NISSAN PICK-UP 1999 Repair Manual

Manufacturer: NISSAN, Model Year: 1999, Model line: PICK-UP, Model: NISSAN PICK-UP 1999Pages: 666, PDF Size: 16.21 MB

Page 371 of 666

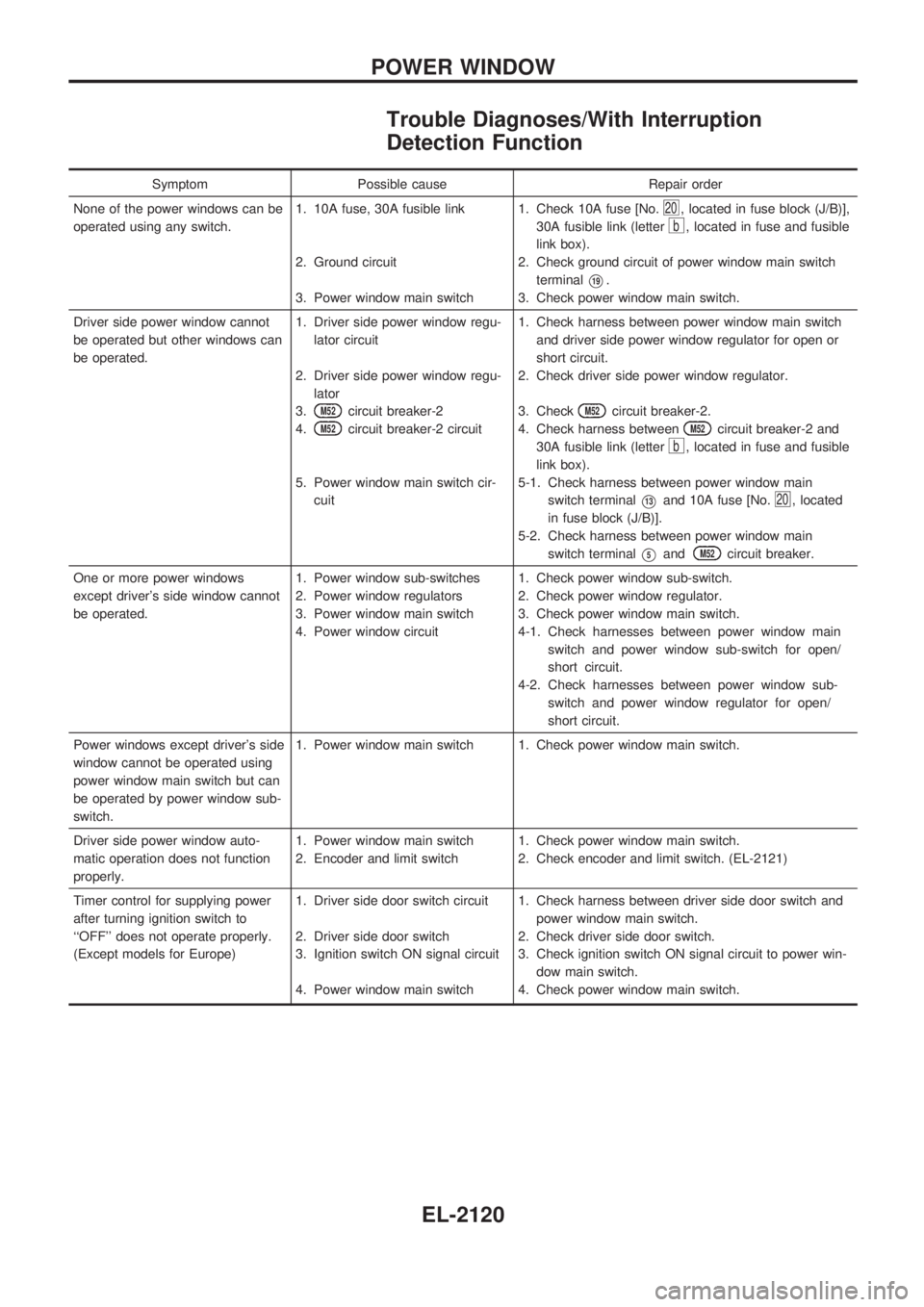

Trouble Diagnoses/With Interruption

Detection Function

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 10A fuse, 30A fusible link

2. Ground circuit

3. Power window main switch1. Check 10A fuse [No.

20, located in fuse block (J/B)],

30A fusible link (letter

b, located in fuse and fusible

link box).

2. Check ground circuit of power window main switch

terminal

V19.

3. Check power window main switch.

Driver side power window cannot

be operated but other windows can

be operated.1. Driver side power window regu-

lator circuit

2. Driver side power window regu-

lator

3.

M52circuit breaker-2

4.

M52circuit breaker-2 circuit

5. Power window main switch cir-

cuit1. Check harness between power window main switch

and driver side power window regulator for open or

short circuit.

2. Check driver side power window regulator.

3. Check

M52circuit breaker-2.

4. Check harness between

M52circuit breaker-2 and

30A fusible link (letter

b, located in fuse and fusible

link box).

5-1. Check harness between power window main

switch terminal

V13and 10A fuse [No.20, located

in fuse block (J/B)].

5-2. Check harness between power window main

switch terminal

V5andM52circuit breaker.

One or more power windows

except driver's side window cannot

be operated.1. Power window sub-switches

2. Power window regulators

3. Power window main switch

4. Power window circuit1. Check power window sub-switch.

2. Check power window regulator.

3. Check power window main switch.

4-1. Check harnesses between power window main

switch and power window sub-switch for open/

short circuit.

4-2. Check harnesses between power window sub-

switch and power window regulator for open/

short circuit.

Power windows except driver's side

window cannot be operated using

power window main switch but can

be operated by power window sub-

switch.1. Power window main switch 1. Check power window main switch.

Driver side power window auto-

matic operation does not function

properly.1. Power window main switch

2. Encoder and limit switch1. Check power window main switch.

2. Check encoder and limit switch. (EL-2121)

Timer control for supplying power

after turning ignition switch to

``OFF'' does not operate properly.

(Except models for Europe)1. Driver side door switch circuit

2. Driver side door switch

3. Ignition switch ON signal circuit

4. Power window main switch1. Check harness between driver side door switch and

power window main switch.

2. Check driver side door switch.

3. Check ignition switch ON signal circuit to power win-

dow main switch.

4. Check power window main switch.

POWER WINDOW

EL-2120

Page 372 of 666

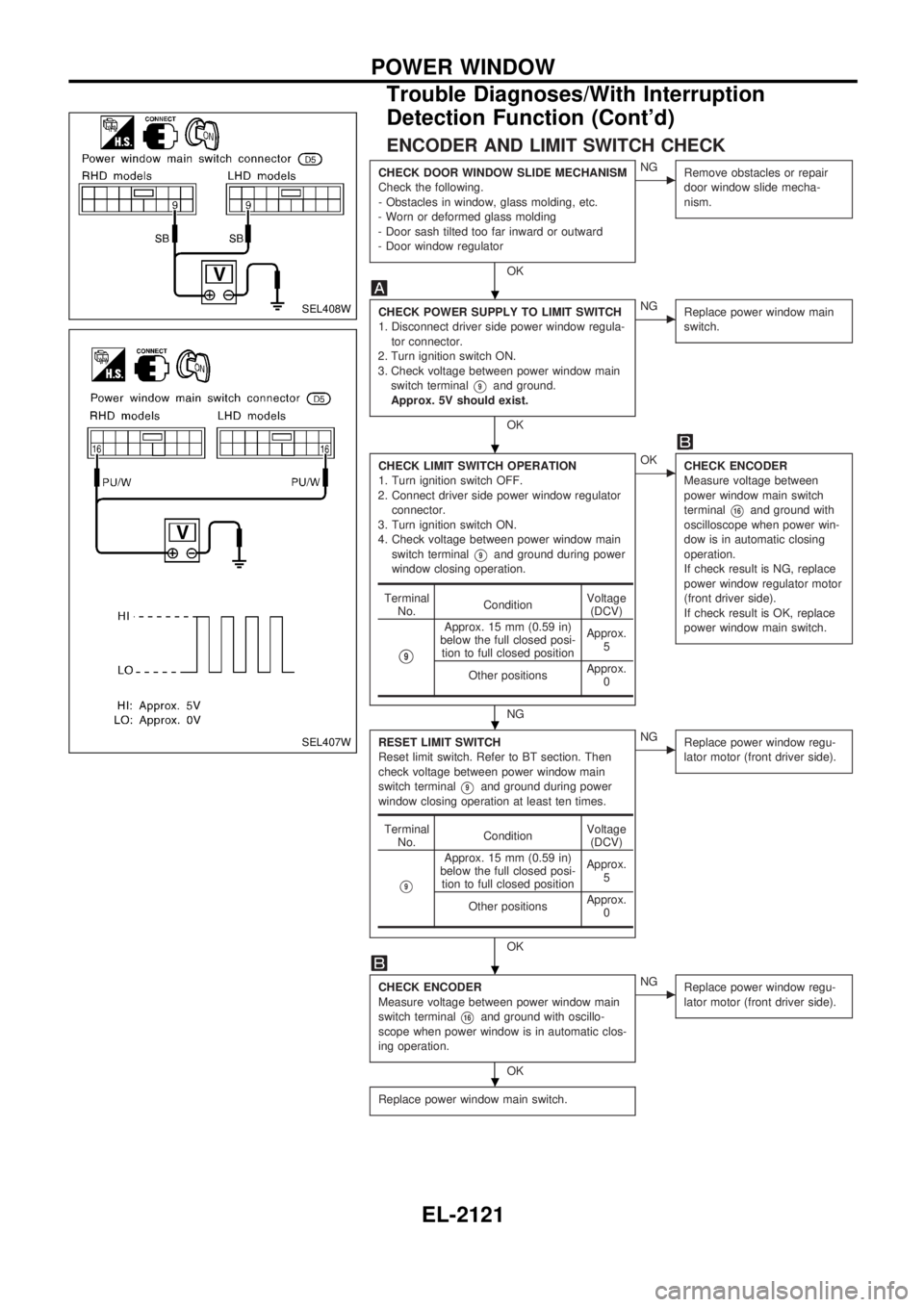

ENCODER AND LIMIT SWITCH CHECK

CHECK DOOR WINDOW SLIDE MECHANISM

Check the following.

- Obstacles in window, glass molding, etc.

- Worn or deformed glass molding

- Door sash tilted too far inward or outward

- Door window regulator

OK

cNG

Remove obstacles or repair

door window slide mecha-

nism.

CHECK POWER SUPPLY TO LIMIT SWITCH

1. Disconnect driver side power window regula-

tor connector.

2. Turn ignition switch ON.

3. Check voltage between power window main

switch terminal

V9and ground.

Approx. 5V should exist.

OK

cNG

Replace power window main

switch.

CHECK LIMIT SWITCH OPERATION

1. Turn ignition switch OFF.

2. Connect driver side power window regulator

connector.

3. Turn ignition switch ON.

4. Check voltage between power window main

switch terminal

V9and ground during power

window closing operation.

NG

cOK

CHECK ENCODER

Measure voltage between

power window main switch

terminal

V16and ground with

oscilloscope when power win-

dow is in automatic closing

operation.

If check result is NG, replace

power window regulator motor

(front driver side).

If check result is OK, replace

power window main switch.

RESET LIMIT SWITCH

Reset limit switch. Refer to BT section. Then

check voltage between power window main

switch terminal

V9and ground during power

window closing operation at least ten times.

OK

cNG

Replace power window regu-

lator motor (front driver side).

CHECK ENCODER

Measure voltage between power window main

switch terminal

V16and ground with oscillo-

scope when power window is in automatic clos-

ing operation.

OK

cNG

Replace power window regu-

lator motor (front driver side).

Replace power window main switch.

Terminal

No.ConditionVoltage

(DCV)

V9

Approx. 15 mm (0.59 in)

below the full closed posi-

tion to full closed positionApprox.

5

Other positionsApprox.

0

Terminal

No.ConditionVoltage

(DCV)

V9

Approx. 15 mm (0.59 in)

below the full closed posi-

tion to full closed positionApprox.

5

Other positionsApprox.

0

SEL408W

SEL407W

.

.

.

.

.

POWER WINDOW

Trouble Diagnoses/With Interruption

Detection Function (Cont'd)

EL-2121

Page 373 of 666

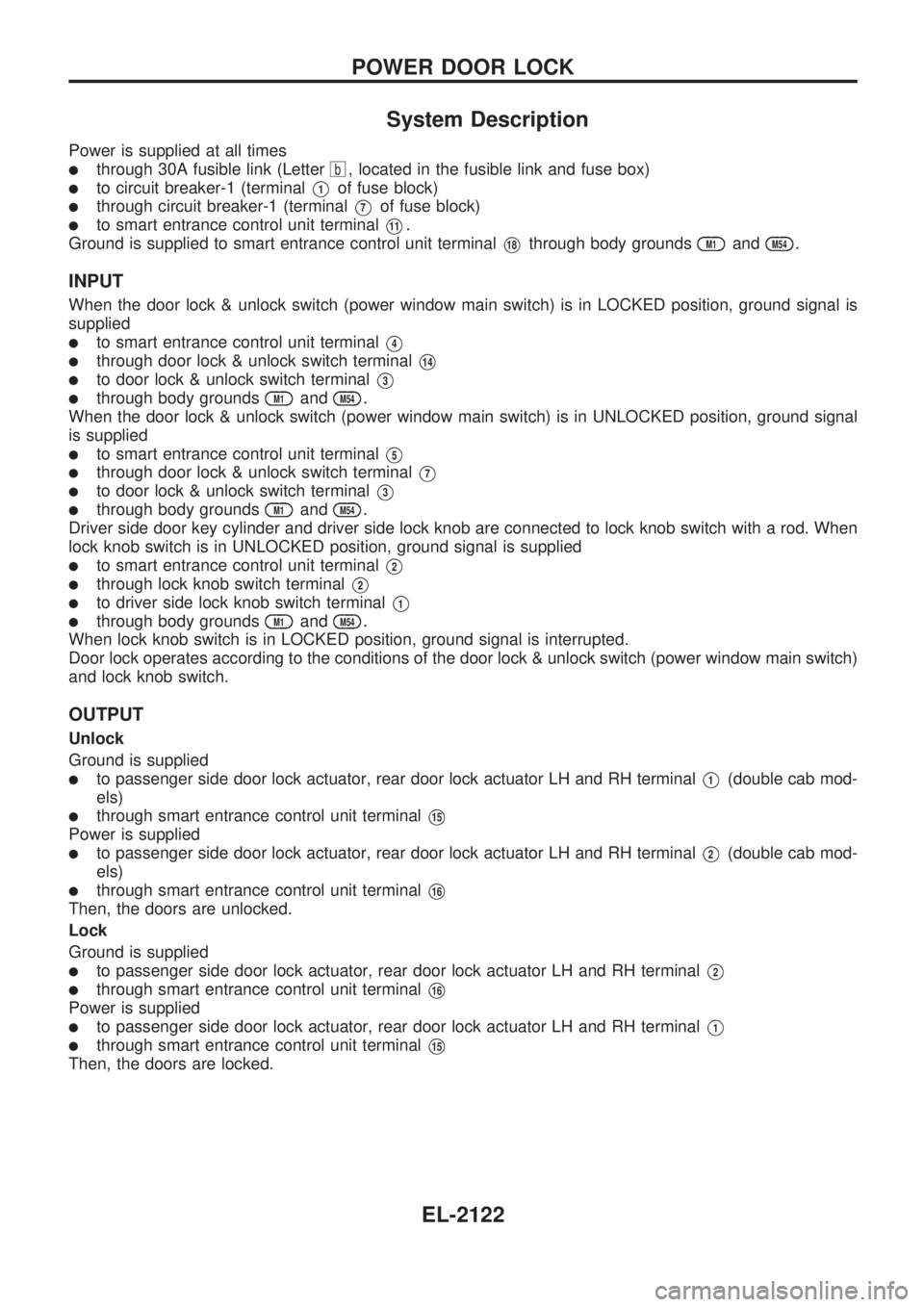

System Description

Power is supplied at all times

lthrough 30A fusible link (Letterb, located in the fusible link and fuse box)

lto circuit breaker-1 (terminalV1of fuse block)

lthrough circuit breaker-1 (terminalV7of fuse block)

lto smart entrance control unit terminalV11.

Ground is supplied to smart entrance control unit terminal

V18through body groundsM1andM54.

INPUT

When the door lock & unlock switch (power window main switch) is in LOCKED position, ground signal is

supplied

lto smart entrance control unit terminalV4

lthrough door lock & unlock switch terminalV14

lto door lock & unlock switch terminalV3

lthrough body groundsM1andM54.

When the door lock & unlock switch (power window main switch) is in UNLOCKED position, ground signal

is supplied

lto smart entrance control unit terminalV5

lthrough door lock & unlock switch terminalV7

lto door lock & unlock switch terminalV3

lthrough body groundsM1andM54.

Driver side door key cylinder and driver side lock knob are connected to lock knob switch with a rod. When

lock knob switch is in UNLOCKED position, ground signal is supplied

lto smart entrance control unit terminalV2

lthrough lock knob switch terminalV2

lto driver side lock knob switch terminalV1

lthrough body groundsM1andM54.

When lock knob switch is in LOCKED position, ground signal is interrupted.

Door lock operates according to the conditions of the door lock & unlock switch (power window main switch)

and lock knob switch.

OUTPUT

Unlock

Ground is supplied

lto passenger side door lock actuator, rear door lock actuator LH and RH terminalV1(double cab mod-

els)

lthrough smart entrance control unit terminalV15

Power is supplied

lto passenger side door lock actuator, rear door lock actuator LH and RH terminalV2(double cab mod-

els)

lthrough smart entrance control unit terminalV16

Then, the doors are unlocked.

Lock

Ground is supplied

lto passenger side door lock actuator, rear door lock actuator LH and RH terminalV2

lthrough smart entrance control unit terminalV16

Power is supplied

lto passenger side door lock actuator, rear door lock actuator LH and RH terminalV1

lthrough smart entrance control unit terminalV15

Then, the doors are locked.

POWER DOOR LOCK

EL-2122

Page 374 of 666

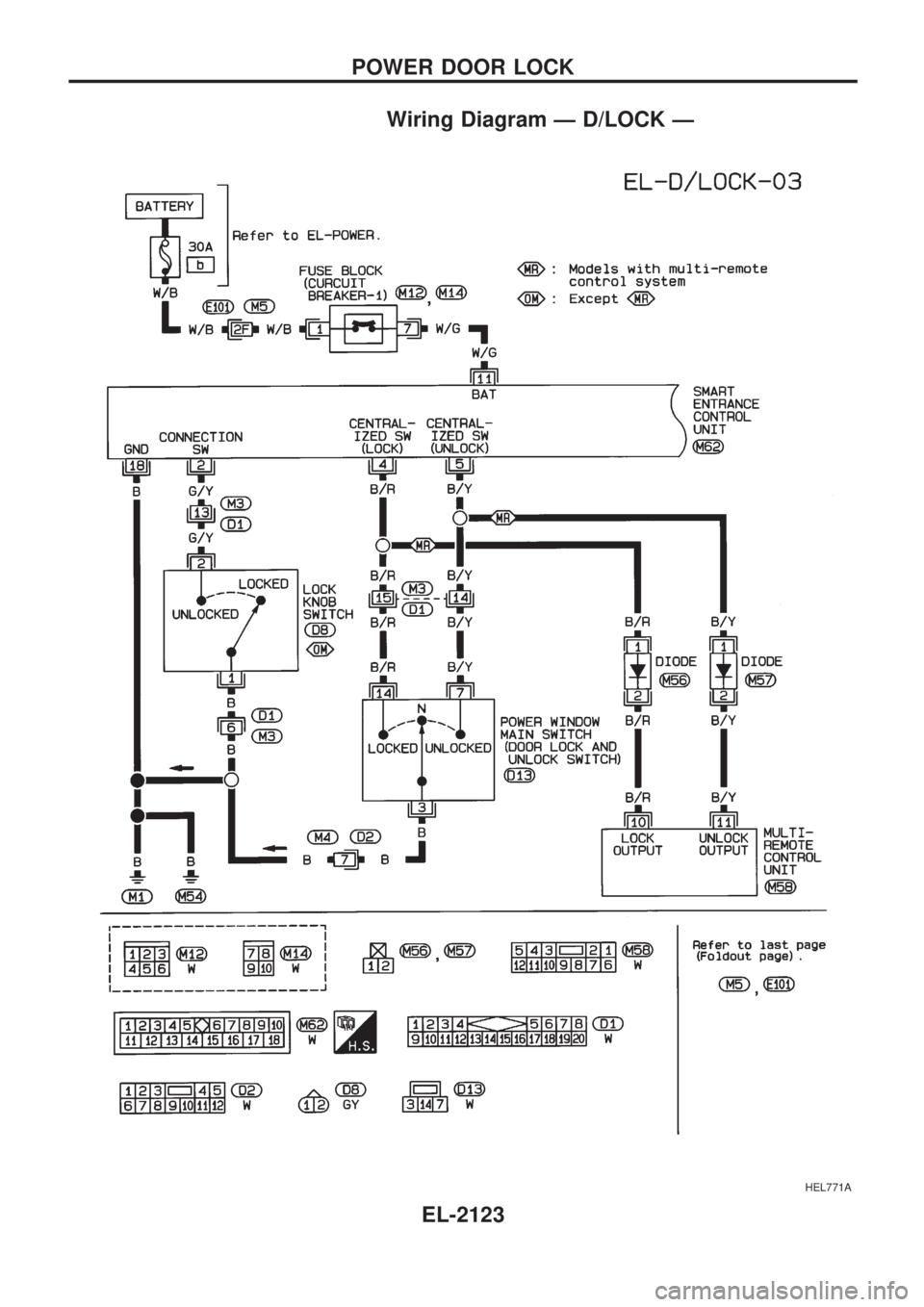

Wiring Diagram Ð D/LOCK Ð

HEL771A

POWER DOOR LOCK

EL-2123

Page 375 of 666

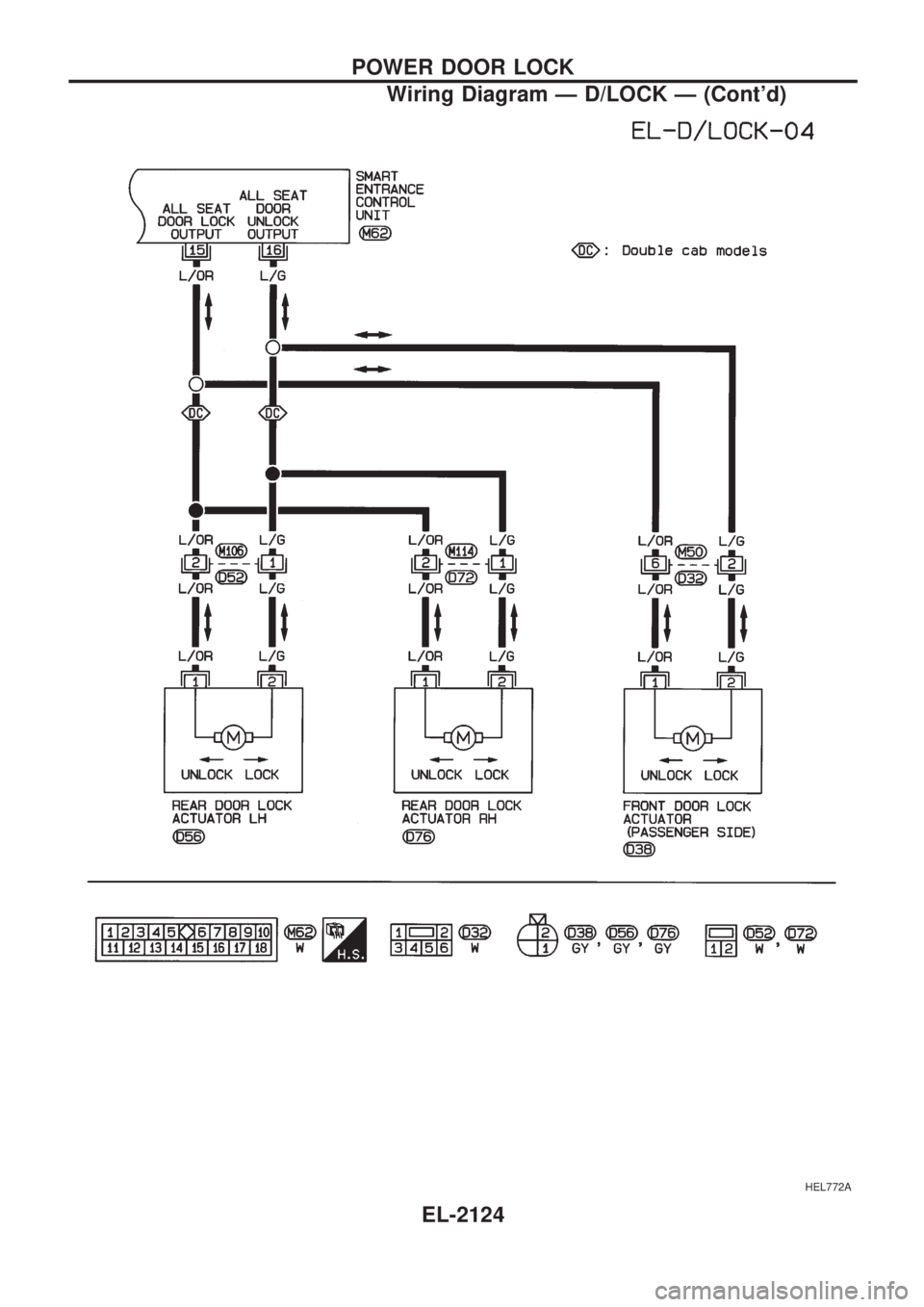

HEL772A

POWER DOOR LOCK

Wiring Diagram Ð D/LOCK Ð (Cont'd)

EL-2124

Page 376 of 666

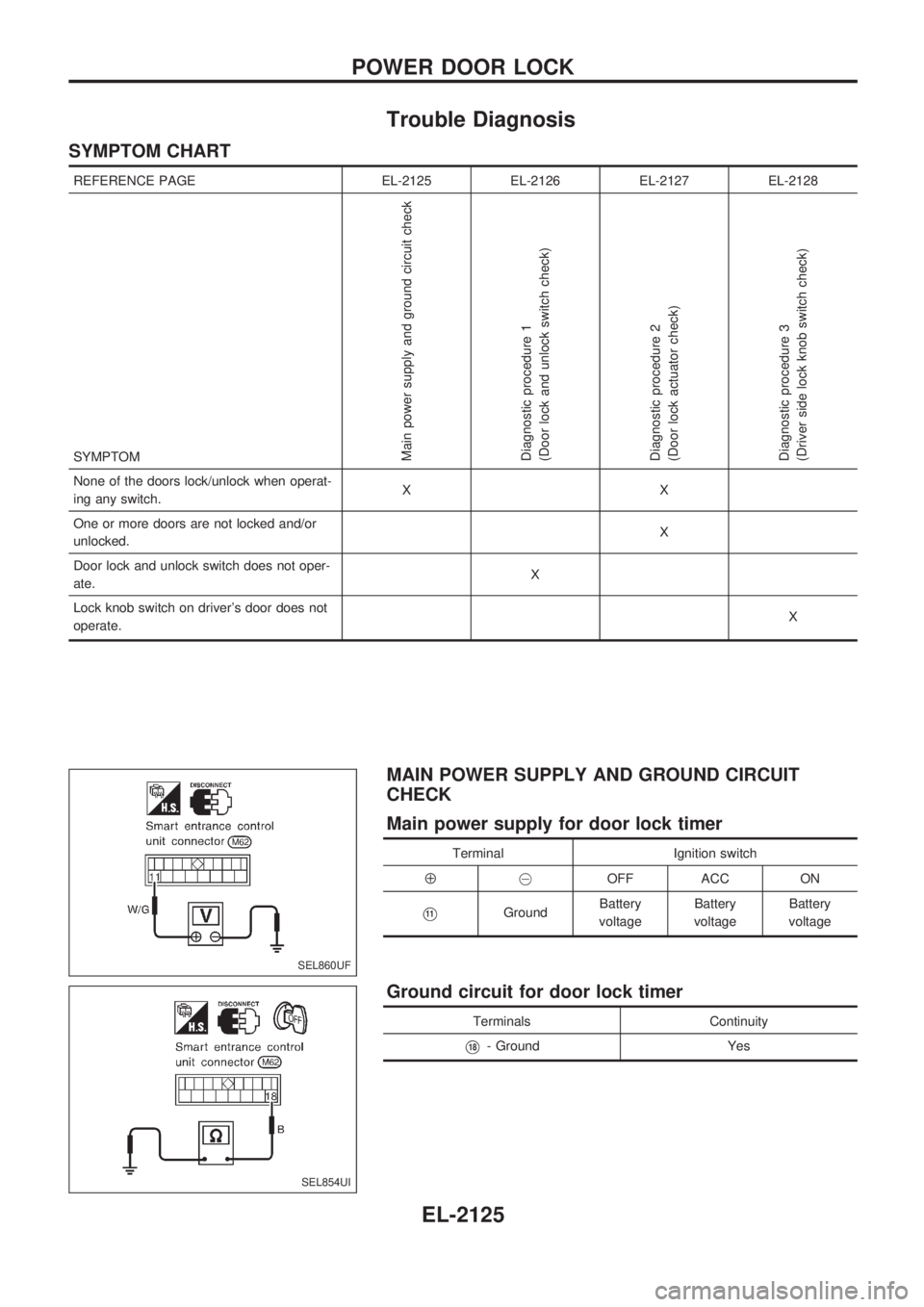

Trouble Diagnosis

SYMPTOM CHART

REFERENCE PAGE EL-2125 EL-2126 EL-2127 EL-2128

SYMPTOM

Main power supply and ground circuit check

Diagnostic procedure 1

(Door lock and unlock switch check)

Diagnostic procedure 2

(Door lock actuator check)

Diagnostic procedure 3

(Driver side lock knob switch check)

None of the doors lock/unlock when operat-

ing any switch.XX

One or more doors are not locked and/or

unlocked.X

Door lock and unlock switch does not oper-

ate.X

Lock knob switch on driver's door does not

operate.X

MAIN POWER SUPPLY AND GROUND CIRCUIT

CHECK

Main power supply for door lock timer

Terminal Ignition switch

Å@OFF ACC ON

V11GroundBattery

voltageBattery

voltageBattery

voltage

Ground circuit for door lock timer

Terminals Continuity

V18- Ground Yes

SEL860UF

SEL854UI

POWER DOOR LOCK

EL-2125

Page 377 of 666

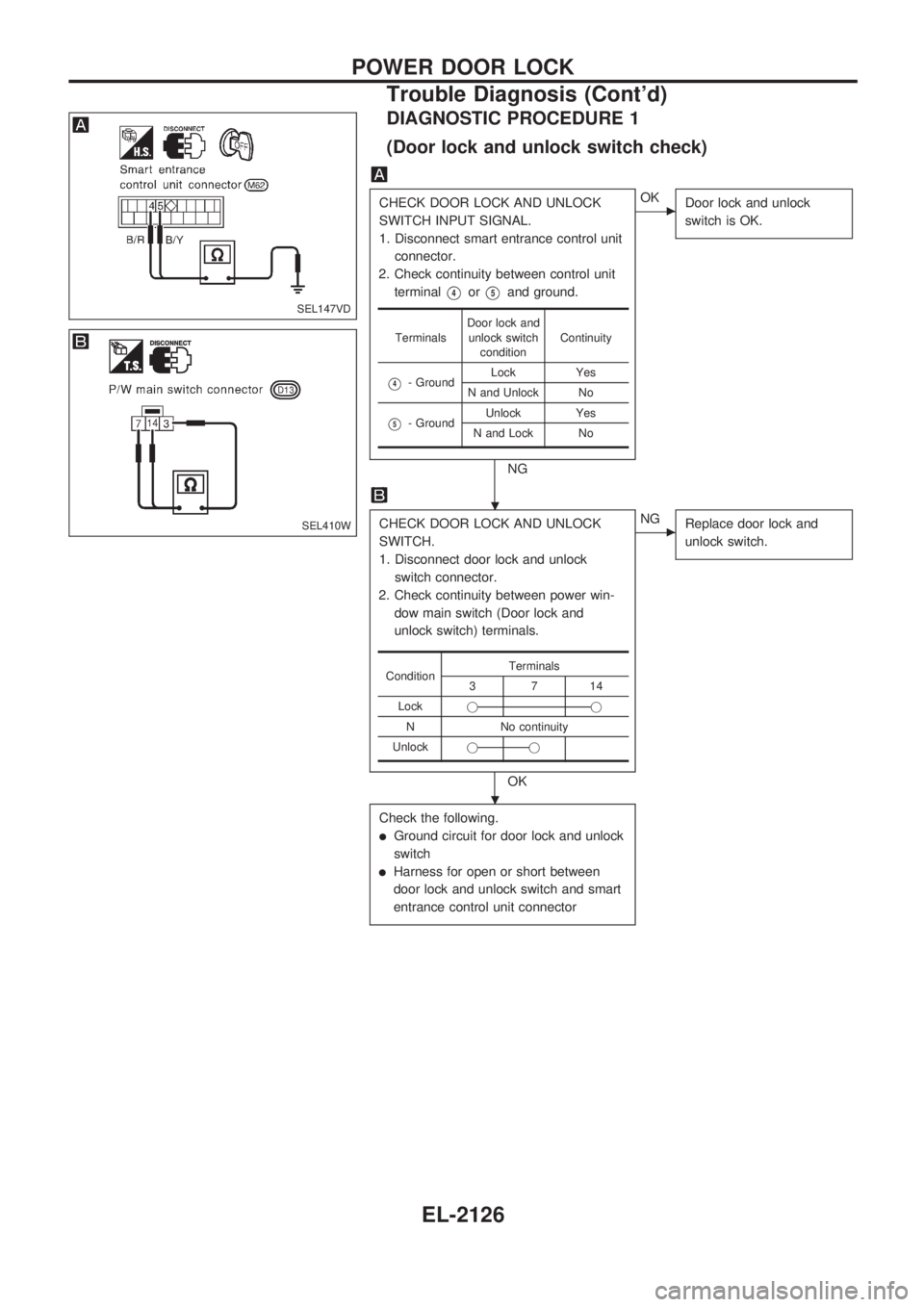

DIAGNOSTIC PROCEDURE 1

(Door lock and unlock switch check)

CHECK DOOR LOCK AND UNLOCK

SWITCH INPUT SIGNAL.

1. Disconnect smart entrance control unit

connector.

2. Check continuity between control unit

terminal

V4orV5and ground.

NG

cOK

Door lock and unlock

switch is OK.

CHECK DOOR LOCK AND UNLOCK

SWITCH.

1. Disconnect door lock and unlock

switch connector.

2. Check continuity between power win-

dow main switch (Door lock and

unlock switch) terminals.

OK

cNG

Replace door lock and

unlock switch.

Check the following.

lGround circuit for door lock and unlock

switch

lHarness for open or short between

door lock and unlock switch and smart

entrance control unit connector

TerminalsDoor lock and

unlock switch

conditionContinuity

V4- GroundLock Yes

N and Unlock No

V5- GroundUnlock Yes

N and Lock No

ConditionTerminals3714

Lockjj

N No continuity

Unlockjj

SEL147VD

SEL410W

.

.

POWER DOOR LOCK

Trouble Diagnosis (Cont'd)

EL-2126

Page 378 of 666

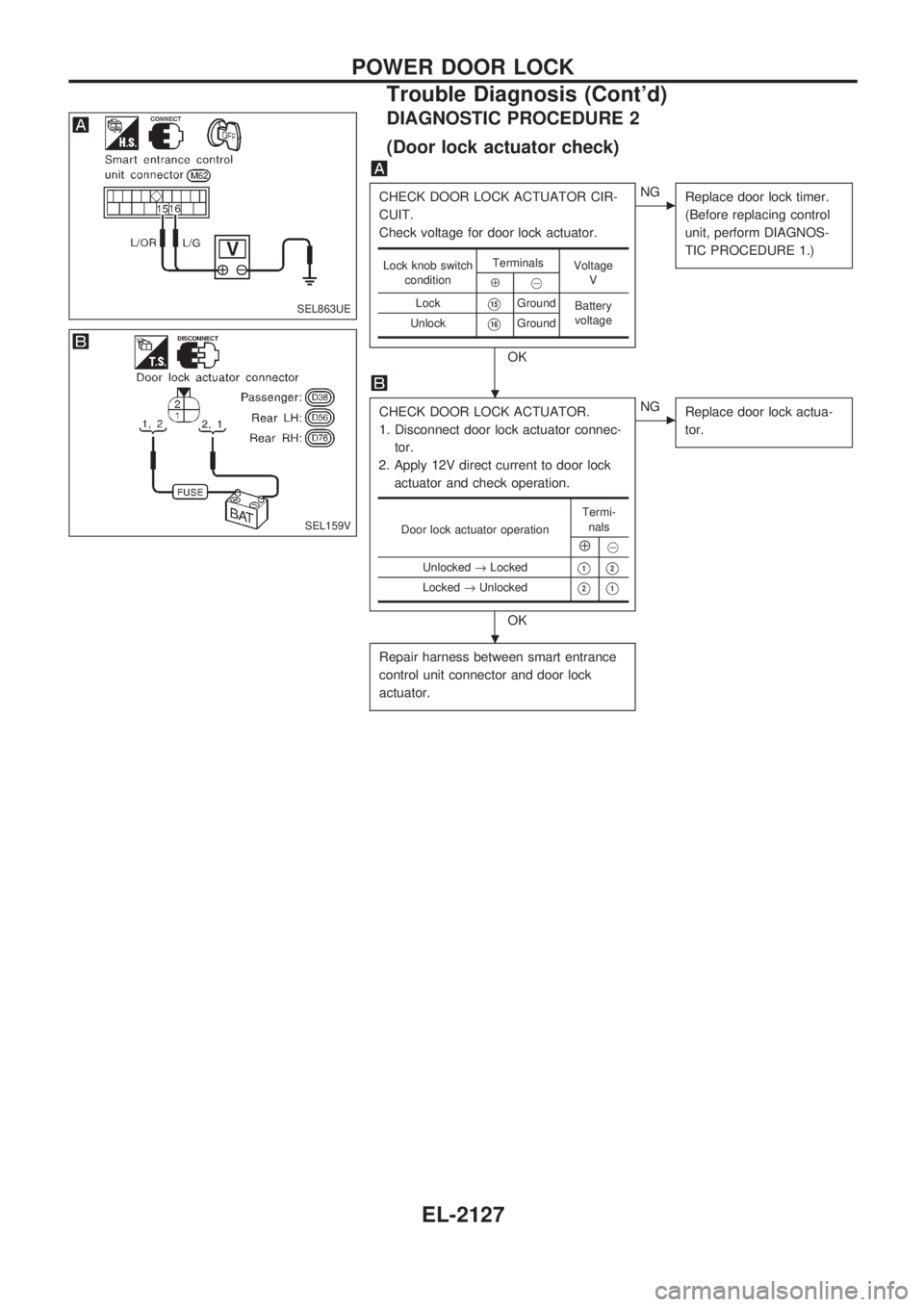

DIAGNOSTIC PROCEDURE 2

(Door lock actuator check)

CHECK DOOR LOCK ACTUATOR CIR-

CUIT.

Check voltage for door lock actuator.

OK

cNG

Replace door lock timer.

(Before replacing control

unit, perform DIAGNOS-

TIC PROCEDURE 1.)

CHECK DOOR LOCK ACTUATOR.

1. Disconnect door lock actuator connec-

tor.

2. Apply 12V direct current to door lock

actuator and check operation.

OK

cNG

Replace door lock actua-

tor.

Repair harness between smart entrance

control unit connector and door lock

actuator.

Lock knob switch

conditionTerminals

Voltage

V

Å@

Lock

V15Ground

Battery

voltage

Unlock

V16Ground

Door lock actuator operationTermi-

nals

Å@

Unlocked®Locked

V1V2

Locked®UnlockedV2V1

SEL863UE

SEL159V

.

.

POWER DOOR LOCK

Trouble Diagnosis (Cont'd)

EL-2127

Page 379 of 666

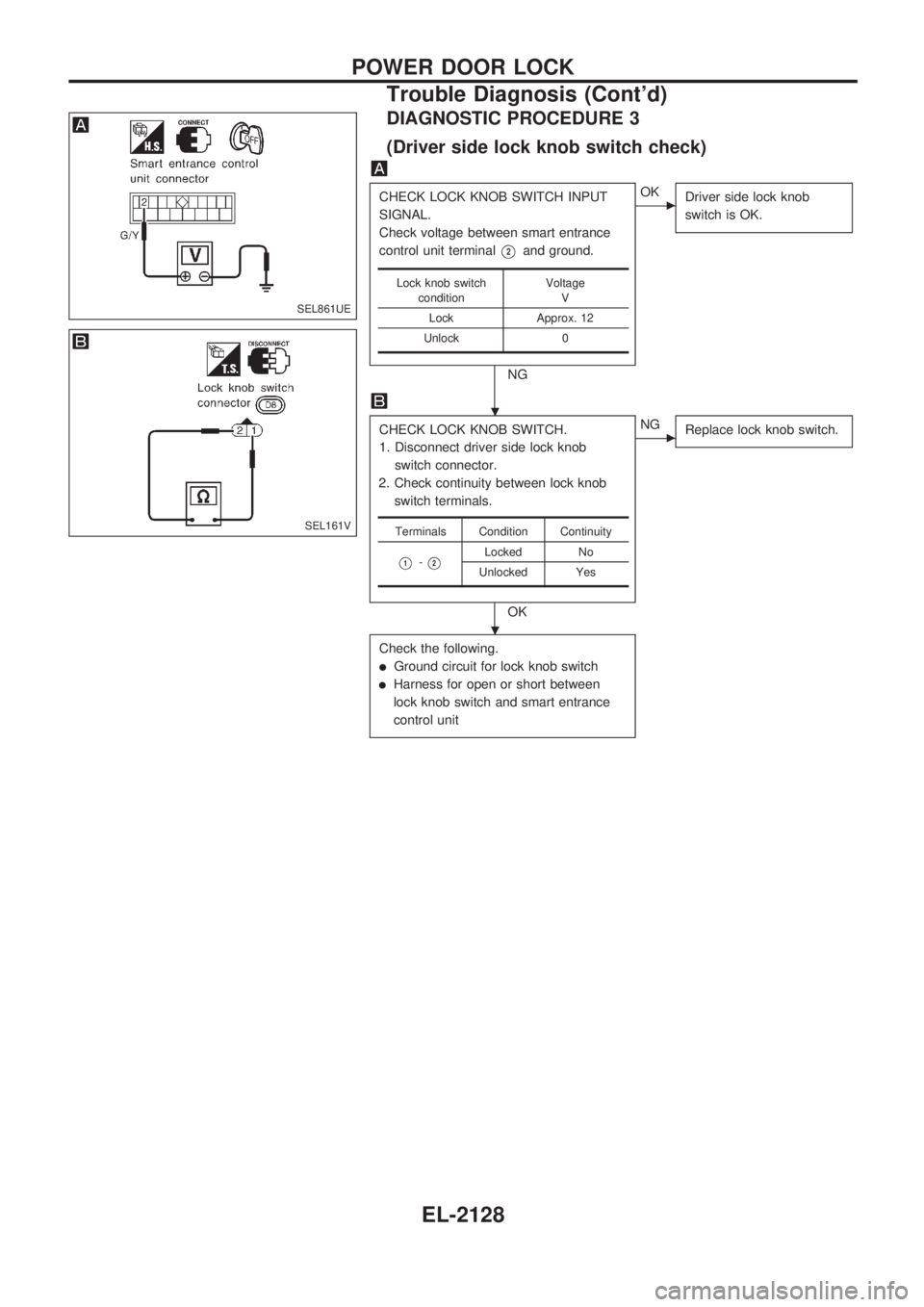

DIAGNOSTIC PROCEDURE 3

(Driver side lock knob switch check)

CHECK LOCK KNOB SWITCH INPUT

SIGNAL.

Check voltage between smart entrance

control unit terminal

V2and ground.

NG

cOK

Driver side lock knob

switch is OK.

CHECK LOCK KNOB SWITCH.

1. Disconnect driver side lock knob

switch connector.

2. Check continuity between lock knob

switch terminals.

OK

cNG

Replace lock knob switch.

Check the following.

lGround circuit for lock knob switch

lHarness for open or short between

lock knob switch and smart entrance

control unit

Lock knob switch

conditionVoltage

V

Lock Approx. 12

Unlock 0

Terminals Condition Continuity

V1-V2Locked No

Unlocked Yes

SEL861UE

SEL161V

.

.

POWER DOOR LOCK

Trouble Diagnosis (Cont'd)

EL-2128

Page 380 of 666

System Description

FUNCTION

Multi-remote control system has the following function.

lDoor lock

lDoor unlock

lHazard reminder

LOCK OPERATION

To lock door by multi-remote controller, the following two signals must be received.

lKey switch OFF (when ignition key is not in ignition key cylinder.)

lAll door switches CLOSED

When the LOCK signal is input to multi-remote control unit (the antenna of the system is combined with

multi-remote control unit), ground is supplied

lthrough multi-remote control unit terminalV10

lto smart entrance control unit terminalV4and

lto door lock relay terminalV6.

Then smart entrance control unit operates to lock doors (except for driver's door) and door lock relay ener-

gized to lock driver's door.

UNLOCK OPERATION

To unlock door by multi-remote controller, the following signal must be received.

lKey switch OFF (when ignition key is not in ignition key cylinder)

When the UNLOCK signal is input to multi-remote control unit (the antenna of the system is combined with

multi-remote control unit), ground is supplied

lthrough multi-remote control unit terminalV11

lto smart entrance control unit terminalV5and

lto door lock relay terminalV5.

Then smart entrance control unit operates to unlock doors (except for driver's door) and door lock relay is

energized to unlock driver's door.

HAZARD REMINDER

When the doors and locked or unlocked by multi-remote controller, ground is supplied

lto terminalV1of multi-remote control relay-1 and 2

lthrough multi-remote control unit terminalV12.

Then the relays are energized and hazard warning lamp flashes as follows

lLock operation: Flash once

lUnlock operation: Flash twice

MULTI-REMOTE CONTROLLER ID CODE ENTRY

A maximum of four remote controllers can be entered. Any attempt to enter a remote controller will erase

all ID codes previously entered. Therefore, be sure to receive all remote controllers from the vehicle owner

when any ID code entry is performed.

To enter ID code entry, the following signals must be input to the multi-remote control unit.

lDriver side LOCKED signal (from driver side door unlock sensor)

lDoor switch CLOSED signal

lKey switch signal (INSERTED/WITHDRAWN)

lAccessory power supply

lSignal from remote controller

For detailed procedure, refer to ``ID Code Entry Procedure'' in EL-2139.

MULTI-REMOTE CONTROL SYSTEM

EL-2129