NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 121 of 1033

VA

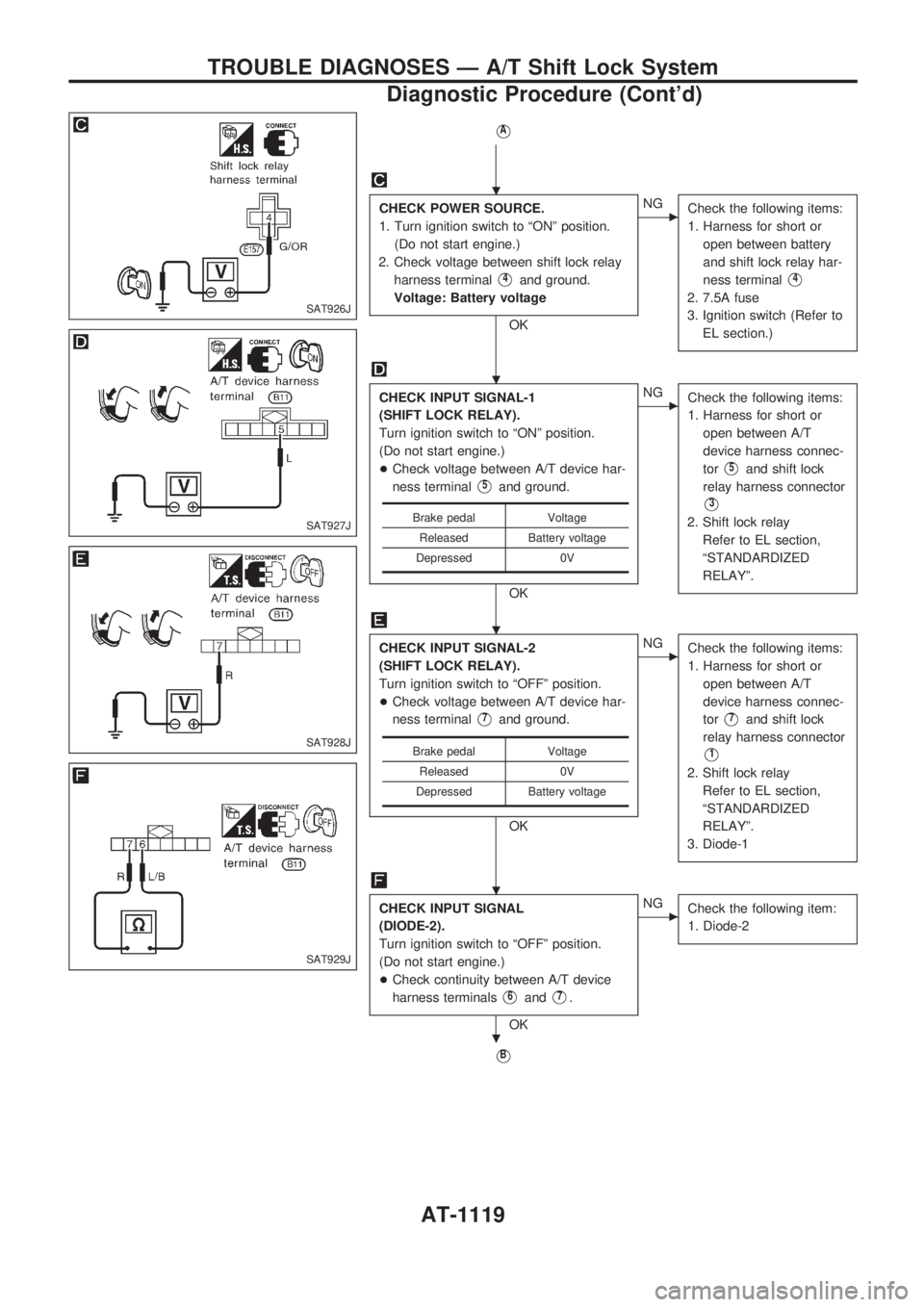

CHECK POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between shift lock relay

harness terminal

V4and ground.

Voltage: Battery voltage

OK

cNG

Check the following items:

1. Harness for short or

open between battery

and shift lock relay har-

ness terminal

V4

2. 7.5A fuse

3. Ignition switch (Refer to

EL section.)

CHECK INPUT SIGNAL-1

(SHIFT LOCK RELAY).

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device har-

ness terminal

V5and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between A/T

device harness connec-

tor

V5and shift lock

relay harness connector

V3

2. Shift lock relay

Refer to EL section,

ªSTANDARDIZED

RELAYº.

CHECK INPUT SIGNAL-2

(SHIFT LOCK RELAY).

Turn ignition switch to ªOFFº position.

+Check voltage between A/T device har-

ness terminal

V7and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between A/T

device harness connec-

tor

V7and shift lock

relay harness connector

V1

2. Shift lock relay

Refer to EL section,

ªSTANDARDIZED

RELAYº.

3. Diode-1

CHECK INPUT SIGNAL

(DIODE-2).

Turn ignition switch to ªOFFº position.

(Do not start engine.)

+Check continuity between A/T device

harness terminals

V6andV7.

OK

cNG

Check the following item:

1. Diode-2

VB

Brake pedal Voltage

Released Battery voltage

Depressed 0V

Brake pedal Voltage

Released 0V

Depressed Battery voltage

SAT926J

SAT927J

SAT928J

SAT929J

.

.

.

.

.

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Diagnostic Procedure (Cont'd)

AT-1119

Page 122 of 1033

VB

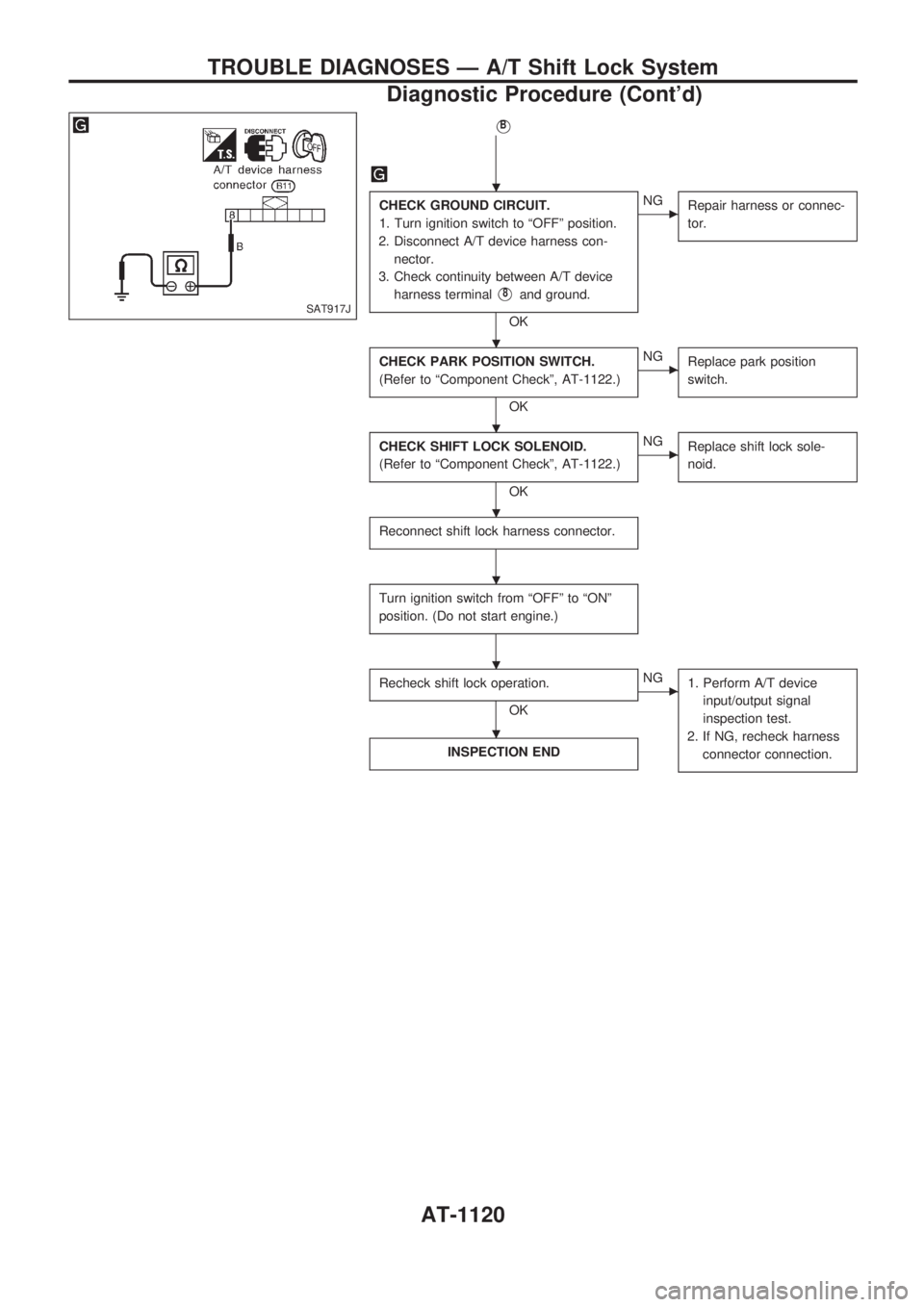

CHECK GROUND CIRCUIT.

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness con-

nector.

3. Check continuity between A/T device

harness terminal

V8and ground.

OK

cNG

Repair harness or connec-

tor.

CHECK PARK POSITION SWITCH.

(Refer to ªComponent Checkº, AT-1122.)

OK

cNG

Replace park position

switch.

CHECK SHIFT LOCK SOLENOID.

(Refer to ªComponent Checkº, AT-1122.)

OK

cNG

Replace shift lock sole-

noid.

Reconnect shift lock harness connector.

Turn ignition switch from ªOFFº to ªONº

position. (Do not start engine.)

Recheck shift lock operation.

OK

cNG

1. Perform A/T device

input/output signal

inspection test.

2. If NG, recheck harness

connector connection.

INSPECTION END

SAT917J

.

.

.

.

.

.

.

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Diagnostic Procedure (Cont'd)

AT-1120

Page 123 of 1033

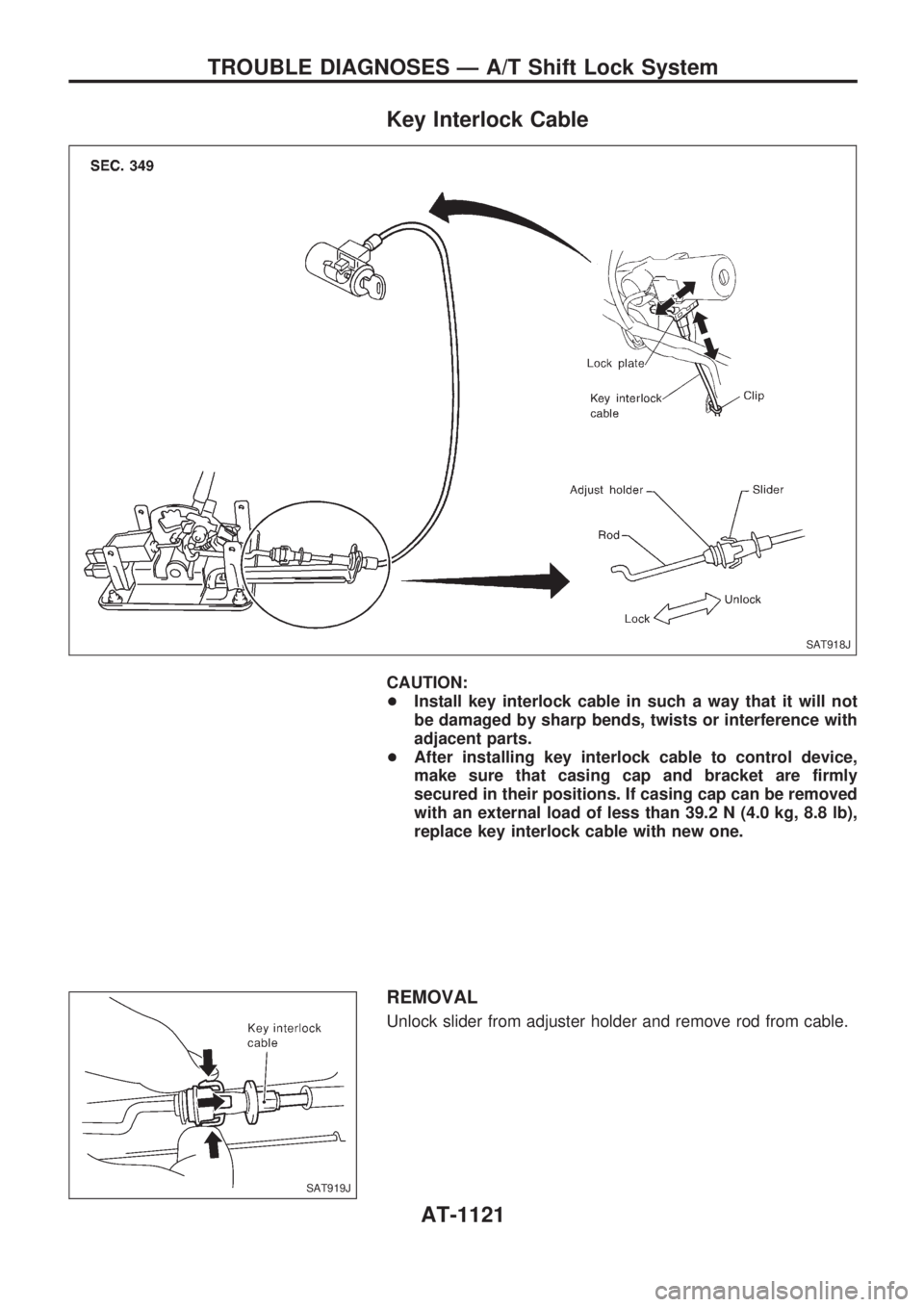

Key Interlock Cable

CAUTION:

+Install key interlock cable in such a way that it will not

be damaged by sharp bends, twists or interference with

adjacent parts.

+After installing key interlock cable to control device,

make sure that casing cap and bracket are firmly

secured in their positions. If casing cap can be removed

with an external load of less than 39.2 N (4.0 kg, 8.8 lb),

replace key interlock cable with new one.

REMOVAL

Unlock slider from adjuster holder and remove rod from cable.

SAT918J

SAT919J

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-1121

Page 124 of 1033

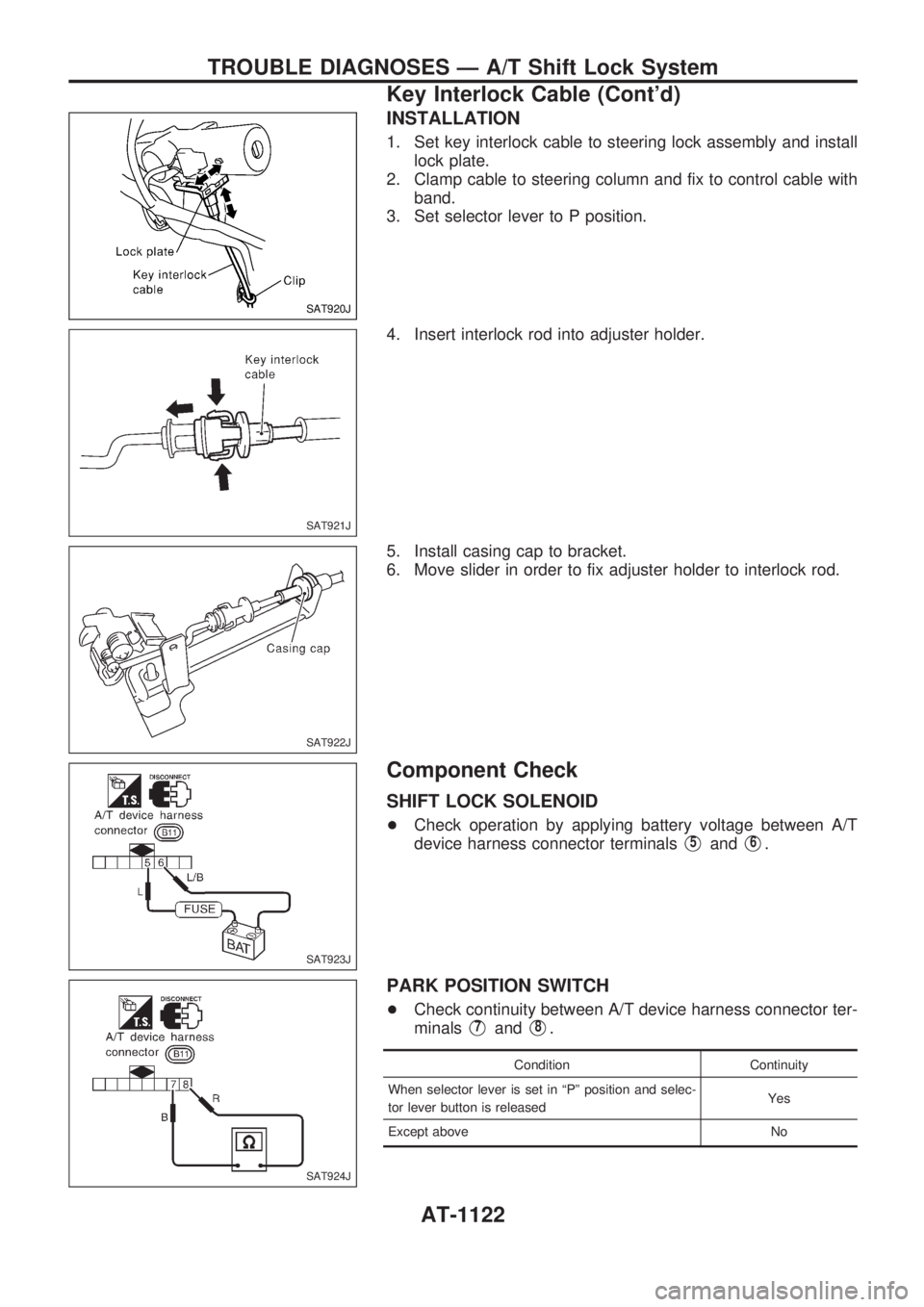

INSTALLATION

1. Set key interlock cable to steering lock assembly and install

lock plate.

2. Clamp cable to steering column and fix to control cable with

band.

3. Set selector lever to P position.

4. Insert interlock rod into adjuster holder.

5. Install casing cap to bracket.

6. Move slider in order to fix adjuster holder to interlock rod.

Component Check

SHIFT LOCK SOLENOID

+Check operation by applying battery voltage between A/T

device harness connector terminals

V5andV6.

PARK POSITION SWITCH

+Check continuity between A/T device harness connector ter-

minals

V7andV8.

Condition Continuity

When selector lever is set in ªPº position and selec-

tor lever button is releasedYes

Except above No

SAT920J

SAT921J

SAT922J

SAT923J

SAT924J

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Key Interlock Cable (Cont'd)

AT-1122

Page 125 of 1033

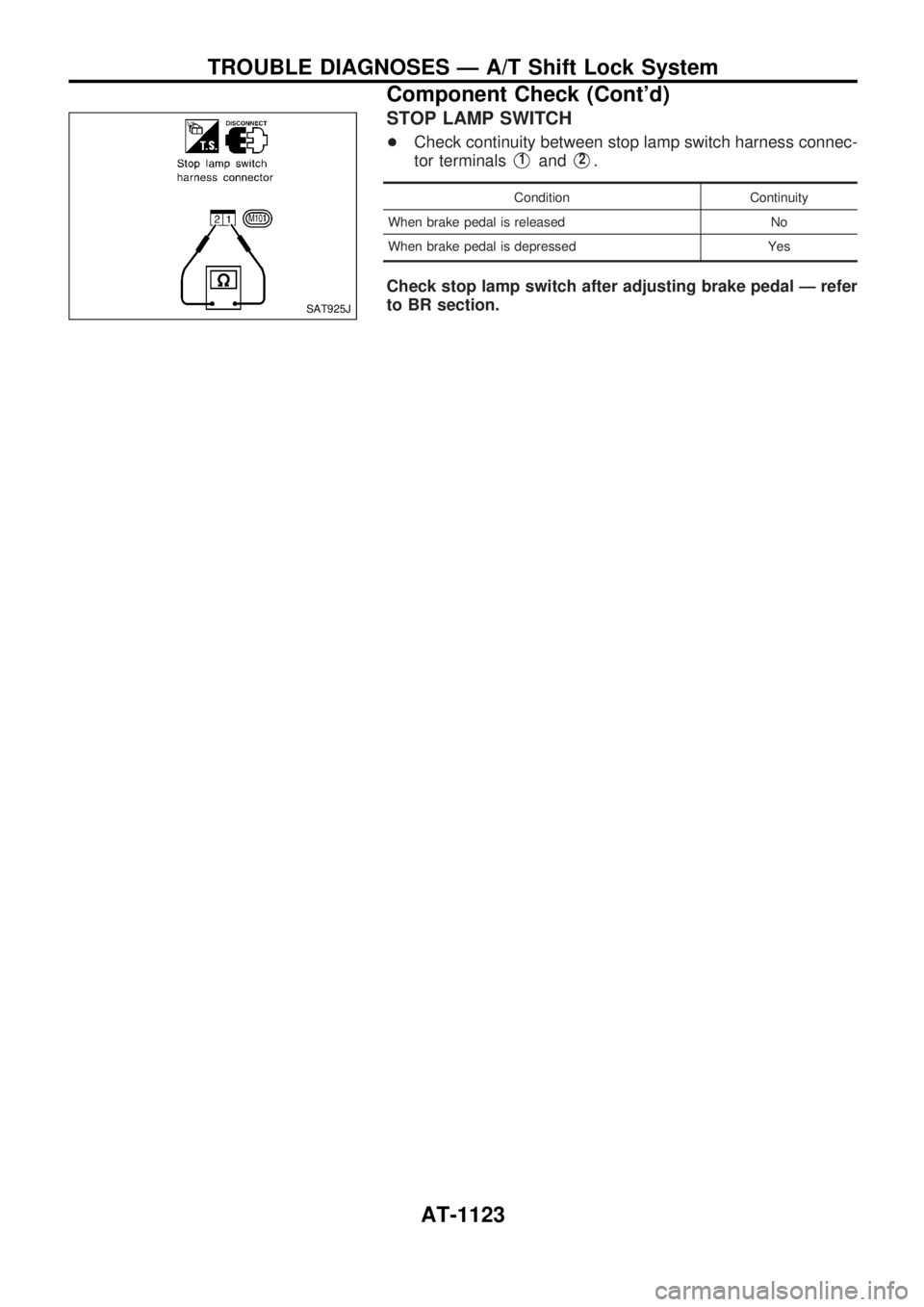

STOP LAMP SWITCH

+Check continuity between stop lamp switch harness connec-

tor terminals

V1andV2.

Condition Continuity

When brake pedal is released No

When brake pedal is depressed Yes

Check stop lamp switch after adjusting brake pedal Ð refer

to BR section.

SAT925J

TROUBLE DIAGNOSES Ð A/T Shift Lock System

Component Check (Cont'd)

AT-1123

Page 126 of 1033

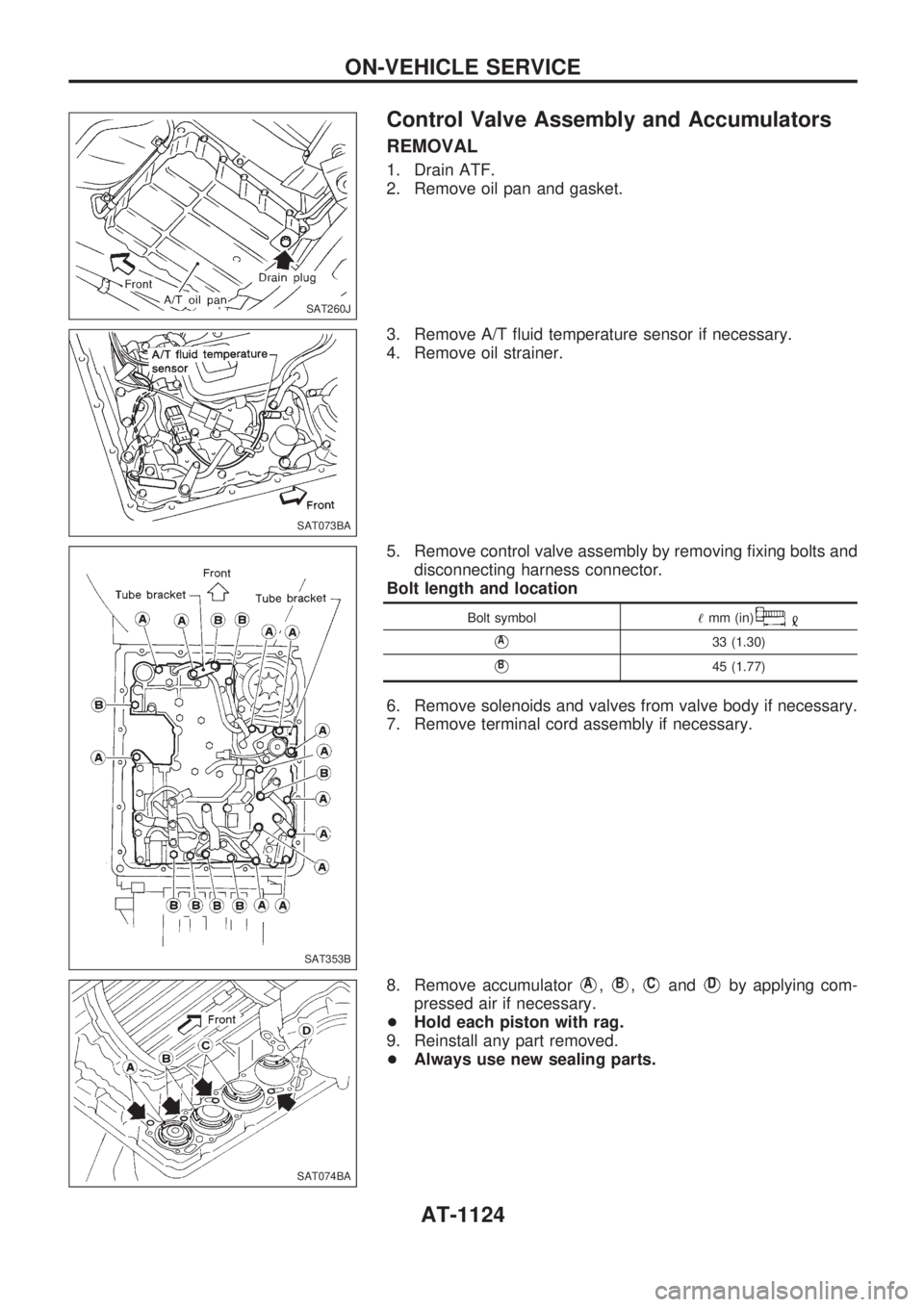

Control Valve Assembly and Accumulators

REMOVAL

1. Drain ATF.

2. Remove oil pan and gasket.

3. Remove A/T fluid temperature sensor if necessary.

4. Remove oil strainer.

5. Remove control valve assembly by removing fixing bolts and

disconnecting harness connector.

Bolt length and location

Bolt symbol!mm (in)

VA33 (1.30)

VB45 (1.77)

6. Remove solenoids and valves from valve body if necessary.

7. Remove terminal cord assembly if necessary.

8. Remove accumulator

VA,VB,VCandVDby applying com-

pressed air if necessary.

+Hold each piston with rag.

9. Reinstall any part removed.

+Always use new sealing parts.

SAT260J

SAT073BA

SAT353B

SAT074BA

ON-VEHICLE SERVICE

AT-1124

Page 127 of 1033

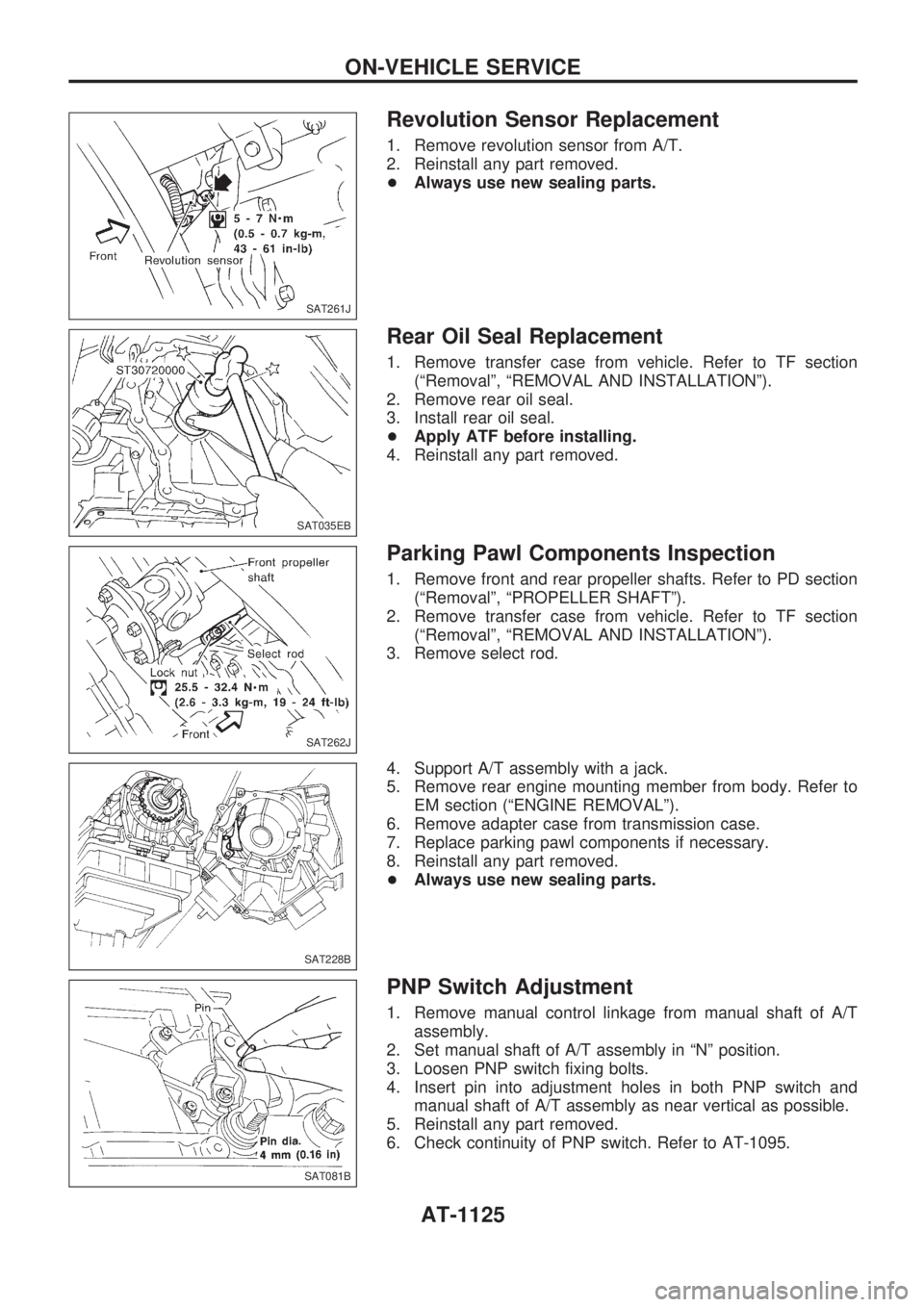

Revolution Sensor Replacement

1. Remove revolution sensor from A/T.

2. Reinstall any part removed.

+Always use new sealing parts.

Rear Oil Seal Replacement

1. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

2. Remove rear oil seal.

3. Install rear oil seal.

+Apply ATF before installing.

4. Reinstall any part removed.

Parking Pawl Components Inspection

1. Remove front and rear propeller shafts. Refer to PD section

(ªRemovalº, ªPROPELLER SHAFTº).

2. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

3. Remove select rod.

4. Support A/T assembly with a jack.

5. Remove rear engine mounting member from body. Refer to

EM section (ªENGINE REMOVALº).

6. Remove adapter case from transmission case.

7. Replace parking pawl components if necessary.

8. Reinstall any part removed.

+Always use new sealing parts.

PNP Switch Adjustment

1. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen PNP switch fixing bolts.

4. Insert pin into adjustment holes in both PNP switch and

manual shaft of A/T assembly as near vertical as possible.

5. Reinstall any part removed.

6. Check continuity of PNP switch. Refer to AT-1095.

SAT261J

SAT035EB

SAT262J

SAT228B

SAT081B

ON-VEHICLE SERVICE

AT-1125

Page 128 of 1033

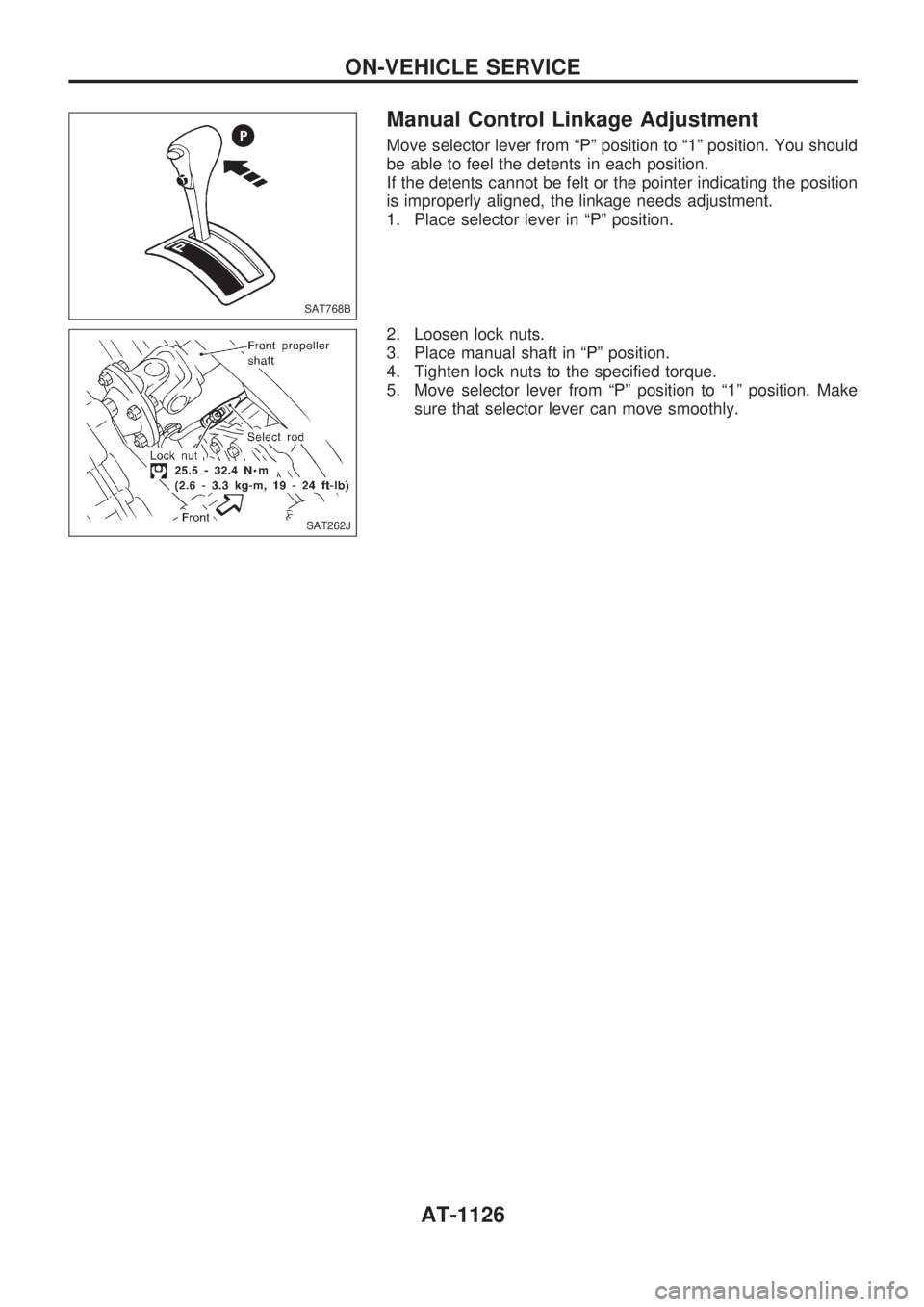

Manual Control Linkage Adjustment

Move selector lever from ªPº position to ª1º position. You should

be able to feel the detents in each position.

If the detents cannot be felt or the pointer indicating the position

is improperly aligned, the linkage needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen lock nuts.

3. Place manual shaft in ªPº position.

4. Tighten lock nuts to the specified torque.

5. Move selector lever from ªPº position to ª1º position. Make

sure that selector lever can move smoothly.

SAT768B

SAT262J

ON-VEHICLE SERVICE

AT-1126

Page 129 of 1033

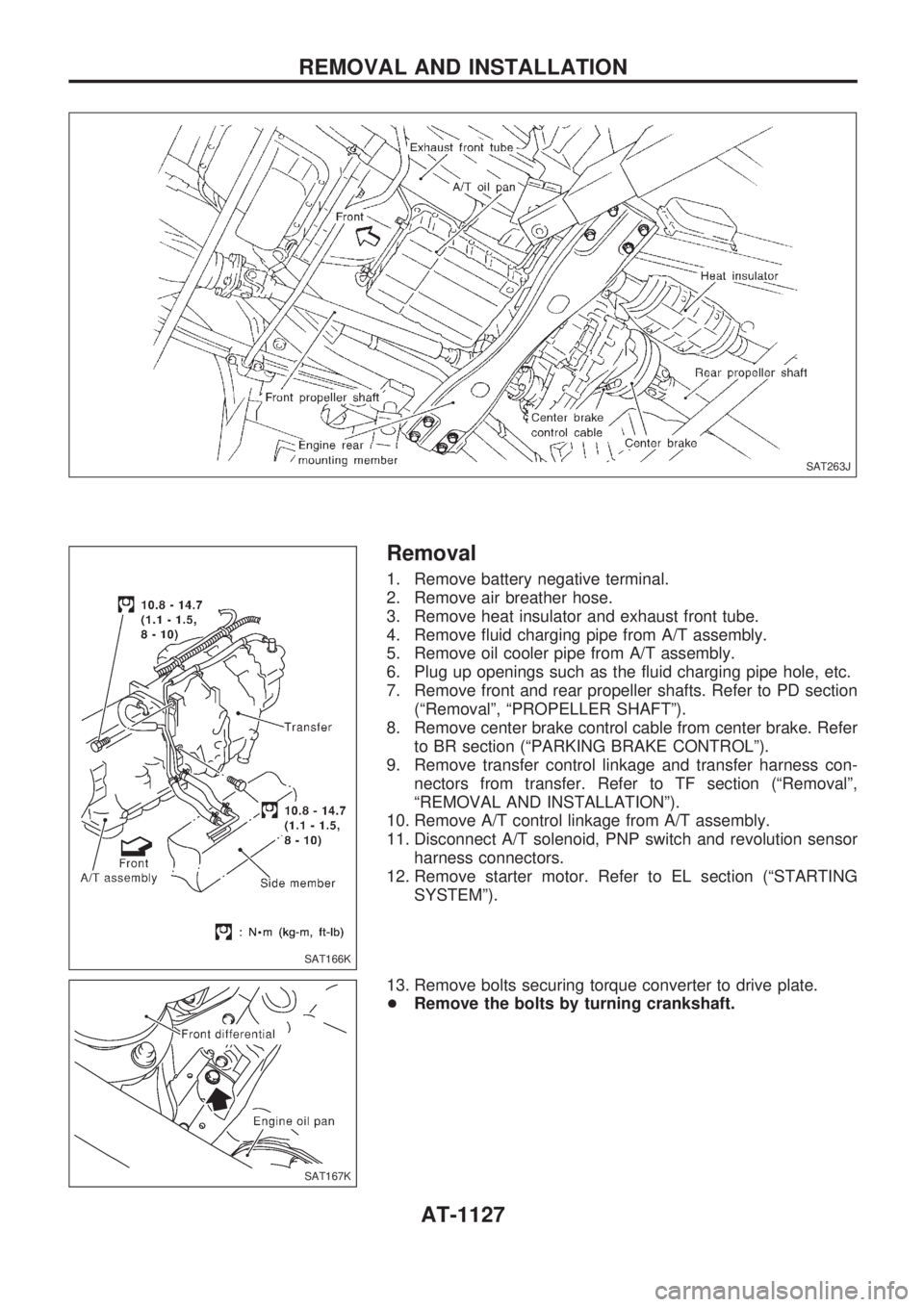

Removal

1. Remove battery negative terminal.

2. Remove air breather hose.

3. Remove heat insulator and exhaust front tube.

4. Remove fluid charging pipe from A/T assembly.

5. Remove oil cooler pipe from A/T assembly.

6. Plug up openings such as the fluid charging pipe hole, etc.

7. Remove front and rear propeller shafts. Refer to PD section

(ªRemovalº, ªPROPELLER SHAFTº).

8. Remove center brake control cable from center brake. Refer

to BR section (ªPARKING BRAKE CONTROLº).

9. Remove transfer control linkage and transfer harness con-

nectors from transfer. Refer to TF section (ªRemovalº,

ªREMOVAL AND INSTALLATIONº).

10. Remove A/T control linkage from A/T assembly.

11. Disconnect A/T solenoid, PNP switch and revolution sensor

harness connectors.

12. Remove starter motor. Refer to EL section (ªSTARTING

SYSTEMº).

13. Remove bolts securing torque converter to drive plate.

+Remove the bolts by turning crankshaft.

SAT263J

SAT166K

SAT167K

REMOVAL AND INSTALLATION

AT-1127

Page 130 of 1033

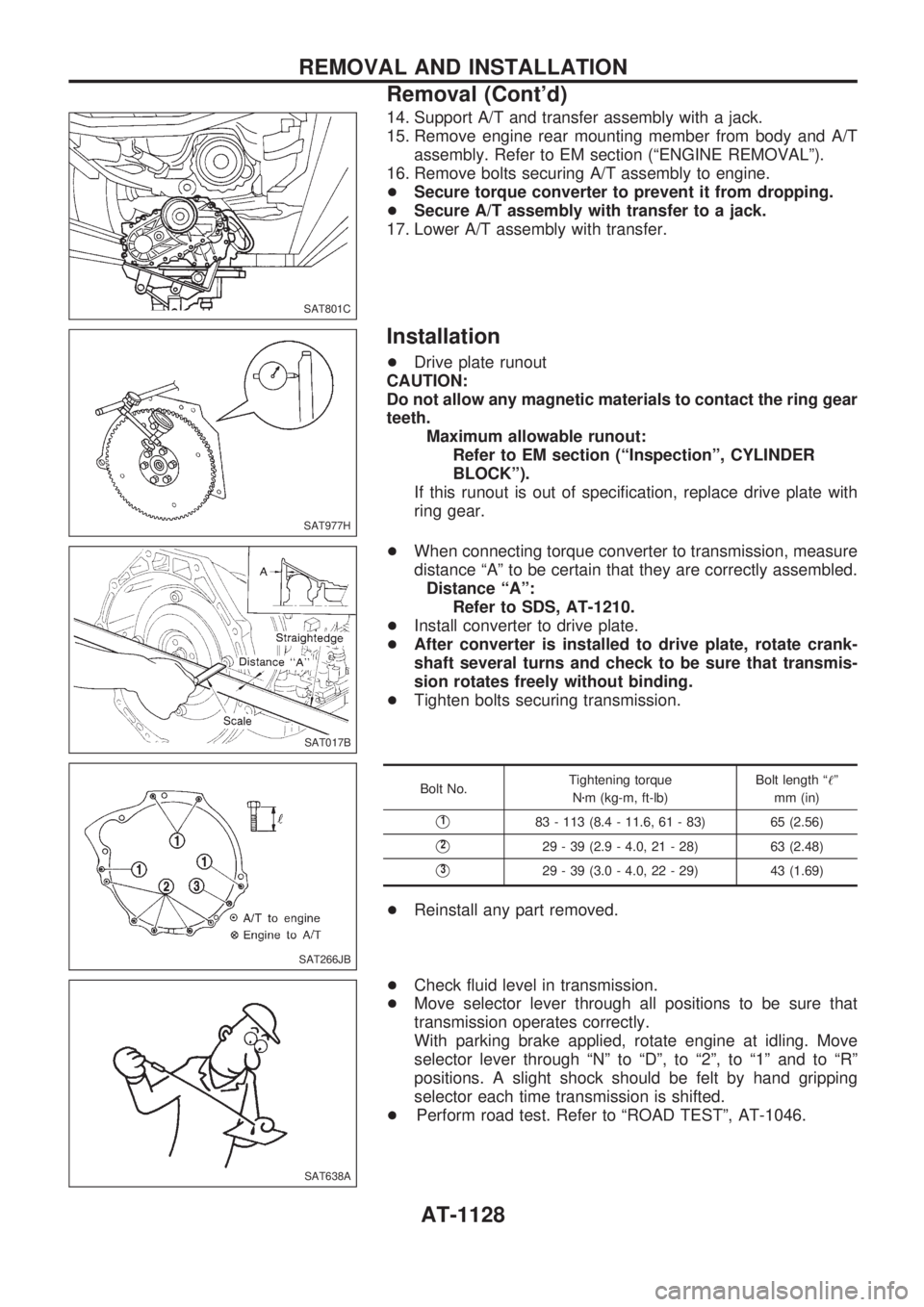

14. Support A/T and transfer assembly with a jack.

15. Remove engine rear mounting member from body and A/T

assembly. Refer to EM section (ªENGINE REMOVALº).

16. Remove bolts securing A/T assembly to engine.

+Secure torque converter to prevent it from dropping.

+Secure A/T assembly with transfer to a jack.

17. Lower A/T assembly with transfer.

Installation

+Drive plate runout

CAUTION:

Do not allow any magnetic materials to contact the ring gear

teeth.

Maximum allowable runout:

Refer to EM section (ªInspectionº, CYLINDER

BLOCKº).

If this runout is out of specification, replace drive plate with

ring gear.

+When connecting torque converter to transmission, measure

distance ªAº to be certain that they are correctly assembled.

Distance ªAº:

Refer to SDS, AT-1210.

+Install converter to drive plate.

+After converter is installed to drive plate, rotate crank-

shaft several turns and check to be sure that transmis-

sion rotates freely without binding.

+Tighten bolts securing transmission.

Bolt No.Tightening torque

Nzm (kg-m, ft-lb)Bolt length ª!º

mm (in)

V183 - 113 (8.4 - 11.6, 61 - 83) 65 (2.56)

V229 - 39 (2.9 - 4.0, 21 - 28) 63 (2.48)

V329 - 39 (3.0 - 4.0, 22 - 29) 43 (1.69)

+Reinstall any part removed.

+Check fluid level in transmission.

+Move selector lever through all positions to be sure that

transmission operates correctly.

With parking brake applied, rotate engine at idling. Move

selector lever through ªNº to ªDº, to ª2º, to ª1º and to ªRº

positions. A slight shock should be felt by hand gripping

selector each time transmission is shifted.

+Perform road test. Refer to ªROAD TESTº, AT-1046.

SAT801C

SAT977H

SAT017B

SAT266JB

SAT638A

REMOVAL AND INSTALLATION

Removal (Cont'd)

AT-1128