display NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 60 of 1659

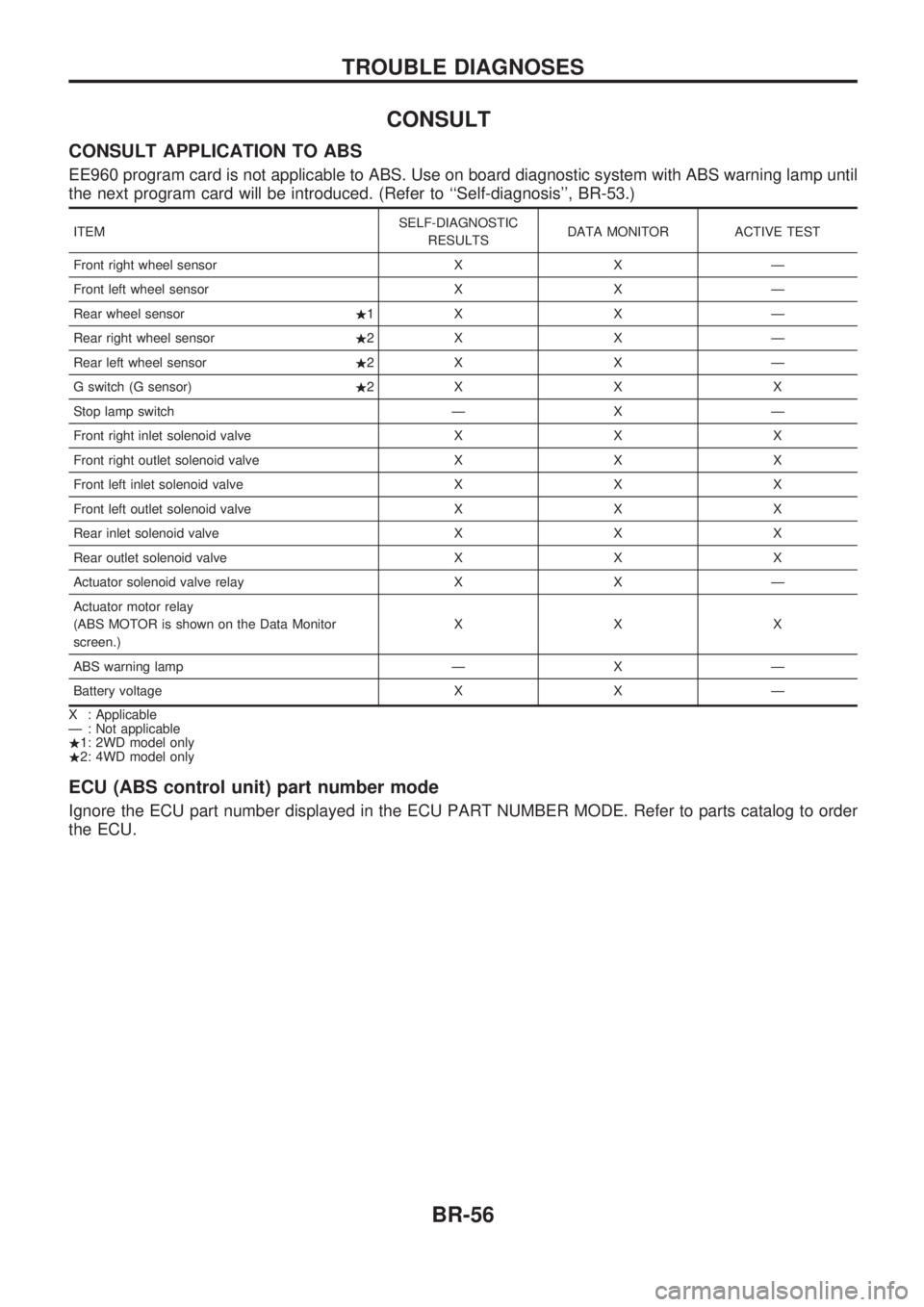

CONSULT

CONSULT APPLICATION TO ABS

EE960 program card is not applicable to ABS. Use on board diagnostic system with ABS warning lamp until

the next program card will be introduced. (Refer to ``Self-diagnosis'', BR-53.)

ITEMSELF-DIAGNOSTIC

RESULTSDATA MONITOR ACTIVE TEST

Front right wheel sensor X X Ð

Front left wheel sensor X X Ð

Rear wheel sensor.1X X Ð

Rear right wheel sensor.2X X Ð

Rear left wheel sensor.2X X Ð

G switch (G sensor).2XXX

Stop lamp switch Ð X Ð

Front right inlet solenoid valve X X X

Front right outlet solenoid valve X X X

Front left inlet solenoid valve X X X

Front left outlet solenoid valve X X X

Rear inlet solenoid valve X X X

Rear outlet solenoid valve X X X

Actuator solenoid valve relay X X Ð

Actuator motor relay

(ABS MOTOR is shown on the Data Monitor

screen.)XXX

ABS warning lamp Ð X Ð

Battery voltage X X Ð

X : Applicable

Ð : Not applicable

.1: 2WD model only

.2: 4WD model only

ECU (ABS control unit) part number mode

Ignore the ECU part number displayed in the ECU PART NUMBER MODE. Refer to parts catalog to order

the ECU.

TROUBLE DIAGNOSES

BR-56

Page 158 of 1659

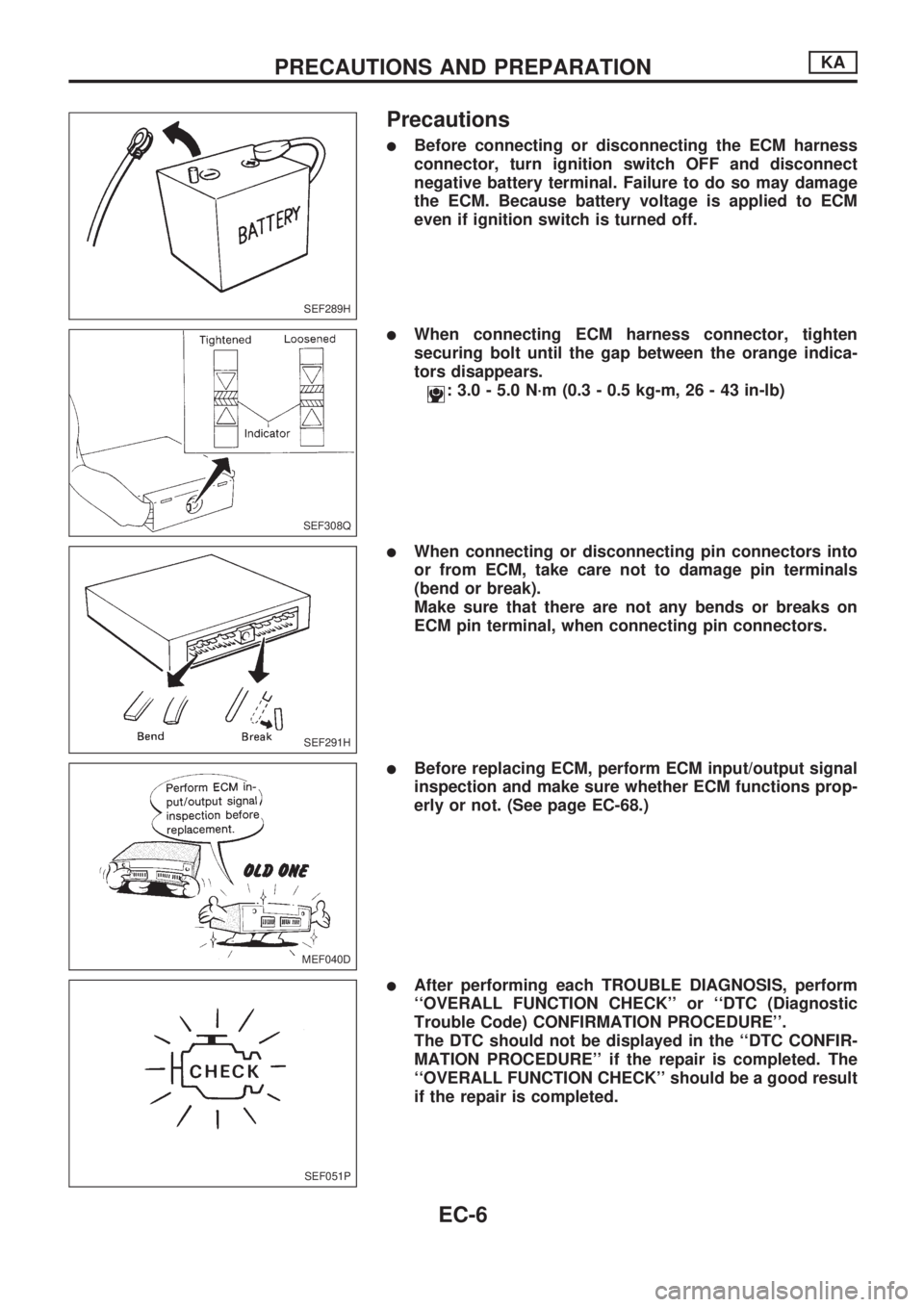

Precautions

lBefore connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect

negative battery terminal. Failure to do so may damage

the ECM. Because battery voltage is applied to ECM

even if ignition switch is turned off.

lWhen connecting ECM harness connector, tighten

securing bolt until the gap between the orange indica-

tors disappears.

: 3.0 - 5.0 N´m (0.3 - 0.5 kg-m, 26 - 43 in-lb)

lWhen connecting or disconnecting pin connectors into

or from ECM, take care not to damage pin terminals

(bend or break).

Make sure that there are not any bends or breaks on

ECM pin terminal, when connecting pin connectors.

lBefore replacing ECM, perform ECM input/output signal

inspection and make sure whether ECM functions prop-

erly or not. (See page EC-68.)

lAfter performing each TROUBLE DIAGNOSIS, perform

``OVERALL FUNCTION CHECK'' or ``DTC (Diagnostic

Trouble Code) CONFIRMATION PROCEDURE''.

The DTC should not be displayed in the ``DTC CONFIR-

MATION PROCEDURE'' if the repair is completed. The

``OVERALL FUNCTION CHECK'' should be a good result

if the repair is completed.

SEF289H

SEF308Q

SEF291H

MEF040D

SEF051P

PRECAUTIONS AND PREPARATIONKA

EC-6

Page 188 of 1659

Introduction

The ECM (ECCS control module) has an on board diagnostic system, which detects malfunctions related to

engine sensors or actuators. Self-diagnosis items are listed in ``DIAGNOSTIC TROUBLE CODE INDEX'',

EC-1.

The malfunction indicator lamp (MIL) on the instrument panel lights up when a malfunction is detected, or

when the ECM enters fail-safe mode (Refer to EC-61).

Diagnostic Trouble Code (DTC)

HOW TO CONFIRM MALFUNCTION ITEMS

Malfunction items can be confirmed by the following methods.

1. The number of blinks of the malfunction indicator lamp in the Diagnostic Test Mode II (Self- Diag-

nostic Results) indicates the DTC. Examples: 11, 21 etc.

2. CONSULT displays the malfunctioning component or system in ``SELF DIAGNOSTIC RESULTS''

mode.

lOutput of a DTC indicates a malfunction. However, Mode II does not indicate whether the mal-

function is still occurring or has occurred in the past and has returned to normal.

CONSULT can identify malfunction status as shown below. Therefore, using CONSULT (if avail-

able) is recommended.

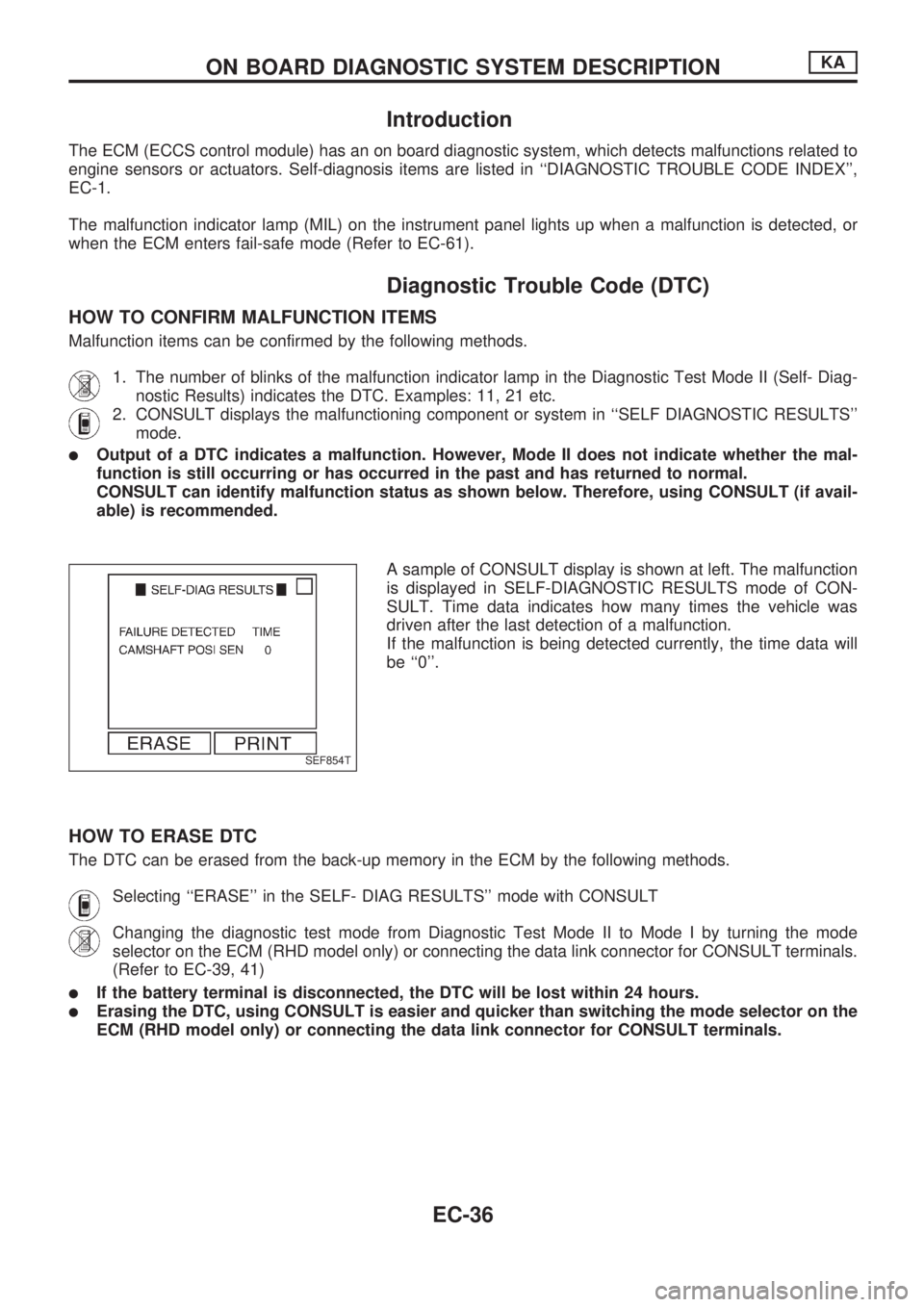

A sample of CONSULT display is shown at left. The malfunction

is displayed in SELF-DIAGNOSTIC RESULTS mode of CON-

SULT. Time data indicates how many times the vehicle was

driven after the last detection of a malfunction.

If the malfunction is being detected currently, the time data will

be ``0''.

HOW TO ERASE DTC

The DTC can be erased from the back-up memory in the ECM by the following methods.

Selecting ``ERASE'' in the SELF- DIAG RESULTS'' mode with CONSULT

Changing the diagnostic test mode from Diagnostic Test Mode II to Mode I by turning the mode

selector on the ECM (RHD model only) or connecting the data link connector for CONSULT terminals.

(Refer to EC-39, 41)

lIf the battery terminal is disconnected, the DTC will be lost within 24 hours.

lErasing the DTC, using CONSULT is easier and quicker than switching the mode selector on the

ECM (RHD model only) or connecting the data link connector for CONSULT terminals.

SEF854T

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

EC-36

Page 195 of 1659

DIAGNOSTIC TEST MODE IÐBULB CHECK

In this mode, the MALFUNCTION INDICATOR LAMP on the instrument panel should stay ON. If it remains

OFF, check the bulb. (See the WARNING LAMPS AND CHIME in the EL section. Or see EC-173, 174.)

DIAGNOSTIC TEST MODE IÐMALFUNCTION WARNING

MALFUNCTION

INDICATOR LAMPCondition

ON When the malfunction is detected (Refer to EC-1.) or the ECM's CPU is malfunctioning.

OFF No malfunction

lThese Diagnostic Trouble Code Numbers are clarified in Diagnostic Test Mode II (SELF-DIAGNOSTIC

RESULTS).

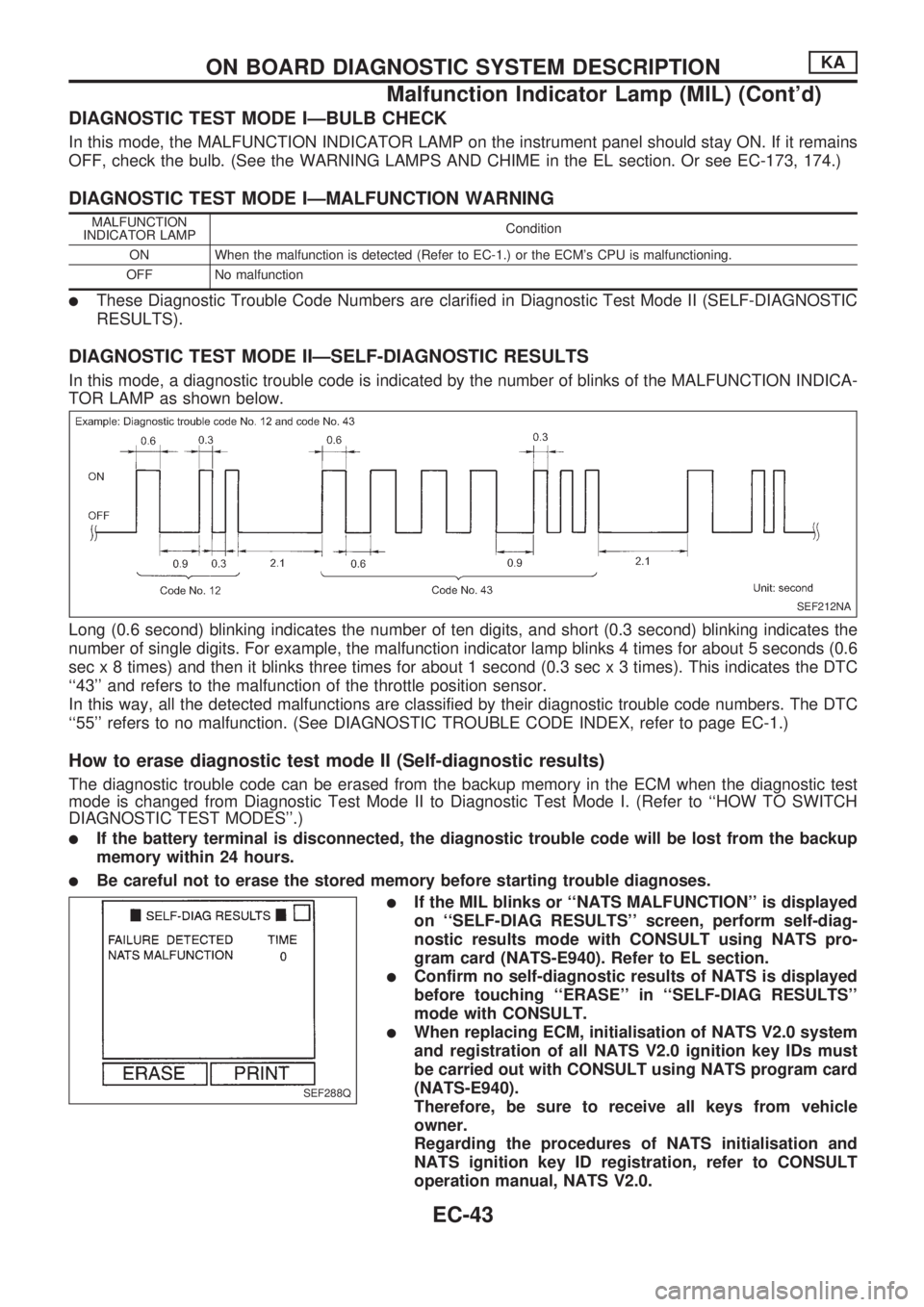

DIAGNOSTIC TEST MODE IIÐSELF-DIAGNOSTIC RESULTS

In this mode, a diagnostic trouble code is indicated by the number of blinks of the MALFUNCTION INDICA-

TOR LAMP as shown below.

Long (0.6 second) blinking indicates the number of ten digits, and short (0.3 second) blinking indicates the

number of single digits. For example, the malfunction indicator lamp blinks 4 times for about 5 seconds (0.6

sec x 8 times) and then it blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC

``43'' and refers to the malfunction of the throttle position sensor.

In this way, all the detected malfunctions are classified by their diagnostic trouble code numbers. The DTC

``55'' refers to no malfunction. (See DIAGNOSTIC TROUBLE CODE INDEX, refer to page EC-1.)

How to erase diagnostic test mode II (Self-diagnostic results)

The diagnostic trouble code can be erased from the backup memory in the ECM when the diagnostic test

mode is changed from Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to ``HOW TO SWITCH

DIAGNOSTIC TEST MODES''.)

lIf the battery terminal is disconnected, the diagnostic trouble code will be lost from the backup

memory within 24 hours.

lBe careful not to erase the stored memory before starting trouble diagnoses.

lIf the MIL blinks or ``NATS MALFUNCTION'' is displayed

on ``SELF-DIAG RESULTS'' screen, perform self-diag-

nostic results mode with CONSULT using NATS pro-

gram card (NATS-E940). Refer to EL section.

lConfirm no self-diagnostic results of NATS is displayed

before touching ``ERASE'' in ``SELF-DIAG RESULTS''

mode with CONSULT.

lWhen replacing ECM, initialisation of NATS V2.0 system

and registration of all NATS V2.0 ignition key IDs must

be carried out with CONSULT using NATS program card

(NATS-E940).

Therefore, be sure to receive all keys from vehicle

owner.

Regarding the procedures of NATS initialisation and

NATS ignition key ID registration, refer to CONSULT

operation manual, NATS V2.0.

SEF212NA

SEF288Q

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-43

Page 196 of 1659

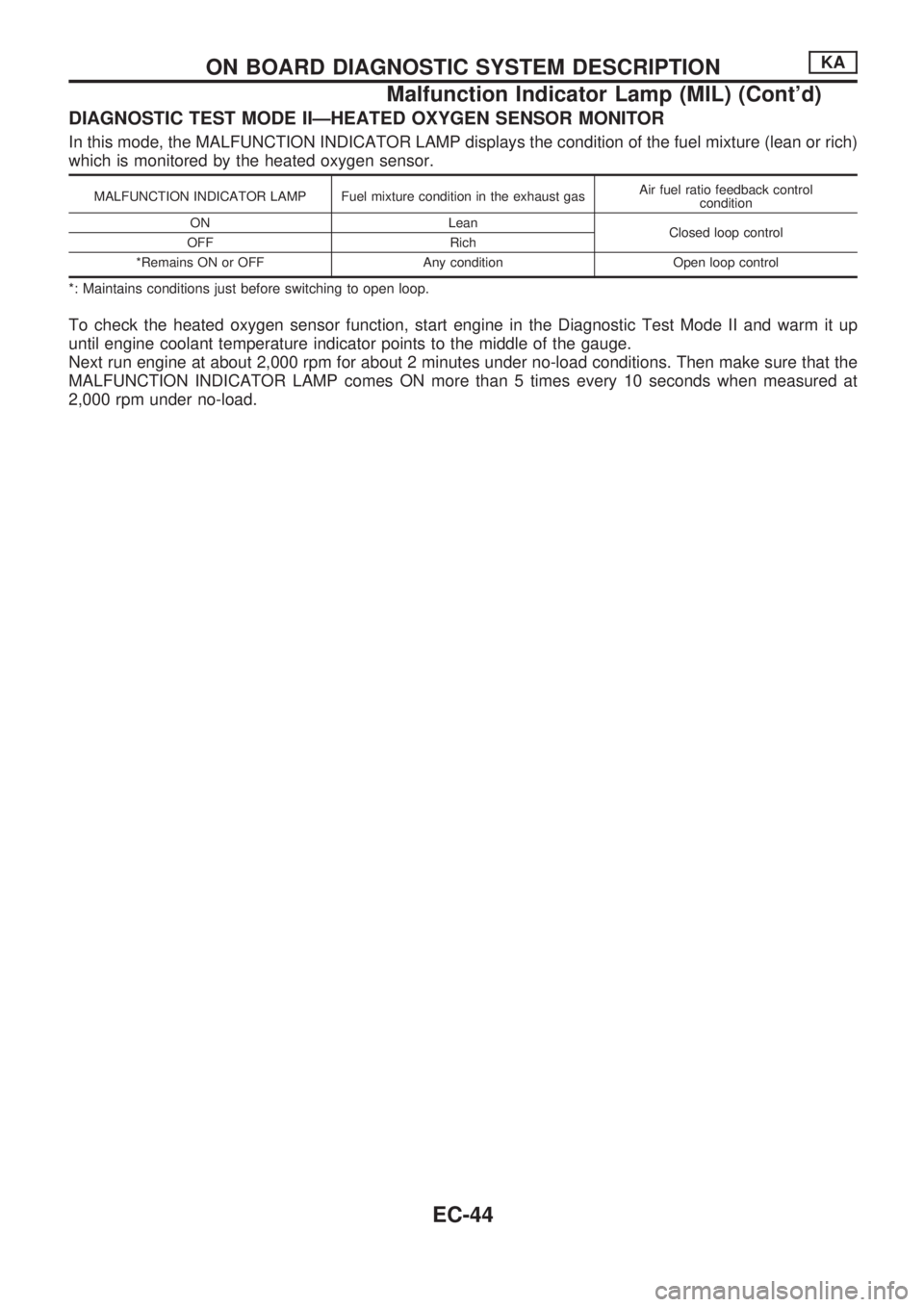

DIAGNOSTIC TEST MODE IIÐHEATED OXYGEN SENSOR MONITOR

In this mode, the MALFUNCTION INDICATOR LAMP displays the condition of the fuel mixture (lean or rich)

which is monitored by the heated oxygen sensor.

MALFUNCTION INDICATOR LAMP Fuel mixture condition in the exhaust gasAir fuel ratio feedback control

condition

ON Lean

Closed loop control

OFF Rich

*Remains ON or OFF Any condition Open loop control

*: Maintains conditions just before switching to open loop.

To check the heated oxygen sensor function, start engine in the Diagnostic Test Mode II and warm it up

until engine coolant temperature indicator points to the middle of the gauge.

Next run engine at about 2,000 rpm for about 2 minutes under no-load conditions. Then make sure that the

MALFUNCTION INDICATOR LAMP comes ON more than 5 times every 10 seconds when measured at

2,000 rpm under no-load.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

Malfunction Indicator Lamp (MIL) (Cont'd)

EC-44

Page 200 of 1659

![NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr NISSAN PICK-UP 1998 Repair Manual SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX, EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescr](/img/5/57374/w960_57374-199.png)

SELF-DIAGNOSTIC MODE

Regarding items detected in ``SELF-DIAG RESULTS'' mode, refer to ``DIAGNOSTIC TROUBLE CODE

INDEX'', EC-1.

DATA MONITOR MODE

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

CMPSRPM

(POS) [rpm]

jj

lIndicates the engine speed computed

from the POS signal (1É signal) of the

camshaft position sensor.

MAS AIR/FL SE [V]

jjlThe signal voltage of the mass air flow

sensor is displayed.lWhen the engine is stopped, a certain

value is indicated.

COOLAN TEMP/S

[ÉC] or [ÉF]

jj

lThe engine coolant temperature (deter-

mined by the signal voltage of the engine

coolant temperature sensor) is displayed.lWhen the engine coolant temperature

sensor is open or short-circuited, ECM

enters fail-safe mode. The engine coolant

temperature determined by the ECM is

displayed.

O2 SEN [V]

jjlThe signal voltage of the heated oxygen

sensor is displayed.lLHD models only

M/R F/C MNT

[RICH/LEAN]

jj

lDisplay of heated oxygen sensor signal

during air-fuel ratio feedback control:

RICH ... means the mixture became

``rich'', and control is being affected

toward a leaner mixture.

LEAN ... means the mixture became

``lean'', and control is being affected

toward a rich mixture.lAfter turning ON the ignition switch,

``RICH'' is displayed until air-fuel mixture

ratio feedback control begins.

lWhen the air-fuel ratio feedback is

clamped, the value just before the clamp-

ing is displayed continuously.

lLHD models only

VHCL SPEED SE

[km/h] or [mph]

jjlThe vehicle speed computed from the

vehicle speed sensor signal is displayed.

BATTERY VOLT [V]

jjlThe power supply voltage of ECM is dis-

played.

THRTL POS SEN [V]

jjlThe throttle position sensor signal volt-

age is displayed.

INT/A TEMP SE

[ÉC] or [ÉF]

j

lThe intake air temperature (determined

by the signal voltage of the intake air

temperature sensor) is indicated.

START SIGNAL

[ON/OFF]

jjlIndicates [ON/OFF] condition from the

starter signal.lAfter starting the engine, [OFF] is

displayed regardless of the starter signal.

CLSD THL/POSI

[ON/OFF]

jj

lIndicates [ON/OFF] condition from the

throttle position sensor signal.

AIR COND SIG

[ON/OFF]

jj

lIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]

jj

lIndicates [ON/OFF] condition from the

park/neutral position switch signal.

PW/ST SIGNAL

[ON/OFF]

jj

l[ON/OFF] condition of the power steering

oil pressure switch determined by the

power steering oil pressure signal is indi-

cated.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-48

Page 201 of 1659

![NISSAN PICK-UP 1998 Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

INJ PULSE [msec]

j

lIndicates the actual fuel injection pulse

width compensated by ECM according to

the input signals.lWhen the en NISSAN PICK-UP 1998 Repair Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

INJ PULSE [msec]

j

lIndicates the actual fuel injection pulse

width compensated by ECM according to

the input signals.lWhen the en](/img/5/57374/w960_57374-200.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

INJ PULSE [msec]

j

lIndicates the actual fuel injection pulse

width compensated by ECM according to

the input signals.lWhen the engine is stopped, a certain

computed value is indicated.

IGN TIMING [BTDC]

j

lIndicates the ignition timing computed by

ECM according to the input signals.lWhen the engine is stopped, a certain

value is indicated.

IACV-AAC/V [%]

j

lIndicates the idle air control valve (AAC

valve) control value computed by ECM

according to the input signals.

A/F ALPHA [%]

j

lThe mean value of the air-fuel ratio feed-

back correction factor per cycle is indi-

cated.lWhen the engine is stopped, a certain

value is indicated.

lThis data also includes the data for the

air-fuel ratio learning control.

AIR COND RLY

[ON/OFF]

j

lThe air conditioner relay control condition

(determined by ECM according to the

input signal) is indicated.

FUEL PUMP RLY

[ON/OFF]

j

lIndicates the fuel pump relay control con-

dition determined by ECM according to

the input signals.

SWRL CONT S/V

[ON/OFF]

j

lThe control condition of the swirl control

valve control solenoid valve (determined

by the ECM according to the input signal)

is indicated.

ON ... Swirl control valve is closed

OFF ... Swirl control valve is open

EGRC SOL/V

(EVAP canister purge

control solenoid

valve) [ON/OFF]

j

lThe control condition of the EVAP canis-

ter purge control solenoid valve (deter-

mined by ECM according to the input

signal) is indicated.

ON ... EVAP canister purge control is not

operating

OFF ... EVAP canister purge control is

operational.

VOLTAGE

[V]

lVoltage measured by the voltage probe.

PULSE

[msec] or [Hz] or [%]

lPulse width, frequency or duty cycle

measured by the pulse probe.lOnly ``#'' is displayed if item is unable to

be measured.

lFigures with ``#''s are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-49

Page 203 of 1659

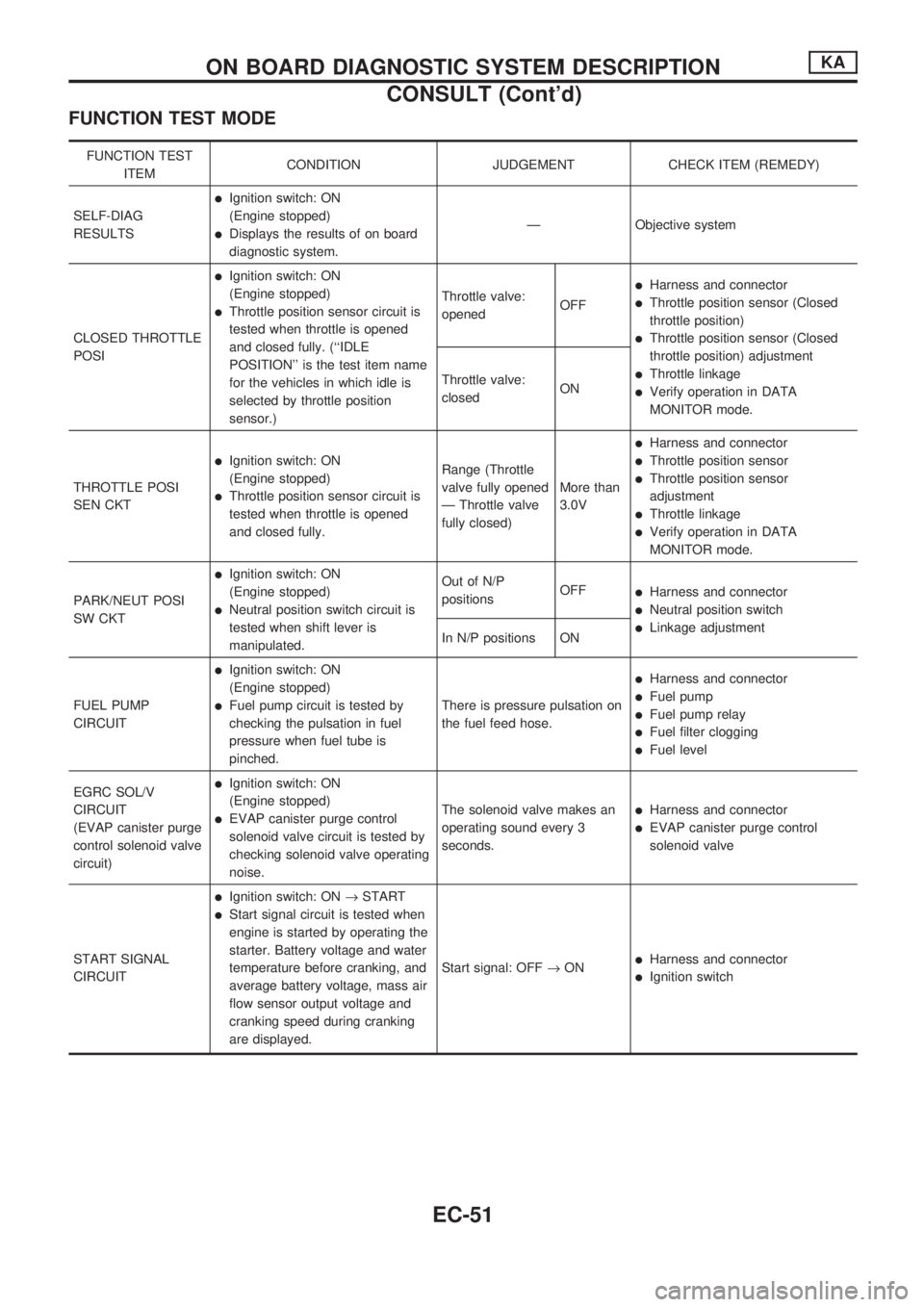

FUNCTION TEST MODE

FUNCTION TEST

ITEMCONDITION JUDGEMENT CHECK ITEM (REMEDY)

SELF-DIAG

RESULTS

lIgnition switch: ON

(Engine stopped)

lDisplays the results of on board

diagnostic system.Ð Objective system

CLOSED THROTTLE

POSI

lIgnition switch: ON

(Engine stopped)

lThrottle position sensor circuit is

tested when throttle is opened

and closed fully. (``IDLE

POSITION'' is the test item name

for the vehicles in which idle is

selected by throttle position

sensor.)Throttle valve:

openedOFF

lHarness and connector

lThrottle position sensor (Closed

throttle position)

lThrottle position sensor (Closed

throttle position) adjustment

lThrottle linkage

lVerify operation in DATA

MONITOR mode. Throttle valve:

closedON

THROTTLE POSI

SEN CKT

lIgnition switch: ON

(Engine stopped)

lThrottle position sensor circuit is

tested when throttle is opened

and closed fully.Range (Throttle

valve fully opened

Ð Throttle valve

fully closed)More than

3.0V

lHarness and connector

lThrottle position sensor

lThrottle position sensor

adjustment

lThrottle linkage

lVerify operation in DATA

MONITOR mode.

PARK/NEUT POSI

SW CKT

lIgnition switch: ON

(Engine stopped)

lNeutral position switch circuit is

tested when shift lever is

manipulated.Out of N/P

positionsOFF

lHarness and connector

lNeutral position switch

lLinkage adjustment

In N/P positions ON

FUEL PUMP

CIRCUIT

lIgnition switch: ON

(Engine stopped)

lFuel pump circuit is tested by

checking the pulsation in fuel

pressure when fuel tube is

pinched.There is pressure pulsation on

the fuel feed hose.

lHarness and connector

lFuel pump

lFuel pump relay

lFuel filter clogging

lFuel level

EGRC SOL/V

CIRCUIT

(EVAP canister purge

control solenoid valve

circuit)

lIgnition switch: ON

(Engine stopped)

lEVAP canister purge control

solenoid valve circuit is tested by

checking solenoid valve operating

noise.The solenoid valve makes an

operating sound every 3

seconds.lHarness and connector

lEVAP canister purge control

solenoid valve

START SIGNAL

CIRCUIT

lIgnition switch: ON®START

lStart signal circuit is tested when

engine is started by operating the

starter. Battery voltage and water

temperature before cranking, and

average battery voltage, mass air

flow sensor output voltage and

cranking speed during cranking

are displayed.Start signal: OFF®ON

lHarness and connector

lIgnition switch

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-51

Page 204 of 1659

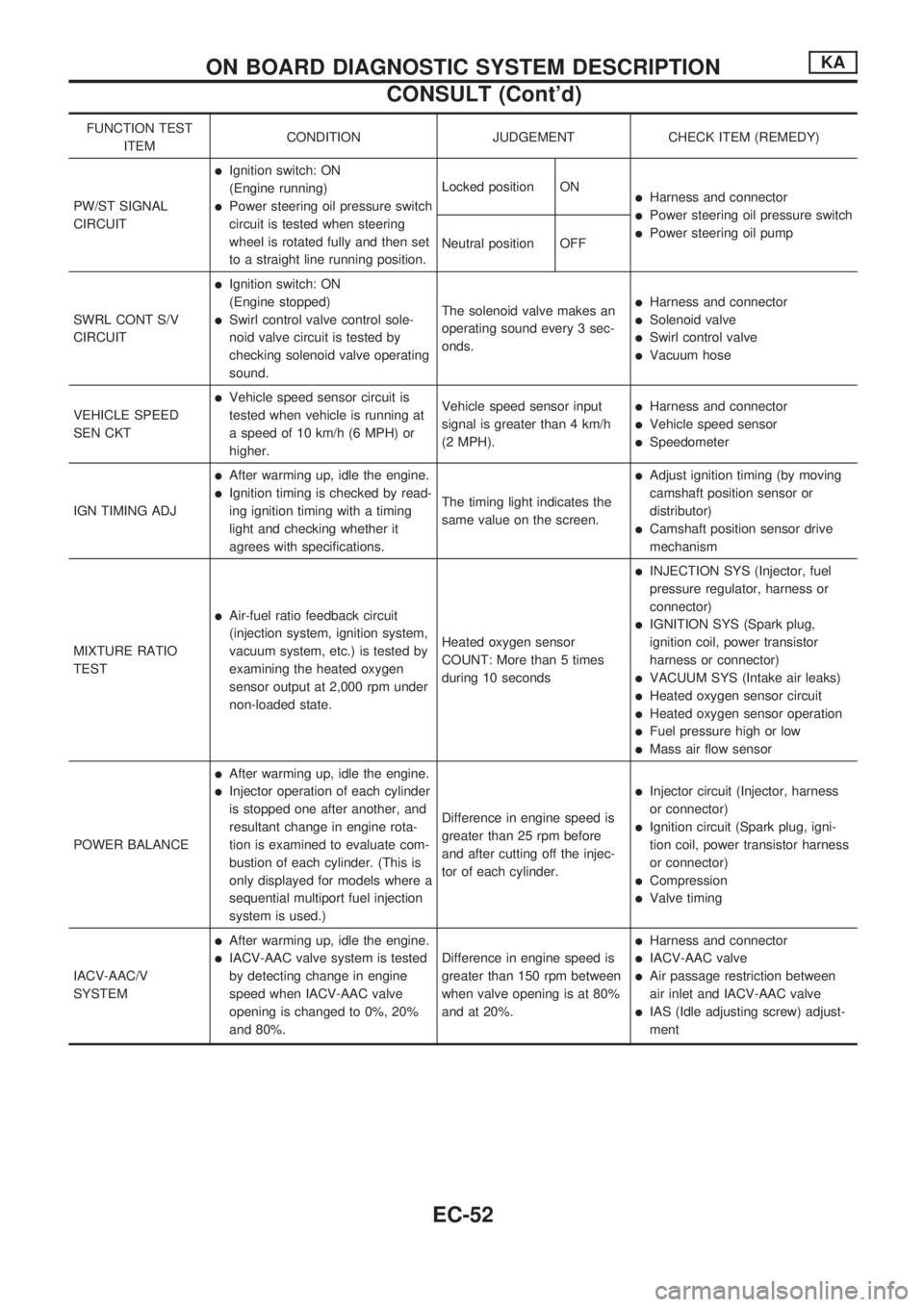

FUNCTION TEST

ITEMCONDITION JUDGEMENT CHECK ITEM (REMEDY)

PW/ST SIGNAL

CIRCUIT

lIgnition switch: ON

(Engine running)

lPower steering oil pressure switch

circuit is tested when steering

wheel is rotated fully and then set

to a straight line running position.Locked position ONlHarness and connector

lPower steering oil pressure switch

lPower steering oil pump

Neutral position OFF

SWRL CONT S/V

CIRCUIT

lIgnition switch: ON

(Engine stopped)

lSwirl control valve control sole-

noid valve circuit is tested by

checking solenoid valve operating

sound.The solenoid valve makes an

operating sound every 3 sec-

onds.

lHarness and connector

lSolenoid valve

lSwirl control valve

lVacuum hose

VEHICLE SPEED

SEN CKT

lVehicle speed sensor circuit is

tested when vehicle is running at

a speed of 10 km/h (6 MPH) or

higher.Vehicle speed sensor input

signal is greater than 4 km/h

(2 MPH).lHarness and connector

lVehicle speed sensor

lSpeedometer

IGN TIMING ADJ

lAfter warming up, idle the engine.

lIgnition timing is checked by read-

ing ignition timing with a timing

light and checking whether it

agrees with specifications.The timing light indicates the

same value on the screen.

lAdjust ignition timing (by moving

camshaft position sensor or

distributor)

lCamshaft position sensor drive

mechanism

MIXTURE RATIO

TEST

lAir-fuel ratio feedback circuit

(injection system, ignition system,

vacuum system, etc.) is tested by

examining the heated oxygen

sensor output at 2,000 rpm under

non-loaded state.Heated oxygen sensor

COUNT: More than 5 times

during 10 seconds

lINJECTION SYS (Injector, fuel

pressure regulator, harness or

connector)

lIGNITION SYS (Spark plug,

ignition coil, power transistor

harness or connector)

lVACUUM SYS (Intake air leaks)

lHeated oxygen sensor circuit

lHeated oxygen sensor operation

lFuel pressure high or low

lMass air flow sensor

POWER BALANCE

lAfter warming up, idle the engine.

lInjector operation of each cylinder

is stopped one after another, and

resultant change in engine rota-

tion is examined to evaluate com-

bustion of each cylinder. (This is

only displayed for models where a

sequential multiport fuel injection

system is used.)Difference in engine speed is

greater than 25 rpm before

and after cutting off the injec-

tor of each cylinder.lInjector circuit (Injector, harness

or connector)

lIgnition circuit (Spark plug, igni-

tion coil, power transistor harness

or connector)

lCompression

lValve timing

IACV-AAC/V

SYSTEM

lAfter warming up, idle the engine.

lIACV-AAC valve system is tested

by detecting change in engine

speed when IACV-AAC valve

opening is changed to 0%, 20%

and 80%.Difference in engine speed is

greater than 150 rpm between

when valve opening is at 80%

and at 20%.

lHarness and connector

lIACV-AAC valve

lAir passage restriction between

air inlet and IACV-AAC valve

lIAS (Idle adjusting screw) adjust-

ment

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-52

Page 205 of 1659

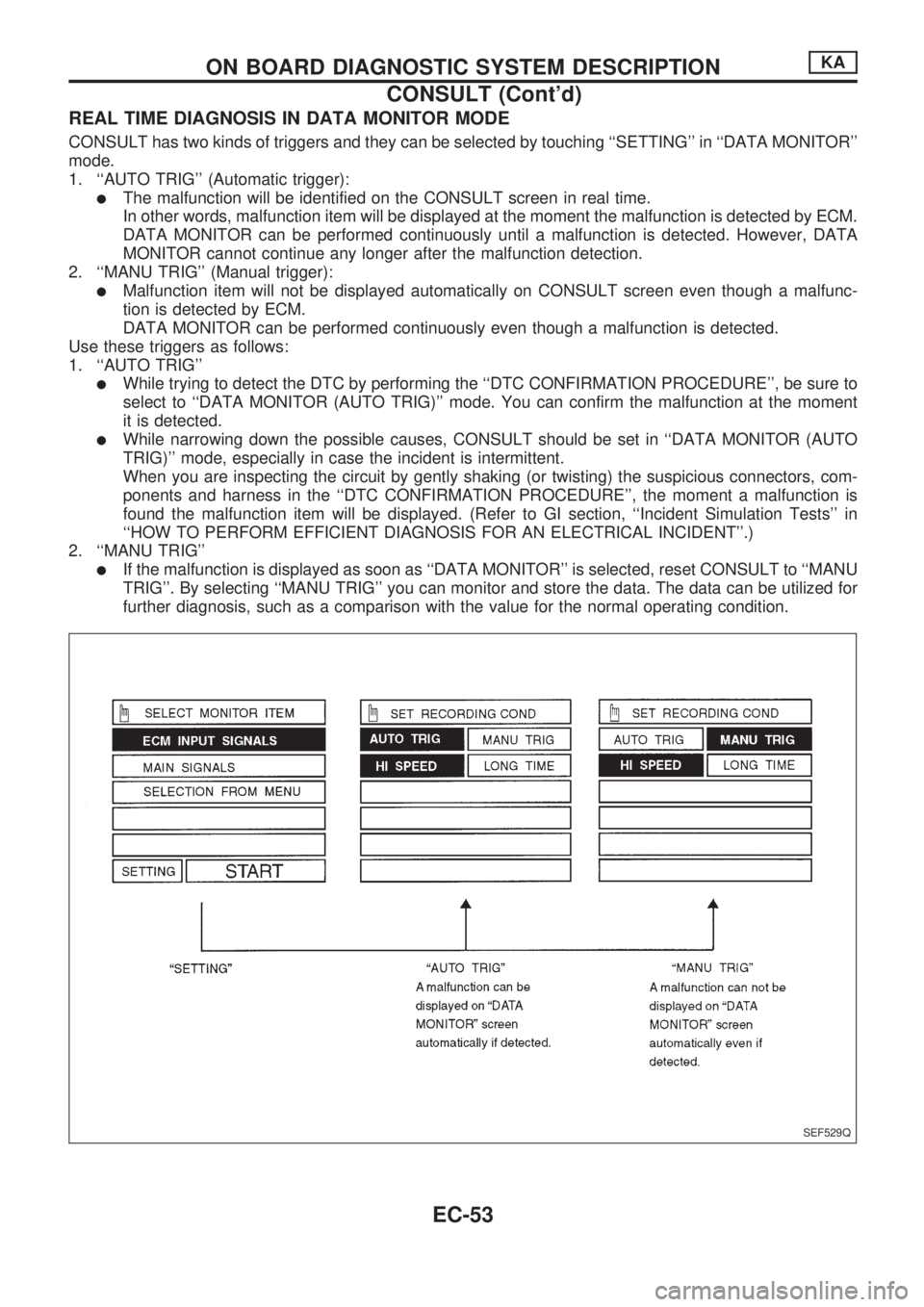

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

CONSULT has two kinds of triggers and they can be selected by touching ``SETTING'' in ``DATA MONITOR''

mode.

1. ``AUTO TRIG'' (Automatic trigger):

lThe malfunction will be identified on the CONSULT screen in real time.

In other words, malfunction item will be displayed at the moment the malfunction is detected by ECM.

DATA MONITOR can be performed continuously until a malfunction is detected. However, DATA

MONITOR cannot continue any longer after the malfunction detection.

2. ``MANU TRIG'' (Manual trigger):

lMalfunction item will not be displayed automatically on CONSULT screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though a malfunction is detected.

Use these triggers as follows:

1. ``AUTO TRIG''

lWhile trying to detect the DTC by performing the ``DTC CONFIRMATION PROCEDURE'', be sure to

select to ``DATA MONITOR (AUTO TRIG)'' mode. You can confirm the malfunction at the moment

it is detected.

lWhile narrowing down the possible causes, CONSULT should be set in ``DATA MONITOR (AUTO

TRIG)'' mode, especially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twisting) the suspicious connectors, com-

ponents and harness in the ``DTC CONFIRMATION PROCEDURE'', the moment a malfunction is

found the malfunction item will be displayed. (Refer to GI section, ``Incident Simulation Tests'' in

``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT''.)

2. ``MANU TRIG''

lIf the malfunction is displayed as soon as ``DATA MONITOR'' is selected, reset CONSULT to ``MANU

TRIG''. By selecting ``MANU TRIG'' you can monitor and store the data. The data can be utilized for

further diagnosis, such as a comparison with the value for the normal operating condition.

SEF529Q

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONKA

CONSULT (Cont'd)

EC-53