NISSAN PATROL 2006 Manual PDF

Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 71 of 1226

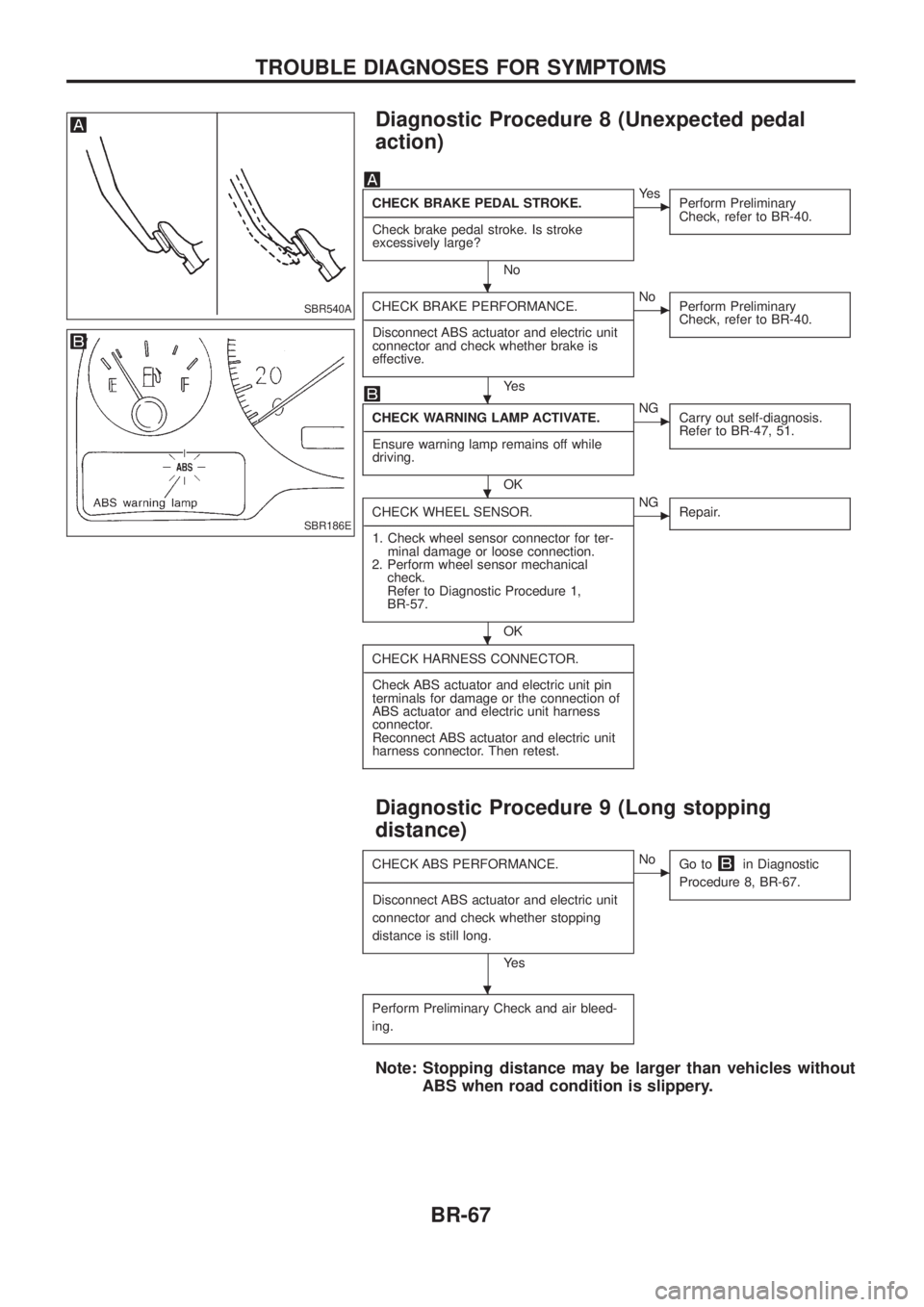

Diagnostic Procedure 8 (Unexpected pedal

action)

CHECK BRAKE PEDAL STROKE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check brake pedal stroke. Is stroke

excessively large?

No

cYe s Perform Preliminary

Check, refer to BR-40.

CHECK BRAKE PERFORMANCE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector and check whether brake is

effective.

Ye s

cNo Perform Preliminary

Check, refer to BR-40.

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Ensure warning lamp remains off while

driving.

OK

cNG Carry out self-diagnosis.

Refer to BR-47, 51.

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Check wheel sensor connector for ter- minal damage or loose connection.

2. Perform wheel sensor mechanical check.

Refer to Diagnostic Procedure 1,

BR-57.

OK

cNG Repair.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

Diagnostic Procedure 9 (Long stopping

distance)

CHECK ABS PERFORMANCE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector and check whether stopping

distance is still long.

Ye s

cNo Go toin Diagnostic

Procedure 8, BR-67.

Perform Preliminary Check and air bleed-

ing.

Note: Stopping distance may be larger than vehicles without ABS when road condition is slippery.

SBR540A

SBR186E

.

.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-67

Page 72 of 1226

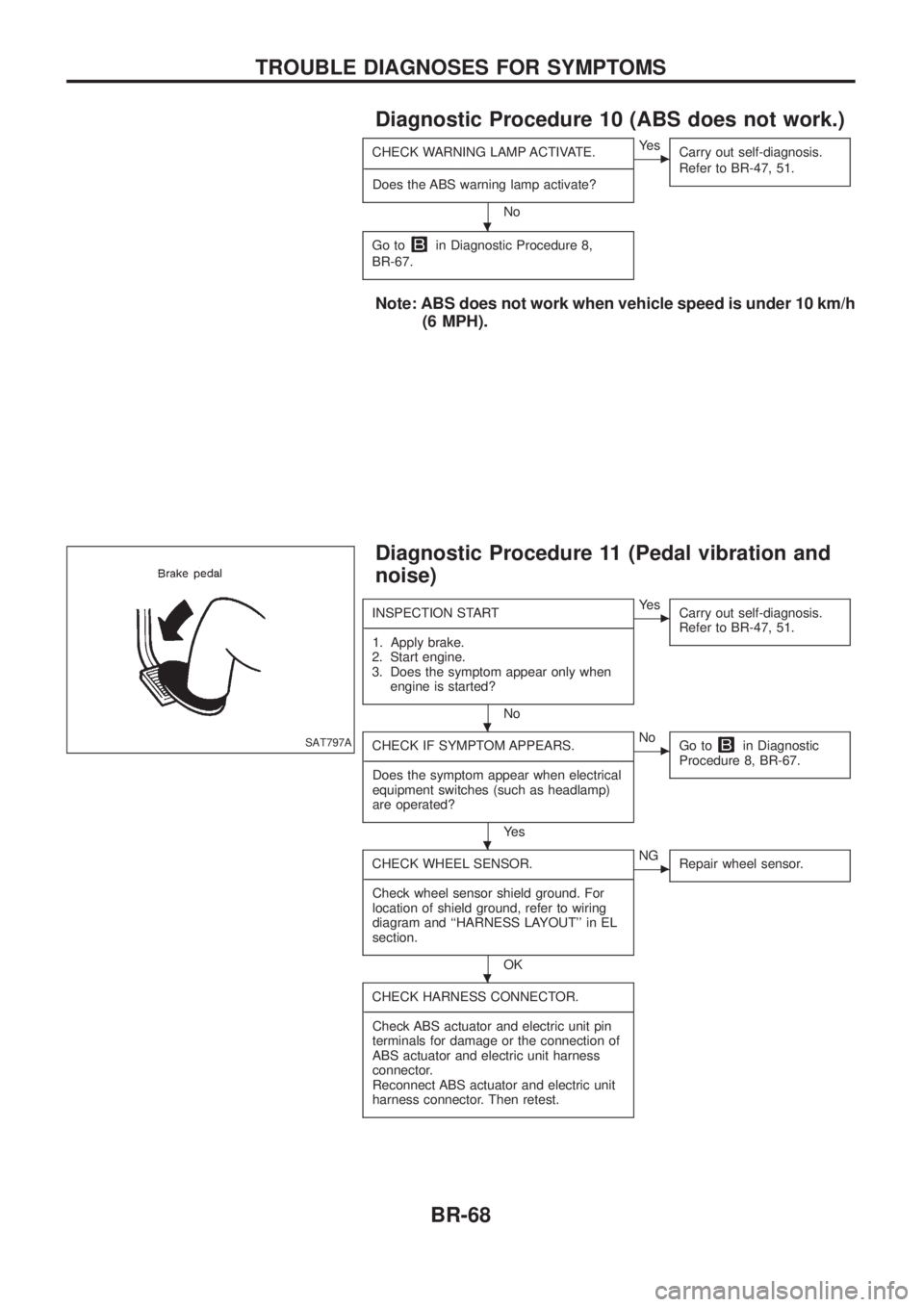

Diagnostic Procedure 10 (ABS does not work.)

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Does the ABS warning lamp activate?

No

cYe s Carry out self-diagnosis.

Refer to BR-47, 51.

Go toin Diagnostic Procedure 8,

BR-67.

Note: ABS does not work when vehicle speed is under 10 km/h (6 MPH).

Diagnostic Procedure 11 (Pedal vibration and

noise)

INSPECTION START

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Apply brake.

2. Start engine.

3. Does the symptom appear only when engine is started?

No

cYe s Carry out self-diagnosis.

Refer to BR-47, 51.

CHECK IF SYMPTOM APPEARS.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Does the symptom appear when electrical

equipment switches (such as headlamp)

are operated?

Ye s

cNo Go toin Diagnostic

Procedure 8, BR-67.

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check wheel sensor shield ground. For

location of shield ground, refer to wiring

diagram and ``HARNESS LAYOUT'' in EL

section.

OK

cNG Repair wheel sensor.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

SAT797A

.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-68

Page 73 of 1226

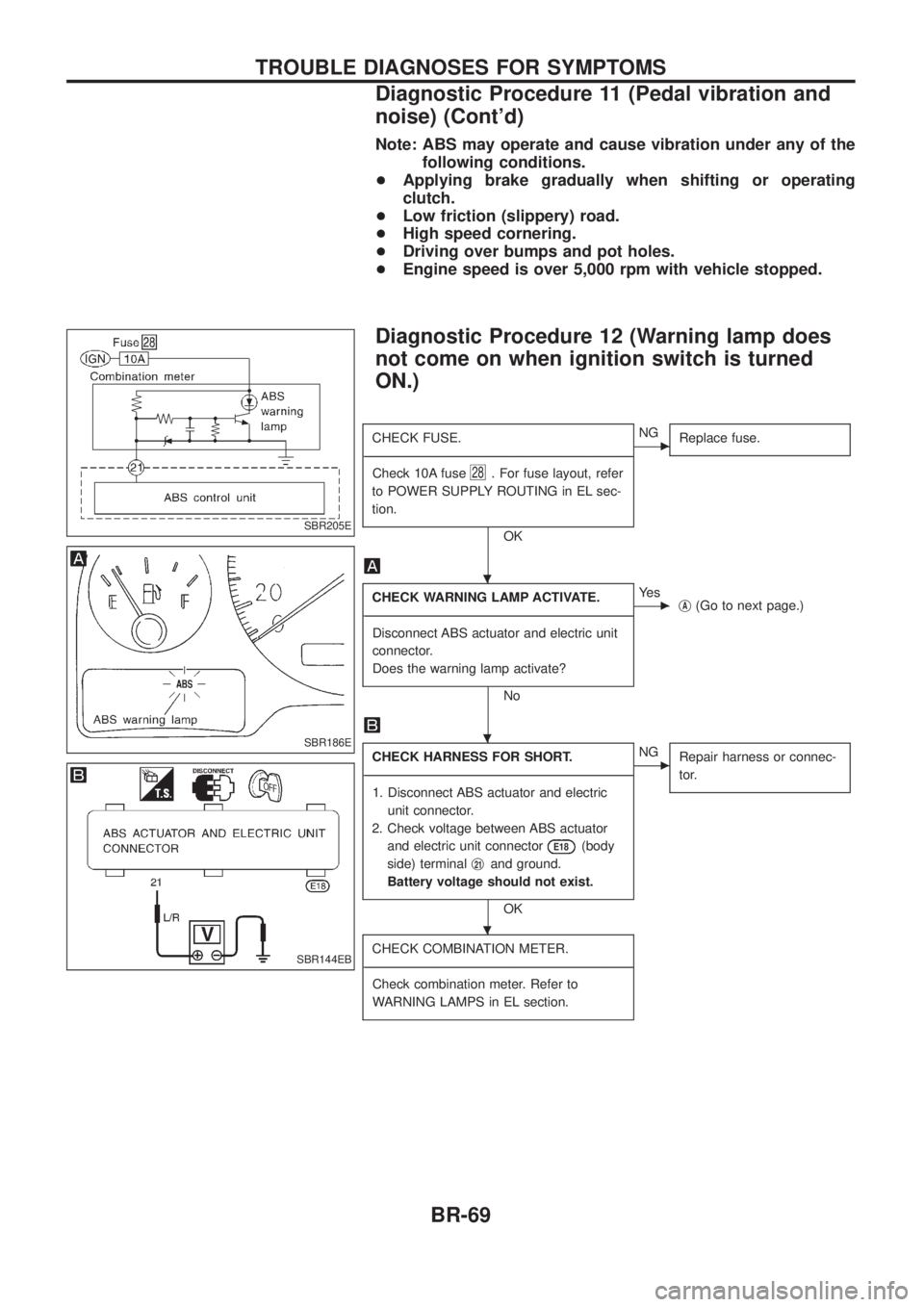

Note: ABS may operate and cause vibration under any of thefollowing conditions.

+ Applying brake gradually when shifting or operating

clutch.

+ Low friction (slippery) road.

+ High speed cornering.

+ Driving over bumps and pot holes.

+ Engine speed is over 5,000 rpm with vehicle stopped.

Diagnostic Procedure 12 (Warning lamp does

not come on when ignition switch is turned

ON.)

CHECK FUSE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 10A fuse

28. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

cNG Replace fuse.

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector.

Does the warning lamp activate?

No

cYe s jA(Go to next page.)

CHECK HARNESS FOR SHORT.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector

E18(body

side) terminal j

21and ground.

Battery voltage should not exist.

OK

cNG Repair harness or connec-

tor.

CHECK COMBINATION METER.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check combination meter. Refer to

WARNING LAMPS in EL section.

SBR205E

SBR186E

SBR144EB

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

Diagnostic Procedure 11 (Pedal vibration and

noise) (Cont'd)

BR-69

Page 74 of 1226

jA

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

NG

cOK Inspection end

REPLACE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace ABS actuator and electric unit.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

Diagnostic Procedure 12 (Warning lamp does

not come on when ignition switch is turned

ON.) (Cont'd)

BR-70

Page 75 of 1226

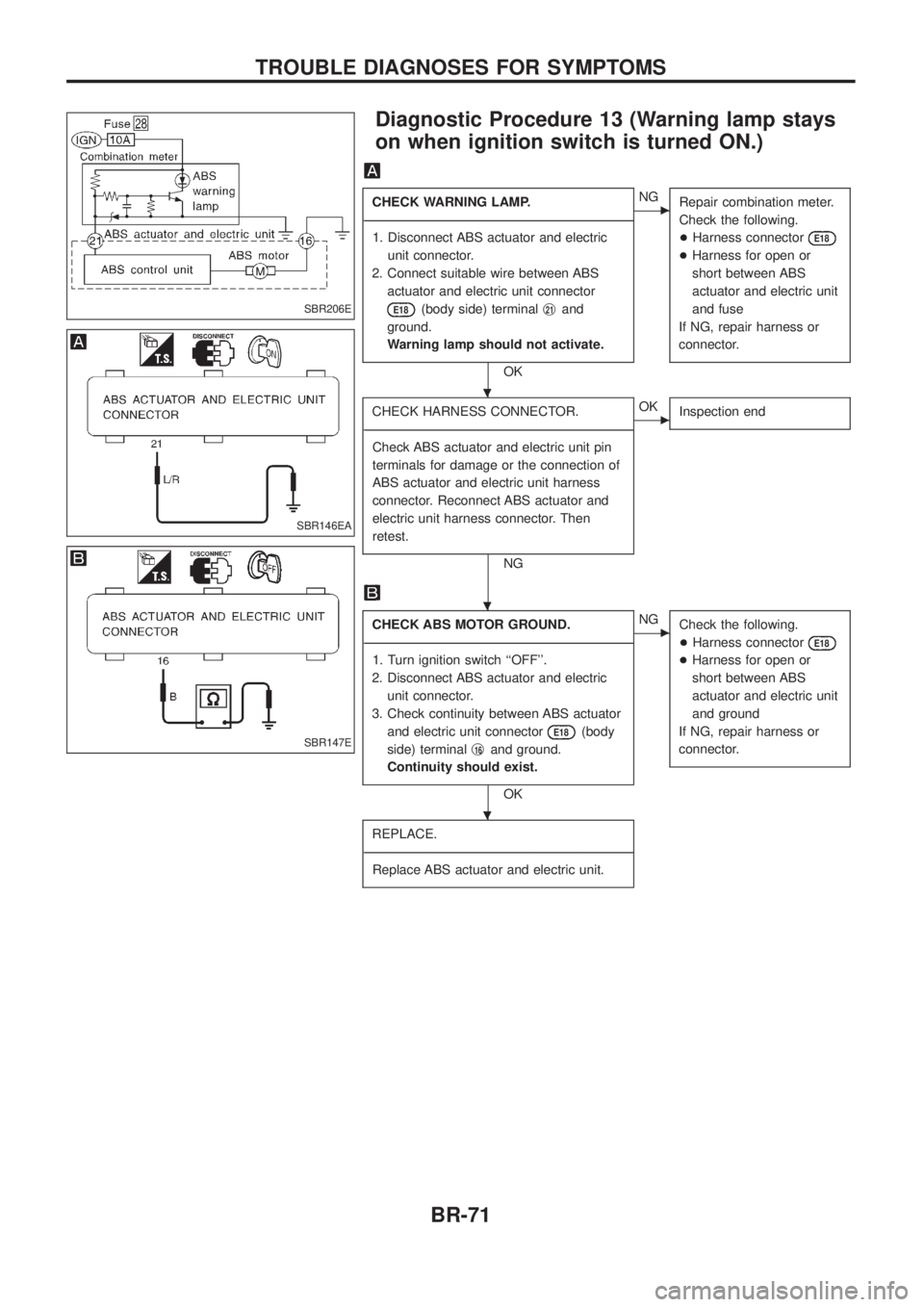

Diagnostic Procedure 13 (Warning lamp stays

on when ignition switch is turned ON.)

CHECK WARNING LAMP.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric unit connector.

2. Connect suitable wire between ABS actuator and electric unit connector

E18(body side) terminal j21and

ground.

Warning lamp should not activate.

OK

cNG Repair combination meter.

Check the following.

+Harness connector

E18

+Harness for open or

short between ABS

actuator and electric unit

and fuse

If NG, repair harness or

connector.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector. Reconnect ABS actuator and

electric unit harness connector. Then

retest.

NG

cOK Inspection end

CHECK ABS MOTOR GROUND.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Turn ignition switch ``OFF''.

2. Disconnect ABS actuator and electric unit connector.

3. Check continuity between ABS actuator and electric unit connector

E18(body

side) terminal j

16and ground.

Continuity should exist.

OK

cNG Check the following.

+Harness connector

E18

+Harness for open or

short between ABS

actuator and electric unit

and ground

If NG, repair harness or

connector.

REPLACE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Replace ABS actuator and electric unit.

SBR206E

SBR146EA

SBR147E

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-71

Page 76 of 1226

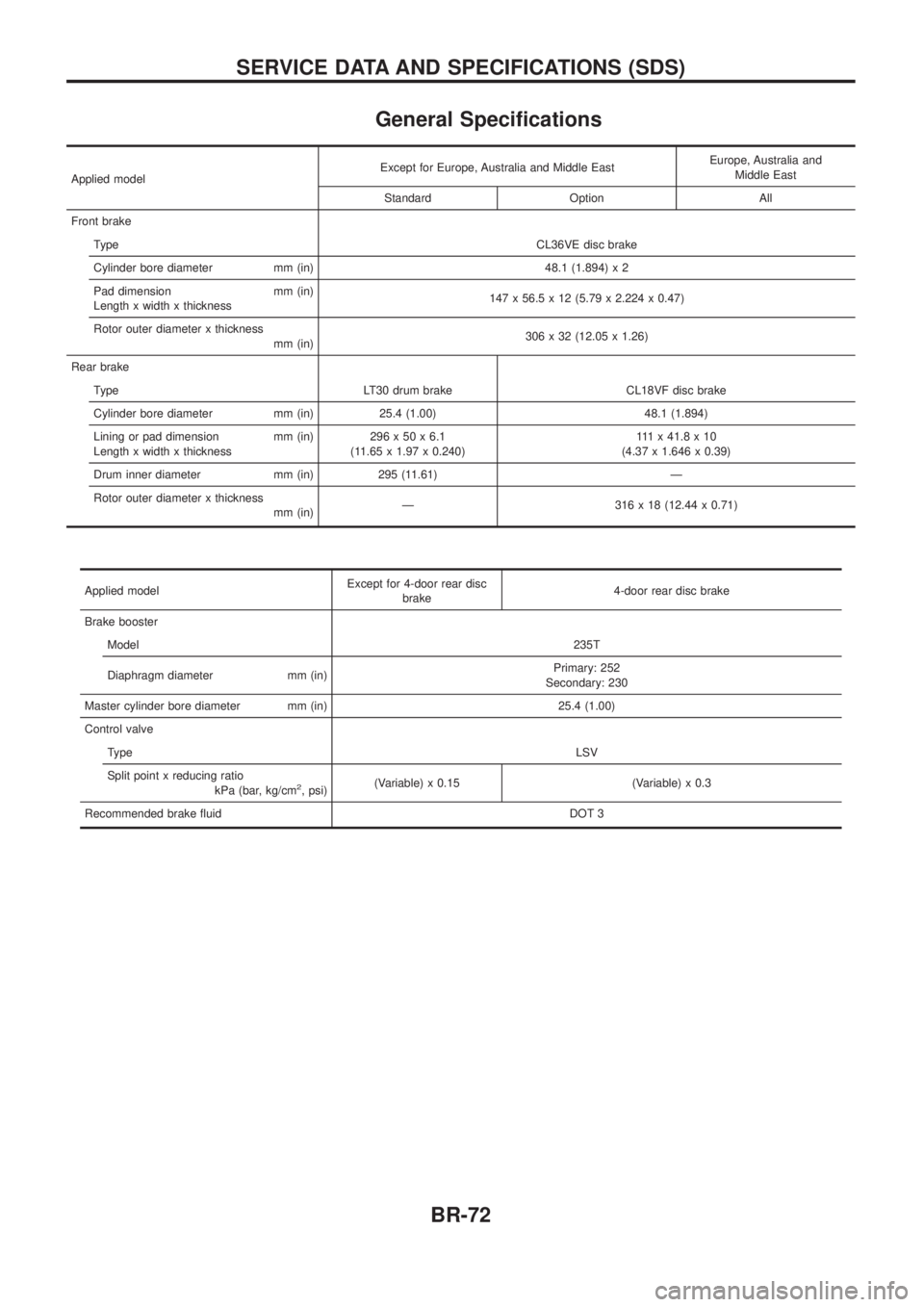

General Speci®cations

Applied modelExcept for Europe, Australia and Middle East

Europe, Australia and

Middle East

Standard Option All

Front brake Type CL36VE disc brake

Cylinder bore diameter mm (in) 48.1 (1.894) x 2

Pad dimension mm (in)

Length x width x thickness 147 x 56.5 x 12 (5.79 x 2.224 x 0.47)

Rotor outer diameter x thickness mm (in) 306 x 32 (12.05 x 1.26)

Rear brake Type LT30 drum brake CL18VF disc brake

Cylinder bore diameter mm (in) 25.4 (1.00) 48.1 (1.894)

Lining or pad dimension mm (in)

Length x width x thickness 296x50x6.1

(11.65 x 1.97 x 0.240) 111x41.8x10

(4.37 x 1.646 x 0.39)

Drum inner diameter mm (in) 295 (11.61) Ð

Rotor outer diameter x thickness mm (in)Ð 316 x 18 (12.44 x 0.71)

Applied model Except for 4-door rear disc

brake 4-door rear disc brake

Brake booster Model 235T

Diaphragm diameter mm (in) Primary: 252

Secondary: 230

Master cylinder bore diameter mm (in) 25.4 (1.00)

Control valve Type LSV

Split point x reducing ratio kPa (bar, kg/cm

2, psi)(Variable) x 0.15 (Variable) x 0.3

Recommended brake ¯uid DOT 3

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-72

Page 77 of 1226

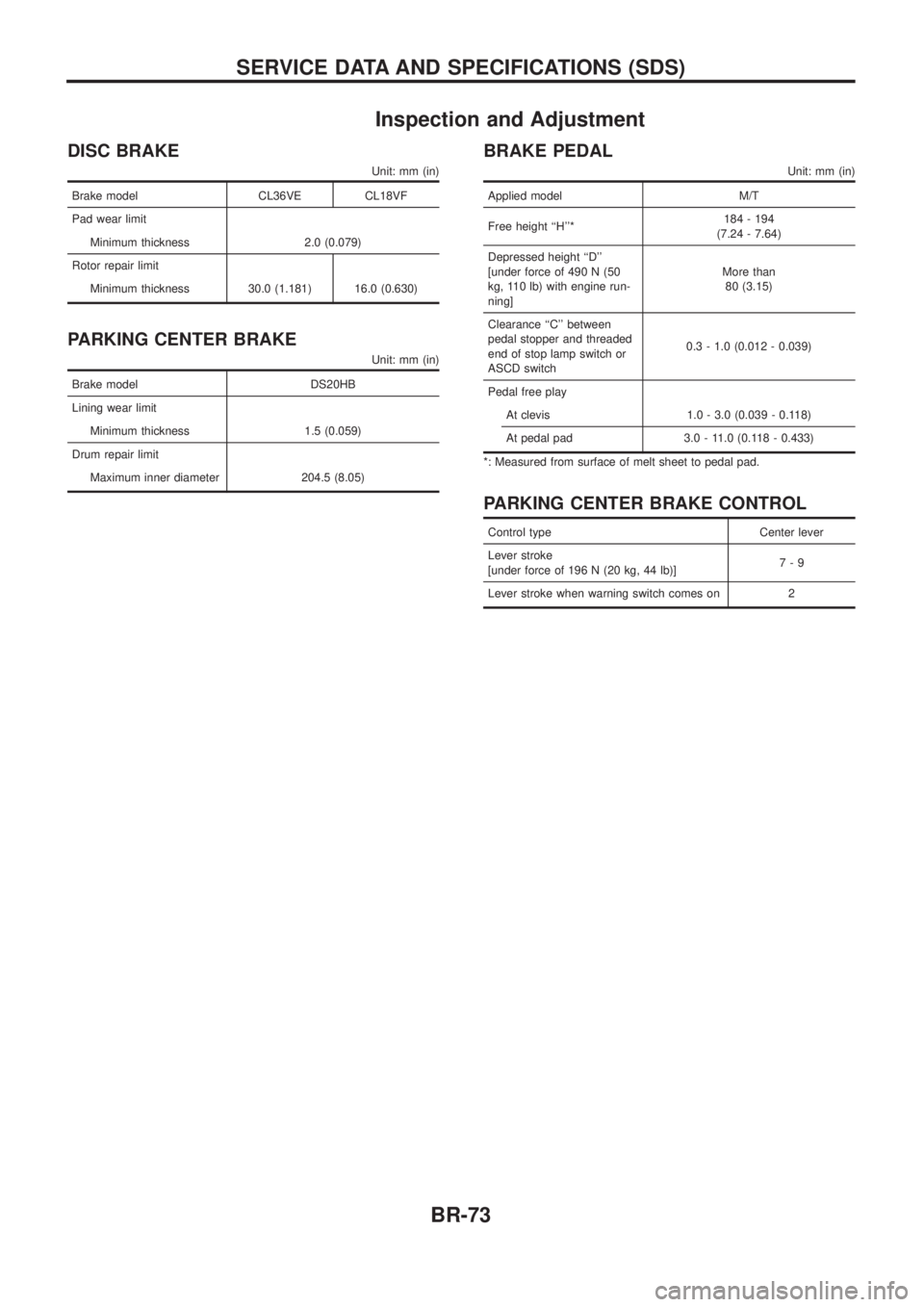

Inspection and Adjustment

DISC BRAKE

Unit: mm (in)

Brake model CL36VE CL18VF

Pad wear limit

Minimum thickness 2.0 (0.079)

Rotor repair limit

Minimum thickness 30.0 (1.181) 16.0 (0.630)

PARKING CENTER BRAKE

Unit: mm (in)

Brake model DS20HB

Lining wear limit

Minimum thickness 1.5 (0.059)

Drum repair limit

Maximum inner diameter 204.5 (8.05)

BRAKE PEDAL

Unit: mm (in)

Applied model M/T

Free height ``H''*184 - 194

(7.24 - 7.64)

Depressed height ``D''

[under force of 490 N (50

kg, 110 lb) with engine run-

ning]More than

80 (3.15)

Clearance ``C'' between

pedal stopper and threaded

end of stop lamp switch or

ASCD switch0.3 - 1.0 (0.012 - 0.039)

Pedal free play

At clevis 1.0 - 3.0 (0.039 - 0.118)

At pedal pad 3.0 - 11.0 (0.118 - 0.433)

*: Measured from surface of melt sheet to pedal pad.

PARKING CENTER BRAKE CONTROL

Control type Center lever

Lever stroke

[under force of 196 N (20 kg, 44 lb)]7-9

Lever stroke when warning switch comes on 2

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-73

Page 78 of 1226

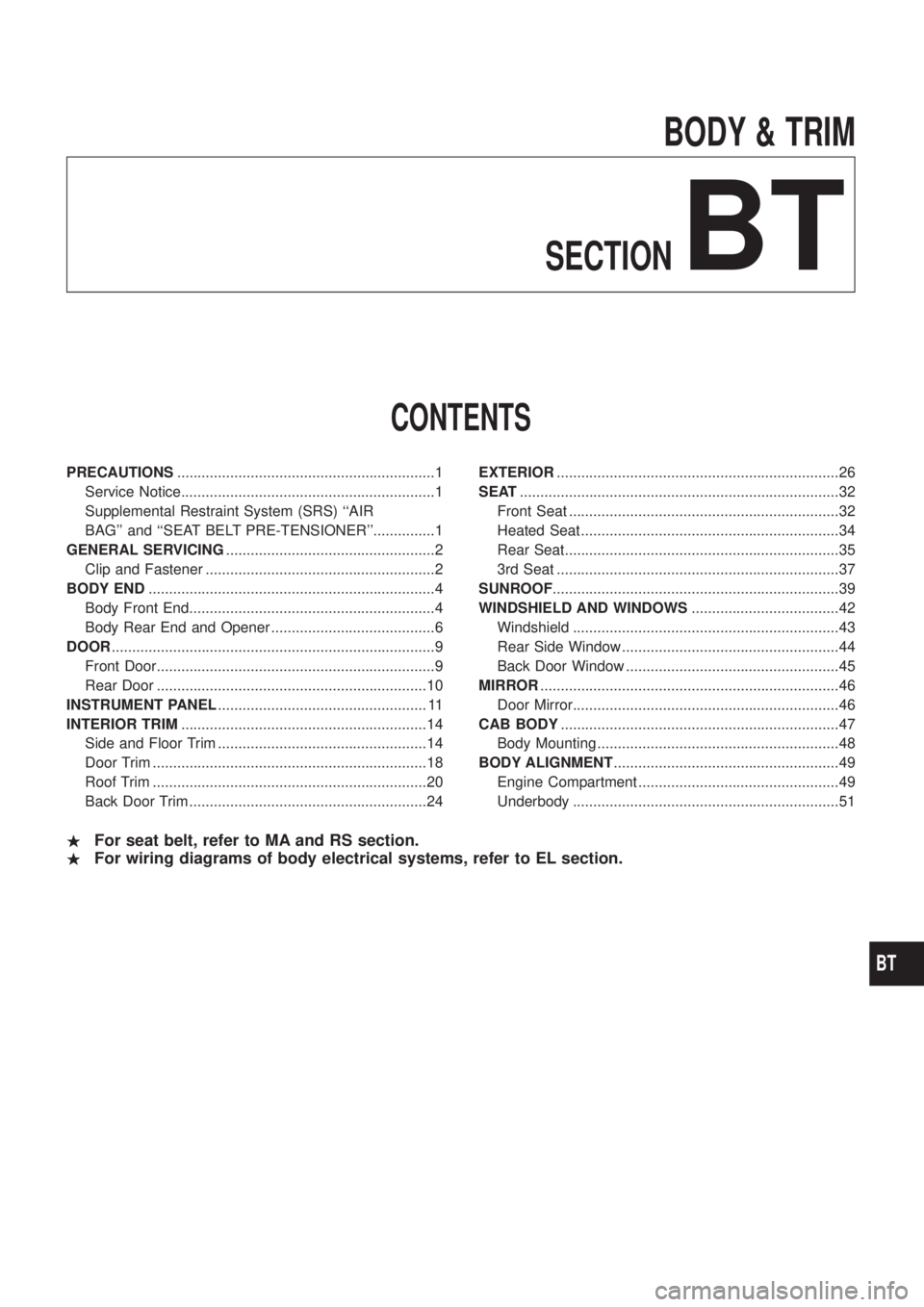

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS ...............................................................1

Service Notice..............................................................1

Supplemental Restraint System (SRS) ``AIR

BAG''and``SEATBELTPRE-TENSIONER''...............1

GENERAL SERVICING ...................................................2

Clip and Fastener ........................................................2

BODY END ......................................................................4

Body Front End............................................................4

Body Rear End and Opener ........................................6

DOOR ........................................................................\

.......9

Front Door....................................................................9

Rear Door ..................................................................10

INSTRUMENT PANEL ................................................... 11

INTERIOR TRIM ............................................................14

Side and Floor Trim ...................................................14

Door Trim ...................................................................18

Roof Trim ...................................................................20

Back Door Trim ..........................................................24 EXTERIOR

.....................................................................26

SEAT ........................................................................\

......32

Front Seat ..................................................................32

Heated Seat ...............................................................34

Rear Seat...................................................................35

3rd Seat .....................................................................37

SUNROOF ......................................................................39

WINDSHIELD AND WINDOWS ....................................42

Windshield .................................................................43

Rear Side Window .....................................................44

Back Door Window ....................................................45

MIRROR ........................................................................\

.46

Door Mirror.................................................................46

CAB BODY ....................................................................47

Body Mounting ...........................................................48

BODY ALIGNMENT .......................................................49

Engine Compartment .................................................49

Underbody .................................................................51

. For seat belt, refer to MA and RS section.

. For wiring diagrams of body electrical systems, refer to EL section.

BT

Page 79 of 1226

Service Notice

+When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

+Handle trim, molding, instruments, grille, etc. carefully during removing or installing. Be careful not to soil

or damage them.

+Apply sealing compound where necessary when installing parts.

+When applying sealing compound, be careful that the sealing compound does not protrude from parts.

+When replacing any metal parts (for example body outer panel, members, etc.), be sure to take rust pre-

vention measures.

Supplemental Restraint System (SRS) ``AIR

BAG'' and ``SEAT BELT PRE-TENSIONER''

The Supplemental Restraint System such as ``AIR BAG'' and ``SEAT BELT PRE-TENSIONER'' used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger in a frontal collision.

The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The composition var-

ies according to the destination.):

Driver air bag module (located in the center of the steering wheel), front passenger air bag module (located

on the instrument panel on passenger side), seat belt pre-tensioner, a diagnosis sensor unit, warning lamp,

wiring harness and spiral cable.

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag in¯ation, all maintenance must be performed

by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation either just before

the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

BT-1

Page 80 of 1226

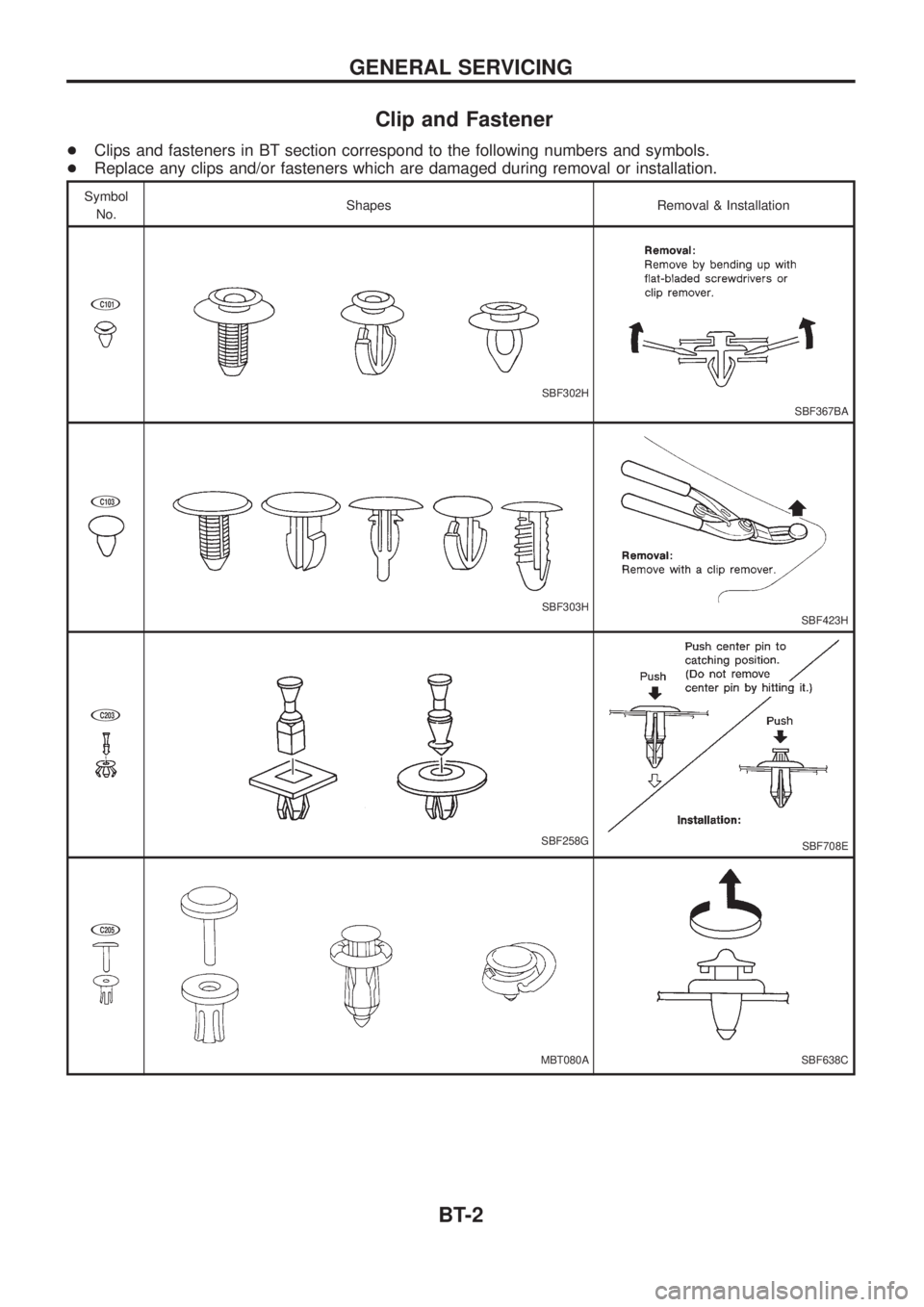

Clip and Fastener

+Clips and fasteners in BT section correspond to the following numbers and symbols.

+Replace any clips and/or fasteners which are damaged during removal or installation.

Symbol

No.Shapes Removal & Installation

jC101

SBF302H

SBF367BA

jC103

SBF303HSBF423H

jC203

SBF258GSBF708E

jC205

MBT080ASBF638C

GENERAL SERVICING

BT-2