the following items:

+Harness for short or

open between ignition

switch and TCM (Main

harness)

+Ignition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminals

V8andV9when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

4. Reinstall any part removed.

OK

cNG

1. Remove oil pan.

2. Check the following

items:

+A/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

+Harness of terminal cord

assembly for short or

open

VA

(Go to next page.)

SAT248J

SAT249J

.

.

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM

Power Source (Cont'd)

AT-1080

Page 83 of 1033

![NISSAN PATROL 2000 Electronic Manual Online VA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot NISSAN PATROL 2000 Electronic Manual Online VA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot](/img/5/57367/w960_57367-82.png)

VA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot [80ÉC (176ÉF)]:

Approximately

1.5V®0.5V

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM

terminal

V47and ground while

warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot [80ÉC (176ÉF)]:

Approximately

1.5V®0.5V

OK

cNG

Check the following item:

+Harness for short or

open between TCM and

terminal cord assembly

(Main harness)

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1079.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

A/T fluid temperature sensor

+For removal, refer to AT-1124.

+Check resistance between terminals

V8andV9while chang-

ing temperature as shown at left.

Temperature ÉC (ÉF) Resistance

20 (68) Approximately 2.5 kW

80 (176) Approximately 0.3 kW

SAT738J

SAT250J

SAT252J

.

.

.

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM

Power Source (Cont'd)

AT-1081

Page 84 of 1033

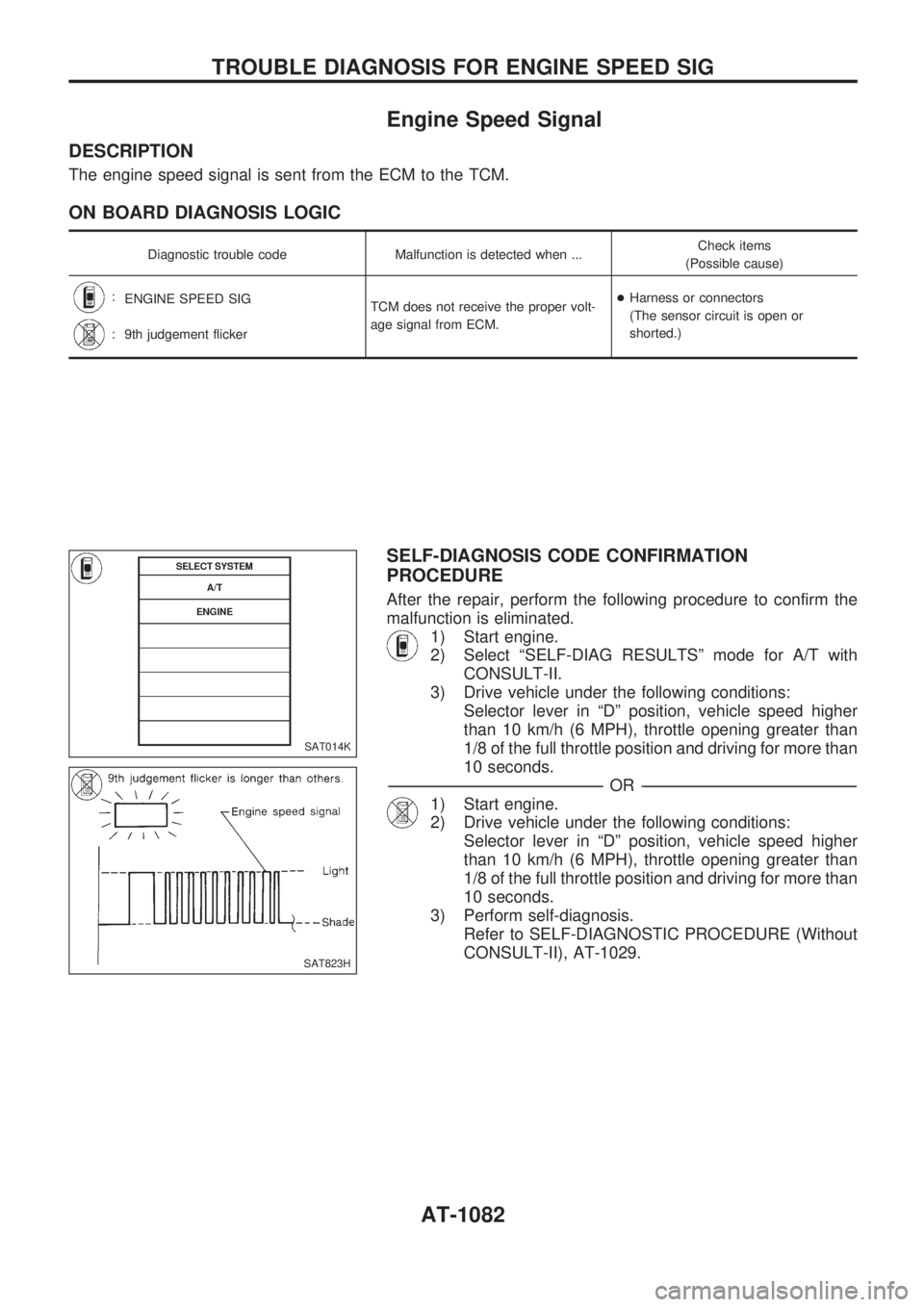

Engine Speed Signal

DESCRIPTION

The engine speed signal is sent from the ECM to the TCM.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

:

ENGINE SPEED SIG

TCM does not receive the proper volt-

age signal from ECM.+Harness or connectors

(The sensor circuit is open or

shorted.)

:

9th judgement flicker

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/8 of the full throttle position and driving for more than

10 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/8 of the full throttle position and driving for more than

10 seconds.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT014K

SAT823H

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG

AT-1082

Page 85 of 1033

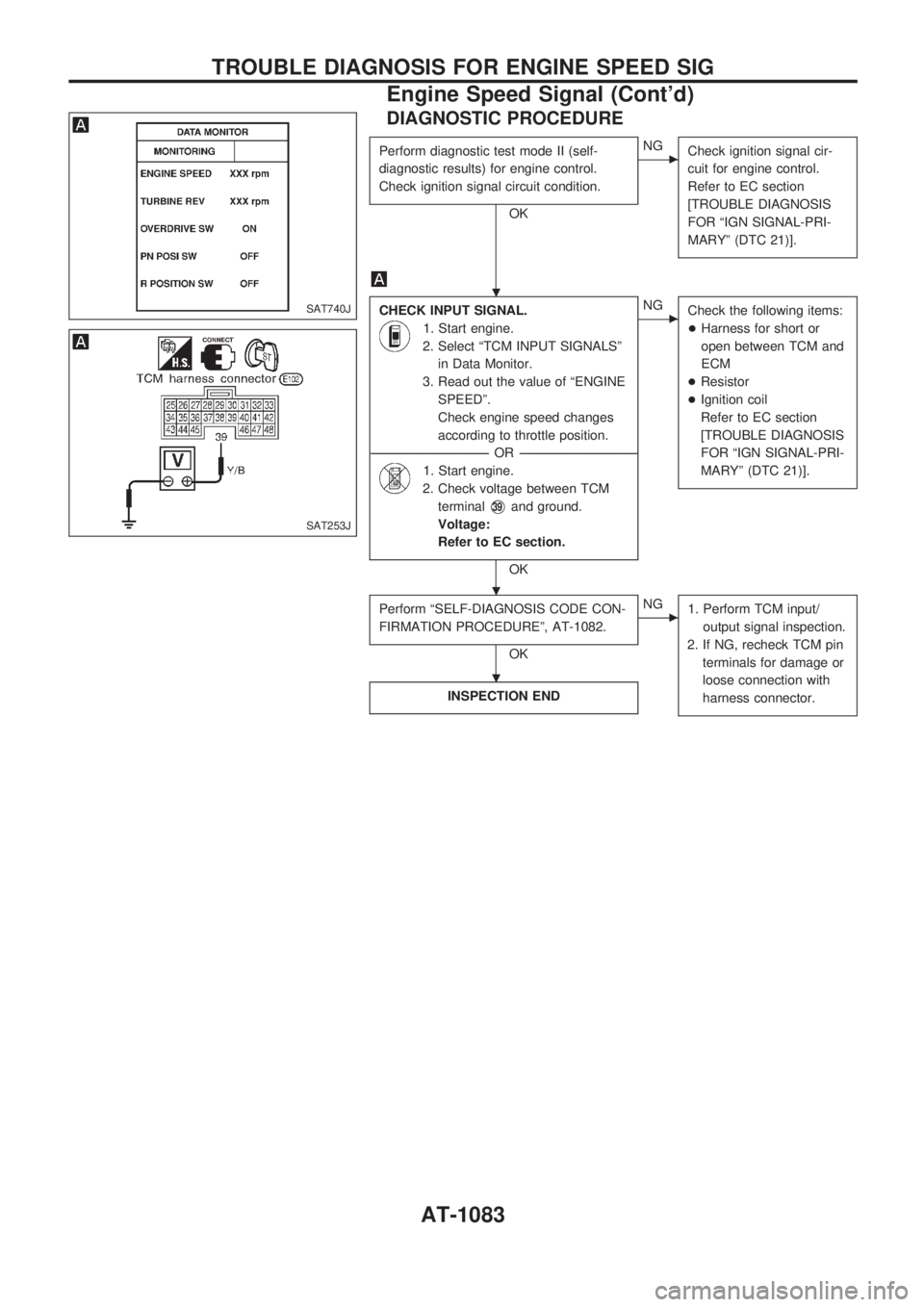

DIAGNOSTIC PROCEDURE

Perform diagnostic test mode II (self-

diagnostic results) for engine control.

Check ignition signal circuit condition.

OK

cNG

Check ignition signal cir-

cuit for engine control.

Refer to EC section

[TROUBLE DIAGNOSIS

FOR ªIGN SIGNAL-PRI-

MARYº (DTC 21)].

CHECK INPUT SIGNAL.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªENGINE

SPEEDº.

Check engine speed changes

according to throttle position.

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM

terminal

V39and ground.

Voltage:

Refer to EC section.

OK

cNG

Check the following items:

+Harness for short or

open between TCM and

ECM

+Resistor

+Ignition coil

Refer to EC section

[TROUBLE DIAGNOSIS

FOR ªIGN SIGNAL-PRI-

MARYº (DTC 21)].

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1082.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT740J

SAT253J

.

.

.

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG

Engine Speed Signal (Cont'd)

AT-1083

Page 86 of 1033

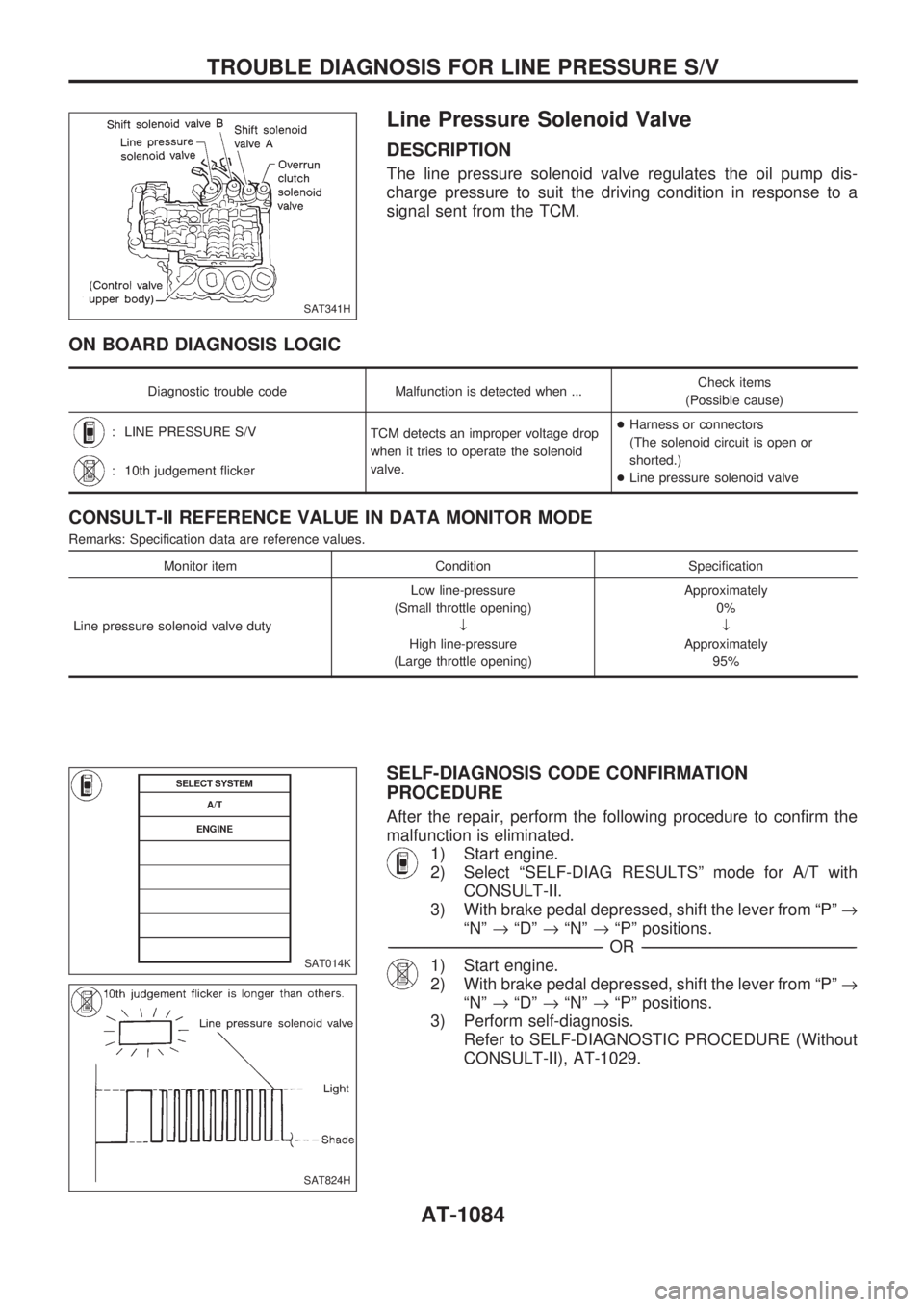

Line Pressure Solenoid Valve

DESCRIPTION

The line pressure solenoid valve regulates the oil pump dis-

charge pressure to suit the driving condition in response to a

signal sent from the TCM.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

: LINE PRESSURE S/V

TCM detects an improper voltage drop

when it tries to operate the solenoid

valve.+Harness or connectors

(The solenoid circuit is open or

shorted.)

+Line pressure solenoid valve

: 10th judgement flicker

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Remarks: Specification data are reference values.

Monitor item Condition Specification

Line pressure solenoid valve dutyLow line-pressure

(Small throttle opening)

¯

High line-pressure

(Large throttle opening)Approximately

0%

¯

Approximately

95%

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) With brake pedal depressed, shift the lever from ªPº®

ªNº®ªDº®ªNº®ªPº positions.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) With brake pedal depressed, shift the lever from ªPº®

ªNº®ªDº®ªNº®ªPº positions.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT341H

SAT014K

SAT824H

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

AT-1084

Page 87 of 1033

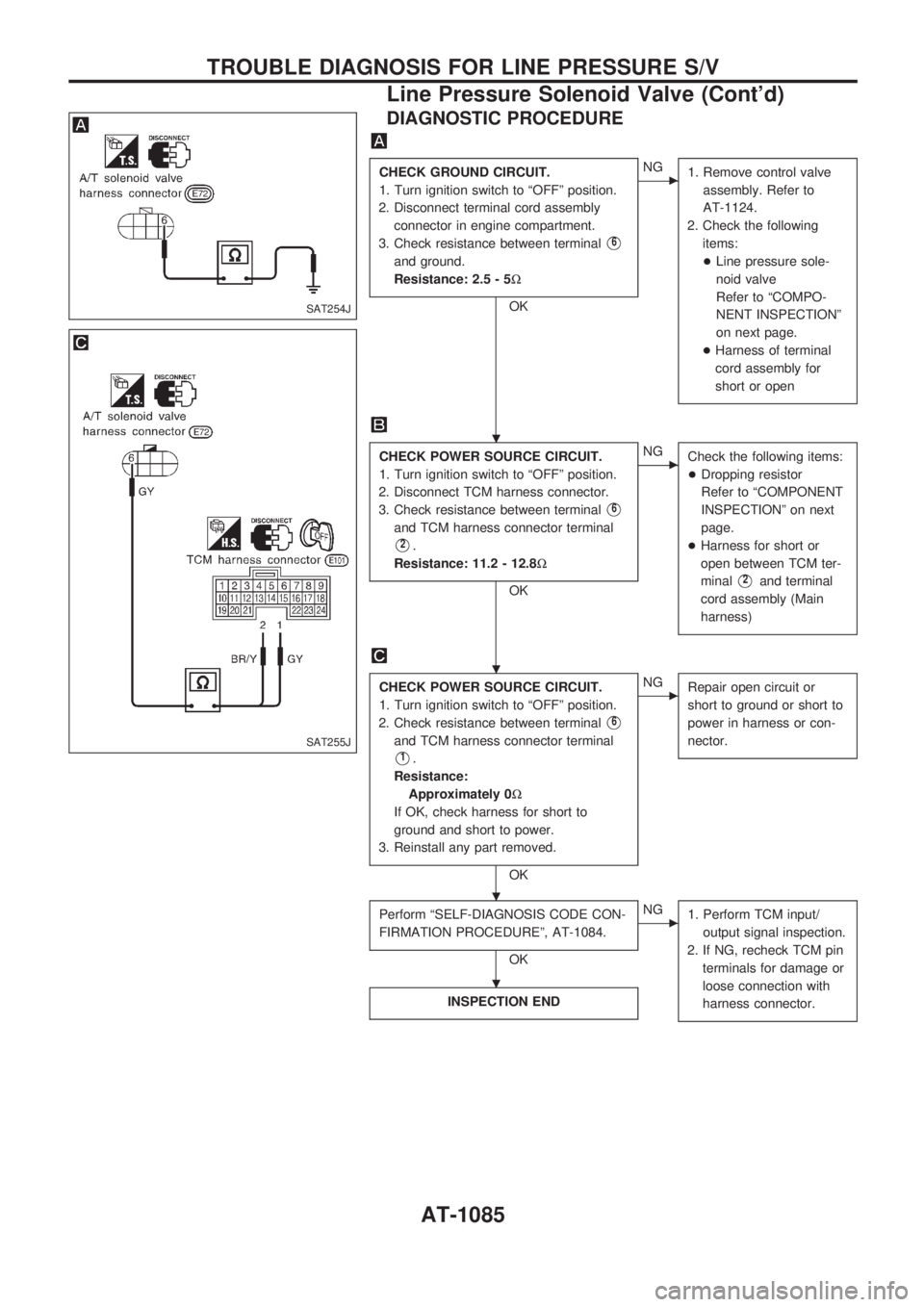

DIAGNOSTIC PROCEDURE

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminal

V6

and ground.

Resistance: 2.5 - 5W

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Line pressure sole-

noid valve

Refer to ªCOMPO-

NENT INSPECTIONº

on next page.

+Harness of terminal

cord assembly for

short or open

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal

V6

and TCM harness connector terminal

V2.

Resistance: 11.2 - 12.8W

OK

cNG

Check the following items:

+Dropping resistor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

+Harness for short or

open between TCM ter-

minal

V2and terminal

cord assembly (Main

harness)

CHECK POWER SOURCE CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Check resistance between terminal

V6

and TCM harness connector terminal

V1.

Resistance:

Approximately 0W

If OK, check harness for short to

ground and short to power.

3. Reinstall any part removed.

OK

cNG

Repair open circuit or

short to ground or short to

power in harness or con-

nector.

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1084.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT254J

SAT255J

.

.

.

.

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

Line Pressure Solenoid Valve (Cont'd)

AT-1085

Page 88 of 1033

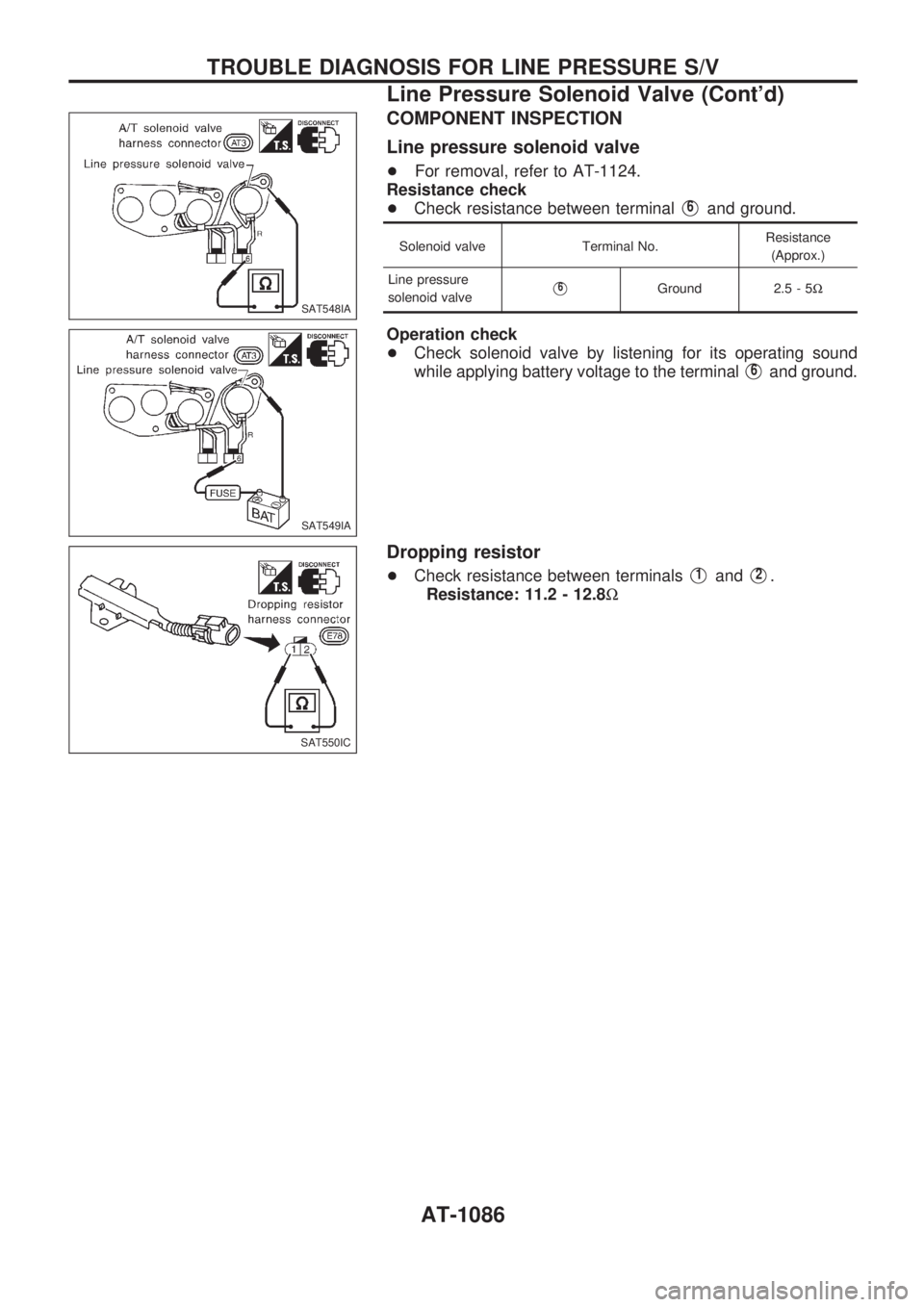

COMPONENT INSPECTION

Line pressure solenoid valve

+For removal, refer to AT-1124.

Resistance check

+Check resistance between terminal

V6and ground.

Solenoid valve Terminal No.Resistance

(Approx.)

Line pressure

solenoid valve

V6Ground 2.5 - 5W

Operation check

+Check solenoid valve by listening for its operating sound

while applying battery voltage to the terminal

V6and ground.

Dropping resistor

+Check resistance between terminalsV1andV2.

Resistance: 11.2 - 12.8W

SAT548IA

SAT549IA

SAT550IC

TROUBLE DIAGNOSIS FOR LINE PRESSURE S/V

Line Pressure Solenoid Valve (Cont'd)

AT-1086

Page 89 of 1033

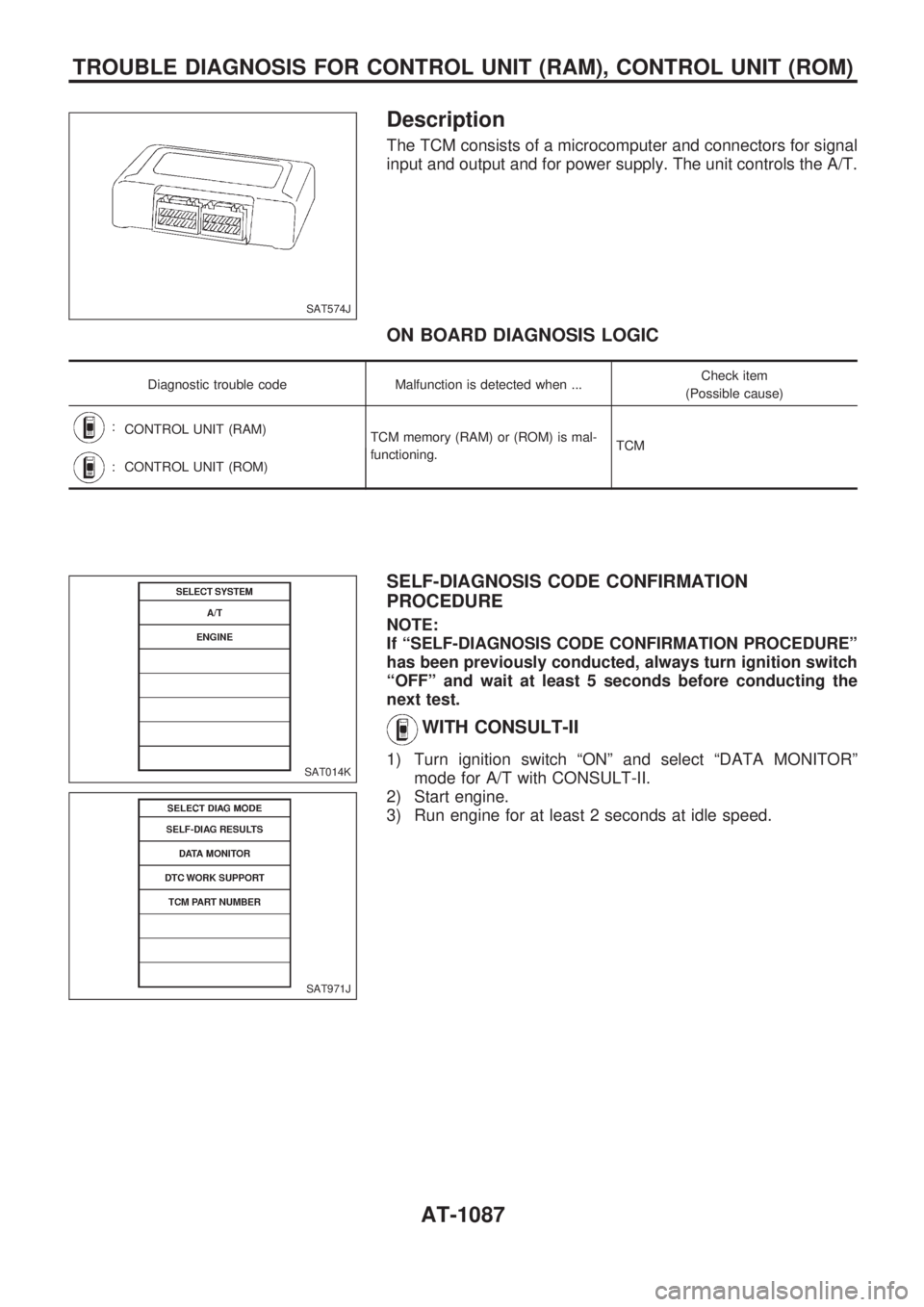

Description

The TCM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the A/T.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check item

(Possible cause)

:

CONTROL UNIT (RAM)

TCM memory (RAM) or (ROM) is mal-

functioning.TCM

:CONTROL UNIT (ROM)

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

NOTE:

If ªSELF-DIAGNOSIS CODE CONFIRMATION PROCEDUREº

has been previously conducted, always turn ignition switch

ªOFFº and wait at least 5 seconds before conducting the

next test.

WITH CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº

mode for A/T with CONSULT-II.

2) Start engine.

3) Run engine for at least 2 seconds at idle speed.

SAT574J

SAT014K

SAT971J

TROUBLE DIAGNOSIS FOR CONTROL UNIT (RAM), CONTROL UNIT (ROM)

AT-1087

Page 90 of 1033

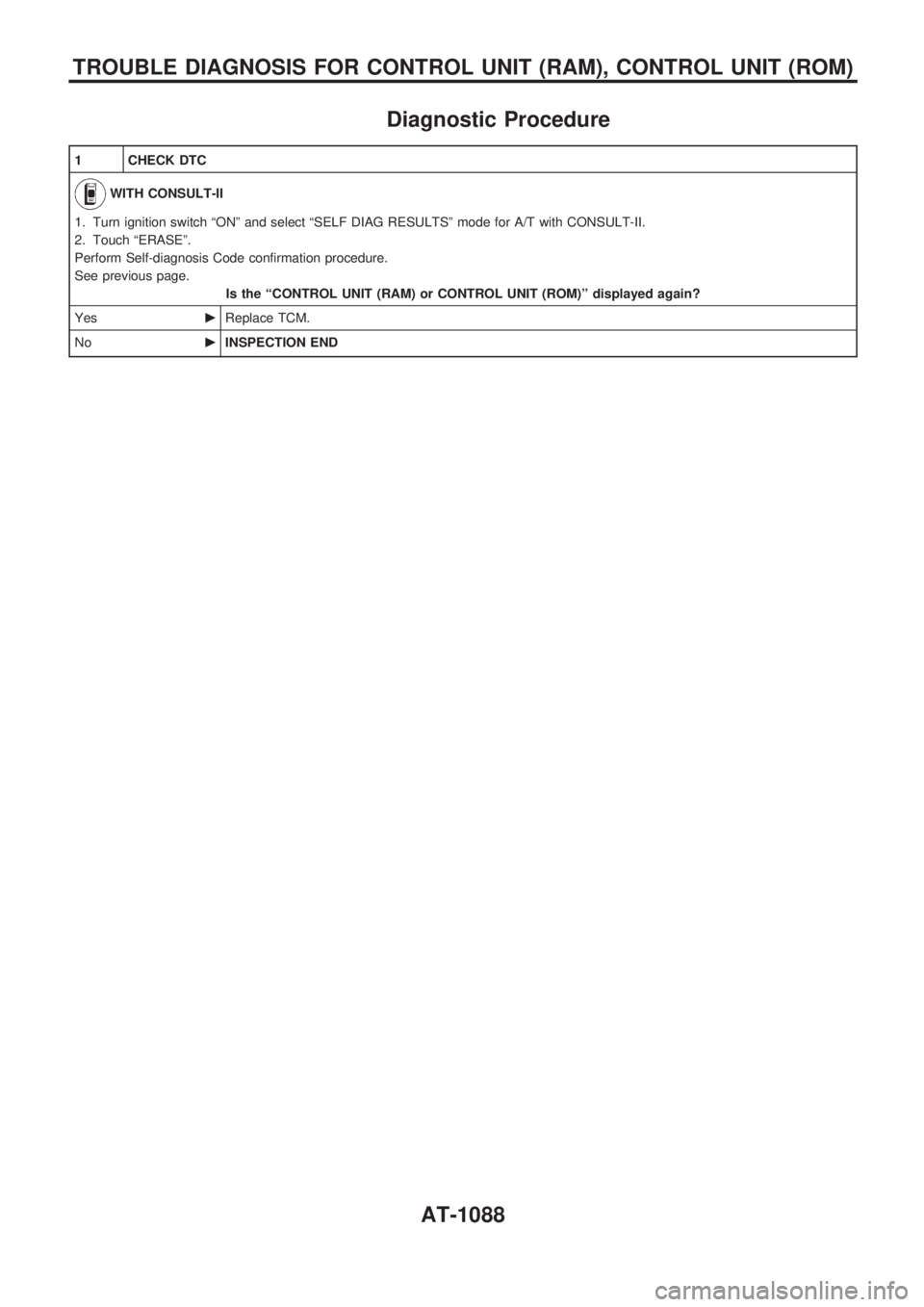

Diagnostic Procedure

1 CHECK DTC

WITH CONSULT-II

1. Turn ignition switch ªONº and select ªSELF DIAG RESULTSº mode for A/T with CONSULT-II.

2. Touch ªERASEº.

Perform Self-diagnosis Code confirmation procedure.

See previous page.

Is the ªCONTROL UNIT (RAM) or CONTROL UNIT (ROM)º displayed again?

YescReplace TCM.

NocINSPECTION END

TROUBLE DIAGNOSIS FOR CONTROL UNIT (RAM), CONTROL UNIT (ROM)

AT-1088