dimensions NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 143 of 1659

lAll dimensions indicated in figures are actual ones.

lWhen using a tracking gauge, adjust both pointers to equal length. Make sure there is no free play.

lWhen a measuring tape is used, check to be sure there is no elongation, twisting or bending.

lMeasurements should be taken at the center of the mounting holes.

lAll measurements and mounting hole diameters are expressed in millimeters (mm).

lAn asterisk (*) following the value at the measuring point indicates that the measuring point on the other

side is symmetrically the same value.

lThe coordinates of the measurement points are the distances measured from the respective dimension

lines in the directions of ``x'', ``y'' and ``z''.

Dimension lines: ``x'' line Ð Center line of vehicle

``y'' line Ð Center line of front axle (Any measurement point in front of the dimension

line refers to a minus ``Ð'' value.)

``z'' line Ð Datum line (Any measurement point under the dimension line refers to a

minus ``Ð'' value.)

2W.SB: Short wheelbase (2WD)

2W.LB

: Long wheelbase (2WD)

4W.LB

: Long wheelbase (4WD)

BODY ALIGNMENT

BT-43

Page 386 of 1659

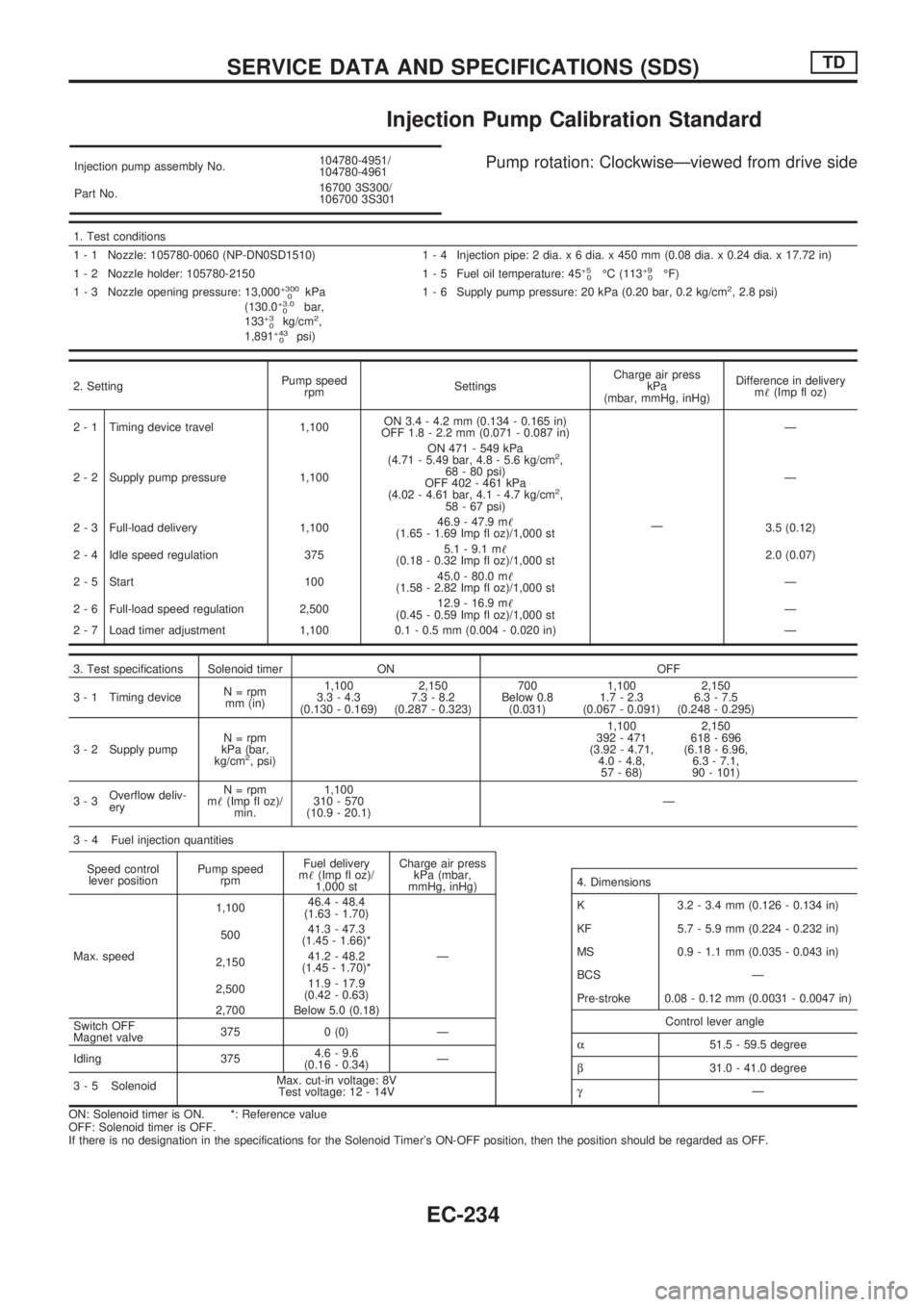

Injection Pump Calibration Standard

Injection pump assembly No.104780-4951/

104780-4961

Part No.16700 3S300/

106700 3S301Pump rotation: ClockwiseÐviewed from drive side

1. Test conditions

1 - 1 Nozzle: 105780-0060 (NP-DN0SD1510) 1 - 4 Injection pipe: 2 dia. x 6 dia. x 450 mm (0.08 dia. x 0.24 dia. x 17.72 in)

1 - 2 Nozzle holder: 105780-2150 1 - 5 Fuel oil temperature: 45

+5

0ÉC (113+9

0ÉF)

1 - 3 Nozzle opening pressure: 13,000+300

0kPa

(130.0+3.0

0bar,

133+3

0kg/cm2,

1,891+43

0psi)1 - 6 Supply pump pressure: 20 kPa (0.20 bar, 0.2 kg/cm

2, 2.8 psi)

2. SettingPump speed

rpmSettingsCharge air press

kPa

(mbar, mmHg, inHg)Difference in delivery

m!(Imp fl oz)

2 - 1 Timing device travel 1,100ON 3.4 - 4.2 mm (0.134 - 0.165 in)

OFF 1.8 - 2.2 mm (0.071 - 0.087 in)

ÐÐ

2 - 2 Supply pump pressure 1,100ON 471 - 549 kPa

(4.71 - 5.49 bar, 4.8 - 5.6 kg/cm

2,

68 - 80 psi)

OFF 402 - 461 kPa

(4.02 - 4.61 bar, 4.1 - 4.7 kg/cm

2,

58 - 67 psi)Ð

2 - 3 Full-load delivery 1,10046.9 - 47.9 m!

(1.65 - 1.69 Imp fl oz)/1,000 st3.5 (0.12)

2 - 4 Idle speed regulation 3755.1 - 9.1 m!

(0.18 - 0.32 Imp fl oz)/1,000 st2.0 (0.07)

2 - 5 Start 10045.0 - 80.0 m!

(1.58 - 2.82 Imp fl oz)/1,000 stÐ

2 - 6 Full-load speed regulation 2,50012.9 - 16.9 m!

(0.45 - 0.59 Imp fl oz)/1,000 stÐ

2 - 7 Load timer adjustment 1,100 0.1 - 0.5 mm (0.004 - 0.020 in) Ð

3. Test specifications Solenoid timer ON OFF

3 - 1 Timing deviceN = rpm

mm (in)1,100

3.3 - 4.3

(0.130 - 0.169)2,150

7.3 - 8.2

(0.287 - 0.323)700

Below 0.8

(0.031)1,100

1.7 - 2.3

(0.067 - 0.091)2,150

6.3 - 7.5

(0.248 - 0.295)

3 - 2 Supply pumpN = rpm

kPa (bar,

kg/cm

2, psi)1,100

392 - 471

(3.92 - 4.71,

4.0 - 4.8,

57 - 68)2,150

618 - 696

(6.18 - 6.96,

6.3 - 7.1,

90 - 101)

3-3Overflow deliv-

eryN = rpm

m!(Imp fl oz)/

min.1,100

310 - 570

(10.9 - 20.1)Ð

3 - 4 Fuel injection quantities

Speed control

lever positionPump speed

rpmFuel delivery

m!(Imp fl oz)/

1,000 stCharge air press

kPa (mbar,

mmHg, inHg)

Max. speed1,10046.4 - 48.4

(1.63 - 1.70)

Ð 50041.3 - 47.3

(1.45 - 1.66)*

2,15041.2 - 48.2

(1.45 - 1.70)*

2,50011.9 - 17.9

(0.42 - 0.63)

2,700 Below 5.0 (0.18)

Switch OFF

Magnet valve375 0 (0) Ð

Idling 3754.6 - 9.6

(0.16 - 0.34)Ð

3 - 5 SolenoidMax. cut-in voltage: 8V

Test voltage: 12 - 14V

ON: Solenoid timer is ON. *: Reference value

OFF: Solenoid timer is OFF.

If there is no designation in the specifications for the Solenoid Timer's ON-OFF position, then the position should be regarded as OFF.

4. Dimensions

K 3.2 - 3.4 mm (0.126 - 0.134 in)

KF 5.7 - 5.9 mm (0.224 - 0.232 in)

MS 0.9 - 1.1 mm (0.035 - 0.043 in)

BCS Ð

Pre-stroke 0.08 - 0.12 mm (0.0031 - 0.0047 in)

Control lever angle

a51.5 - 59.5 degree

b31.0 - 41.0 degree

gÐ

SERVICE DATA AND SPECIFICATIONS (SDS)TD

EC-234

Page 676 of 1659

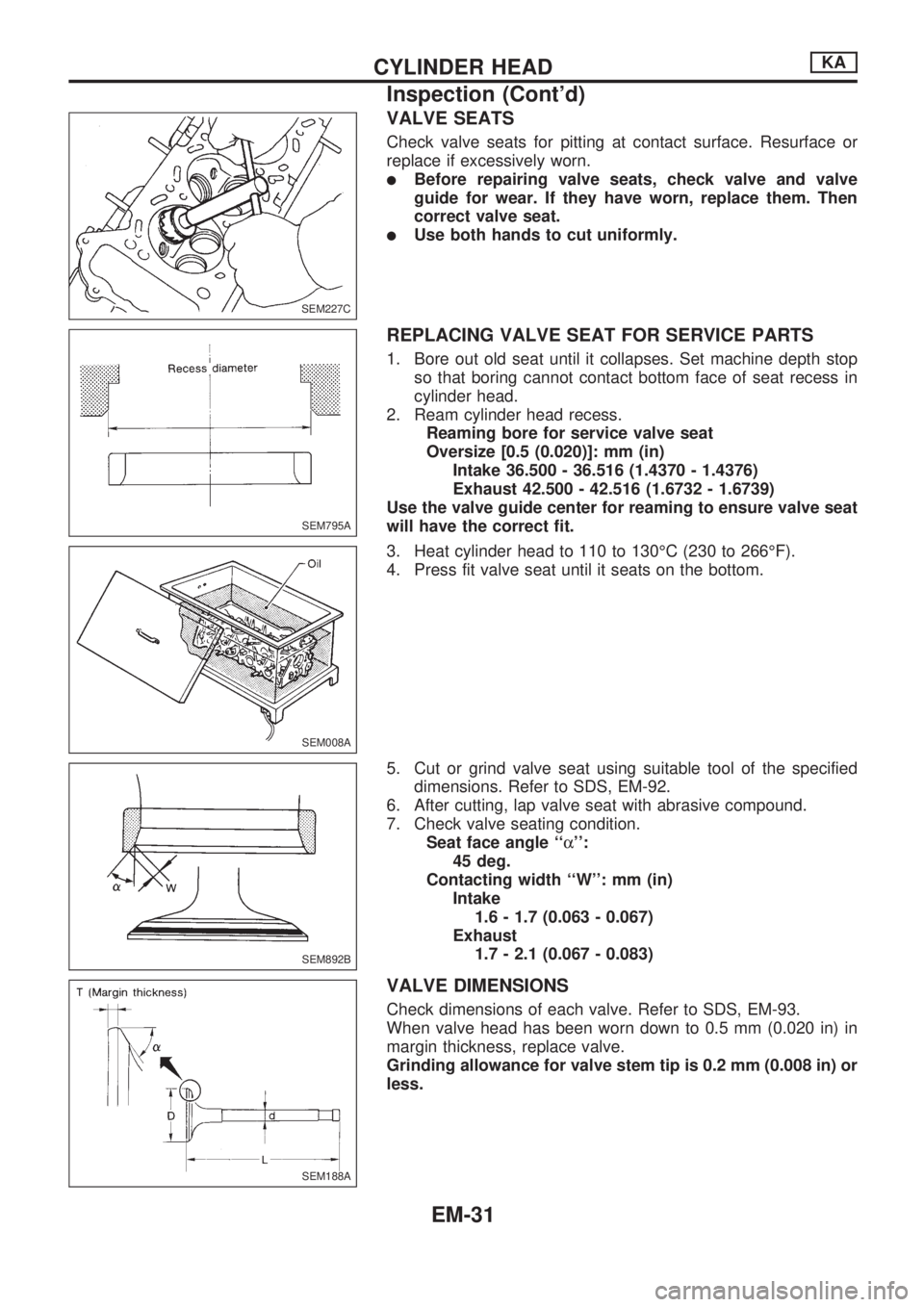

VALVE SEATS

Check valve seats for pitting at contact surface. Resurface or

replace if excessively worn.

lBefore repairing valve seats, check valve and valve

guide for wear. If they have worn, replace them. Then

correct valve seat.

lUse both hands to cut uniformly.

REPLACING VALVE SEAT FOR SERVICE PARTS

1. Bore out old seat until it collapses. Set machine depth stop

so that boring cannot contact bottom face of seat recess in

cylinder head.

2. Ream cylinder head recess.

Reaming bore for service valve seat

Oversize [0.5 (0.020)]: mm (in)

Intake 36.500 - 36.516 (1.4370 - 1.4376)

Exhaust 42.500 - 42.516 (1.6732 - 1.6739)

Use the valve guide center for reaming to ensure valve seat

will have the correct fit.

3. Heat cylinder head to 110 to 130ÉC (230 to 266ÉF).

4. Press fit valve seat until it seats on the bottom.

5. Cut or grind valve seat using suitable tool of the specified

dimensions. Refer to SDS, EM-92.

6. After cutting, lap valve seat with abrasive compound.

7. Check valve seating condition.

Seat face angle ``a'':

45 deg.

Contacting width ``W'': mm (in)

Intake

1.6 - 1.7 (0.063 - 0.067)

Exhaust

1.7 - 2.1 (0.067 - 0.083)

VALVE DIMENSIONS

Check dimensions of each valve. Refer to SDS, EM-93.

When valve head has been worn down to 0.5 mm (0.020 in) in

margin thickness, replace valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM227C

SEM795A

SEM008A

SEM892B

SEM188A

CYLINDER HEADKA

Inspection (Cont'd)

EM-31

Page 703 of 1659

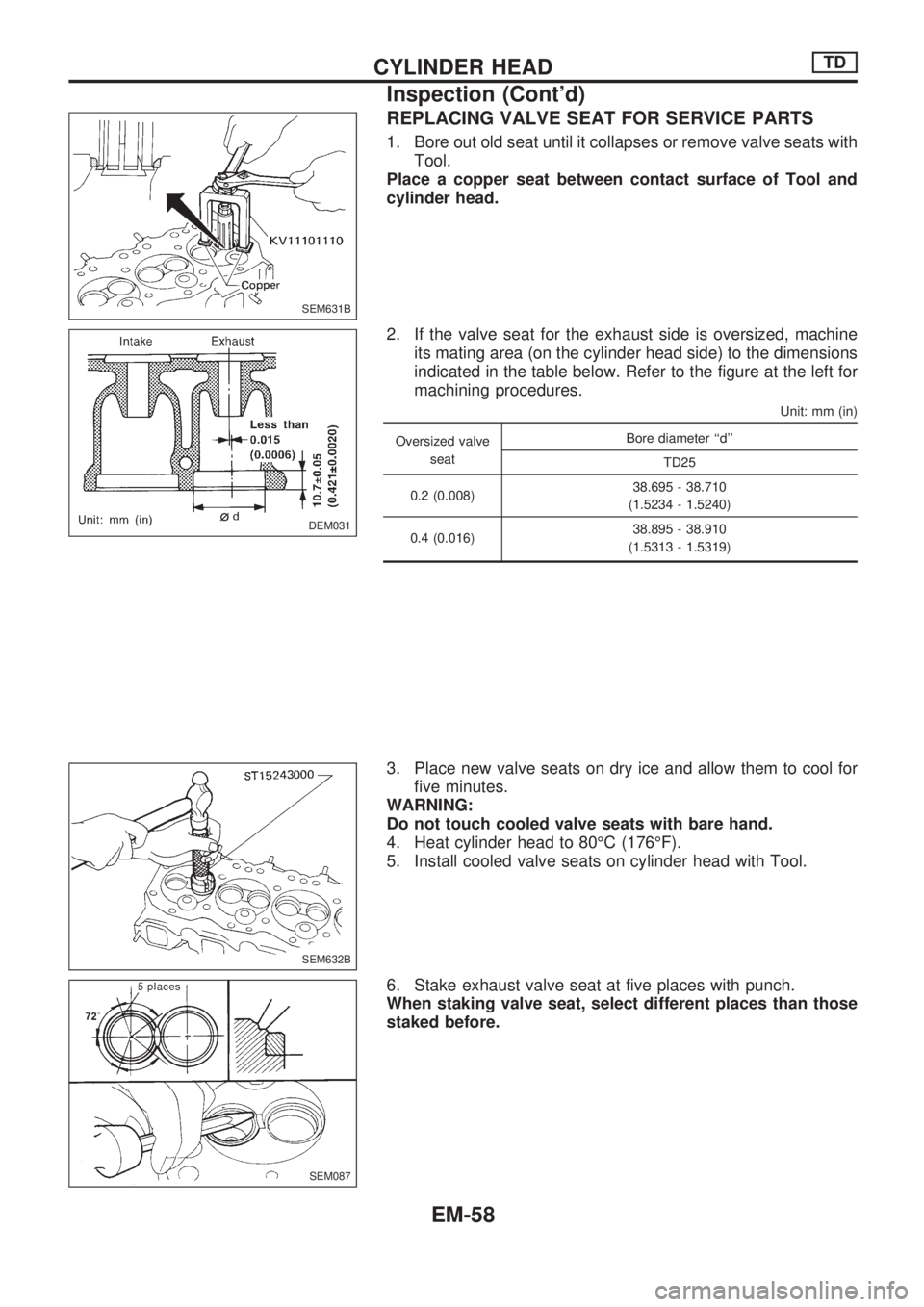

REPLACING VALVE SEAT FOR SERVICE PARTS

1. Bore out old seat until it collapses or remove valve seats with

Tool.

Place a copper seat between contact surface of Tool and

cylinder head.

2. If the valve seat for the exhaust side is oversized, machine

its mating area (on the cylinder head side) to the dimensions

indicated in the table below. Refer to the figure at the left for

machining procedures.

Unit: mm (in)

Oversized valve

seatBore diameter ``d''

TD25

0.2 (0.008)38.695 - 38.710

(1.5234 - 1.5240)

0.4 (0.016)38.895 - 38.910

(1.5313 - 1.5319)

3. Place new valve seats on dry ice and allow them to cool for

five minutes.

WARNING:

Do not touch cooled valve seats with bare hand.

4. Heat cylinder head to 80ÉC (176ÉF).

5. Install cooled valve seats on cylinder head with Tool.

6. Stake exhaust valve seat at five places with punch.

When staking valve seat, select different places than those

staked before.

SEM631B

DEM031

SEM632B

SEM087

CYLINDER HEADTD

Inspection (Cont'd)

EM-58

Page 704 of 1659

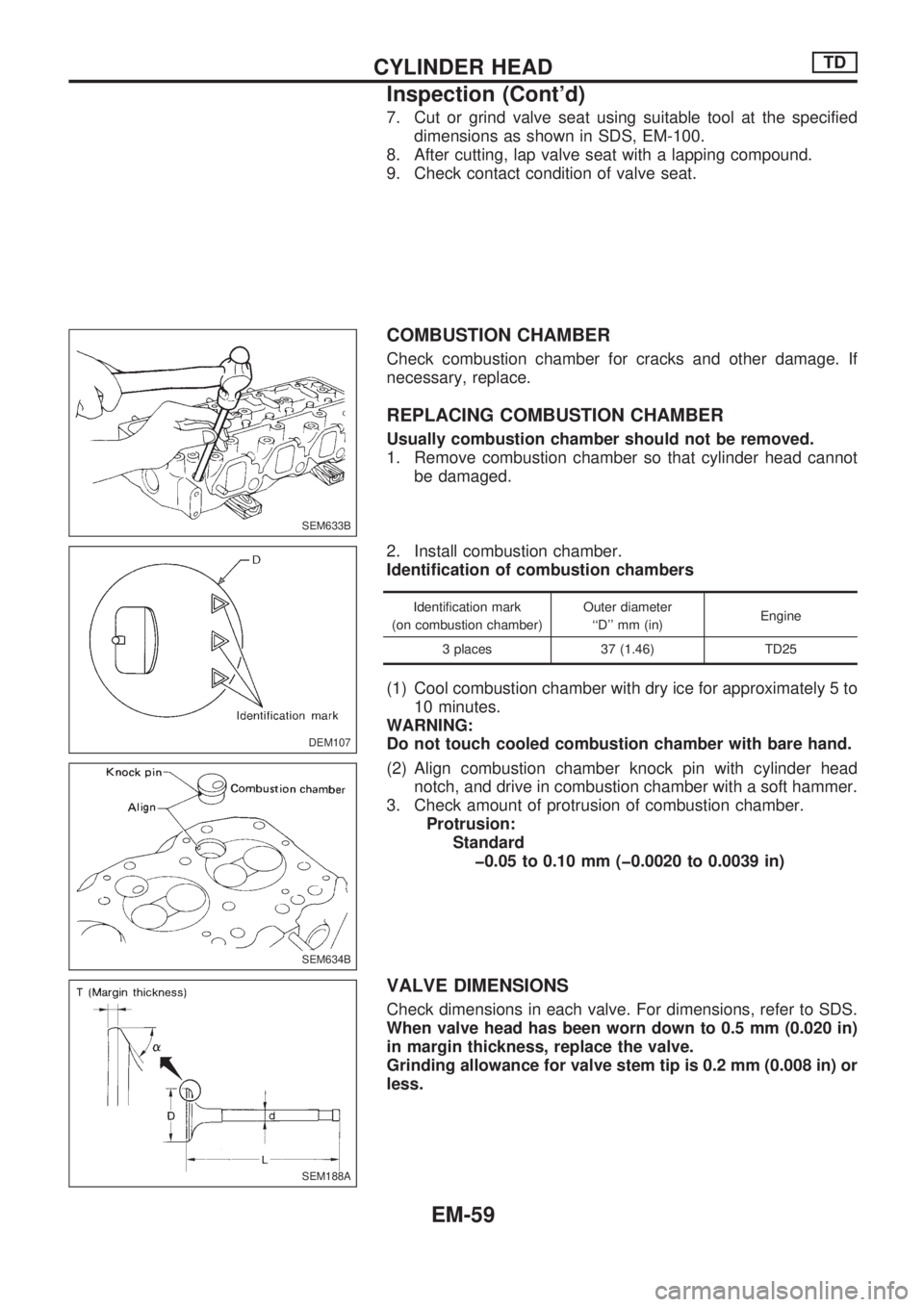

7. Cut or grind valve seat using suitable tool at the specified

dimensions as shown in SDS, EM-100.

8. After cutting, lap valve seat with a lapping compound.

9. Check contact condition of valve seat.

COMBUSTION CHAMBER

Check combustion chamber for cracks and other damage. If

necessary, replace.

REPLACING COMBUSTION CHAMBER

Usually combustion chamber should not be removed.

1. Remove combustion chamber so that cylinder head cannot

be damaged.

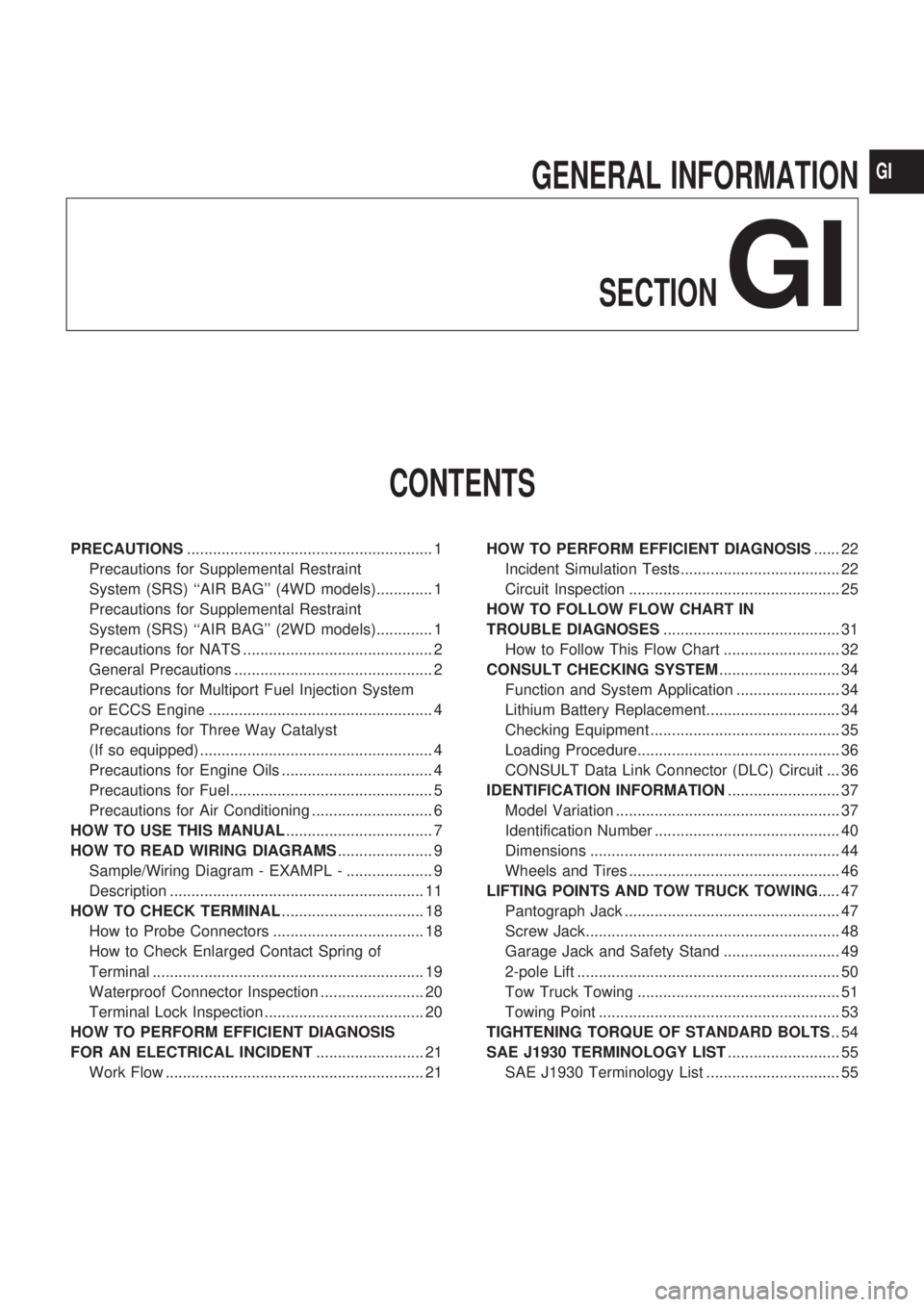

2. Install combustion chamber.

Identification of combustion chambers

Identification mark

(on combustion chamber)Outer diameter

``D'' mm (in)Engine

3 places 37 (1.46) TD25

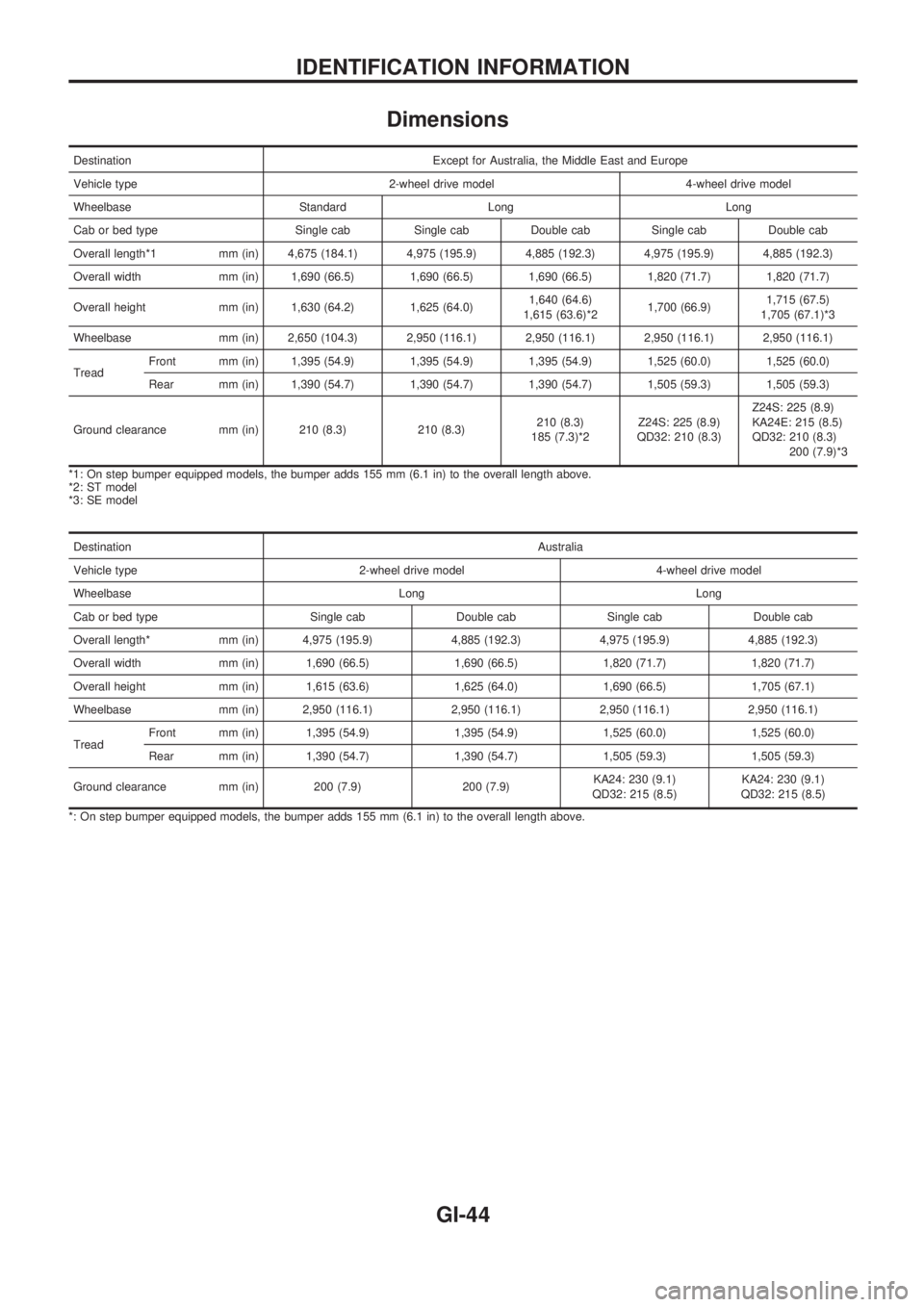

(1) Cool combustion chamber with dry ice for approximately 5 to

10 minutes.

WARNING:

Do not touch cooled combustion chamber with bare hand.

(2) Align combustion chamber knock pin with cylinder head

notch, and drive in combustion chamber with a soft hammer.

3. Check amount of protrusion of combustion chamber.

Protrusion:

Standard

þ0.05 to 0.10 mm (þ0.0020 to 0.0039 in)

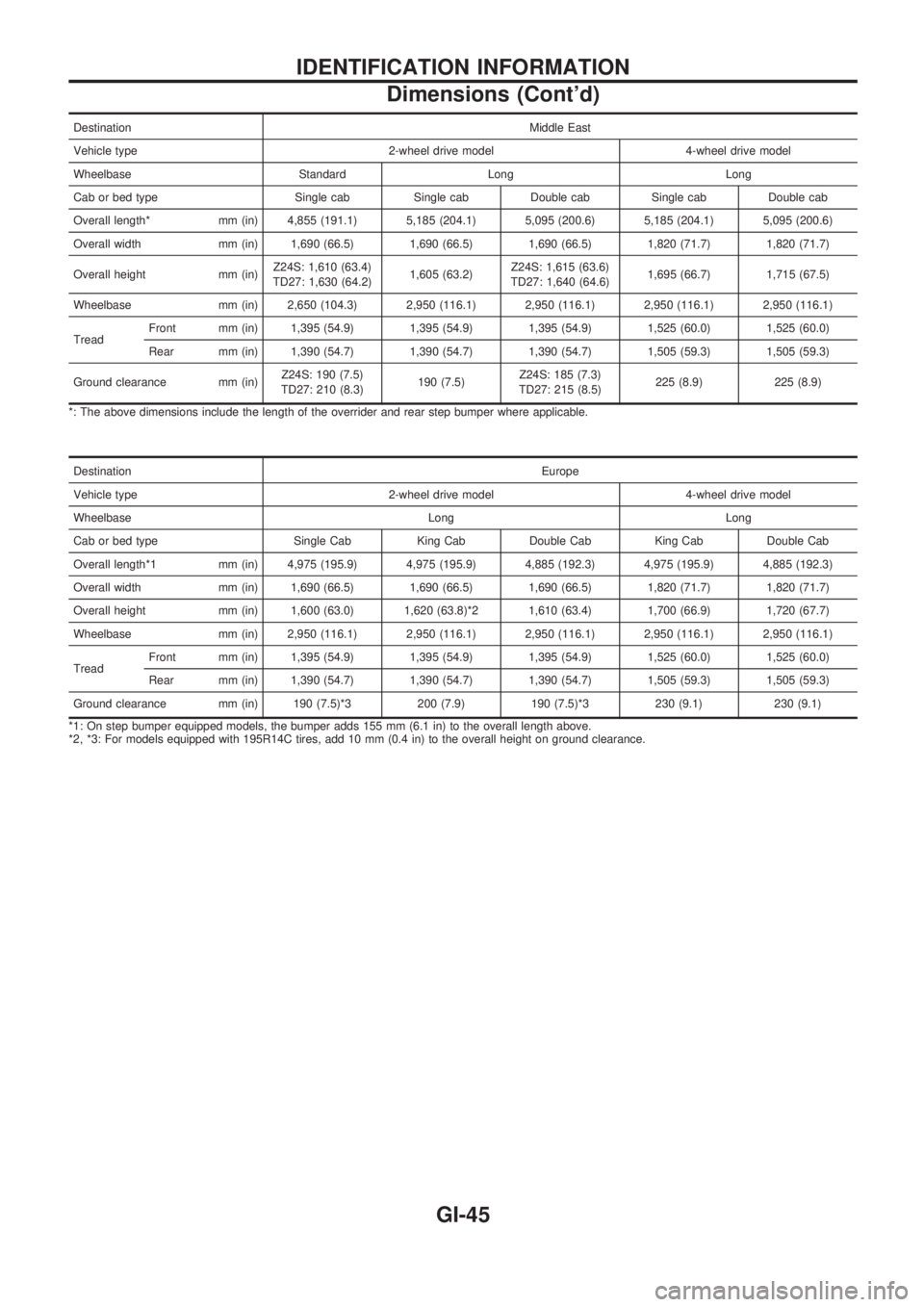

VALVE DIMENSIONS

Check dimensions in each valve. For dimensions, refer to SDS.

When valve head has been worn down to 0.5 mm (0.020 in)

in margin thickness, replace the valve.

Grinding allowance for valve stem tip is 0.2 mm (0.008 in) or

less.

SEM633B

DEM107

.

SEM634B

SEM188A

CYLINDER HEADTD

Inspection (Cont'd)

EM-59

Page 804 of 1659

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS......................................................... 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (4WD models)............. 1

Precautions for Supplemental Restraint

System (SRS) ``AIR BAG'' (2WD models)............. 1

Precautions for NATS ............................................ 2

General Precautions .............................................. 2

Precautions for Multiport Fuel Injection System

or ECCS Engine .................................................... 4

Precautions for Three Way Catalyst

(If so equipped) ...................................................... 4

Precautions for Engine Oils ................................... 4

Precautions for Fuel............................................... 5

Precautions for Air Conditioning ............................ 6

HOW TO USE THIS MANUAL.................................. 7

HOW TO READ WIRING DIAGRAMS...................... 9

Sample/Wiring Diagram - EXAMPL - .................... 9

Description ........................................................... 11

HOW TO CHECK TERMINAL................................. 18

How to Probe Connectors ................................... 18

How to Check Enlarged Contact Spring of

Terminal ............................................................... 19

Waterproof Connector Inspection ........................ 20

Terminal Lock Inspection ..................................... 20

HOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENT......................... 21

Work Flow ............................................................ 21HOW TO PERFORM EFFICIENT DIAGNOSIS...... 22

Incident Simulation Tests..................................... 22

Circuit Inspection ................................................. 25

HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES......................................... 31

How to Follow This Flow Chart ........................... 32

CONSULT CHECKING SYSTEM............................ 34

Function and System Application ........................ 34

Lithium Battery Replacement............................... 34

Checking Equipment ............................................ 35

Loading Procedure............................................... 36

CONSULT Data Link Connector (DLC) Circuit ... 36

IDENTIFICATION INFORMATION.......................... 37

Model Variation .................................................... 37

Identification Number ........................................... 40

Dimensions .......................................................... 44

Wheels and Tires ................................................. 46

LIFTING POINTS AND TOW TRUCK TOWING..... 47

Pantograph Jack .................................................. 47

Screw Jack........................................................... 48

Garage Jack and Safety Stand ........................... 49

2-pole Lift ............................................................. 50

Tow Truck Towing ............................................... 51

Towing Point ........................................................ 53

TIGHTENING TORQUE OF STANDARD BOLTS.. 54

SAE J1930 TERMINOLOGY LIST.......................... 55

SAE J1930 Terminology List ............................... 55

GI

Page 848 of 1659

Dimensions

Destination Except for Australia, the Middle East and Europe

Vehicle type 2-wheel drive model 4-wheel drive model

Wheelbase Standard Long Long

Cab or bed type Single cab Single cab Double cab Single cab Double cab

Overall length*1 mm (in) 4,675 (184.1) 4,975 (195.9) 4,885 (192.3) 4,975 (195.9) 4,885 (192.3)

Overall width mm (in) 1,690 (66.5) 1,690 (66.5) 1,690 (66.5) 1,820 (71.7) 1,820 (71.7)

Overall height mm (in) 1,630 (64.2) 1,625 (64.0)1,640 (64.6)

1,615 (63.6)*21,700 (66.9)1,715 (67.5)

1,705 (67.1)*3

Wheelbase mm (in) 2,650 (104.3) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1)

TreadFront mm (in) 1,395 (54.9) 1,395 (54.9) 1,395 (54.9) 1,525 (60.0) 1,525 (60.0)

Rear mm (in) 1,390 (54.7) 1,390 (54.7) 1,390 (54.7) 1,505 (59.3) 1,505 (59.3)

Ground clearance mm (in) 210 (8.3) 210 (8.3)210 (8.3)

185 (7.3)*2Z24S: 225 (8.9)

QD32: 210 (8.3)Z24S: 225 (8.9)

KA24E: 215 (8.5)

QD32: 210 (8.3)

200 (7.9)*3

*1: On step bumper equipped models, the bumper adds 155 mm (6.1 in) to the overall length above.

*2: ST model

*3: SE model

DestinationAustralia

Vehicle type 2-wheel drive model 4-wheel drive model

Wheelbase Long Long

Cab or bed type Single cab Double cab Single cab Double cab

Overall length* mm (in) 4,975 (195.9) 4,885 (192.3) 4,975 (195.9) 4,885 (192.3)

Overall width mm (in) 1,690 (66.5) 1,690 (66.5) 1,820 (71.7) 1,820 (71.7)

Overall height mm (in) 1,615 (63.6) 1,625 (64.0) 1,690 (66.5) 1,705 (67.1)

Wheelbase mm (in) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1)

TreadFront mm (in) 1,395 (54.9) 1,395 (54.9) 1,525 (60.0) 1,525 (60.0)

Rear mm (in) 1,390 (54.7) 1,390 (54.7) 1,505 (59.3) 1,505 (59.3)

Ground clearance mm (in) 200 (7.9) 200 (7.9)KA24: 230 (9.1)

QD32: 215 (8.5)KA24: 230 (9.1)

QD32: 215 (8.5)

*: On step bumper equipped models, the bumper adds 155 mm (6.1 in) to the overall length above.

IDENTIFICATION INFORMATION

GI-44

Page 849 of 1659

DestinationMiddle East

Vehicle type 2-wheel drive model 4-wheel drive model

Wheelbase Standard Long Long

Cab or bed type Single cab Single cab Double cab Single cab Double cab

Overall length* mm (in) 4,855 (191.1) 5,185 (204.1) 5,095 (200.6) 5,185 (204.1) 5,095 (200.6)

Overall width mm (in) 1,690 (66.5) 1,690 (66.5) 1,690 (66.5) 1,820 (71.7) 1,820 (71.7)

Overall height mm (in)Z24S: 1,610 (63.4)

TD27: 1,630 (64.2)1,605 (63.2)Z24S: 1,615 (63.6)

TD27: 1,640 (64.6)1,695 (66.7) 1,715 (67.5)

Wheelbase mm (in) 2,650 (104.3) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1)

TreadFront mm (in) 1,395 (54.9) 1,395 (54.9) 1,395 (54.9) 1,525 (60.0) 1,525 (60.0)

Rear mm (in) 1,390 (54.7) 1,390 (54.7) 1,390 (54.7) 1,505 (59.3) 1,505 (59.3)

Ground clearance mm (in)Z24S: 190 (7.5)

TD27: 210 (8.3)190 (7.5)Z24S: 185 (7.3)

TD27: 215 (8.5)225 (8.9) 225 (8.9)

*: The above dimensions include the length of the overrider and rear step bumper where applicable.

DestinationEurope

Vehicle type 2-wheel drive model 4-wheel drive model

Wheelbase Long Long

Cab or bed type Single Cab King Cab Double Cab King Cab Double Cab

Overall length*1 mm (in) 4,975 (195.9) 4,975 (195.9) 4,885 (192.3) 4,975 (195.9) 4,885 (192.3)

Overall width mm (in) 1,690 (66.5) 1,690 (66.5) 1,690 (66.5) 1,820 (71.7) 1,820 (71.7)

Overall height mm (in) 1,600 (63.0) 1,620 (63.8)*2 1,610 (63.4) 1,700 (66.9) 1,720 (67.7)

Wheelbase mm (in) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1) 2,950 (116.1)

TreadFront mm (in) 1,395 (54.9) 1,395 (54.9) 1,395 (54.9) 1,525 (60.0) 1,525 (60.0)

Rear mm (in) 1,390 (54.7) 1,390 (54.7) 1,390 (54.7) 1,505 (59.3) 1,505 (59.3)

Ground clearance mm (in) 190 (7.5)*3 200 (7.9) 190 (7.5)*3 230 (9.1) 230 (9.1)

*1: On step bumper equipped models, the bumper adds 155 mm (6.1 in) to the overall length above.

*2, *3: For models equipped with 195R14C tires, add 10 mm (0.4 in) to the overall height on ground clearance.

IDENTIFICATION INFORMATION

Dimensions (Cont'd)

GI-45

Page 865 of 1659

Combination lamp, front, removal and

installation................................................... BT-5

Combination lamp, rear, removal and

installation................................................. BT-24

Combination meter removal and instal-

lation - See Instrument panel ................... BT-12

Combination switch ...................................... EL-42

Combustion chamber replacement ............. EM-59

Compression pressure (KA24 engine) ........ EM-10

Compression pressure (TD25 engine) ........ EM-51

Compressor clutch removal and

installation ................................................ HA-60

Compressor precaution ................................. HA-6

Compressor special service tool ................... HA-6

Connecting rod (KA24 engine).................... EM-40

Connecting rod (TD25 engine).................... EM-77

Connecting rod bearing clearance

(KA24 engine).......................................... EM-44

Connecting rod bearing clearance

(TD25 engine).......................................... EM-77

Connecting rod bushing clearance

(KA24 engine).......................................... EM-45

Connecting rod bushing clearance

(TD25 engine).......................................... EM-78

Connector inspection .................................... GI-18

Control lever (M/T) ...................................... MT-17

Control lever (Transfer) .................................. TF-7

Control units (terminal arrangement) ..........Foldout

Coolant mixture ratio ................................... MA-14

Coolant replacement (KA24 engine) ........... MA-16

Coolant replacement (TD25 engine) ........... MA-25

Cooling circuit (engine)

(KA24 engine) ............................................ LC-6

Cooling circuit (engine)

(TD25 engine) .......................................... LC-19

Cooling fan (KA24 engine)........................... LC-10

Cooling fan (TD25 engine) .................... LC-21, 26

Cooling fan control system .......................... LC-25

Counter gear (M/T) (FS5R30A)................... MT-36

Counter gear (M/T) (FS5W71C).................. MT-15

Counter gear (Transfer) ................................. TF-9

Coupling sleeve (M/T) (FS5R30A) .............. MT-36

Coupling sleeve (M/T) (FS5W71C) ............. MT-15

Crank angle sensor built into distribu-

tor - See Camshaft position sensor ......... EC-82

Crankcase emission control system -

See Positive crankcase ventilation .......... EC-21

Crankcase ventilation system - See

Positive crankcase ventilation.................. EC-21

Crankshaft (KA24 engine) ........................... EM-42

Crankshaft (TD25 engine) ........................... EM-79

Crankshaft position sensor (POS) ............... EC-82

Crankshaft position sensor (REF) ............... EC-82

Cylinder block (KA24 engine) ..................... EM-38

Cylinder block (TD25 engine) ..................... EM-74

Cylinder block boring................................... EM-41

Cylinder head (KA24 engine) ...................... EM-24

Cylinder head (TD25 engine) ...................... EM-53

Cylinder head bolt tightening ...................... EM-64

Cylinder head gasket selection ................... EM-63Cylinder liner ............................................... EM-74

D

D/LOCK - Wiring diagram ...........................EL-167

DEF - Wiring diagram ................................ EL-135

DTRL - Wiring diagram ................................ EL-54

Data link connector for Consult ................... EC-45

Daytime light system .................................... EL-51

Defroster door control rod adjustment......... HA-45

Diagnosis sensor unit .................................. RS-10

Diagnostic trouble code (DTC) for

ECCS OBD system.................................. EC-36

Differential carrier assembly (C200) ............ PD-51

Differential carrier assembly (H233B) ......... PD-72

Differential carrier assembly (R180A) ......... PD-27

Differential carrier disassembly

(C200) ...................................................... PD-34

Differential carrier disassembly

(H233B) .................................................... PD-57

Differential gear oil replacement ................. MA-34

Dim-dip lamp system.................................... EL-58

Dimensions ................................................... GI-44

Distributor ignition (DI) system .................... EC-17

Dome light - See Interior lamp ..................... EL-85

Door glass .................................................... BT-10

Door lock ...................................................... BT-10

Door mirror ................................................... BT-39

Door trim ...................................................... BT-18

Door, front .................................................... BT-10

Door, rear ..................................................... BT-11

Drive belt inspection (KA24 engine) ........... MA-15

Drive belt inspection (TD25 engine) ........... MA-23

Drive chain (Transfer) .................................... TF-9

Drive pinion diff. inspection (C200) ............. PD-38

Drive pinion diff. inspection (H233B) ........... PD-60

Drive pinion height (C200)........................... PD-47

Drive pinion height (H233B) ........................ PD-67

Drive pinion height (R180A) ........................ PD-24

Drive shaft (front) ......................................... FA-21

E

ECCS basic inspection .................................EC-58

ECCS circuit diagram .................................... EC-8

ECCS component parts location ................. EC-10

ECCS fail-safe chart .................................... EC-61

ECCS on board diagnostic system ............. EC-36

ECCS relay .................................................. EC-75

ECCS symptom matrix chart ....................... EC-62

ECCS system diagram .................................. EC-9

ECTS - Wiring diagram ............................... EC-96

EGR control (EGRC) - solenoid valve....... EC-218

EGR control valve...................................... EC-218

EGRC - Wiring diagram............................. EC-213

EVAP canister.............................................. EC-19

EVAP canister purge control solenoid

valve ....................................................... EC-140

ALPHABETICAL INDEX

IDX-3

Page 867 of 1659

HLC - Wiring diagram ................................ EL-130

HORN - Wiring diagram ............................. EL-132

H/SEAT - Wiring diagram........................... EL-152

Harness connector ......................................... EL-2

Harness connector inspection ...................... GI-18

Harness layout ........................................... EL-220

Hazard warning lamp ................................... EL-74

Headlamp ..................................................... EL-44

Headlamp aiming control ............................. EL-63

Headlamp leveler - See Headlamp

aiming control ........................................... EL-63

Headlamp washer ...................................... EL-130

Heated oxygen sensor (HO2S) ................. EC-123

Heated oxygen sensor heater ................... EC-127

Heated oxygen sensor inspection ............... MA-22

Heated seat .................................................. BT-32

Heated seat ................................................ EL-152

Height (Dimensions) ..................................... GI-44

Hood ............................................................... BT-5

Horn ............................................................ EL-132

How to erase DTC for ECCS OBD

system ...................................................... EC-36

I

IACV-AAC valve .................................EC-131, 135

IACV-FICD solenoid valve

(KA24 engine) ........................................ EC-168

IACV-FICD solenoid valve

(TD25 engine) ........................................ EC-231

IATS - Wiring diagram ............................... EC-110

IGN/SG - Wiring diagram .......................... EC-101

ILL - Wiring diagram..................................... EL-81

INJECT - Wiring diagram .......................... EC-144

INT/L - Wiring diagram ................................. EL-85

Identification plate ......................................... GI-42

Idle mixture ratio .......................................... EC-25

Idle speed .................................................... EC-25

Idle speed inspection .................................. MA-30

Ignition coil ................................................. EC-105

Ignition timing............................................... EC-25

Ignition wire inspection ................................ MA-21

Illumination ................................................... EL-81

Injection nozzle inspection .......................... MA-29

Injection nozzle .......................................... EC-186

Injector ............................................... EC-144, 148

Injector removal and installation .................. EC-23

Instrument panel .......................................... BT-12

Intake air temperature sensor ................... EC-109

Intake door control linkage

adjustment................................................ HA-47

Intake manifold .............................................. EM-9

Interior lamp ................................................. EL-85

Interior .......................................................... BT-15

J

Jacking points ................................................GI-47Journal bearing assembly

(propeller shaft) ........................................ PD-11

Journal bearing disassembly

(propeller shaft) ........................................ PD-10

Jump seat..................................................... BT-34

K

Keyless entry system - See Multi-remote

control system .............................................EL-173

Knuckle spindle ............................................ FA-18

L

LSV (Load sensing valve)...............................BR-7

Leaf spring (rear) ......................................... RA-13

Length (Dimensions) ..................................... GI-44

License lamp ................................................ EL-66

Lifting points .................................................. GI-47

Limited slip diff. adjustment (C200) ............. PD-41

Limited slip diff. adjustment (H233B) .......... PD-63

Limited slip diff. assembly (C200) ............... PD-43

Limited slip diff. assembly (H233B) ............. PD-64

Limited slip diff. disassembly (C200)........... PD-39

Limited slip diff. disassembly (H233B) ........ PD-61

Limited slip diff. inspection (C200) .............. PD-40

Limited slip diff. inspection (H233B) ............ PD-62

Liquid gasket application ............................... EM-1

Location of electrical units.......................... EL-217

Lock, door .................................................... BT-10

Lubricant (R134a) A/C ................................. HA-50

Lubricants .................................................... MA-12

Lubrication circuit (engine)

(KA24 engine) ............................................ LC-3

Lubrication circuit (engine)

(TD25 engine) .......................................... LC-12

Lubrication-locks, hinges and hood

latches ..................................................... MA-39

M

M/T major overhaul (FS5R30A) ...................MT-35

M/T major overhaul (FS5W71C) ................. MT-14

M/T removal and installation ....................... MT-11

MAFS - Wiring diagram ............................... EC-91

MAIN - Wiring diagram ................................ EC-76

METER - Wiring diagram ............................. EL-90

MIL & Data link connectors ....................... EC-173

MIRROR - Wiring diagram ......................... EL-150

MULTI - Wiring diagram ............................. EL-175

Main drive gear (M/T) (FS5R30A)............... MT-36

Main drive gear (M/T) (FS5W71C).............. MT-15

Main gear (Transfer) ...................................... TF-9

Mainshaft (M/T) (FS5R30A) ........................ MT-36

Mainshaft (M/T) (FS5W71C) ....................... MT-15

Mainshaft (Transfer) ....................................... TF-9

Maintenance (engine) (KA24 engine) ......... MA-15

ALPHABETICAL INDEX

IDX-5