NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 111 of 1033

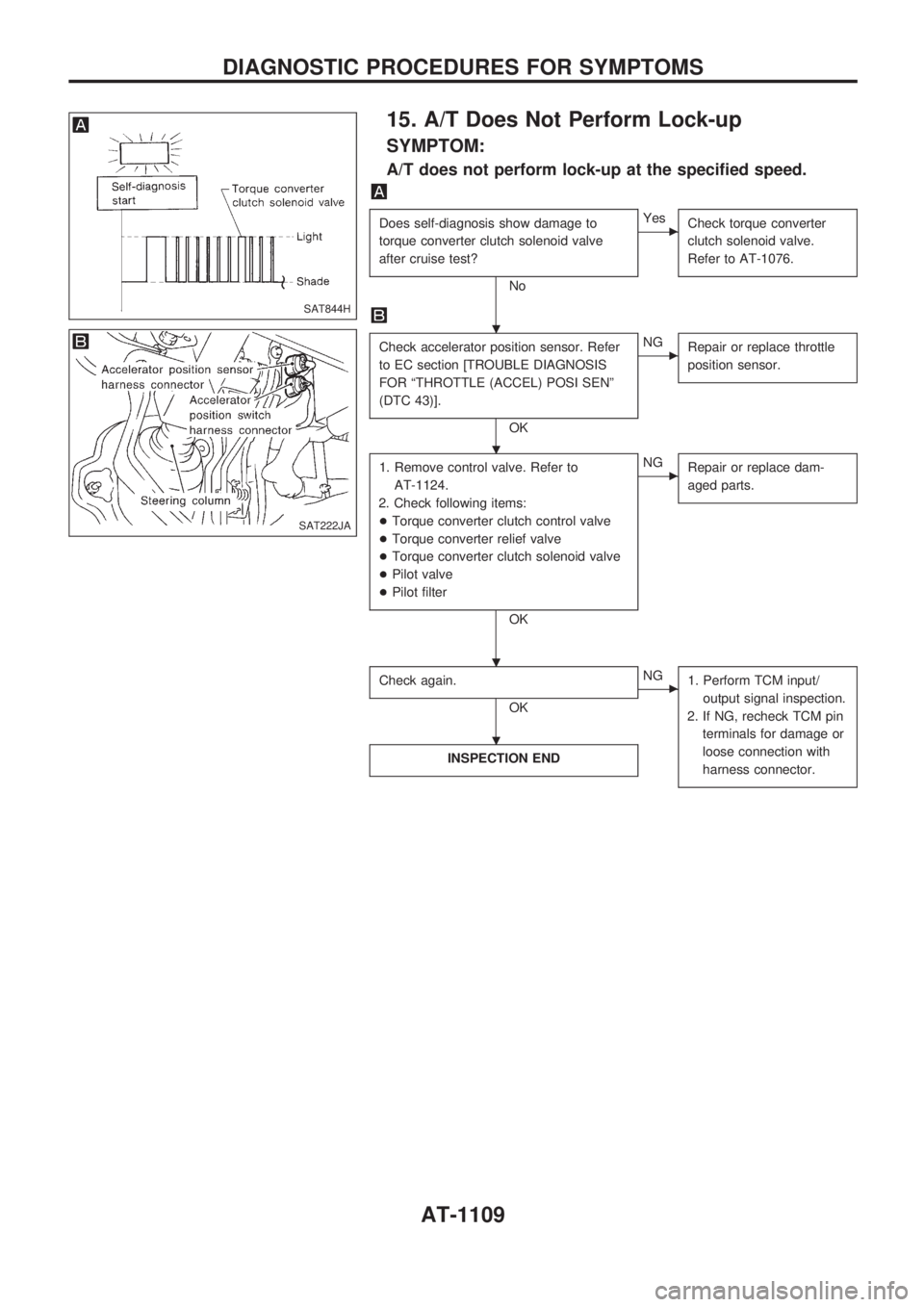

15. A/T Does Not Perform Lock-up

SYMPTOM:

A/T does not perform lock-up at the specified speed.

Does self-diagnosis show damage to

torque converter clutch solenoid valve

after cruise test?

No

cYes

Check torque converter

clutch solenoid valve.

Refer to AT-1076.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove control valve. Refer to

AT-1124.

2. Check following items:

+Torque converter clutch control valve

+Torque converter relief valve

+Torque converter clutch solenoid valve

+Pilot valve

+Pilot filter

OK

cNG

Repair or replace dam-

aged parts.

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT844H

SAT222JA

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1109

Page 112 of 1033

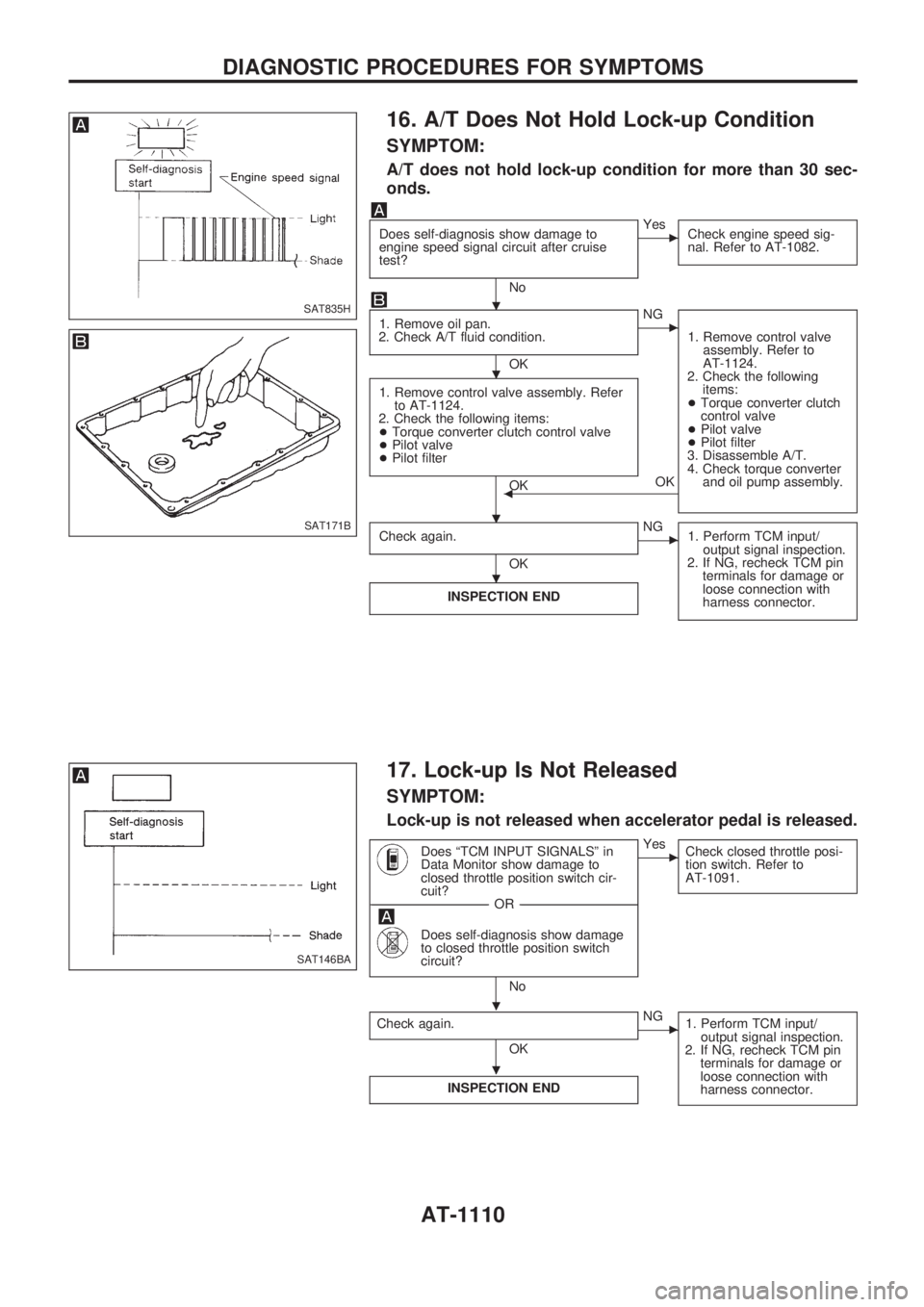

16. A/T Does Not Hold Lock-up Condition

SYMPTOM:

A/T does not hold lock-up condition for more than 30 sec-

onds.

Does self-diagnosis show damage to

engine speed signal circuit after cruise

test?

No

cYes

Check engine speed sig-

nal. Refer to AT-1082.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Torque converter clutch

control valve

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check torque converter

and oil pump assembly.

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Torque converter clutch control valve

+Pilot valve

+Pilot filter

OKOKb

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

17. Lock-up Is Not Released

SYMPTOM:

Lock-up is not released when accelerator pedal is released.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

closed throttle position switch cir-

cuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to closed throttle position switch

circuit?

No

cYes

Check closed throttle posi-

tion switch. Refer to

AT-1091.

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT835H

SAT171B

SAT146BA

.

.

. .

.

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1110

Page 113 of 1033

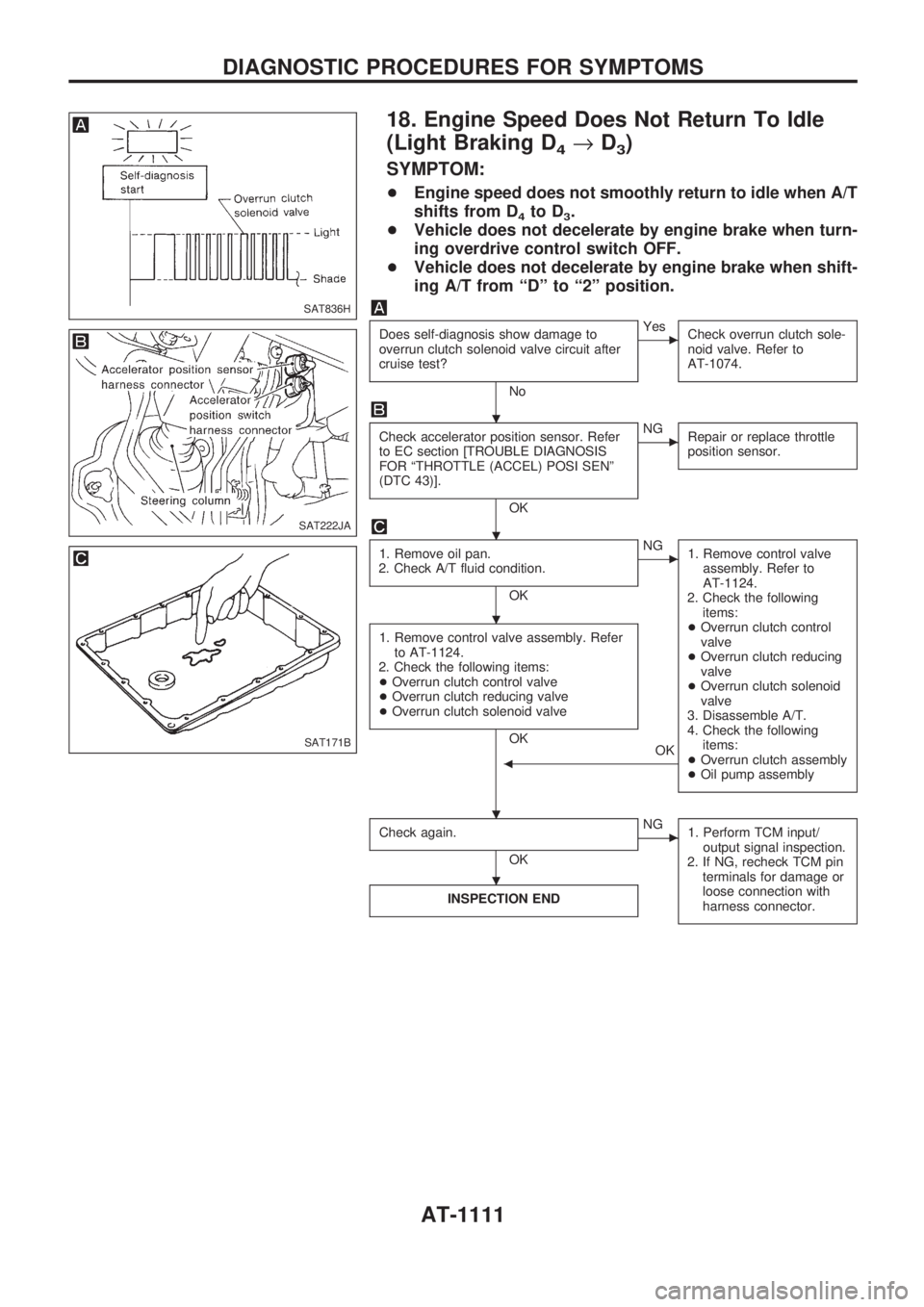

18. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3)

SYMPTOM:

+Engine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

+Vehicle does not decelerate by engine brake when turn-

ing overdrive control switch OFF.

+Vehicle does not decelerate by engine brake when shift-

ing A/T from ªDº to ª2º position.

Does self-diagnosis show damage to

overrun clutch solenoid valve circuit after

cruise test?

No

cYes

Check overrun clutch sole-

noid valve. Refer to

AT-1074.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Overrun clutch control

valve

+Overrun clutch reducing

valve

+Overrun clutch solenoid

valve

3. Disassemble A/T.

4. Check the following

items:

+Overrun clutch assembly

+Oil pump assembly

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Overrun clutch control valve

+Overrun clutch reducing valve

+Overrun clutch solenoid valve

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT836H

SAT222JA

SAT171B

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1111

Page 114 of 1033

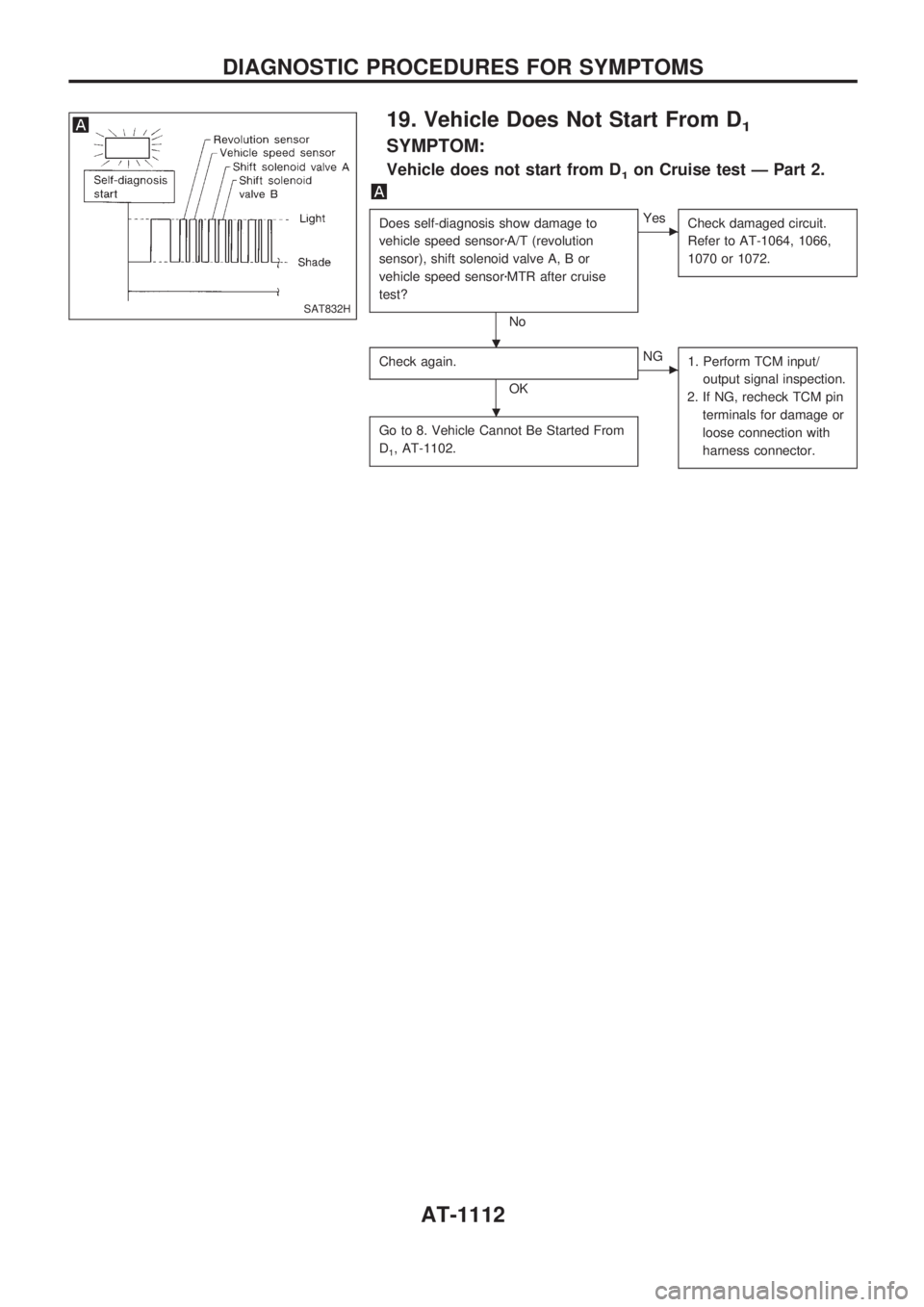

19. Vehicle Does Not Start From D1

SYMPTOM:

Vehicle does not start from D1on Cruise test Ð Part 2.

Does self-diagnosis show damage to

vehicle speed sensorzA/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensorzMTR after cruise

test?

No

cYes

Check damaged circuit.

Refer to AT-1064, 1066,

1070 or 1072.

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

Go to 8. Vehicle Cannot Be Started From

D

1, AT-1102.

SAT832H

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1112

Page 115 of 1033

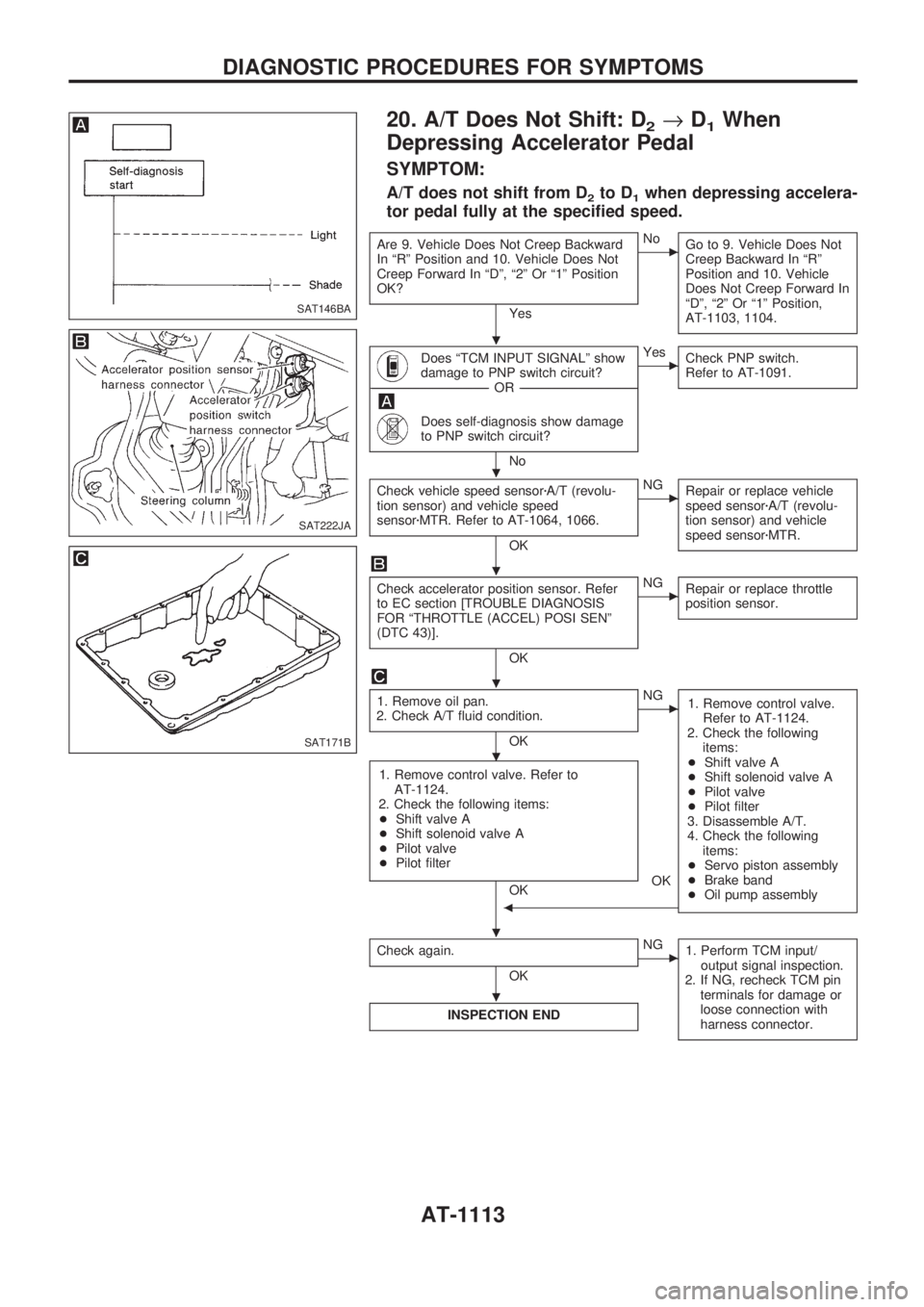

20. A/T Does Not Shift: D2®D1When

Depressing Accelerator Pedal

SYMPTOM:

A/T does not shift from D2to D1when depressing accelera-

tor pedal fully at the specified speed.

Are 9. Vehicle Does Not Creep Backward

In ªRº Position and 10. Vehicle Does Not

Creep Forward In ªDº, ª2º Or ª1º Position

OK?

Yes

cNo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position and 10. Vehicle

Does Not Creep Forward In

ªDº, ª2º Or ª1º Position,

AT-1103, 1104.

Does ªTCM INPUT SIGNALº show

damage to PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch.

Refer to AT-1091.

Check vehicle speed sensorzA/T (revolu-

tion sensor) and vehicle speed

sensorzMTR. Refer to AT-1064, 1066.

OK

cNG

Repair or replace vehicle

speed sensorzA/T (revolu-

tion sensor) and vehicle

speed sensorzMTR.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve.

Refer to AT-1124.

2. Check the following

items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+Brake band

+Oil pump assembly

1. Remove control valve. Refer to

AT-1124.

2. Check the following items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

OK

b

OK

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

SAT222JA

SAT171B

.

.

.

.

.

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1113

Page 116 of 1033

21. A/T Does Not Shift: D4®D3, When

Overdrive Control Switch ªONº®ªOFFº

SYMPTOM:

A/T does not shift from D4to D3when changing overdrive

control switch to ªOFFº position.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

overdrive control switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to overdrive control switch circuit?

No

cYes

Check overdrive control

switch circuit. Refer to

AT-1091.

Go to 10. A/T Does Not Shift: D2®D3,

AT-1104.

22. A/T Does Not Shift: D3®22, When

Selector Lever ªDº®ª2º Position

SYMPTOM:

A/T does not shift from D3to 22when changing selector

lever from ªDº to ª2º position.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch circuit.

Refer to AT-1091.

Go to 12. A/T Does Not Shift: D1®D2Or Does Not Kickdown: D4®D2,

AT-1106.

SAT146BA

SAT146BA

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1114

Page 117 of 1033

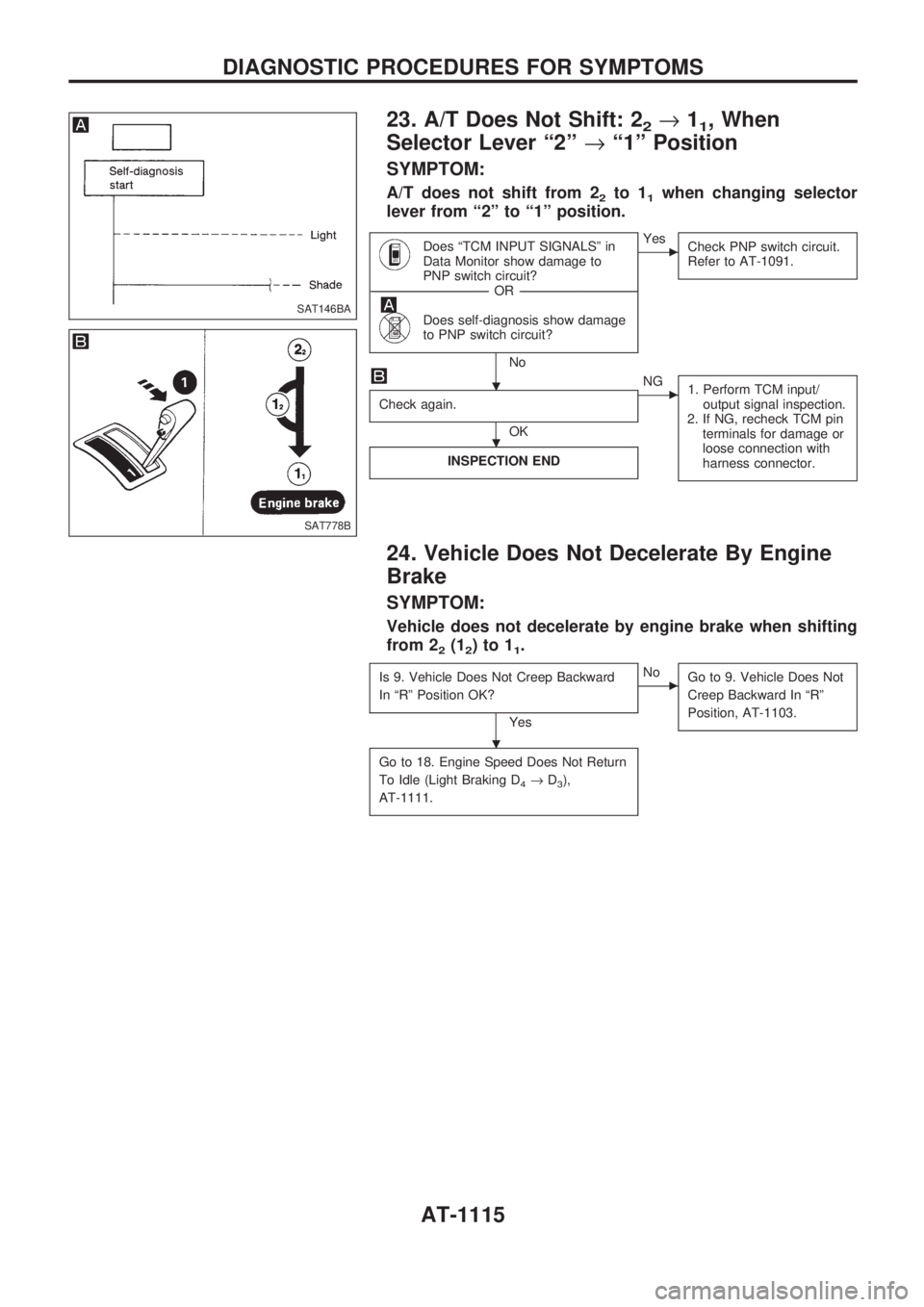

23. A/T Does Not Shift: 22®11, When

Selector Lever ª2º®ª1º Position

SYMPTOM:

A/T does not shift from 22to 11when changing selector

lever from ª2º to ª1º position.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch circuit.

Refer to AT-1091.

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

24. Vehicle Does Not Decelerate By Engine

Brake

SYMPTOM:

Vehicle does not decelerate by engine brake when shifting

from 2

2(12)to11.

Is 9. Vehicle Does Not Creep Backward

In ªRº Position OK?

Yes

cNo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-1103.

Go to 18. Engine Speed Does Not Return

To Idle (Light Braking D

4®D3),

AT-1111.

SAT146BA

SAT778B

.

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1115

Page 118 of 1033

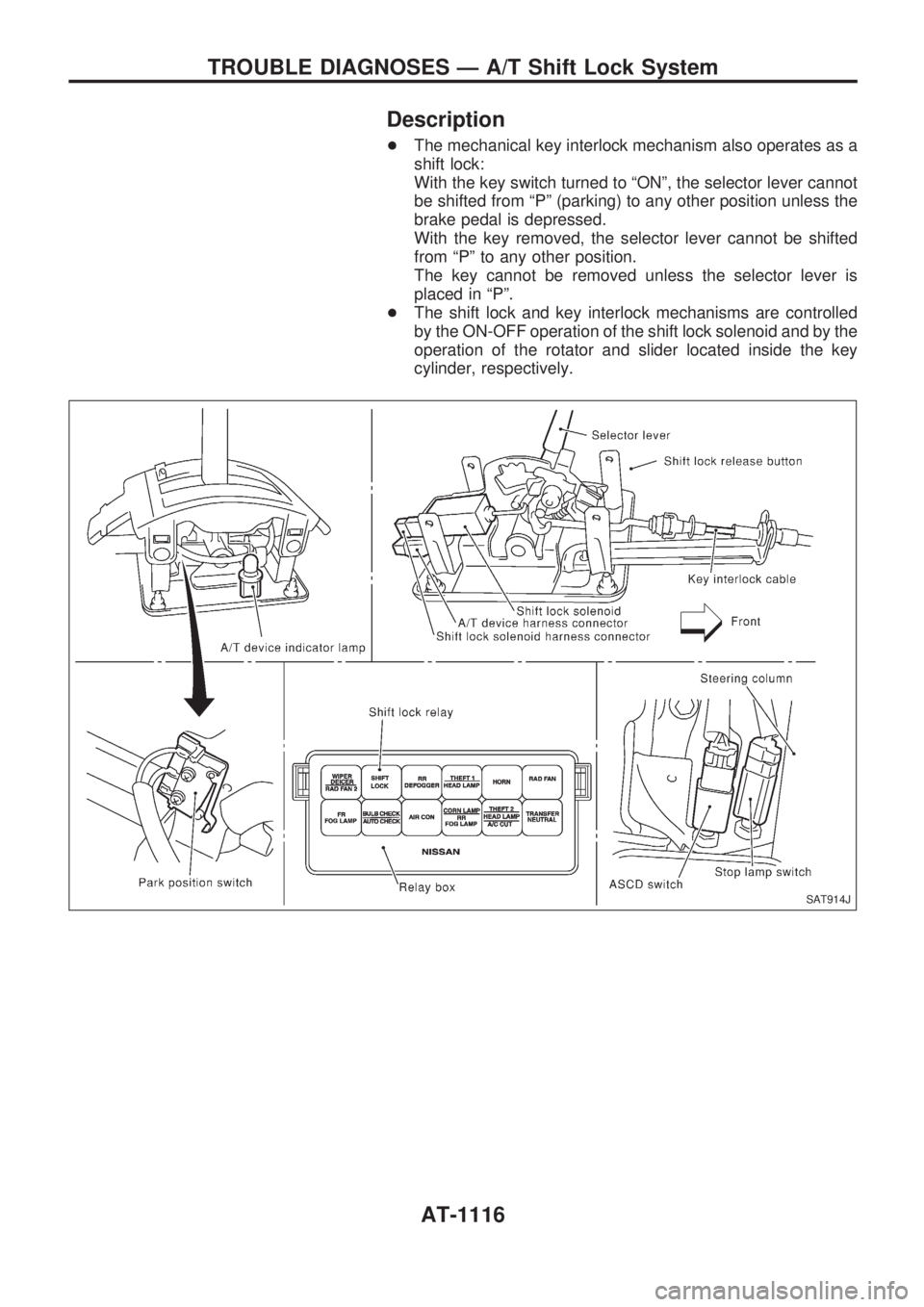

Description

+The mechanical key interlock mechanism also operates as a

shift lock:

With the key switch turned to ªONº, the selector lever cannot

be shifted from ªPº (parking) to any other position unless the

brake pedal is depressed.

With the key removed, the selector lever cannot be shifted

from ªPº to any other position.

The key cannot be removed unless the selector lever is

placed in ªPº.

+The shift lock and key interlock mechanisms are controlled

by the ON-OFF operation of the shift lock solenoid and by the

operation of the rotator and slider located inside the key

cylinder, respectively.

SAT914J

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-1116

Page 119 of 1033

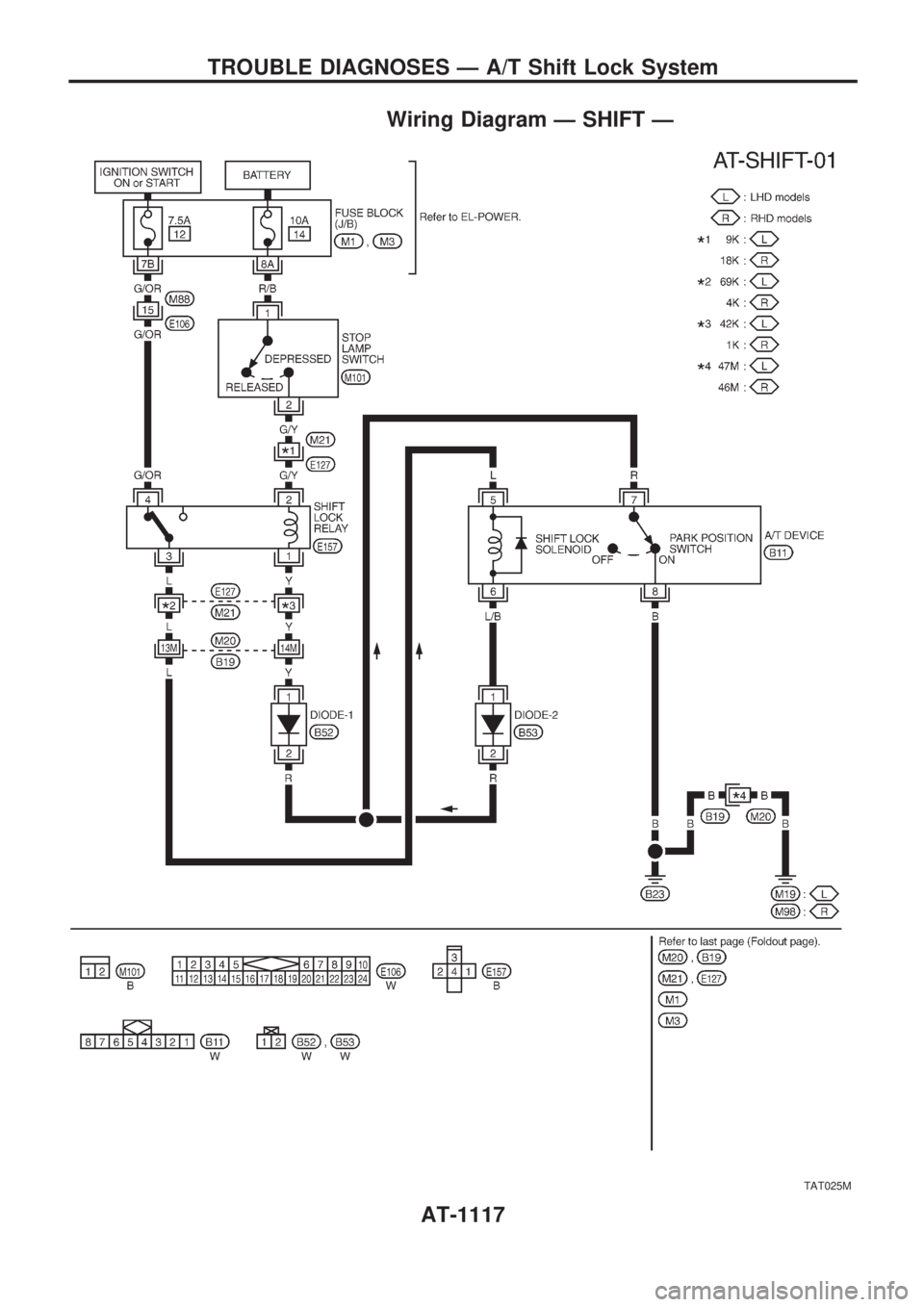

Wiring Diagram Ð SHIFT Ð

TAT025M

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-1117

Page 120 of 1033

Diagnostic Procedure

SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with

key in ªONº position and brake pedal applied.

+Selector lever can be moved from ªPº position with key

in ªONº position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

Check key interlock cable for damage.

OK

cNG

Repair key interlock cable.

Refer to ªKey Interlock

Cableº, AT-1121.

Check selector lever position for damage.

OK

cNG

Check selector lever.

Refer to ªON-VEHICLE

SERVICE Ð PNP Switch

and Manual Control Link-

age Adjustmentº.

CHECK POWER SOURCE.

1. Turn ignition switch to ªOFFº position.

(Do not start engine.)

2. Check voltage between stop lamp

switch harness terminal

V1and

ground.

Voltage: Battery voltage

OK

cNG

Check the following items:

1. Harness for short or

open between battery

and stop lamp switch

harness terminal

V1

2. 10A fuse

CHECK INPUT SIGNAL

(STOP LAMP SWITCH).

Turn ignition switch to ªOFFº position.

(Do not start engine.)

+Check voltage between shift lock relay

harness terminal

V2and ground.

OK

cNG

Check the following items:

1. Harness for short or

open between shift lock

relay harness connector

V2and stop lamp

switch harness connec-

tor

V2

2. Stop lamp switch

(Refer to ªComponent

Checkº, AT-1123.)

VA

Brake pedal Voltage

Released 0V

Depressed Battery voltage

SAT915J

SAT916J

.

.

.

.

TROUBLE DIAGNOSES Ð A/T Shift Lock System

AT-1118