NISSAN PATROL 2006 Service Manual

Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 991 of 1226

4. Check oil level.

5. Start engine. Check area around drain plug and oil ®lter for any

sign of oil leakage.

6. Run engine for a few minutes, then turn it off. After several

minutes check oil level.

Changing Engine Oil Filter

1. Remove oil ®lter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

2. Clean oil ®lter mounting surface on cylinder block. Coat rubber

seal of new oil ®lter with engine oil.

3. Screw in the oil ®lter until a slight resistance is felt, then tighten

an additional 2/3 of a turn.

4. Add engine oil.

Refer to Changing Engine Oil.

+Clean excess oil from engine.

Changing Engine Coolant

WARNING:

To avoid the danger of being scalded, never change the cool-

ant when the engine is hot.

ÐDRAINING ENGINE COOLANTÐ

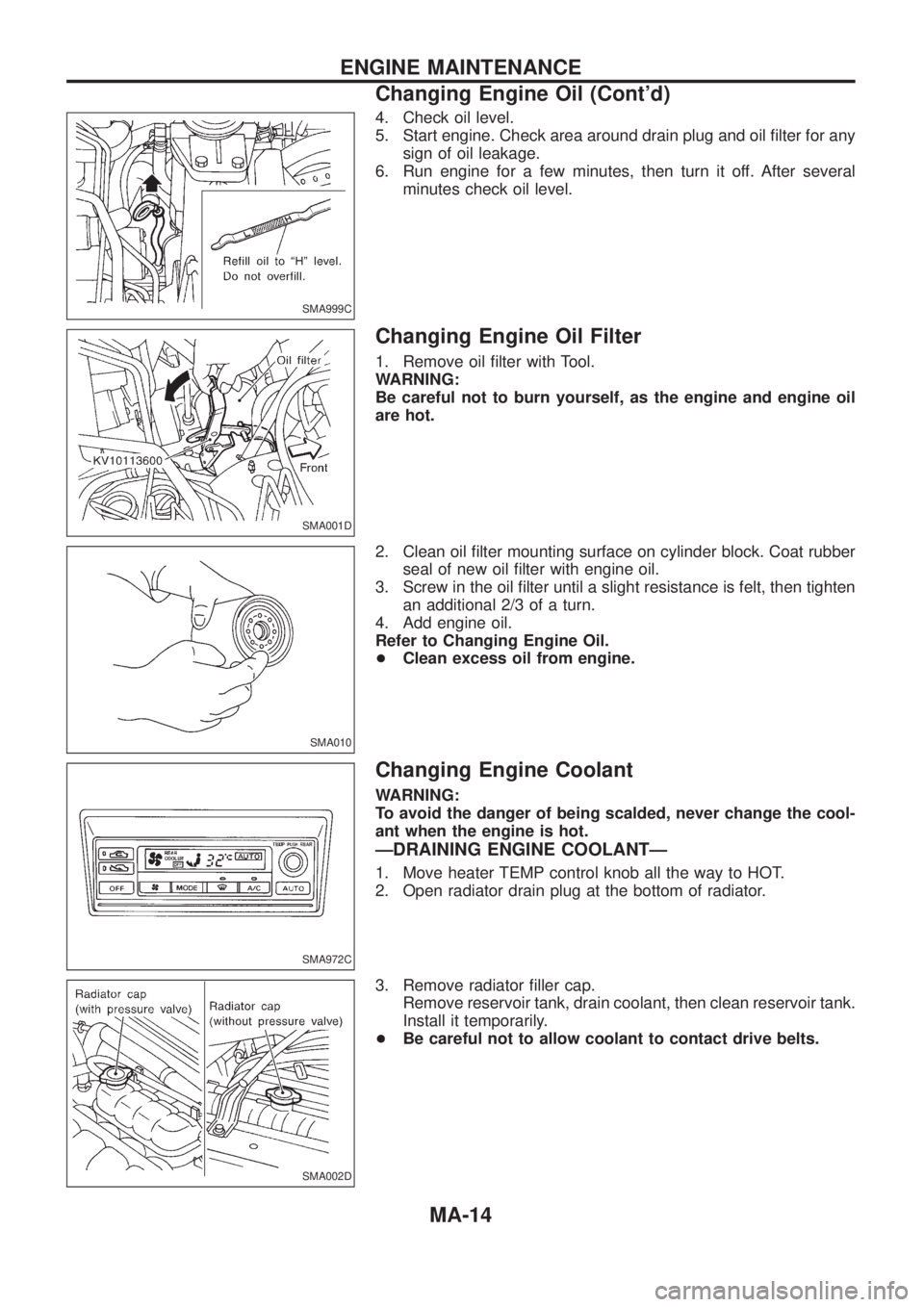

1. Move heater TEMP control knob all the way to HOT.

2. Open radiator drain plug at the bottom of radiator.

3. Remove radiator ®ller cap.

Remove reservoir tank, drain coolant, then clean reservoir tank.

Install it temporarily.

+Be careful not to allow coolant to contact drive belts.

SMA999C

SMA001D

SMA010

SMA972C

SMA002D

ENGINE MAINTENANCE

Changing Engine Oil (Cont'd)

MA-14

Page 992 of 1226

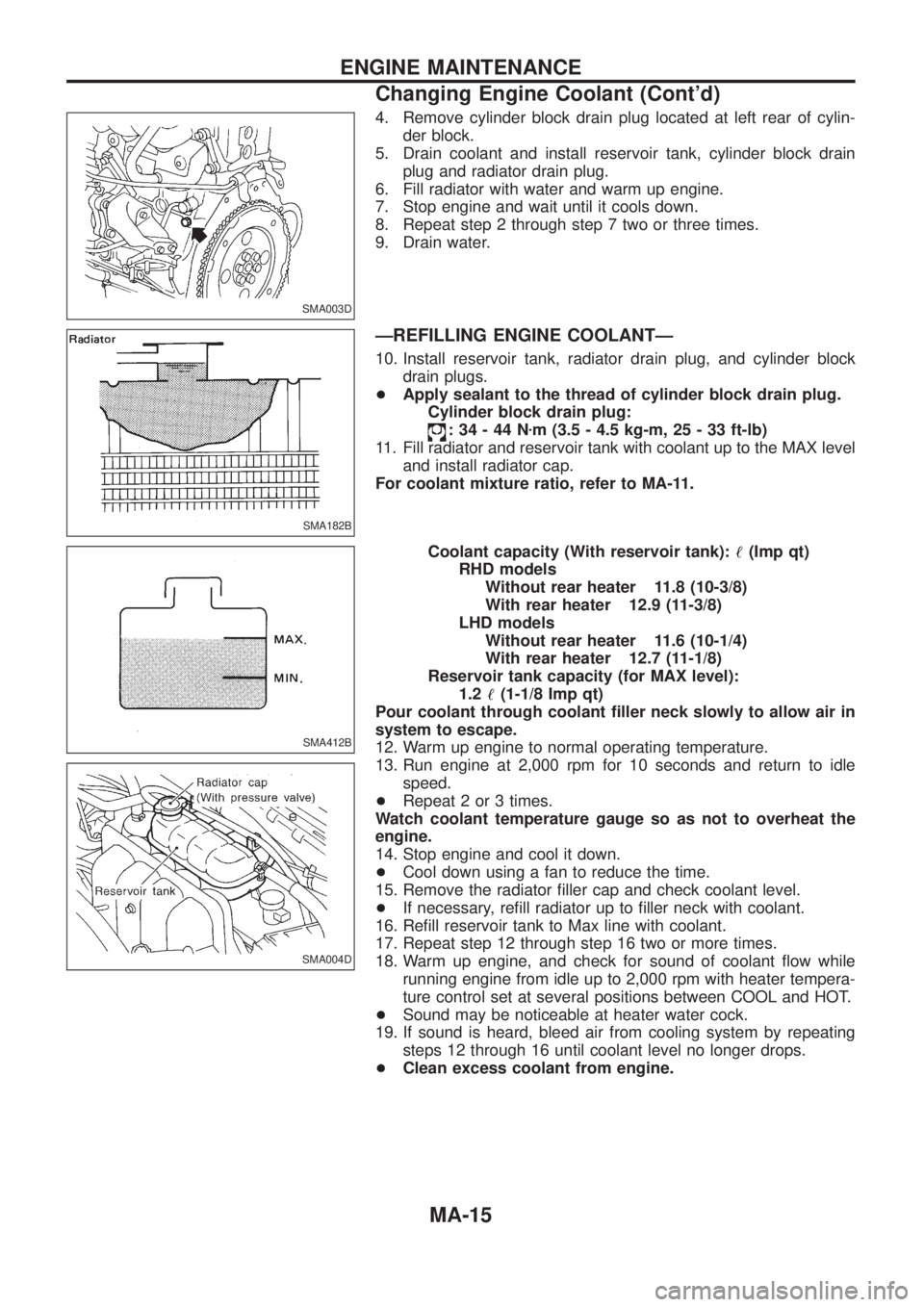

4. Remove cylinder block drain plug located at left rear of cylin-

der block.

5. Drain coolant and install reservoir tank, cylinder block drain

plug and radiator drain plug.

6. Fill radiator with water and warm up engine.

7. Stop engine and wait until it cools down.

8. Repeat step 2 through step 7 two or three times.

9. Drain water.

ÐREFILLING ENGINE COOLANTÐ

10. Install reservoir tank, radiator drain plug, and cylinder block

drain plugs.

+Apply sealant to the thread of cylinder block drain plug.

Cylinder block drain plug:

:34-44Nzm (3.5 - 4.5 kg-m, 25 - 33 ft-lb)

11. Fill radiator and reservoir tank with coolant up to the MAX level

and install radiator cap.

For coolant mixture ratio, refer to MA-11.

Coolant capacity (With reservoir tank):!(Imp qt)

RHD models

Without rear heater 11.8 (10-3/8)

With rear heater 12.9 (11-3/8)

LHD models

Without rear heater 11.6 (10-1/4)

With rear heater 12.7 (11-1/8)

Reservoir tank capacity (for MAX level):

1.2!(1-1/8 Imp qt)

Pour coolant through coolant ®ller neck slowly to allow air in

system to escape.

12. Warm up engine to normal operating temperature.

13. Run engine at 2,000 rpm for 10 seconds and return to idle

speed.

+Repeat 2 or 3 times.

Watch coolant temperature gauge so as not to overheat the

engine.

14. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

15. Remove the radiator ®ller cap and check coolant level.

+If necessary, re®ll radiator up to ®ller neck with coolant.

16. Re®ll reservoir tank to Max line with coolant.

17. Repeat step 12 through step 16 two or more times.

18. Warm up engine, and check for sound of coolant ¯ow while

running engine from idle up to 2,000 rpm with heater tempera-

ture control set at several positions between COOL and HOT.

+Sound may be noticeable at heater water cock.

19. If sound is heard, bleed air from cooling system by repeating

steps 12 through 16 until coolant level no longer drops.

+Clean excess coolant from engine.

SMA003D

SMA182B

SMA412B

SMA004D

ENGINE MAINTENANCE

Changing Engine Coolant (Cont'd)

MA-15

Page 993 of 1226

Checking Cooling System

CHECKING HOSES AND CLAMPS

Check hoses and clamps for proper attachment, leaks, cracks,

damage, loose connections, cha®ng and deterioration.

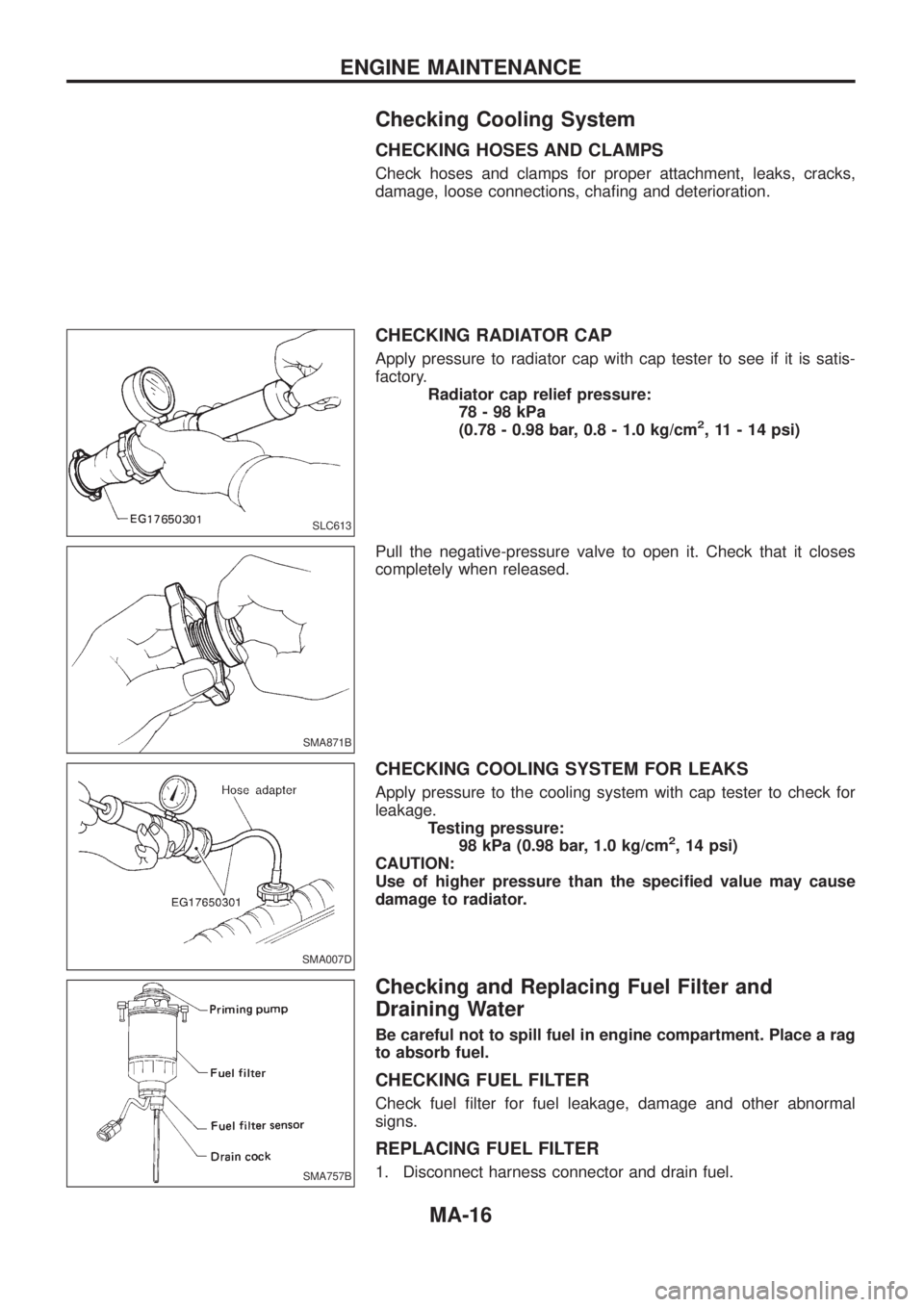

CHECKING RADIATOR CAP

Apply pressure to radiator cap with cap tester to see if it is satis-

factory.

Radiator cap relief pressure:

78-98kPa

(0.78 - 0.98 bar, 0.8 - 1.0 kg/cm

2, 11 - 14 psi)

Pull the negative-pressure valve to open it. Check that it closes

completely when released.

CHECKING COOLING SYSTEM FOR LEAKS

Apply pressure to the cooling system with cap tester to check for

leakage.

Testing pressure:

98 kPa (0.98 bar, 1.0 kg/cm

2, 14 psi)

CAUTION:

Use of higher pressure than the speci®ed value may cause

damage to radiator.

Checking and Replacing Fuel Filter and

Draining Water

Be careful not to spill fuel in engine compartment. Place a rag

to absorb fuel.

CHECKING FUEL FILTER

Check fuel ®lter for fuel leakage, damage and other abnormal

signs.

REPLACING FUEL FILTER

1. Disconnect harness connector and drain fuel.

SLC613

SMA871B

SMA007D

SMA757B

ENGINE MAINTENANCE

MA-16

Page 994 of 1226

2. Remove fuel ®lter using band-type ®lter wrench.

Remove fuel ®lter and fuel ®lter sensor.

CAUTION:

Remove fuel ®lter without spilling fuel. If spilt, wipe off imme-

diately. Be specially careful not to spill fuel on engine mount

insulator.

3. Wipe clean fuel ®lter mounting surface on fuel ®lter bracket and

smear a little fuel on rubber seal of fuel ®lter.

4. Screw fuel ®lter on until a slight resistance is felt, then tighten

an additional more than 2/3 of a turn.

5. Install fuel ®lter sensor to new fuel ®lter.

6. Bleed air from fuel line.

Refer to Bleeding Fuel System in EC section.

7. Start engine and check for leaks.

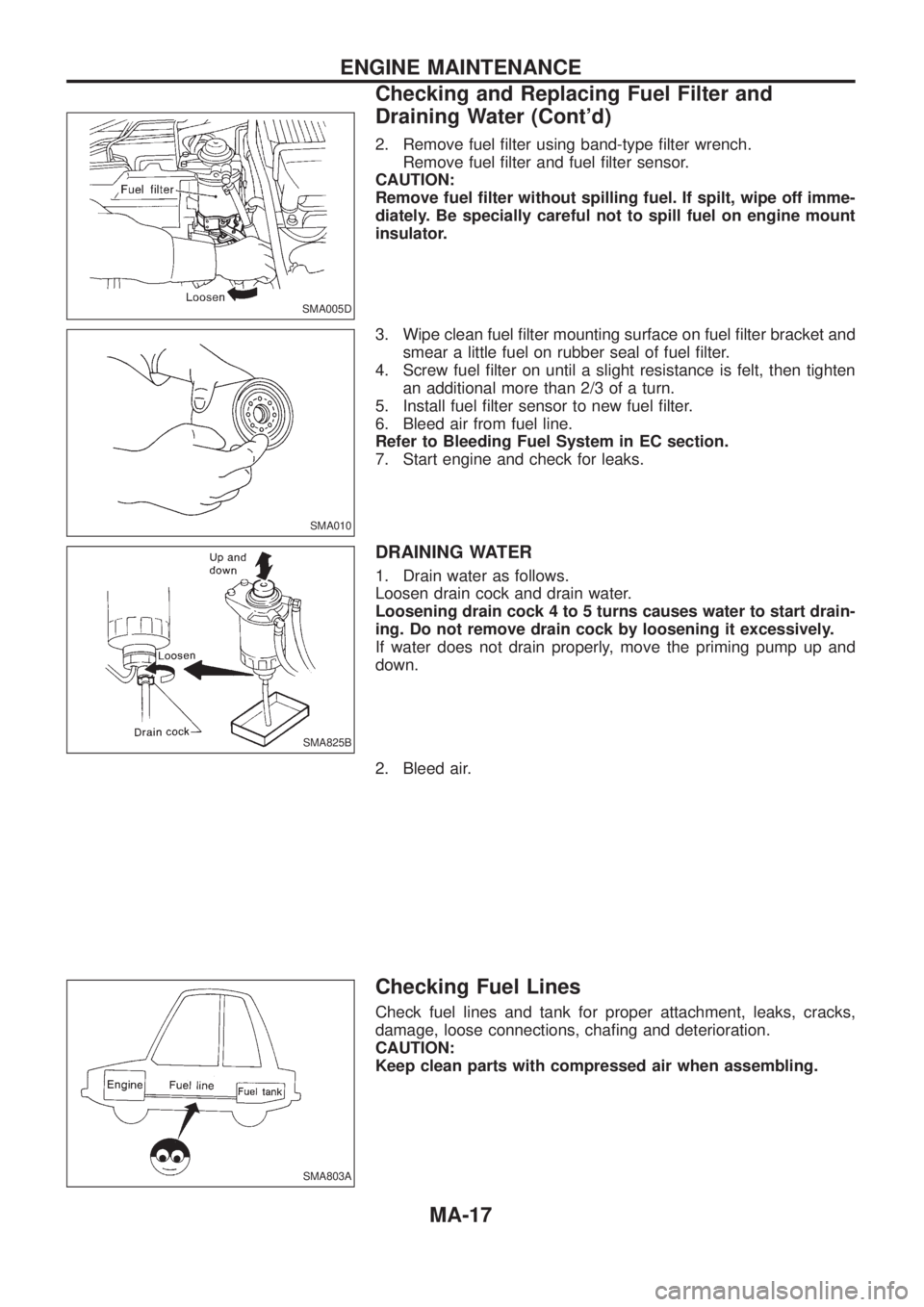

DRAINING WATER

1. Drain water as follows.

Loosen drain cock and drain water.

Loosening drain cock 4 to 5 turns causes water to start drain-

ing. Do not remove drain cock by loosening it excessively.

If water does not drain properly, move the priming pump up and

down.

2. Bleed air.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, cha®ng and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA005D

SMA010

SMA825B

SMA803A

ENGINE MAINTENANCE

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-17

Page 995 of 1226

Cleaning and Replacing Air Cleaner Filter

VISCOUS PAPER TYPE

The viscous paper type air cleaner ®lter does not require any clean-

ing operation between renewal.

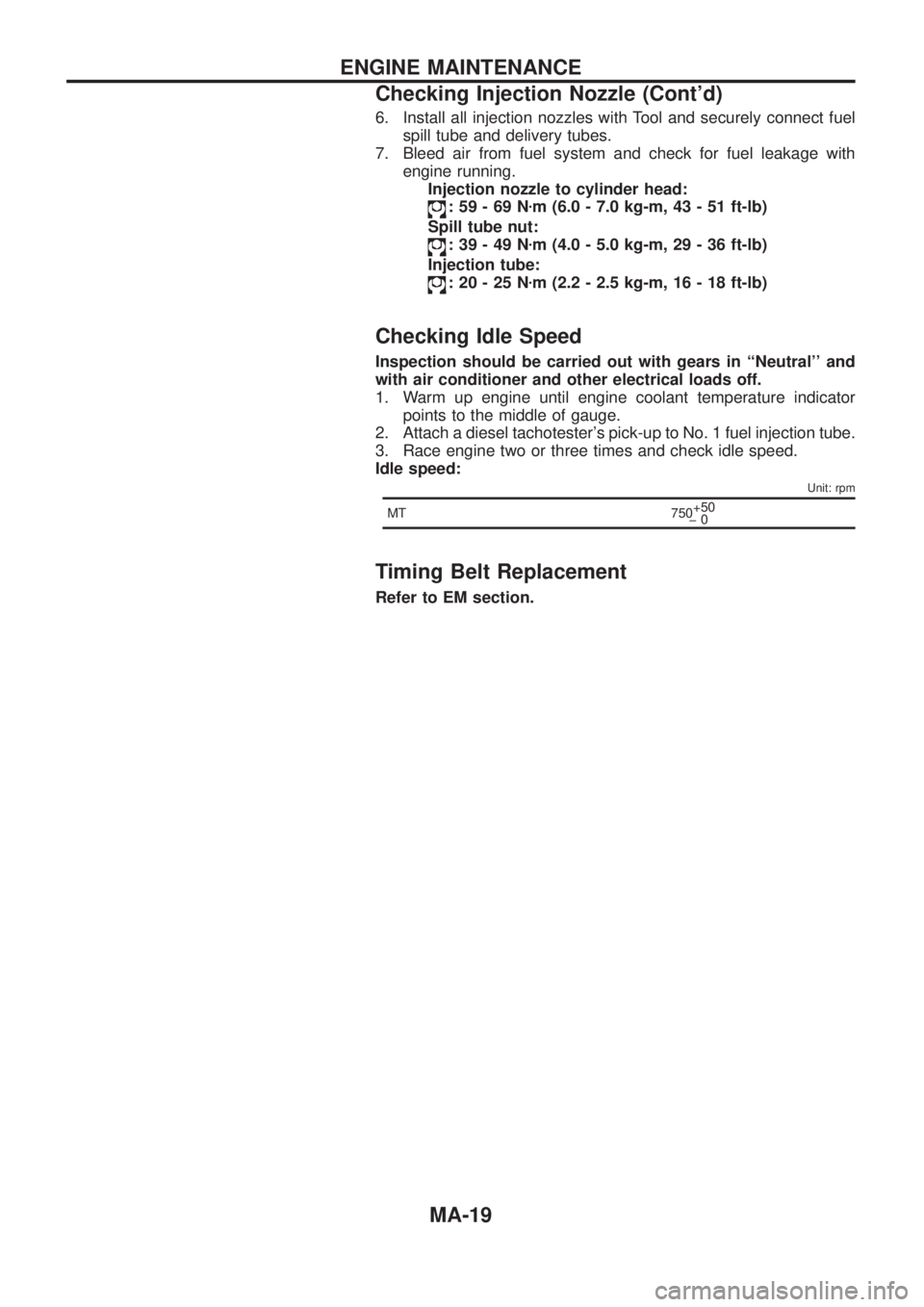

Checking Injection Nozzle

WARNING:

When using nozzle tester, be careful not to allow diesel fuel

sprayed from nozzle to come into contact with your hand or

body, and make sure that your eyes are properly protected.

1. Install nozzle to injection nozzle tester and bleed air from ¯are

nut.

2. Check initial injection pressure by pumping tester handle one

full stroke per second.

Initial injection pressure:

Used nozzle

More than 14,220 kPa

(142.2 bar, 145 kg/cm

2, 2,062 psi)

New nozzle

14,711 - 15,495 kPa

(147.1 - 155.0 bar, 150 - 158 kg/cm

2,

2,133 - 2,247 psi)

+Always check initial injection pressure before installing

new nozzle.

3. Check spray pattern by pumping tester handle one full stroke

per second.

a. If main spray angle is within 30 degrees as shown, injec-

tion nozzle is good.

b. It is still normal even if a thin stream of spray deviates from

main spray (pattern B).

4. If initial injection pressure or injection nozzle is not normal,

adjust or clean injection nozzle.

5. Test again. If it is not corrected, replace nozzle.

Refer to EC section for injection pressure adjustment, clean-

ing and replacement.

SMA006D

EF791A

SEF672A

SEF079S

ENGINE MAINTENANCE

MA-18

Page 996 of 1226

6. Install all injection nozzles with Tool and securely connect fuel

spill tube and delivery tubes.

7. Bleed air from fuel system and check for fuel leakage with

engine running.

Injection nozzle to cylinder head:

:59-69Nzm (6.0 - 7.0 kg-m, 43 - 51 ft-lb)

Spill tube nut:

:39-49Nzm (4.0 - 5.0 kg-m, 29 - 36 ft-lb)

Injection tube:

:20-25Nzm (2.2 - 2.5 kg-m, 16 - 18 ft-lb)

Checking Idle Speed

Inspection should be carried out with gears in ``Neutral'' and

with air conditioner and other electrical loads off.

1. Warm up engine until engine coolant temperature indicator

points to the middle of gauge.

2. Attach a diesel tachotester's pick-up to No. 1 fuel injection tube.

3. Race engine two or three times and check idle speed.

Idle speed:

Unit: rpm

MT 750+50

þ0

Timing Belt Replacement

Refer to EM section.

ENGINE MAINTENANCE

Checking Injection Nozzle (Cont'd)

MA-19

Page 997 of 1226

Checking Exhaust System

Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, loose connections, cha®ng and

deterioration.

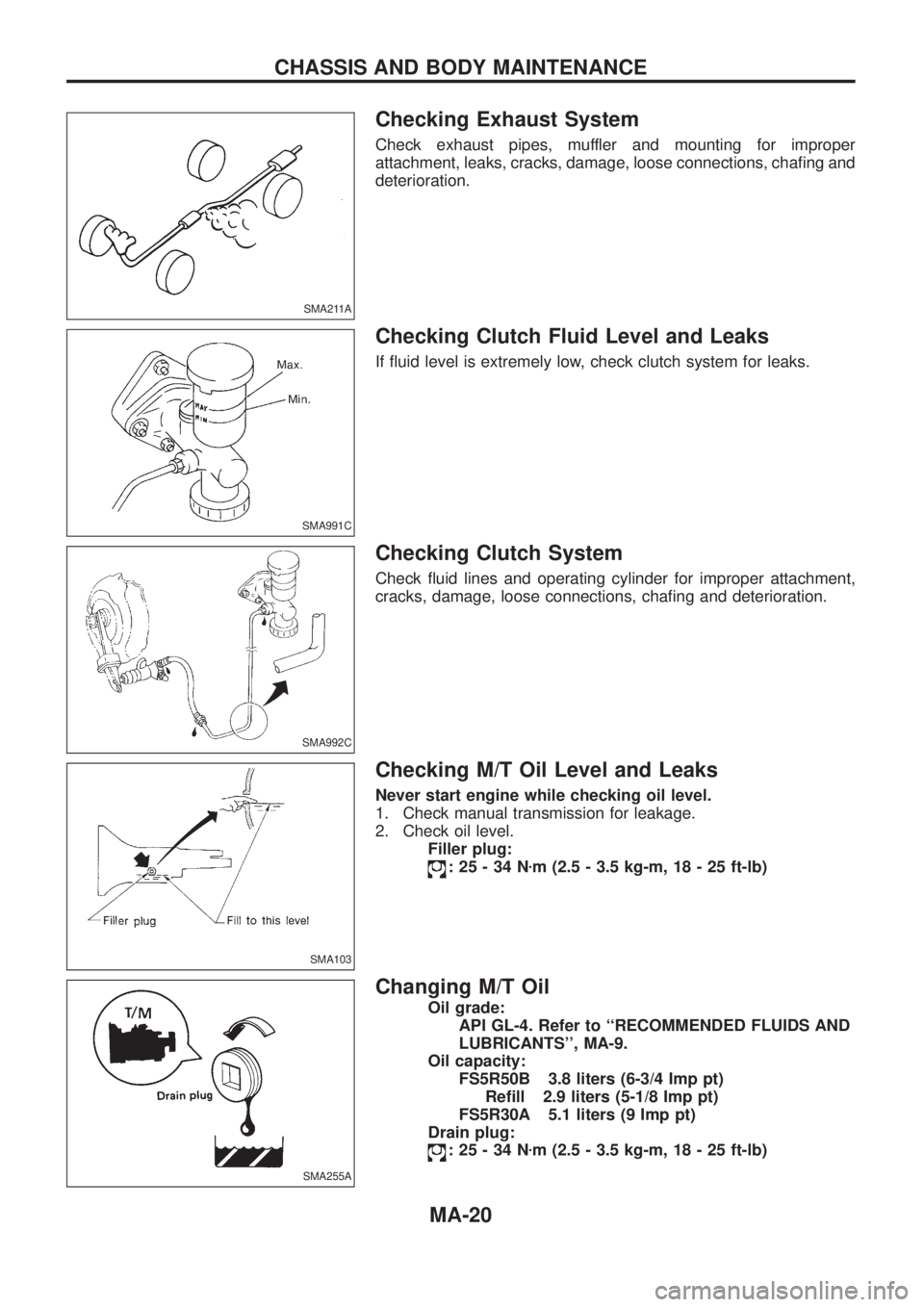

Checking Clutch Fluid Level and Leaks

If ¯uid level is extremely low, check clutch system for leaks.

Checking Clutch System

Check ¯uid lines and operating cylinder for improper attachment,

cracks, damage, loose connections, cha®ng and deterioration.

Checking M/T Oil Level and Leaks

Never start engine while checking oil level.

1. Check manual transmission for leakage.

2. Check oil level.

Filler plug:

:25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing M/T Oil

Oil grade:

API GL-4. Refer to ``RECOMMENDED FLUIDS AND

LUBRICANTS'', MA-9.

Oil capacity:

FS5R50B 3.8 liters (6-3/4 Imp pt)

Re®ll 2.9 liters (5-1/8 Imp pt)

FS5R30A 5.1 liters (9 Imp pt)

Drain plug:

:25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

SMA211A

SMA991C

SMA992C

SMA103

SMA255A

CHASSIS AND BODY MAINTENANCE

MA-20

Page 998 of 1226

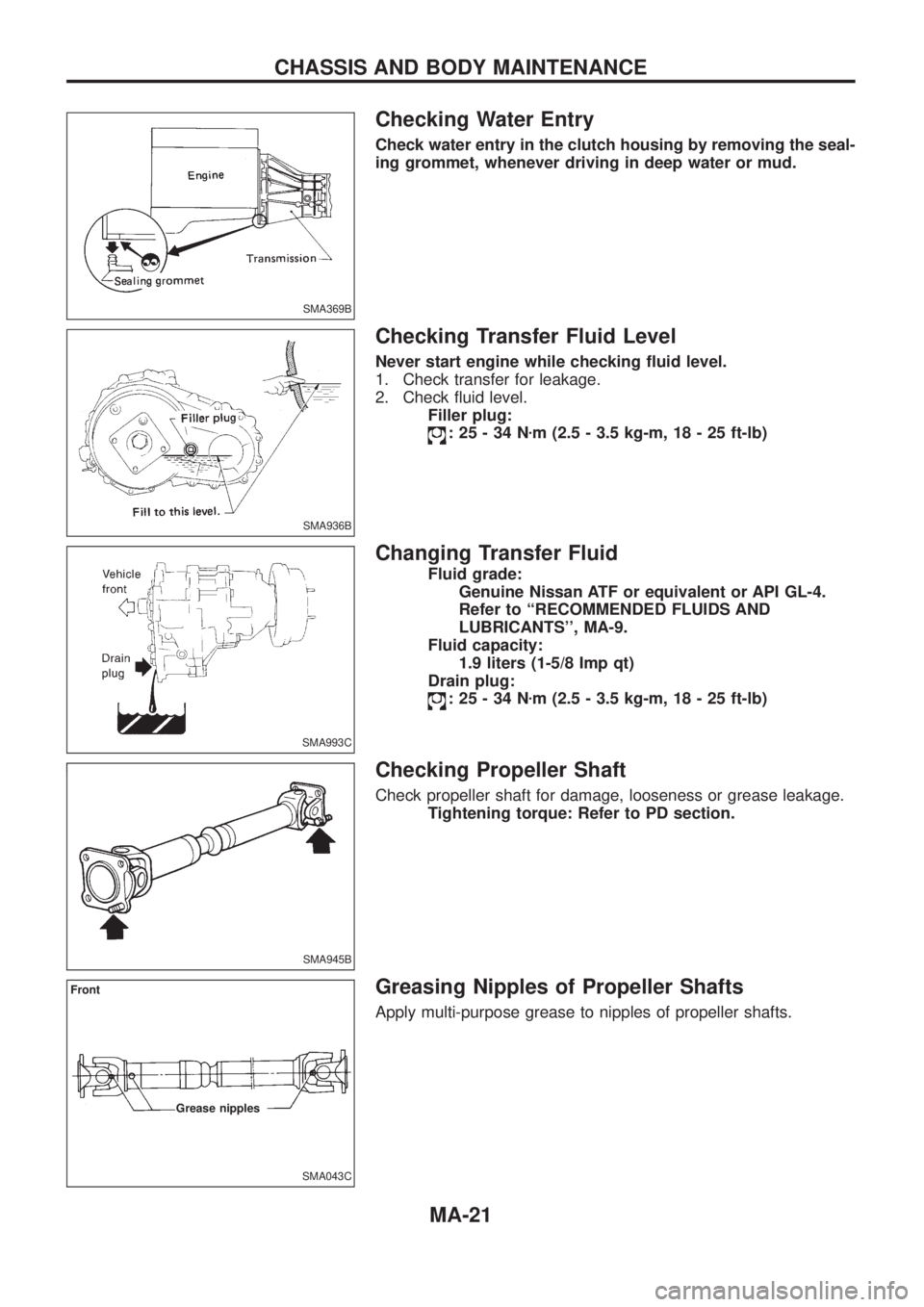

Checking Water Entry

Check water entry in the clutch housing by removing the seal-

ing grommet, whenever driving in deep water or mud.

Checking Transfer Fluid Level

Never start engine while checking ¯uid level.

1. Check transfer for leakage.

2. Check ¯uid level.

Filler plug:

:25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Changing Transfer Fluid

Fluid grade:

Genuine Nissan ATF or equivalent or API GL-4.

Refer to ``RECOMMENDED FLUIDS AND

LUBRICANTS'', MA-9.

Fluid capacity:

1.9 liters (1-5/8 Imp qt)

Drain plug:

:25-34Nzm (2.5 - 3.5 kg-m, 18 - 25 ft-lb)

Checking Propeller Shaft

Check propeller shaft for damage, looseness or grease leakage.

Tightening torque: Refer to PD section.

Greasing Nipples of Propeller Shafts

Apply multi-purpose grease to nipples of propeller shafts.

SMA369B

SMA936B

SMA993C

SMA945B

SMA043C

Front

Grease nipples

CHASSIS AND BODY MAINTENANCE

MA-21

Page 999 of 1226

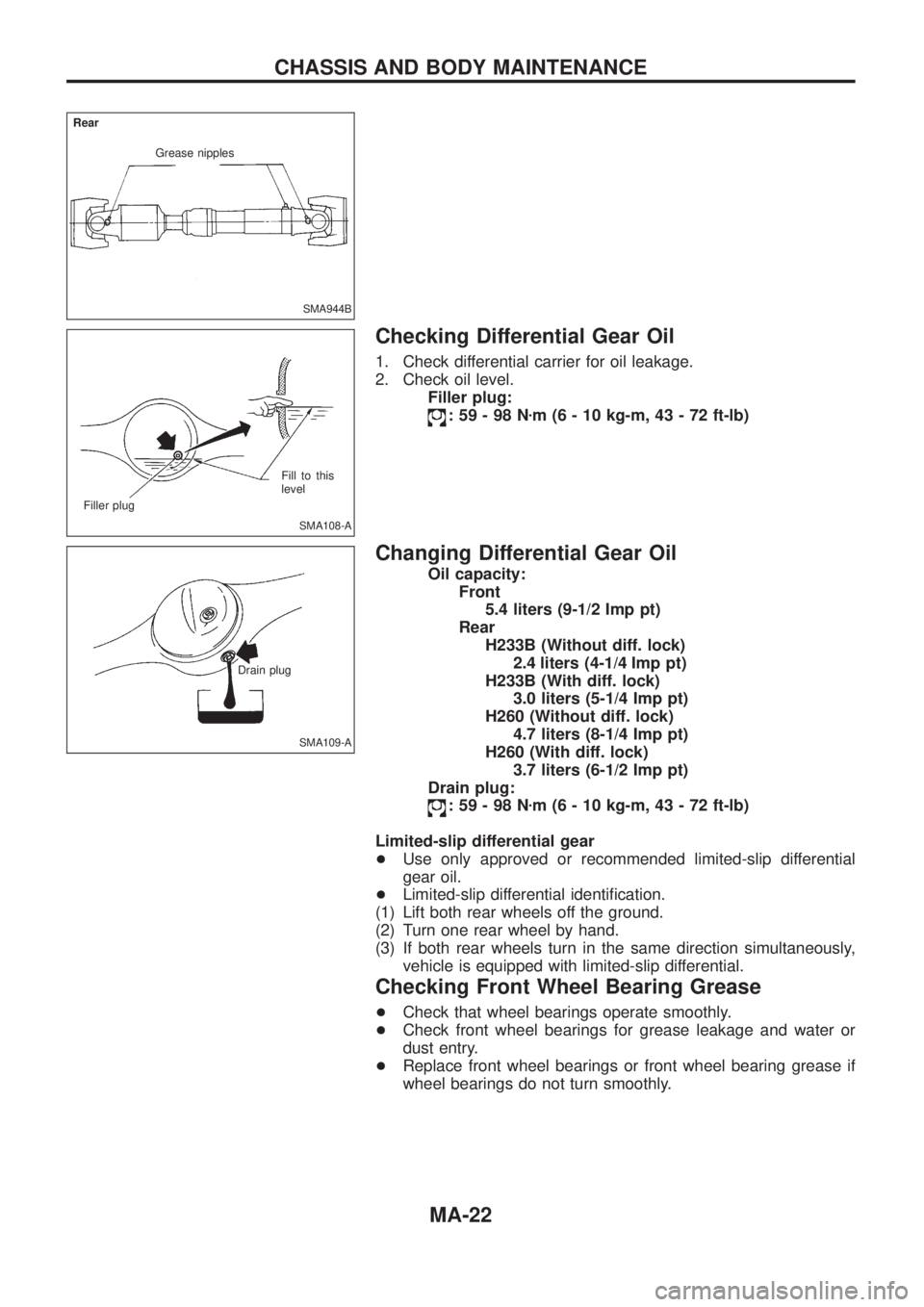

Checking Differential Gear Oil

1. Check differential carrier for oil leakage.

2. Check oil level.Filler plug:

:59-98N zm (6 - 10 kg-m, 43 - 72 ft-lb)

Changing Differential Gear Oil

Oil capacity:

Front5.4 liters (9-1/2 Imp pt)

Rear H233B (Without diff. lock) 2.4 liters(4-1/4 Imppt)

H233B (With diff. lock) 3.0 liters (5-1/4 Imp pt)

H260 (Without diff. lock) 4.7 liters (8-1/4 Imp pt)

H260 (With diff. lock) 3.7 liters (6-1/2 Imp pt)

Drain plug:

:59-98N zm (6 - 10 kg-m, 43 - 72 ft-lb)

Limited-slip differential gear

+ Use only approved or recommended limited-slip differential

gear oil.

+ Limited-slip differential identi®cation.

(1) Lift both rear wheels off the ground.

(2) Turn one rear wheel by hand.

(3) If both rear wheels turn in the same direction simultaneously, vehicle is equipped with limited-slip differential.

Checking Front Wheel Bearing Grease

+Check that wheel bearings operate smoothly.

+ Check front wheel bearings for grease leakage and water or

dust entry.

+ Replace front wheel bearings or front wheel bearing grease if

wheel bearings do not turn smoothly.

SMA944B

Grease nipples

Rear

SMA108-A

Filler plug

Fill to this

level

SMA109-A

Drain plug

CHASSIS AND BODY MAINTENANCE

MA-22

Page 1000 of 1226

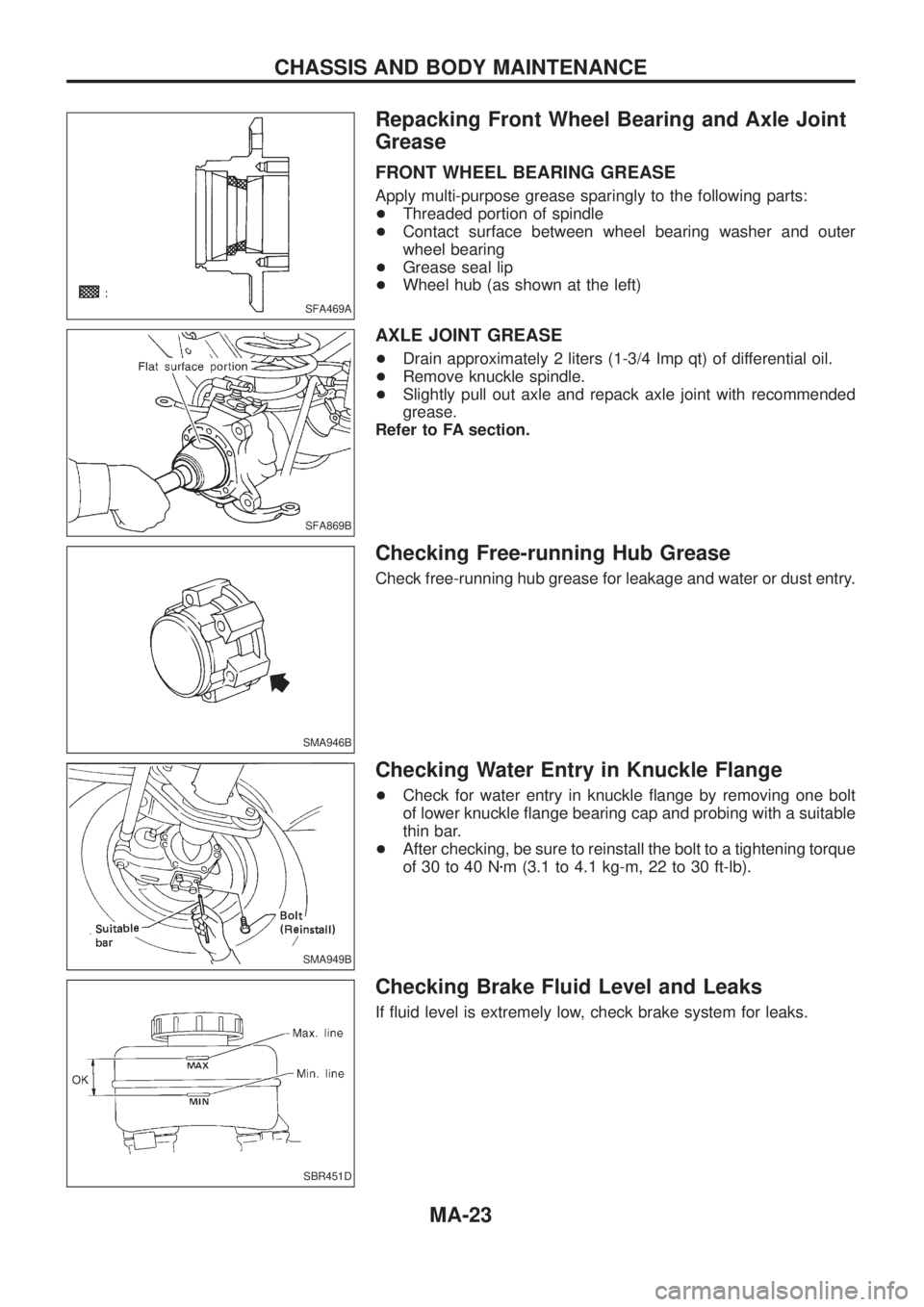

Repacking Front Wheel Bearing and Axle Joint

Grease

FRONT WHEEL BEARING GREASE

Apply multi-purpose grease sparingly to the following parts:

+Threaded portion of spindle

+Contact surface between wheel bearing washer and outer

wheel bearing

+Grease seal lip

+Wheel hub (as shown at the left)

AXLE JOINT GREASE

+Drain approximately 2 liters (1-3/4 Imp qt) of differential oil.

+Remove knuckle spindle.

+Slightly pull out axle and repack axle joint with recommended

grease.

Refer to FA section.

Checking Free-running Hub Grease

Check free-running hub grease for leakage and water or dust entry.

Checking Water Entry in Knuckle Flange

+Check for water entry in knuckle ¯ange by removing one bolt

of lower knuckle ¯ange bearing cap and probing with a suitable

thin bar.

+After checking, be sure to reinstall the bolt to a tightening torque

of 30 to 40 Nzm (3.1 to 4.1 kg-m, 22 to 30 ft-lb).

Checking Brake Fluid Level and Leaks

If ¯uid level is extremely low, check brake system for leaks.

SFA469A

SFA869B

SMA946B

SMA949B

SBR451D

CHASSIS AND BODY MAINTENANCE

MA-23