NISSAN PATROL 2000 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 101 of 1033

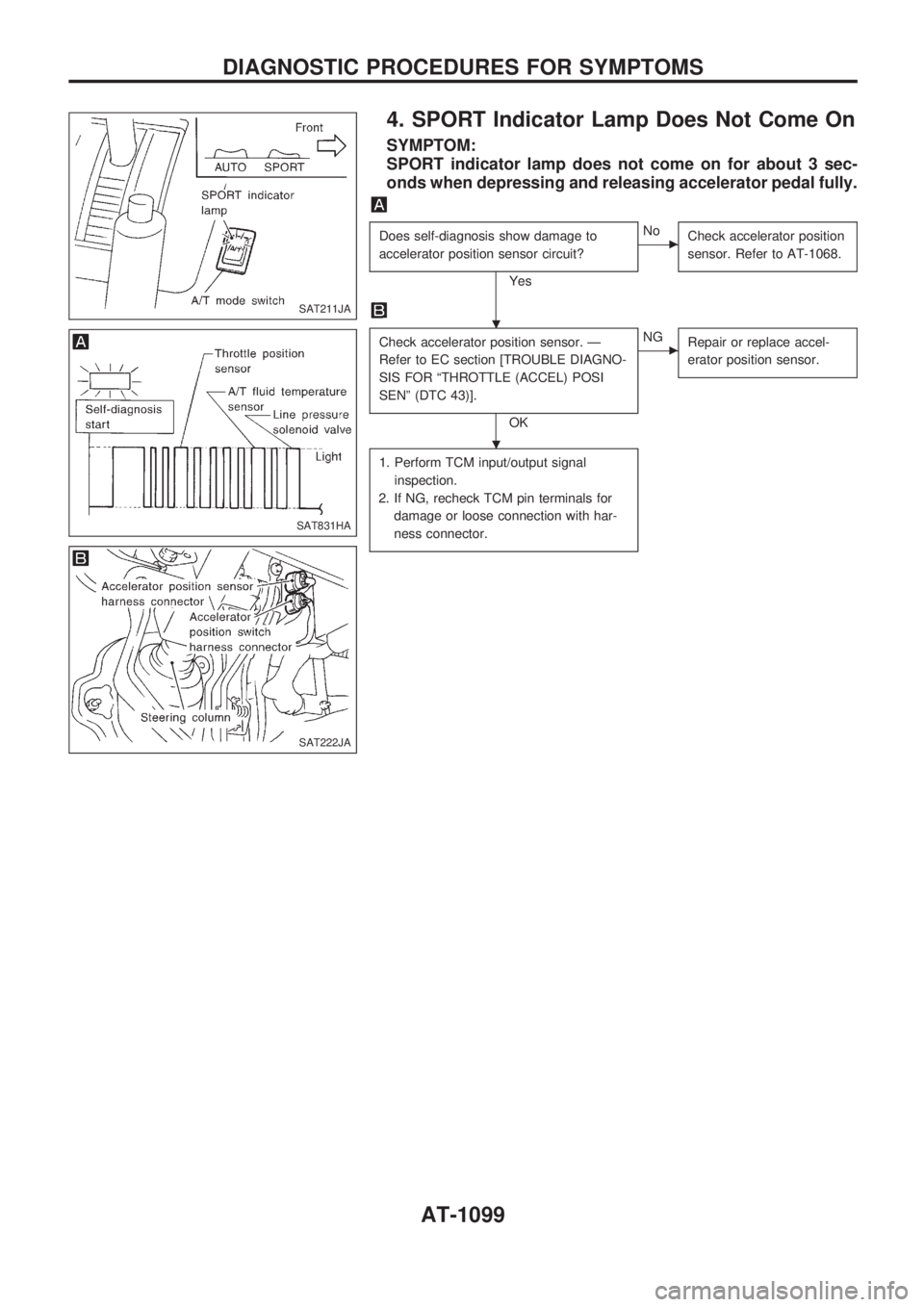

4. SPORT Indicator Lamp Does Not Come On

SYMPTOM:

SPORT indicator lamp does not come on for about 3 sec-

onds when depressing and releasing accelerator pedal fully.

Does self-diagnosis show damage to

accelerator position sensor circuit?

Yes

cNo

Check accelerator position

sensor. Refer to AT-1068.

Check accelerator position sensor. Ð

Refer to EC section [TROUBLE DIAGNO-

SIS FOR ªTHROTTLE (ACCEL) POSI

SENº (DTC 43)].

OK

cNG

Repair or replace accel-

erator position sensor.

1. Perform TCM input/output signal

inspection.

2. If NG, recheck TCM pin terminals for

damage or loose connection with har-

ness connector.

SAT211JA

SAT831HA

SAT222JA

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1099

Page 102 of 1033

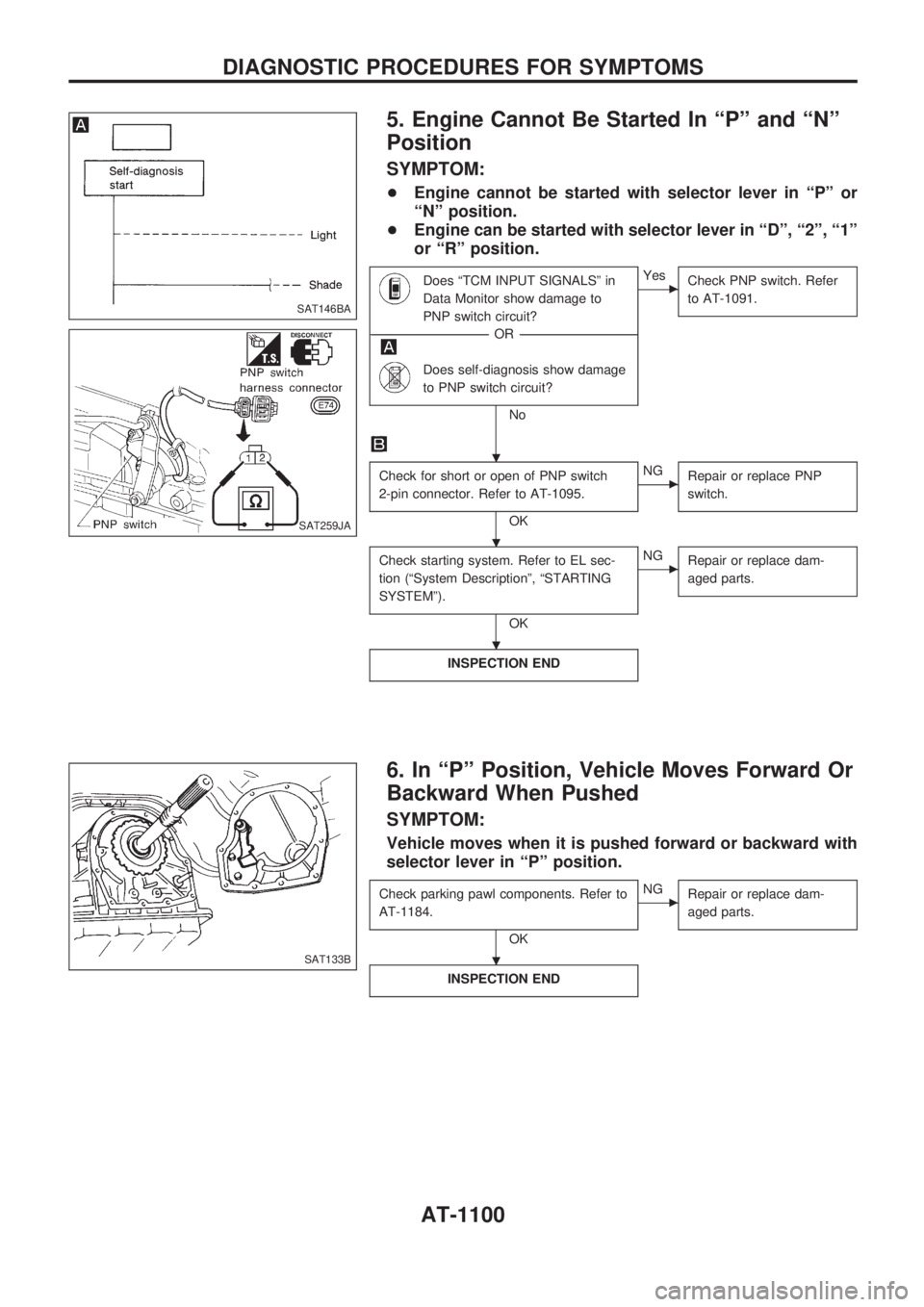

5. Engine Cannot Be Started In ªPº and ªNº

Position

SYMPTOM:

+Engine cannot be started with selector lever in ªPº or

ªNº position.

+Engine can be started with selector lever in ªDº, ª2º, ª1º

or ªRº position.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch. Refer

to AT-1091.

Check for short or open of PNP switch

2-pin connector. Refer to AT-1095.

OK

cNG

Repair or replace PNP

switch.

Check starting system. Refer to EL sec-

tion (ªSystem Descriptionº, ªSTARTING

SYSTEMº).

OK

cNG

Repair or replace dam-

aged parts.

INSPECTION END

6. In ªPº Position, Vehicle Moves Forward Or

Backward When Pushed

SYMPTOM:

Vehicle moves when it is pushed forward or backward with

selector lever in ªPº position.

Check parking pawl components. Refer to

AT-1184.

OK

cNG

Repair or replace dam-

aged parts.

INSPECTION END

SAT146BA

SAT259JA

SAT133B

.

.

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1100

Page 103 of 1033

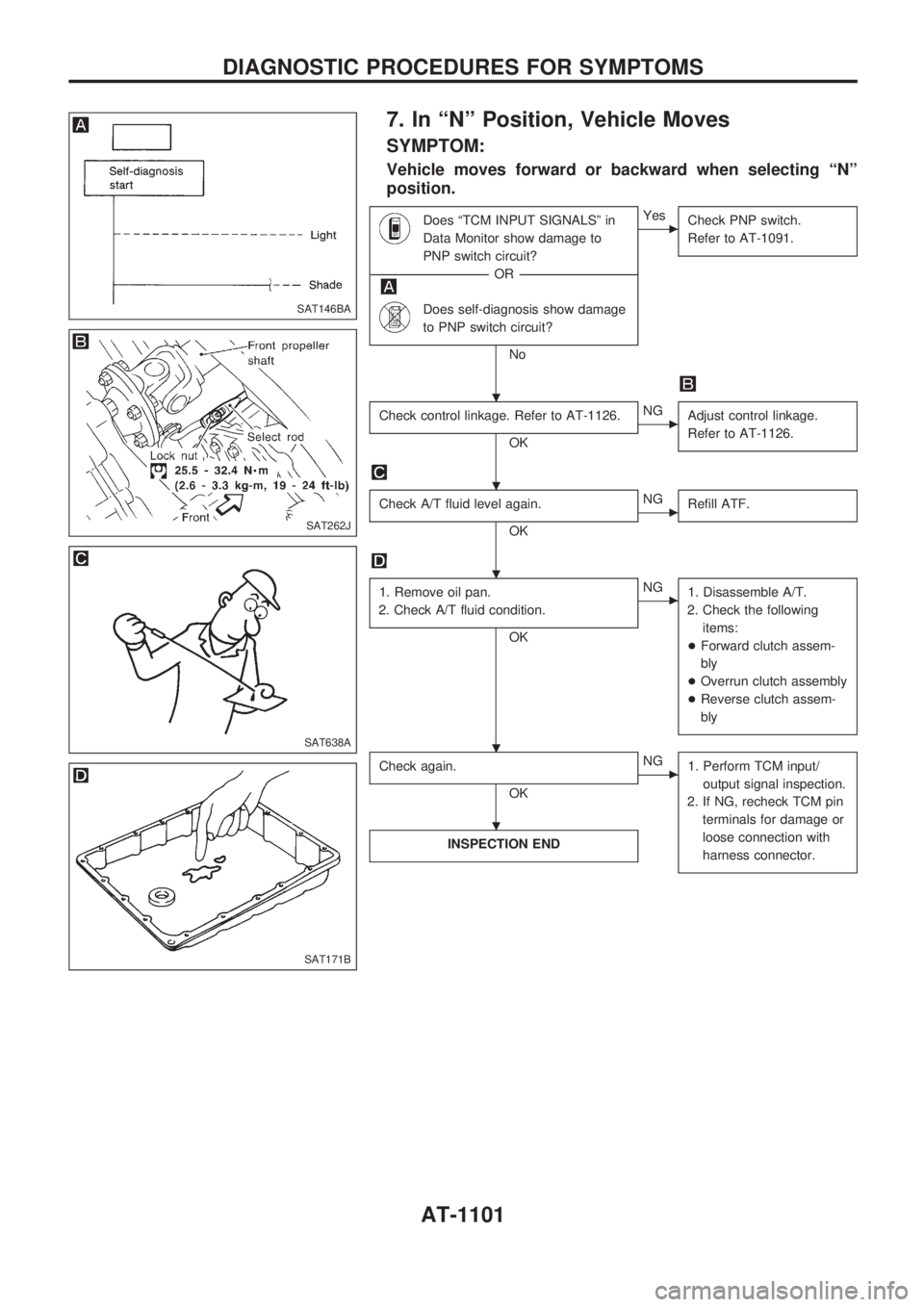

7. In ªNº Position, Vehicle Moves

SYMPTOM:

Vehicle moves forward or backward when selecting ªNº

position.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch.

Refer to AT-1091.

Check control linkage. Refer to AT-1126.

OK

cNG

Adjust control linkage.

Refer to AT-1126.

Check A/T fluid level again.

OK

cNG

Refill ATF.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Disassemble A/T.

2. Check the following

items:

+Forward clutch assem-

bly

+Overrun clutch assembly

+Reverse clutch assem-

bly

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

SAT262J

SAT638A

SAT171B

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1101

Page 104 of 1033

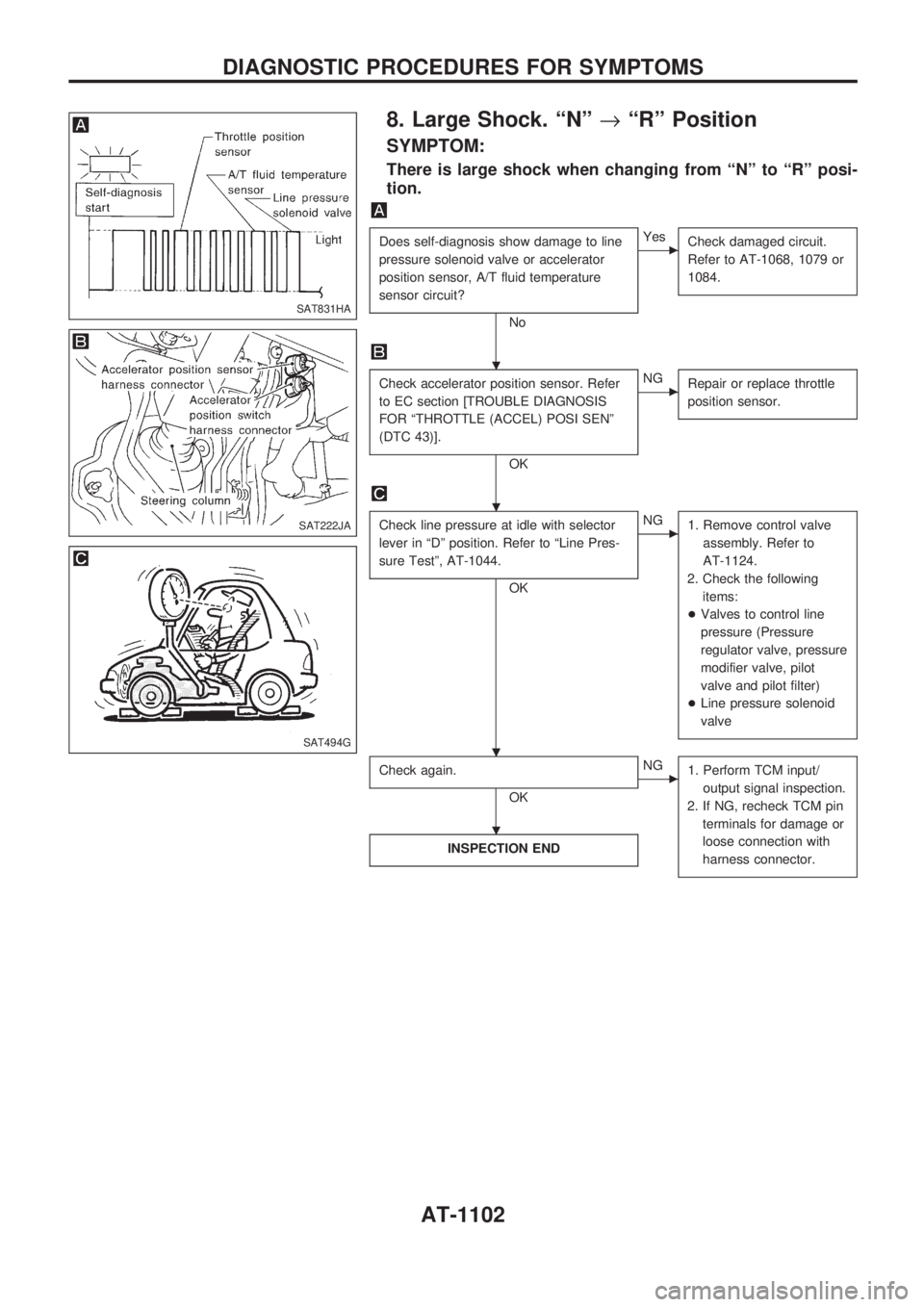

8. Large Shock. ªNº®ªRº Position

SYMPTOM:

There is large shock when changing from ªNº to ªRº posi-

tion.

Does self-diagnosis show damage to line

pressure solenoid valve or accelerator

position sensor, A/T fluid temperature

sensor circuit?

No

cYes

Check damaged circuit.

Refer to AT-1068, 1079 or

1084.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

Check line pressure at idle with selector

lever in ªDº position. Refer to ªLine Pres-

sure Testº, AT-1044.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Valves to control line

pressure (Pressure

regulator valve, pressure

modifier valve, pilot

valve and pilot filter)

+Line pressure solenoid

valve

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT831HA

SAT222JA

SAT494G

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1102

Page 105 of 1033

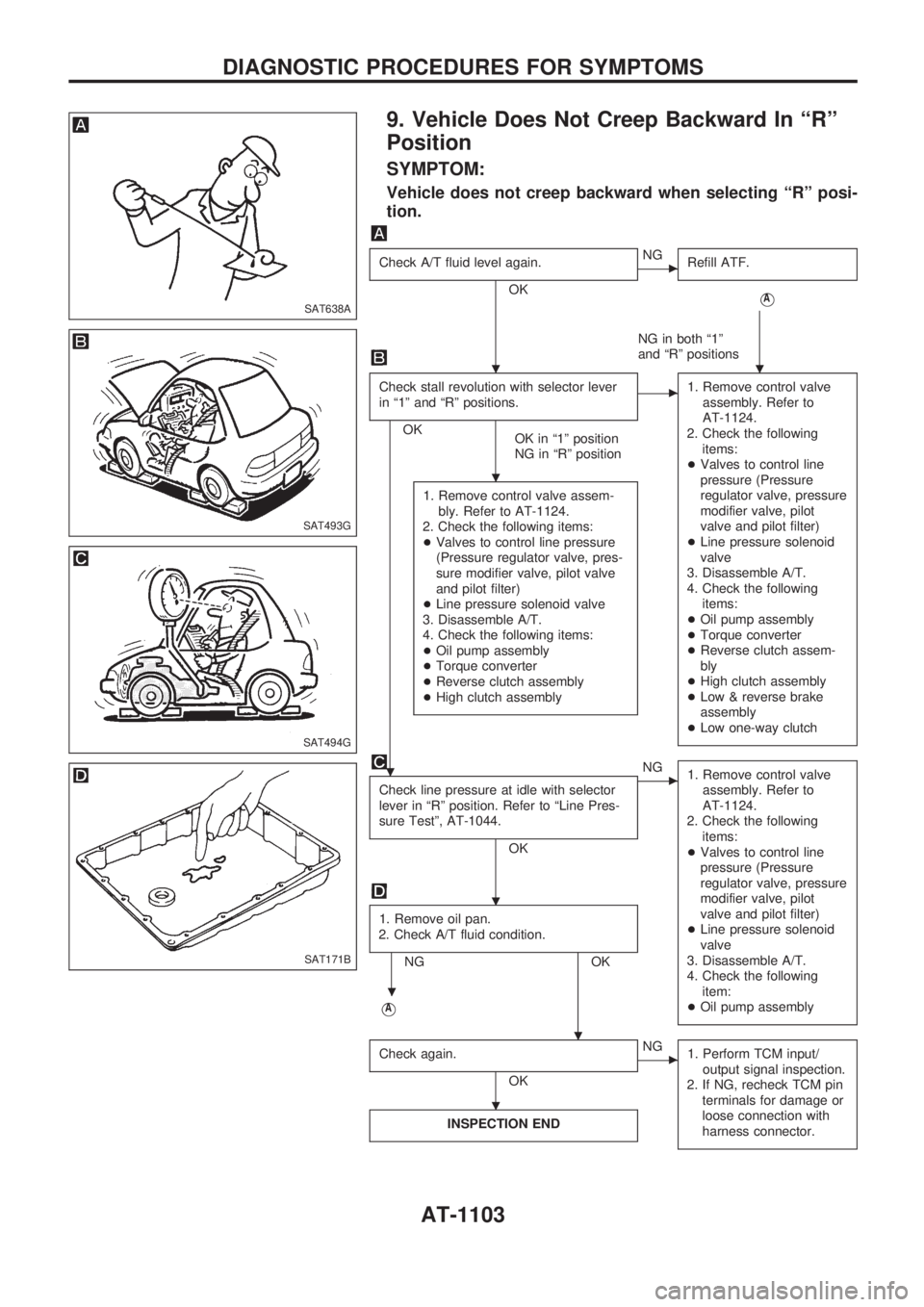

9. Vehicle Does Not Creep Backward In ªRº

Position

SYMPTOM:

Vehicle does not creep backward when selecting ªRº posi-

tion.

Check A/T fluid level again.

OK

cNG

Refill ATF.

VA

NG in both ª1º

and ªRº positions

Check stall revolution with selector lever

in ª1º and ªRº positions.

OK

OK in ª1º position

NG in ªRº position

c1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Valves to control line

pressure (Pressure

regulator valve, pressure

modifier valve, pilot

valve and pilot filter)

+Line pressure solenoid

valve

3. Disassemble A/T.

4. Check the following

items:

+Oil pump assembly

+Torque converter

+Reverse clutch assem-

bly

+High clutch assembly

+Low & reverse brake

assembly

+Low one-way clutch

1. Remove control valve assem-

bly. Refer to AT-1124.

2. Check the following items:

+Valves to control line pressure

(Pressure regulator valve, pres-

sure modifier valve, pilot valve

and pilot filter)

+Line pressure solenoid valve

3. Disassemble A/T.

4. Check the following items:

+Oil pump assembly

+Torque converter

+Reverse clutch assembly

+High clutch assembly

Check line pressure at idle with selector

lever in ªRº position. Refer to ªLine Pres-

sure Testº, AT-1044.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Valves to control line

pressure (Pressure

regulator valve, pressure

modifier valve, pilot

valve and pilot filter)

+Line pressure solenoid

valve

3. Disassemble A/T.

4. Check the following

item:

+Oil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

NG OK

VA

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

..

.

.

.

.

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1103

Page 106 of 1033

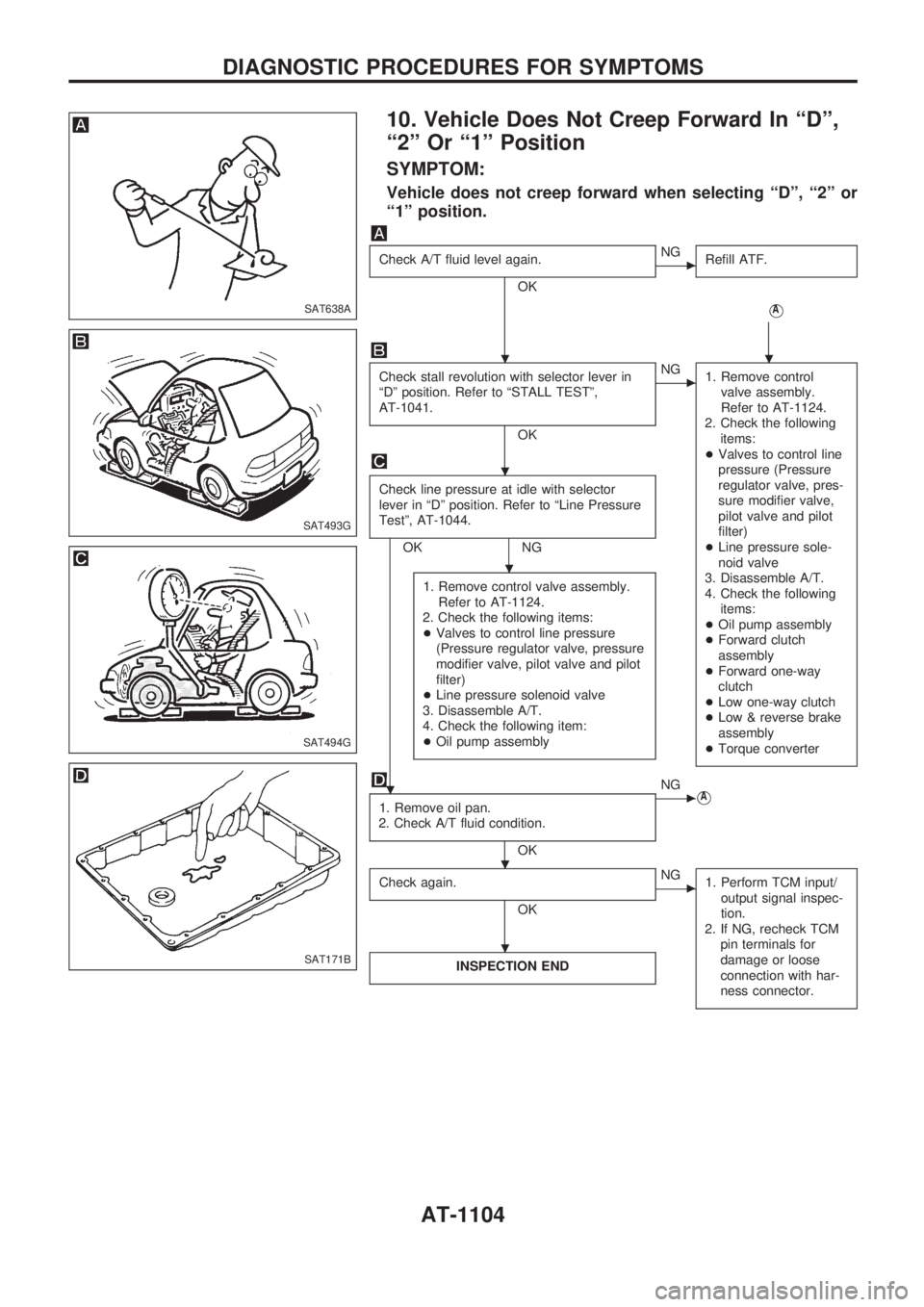

10. Vehicle Does Not Creep Forward In ªDº,

ª2º Or ª1º Position

SYMPTOM:

Vehicle does not creep forward when selecting ªDº, ª2º or

ª1º position.

Check A/T fluid level again.

OK

cNG

Refill ATF.

VA

Check stall revolution with selector lever in

ªDº position. Refer to ªSTALL TESTº,

AT-1041.

OK

cNG

1. Remove control

valve assembly.

Refer to AT-1124.

2. Check the following

items:

+Valves to control line

pressure (Pressure

regulator valve, pres-

sure modifier valve,

pilot valve and pilot

filter)

+Line pressure sole-

noid valve

3. Disassemble A/T.

4. Check the following

items:

+Oil pump assembly

+Forward clutch

assembly

+Forward one-way

clutch

+Low one-way clutch

+Low & reverse brake

assembly

+Torque converter

Check line pressure at idle with selector

lever in ªDº position. Refer to ªLine Pressure

Testº, AT-1044.

OK NG

1. Remove control valve assembly.

Refer to AT-1124.

2. Check the following items:

+Valves to control line pressure

(Pressure regulator valve, pressure

modifier valve, pilot valve and pilot

filter)

+Line pressure solenoid valve

3. Disassemble A/T.

4. Check the following item:

+Oil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNGVA

Check again.

OK

cNG

1. Perform TCM input/

output signal inspec-

tion.

2. If NG, recheck TCM

pin terminals for

damage or loose

connection with har-

ness connector.

INSPECTION END

SAT638A

SAT493G

SAT494G

SAT171B

..

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1104

Page 107 of 1033

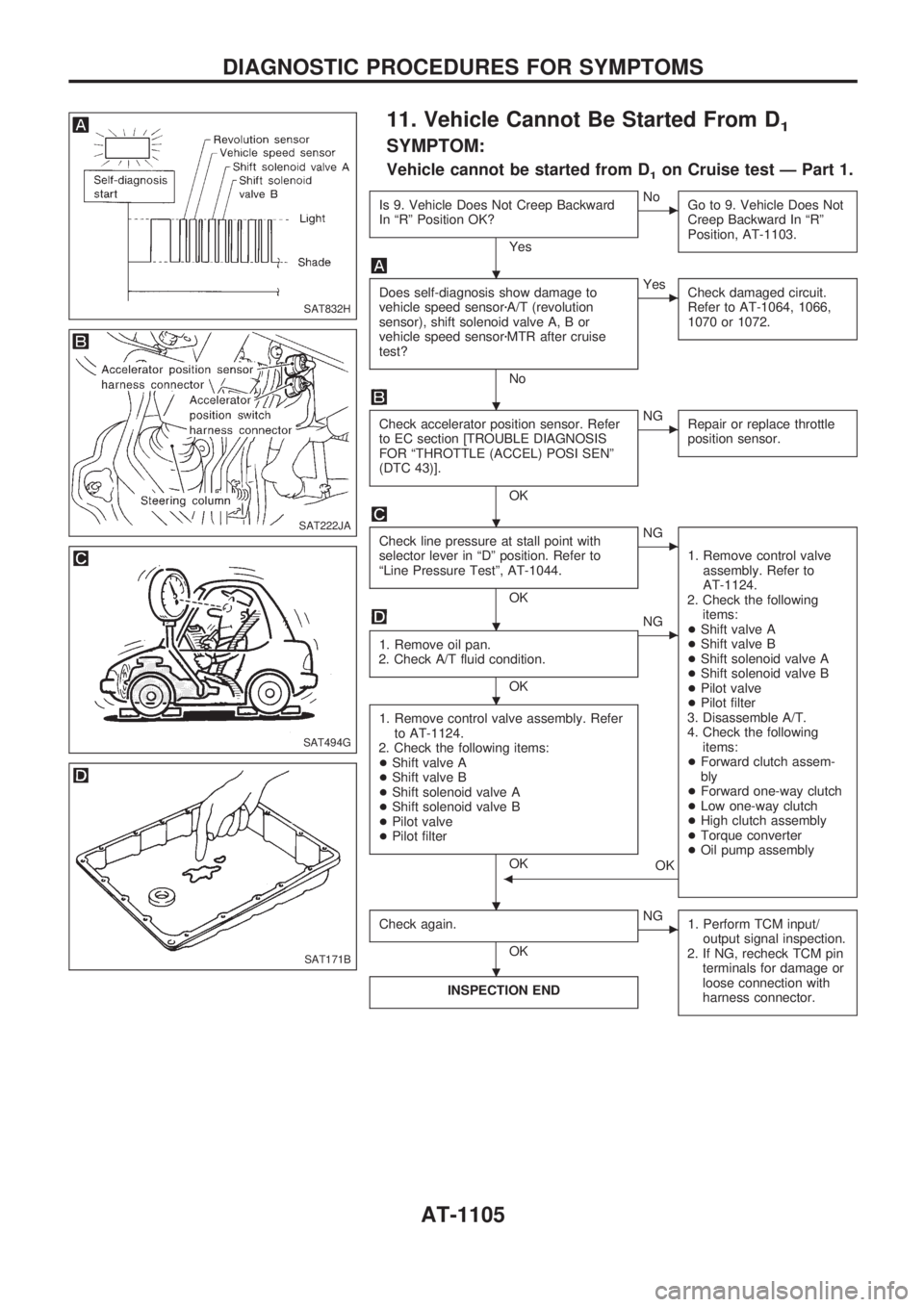

11. Vehicle Cannot Be Started From D1

SYMPTOM:

Vehicle cannot be started from D1on Cruise test Ð Part 1.

Is 9. Vehicle Does Not Creep Backward

In ªRº Position OK?

Yes

cNo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-1103.

Does self-diagnosis show damage to

vehicle speed sensorzA/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensorzMTR after cruise

test?

No

cYes

Check damaged circuit.

Refer to AT-1064, 1066,

1070 or 1072.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

Check line pressure at stall point with

selector lever in ªDº position. Refer to

ªLine Pressure Testº, AT-1044.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift valve A

+Shift valve B

+Shift solenoid valve A

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Forward clutch assem-

bly

+Forward one-way clutch

+Low one-way clutch

+High clutch assembly

+Torque converter

+Oil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Shift valve A

+Shift valve B

+Shift solenoid valve A

+Shift solenoid valve B

+Pilot valve

+Pilot filter

OK

OKb

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT832H

SAT222JA

SAT494G

SAT171B

.

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1105

Page 108 of 1033

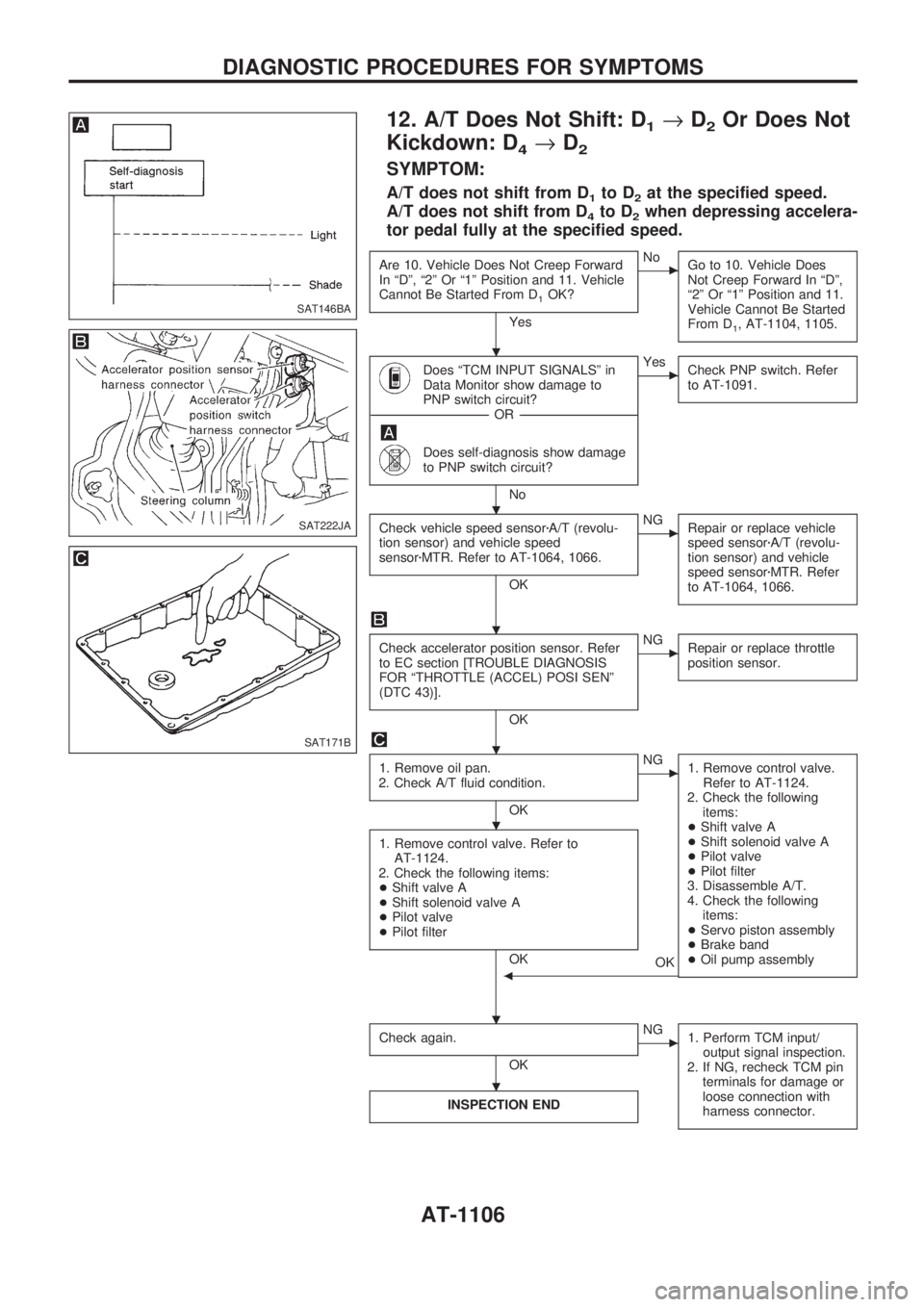

12. A/T Does Not Shift: D1®D2Or Does Not

Kickdown: D

4®D2

SYMPTOM:

A/T does not shift from D1to D2at the specified speed.

A/T does not shift from D

4to D2when depressing accelera-

tor pedal fully at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Yes

cNo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-1104, 1105.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch. Refer

to AT-1091.

Check vehicle speed sensorzA/T (revolu-

tion sensor) and vehicle speed

sensorzMTR. Refer to AT-1064, 1066.

OK

cNG

Repair or replace vehicle

speed sensorzA/T (revolu-

tion sensor) and vehicle

speed sensorzMTR. Refer

to AT-1064, 1066.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve.

Refer to AT-1124.

2. Check the following

items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+Brake band

+Oil pump assembly

1. Remove control valve. Refer to

AT-1124.

2. Check the following items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

SAT222JA

SAT171B

.

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1106

Page 109 of 1033

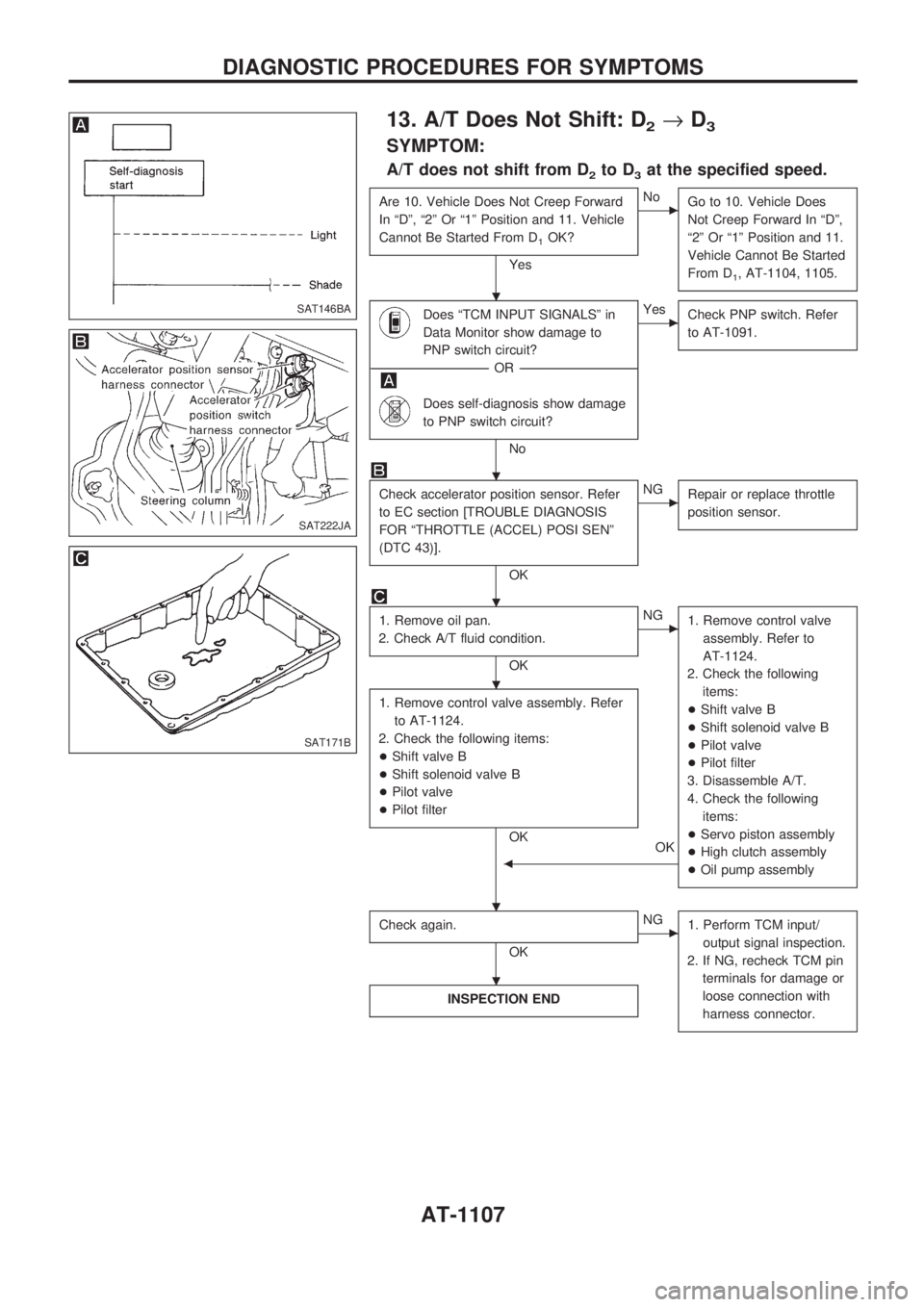

13. A/T Does Not Shift: D2®D3

SYMPTOM:

A/T does not shift from D2to D3at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Yes

cNo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-1104, 1105.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch. Refer

to AT-1091.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift valve B

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+High clutch assembly

+Oil pump assembly

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Shift valve B

+Shift solenoid valve B

+Pilot valve

+Pilot filter

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

SAT222JA

SAT171B

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1107

Page 110 of 1033

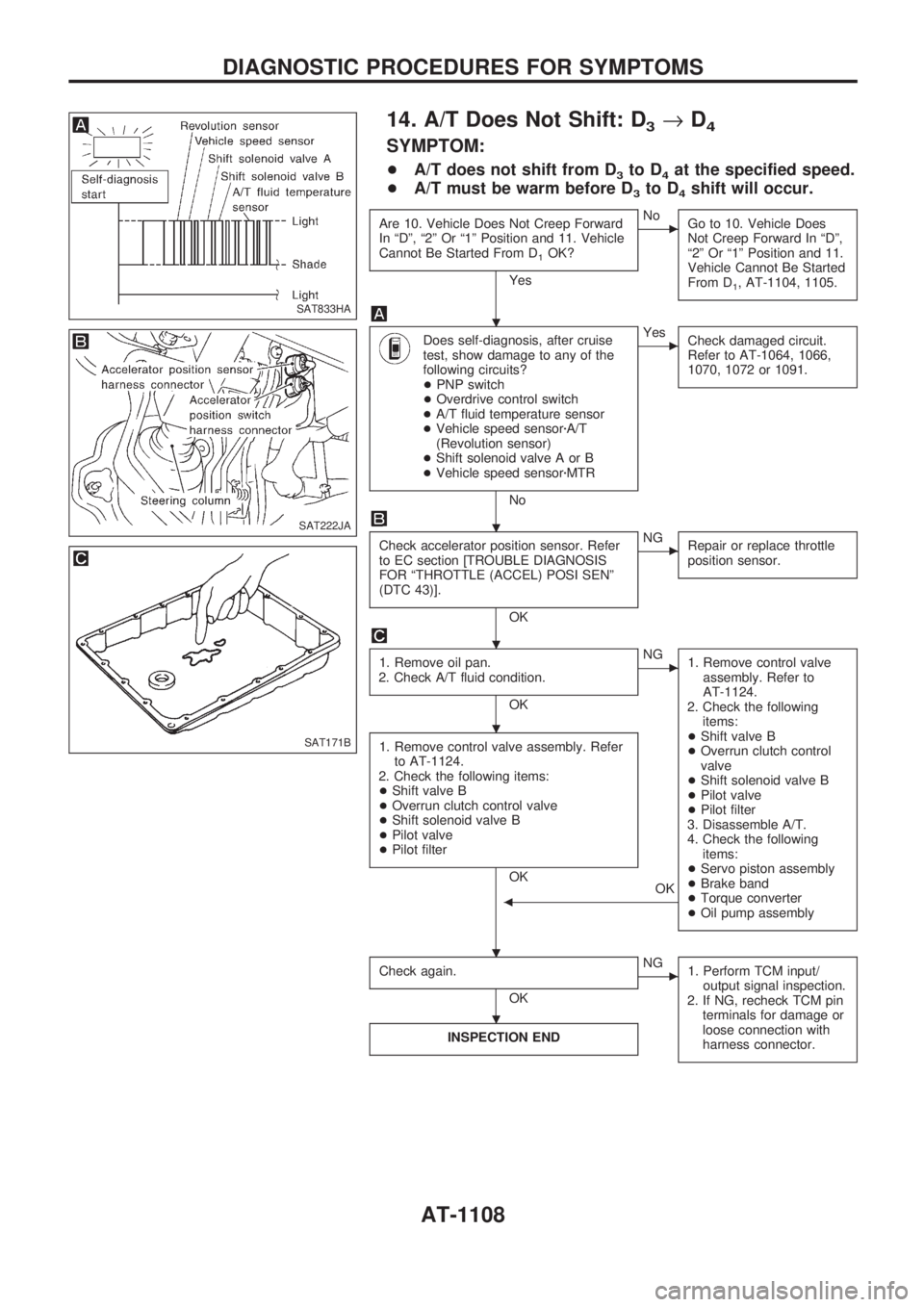

14. A/T Does Not Shift: D3®D4

SYMPTOM:

+A/T does not shift from D3to D4at the specified speed.

+A/T must be warm before D

3to D4shift will occur.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Yes

cNo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-1104, 1105.

Does self-diagnosis, after cruise

test, show damage to any of the

following circuits?

+PNP switch

+Overdrive control switch

+A/T fluid temperature sensor

+Vehicle speed sensorzA/T

(Revolution sensor)

+Shift solenoid valve A or B

+Vehicle speed sensorzMTR

No

cYes

Check damaged circuit.

Refer to AT-1064, 1066,

1070, 1072 or 1091.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift valve B

+Overrun clutch control

valve

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+Brake band

+Torque converter

+Oil pump assembly

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Shift valve B

+Overrun clutch control valve

+Shift solenoid valve B

+Pilot valve

+Pilot filter

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT833HA

SAT222JA

SAT171B

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1108