NISSAN PICK-UP 2001 Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: PICK-UP, Model: NISSAN PICK-UP 2001Pages: 1306, PDF Size: 31.7 MB

Page 291 of 1306

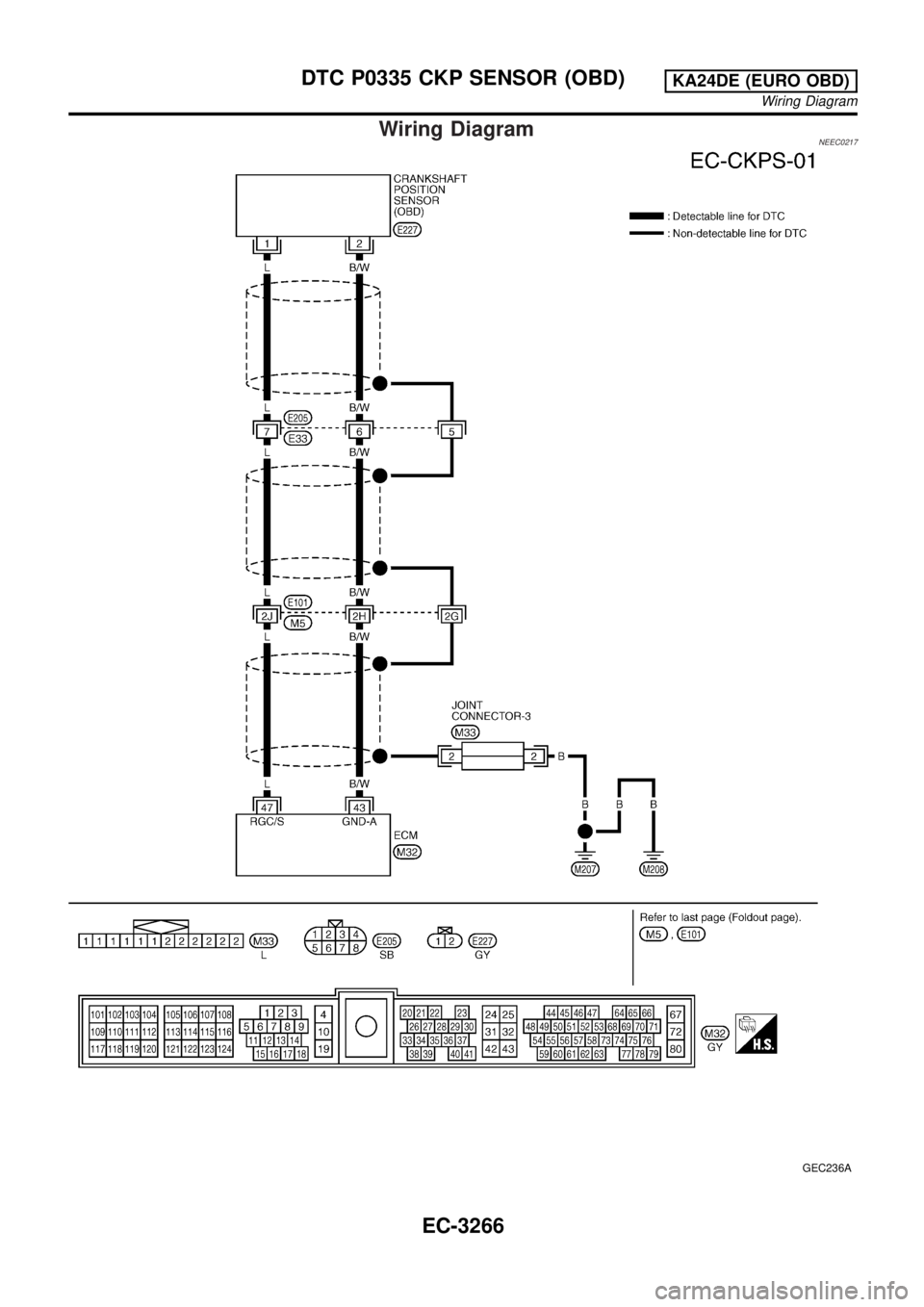

Wiring DiagramNEEC0217

GEC236A

DTC P0335 CKP SENSOR (OBD)KA24DE (EURO OBD)

Wiring Diagram

EC-3266

Page 292 of 1306

Diagnostic ProcedureNEEC0218

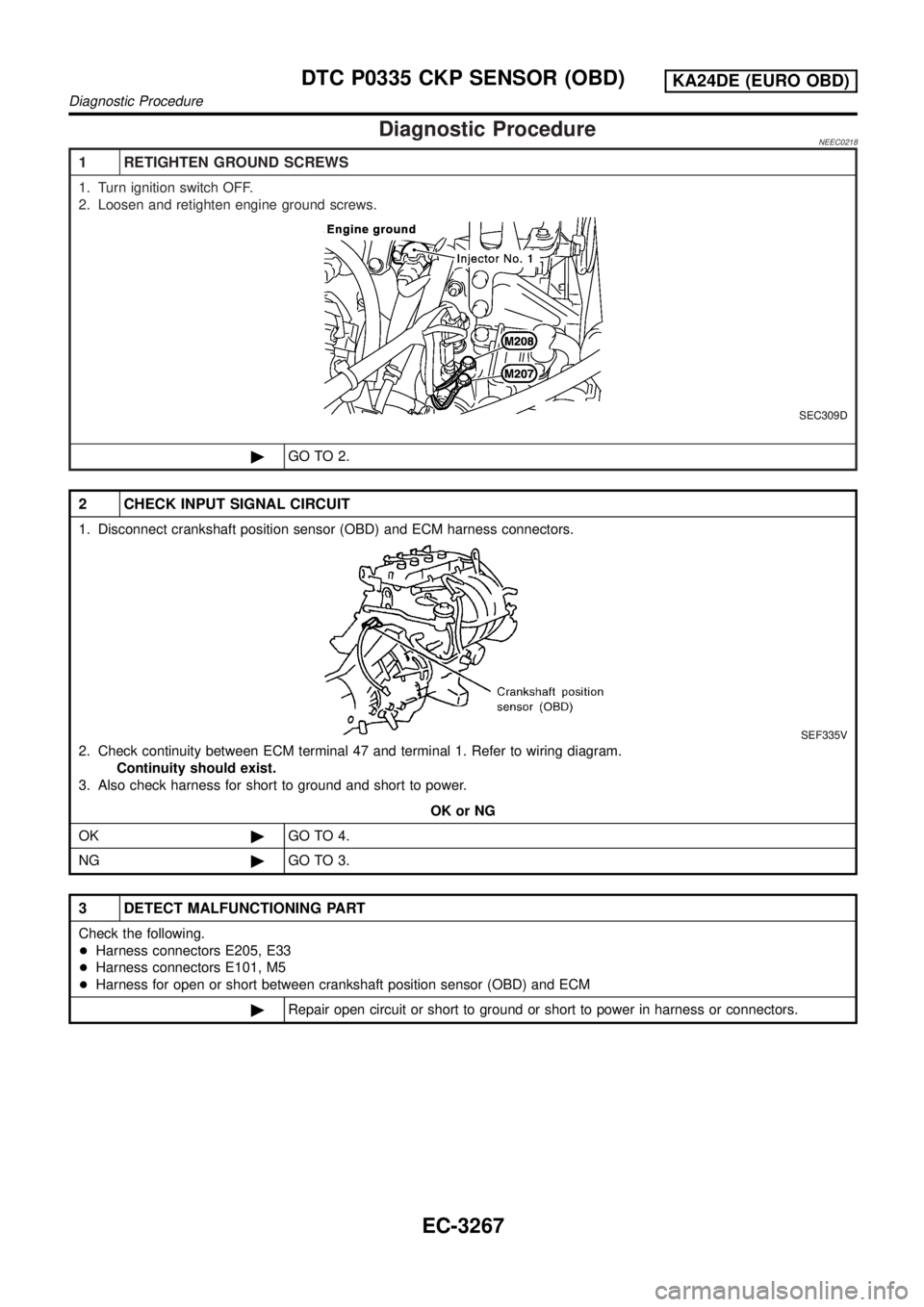

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch OFF.

2. Loosen and retighten engine ground screws.

SEC309D

©GO TO 2.

2 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect crankshaft position sensor (OBD) and ECM harness connectors.

SEF335V

2. Check continuity between ECM terminal 47 and terminal 1. Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E205, E33

+Harness connectors E101, M5

+Harness for open or short between crankshaft position sensor (OBD) and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0335 CKP SENSOR (OBD)KA24DE (EURO OBD)

Diagnostic Procedure

EC-3267

Page 293 of 1306

4 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connector.

2. Check harness continuity between crankshaft position sensor (OBD) terminal 2 and engine ground. Refer to the wiring

diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E205, E33

+Harness connectors E101, M5

+Harness for open or short between crankshaft position sensor (OBD) and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK SHIELD CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect harness connectors E205, E33.

3. Check harness continuity between harness connector E33 terminal 5 and ground. Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to power.

5. Then reconnect harness connectors.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E101, M5

+Joint connector-3 (Refer to ªHARNESS LAYOUTº, EL section.)

+Harness for open or short between harness connector E33 and engine ground

©Repair open circuit or short to power in harness or connectors.

DTC P0335 CKP SENSOR (OBD)KA24DE (EURO OBD)

Diagnostic Procedure

EC-3268

Page 294 of 1306

8 CHECK CRANKSHAFT POSITION SENSOR (OBD)

1. Disconnect crankshaft position sensor (OBD) harness connector.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

SEF960N

5. Check resistance as shown in the figure.

SEF231W

Resistance: Approximately 512 - 632W[at 20ÉC (68ÉF)]

OK or NG

OK©GO TO 9.

NG©Replace crankshaft position sensor (OBD).

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-3123.

©INSPECTION END

DTC P0335 CKP SENSOR (OBD)KA24DE (EURO OBD)

Diagnostic Procedure

EC-3269

Page 295 of 1306

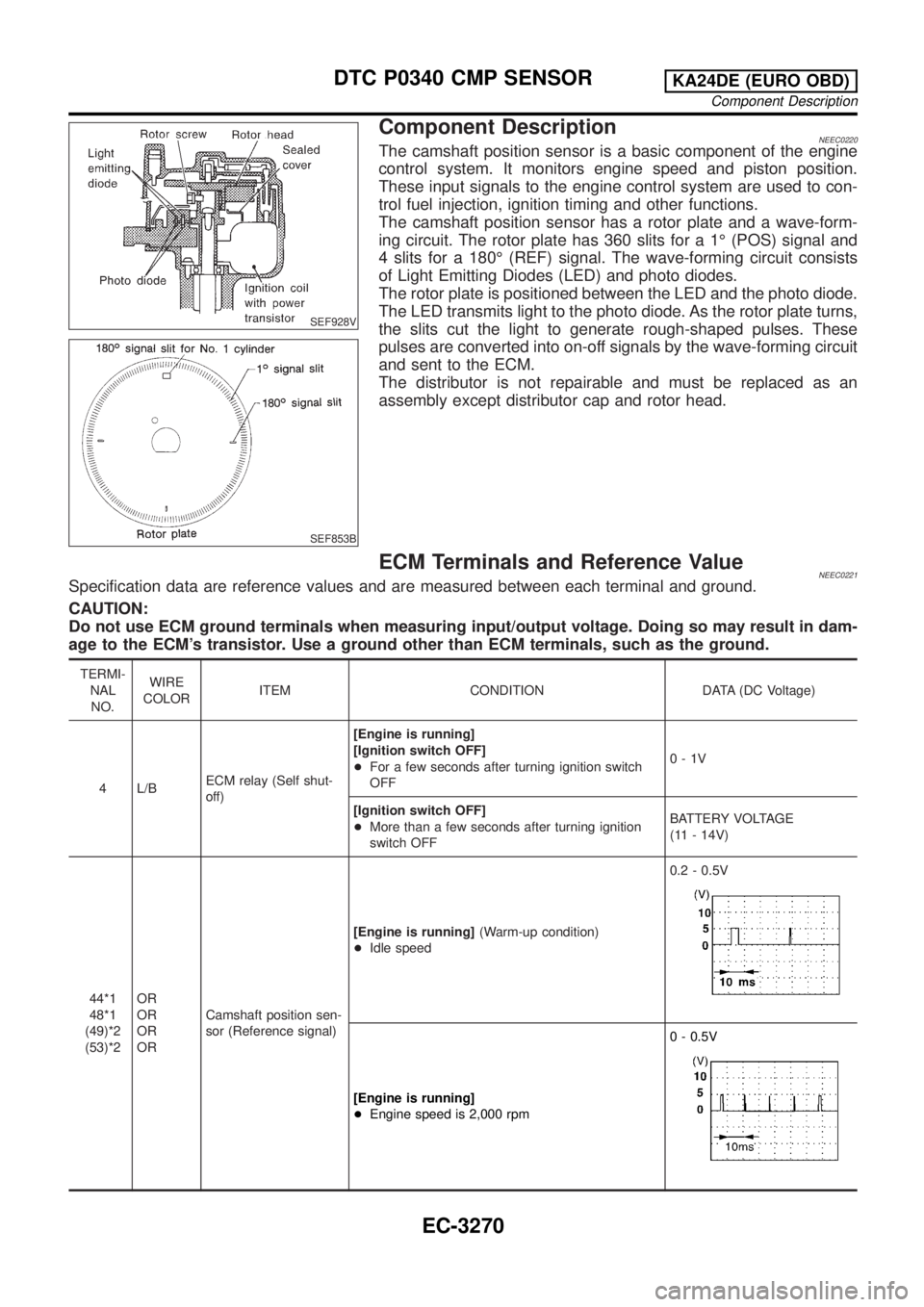

SEF928V

SEF853B

Component DescriptionNEEC0220The camshaft position sensor is a basic component of the engine

control system. It monitors engine speed and piston position.

These input signals to the engine control system are used to con-

trol fuel injection, ignition timing and other functions.

The camshaft position sensor has a rotor plate and a wave-form-

ing circuit. The rotor plate has 360 slits for a 1É (POS) signal and

4 slits for a 180É (REF) signal. The wave-forming circuit consists

of Light Emitting Diodes (LED) and photo diodes.

The rotor plate is positioned between the LED and the photo diode.

The LED transmits light to the photo diode. As the rotor plate turns,

the slits cut the light to generate rough-shaped pulses. These

pulses are converted into on-off signals by the wave-forming circuit

and sent to the ECM.

The distributor is not repairable and must be replaced as an

assembly except distributor cap and rotor head.

ECM Terminals and Reference ValueNEEC0221Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

4 L/BECM relay (Self shut-

off)[Engine is running]

[Ignition switch OFF]

+For a few seconds after turning ignition switch

OFF0-1V

[Ignition switch OFF]

+More than a few seconds after turning ignition

switch OFFBATTERY VOLTAGE

(11 - 14V)

44*1

48*1

(49)*2

(53)*2OR

OR

OR

ORCamshaft position sen-

sor (Reference signal)[Engine is running](Warm-up condition)

+Idle speed0.2 - 0.5V

[Engine is running]

+Engine speed is 2,000 rpm0 - 0.5V

DTC P0340 CMP SENSORKA24DE (EURO OBD)

Component Description

EC-3270

Page 296 of 1306

![NISSAN PICK-UP 2001 Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

(44)*2

49*1WCamshaft position sen-

sor (Position signal)[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

[Engine is running NISSAN PICK-UP 2001 Repair Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

(44)*2

49*1WCamshaft position sen-

sor (Position signal)[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

[Engine is running](/img/5/57372/w960_57372-295.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

(44)*2

49*1WCamshaft position sen-

sor (Position signal)[Engine is running]

+Warm-up condition

+Idle speedApproximately 2.5V

[Engine is running]

+Engine speed is 2,000 rpmApproximately 1.0V

67 W

Power supply for ECM[Ignition switch ON]BATTERY VOLTAGE

(11 - 14V)

72 W

117 W Current return[Engine is running]

+Idle speedBATTERY VOLTAGE

(11 - 14V)

*1: Model without NATS (Nissan Anti-Theft System)

*2: Model with NATS (Nissan Anti-Theft System)

On Board Diagnosis LogicNEEC0222

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0340

0340A) Either 1É or 180É signal is not sent to ECM for the

first few seconds during engine cranking.+Harness or connectors

(The camshaft position sensor circuit is open or

shorted.)

+Camshaft position sensor

+Starter motor (Refer to SC section.)

+Starting system circuit (Refer to SC section.)

+Dead (Weak) battery B) Either 1É or 180É signal is not sent to ECM often

enough while the engine speed is higher than the

specified engine speed.

C) The relation between 1É and 180É signal is not in

the normal range during the specified engine

speed.

DTC P0340 CMP SENSORKA24DE (EURO OBD)

ECM Terminals and Reference Value

EC-3271

Page 297 of 1306

DTC Confirmation Procedure=NEEC0223Perform ªProcedure for malfunction Aº first. If DTC cannot be

confirmed, perform ªProcedure for malfunction B and Cº.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch OFF and wait at least 5 seconds before

conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V.

SEF058Y

PROCEDURE FOR MALFUNCTION ANEEC0223S01With CONSULT-II

1) Turn ignition switch ON.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Crank engine for at least 2 seconds.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-3274.

With GST

Follow the procedure ªWith CONSULT-IIº.

SEF058Y

PROCEDURE FOR MALFUNCTION B AND CNEEC0223S02With CONSULT-II

1) Turn ignition switch ON.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-3274.

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0340 CMP SENSORKA24DE (EURO OBD)

DTC Confirmation Procedure

EC-3272

Page 298 of 1306

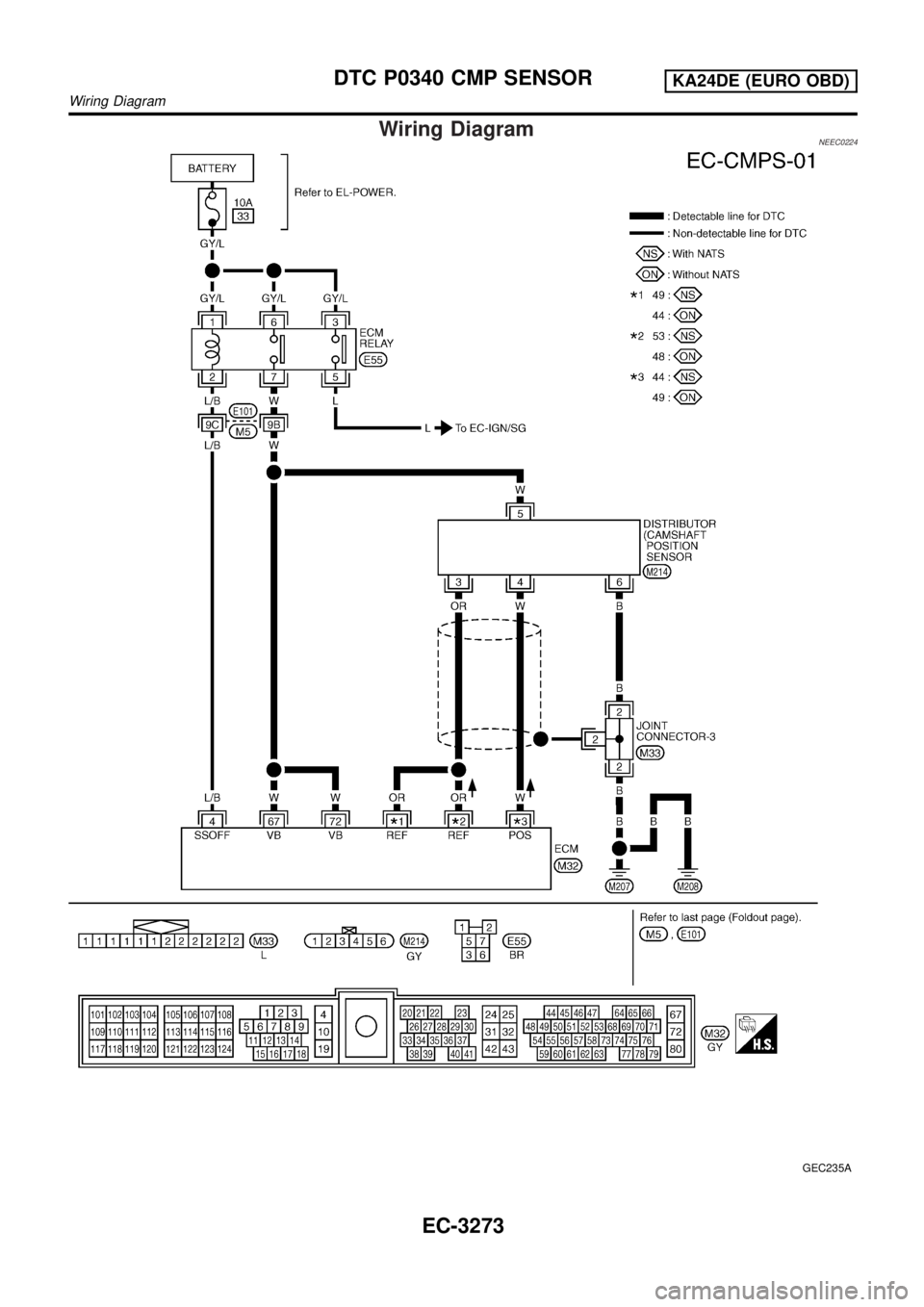

Wiring DiagramNEEC0224

GEC235A

DTC P0340 CMP SENSORKA24DE (EURO OBD)

Wiring Diagram

EC-3273

Page 299 of 1306

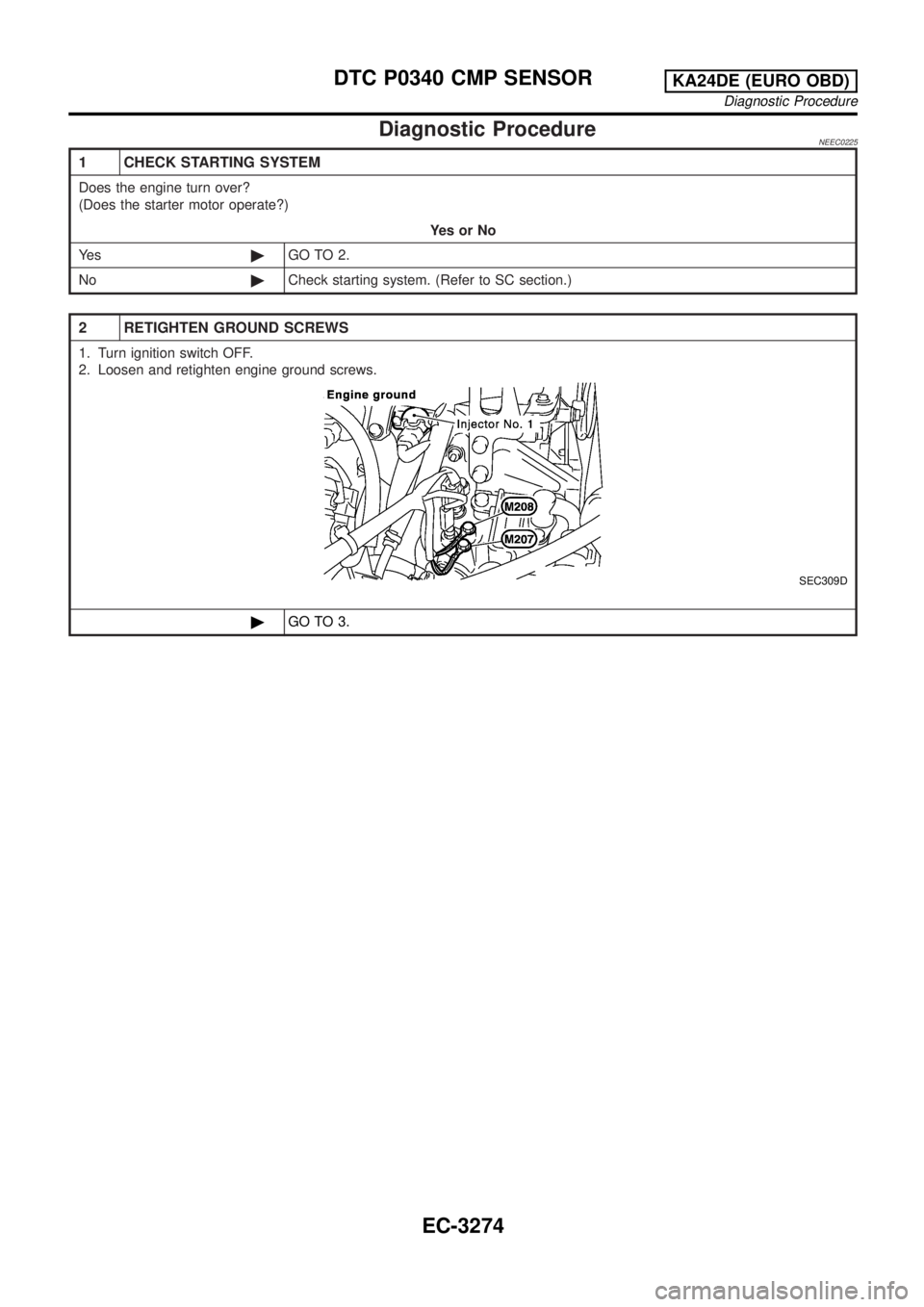

Diagnostic ProcedureNEEC0225

1 CHECK STARTING SYSTEM

Does the engine turn over?

(Does the starter motor operate?)

YesorNo

Ye s©GO TO 2.

No©Check starting system. (Refer to SC section.)

2 RETIGHTEN GROUND SCREWS

1. Turn ignition switch OFF.

2. Loosen and retighten engine ground screws.

SEC309D

©GO TO 3.

DTC P0340 CMP SENSORKA24DE (EURO OBD)

Diagnostic Procedure

EC-3274

Page 300 of 1306

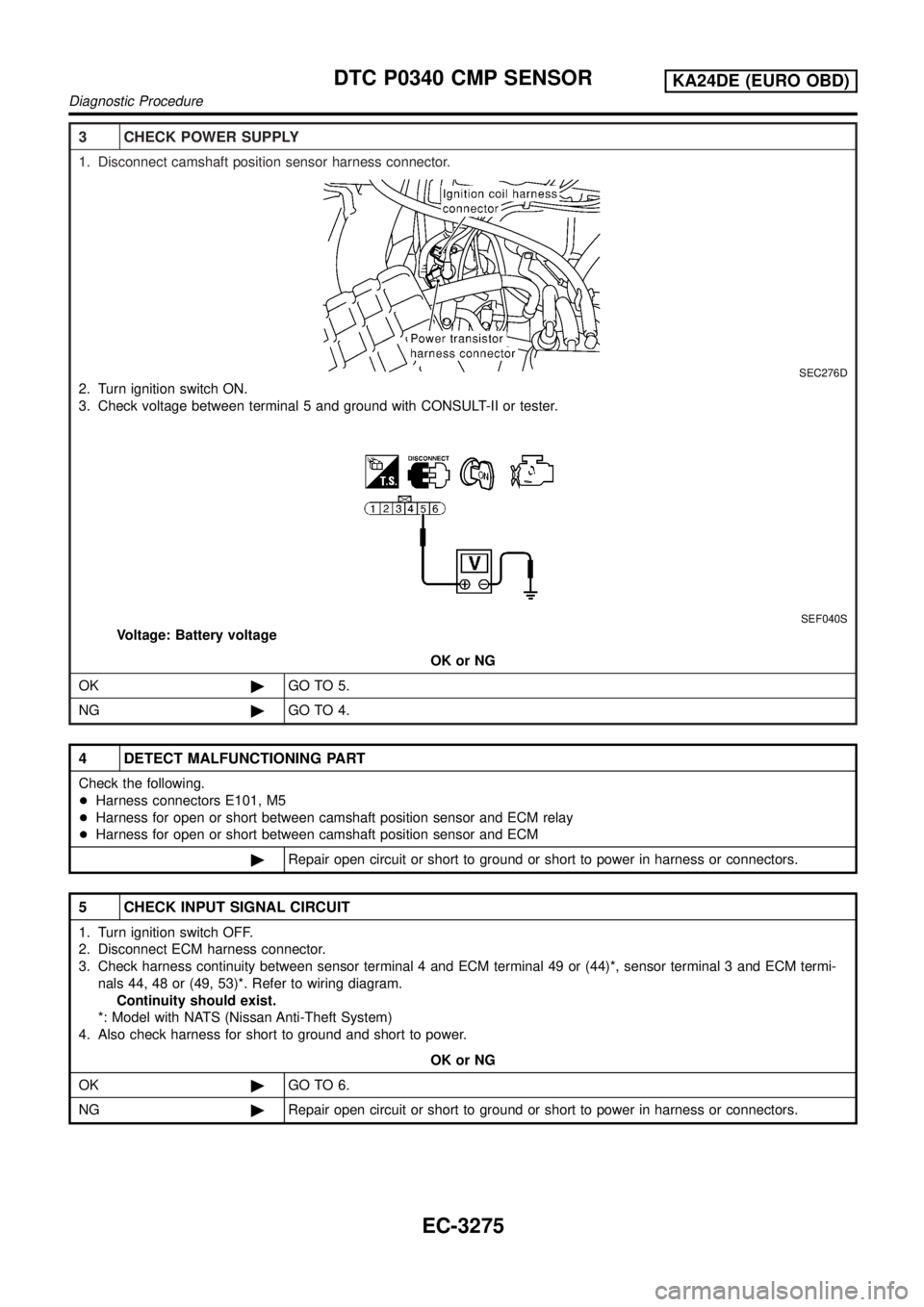

3 CHECK POWER SUPPLY

1. Disconnect camshaft position sensor harness connector.

SEC276D

2. Turn ignition switch ON.

3. Check voltage between terminal 5 and ground with CONSULT-II or tester.

SEF040S

Voltage: Battery voltage

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors E101, M5

+Harness for open or short between camshaft position sensor and ECM relay

+Harness for open or short between camshaft position sensor and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between sensor terminal 4 and ECM terminal 49 or (44)*, sensor terminal 3 and ECM termi-

nals 44, 48 or (49, 53)*. Refer to wiring diagram.

Continuity should exist.

*: Model with NATS (Nissan Anti-Theft System)

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0340 CMP SENSORKA24DE (EURO OBD)

Diagnostic Procedure

EC-3275