oil type NISSAN PICK-UP 1998 Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 27 of 1659

Disassembly

WARNING:

Do not place your fingers in front of piston.

CAUTION:

lDo not scratch or score cylinder wall.

lCL28VD type front disc brake uses plastic pistons,

handle them carefully.

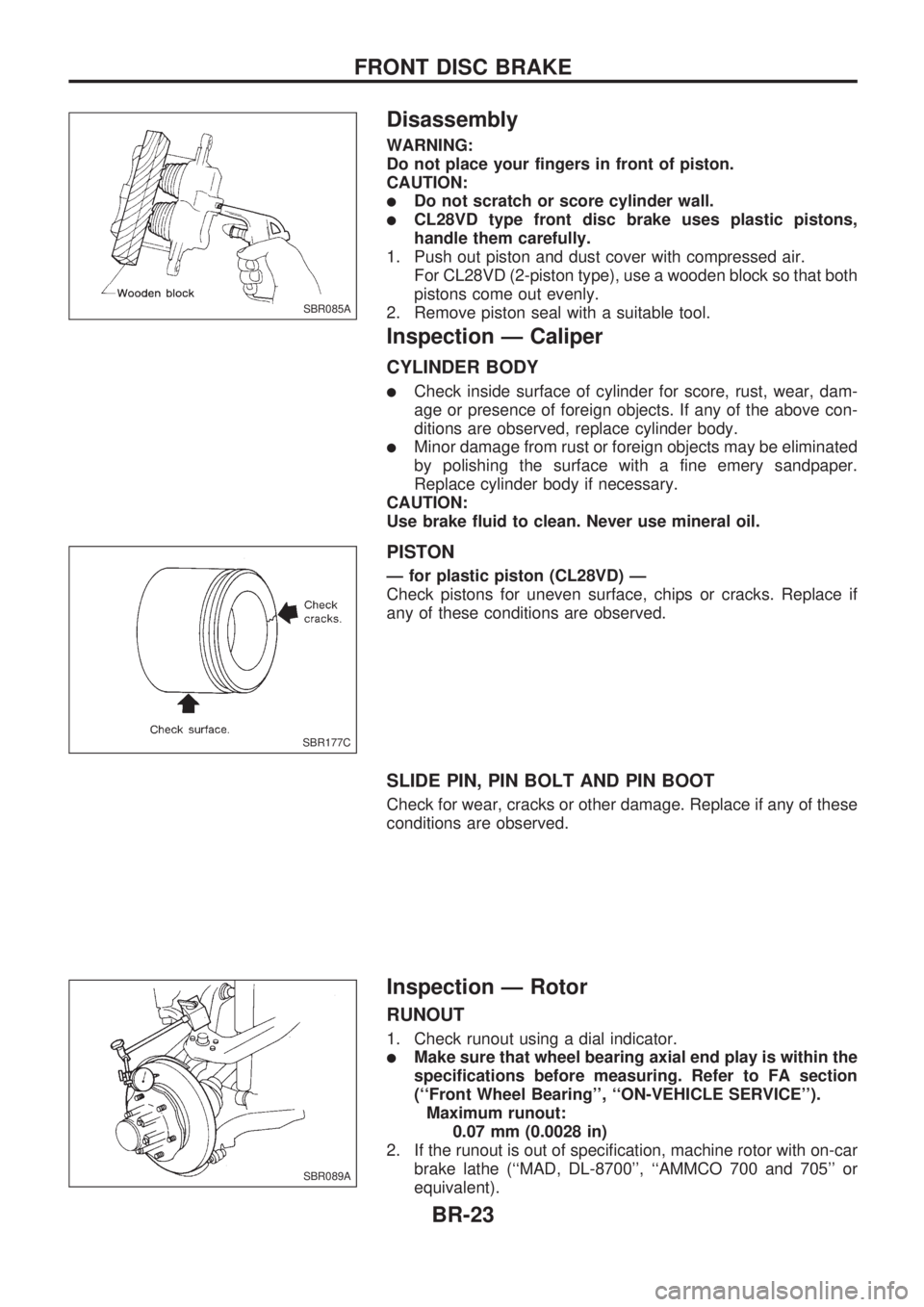

1. Push out piston and dust cover with compressed air.

For CL28VD (2-piston type), use a wooden block so that both

pistons come out evenly.

2. Remove piston seal with a suitable tool.

Inspection Ð Caliper

CYLINDER BODY

lCheck inside surface of cylinder for score, rust, wear, dam-

age or presence of foreign objects. If any of the above con-

ditions are observed, replace cylinder body.

lMinor damage from rust or foreign objects may be eliminated

by polishing the surface with a fine emery sandpaper.

Replace cylinder body if necessary.

CAUTION:

Use brake fluid to clean. Never use mineral oil.

PISTON

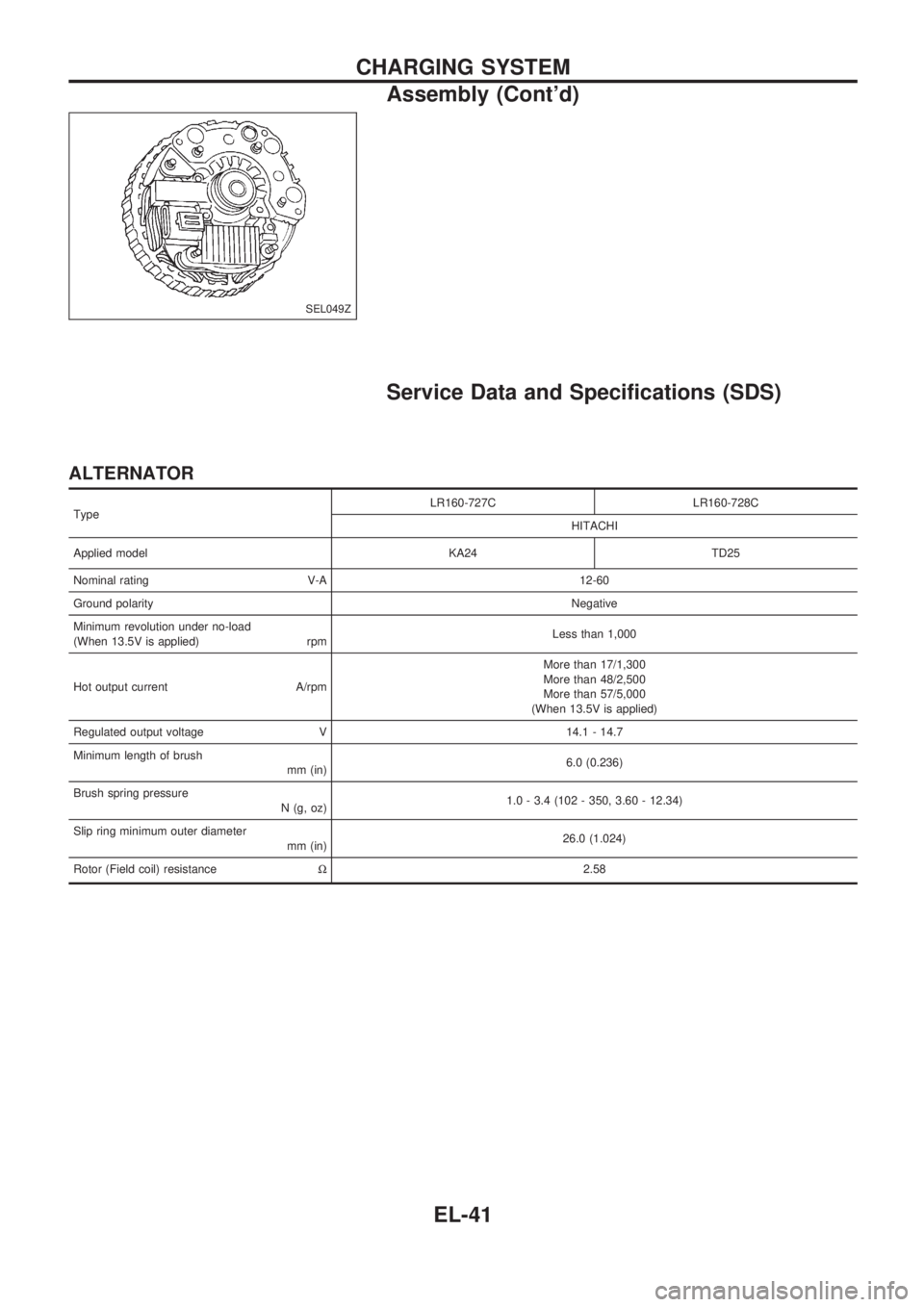

Ð for plastic piston (CL28VD) Ð

Check pistons for uneven surface, chips or cracks. Replace if

any of these conditions are observed.

SLIDE PIN, PIN BOLT AND PIN BOOT

Check for wear, cracks or other damage. Replace if any of these

conditions are observed.

Inspection Ð Rotor

RUNOUT

1. Check runout using a dial indicator.

lMake sure that wheel bearing axial end play is within the

specifications before measuring. Refer to FA section

(``Front Wheel Bearing'', ``ON-VEHICLE SERVICE'').

Maximum runout:

0.07 mm (0.0028 in)

2. If the runout is out of specification, machine rotor with on-car

brake lathe (``MAD, DL-8700'', ``AMMCO 700 and 705'' or

equivalent).

SBR085A

SBR177C

SBR089A

FRONT DISC BRAKE

BR-23

Page 431 of 1659

Service Data and Specifications (SDS)

ALTERNATOR

TypeLR160-727C LR160-728C

HITACHI

Applied model KA24 TD25

Nominal rating V-A 12-60

Ground polarityNegative

Minimum revolution under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current A/rpmMore than 17/1,300

More than 48/2,500

More than 57/5,000

(When 13.5V is applied)

Regulated output voltage V 14.1 - 14.7

Minimum length of brush

mm (in)6.0 (0.236)

Brush spring pressure

N (g, oz)1.0 - 3.4 (102 - 350, 3.60 - 12.34)

Slip ring minimum outer diameter

mm (in)26.0 (1.024)

Rotor (Field coil) resistanceW2.58

SEL049Z

CHARGING SYSTEM

Assembly (Cont'd)

EL-41

Page 439 of 1659

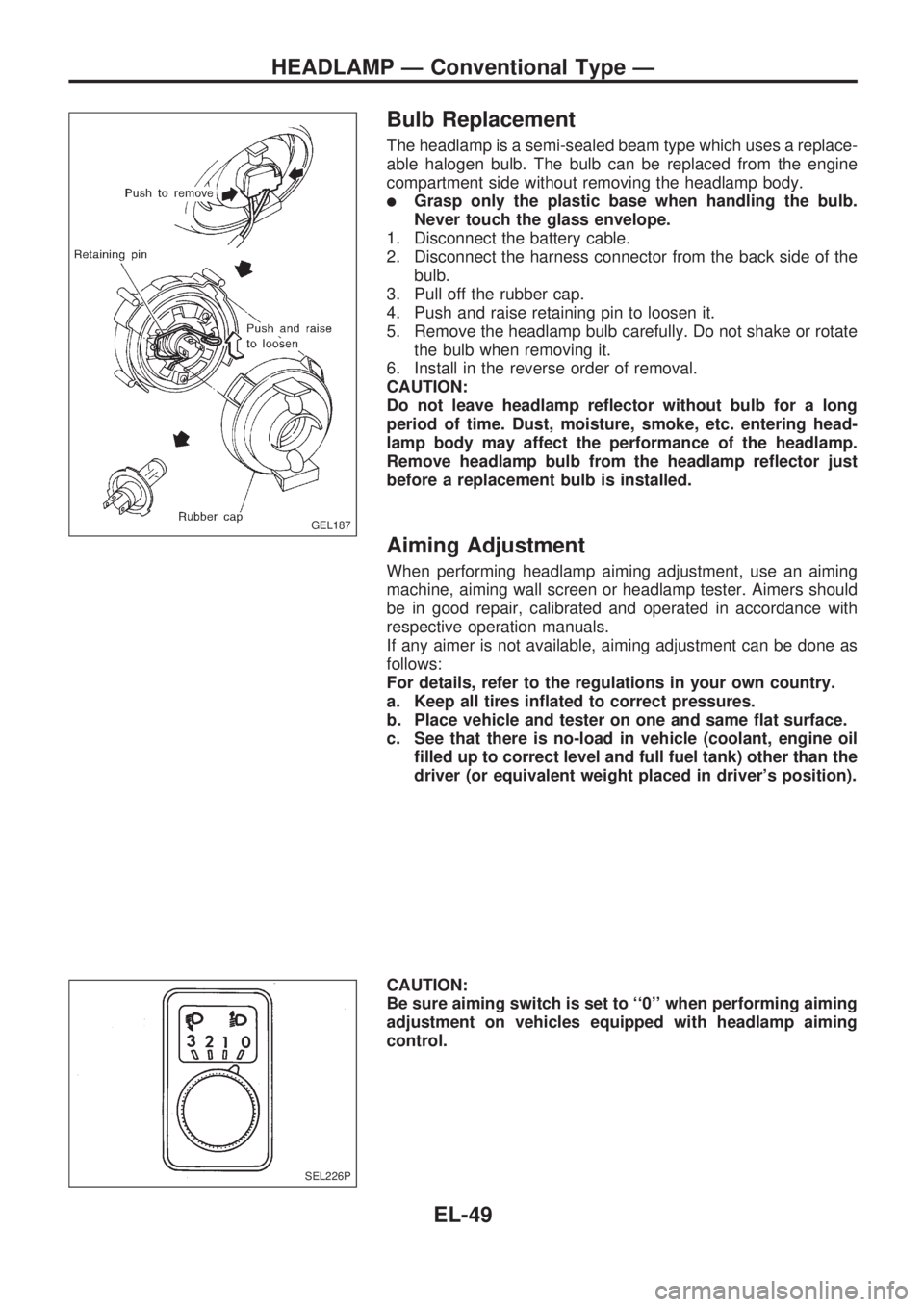

Bulb Replacement

The headlamp is a semi-sealed beam type which uses a replace-

able halogen bulb. The bulb can be replaced from the engine

compartment side without removing the headlamp body.

lGrasp only the plastic base when handling the bulb.

Never touch the glass envelope.

1. Disconnect the battery cable.

2. Disconnect the harness connector from the back side of the

bulb.

3. Pull off the rubber cap.

4. Push and raise retaining pin to loosen it.

5. Remove the headlamp bulb carefully. Do not shake or rotate

the bulb when removing it.

6. Install in the reverse order of removal.

CAUTION:

Do not leave headlamp reflector without bulb for a long

period of time. Dust, moisture, smoke, etc. entering head-

lamp body may affect the performance of the headlamp.

Remove headlamp bulb from the headlamp reflector just

before a replacement bulb is installed.

Aiming Adjustment

When performing headlamp aiming adjustment, use an aiming

machine, aiming wall screen or headlamp tester. Aimers should

be in good repair, calibrated and operated in accordance with

respective operation manuals.

If any aimer is not available, aiming adjustment can be done as

follows:

For details, refer to the regulations in your own country.

a. Keep all tires inflated to correct pressures.

b. Place vehicle and tester on one and same flat surface.

c. See that there is no-load in vehicle (coolant, engine oil

filled up to correct level and full fuel tank) other than the

driver (or equivalent weight placed in driver's position).

CAUTION:

Be sure aiming switch is set to ``0'' when performing aiming

adjustment on vehicles equipped with headlamp aiming

control.

GEL187

SEL226P

HEADLAMP Ð Conventional Type Ð

EL-49

Page 506 of 1659

Electrical Components Inspection

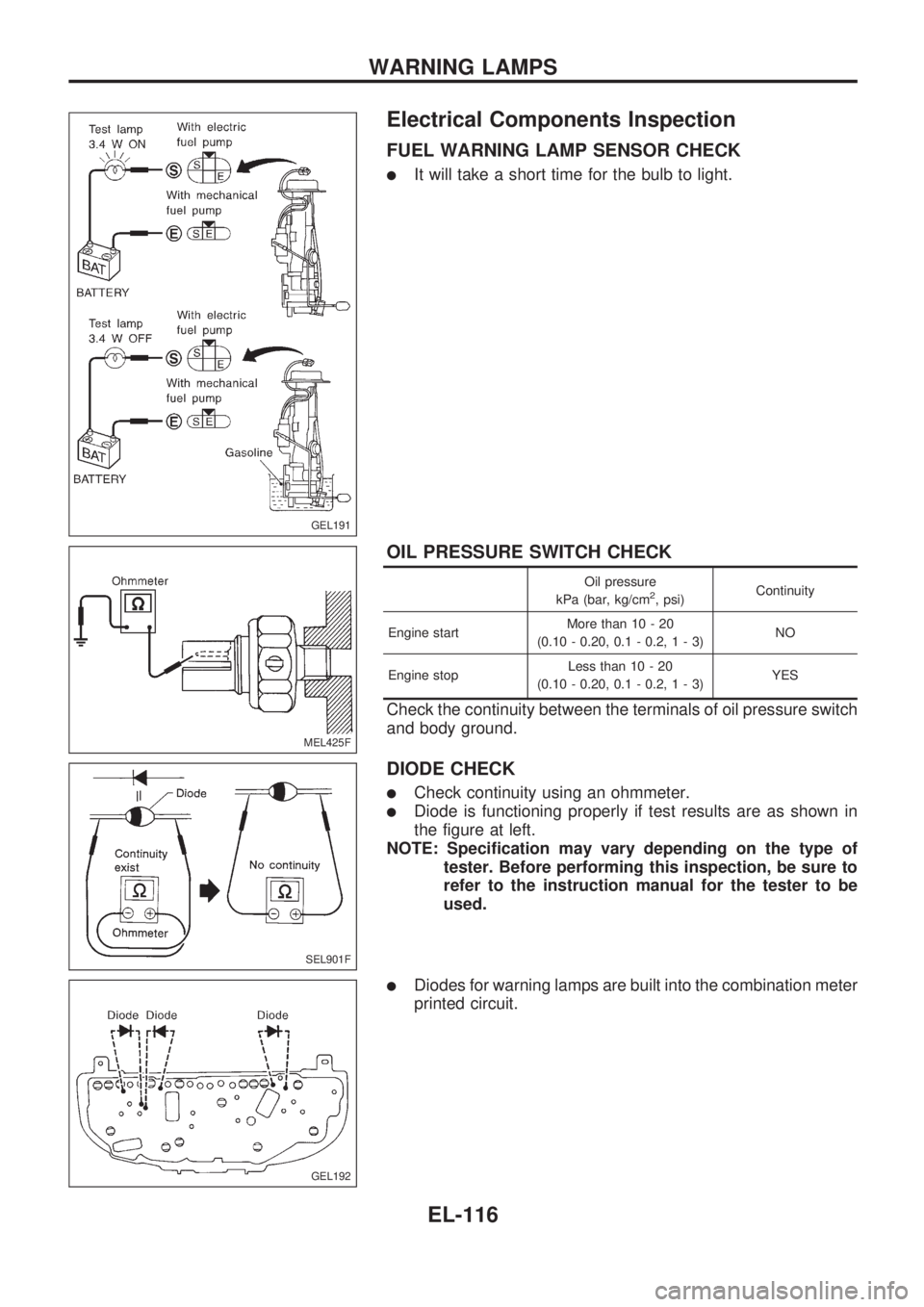

FUEL WARNING LAMP SENSOR CHECK

lIt will take a short time for the bulb to light.

OIL PRESSURE SWITCH CHECK

Oil pressure

kPa (bar, kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)NO

Engine stopLess than 10 - 20

(0.10 - 0.20, 0.1 - 0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

DIODE CHECK

lCheck continuity using an ohmmeter.

lDiode is functioning properly if test results are as shown in

the figure at left.

NOTE: Specification may vary depending on the type of

tester. Before performing this inspection, be sure to

refer to the instruction manual for the tester to be

used.

lDiodes for warning lamps are built into the combination meter

printed circuit.

GEL191

MEL425F

SEL901F

GEL192

WARNING LAMPS

EL-116

Page 678 of 1659

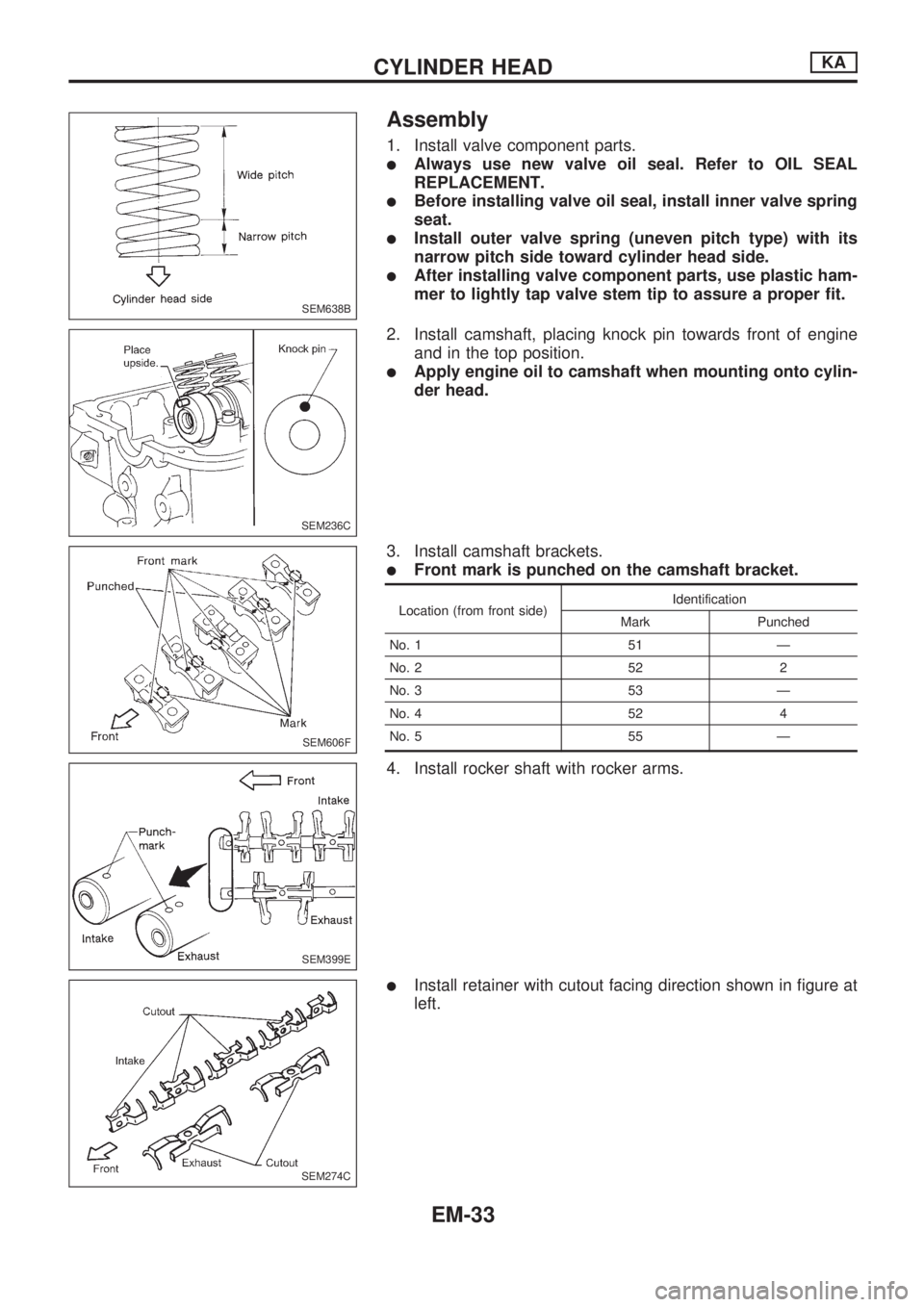

Assembly

1. Install valve component parts.

lAlways use new valve oil seal. Refer to OIL SEAL

REPLACEMENT.

lBefore installing valve oil seal, install inner valve spring

seat.

lInstall outer valve spring (uneven pitch type) with its

narrow pitch side toward cylinder head side.

lAfter installing valve component parts, use plastic ham-

mer to lightly tap valve stem tip to assure a proper fit.

2. Install camshaft, placing knock pin towards front of engine

and in the top position.

lApply engine oil to camshaft when mounting onto cylin-

der head.

3. Install camshaft brackets.

lFront mark is punched on the camshaft bracket.

Location (from front side)Identification

Mark Punched

No. 1 51 Ð

No. 2 52 2

No. 3 53 Ð

No. 4 52 4

No. 5 55 Ð

4. Install rocker shaft with rocker arms.

lInstall retainer with cutout facing direction shown in figure at

left.

SEM638B

SEM236C

SEM606F

SEM399E

SEM274C

CYLINDER HEADKA

EM-33

Page 707 of 1659

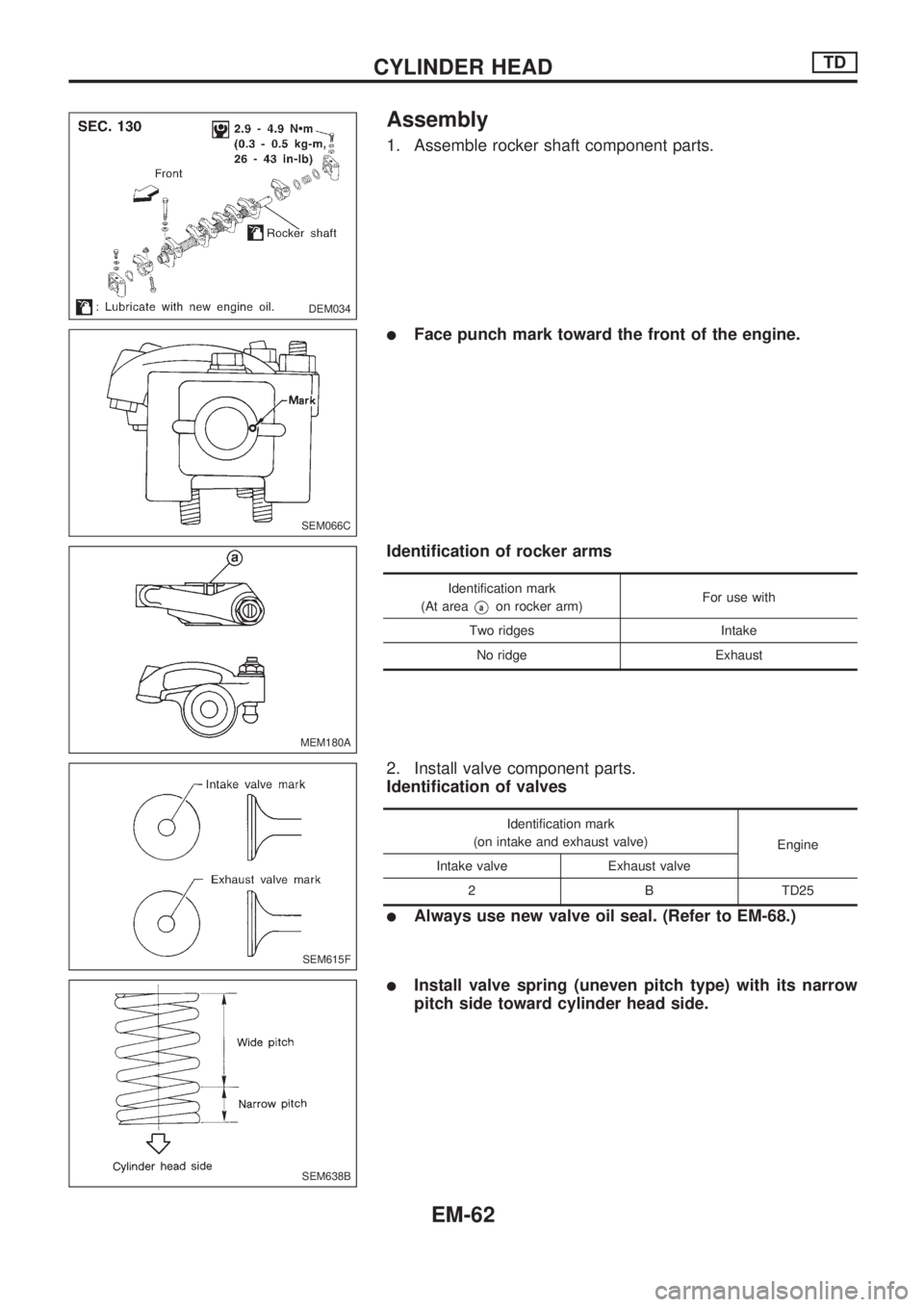

Assembly

1. Assemble rocker shaft component parts.

lFace punch mark toward the front of the engine.

Identification of rocker arms

Identification mark

(At area

Vaon rocker arm)For use with

Two ridges Intake

No ridge Exhaust

2. Install valve component parts.

Identification of valves

Identification mark

(on intake and exhaust valve)

Engine

Intake valve Exhaust valve

2 B TD25

lAlways use new valve oil seal. (Refer to EM-68.)

lInstall valve spring (uneven pitch type) with its narrow

pitch side toward cylinder head side.

DEM034

SEM066C

MEM180A

SEM615F

SEM638B

CYLINDER HEADTD

EM-62

Page 712 of 1659

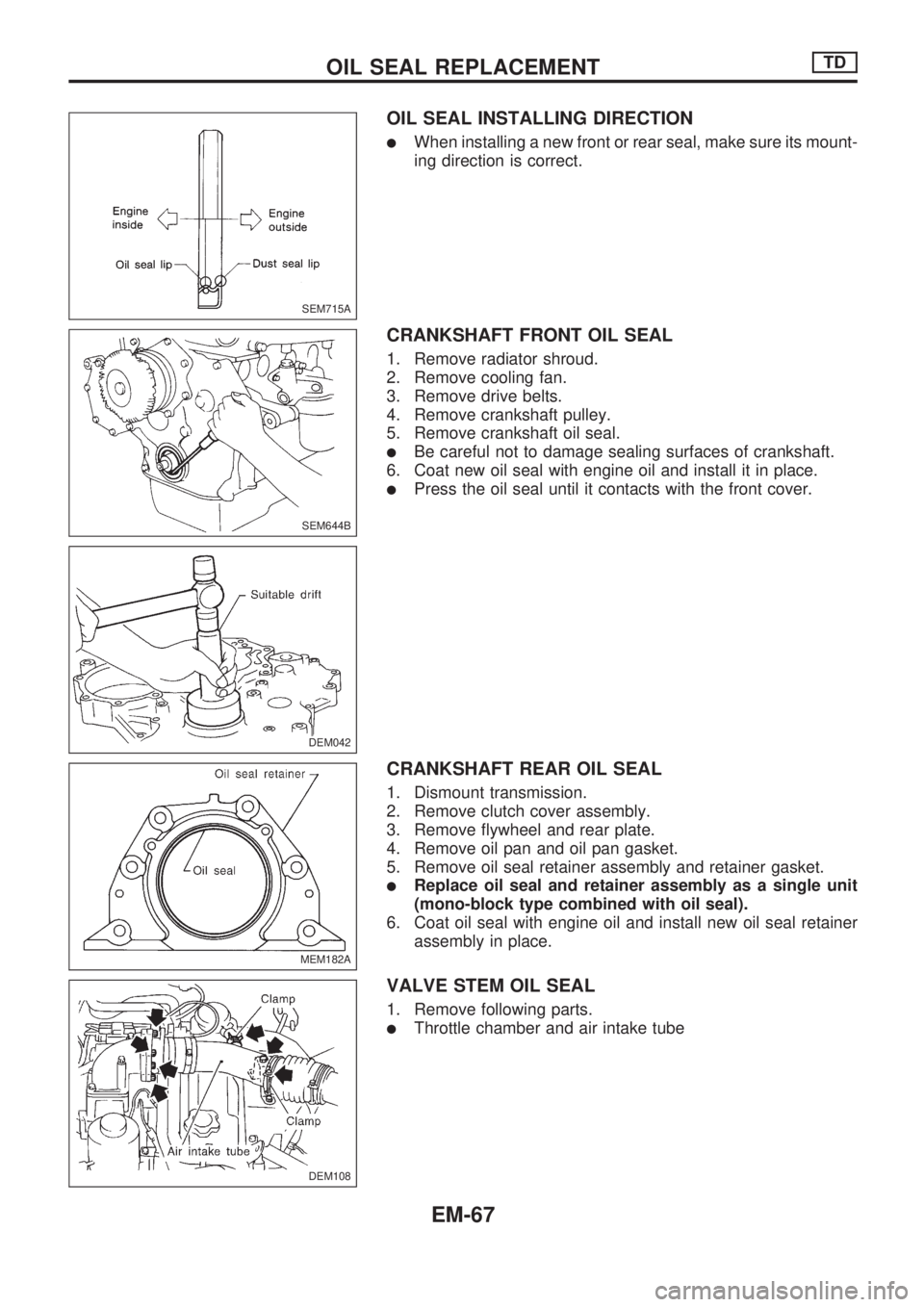

OIL SEAL INSTALLING DIRECTION

lWhen installing a new front or rear seal, make sure its mount-

ing direction is correct.

CRANKSHAFT FRONT OIL SEAL

1. Remove radiator shroud.

2. Remove cooling fan.

3. Remove drive belts.

4. Remove crankshaft pulley.

5. Remove crankshaft oil seal.

lBe careful not to damage sealing surfaces of crankshaft.

6. Coat new oil seal with engine oil and install it in place.

lPress the oil seal until it contacts with the front cover.

CRANKSHAFT REAR OIL SEAL

1. Dismount transmission.

2. Remove clutch cover assembly.

3. Remove flywheel and rear plate.

4. Remove oil pan and oil pan gasket.

5. Remove oil seal retainer assembly and retainer gasket.

lReplace oil seal and retainer assembly as a single unit

(mono-block type combined with oil seal).

6. Coat oil seal with engine oil and install new oil seal retainer

assembly in place.

VALVE STEM OIL SEAL

1. Remove following parts.

lThrottle chamber and air intake tube

SEM715A

SEM644B

DEM042

MEM182A

DEM108

.

OIL SEAL REPLACEMENTTD

EM-67

Page 733 of 1659

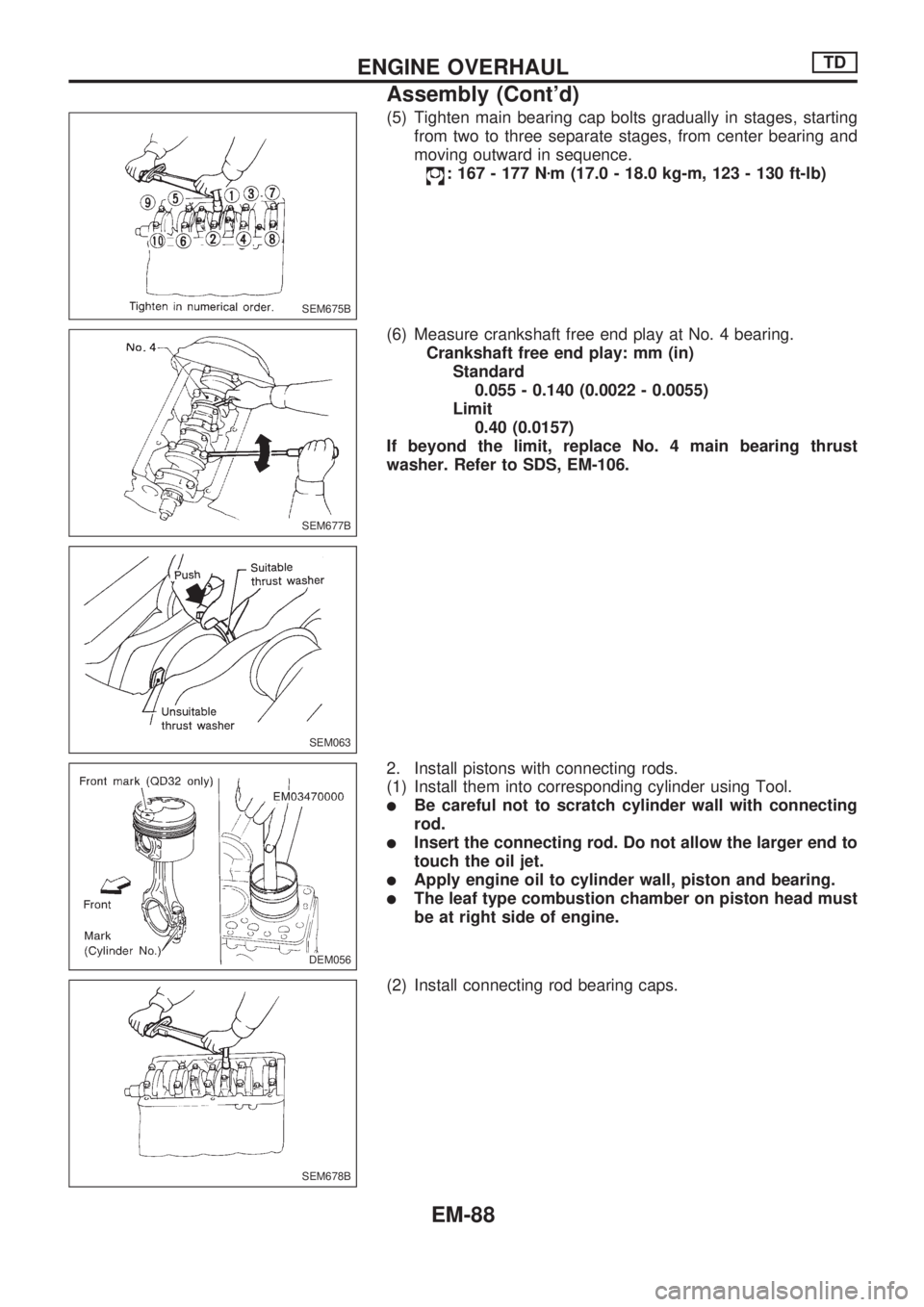

(5) Tighten main bearing cap bolts gradually in stages, starting

from two to three separate stages, from center bearing and

moving outward in sequence.

: 167 - 177 Nzm (17.0 - 18.0 kg-m, 123 - 130 ft-lb)

(6) Measure crankshaft free end play at No. 4 bearing.

Crankshaft free end play: mm (in)

Standard

0.055 - 0.140 (0.0022 - 0.0055)

Limit

0.40 (0.0157)

If beyond the limit, replace No. 4 main bearing thrust

washer. Refer to SDS, EM-106.

2. Install pistons with connecting rods.

(1) Install them into corresponding cylinder using Tool.

lBe careful not to scratch cylinder wall with connecting

rod.

lInsert the connecting rod. Do not allow the larger end to

touch the oil jet.

lApply engine oil to cylinder wall, piston and bearing.

lThe leaf type combustion chamber on piston head must

be at right side of engine.

(2) Install connecting rod bearing caps.

SEM675B

SEM677B

SEM063

DEM056.DEM056

SEM678B

ENGINE OVERHAULTD

Assembly (Cont'd)

EM-88

Page 810 of 1659

DIESEL ENGINE*:

For Europe: diesel fuel of above 50 cetane

* If two types of diesel fuel are available, use summer or win-

ter fuel properly according to the following temperature con-

ditions.

lAbove þ7ÉC (20ÉF) ... Summer type diesel fuel.

lBelow þ7ÉC (20ÉF) ... Winter type diesel fuel.

CAUTION:

lDo not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

lDo not use summer fuel at temperature below þ7ÉC

(20ÉF). The cold temperature will cause wax to form in

the fuel. As a result, it may prevent the engine from run-

ning smoothly.

lDo not add gasoline or other alternate fuels to diesel

fuel.

Precautions for Air Conditioning

Use an approved refrigerant recovery unit any time the air con-

ditioning system must be discharged. Refer to HA section

(``HFC-134a (R-134a) Service Procedure'', ``SERVICE PRO-

CEDURES'') for specific instructions.

PRECAUTIONS

Precautions for Fuel (Cont'd)

GI-6

Page 812 of 1659

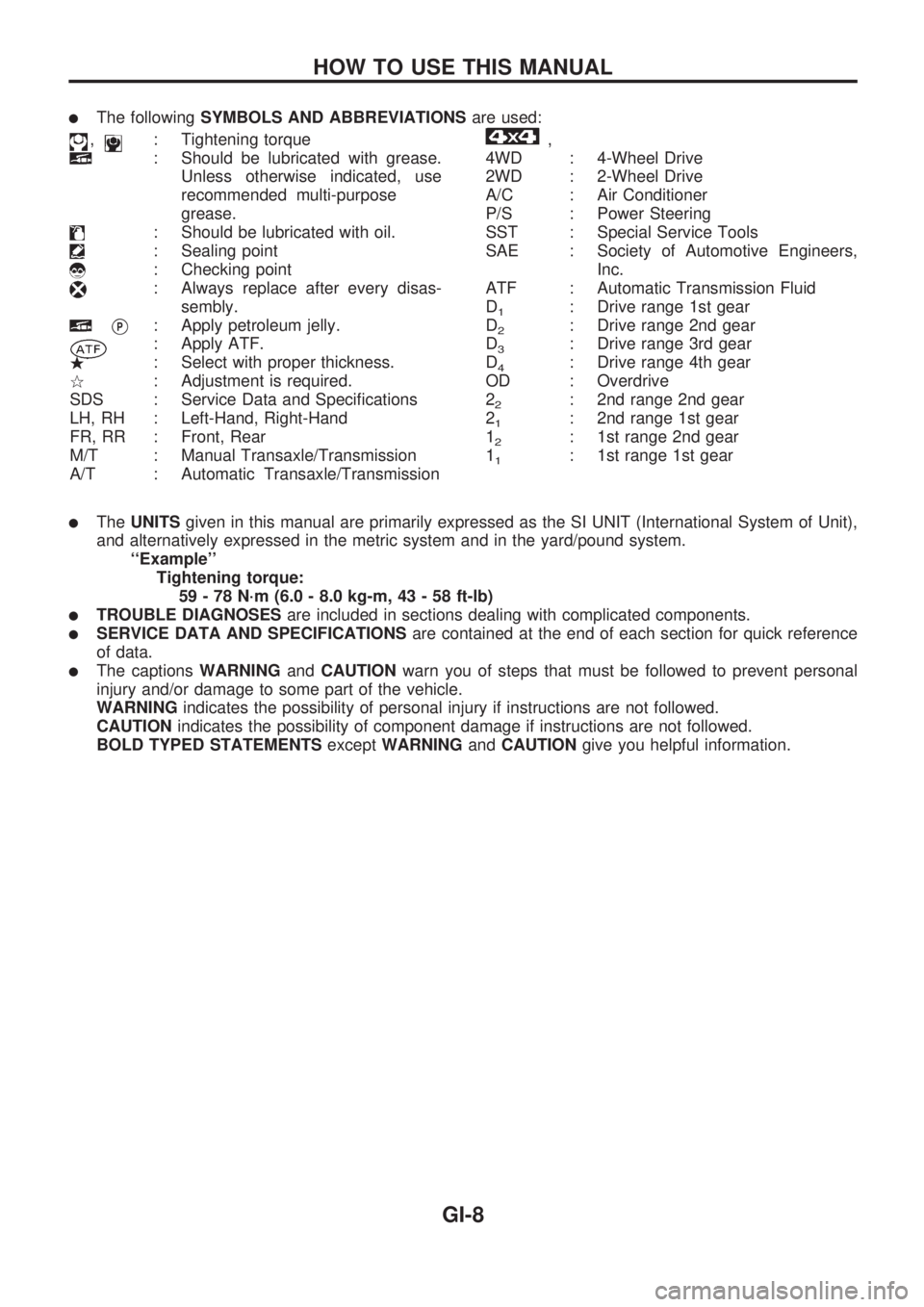

lThe followingSYMBOLS AND ABBREVIATIONSare used:

,: Tightening torque

: Should be lubricated with grease.

Unless otherwise indicated, use

recommended multi-purpose

grease.

: Should be lubricated with oil.

: Sealing point

: Checking point

: Always replace after every disas-

sembly.

VP: Apply petroleum jelly.

: Apply ATF.

.: Select with proper thickness.

>: Adjustment is required.

SDS : Service Data and Specifications

LH, RH : Left-Hand, Right-Hand

FR, RR : Front, Rear

M/T : Manual Transaxle/Transmission

A/T : Automatic Transaxle/Transmission

,

4WD : 4-Wheel Drive

2WD : 2-Wheel Drive

A/C : Air Conditioner

P/S : Power Steering

SST : Special Service Tools

SAE : Society of Automotive Engineers,

Inc.

ATF : Automatic Transmission Fluid

D

1: Drive range 1st gear

D

2: Drive range 2nd gear

D

3: Drive range 3rd gear

D

4: Drive range 4th gear

OD : Overdrive

2

2: 2nd range 2nd gear

2

1: 2nd range 1st gear

1

2: 1st range 2nd gear

1

1: 1st range 1st gear

lTheUNITSgiven in this manual are primarily expressed as the SI UNIT (International System of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

``Example''

Tightening torque:

59 - 78 N´m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

lTROUBLE DIAGNOSESare included in sections dealing with complicated components.

lSERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference

of data.

lThe captionsWARNINGandCAUTIONwarn you of steps that must be followed to prevent personal

injury and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

HOW TO USE THIS MANUAL

GI-8