NISSAN PATROL 2006 Service Manual

Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 1001 of 1226

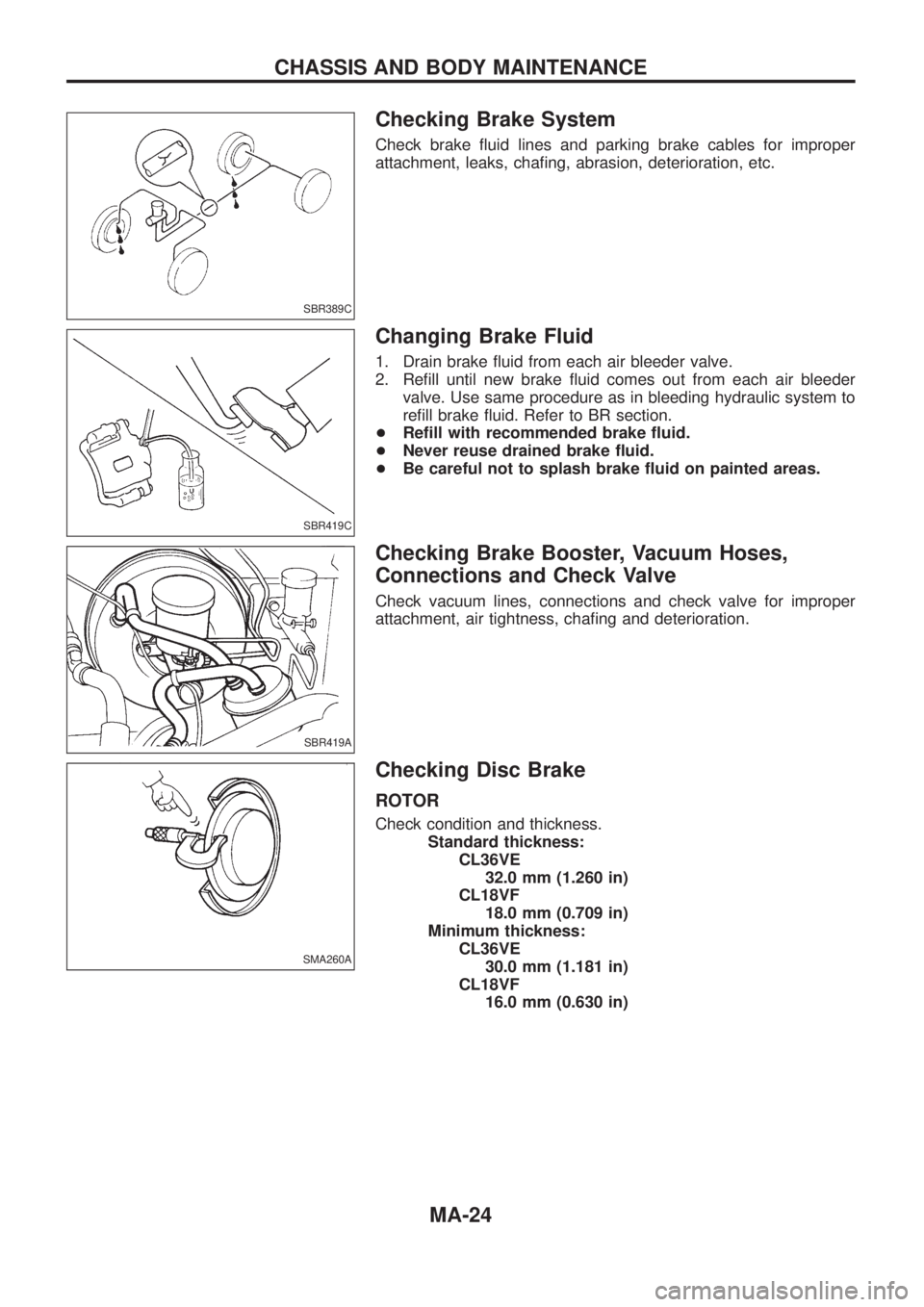

Checking Brake System

Check brake ¯uid lines and parking brake cables for improper

attachment, leaks, cha®ng, abrasion, deterioration, etc.

Changing Brake Fluid

1. Drain brake ¯uid from each air bleeder valve.

2. Re®ll until new brake ¯uid comes out from each air bleeder

valve. Use same procedure as in bleeding hydraulic system to

re®ll brake ¯uid. Refer to BR section.

+Re®ll with recommended brake ¯uid.

+Never reuse drained brake ¯uid.

+Be careful not to splash brake ¯uid on painted areas.

Checking Brake Booster, Vacuum Hoses,

Connections and Check Valve

Check vacuum lines, connections and check valve for improper

attachment, air tightness, cha®ng and deterioration.

Checking Disc Brake

ROTOR

Check condition and thickness.

Standard thickness:

CL36VE

32.0 mm (1.260 in)

CL18VF

18.0 mm (0.709 in)

Minimum thickness:

CL36VE

30.0 mm (1.181 in)

CL18VF

16.0 mm (0.630 in)

SBR389C

SBR419C

SBR419A

SMA260A

CHASSIS AND BODY MAINTENANCE

MA-24

Page 1002 of 1226

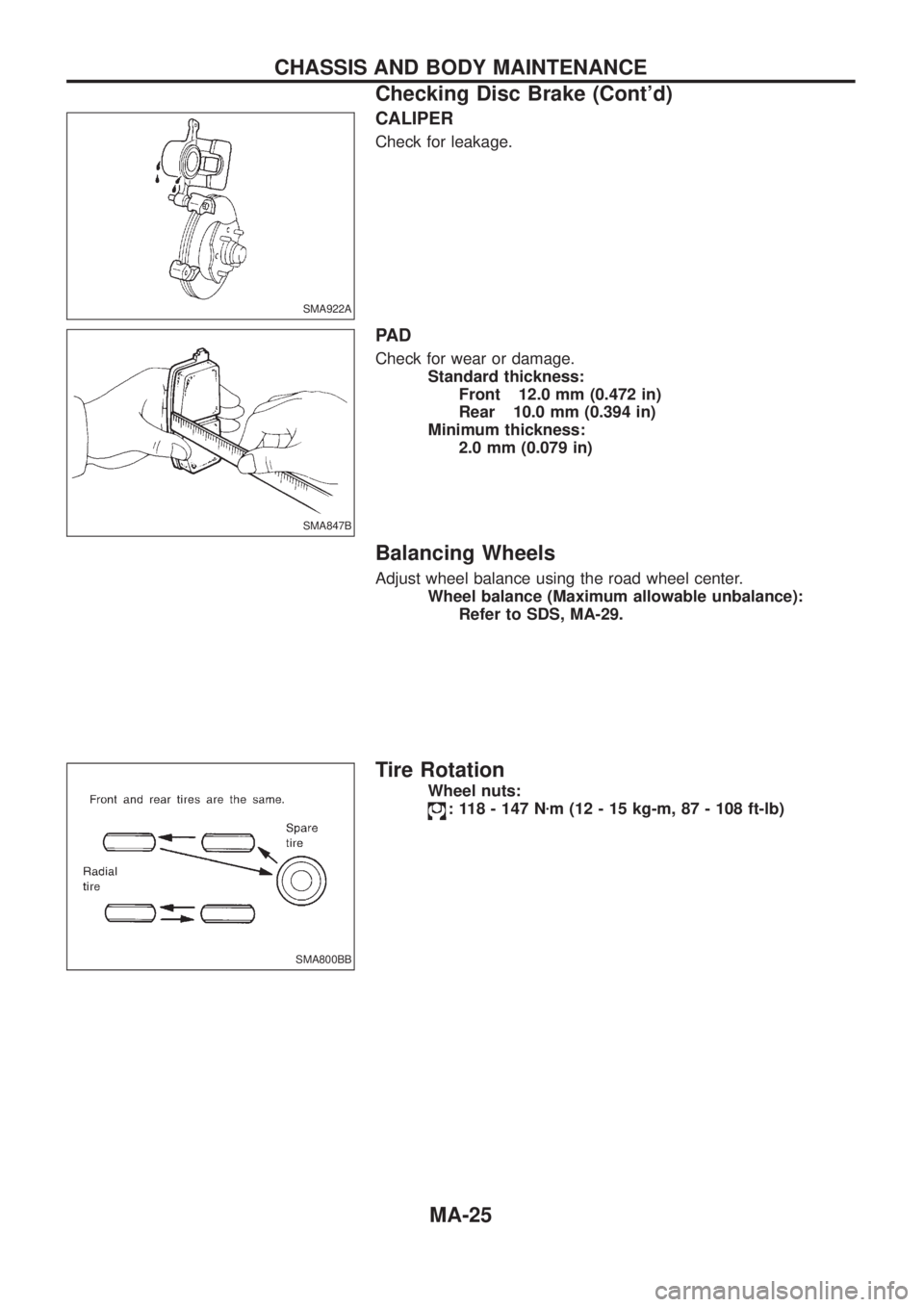

CALIPER

Check for leakage.

PA D

Check for wear or damage.

Standard thickness:

Front 12.0 mm (0.472 in)

Rear 10.0 mm (0.394 in)

Minimum thickness:

2.0 mm (0.079 in)

Balancing Wheels

Adjust wheel balance using the road wheel center.

Wheel balance (Maximum allowable unbalance):

Refer to SDS, MA-29.

Tire Rotation

Wheel nuts:

: 118 - 147 Nzm (12 - 15 kg-m, 87 - 108 ft-lb)

SMA922A

SMA847B

SMA800BB

CHASSIS AND BODY MAINTENANCE

Checking Disc Brake (Cont'd)

MA-25

Page 1003 of 1226

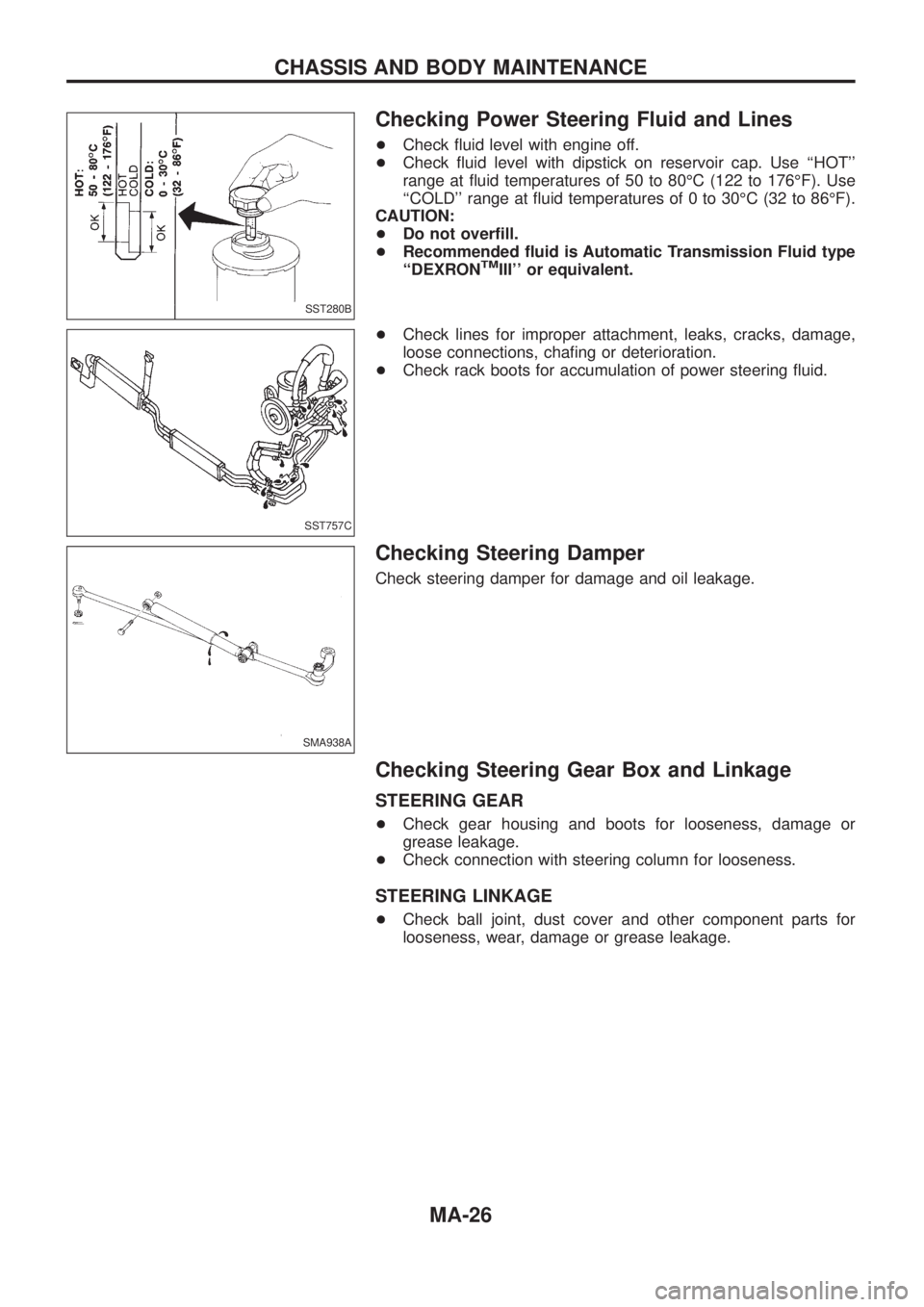

Checking Power Steering Fluid and Lines

+Check ¯uid level with engine off.

+Check ¯uid level with dipstick on reservoir cap. Use ``HOT''

range at ¯uid temperatures of 50 to 80ÉC (122 to 176ÉF). Use

``COLD'' range at ¯uid temperatures of 0 to 30ÉC (32 to 86ÉF).

CAUTION:

+Do not over®ll.

+Recommended ¯uid is Automatic Transmission Fluid type

``DEXRON

TMIII'' or equivalent.

+Check lines for improper attachment, leaks, cracks, damage,

loose connections, cha®ng or deterioration.

+Check rack boots for accumulation of power steering ¯uid.

Checking Steering Damper

Check steering damper for damage and oil leakage.

Checking Steering Gear Box and Linkage

STEERING GEAR

+Check gear housing and boots for looseness, damage or

grease leakage.

+Check connection with steering column for looseness.

STEERING LINKAGE

+Check ball joint, dust cover and other component parts for

looseness, wear, damage or grease leakage.

SST280B

SST757C

SMA938A

CHASSIS AND BODY MAINTENANCE

MA-26

Page 1004 of 1226

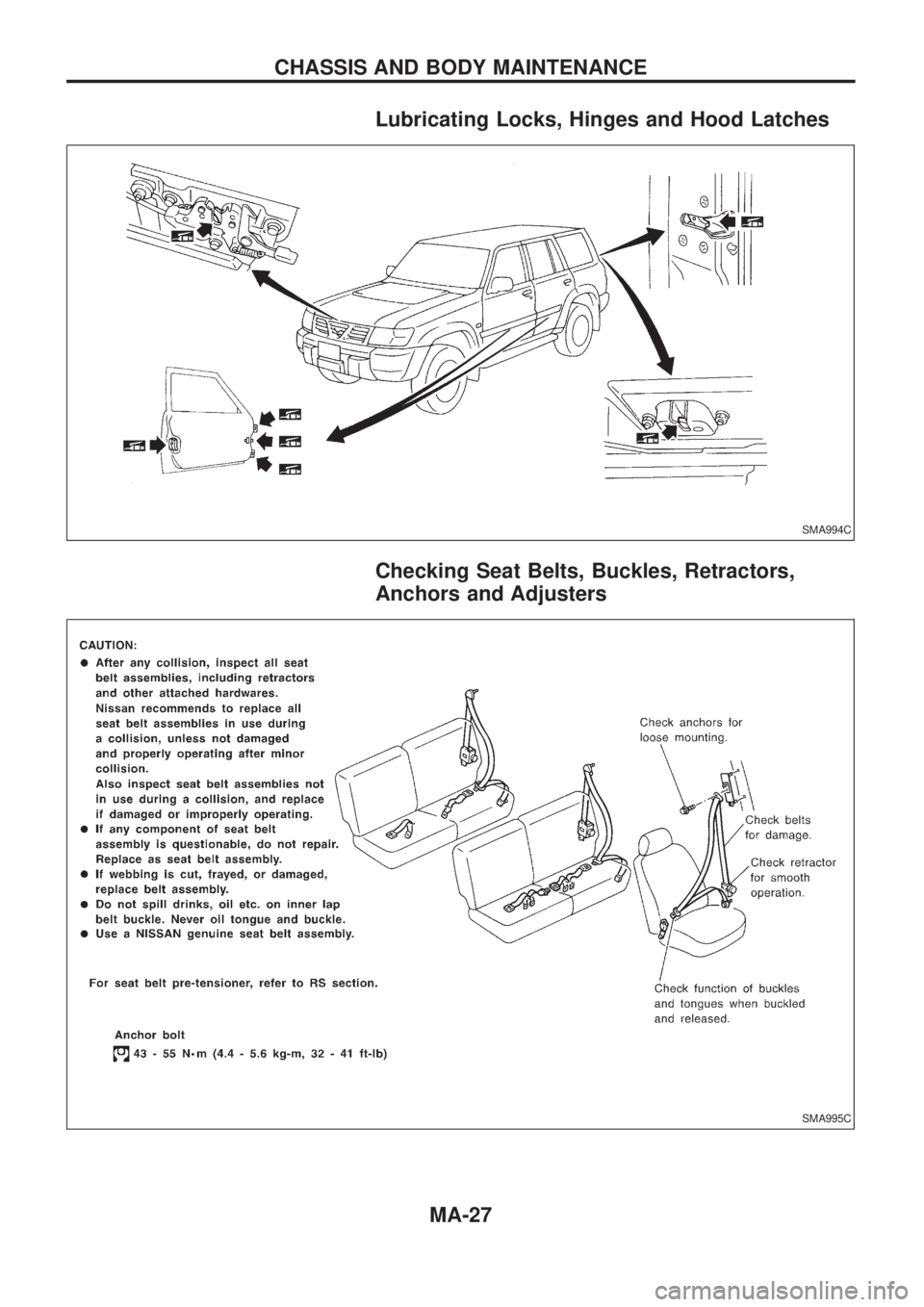

Lubricating Locks, Hinges and Hood Latches

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters

SMA994C

SMA995C

CHASSIS AND BODY MAINTENANCE

MA-27

Page 1005 of 1226

Checking Body Corrosion

Visually check the body sheet metal panel for corrosion, paint damage (scratches, chipping, rubbing, etc.) or

damage to the anti-corrosion materials. In particular, check the following locations.

Hemmed portion

Hood front end, door lower end, trunk lid rear end, etc.

Panel joint

Side sill of rear fender and center pillar, rear wheel housing of rear fender, around strut tower in engine

compartment, etc.

Panel edge

Trunk lid opening, sunroof opening, fender wheelarch ¯ange, fuel ®ller lid ¯ange, around holes in panel, etc.

Parts contact

Waist molding, windshield molding, bumper, etc.

Protectors

Damage or condition of mudguard, fender protector, chipping protector, etc.

Anti-corrosion materials

Damage or separation of anti-corrosion materials under the body.

Drain holes

Condition of drain holes at door and side sill.

When repairing corroded areas, refer to the Corrosion Repair Manual.

CHASSIS AND BODY MAINTENANCE

MA-28

Page 1006 of 1226

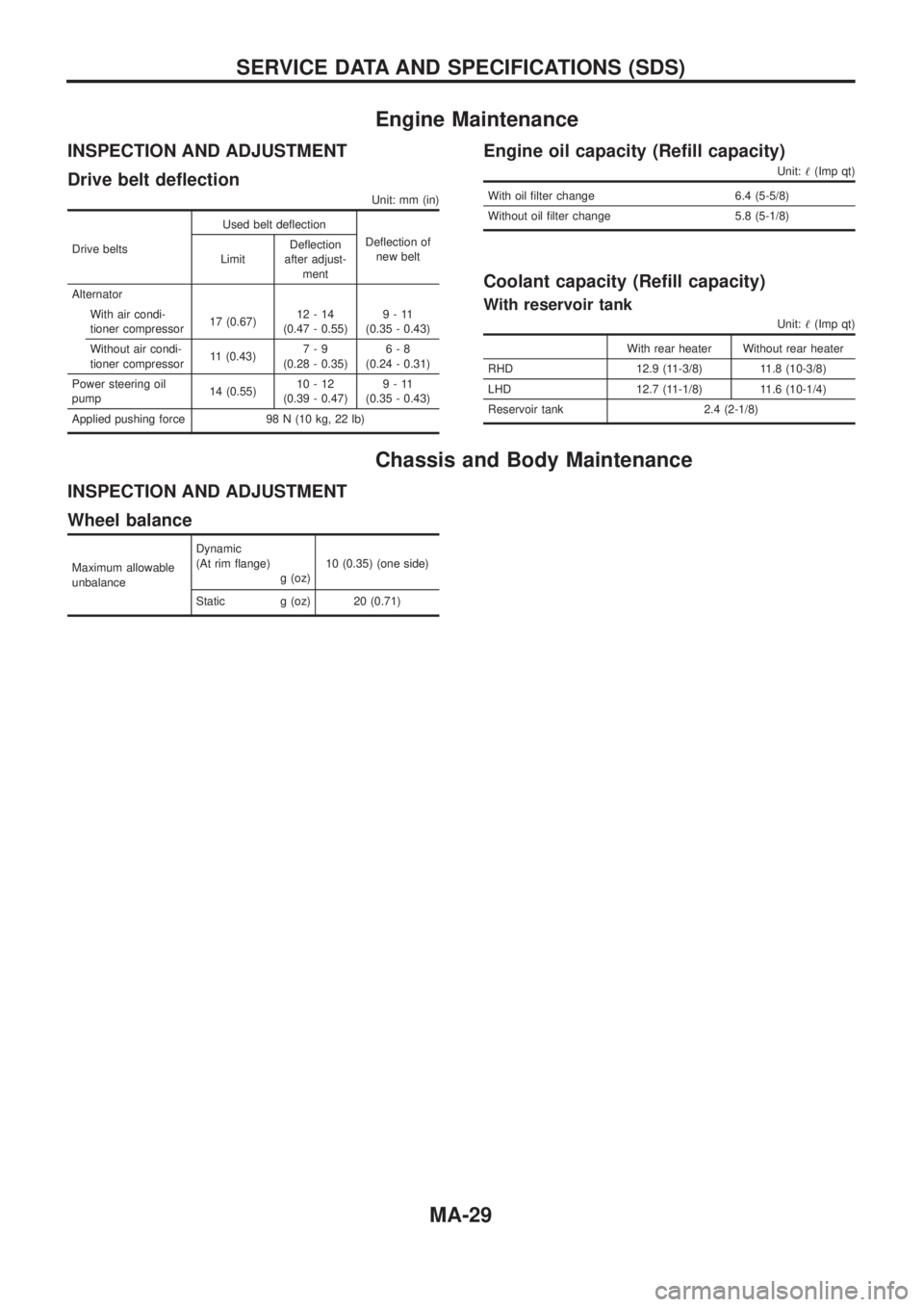

Engine Maintenance

INSPECTION AND ADJUSTMENT

Drive belt de¯ection

Unit: mm (in)

Drive beltsUsed belt de¯ection

De¯ection of

new belt

LimitDe¯ection

after adjust-

ment

Alternator

With air condi-

tioner compressor17 (0.67)12-14

(0.47 - 0.55)9-11

(0.35 - 0.43)

Without air condi-

tioner compressor11 (0.43)7-9

(0.28 - 0.35)6-8

(0.24 - 0.31)

Power steering oil

pump14 (0.55)10-12

(0.39 - 0.47)9-11

(0.35 - 0.43)

Applied pushing force 98 N (10 kg, 22 lb)

Engine oil capacity (Re®ll capacity)

Unit:!(Imp qt)

With oil ®lter change 6.4 (5-5/8)

Without oil ®lter change 5.8 (5-1/8)

Coolant capacity (Re®ll capacity)

With reservoir tank

Unit:!(Imp qt)

With rear heater Without rear heater

RHD 12.9 (11-3/8) 11.8 (10-3/8)

LHD 12.7 (11-1/8) 11.6 (10-1/4)

Reservoir tank 2.4 (2-1/8)

Chassis and Body Maintenance

INSPECTION AND ADJUSTMENT

Wheel balance

Maximum allowable

unbalanceDynamic

(At rim ¯ange)

g (oz)10 (0.35) (one side)

Static g (oz) 20 (0.71)

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-29

Page 1007 of 1226

MANUAL TRANSMISSION

SECTION

MT

CONTENTS

PREPARATION................................................................1

Special Service Tools ..................................................1

Commercial Service Tools ...........................................2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................3

NVH Troubleshooting Chart.........................................3

ON-VEHICLE SERVICE..................................................4

Replacing Rear Oil Seal ..............................................4

Position Switch Check .................................................4

REMOVAL AND INSTALLATION....................................5

Removal .......................................................................5

Installation ....................................................................6

DESCRIPTION.................................................................7

Cross-sectional View ...................................................7

AIR BREATHER..............................................................8

Air Breather Piping ......................................................8

MAJOR OVERHAUL.......................................................9Case Components .......................................................9

Gear Components .....................................................10

Shift Control Components .........................................12

DISASSEMBLY..............................................................13

Case Components .....................................................13

Shift Control Components .........................................14

Gear Components .....................................................15

INSPECTION..................................................................19

Shift Control Components .........................................19

Gear Components .....................................................19

ASSEMBLY....................................................................21

Gear Components .....................................................21

Shift Control Components .........................................29

Case Components .....................................................29

SERVICE DATA AND SPECIFICATIONS (SDS)..........32

General Speci®cations ...............................................32

Inspection and Adjustment ........................................33

MT

Page 1008 of 1226

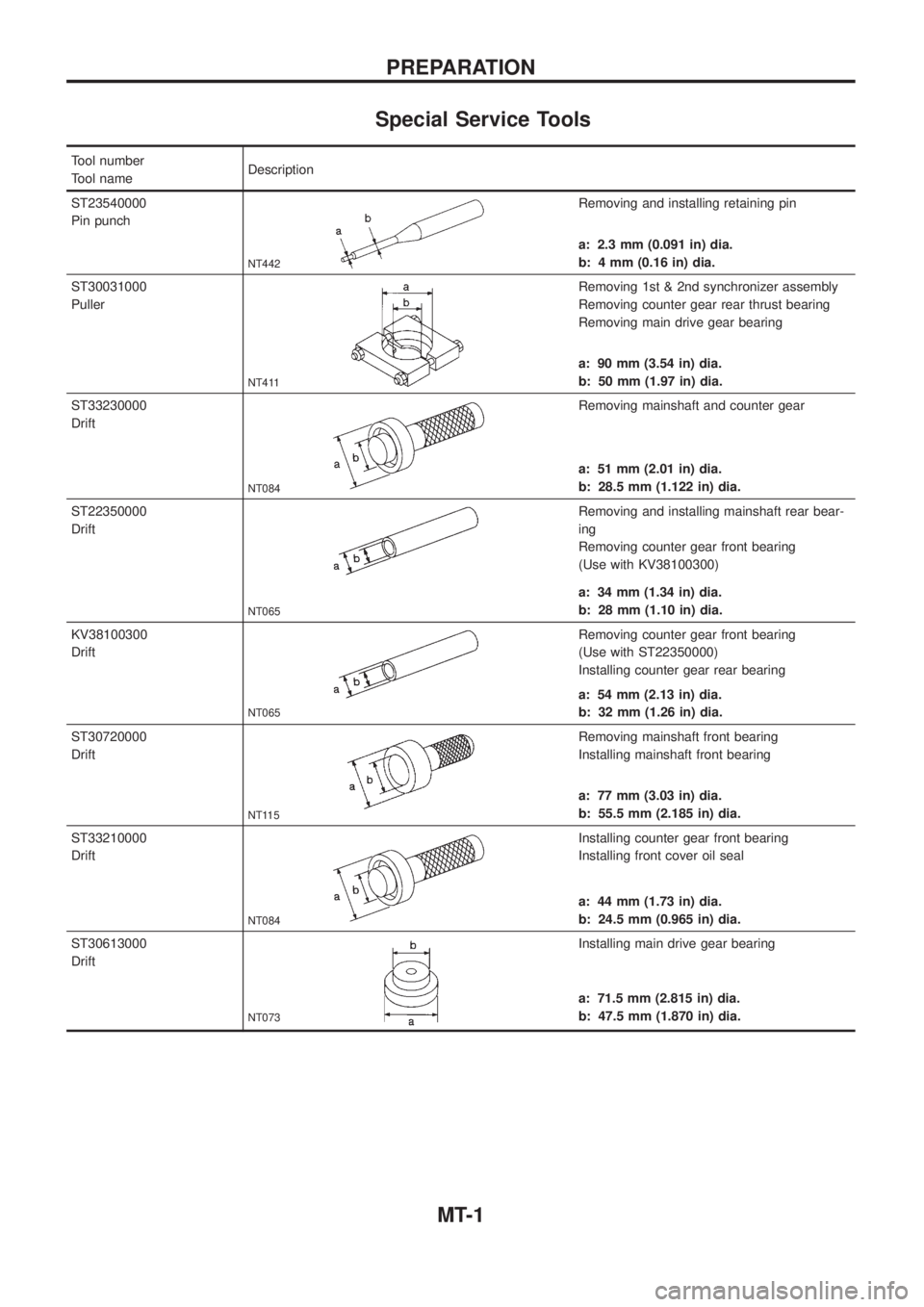

Special Service Tools

Tool number

Tool nameDescription

ST23540000

Pin punch

NT442

Removing and installing retaining pin

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

ST30031000

Puller

NT411

Removing 1st & 2nd synchronizer assembly

Removing counter gear rear thrust bearing

Removing main drive gear bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

ST33230000

Drift

NT084

Removing mainshaft and counter gear

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

ST22350000

Drift

NT065

Removing and installing mainshaft rear bear-

ing

Removing counter gear front bearing

(Use with KV38100300)

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

KV38100300

Drift

NT065

Removing counter gear front bearing

(Use with ST22350000)

Installing counter gear rear bearing

a: 54 mm (2.13 in) dia.

b: 32 mm (1.26 in) dia.

ST30720000

Drift

NT115

Removing mainshaft front bearing

Installing mainshaft front bearing

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

ST33210000

Drift

NT084

Installing counter gear front bearing

Installing front cover oil seal

a: 44 mm (1.73 in) dia.

b: 24.5 mm (0.965 in) dia.

ST30613000

Drift

NT073

Installing main drive gear bearing

a: 71.5 mm (2.815 in) dia.

b: 47.5 mm (1.870 in) dia.

PREPARATION

MT-1

Page 1009 of 1226

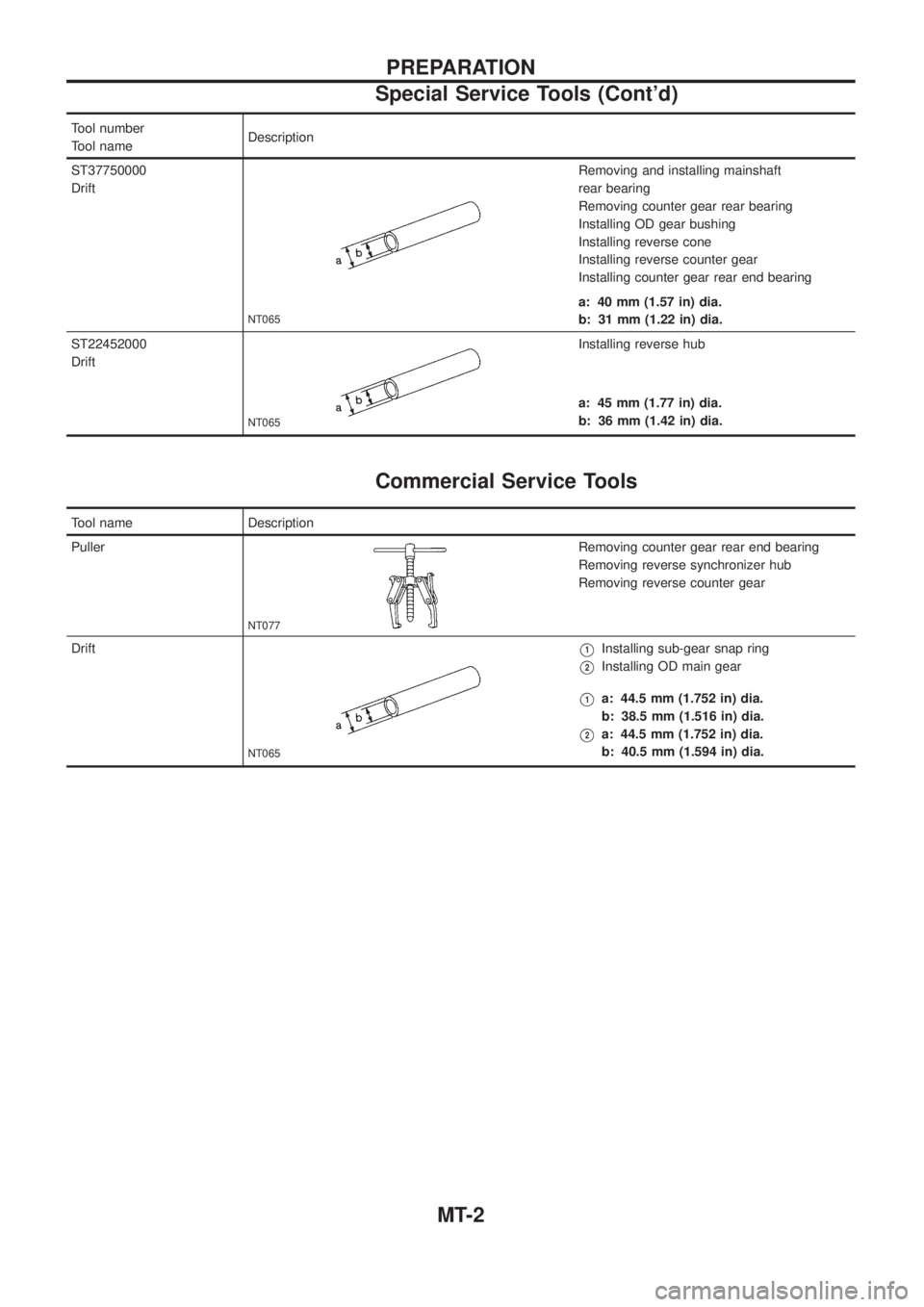

Tool number

Tool nameDescription

ST37750000

Drift

NT065

Removing and installing mainshaft

rear bearing

Removing counter gear rear bearing

Installing OD gear bushing

Installing reverse cone

Installing reverse counter gear

Installing counter gear rear end bearing

a: 40 mm (1.57 in) dia.

b: 31 mm (1.22 in) dia.

ST22452000

Drift

NT065

Installing reverse hub

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

Commercial Service Tools

Tool name Description

Puller

NT077

Removing counter gear rear end bearing

Removing reverse synchronizer hub

Removing reverse counter gear

Drift

NT065

V1Installing sub-gear snap ring

V2Installing OD main gear

V1a: 44.5 mm (1.752 in) dia.

b: 38.5 mm (1.516 in) dia.

V2a: 44.5 mm (1.752 in) dia.

b: 40.5 mm (1.594 in) dia.

PREPARATION

Special Service Tools (Cont'd)

MT-2

Page 1010 of 1226

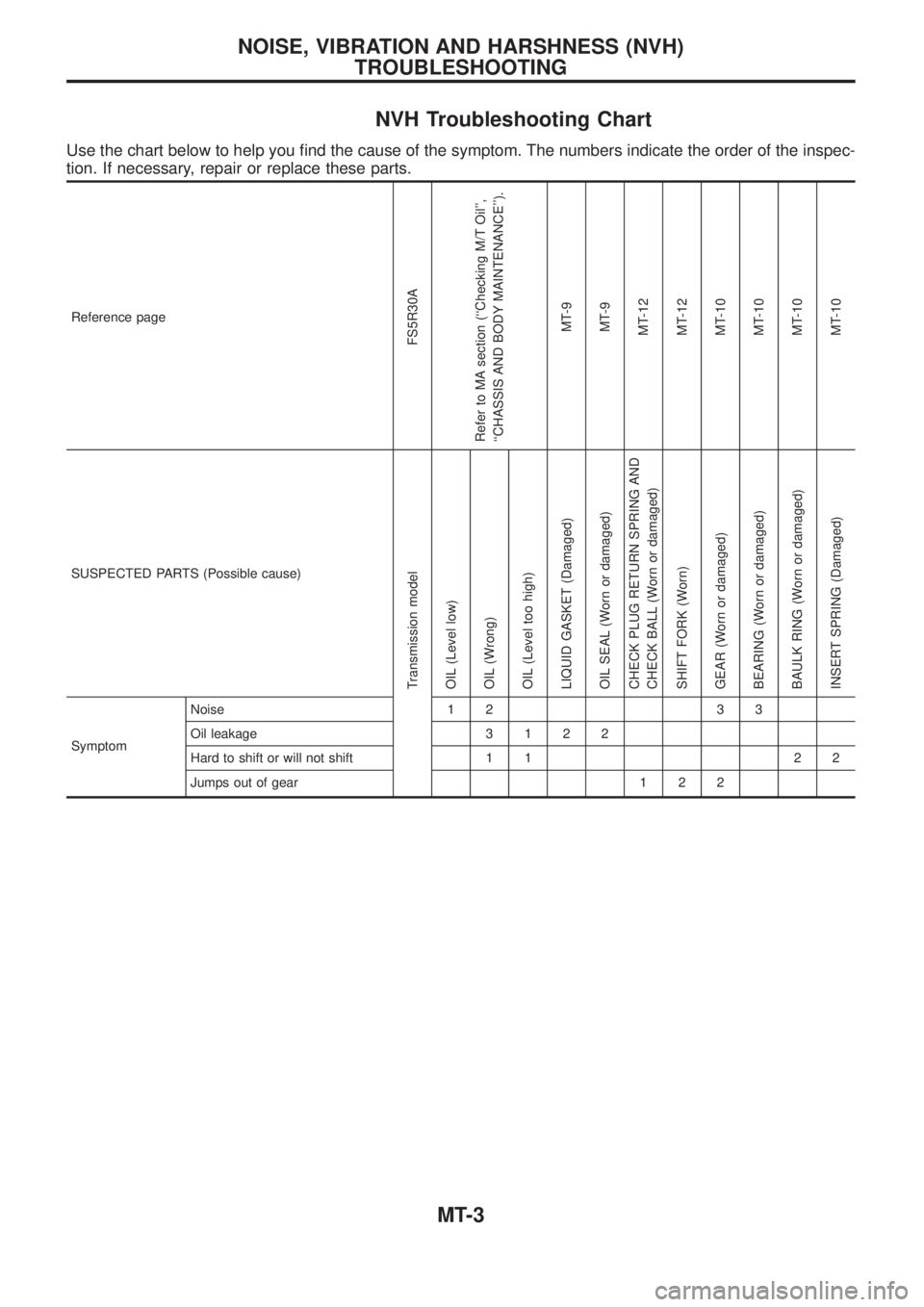

NVH Troubleshooting Chart

Use the chart below to help you ®nd the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference page

FS5R30A

Refer to MA section (``Checking M/T Oil'',

``CHASSIS AND BODY MAINTENANCE'').

MT-9

MT-9

MT-12

MT-12

MT-10

MT-10

MT-10

MT-10

SUSPECTED PARTS (Possible cause)

Transmission model

OIL (Level low)

OIL (Wrong)

OIL (Level too high)

LIQUID GASKET (Damaged)

OIL SEAL (Worn or damaged)

CHECK PLUG RETURN SPRING AND

CHECK BALL (Worn or damaged)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

SymptomNoise 1 2 3 3

Oil leakage3122

Hard to shift or will not shift 1 1 2 2

Jumps out of gear 1 2 2

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING

MT-3